Patents

Literature

66results about How to "Stable cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal Mine Underground Fire Monitoring System Based on Wireless Sensor Network

InactiveCN102269014AExtended service lifeControl energy consumptionMining devicesLine sensorWireless mesh network

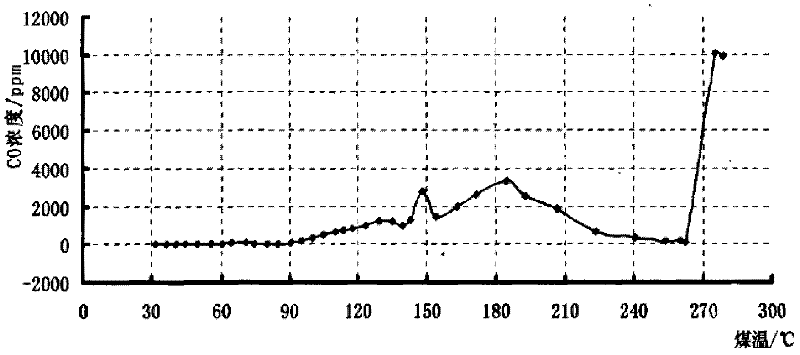

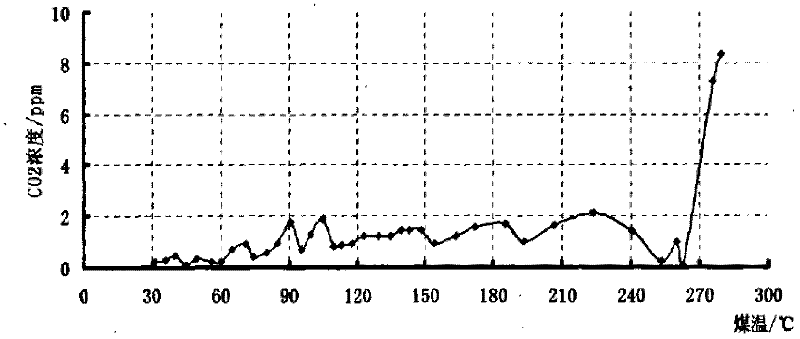

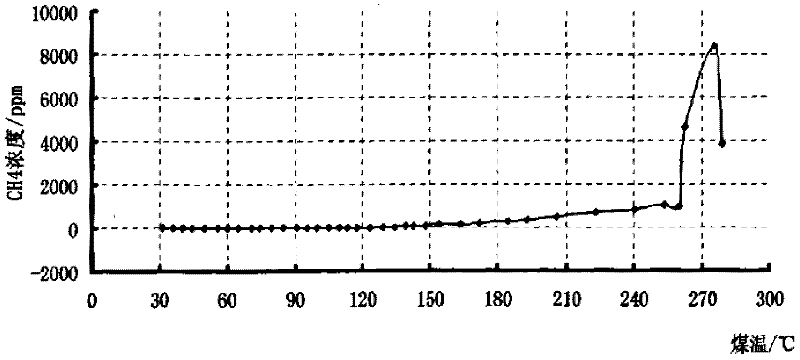

The invention provides a coal mine down-hole fire monitoring system based on a wireless sensor network. The system comprises a monitoring host, a communication master station and the wireless sensor network, wherein the wireless sensor network communicates with the monitoring host through the communication master station, is a ZigBee wireless self-organized network and comprises a wireless sensorand a wireless gateway; and the wireless sensor is used for acquiring coal mine safety data and wirelessly transmitting the coal mine safety data and comprises a wireless carbon monoxide sensor, a wireless wind pressure sensor and a wireless temperature sensor. Therefore, according to the coal mine down-hole fire monitoring system based on the wireless sensor network provided by the embodiment ofthe invention, coal mine down-hole fire conditions can be timely and accurately monitored, the energy consumption of a wireless sensor network node can be effectively controlled, and the service lifeof the wireless sensor network can be prolonged.

