Patents

Literature

116 results about "Cuo nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

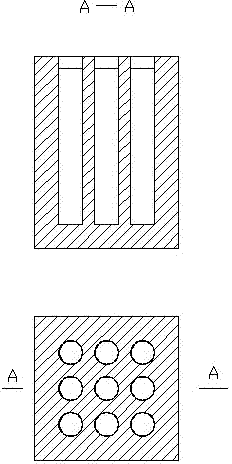

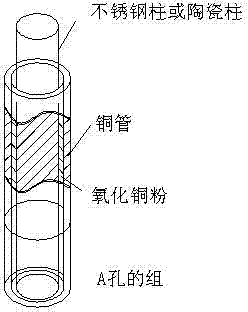

Method for preparing high-efficiency micro heat tube by combining copper powder with copper oxide powder

InactiveCN104776740ASpeed up the cycleReduce thermal resistanceIndirect heat exchangersPorosityHeat resistance

The invention discloses a method for preparing a high-efficiency micro heat tube by combining copper powder with copper oxide powder. An evaporation section and a condensation section of the heat tube respectively consist of sintered coppers with different porosities, wherein the evaporation section is formed by sintering micron-sized copper powder, and the porosity is within 40-50%; and the condensation section and a thermal insulating section consist of high-porosity sintered coppers mixed, reduced and sintered by millimeter-sized, micron-sized or nanometer-sized copper oxide powder or copper oxide powder with different particle sizes, and the porosity reaches 60-85%. The low porosity and the small aperture of the evaporation section are convenient to quickly vaporize a liquid-phase medium; and the condensation section and the thermal insulating section use the high-porosity sintered coppers as liquid absorbing cores, so that the liquid-phase reflowing heat resistance is low, liquid quickly flows back to the evaporation section, and the phase change circulation is accelerated. The method respectively injects the needed weights of the copper powder and the oxide copper powder through calculation according to the design requirements of the heat tube to produce the heat tube with different porosities and composite structure; the radiating efficiency is greatly improved, the heat resistance is low, and the quick high-efficiency radiating effect is achieved. The method is easy in operation, simple in equipment, low in production cost and suitable for industrialized production.

Owner:JIANGSU GREEN NEW MATERIALS TECH CO LTD

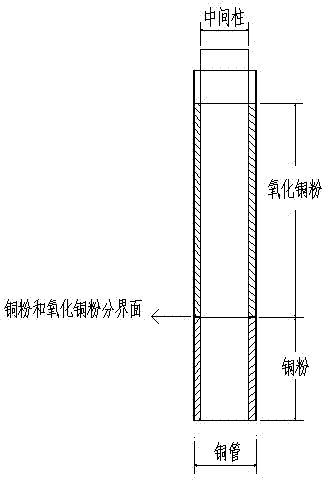

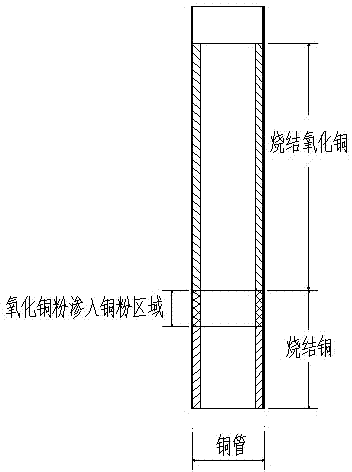

Method for manufacturing micro heat pipe by reducing copper oxide powder

ActiveCN104759627AStrong capillary suctionIncrease backflow resistanceIndirect heat exchangersLiquid mediumHeat resistance

The invention discloses a method for manufacturing a micro high-porosity sintered copper heat pipe by using millimeter, micron or nanometer copper oxide powder. The method is similar to that of a conventional sintered copper heat pipe; and the difference is that the method prepares the heat pipe with needed high-porosity sintered copper as a liquid absorbing wick by adding copper oxide powder or copper oxide powder containing particles of different sizes and carrying out the hydrogen reduction and the sintering treatment. The micro heat pipe is generally manufactured by directly sintering the copper powder; and the porosity of the sintered copper liquid absorbing wick is generally 40-50%. The obtained sintered copper porosity of the sintered copper heat pipe manufactured by using the millimeter, micron or nanometer copper oxide powder or the mixture thereof containing particles of different sizes reaches up to 60-80%; and the porosity can be designed as required. The method can increase the backflow speed of a liquid medium in the high-porosity sintered copper liquid absorbing wick, greatly reduce the heat resistance of the medium in the heat pipe in the liquid-steam phase change circulating process, and improve the radiating efficiency. The manufacturing method is simple, free of pollution in the production process, low in cost and suitable for industrial production.

Owner:杭州良格子材料有限公司

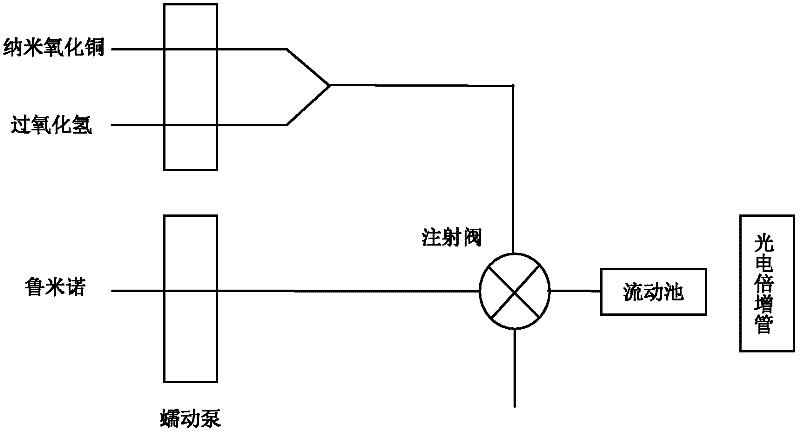

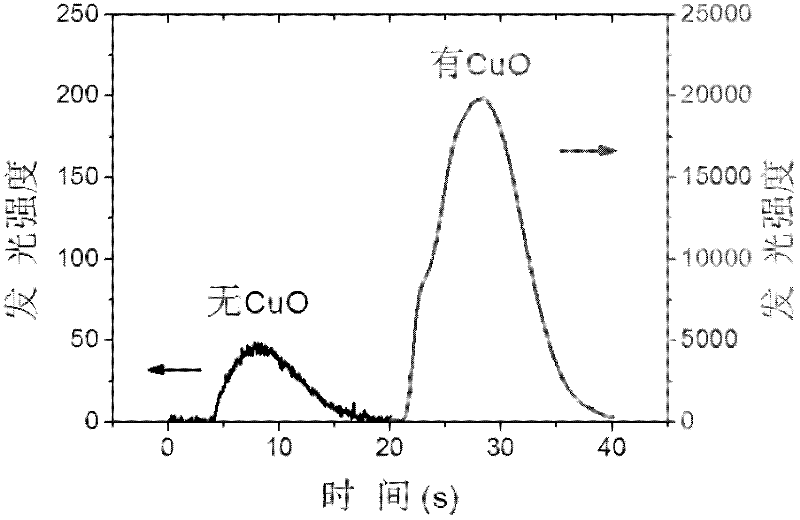

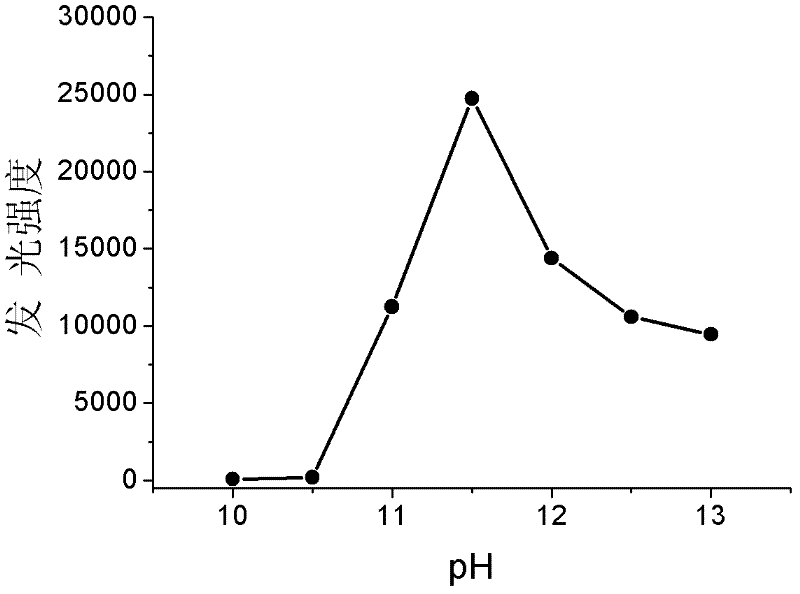

Method for enhancing luminol chemoluminescence using copper oxide nanoparticles

InactiveCN102507543ARealize determinationReduce demandChemiluminescene/bioluminescencePeristaltic pumpFlow cell

The invention discloses a method for enhancing luminol chemoluminescence by using copper oxide nanoparticles and is characterized in that the method comprises the following steps of: firstly pumping a copper oxide nanoparticle colloid solution and a hydrogen peroxide solution into a mixer for mixing through peristaltic pumps respectively, then mixing with a luminol solution, loading the resulting mixture to a flow cell for reaction, and detecting chemoluminescence intensity by a photomultiplier tube. The copper oxide nanoparticles are added to the luminol-hydrogen peroxide system, so as to significantly enhance chemoluminescence signals. The luminol-hydrogen peroxide-copper oxide nanoparticle flow injection chemiluminescence detection can be applied to glucose content determination, with a linear range of 5 mumol / L to 60 mumol / L.

Owner:FUJIAN MEDICAL UNIV

Multifunctional wallpaper and coating composition for multifunctional wallpaper

The invention discloses multifunctional wallpaper which comprises a base layer and a functional layer. The functional layer comprises a first micro-nano composite material and a second micro-nano composite material. The first micro-nano composite material is one or two selected from nano-titanium dioxide and nano-zinc oxide and one or the combination of more selected from nano-agcl, nano-silver oxide and nano-silver and is carried on an inorganic nonmetal micron carrier; and the second micro-nano composite material is one or two selected from nano-titanium dioxide and nano silicon dioxide hydrate and is carried on an inorganic nonmetal micron carrier. The functional layer can preferably comprise a third micro-nano composite material, and the third micro-nano composite material is nano zinc oxide and one or the combination of more selected from nano-copper oxide, nano-copper hydroxide and nano-cuprous oxide. The multifunctional wallpaper has excellent functions of antibiosis, anti-virus, formaldehyde removal, mold resistance, corrosion resistance, pollution prevention and water repellency. A coating composition for the multifunctional wallpaper is further disclosed.

Owner:SHANGHAI WORLD PROSPECT CHEMTECH

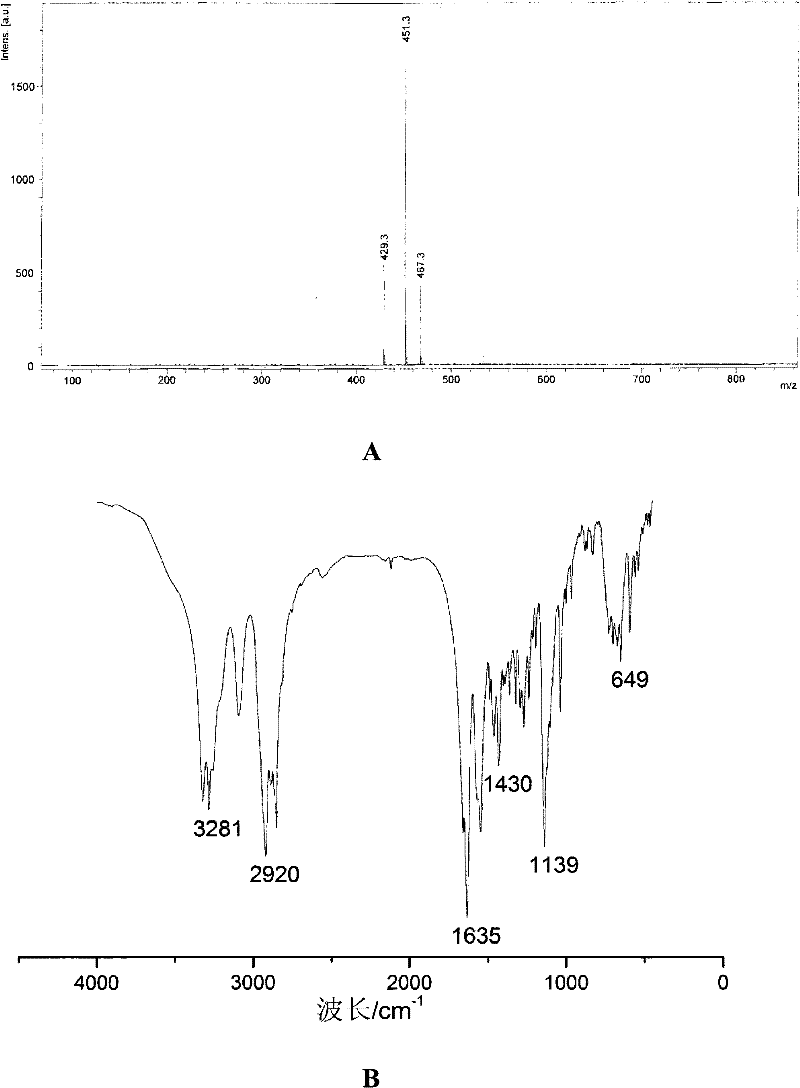

Preparation method and application of flaky nano copper oxide

ActiveCN110436508ASimple preparation processReduce manufacturing costNanotechnologyCopper oxides/halidesPhotocatalytic degradationCopper salt

The invention discloses a preparation method and application of flaky nano copper oxide. The preparation method of the flaky nano copper oxide mainly comprises the following steps: accurately weighingcopper salt and oxalic acid or oxalate, uniformly mixing the copper salt and the oxalic acid or the oxalate, then grinding, adding a proper amount of distilled water in the grinding process to enablethe mixture to be in a fluid state, heating, cleaning and drying after grinding to obtain a precursor copper oxalate, and calcining the precursor copper oxalate to obtain the flaky nano copper oxide.A preparation technology is simple, no organic solvent except ethanol is used in a preparation process, the preparation method is environment-friendly and safe, and prepared flaky nano copper oxide particles are uniform in size and small in particle size, and have good photocatalytic degradation performance on a methylene blue solution.

