Method for enhancing luminol chemoluminescence using copper oxide nanoparticles

A technology of nano-copper oxide and luminol chemistry, which is applied in the field of analytical chemistry and nanometers, can solve the problems of slow reaction speed and low luminous intensity, and achieve the effects of less sample demand, high sensitivity and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

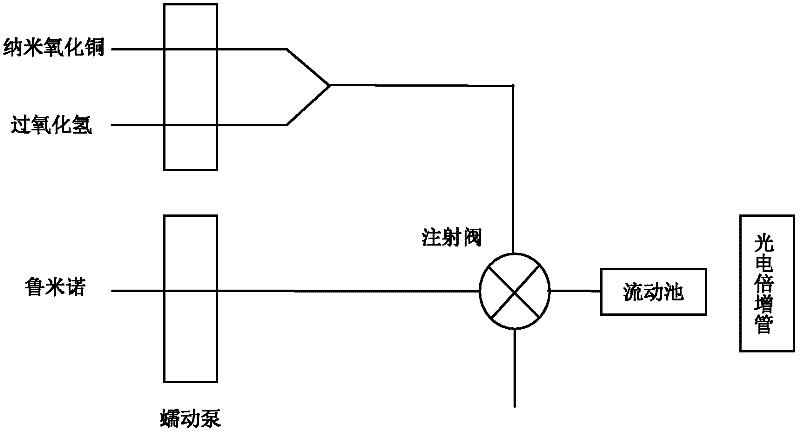

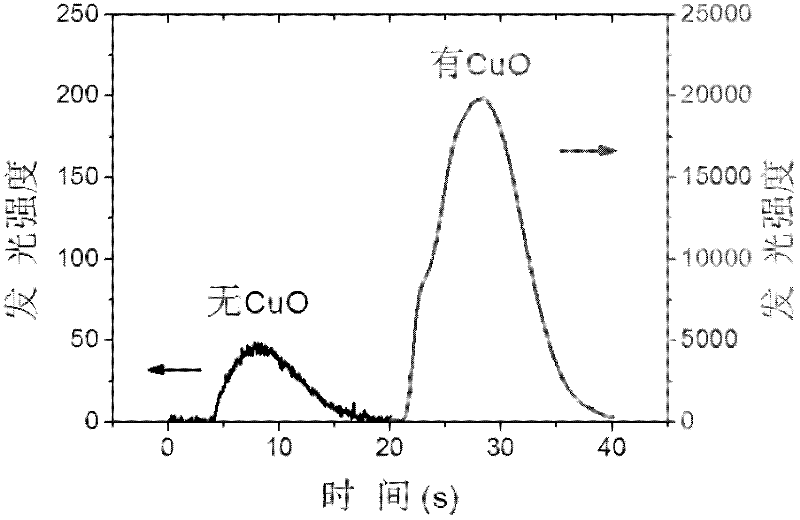

[0039] Flow injection chemiluminescence analysis system such as figure 1 As shown, firstly, 2.0 mg / L nanometer copper oxide colloidal solution and 1.0 mmol / L hydrogen peroxide solution were transported into the mixer through a peristaltic pump for mixing, and then mixed with 0.5 mmol / L luminol (pH 11.5) solution, three These are mixed into the flow cell for reaction, and the intensity of the chemiluminescence produced is detected by a photomultiplier tube. In the blank control experiment, distilled water was used instead of the nano copper oxide colloidal solution. Such as figure 2 As shown, the nano-copper oxide can significantly enhance the luminol chemiluminescence signal, and the enhancement factor is about 400.

Embodiment 2

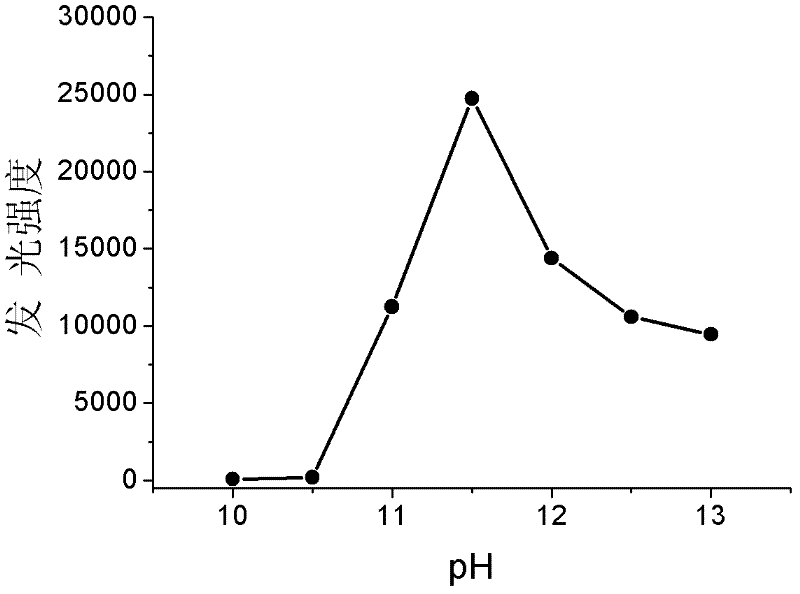

[0041] Flow injection chemiluminescence analysis system such as figure 1 As shown, firstly, 2.0 mg / L nano copper oxide colloidal solution and 1.0 mmol / L hydrogen peroxide solution were transported into the mixer through peristaltic pump and mixed, and then mixed with different pH values (take the value between 10 and 13) 0.5 mmol / L The L luminol solution is mixed, and the three are mixed into the flow cell for reaction, and the intensity of the generated chemiluminescence is detected by a photomultiplier tube. Such as image 3 As shown, the chemiluminescence signal increases with the increase of pH and reaches a peak value at pH 11.5, and the luminescence signal decreases when the pH value continues to increase.

Embodiment 3

[0043] Flow injection chemiluminescence analysis system such as figure 1As shown, firstly, 2.0 mg / L nano copper oxide colloidal solution and 1.0 mmol / L hydrogen peroxide solution were transported into the mixer through peristaltic pump and mixed, and then mixed with different concentrations (take the value between 0.1 and 1.0 mmol / L) Lu Minol solution (pH 11.5) is mixed, and the three are mixed into the flow cell for reaction, and the intensity of chemiluminescence generated is detected by a photomultiplier tube. Such as Figure 4 As shown, the chemiluminescence signal increased with the increase of luminol concentration and reached the peak at the concentration of 0.5 mmol / L, and the luminescence signal decreased when the luminol concentration continued to increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com