Owner:CCTEG CHINA COAL RES INST

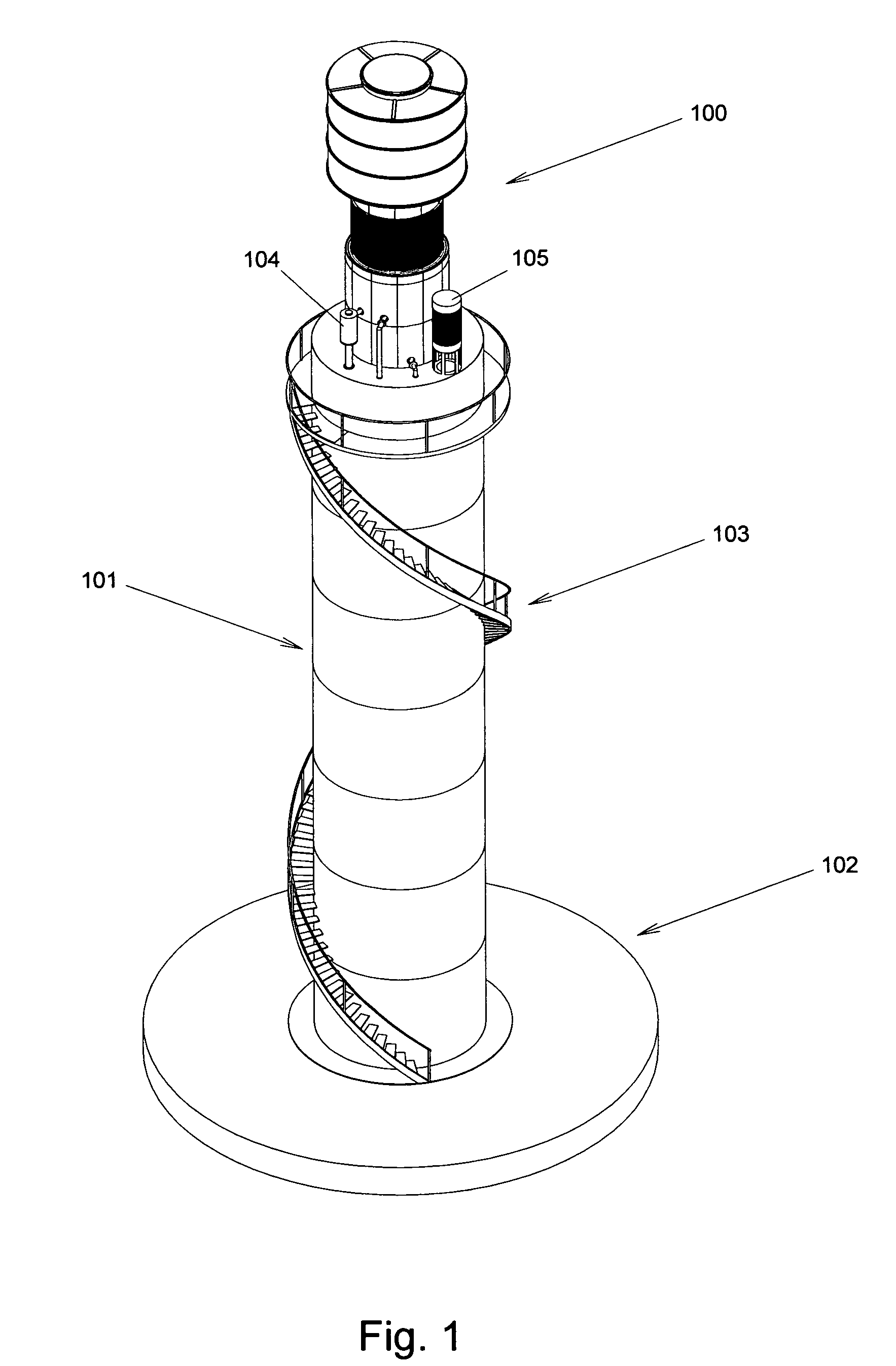

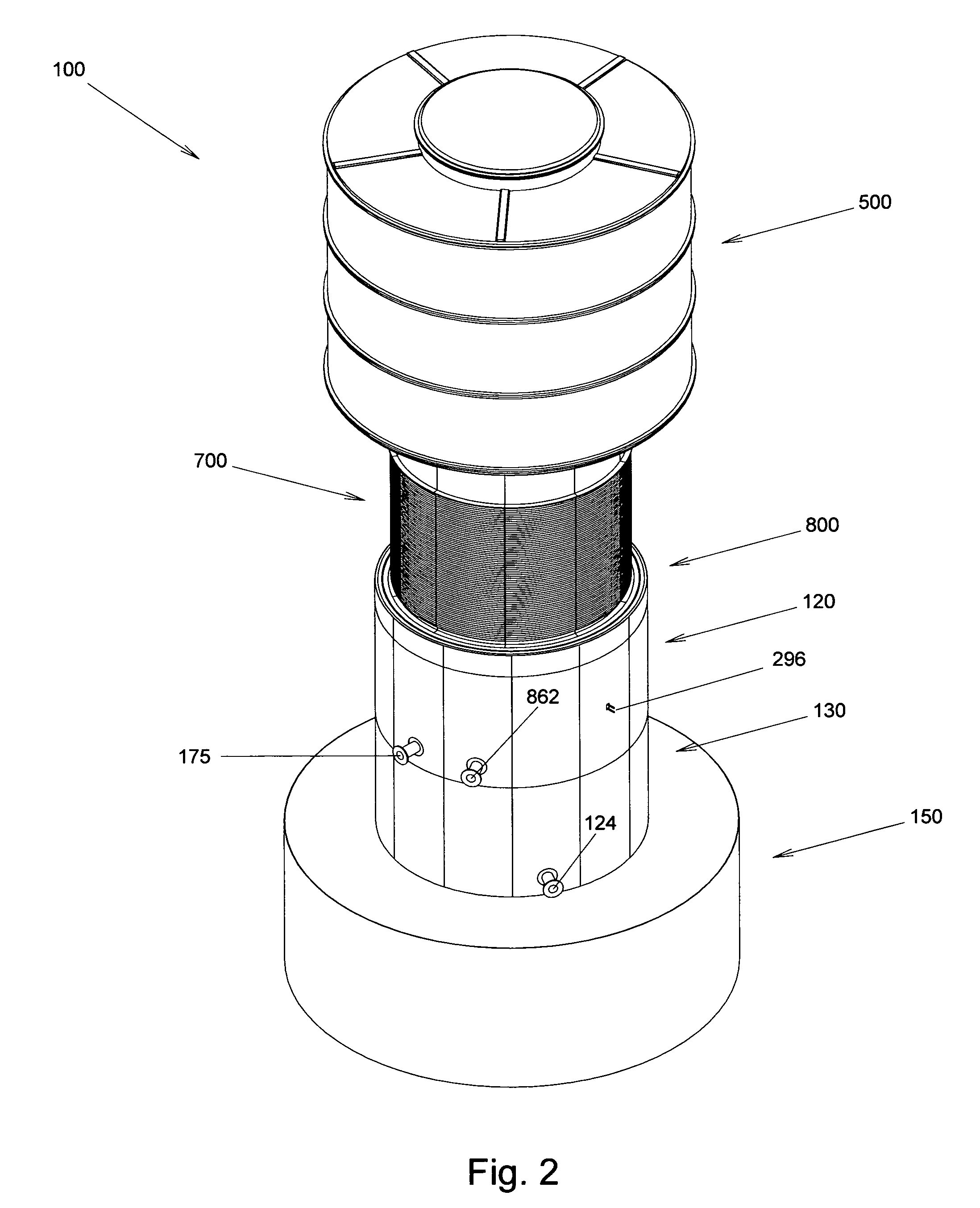