Owner:GANSU AGRI UNIV

Core-shell-structured nano-zinc oxide coated nano-copper oxide composite antibacterial agent as well as preparation method and application

InactiveCN106561712ALight colorEnhanced inhibitory effectBiocideDead animal preservationOxide compositeCopper nitrate

The invention relates to a core-shell-structured nano-zinc oxide coated nano-copper oxide composite antibacterial agent as well as a preparation method and an application. The preparation method comprises the following steps: dissolving copper nitrate and sodium carbonate in water respectively, adding a surfactant in the copper nitrate solution, then dripping the sodium carbonate solution in the copper nitrate solution, reacting and then carrying out centrifugal separation, washing, drying and roasting to obtain black nano-copper oxide; adding the nano-copper oxide in water, stirring, adding zinc nitrate and dissolving the zinc nitrate, dripping ammonia water to adjust the pH value to be about 7 and then obtaining a solid powder, and carrying out centrifugal washing, drying and calcining on the solid powder to obtain nano-zinc oxide coated nano-copper oxide. The nano-zinc oxide coated nano-copper oxide composite antibacterial agent prepared by the method disclosed by the invention has a light colour, can be used for most of household appliances, furniture, wall surfaces and other light-colour areas, and has a high inhibition effect on common bacteria and fungi due to the antibacterial complementary effect of zinc oxide and copper oxide.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

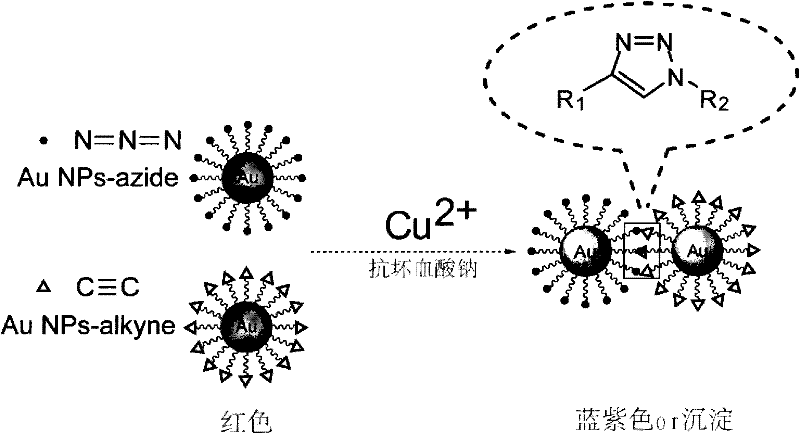

Method, kit and application for visual detection of antigen-antibody reaction

ActiveCN102269758AGet rid of dependenceThe detection system is stableBiological testingDiseaseNanoparticle

The invention relates to a method for visual detection of an antigen-antibody reaction. The method is specifically characterized in that: copper oxide nanoparticle-labeled antibodies react with a sample requiring detection; surface functionalized gold nanoparticles are adopted to detect the copper oxide nanoparticles labeled on the antibodies so as to provide information related to the antigen-antibody reaction, and provide a new tool for the disease detection and the disease diagnosis based on the immunological reaction. With the method provided by the present invention, the detection can be completed by the naked eye without requiring any equipment, and the method is applicable for field work. The invention further provides an application of the method. The invention further provides a kit for the visual detection of the antigen-antibody reaction, and an application thereof.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of RuCl3/Cu-MOF-based composite catalyst and application

InactiveCN110354890ASimple preparation processShort timePhysical/chemical process catalystsElectrodesArgon atmosphereNitrogen gas

The invention discloses a preparation method of a RuCl3 / Cu-MOF-based composite catalyst and application of the catalyst in catalyzing room temperature nitrogen reduction to ammonia, belonging to the technical fields of nanomaterials and catalysis. The method mainly comprises the following steps: mixing a copper acetate solution, a ruthenium trichloride solution and a ligand solution to prepare RuCl3 / Cu-MOF nanocrystals; placing the RuCl3 / Cu-MOF nanocrystals in a tube furnace, and pyrolyzing at 700 DEG C for 2 hours under an argon atmosphere to obtain a carbon-nitrogen matrix nano-porous composite material co-doped with CuO nanoparticles and Ru nanoparticles, namely the RuCl3 / Cu-MOF-based composite catalyst; the catalyst is used in catalyzing room temperature nitrogen reduction to ammonia,and has simple preparation process, low cost and good industrial prospect.

Owner:UNIV OF JINAN

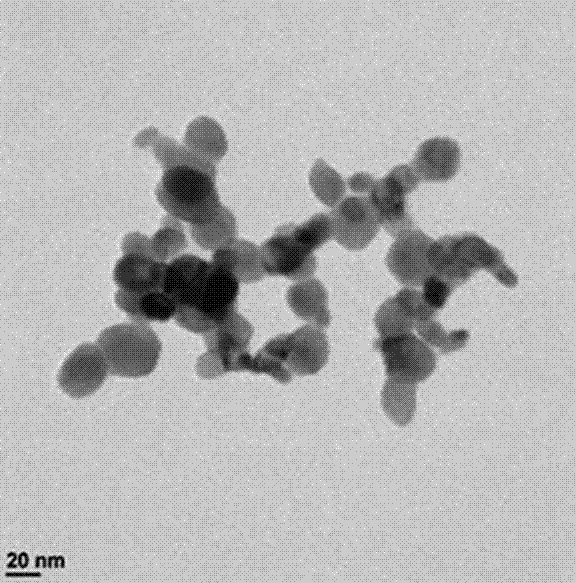

Preparation method of nano-copper oxide catalyst for degrading organic dye wastewater

InactiveCN103537284AReduce pollutionReduce wasteWater contaminantsWaste water treatment from textile industryPtru catalystCu2 ions

The invention belongs to the technical field of preparation of nano-catalytic materials and relates to a preparation method of a nano-copper oxide catalyst for degrading organic dye wastewater. The method comprises the following steps: 1) dissolving a strong base in hydrogen peroxide to prepare a strong base mixed solution, adding a copper ion solution with the concentration of 0.8-1.2mol / L into the strong base mixed solution while stirring, continuing stirring, centrifuging to obtain a precipitate, and washing with water; 2) dispersing the precipitate in deionized water to obtain a suspension, performing sealed aging treatment on the suspension at the temperature of 60 DEG C-100 DEG C for above 4h, then cooling, washing with deionized water and ethanol, and further drying to obtain the nano-copper oxide catalyst. According to the method provided by the invention, the advance preparation of a template and the use of any surfactant are not required, the method has the advantages of mild reaction, simple process, short period and no pollution of raw materials and products, and the prepared nano-copper oxide catalyst has the advantages of regular shape, uniform particle size and good catalytic performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method for nano-copper powders

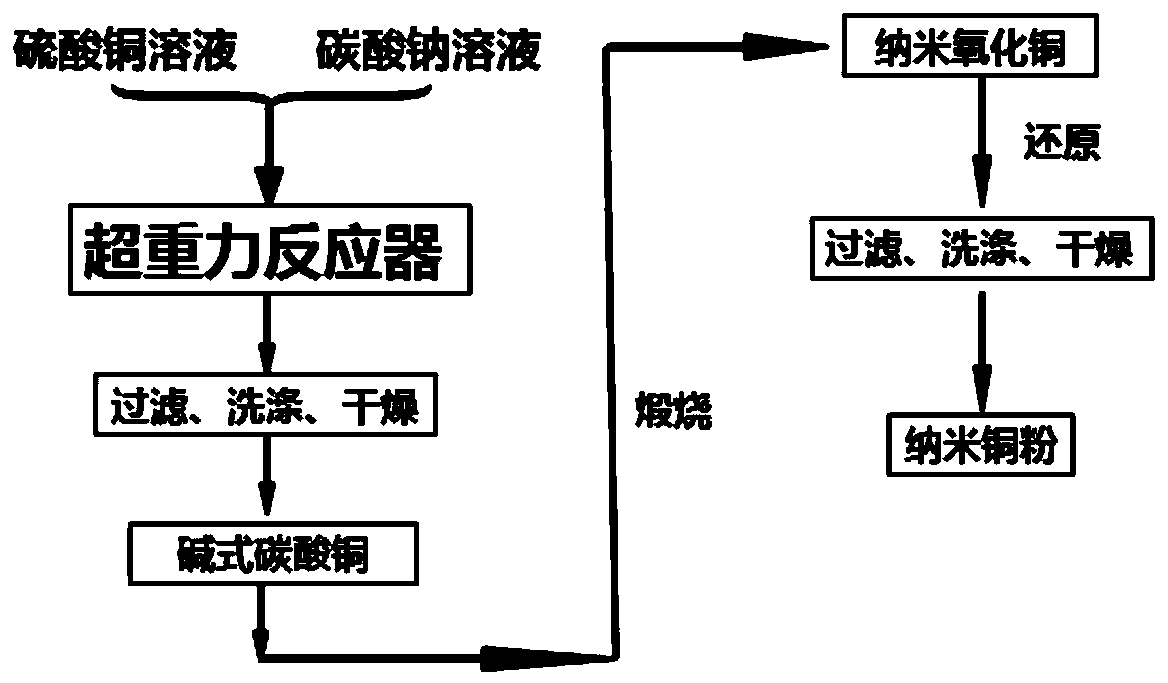

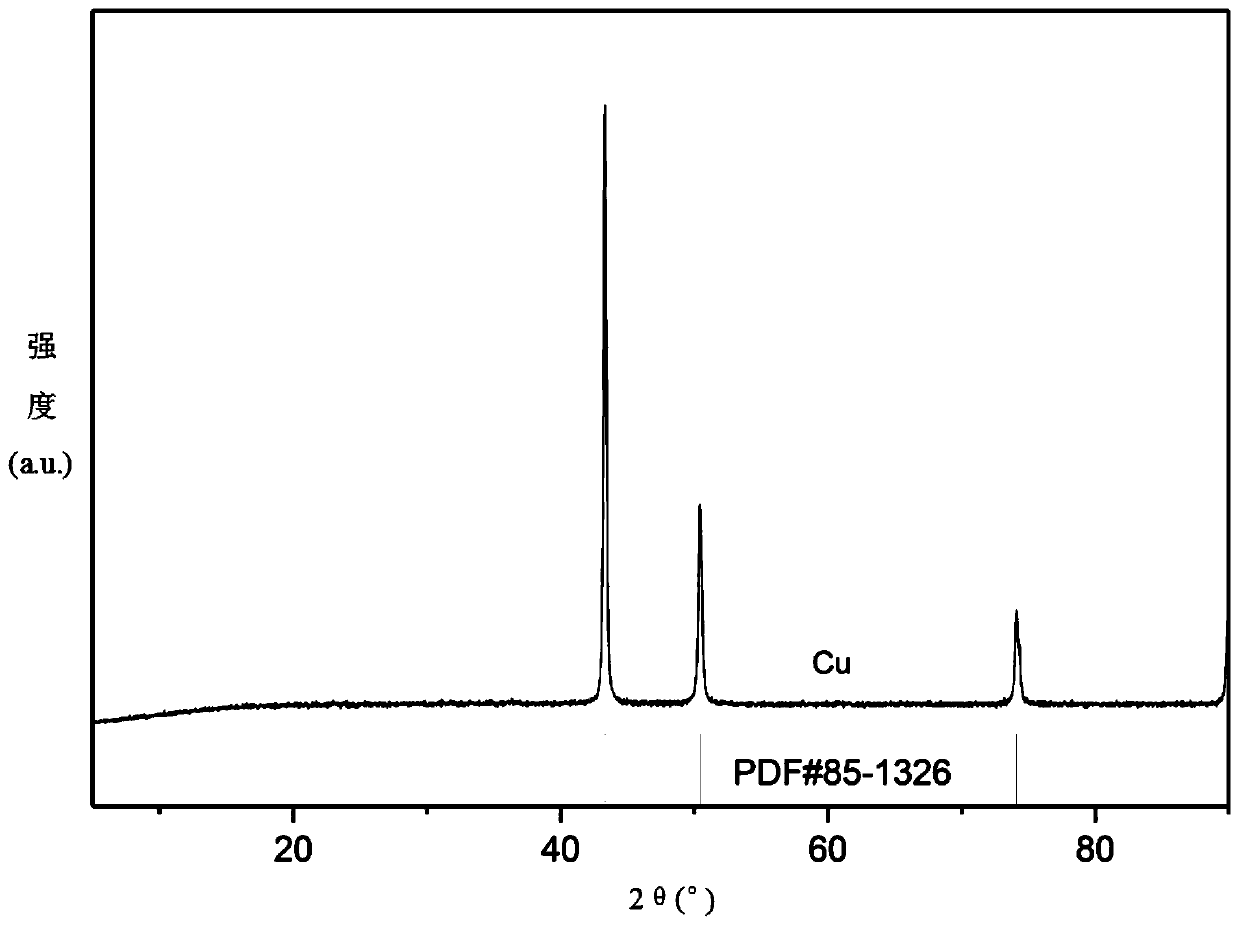

PendingCN110976901ALow costHigh purityMaterial nanotechnologyCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

The invention relates to a preparation method for nano-copper powders. The preparation method comprises the following steps of: A: preparing nanoscale basic cupric carbonate by a method of precipitation: specifically, preparing a bivalent copper ion solution with certain concentration, then, preparing a precipitant solution with certain centration, starting a spiral channel type revolving bed hypergravity reactor, then, independently injecting two solutions into the reactor from different inlets according to a certain revolving speed to react to cause the two solutions to generate precipitation reaction, and after the reaction is finished, filtering, washing and drying a reaction liquid in sequence; B: carrying out calcination on a dried product to obtain a nanometer copper oxide; and C: reducing the nanometer copper oxide to obtain the nano-copper powders. The preparation method can stably produce the nano-copper powders with even particles on batch, and the produced nano-copper powders have a good application prospect on the aspects, including electric conduction, catalysis, lubrication and the like.

