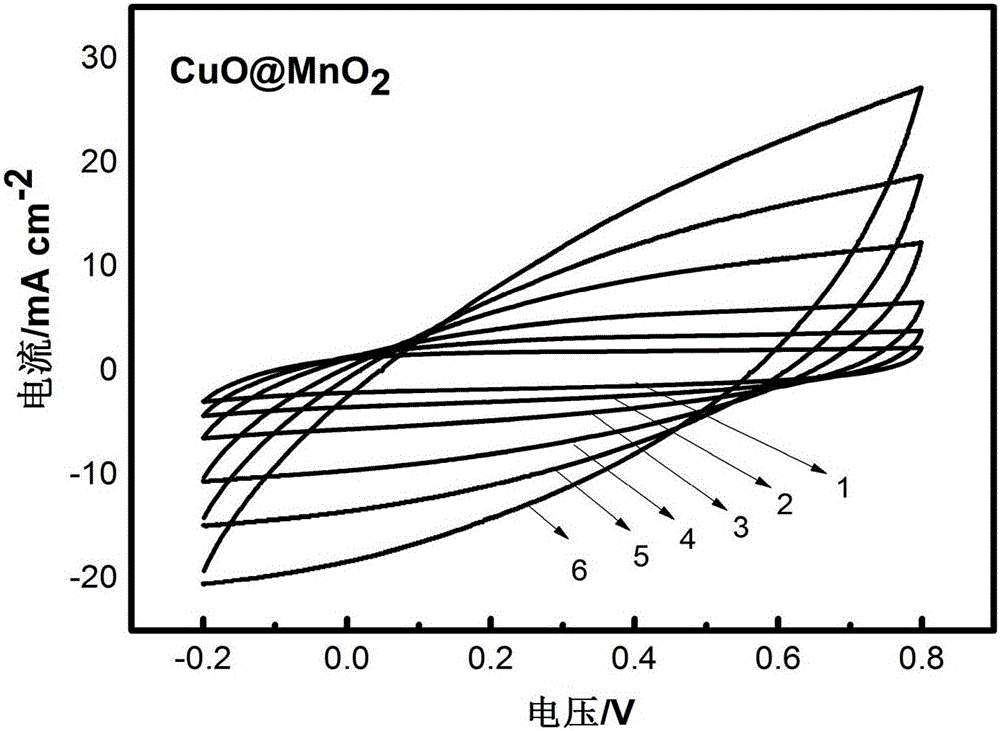

Preparation method and application of copper oxide/manganese dioxide core-shell nanocone electrode material

A manganese dioxide and electrode material technology, applied in the manufacture of hybrid/electric double layer capacitors, nanotechnology, nanotechnology, etc., can solve the problems of low specific capacity, low manganese conductivity, etc. The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