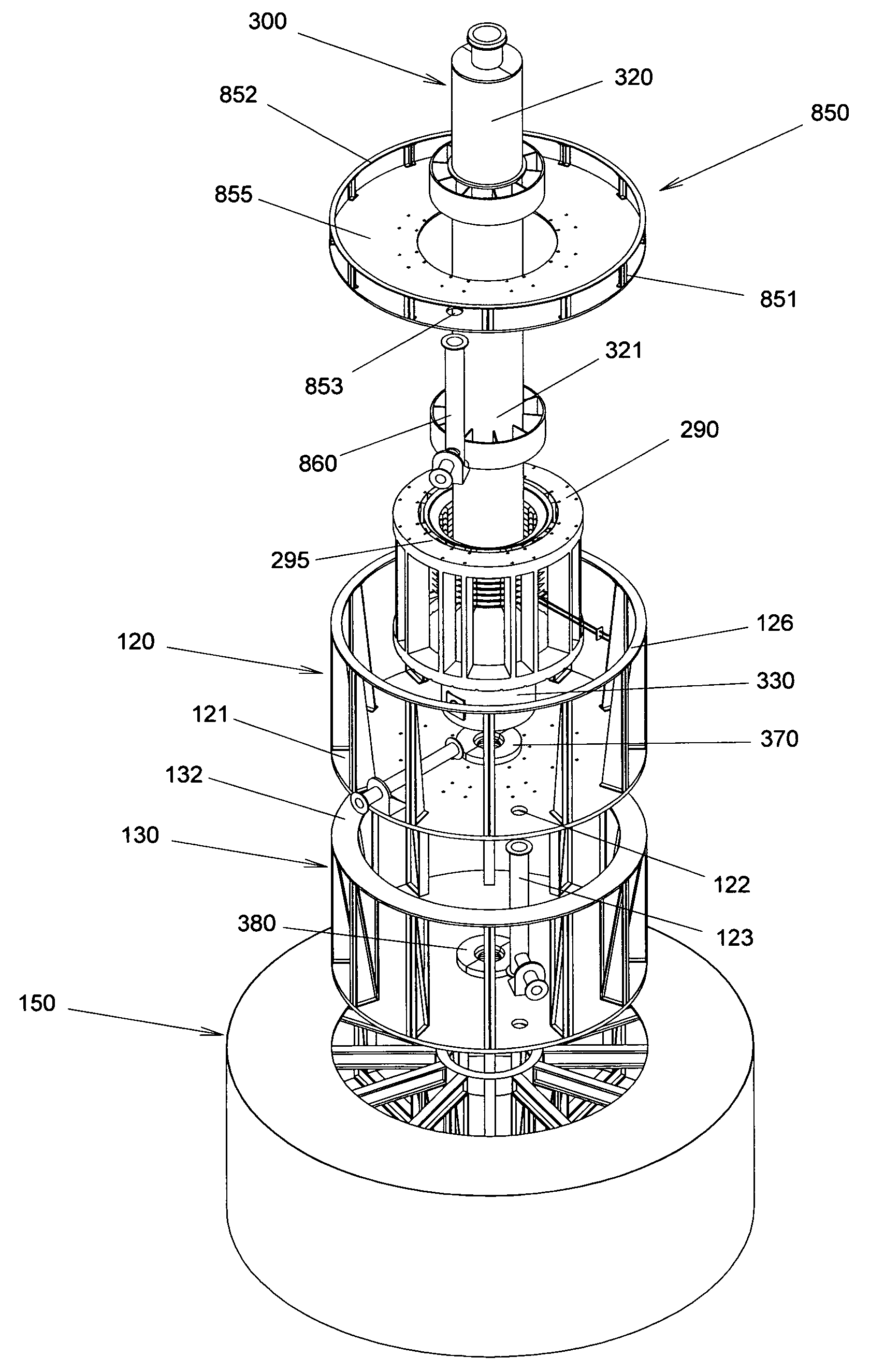

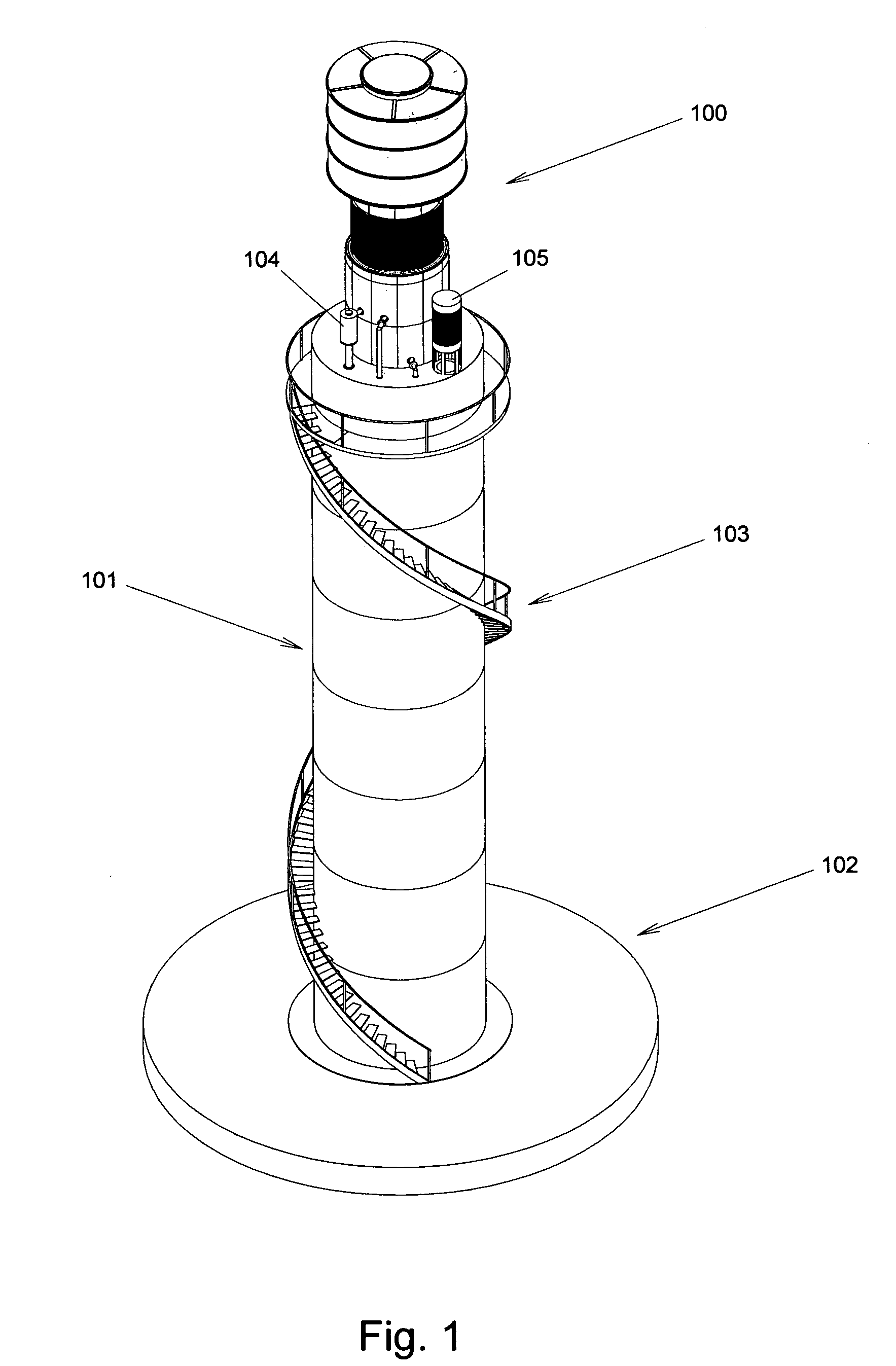