Owner:XIANGTAN UNIV

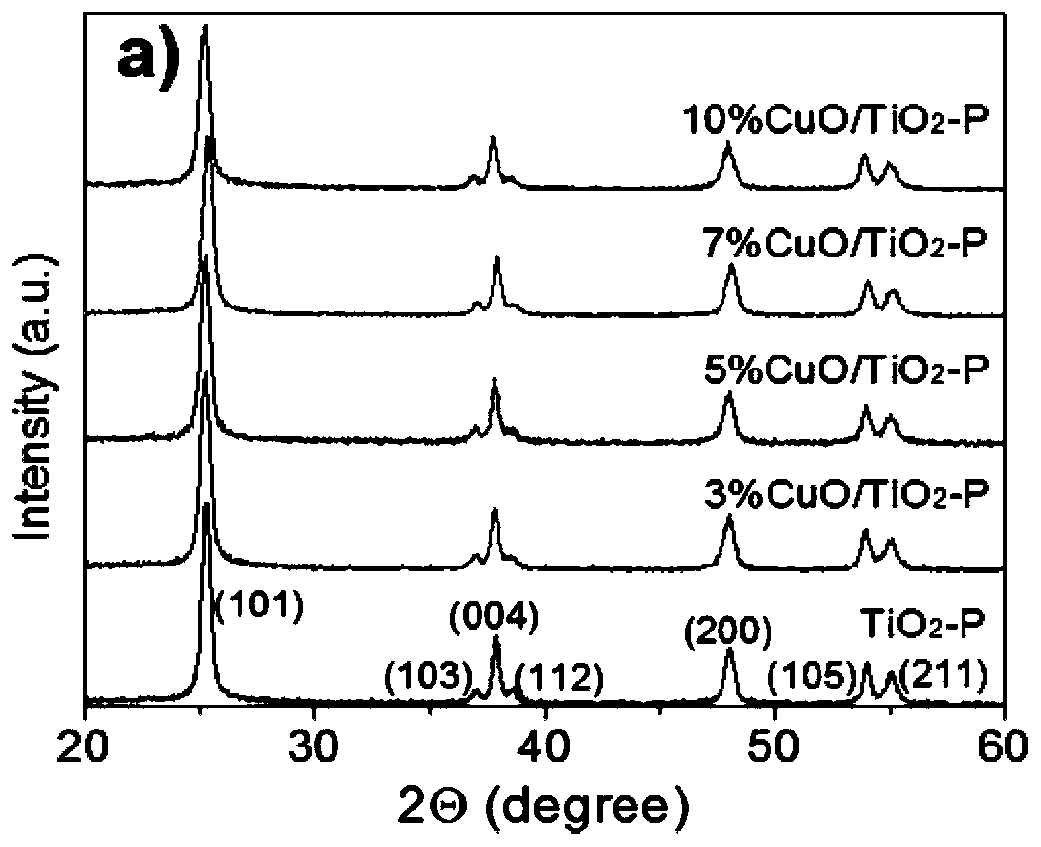

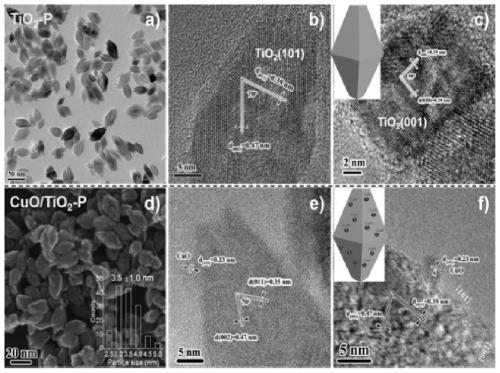

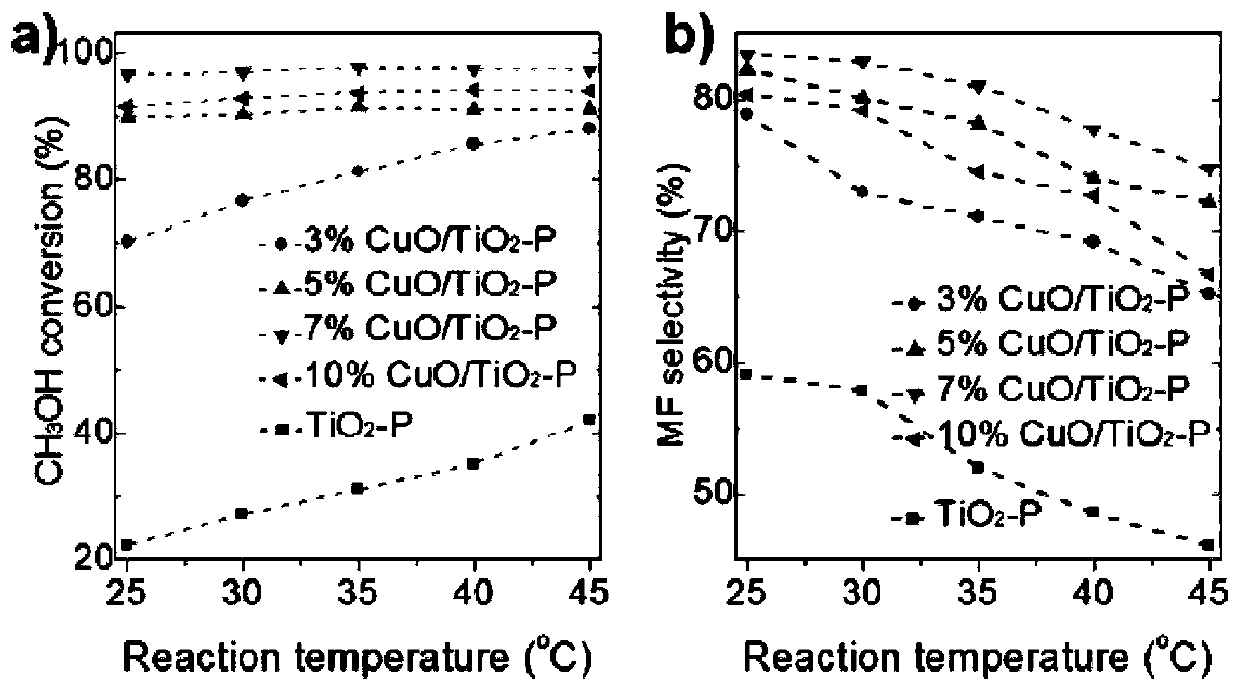

Copper oxide and titanium oxide heterojunction composite catalyst as well as preparation method and application thereof

InactiveCN110449154AEfficient conversionEasy to separateOrganic compound preparationCarboxylic acid esters preparationHeterojunctionCopper nitrate

The invention discloses a copper oxide and titanium oxide heterojunction composite catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a copper nitrate solution with an anatase TiO2 spindle body, adding a sodium borohydride reducing agent, regulating and controlling coordination modes and action force of CuO nanoparticles and {101} and {001} crystal surfaces, and selectively depositing the CuO nanoparticles onto {101} crystal surfaces, so as to establish a copper oxide and titanium oxide heterojunction composite catalyst system. In a reaction that methyl formate is prepared from methanol through photo-catalytic oxidation of a catalyst, the conversion rate of the methanol is up to 95% at 25 DEG C, and the selectivityof the methyl formate is as high as 85%. The copper oxide and titanium oxide heterojunction composite catalyst is reasonably established, separation of photoproduction electrons and holes is achievedto the maximum extent under synergism of heterogeneous interfaces, and the reaction activity and the selectivity can be further improved when the methyl formate is prepared from the methanol throughphoto-catalytic oxidation at a low temperature of 15-45 DEG C.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

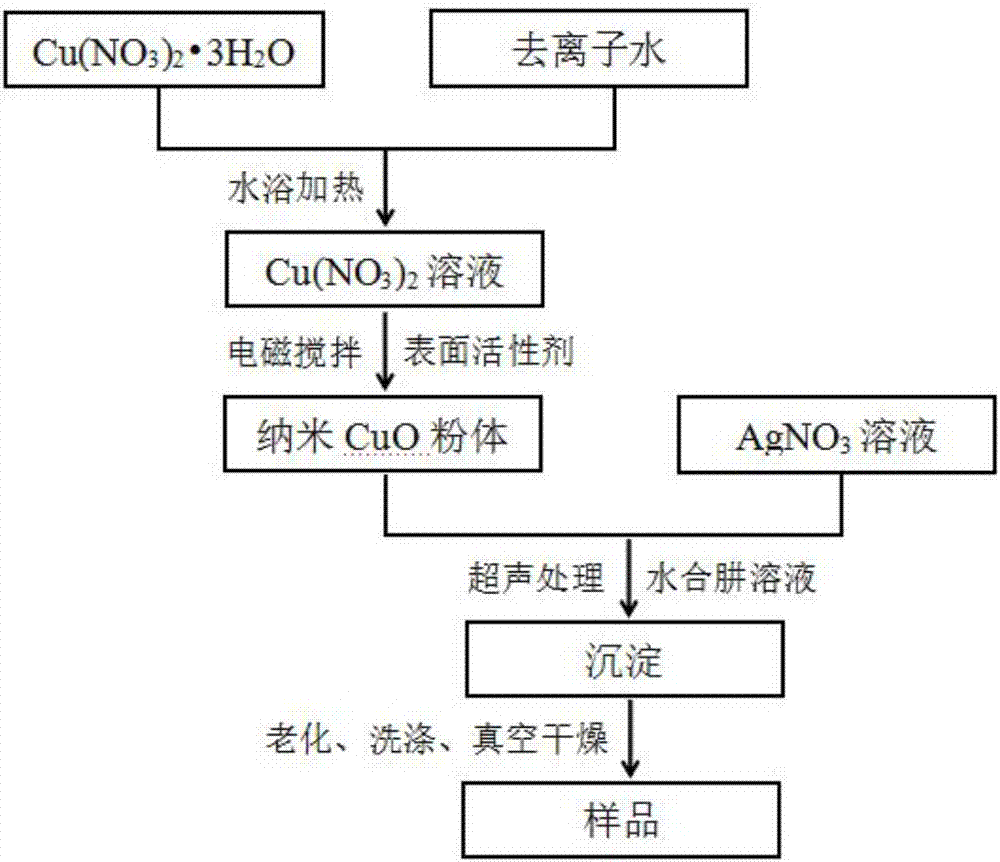

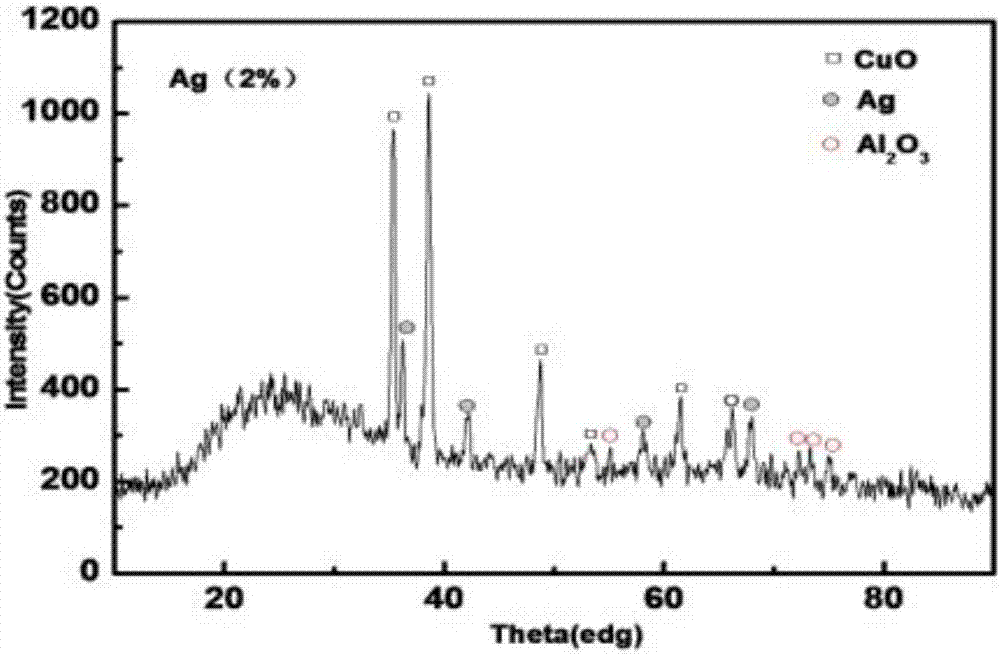

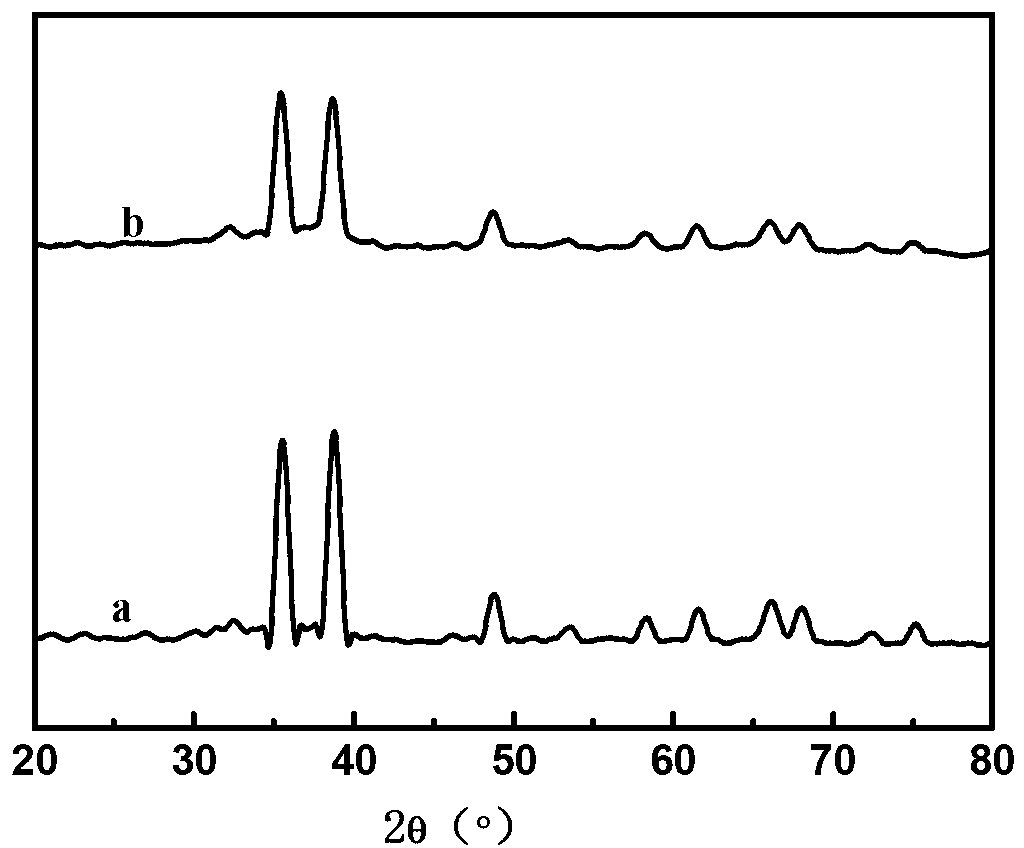

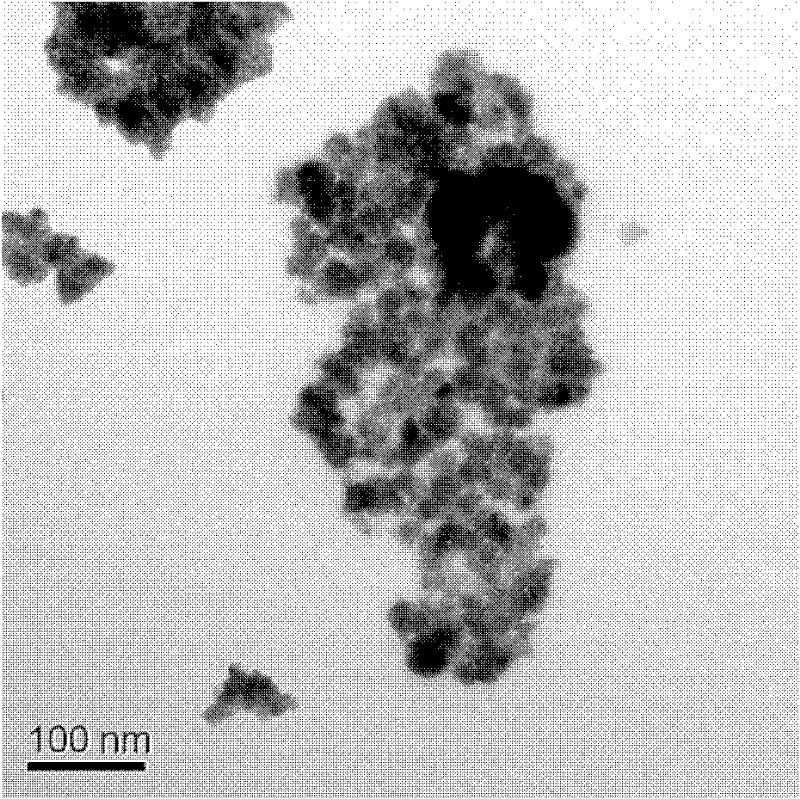

Silver-loaded copper oxide nano composite material preparation method

ActiveCN107413354ALow costSimple equipment and processMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationVacuum drying

The invention discloses a silver-loaded copper oxide nano composite material preparation method which is applied to the field of catalysis. The method includes steps: taking copper nitrate trihydrate as a copper source and sodium hydroxide solution as a precipitant, adding a surfactant, electromagnetically stirring to obtain a precipitate, washing and drying to obtain nano CuO powder; under the condition of ultrasonic treatment, taking silver nitrate solution as a silver source and hydrazine hydrate as a precipitant to obtain a silver-loaded copper oxide nano composite material through aging, washing and vacuum drying. The preparation method is simple in process, low in cost and low in equipment requirement, an obtained product is small in particle size being about 50nm, large in specific surface area, close in combination of nano silver particles and a copper oxide matrix and great in catalysis performance, problems of complex preparation process, long production period, high production cost and the like of the nano copper oxide composite material are solved, and a promising industrial application prospect is achieved.