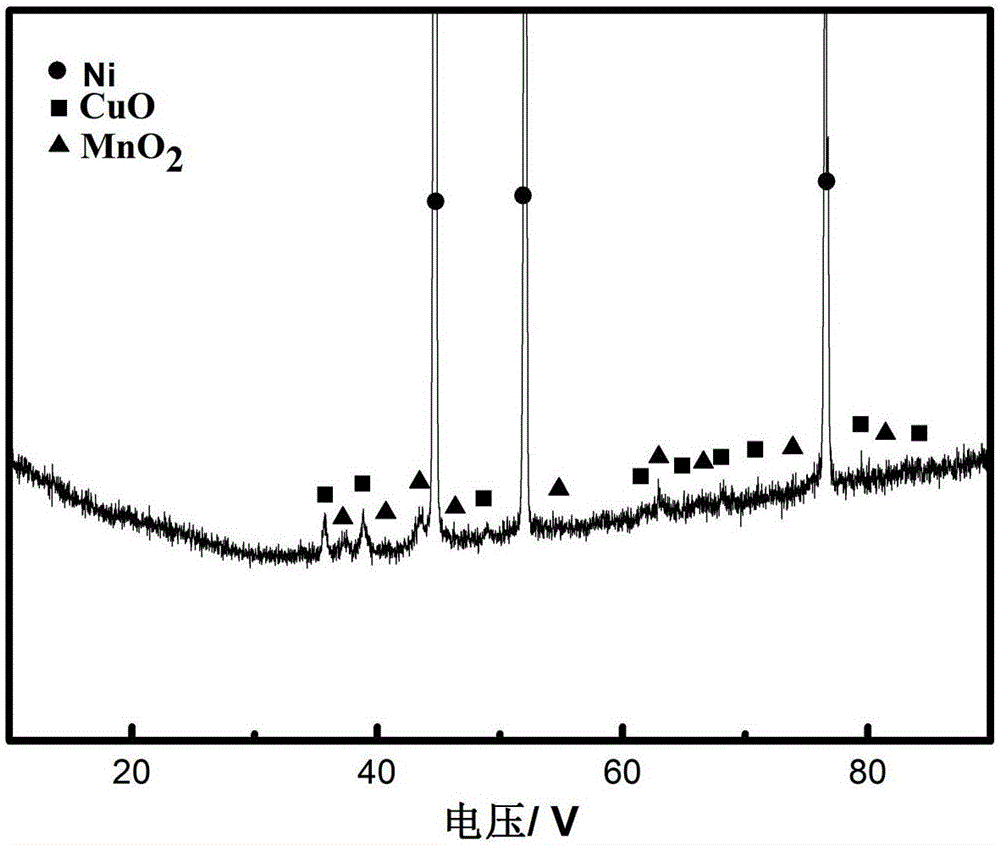

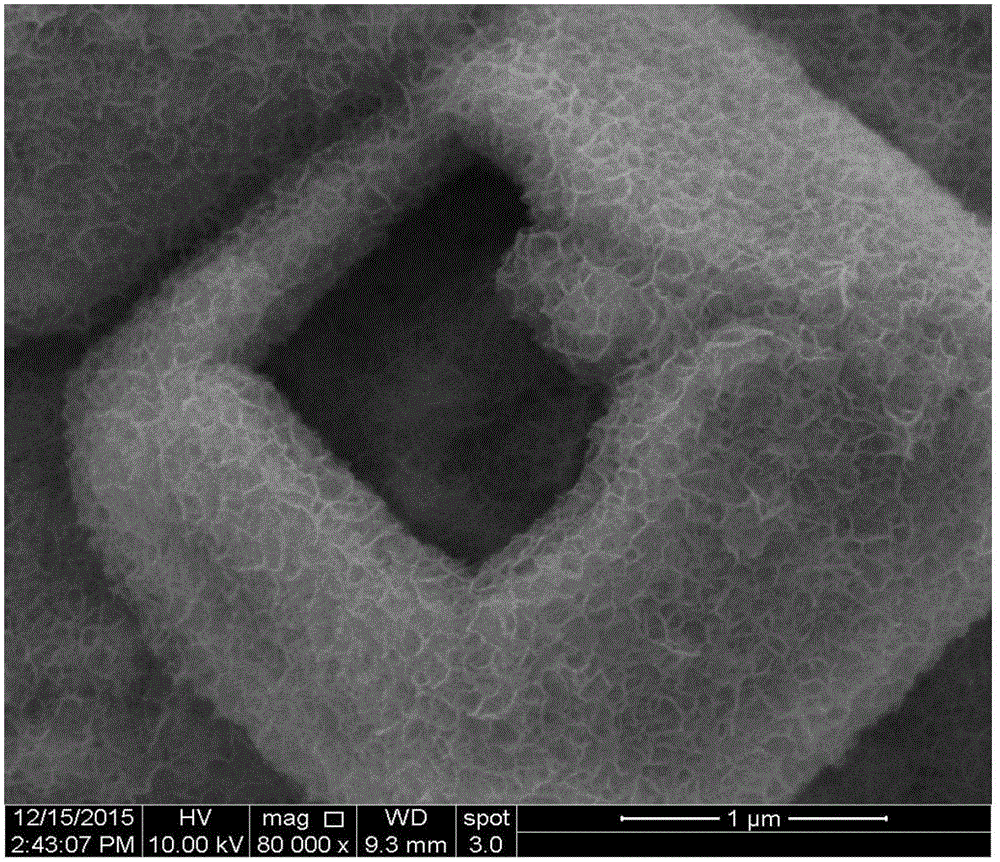

[0035] a. Nickel foam pretreatment: Sonicate it with 3mol / L dilute hydrochloric acid, absolute ethanol, and distilled water for 0.5h in sequence, and vacuum-dry it. Configure copper nitrate aqueous solution: weigh 0.3738g copper nitrate, 0.3g ammonium fluoride and 0.6g urea and add 40mL H 2 Stir in O until dissolved, pour it into a 50mL hydrothermal kettle, and then put the pretreated 2X2.5cm 2 The nickel foam was placed therein, reacted at 120° C. for 9 hours, cooled to room temperature, the nickel foam was taken out, cleaned, and dried in vacuum. Then calcined at 400°C for 4 hours to obtain nickel foam supported by one-dimensional nano-copper oxide cones.

[0036] b. Configure 0.03M potassium permanganate aqueous solution: add 80mL H to 0.37928g potassium permanganate 2 O and stirred until dissolved. Take 40mL of potassium permanganate aqueous solution and pour it into a hydrothermal kettle, then put the nickel foam supported by the one-dimensional nano-copper oxide cone ...

Embodiment 2

[0044] a. Nickel foam pretreatment: Sonicate it with 2mol / L dilute hydrochloric acid, absolute ethanol, and distilled water for 0.5h in sequence, and vacuum-dry it. Configure copper nitrate aqueous solution: weigh 0.3738g copper nitrate, 0.3g ammonium fluoride and 0.6g urea and add 40mL H 2 Stir in O until dissolved, pour it into a 50mL hydrothermal kettle, and then put the pretreated 2X2.5cm 2 The nickel foam is placed therein, reacted at 80° C. for 12 hours, cooled to room temperature, the nickel foam is taken out, cleaned, and vacuum-dried. Then calcined at 300° C. for 6 hours to obtain nickel foam supported by one-dimensional nano-copper oxide cones.