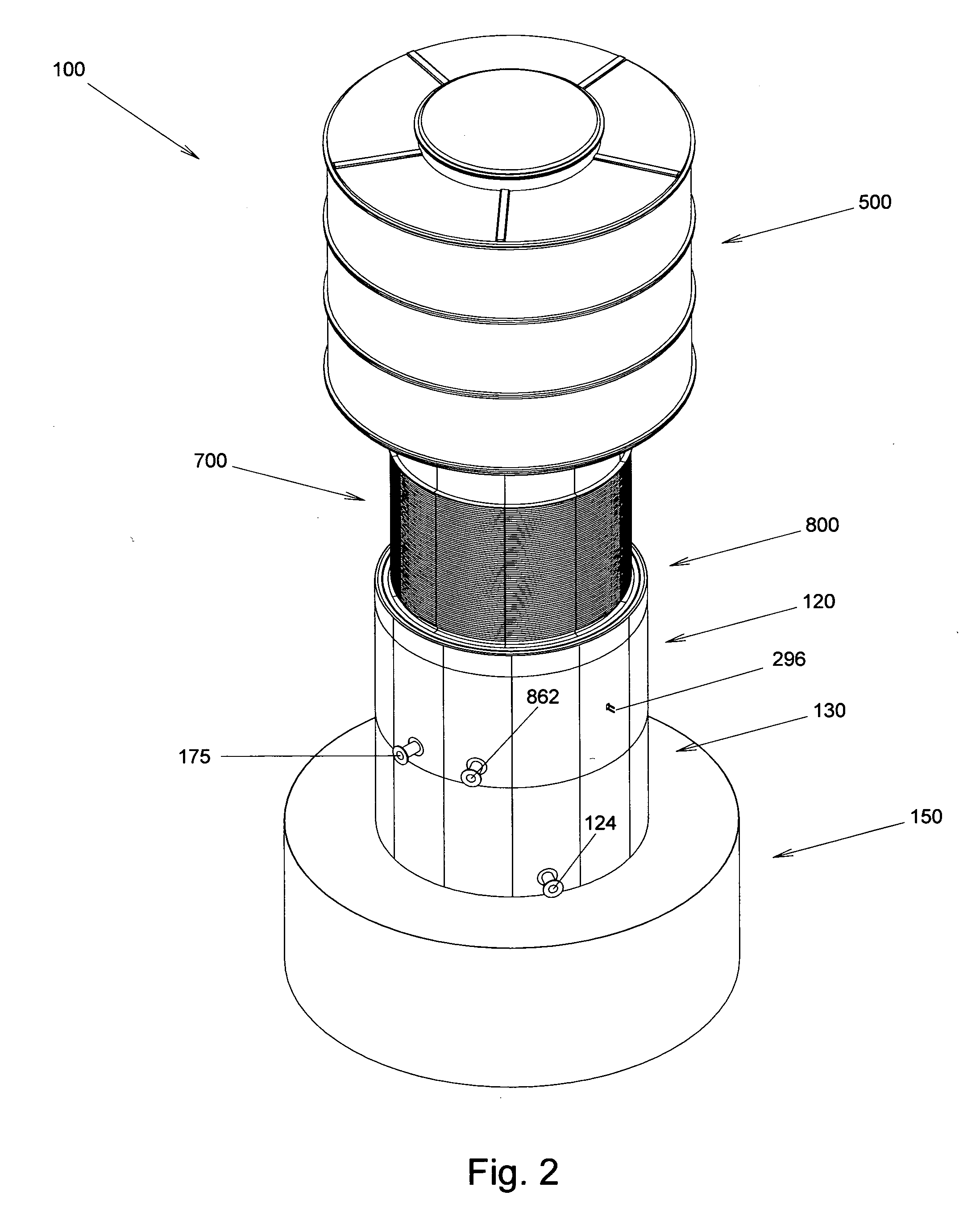

Solar-powered, liquid-hydrocarbon-fuel synthesizer

InactiveUS7752845B2Stable costReduce dependenceAuxillary drivesMechanical energy handlingEngineeringOxygen