Owner:SHANDONG NORMAL UNIV

Method for preparing nanometre copper oxide by solid-phase template method

InactiveCN103303962ALow costReduce pollutionMaterial nanotechnologyCopper oxides/halidesCopper oxideAmination

The invention discloses a method for preparing nanometre copper oxide by a solid-phase template method. The method comprises the following steps of: purifying and degrading lignin at first; then synthesising lignin-amine via amination modification; and finally using the prepared lignin-amine as a template for preparing nanometre copper oxide in a solid phase. Lignin is difficult to dissolve in general solvents, therefore, the template agent is removed by a roasting method. The method disclosed by the invention is simple in synthesis process, low in cost, easily-available in raw materials, high in productivity, and less in environmental pollution; the prepared product is black, various in shape, and wide in application.

Owner:JIANGSU UNIV

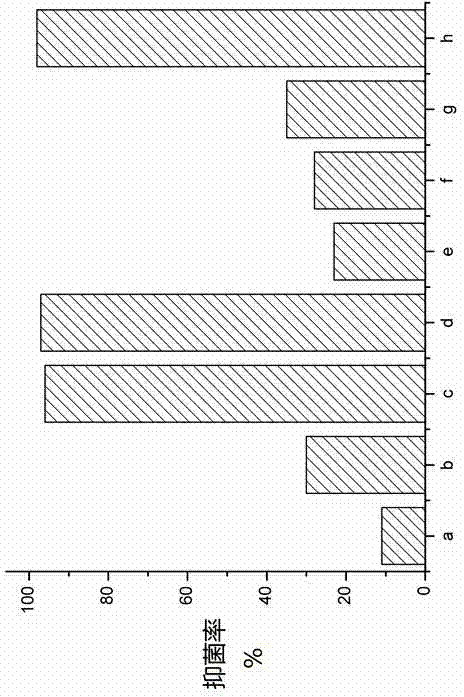

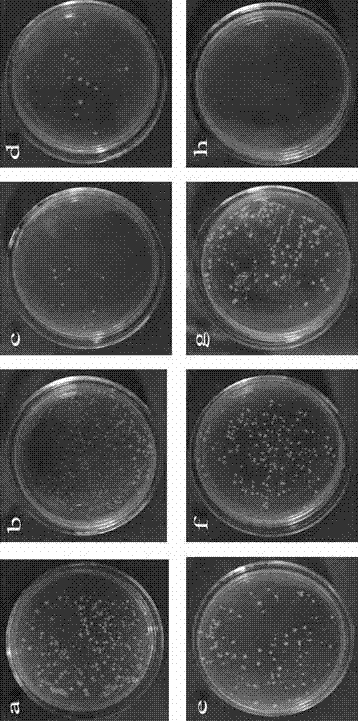

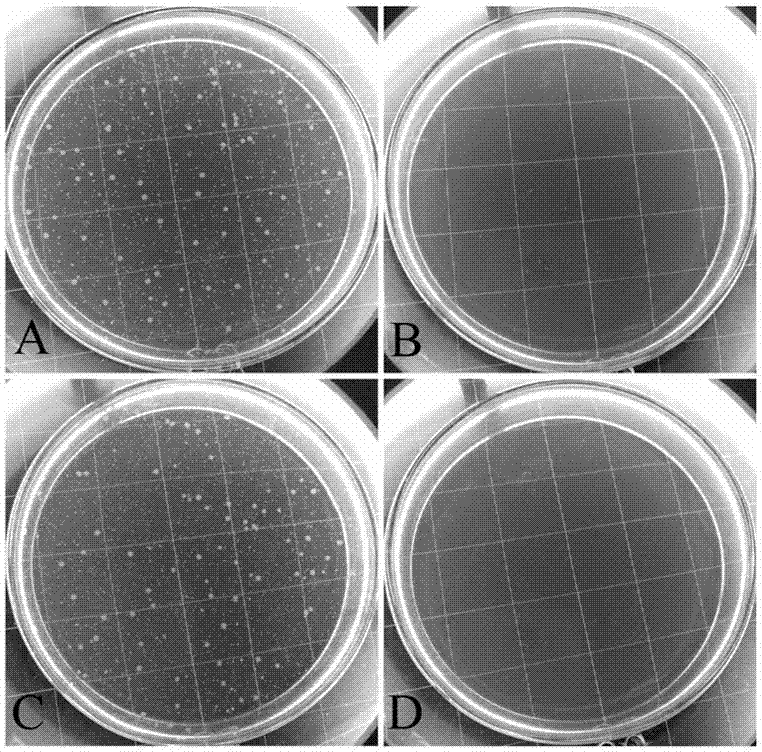

Method for improving antibacterial activity of cephalexin through synergy of nanometer copper oxide

InactiveCN103933066ALower doseGood curative effectAntibacterial agentsOrganic active ingredientsEscherichia coliCefalexin

The invention specifically relates to a method for improving antibacterial activity of cephalexin through synergy of nanometer copper oxide, which belongs to the technical field of biological medicine. According to the method, a nanometer copper oxide inorganic nano-material is added into cephalexin so as to improve antibacterial activity on Escherichia coli. According to results of antibacterial experiments, it is found that nanometer copper oxide has a good synergistic effect on antibacterial activity of cephalexin; drug effects produced in combined usage of nanometer copper oxide and cephalexin are far better than drug effects produced in separate usage of nanometer copper oxide and cephalexin. The method has the advantages of easy availability of raw materials, low cost and simple operation.

Owner:TONGJI UNIV

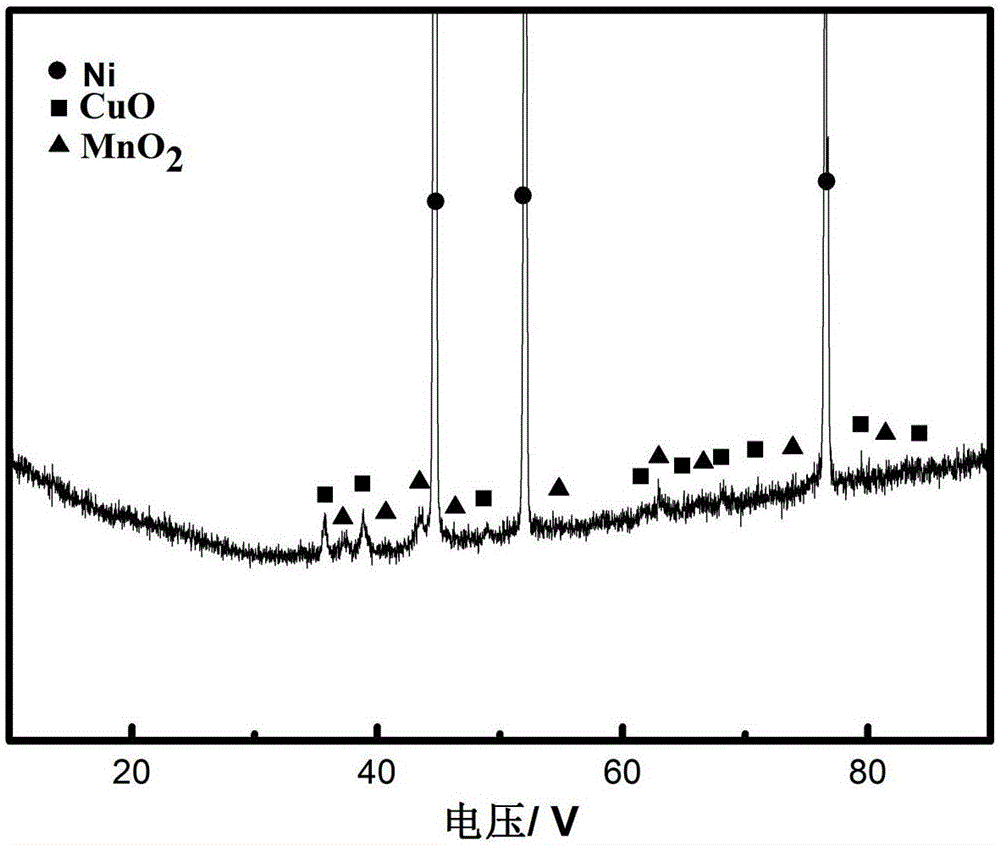

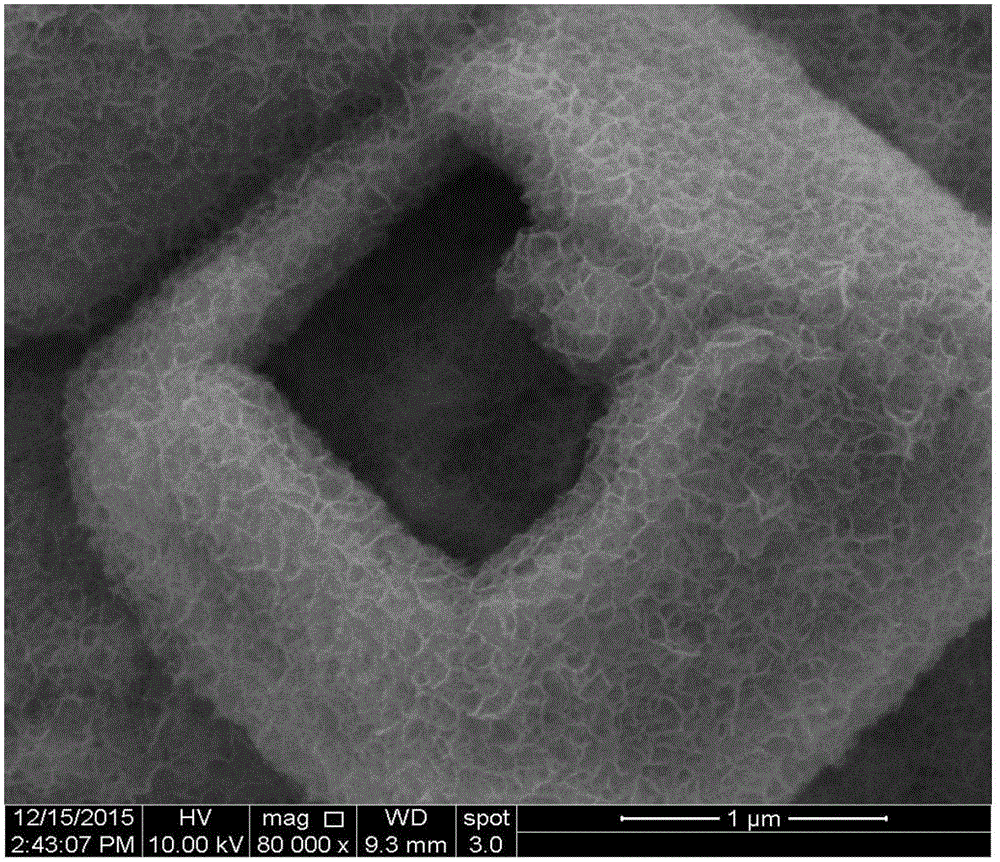

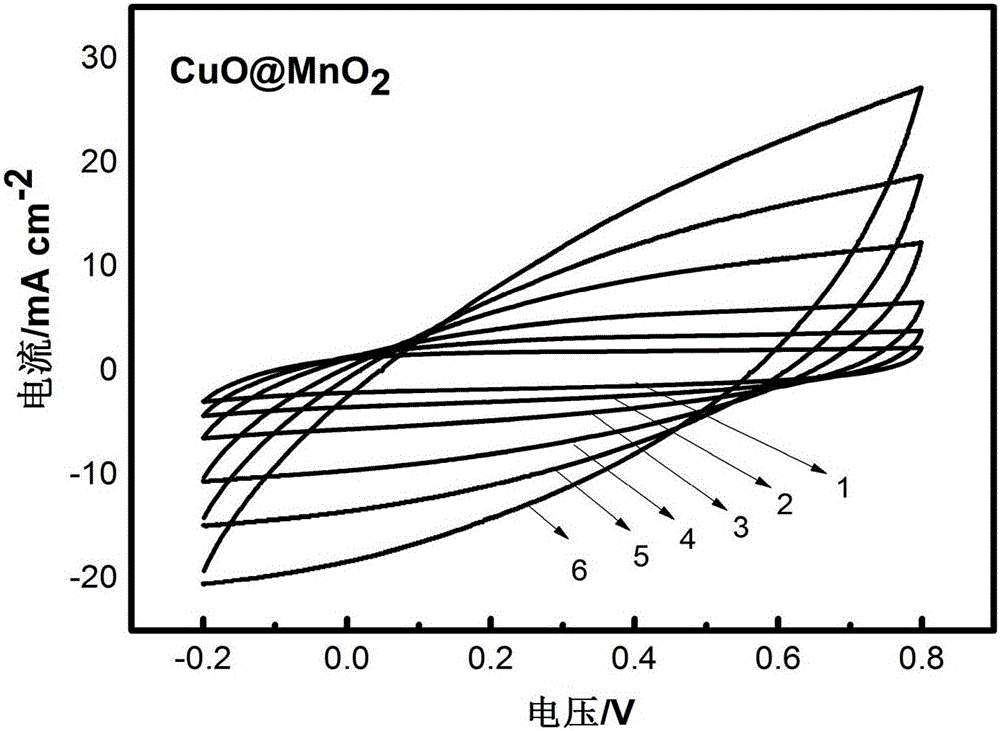

Preparation method and application of copper oxide/manganese dioxide core-shell nanocone electrode material

InactiveCN105869914AReduce resistanceSimple methodMaterial nanotechnologyHybrid capacitor electrodesCopper oxideCharge discharge

The invention discloses a preparation method and application of a copper oxide / manganese dioxide core-shell nano-cone electrode material. The specific steps include: a. placing the pretreated nickel foam and copper nitrate aqueous solution in a hydrothermal kettle, and React at 160°C for 3‑12h; cool to room temperature, take out the foamed nickel, clean it, and dry it in vacuum; calcinate at 300‑500°C for 2‑6h to obtain the nickel foam supported by one-dimensional nano-copper oxide cones. b. the nickel foam supported by the one-dimensional nano-copper oxide cone prepared in step a and the concentration of 0.01-0.05M potassium permanganate aqueous solution are placed in a hydrothermal kettle, and reacted at 140-170°C for 1-5h; cooling After reaching room temperature, take out the nickel foam, clean it, and dry it in vacuum to obtain a nano-cone electrode material with copper oxide as the core and manganese dioxide as the shell grown on the nickel foam substrate. This electrode is used to assemble supercapacitors, at 0.4Ag ‑1 Under the current density, its specific capacity is 650Fg ‑1 ; After 2000 cycles of charging and discharging, its specific capacity remains above 85%.

