Preparing method and application of self-dispersal nanometer copper oxide complexing body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 0.3993g of copper acetate monohydrate in 100ml of absolute ethanol, then add 0.4g of PVP, the solution turns green; heat the water bath to 78°C, add 5ml of deionized water dropwise, and add 7ml of 0.2 M sodium carbonate solution, neutralization reaction for 15 minutes, to obtain nano-copper oxide complex.

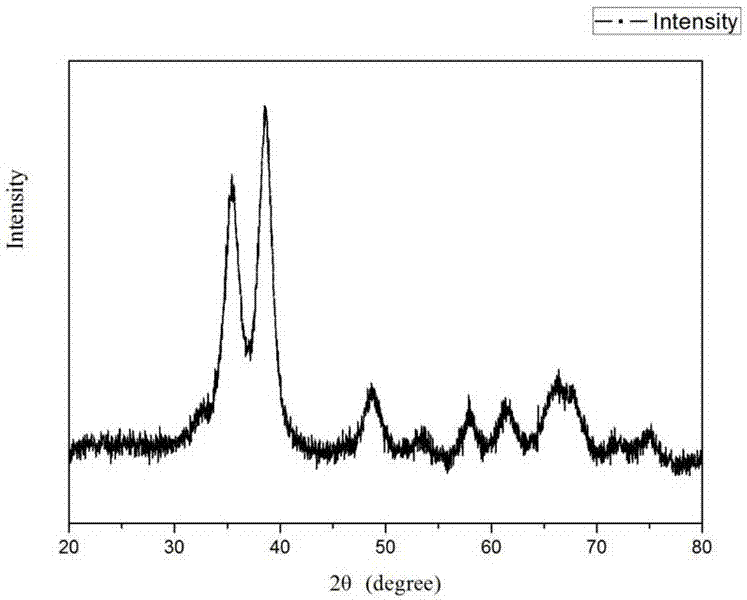

[0029] See attached figure 1 , which is the XRD diffraction pattern of copper oxide provided in this example, compared with the standard card (PDF # 48-1548), it proves that the obtained product is pure phase copper oxide.

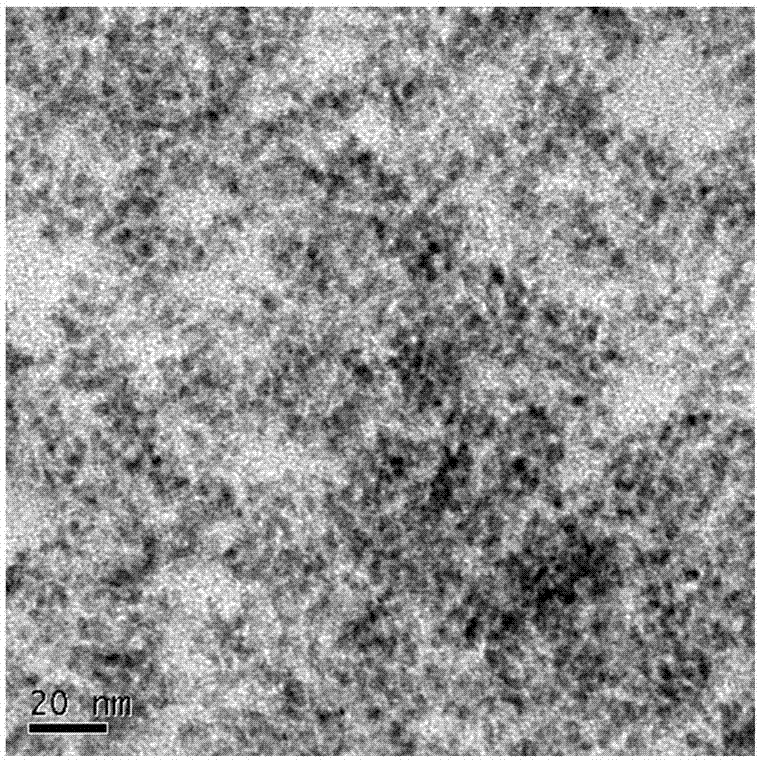

[0030] See attached figure 2 , which is a TEM image of the copper oxide provided in this example; the figure shows that the particle size distribution of the product provided in this example is between 2 and 6 nm, and the dispersion is good.

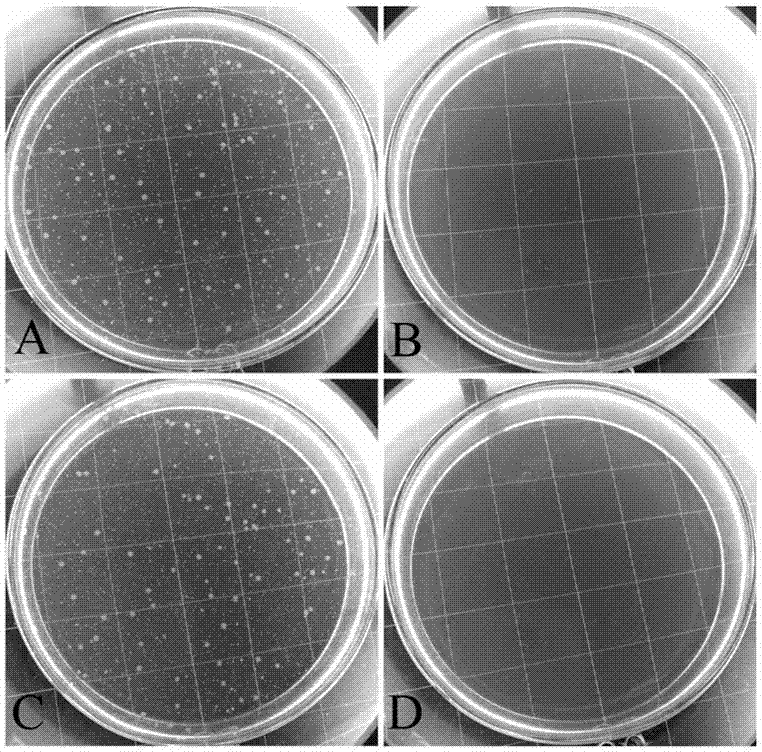

[0031] The obtained copper oxide product is directly diluted 80 times, the cotton textiles are antibacterially finished by dipping technology, and the cotton textiles with antibacterial function...

Embodiment 2

[0035] Dissolve 0.7986g of copper acetate monohydrate and 0.4g of PVP in 100ml of absolute ethanol, heat in a water bath to 78°C, add 5ml of deionized water dropwise, and then add 7ml of 0.2M sodium carbonate solution dropwise after 15min, and react for 15min. The resulting product is directly diluted 100 times, and the padding process is used to carry out antibacterial finishing on chemical fiber textiles.

Embodiment 3

[0037] Dissolve 0.3993g of copper acetate monohydrate and 0.4g of PEG in 100ml of absolute ethanol, heat in a water bath to 78°C, add 5ml of deionized water dropwise, and then add 7ml of 0.2M sodium carbonate solution dropwise after 15min, and react for 15min. The resulting product is directly diluted 50 times, and the spray process is used to carry out antibacterial finishing on silk and wool blended textiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com