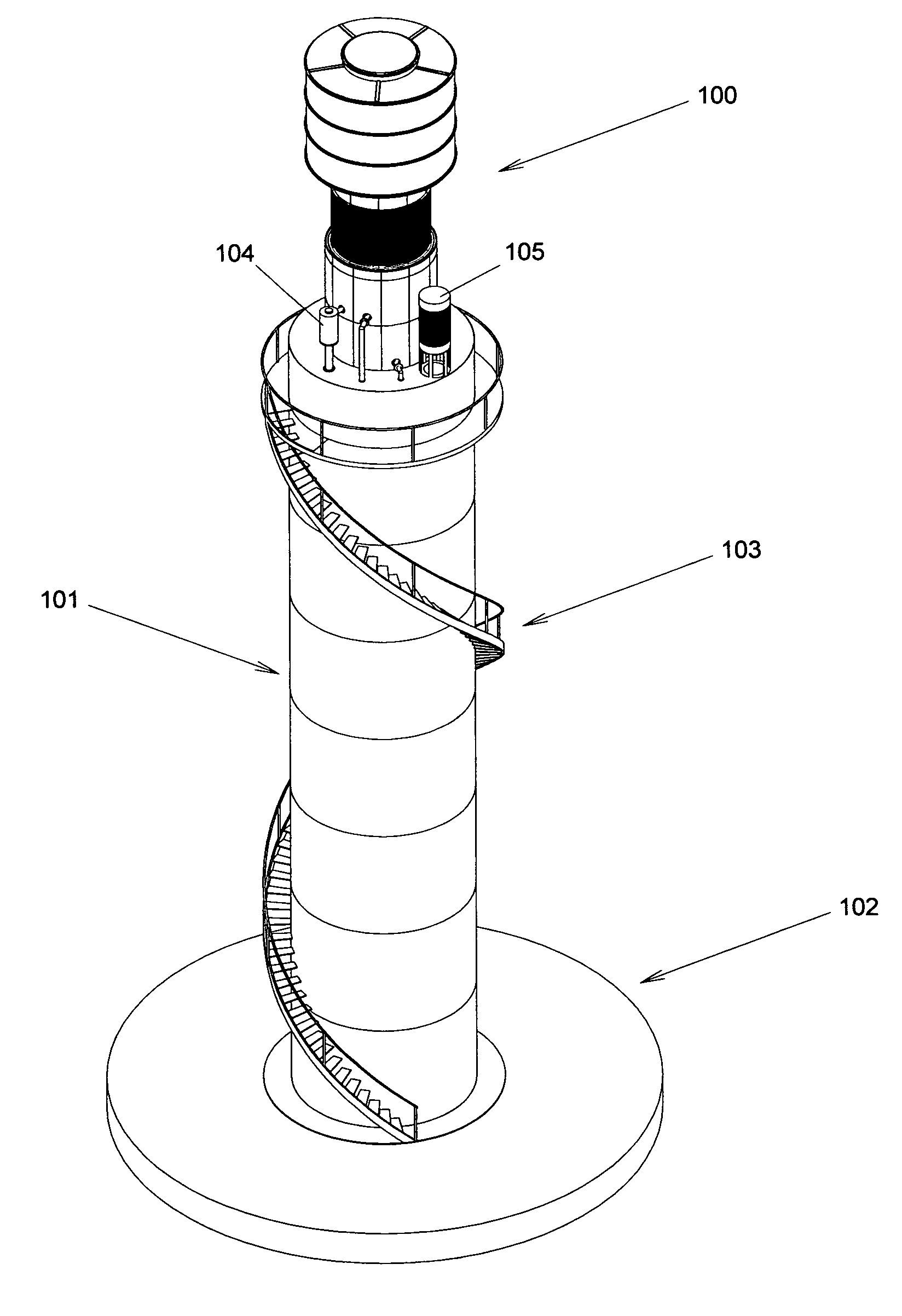

A synchronous reaction cell, rotating as a unit, disassociates hydrogen from water, traps and filters hydrogen, mixes and pressurizes hydrogen and ingested carbon, hydrogenates carbon by surface catalysis, isolates and exhausts liquid hydrocarbon products above a desired density, recirculates gaseous products for further reaction, and expands steam through a turbine to produce rotation and turn an electrical generator. Solar energy focused by heliostats is one means of supplying process heat. Burning natural gas or another fossil fuel in oxygen freed by the disassociation of water provides alternative sources of heat. The reaction cell has a vertical axis-of-rotation making it conducive to mounting on a tower disposed at the center of an array of heliostats. The rotating reaction cell has a large, cylindrical heat-absorbing surface. Electrical output might be used to aim heliostats. Excess electrical generation might be added to the local electrical grid and sold for its value.