Owner:SOUTHEAST UNIV

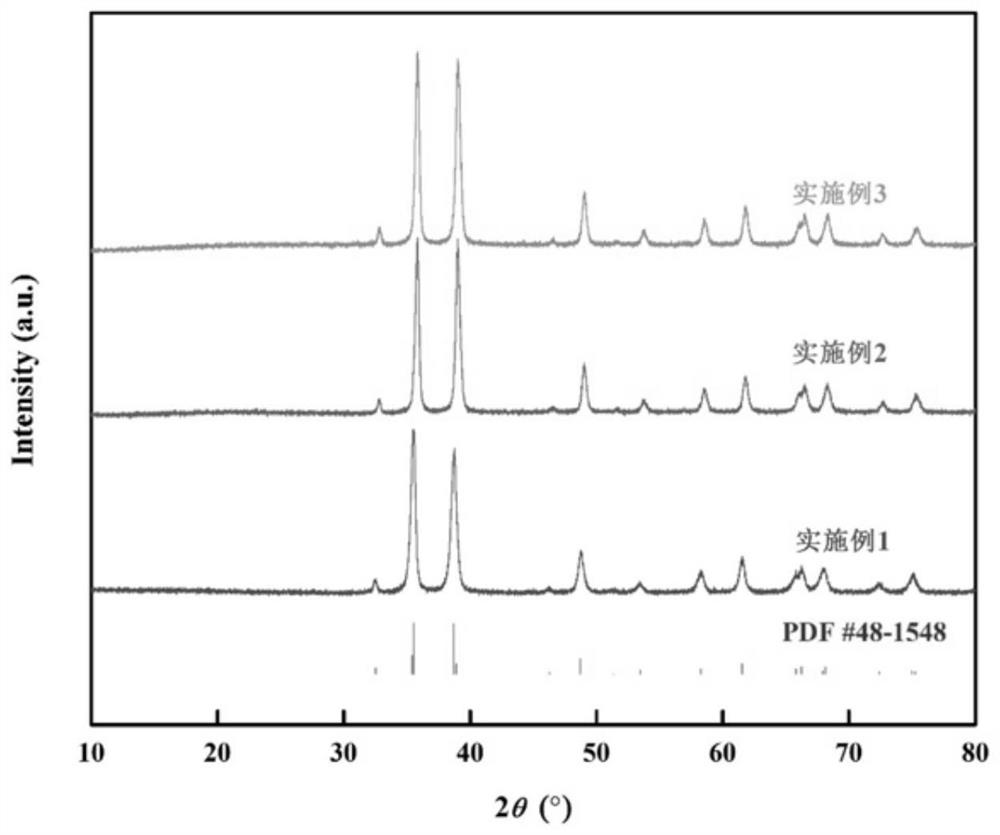

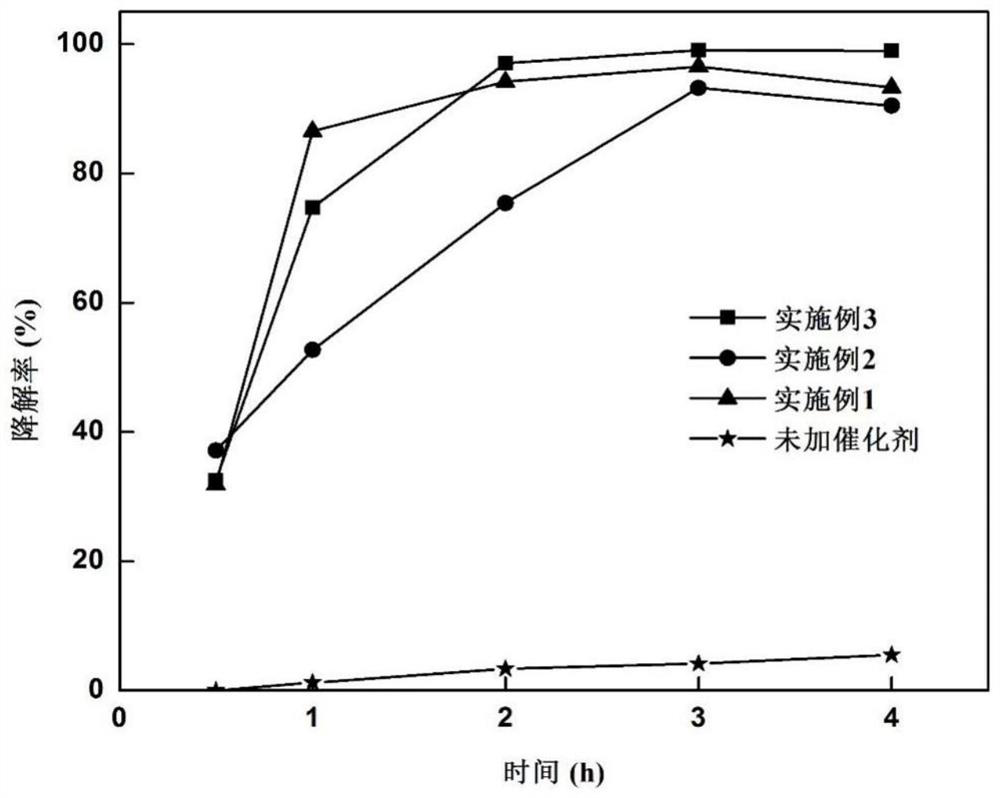

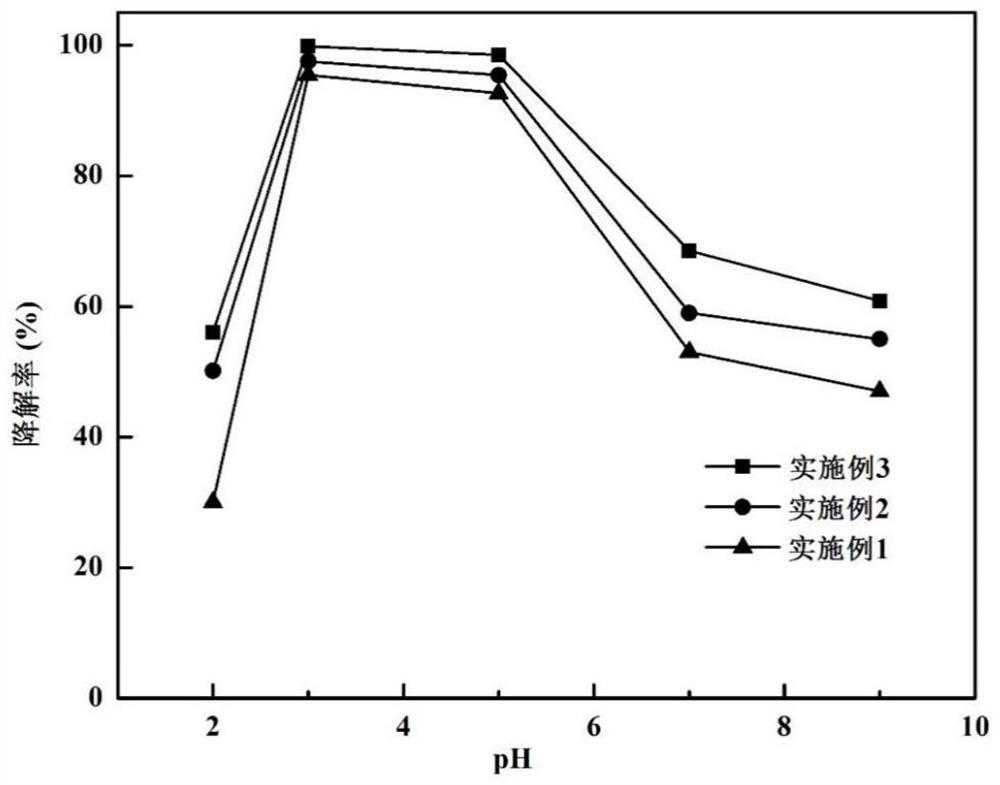

Preparation method of nano copper oxide and application of nano copper oxide in photocatalytic degradation of organic matters

InactiveCN112093816ALarge lattice spacingRegular shapeWater contaminantsCatalyst activation/preparationCopper oxideNitrogen gas

The invention relates to a preparation method of nano copper oxide and an application of the nano copper oxide in photocatalytic degradation of organic matters. The preparation method comprises the following steps: dropwise adding a precipitant solution into a copper ion-containing solution while stirring, continuing to stir for reaction after dropwise adding is completed, then transferring into amicrowave hydrothermal reaction kettle for a microwave hydrothermal reaction, and after the reaction is completed, and separating to obtain a product, washing and drying the product, grinding, and roasting in a tubular furnace in a nitrogen atmosphere to obtain the nano copper oxide. The nano copper oxide prepared by the method is added into wastewater containing methyl orange and other organic matters, hydrogen peroxide is added, the pH value is adjusted, an LED lamp is adopted for visible light irradiation, the highest photocatalytic degradation rate of the nanometer copper oxide prepared by the method on methyl orange can reach 99% or above, and the nano copper oxide can be recycled for five times after being washed and dried. and the photocatalytic degradation rate of methyl orange isstill more than 90%.

Owner:JIANGSU UNIV OF TECH

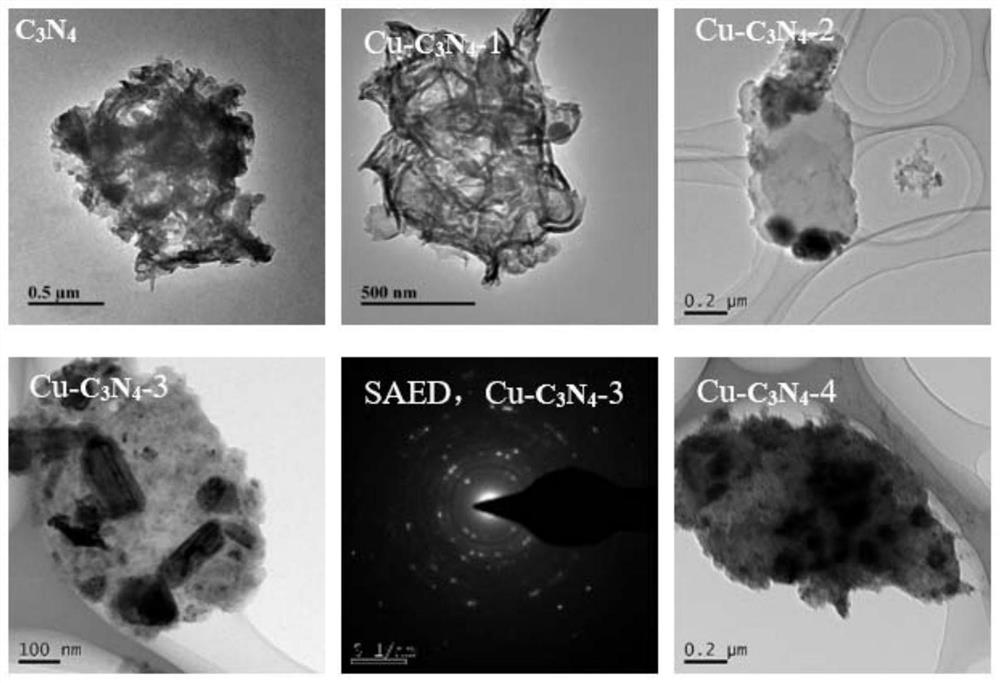

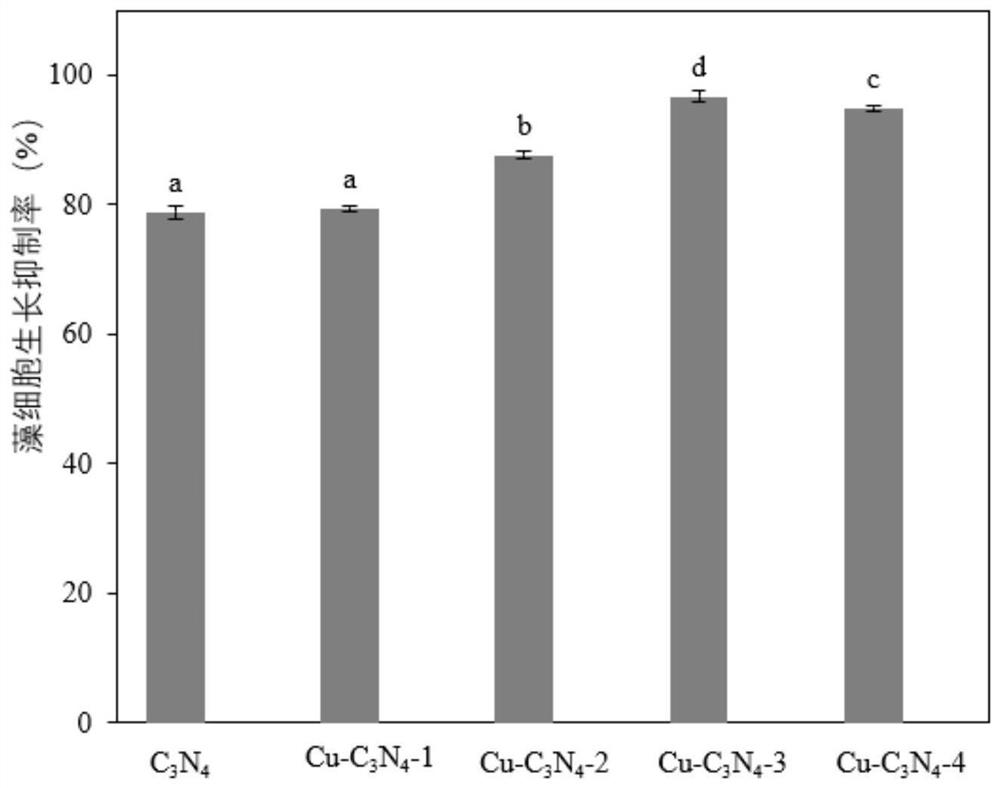

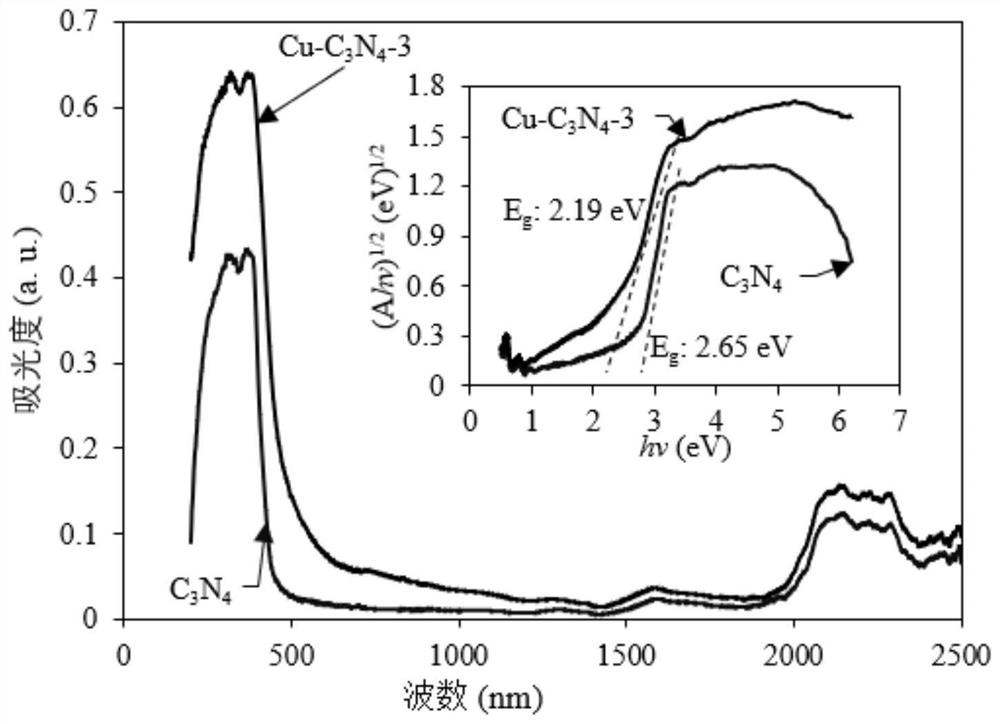

Application of nano copper oxide/carbon nitride composite material in water bloom control

ActiveCN111701613AImprove the effect of algae inhibitionImprove performanceMaterial nanotechnologyWater/sewage treatment by irradiationCarbon compositesEthylic acid

The invention discloses application of a nano copper oxide / carbon nitride composite material in water bloom control, and belongs to the field of water pollution treatment. Carbon nitride and copper acetate are used as raw materials, NaOH is added to react with copper ions to generate CuOH, then the CuOH is attached to C3N4 and converted into CuO through calcination, and thereby the nano copper oxide / carbon nitride composite material is obtained. Compared with copper and carbon nitride, the nano copper oxide / carbon nitride composite material has the advantages that the algal inhibition performance is effectively improved, and the algal inhibition performance of copper-loaded C3N4 prepared under the optimal copper loading ratio is 4.5 times that of C3N4; the nano copper oxide / carbon nitridecomposite material is stable in performance, and still has good water bloom control capacity in natural water with complex components. In addition, the reusability of the nano copper oxide / carbon nitride composite material prepared by the method is better than that of C3N4; therefore, algae inhibition is realized, and algal toxins can be rapidly removed at the same time.