[0045] b. Configure 0.01M potassium permanganate aqueous solution: add 80mL H to 0.1264g potassium permanganate 2 O and stirred until dissolved. Take 40mL of potassium permanganate aqueous solution and pour it into a hydrothermal kettle, then put the nickel foam supported by the one-dimensional nano-copper oxide cone prep...

Embodiment 3

[0048] a. Nickel foam pretreatment: Sonicate it with 3mol / L dilute hydrochloric acid, absolute ethanol, and distilled water for 0.5h in sequence, and vacuum-dry it. Configure copper nitrate aqueous solution: weigh 0.3738g copper nitrate, 0.3g ammonium fluoride and 0.6g urea and add 40mL H 2 Stir in O until dissolved, pour it into a 50mL hydrothermal kettle, and then put the pretreated 2X2.5cm 2 The nickel foam was placed therein, reacted at 140° C. for 6 hours, cooled to room temperature, the nickel foam was taken out, cleaned, and dried in vacuum. Then calcined at 350°C for 5 hours to obtain foamed nickel supported by one-dimensional nano-copper oxide cones.

[0049] b. Configure 0.02M potassium permanganate aqueous solution: add 80mL H to 0.2529g potassium permanganate 2 O and stirred until dissolved. Take 40mL of potassium permanganate aqueous solution and pour it into a hydrothermal kettle, then put the nickel foam supported by the one-dimensional nano-copper oxide cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com