Owner:JOHNSON ROBERT PAUL

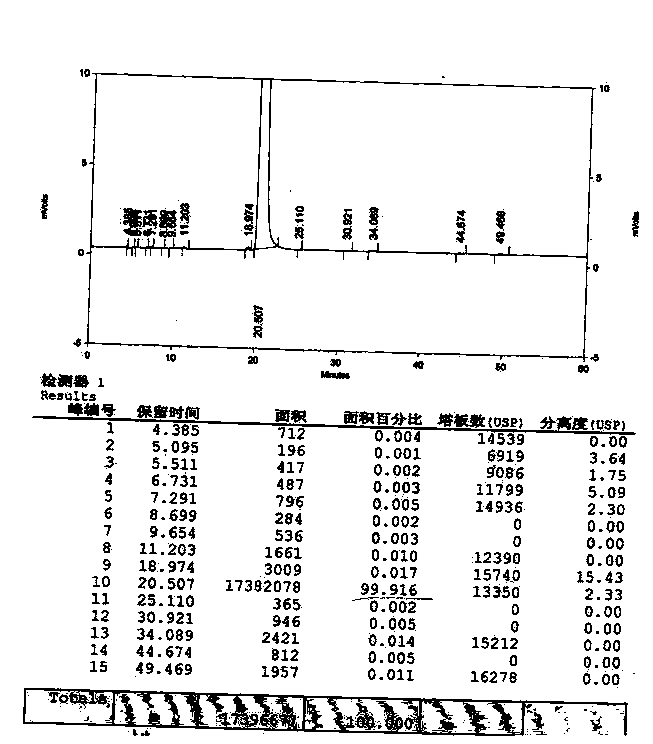

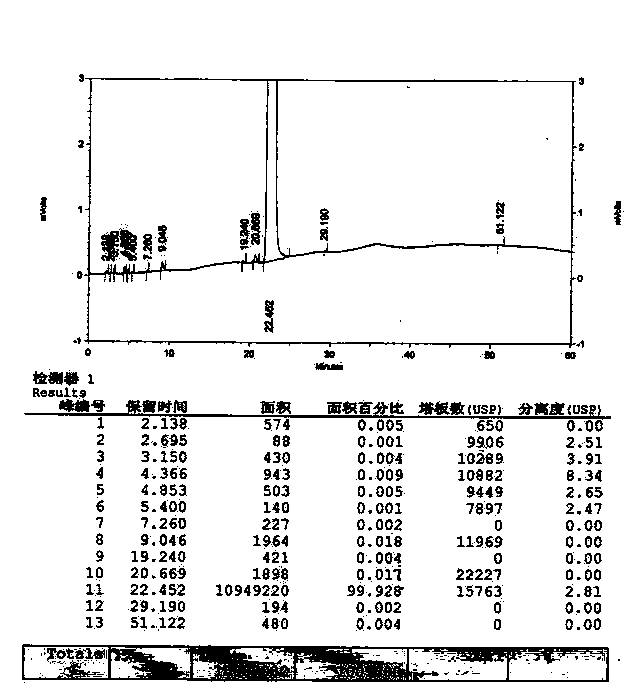

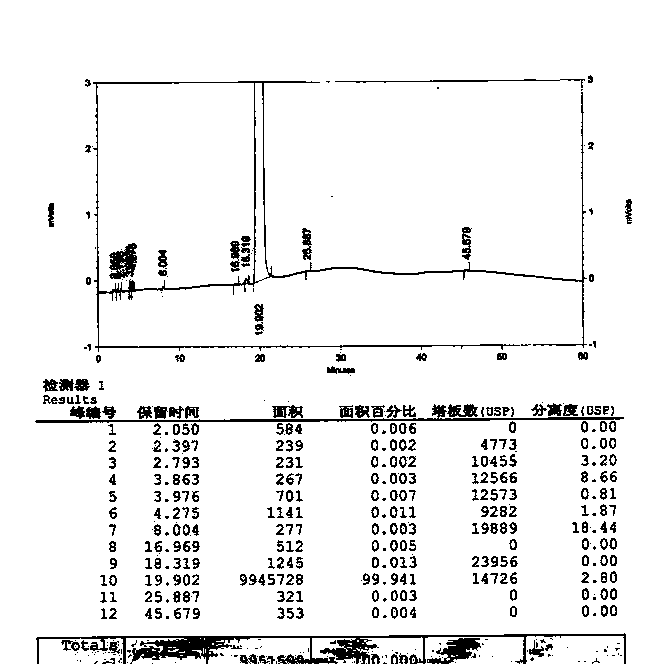

Preparation method of N(2)-L-alanyl-L-glutamine

ActiveCN103626839APrice stabilityMarket sales trend ups and downsPeptide preparation methodsL-alanyl-l-glutamineChloride

The invention belongs to the technical field of medicines, and particularly relates to a preparation method of N(2)-L-alanyl-L-glutamine. The preparation method of the N(2)-L-alanyl-L-glutamine comprises the following steps of (1) preparing L-phthaloyl-alanyl chloride; (2) preparing phthaloyl-L-alanyl-L-glutamic acid; (3) preparing phthaloyl-L-alanyl-L-glutamic acid anhydride; (4) preparing phthaloyl-L-alanyl-L-glutamine; (5) preparing an N(2)-L-alanyl-L-glutamine crude product; (6) preparing an N(2)-L-alanyl-L-glutamine refined product. The product obtained through the final deprotection process of the preparation method as a pilot plant test or a production scale process route is higher in purity; the liquid-phase purity of the product is higher than 99.9% through primary purification, and the product is low in impurity content.

Owner:JINAN CHENGHUI SHUANGDA CHEM

Solar-powered, liquid-hydrocarbon-fuel synthesizer

InactiveUS20080163621A1Easy to containEasy to transportAuxillary drivesMechanical energy handlingVolumetric Mass DensityEngineering

A synchronous reaction cell, rotating as a unit, disassociates hydrogen from water, traps and filters hydrogen, mixes and pressurizes hydrogen and ingested carbon, hydrogenates carbon by surface catalysis, isolates and exhausts liquid hydrocarbon products above a desired density, recirculates gaseous products for further reaction, and expands steam through a turbine to produce rotation and turn an electrical generator. Solar energy focused by heliostats is one means of supplying process heat. Burning natural gas or another fossil fuel in oxygen freed by the disassociation of water provides alternative sources of heat. The reaction cell has a vertical axis-of-rotation making it conducive to mounting on a tower disposed at the center of an array of heliostats. The rotating reaction cell has a large, cylindrical heat-absorbing surface. Electrical output might be used to aim heliostats. Excess electrical generation might be added to the local electrical grid and sold for its value.