Owner:JIANGNAN UNIV

Hollow-structure biomass charcoal/TiO2 multi-wall tube/CuO photocatalyst and preparation method thereof

InactiveCN108855080ALow costStable costWater/sewage treatment by irradiationWater contaminantsAcid washingUltraviolet

The invention belongs to the technical field of water pollution photocatalysts and relates to a hollow-structure biomass charcoal / TiO2 multi-wall tube / CuO photocatalyst. The hollow-structure biomass charcoal / TiO2 multi-wall tube / CuO photocatalyst is prepared through compounding hollow-structure biomass charcoal, TiO2 multi-wall tubes and CuO nanoparticles. The invention further discloses a preparation method of the photocatalyst; the preparation method comprises the following steps: pre-treating biomasses through washing, crushing, acid washing and the like; after dissolving the biomasses intoa titanium solution, carrying out ultrasonic treatment for 20 to 40min; drying for 4 to 8h at 40 to 60 DEG C, so as to obtain a titanium source / biomasses; putting the titanium source / biomasses into amuffle furnace and carrying out high-temperature calcination for 2 to 6h; immersing into a copper solution for 3 to 6h; after washing, immersing into a copper solution and washing; after repeating for 10 to 20 times, drying for 10h at 50 to 70 DEG C; finally, carrying out high-temperature calcination for 2 to 4h under the protection of nitrogen gas and naturally cooling to obtain the photocatalyst. The preparation method disclosed by the invention is controllable and has simple reaction conditions; the high specific surface area of the hollow biomass charcoal is combined with the photocatalysis performance of TiO2 and the catalysis performance of CuO, and ammonia nitrogen is efficiently and rapidly removed. Ammonia nitrogen wastewater is removed through experimental simulation and the highest removal rate under the irradiation of ultraviolet rays reaches 99.5 percent.

Owner:JIANGSU UNIV

Method for manufacturing copper-based nanoparticles

The present invention relates to a method for manufacturing copper-based nanoparticles, in particular, to a method for manufacturing copper-based nanoparticles, wherein the method includes producing CuO nanoparticles by mixing CuO micropowder and alkylamine in a nonpolar solvent and heating the mixture at 60-300° C.; and producing copper-based nanoparticles by mixing a capping molecule and a reducing agent with the CuO nanoparticles and heating the mixture at 60-120° C.According to the present invention, copper-based nanoparticles can be synthesized using CuO, but not requiring any inorganic reducing agent, in a high yield and a high concentration, so that it allows mass production and easy controlling to desired oxidation number of nanoparticles.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

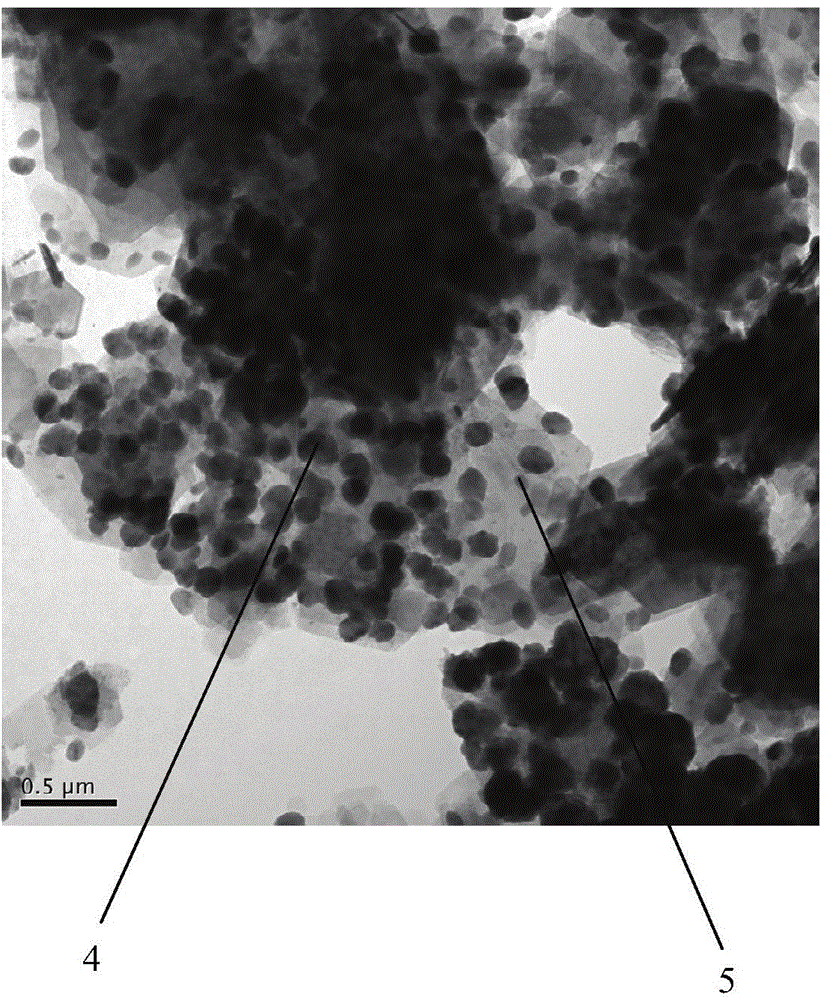

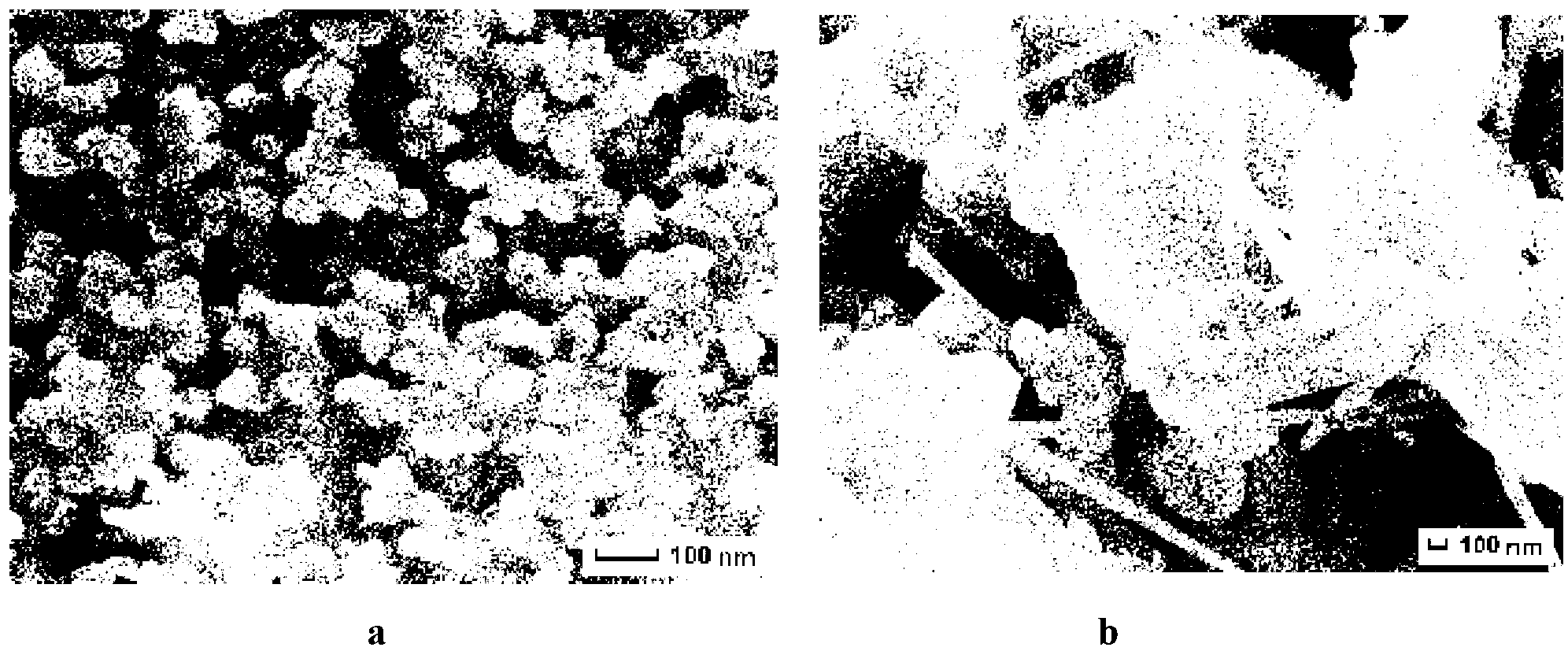

Preparing method and application of self-dispersal nanometer copper oxide complexing body

ActiveCN107140673ASmall particle sizeImprove antibacterial propertiesBiochemical fibre treatmentNanotechnologyDispersityAcetic acid

The invention discloses a preparing method and application of a self-dispersal nanometer copper oxide complexing body, and belongs to the technical field of inorganic nanometer material synthesis. The method comprises the steps that copper acetate and the macromolecule complexing body are dissolved in ethyl alcohol to build an even macromolecule complexing body, the obtained mixed solution is heated until ebullition and added with water dropwise, when the solution turns from green to brownish black, an appropriate alkaline solution is added into the solution dropwise to conduct neutralization, the reaction is conducted for a certain time, and the nanometer copper oxide complexing body is obtained. According to the preparing method, the particle size of a synthetized copper oxide nanometer particle is between 2 nm and 6 nm, the particle has good dispersity in an aqueous solution, the dispersoid is applied to textile finishing without the need of adding adhesive, and the obtained product has excellent and lasting antibiotic property.

Owner:陕西省安贝斯玩具科创有限公司

Nano copper oxide cellulose fiber having strong bacteriostasis and washing-resisting performance

InactiveCN107881763AImprove adhesion performance and antibacterialGood adhesionBiochemical fibre treatmentVegetal fibresChitosan coatingAntibacterial effect

The invention discloses nano copper oxide cellulose fiber having strong bacteriostasis and washing-resisting performance. A preparation method comprises the following steps: cellulose fiber anionization, chitosan modification, nano copper oxide modification, and chitosan coating in order. The nano copper oxide particles are coated between two layers of chitosan, a chitosan / nano copper oxide / chitosan composite functional layer is prepared, chitosan and nano copper oxide perform synergistic antibacterial effect, and adhesion performance, bacteriostasis and washing-resisting performance of the nano copper oxide particles are greatly increased.

Owner:钱景

Copper-base ceramic cylinder sleeve and powder metallurgy preparation method thereof

The invention discloses a copper-base ceramic cylinder sleeve and a powder metallurgy preparation method thereof. The ceramic cylinder sleeve comprises, by weight, 18-31 parts of copper powder, 13-28 parts of nanometer copper oxide particles, 12-15 parts of graphene powder, 9-18 parts of titanium oxide, 14-31 parts of silicon carbide, 9-15 parts of silicon nitride, 10-22 parts of silicon dioxide, 5-14 parts of dispersing agent and 22-36 parts of water. Compared with the prior art, the copper-base ceramic cylinder sleeve and the powder metallurgy preparation method have the following beneficial effects that firstly, by means of the copper-base ceramic cylinder sleeve, metal powder and ceramic materials are mixed evenly through the powder metallurgy method, a blank is manufactured in an isostatic pressing manner, and accordingly it can be guaranteed that the cylinder sleeve obtained through preparing is even in material and not prone to crack; secondly, compared with a cylinder sleeve in the prior art, the abrasive resistance, tenacity, strength, thermal resistance and corrosion resistance of the copper-base ceramic cylinder sleeve are greatly improved, and the long service life is achieved; and thirdly, the preparation method of the copper-base ceramic cylinder sleeve is simple in technology, little in consumed energy and not prone to polluting the environment.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

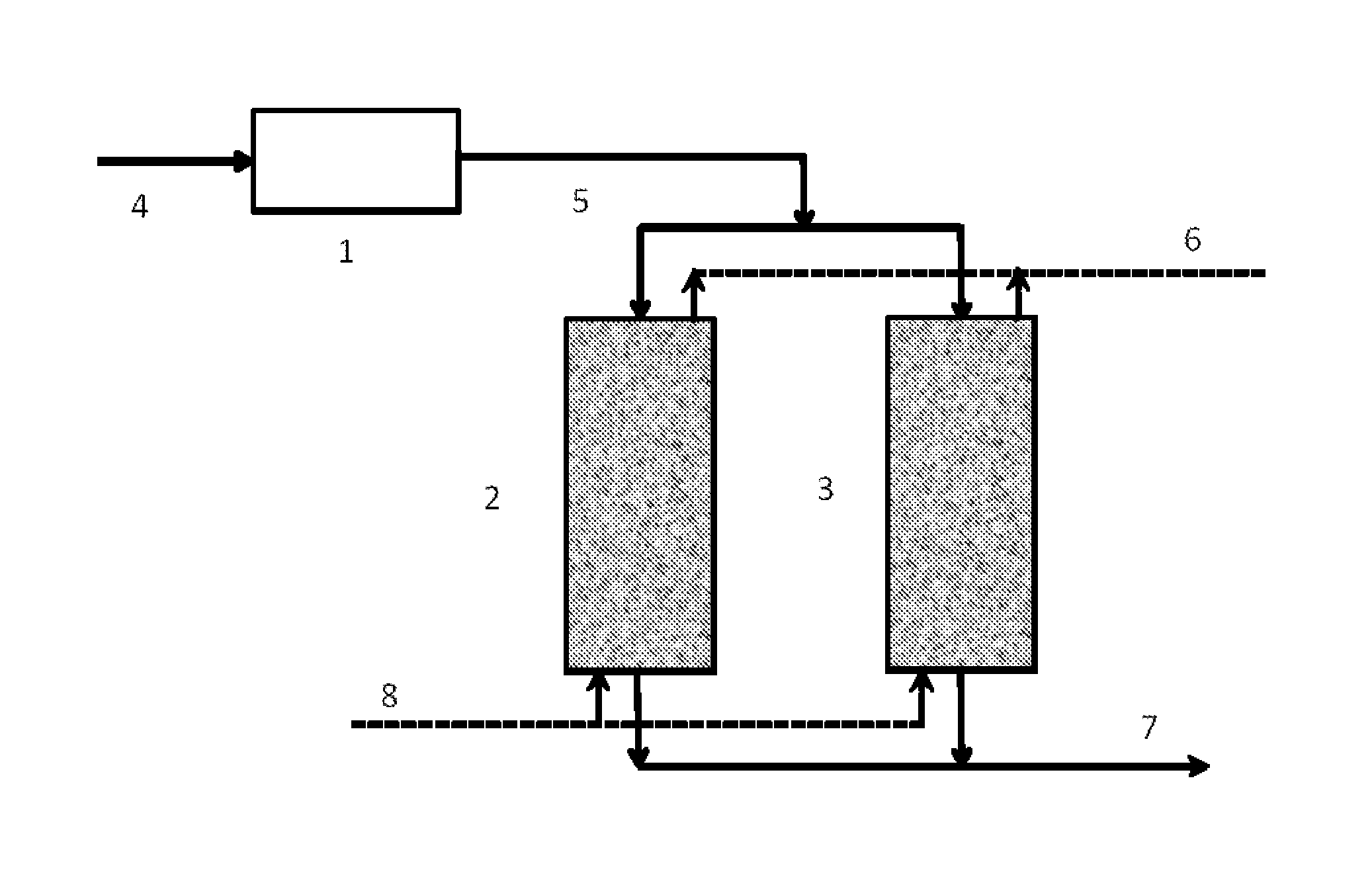

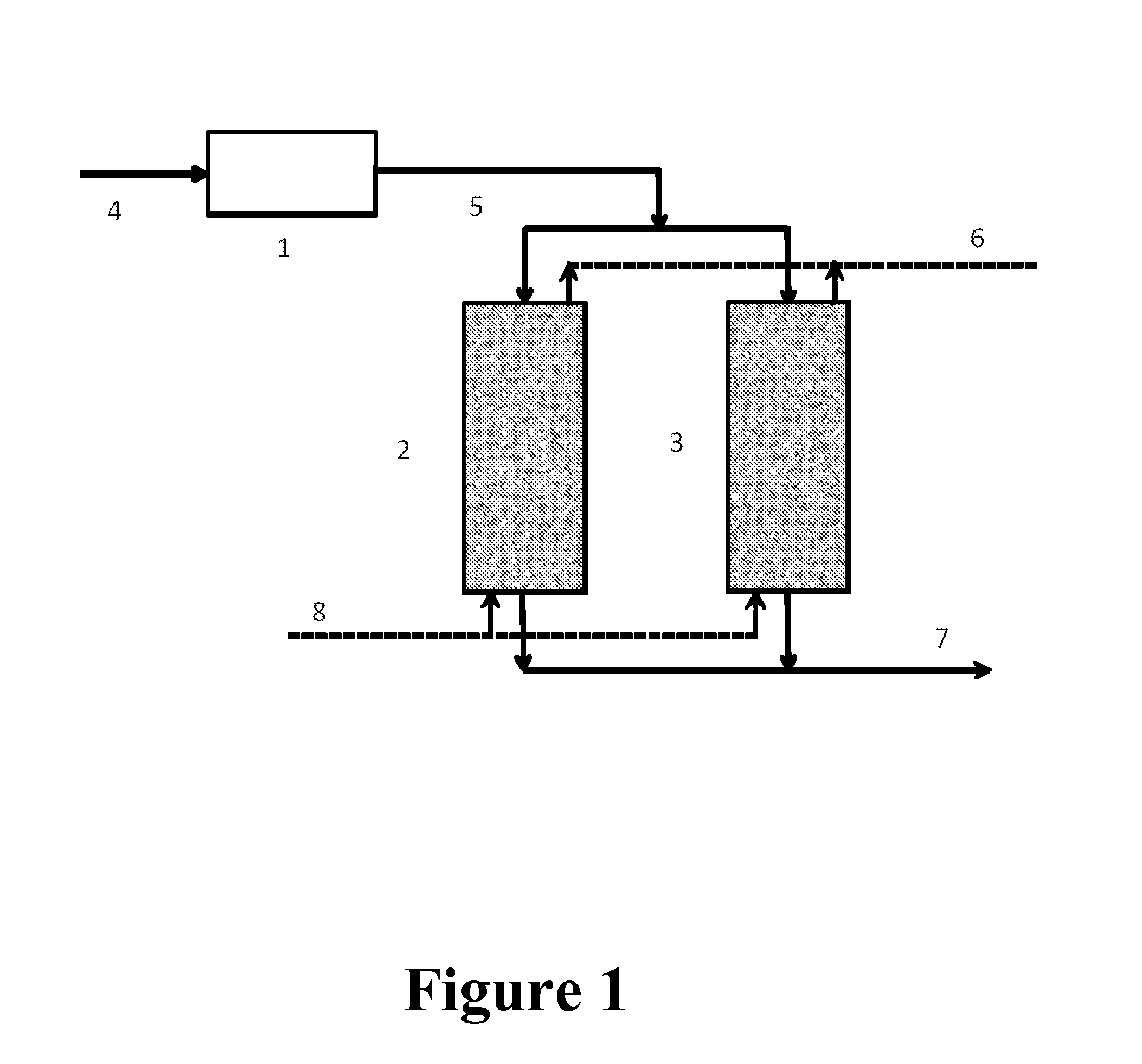

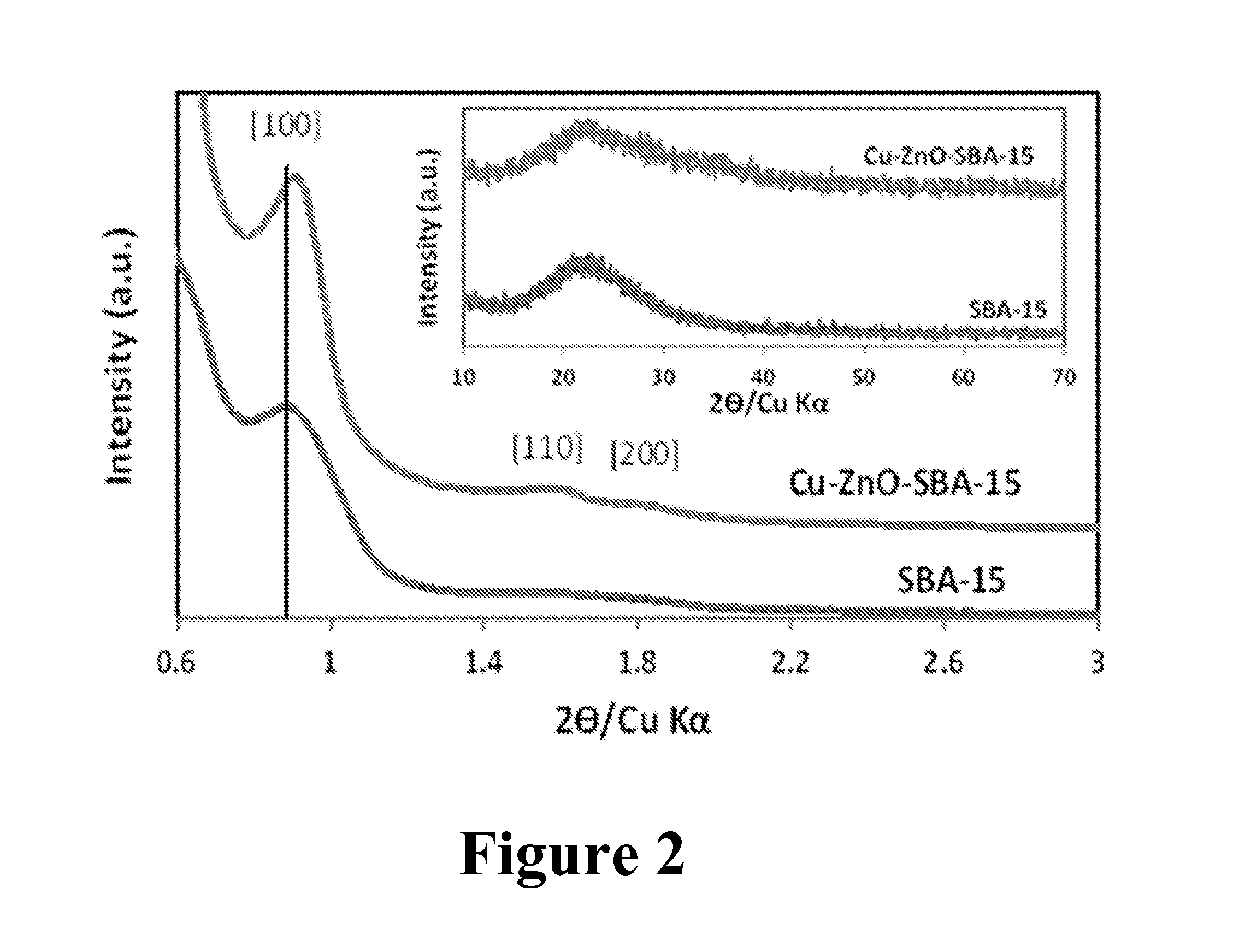

Regenerable system for the removal of sulfur compounds from a gas stream

ActiveUS20160279595A1Easy to produceLower cost of capitalGas treatmentOther chemical processesSorbentSulfur

The disclosure relates to copper oxide-based sorbents, and processes for preparing and using them. The sorbents are preferably used to remove one or more sulfur species from gas streams. The sorbents comprise a porous silica support material impregnated with CuO nanoparticles. The nanoparticles are uniformly distributed throughout the porous silica support and sulfur compounds are adsorbed on the nanoparticles.

Owner:RGT UNIV OF MINNESOTA

Method for manufaturing copper-based nanoparticles

The present invention relates to a method for manufacturing copper-based nanoparticles, in particular, to a method for manufacturing copper-based nanoparticles, wherein the method includes producing CuO nanoparticles by mixing CuO micropowder and alkylamine in a nonpolar solvent and heating the mixture at 60-300° C.; and producing copper-based nanoparticles by mixing a capping molecule and a reducing agent with the CuO nanoparticles and heating the mixture at 60-120° C.According to the present invention, copper-based nanoparticles can be synthesized using CuO, but not requiring any inorganic reducing agent, in a high yield and a high concentration, so that it allows mass production and easy controlling to desired oxidation number of nanoparticles.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

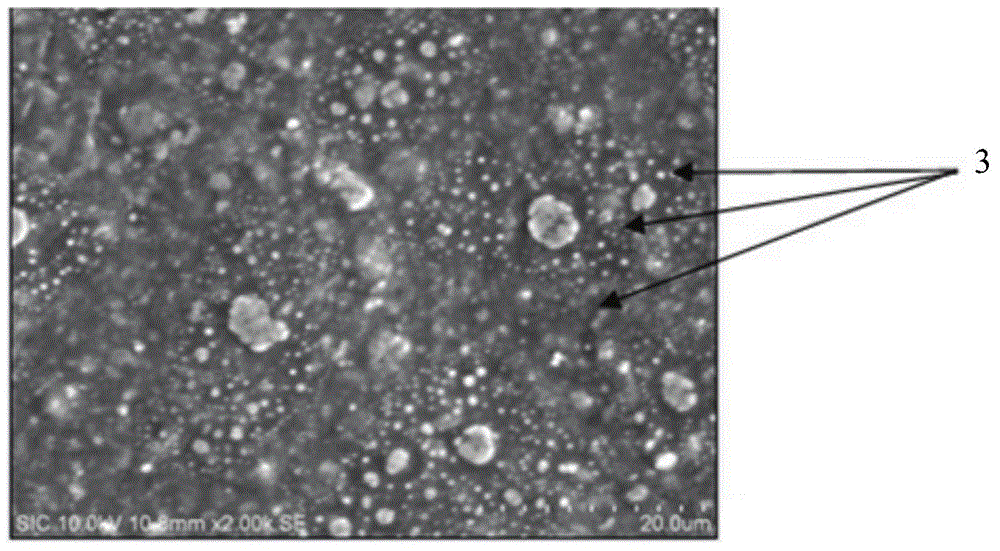

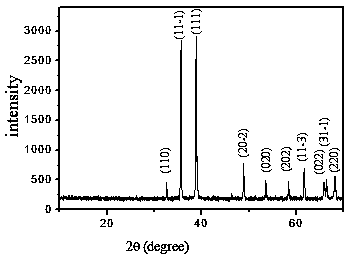

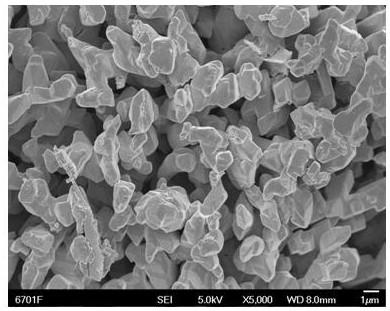

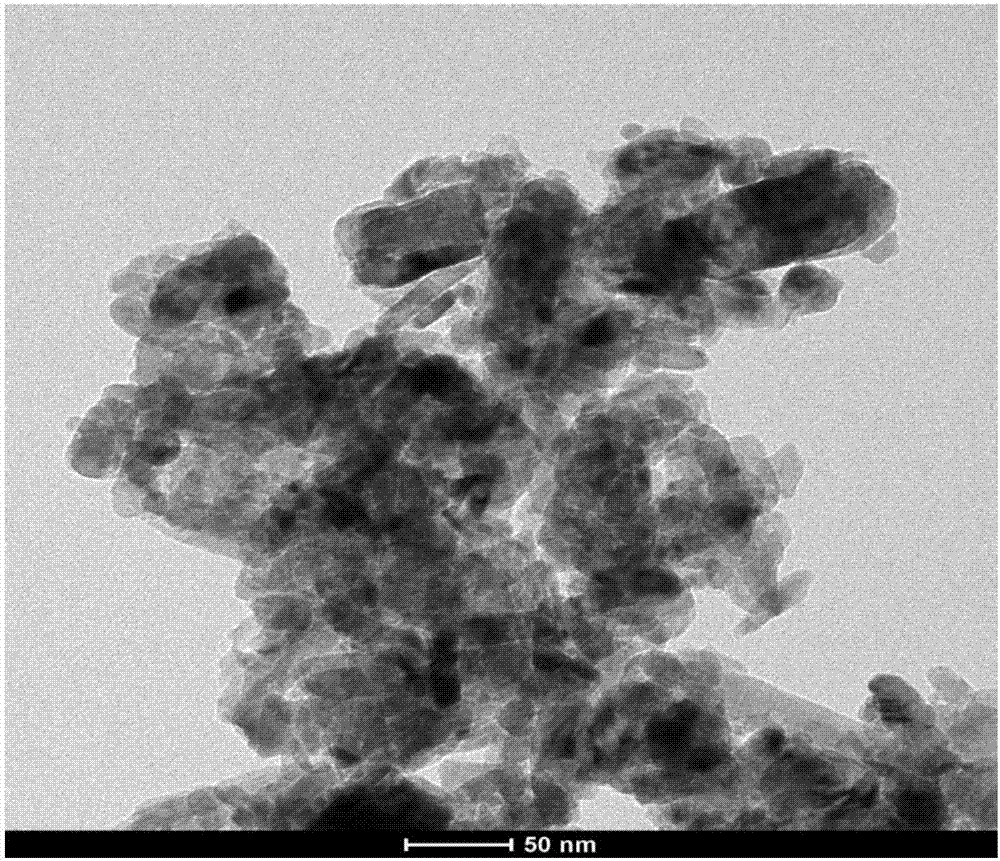

Micro-nano copper oxide and preparation method thereof

InactiveCN104944461ASimple processShape controllableMaterial nanotechnologyCopper oxides/halidesLayered structureCopper salt

The invention provides micro-nano copper oxide which is microparticles formed in such a way that copper oxide layered structures are staggered and arrayed mutually; each copper oxide layered structure is formed through loose arrangement of copper oxide particles; gaps communicated with one another are formed between the copper oxide particles in the same copper oxide layered structure. A preparation method of micro-nano copper oxide comprises the following steps: (1) dissolving soluble copper salt in an organic solvent, sealing and stirring until the soluble copper salt is completely dissolved; (2) dissolving dodecyltrimethylammonium bromide in an obtained solution, sealing and stirring; (3) conducting heat preservation on the obtained solution for 2-12 h at the temperature of 120-200 DEG C, and cooling; (4) filtering a reaction product, centrifugalizing the filtered reaction product, cleaning the centrifugated product, and drying a cleaned product; (5) conducting 400-600-DEG C high-temperature calcinations on a dried product for 1-5 h. Copper oxide is controllable in shape, regular, and high in dispersibility, has a three-dimensional hierarchical structure and more active sites, and is large in specific surface area, and high in gas sensitivity, and the synthetic method is simple and high in repeatability.

Owner:HUBEI UNIV

Method for preparing nanometer copper oxide by using copper scrap

InactiveCN103496731ASimple methodLow costMaterial nanotechnologyCopper oxides/halidesCopper chlorideChloric acid

The invention relates to a method for preparing nanometer copper oxide by using copper scraps. The method comprises the following steps of: immersing the copper scraps into a chloric acid solution, and extracting a clear copper chloride CuCl2 supernatant; regulating and controlling the copper content of a copper chloride CuCl2 solution to 0.5-10 percent by weight, and controlling the potential pH of hydrogen of the copper chloride CuCl2 solution to 0-2; placing the copper chloride CuCl2 solution obtained from the last step into a reaction tank which contains sodium hydroxide NaOH reaction liquid, regulating the pH value of the sodium hydroxide NaOH, wherein the pH value of end reaction is 9-12, the temperature of the reaction tank is controlled at 60-90 DEG C, and the stirring time of the reaction tank is 0.5-2 hours; filtering and washing black precipitates obtained from the last step, and removing sodium Na and chlorine Cl which are contained in a reactant to obtain black nanoscale copper oxide. The method for preparing the nanometer copper oxide through the copper scraps, which is disclosed by the invention, has the advantages of simpleness, effectiveness, low cost, less pollution and high purity.

Owner:江西新金叶实业有限公司

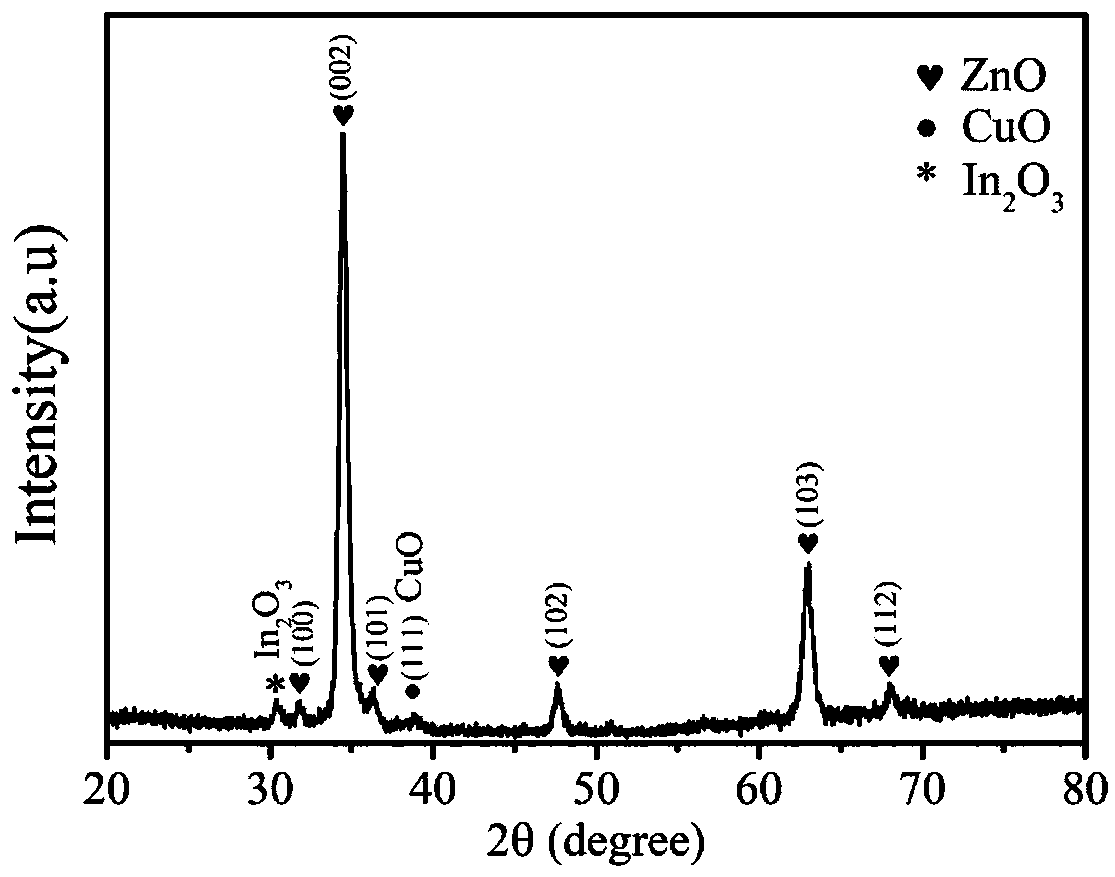

Photoelectric material with CuO nanoparticle modified ZnO nanowire array, preparation and application

ActiveCN110350053AEvenly dispersedReduce dispersionFinal product manufactureNanoopticsHeterojunctionElectron hole

The invention discloses a photoelectric material with a CuO nanoparticle modified ZnO nanowire array, preparation and an application. Firstly, a ZnO seed layer film is prepared by adopting a sol-gel method; a ZnO nanowire array is grown on the ZnO seed layer film by adopting a hydrothermal method; and then CuO nanoparticles are adhered on ZnO nanowires by adopting the sol-gel method to obtain theZnO nanowires with the CuO nanoparticles uniformly dispersed on the surfaces. From a microstructure, the composite material has a large specific surface area; the composite material has a large numberof heterojunctions, photon-generated carrier recombination is reduced, and electron-hole pairs are effectively separated, so that the service life and the concentration of carriers are prolonged andincreased; and from physical property fusion, the composite material not only has the light absorption capability of the ZnO nanowires, but also has the light absorption capability of the CuO nanoparticles, is an excellent photoelectric material and has a great prospect in an application to a photoelectric device.

Owner:NORTHWEST UNIV(CN)

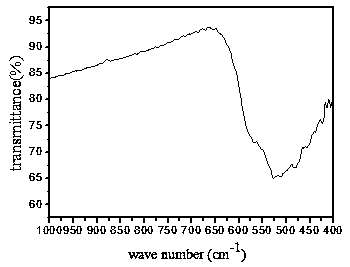

Method for preparing nanometer copper oxide

InactiveCN102351237AReaction conditions require mildSimple and fast operationNanotechnologyCopper oxides/halidesPhysical chemistryCopper oxide

The invention discloses a method for preparing nanometer copper oxide materials, which comprises the following steps that: 1) copper powder is soaked by hydrochloric acid with the mass concentration being 25 percent to 35 percent for 3 to 5min, then, the copper powder is taken out and is placed into acetone for ultrasonic cleaning, and purified copper powder is obtained; 2) iodine simple substances are added into acetonitrile and are dissolved through heating, the acetonitrile solution of iodine is obtained, and the solubility of the iodine in the acetonitrile solution is 3 to 10g / L; 3) the purified copper powder is added into the acetonitrile solution of the iodine, the heating and the stirring are carried out, and the heating temperature is 50 to 70 DEG C; and 4 ) black substances in the solution are precipitated and filtered, and the nanometer copper oxide powder is obtained. The method has the advantages that the copper powder is used as a raw material, is stirred in the acetonitrile solution of the iodine, is heated to 50 to 70 DEG C and is directly oxidized by oxygen gas to obtain the nanometer copper oxide. The reaction condition requirement is mild, in addition, the method has the characteristics that the operation is simple and convenient, the equipment requirement is low, the product purity is high, the cost is low, and the like.

Owner:NINGBO UNIV

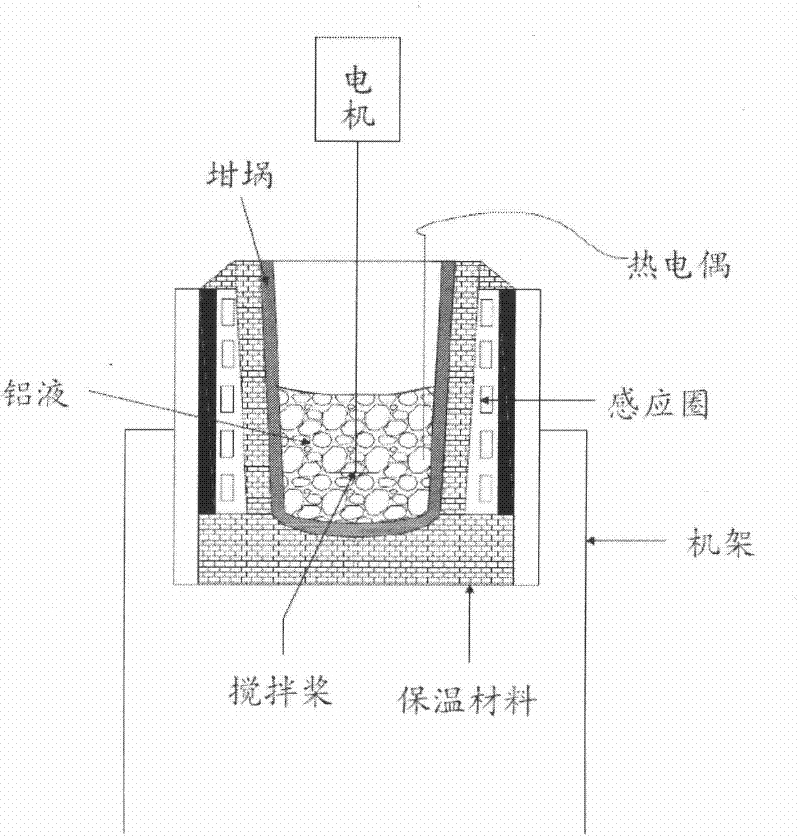

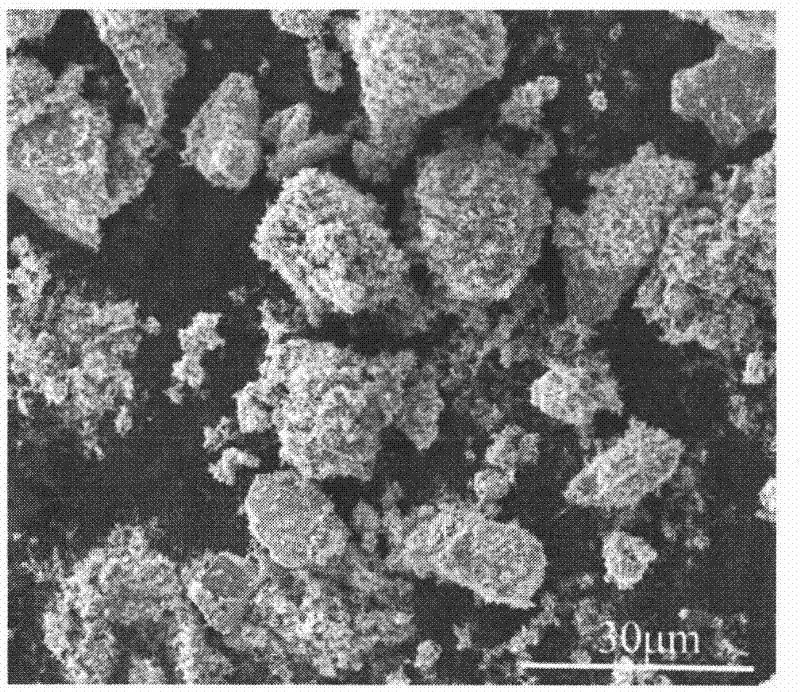

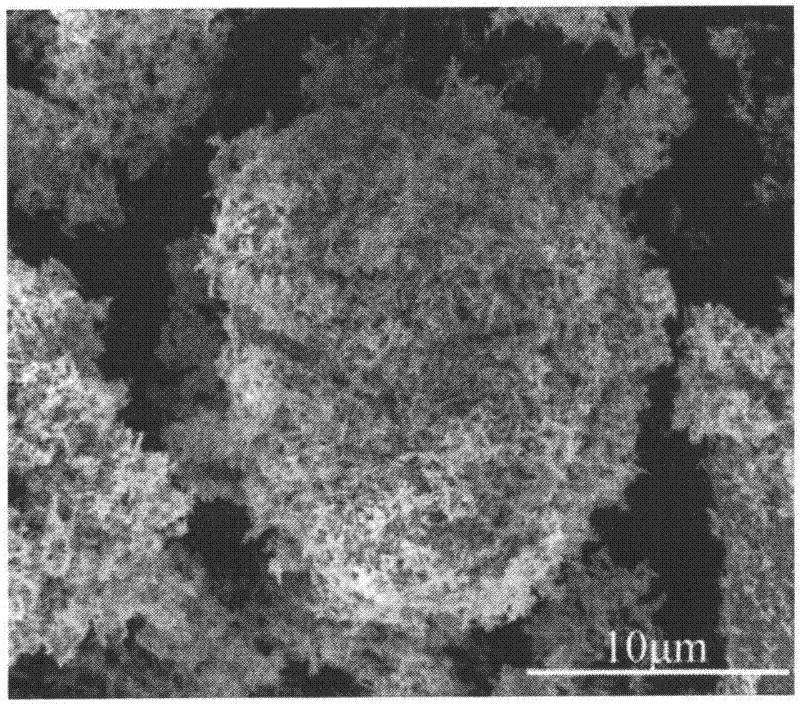

Micro-nano particle reinforced aluminum-based composite material and preparation method thereof

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Electromagnetic-shielding far-infrared polyester fiber

InactiveCN109112662AMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention relates to an electromagnetic-shielding far-infrared polyester fiber. The polyester fiber uses polyester as a substrate and is prepared by adding a composite additive into polyester andcarrying out fusing and blending. The composite additive comprises SiO2 nanoparticles, Fe2O3 nanoparticles, Fe3O4 nanoparticles, SrFe12O19 nanotubes, CuO nanoparticles and CaCO3 nanoparticles.

Owner:FOSHAN NANHAI DISTRICT JIAYAN UNDERWEAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com