Owner:JOHNSON ROBERT PAUL

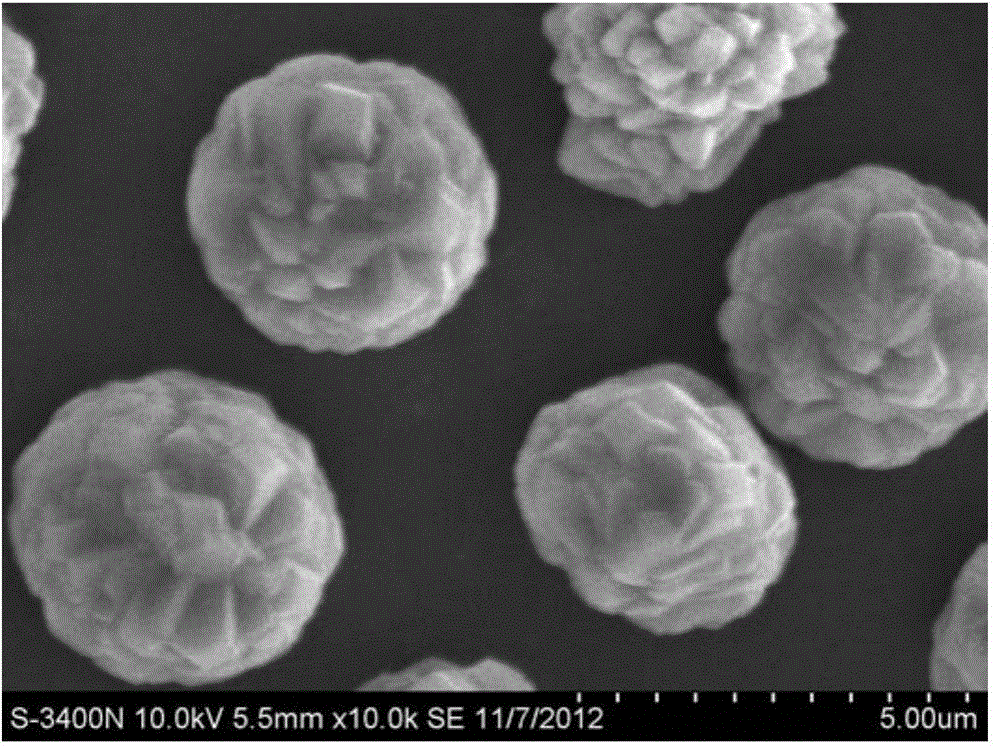

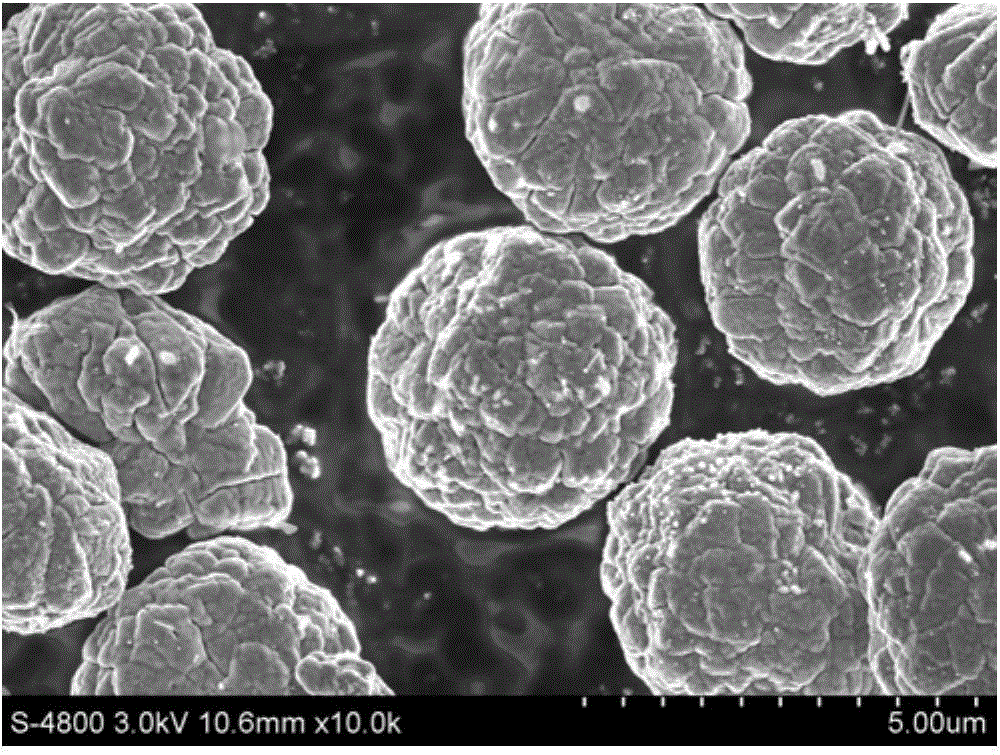

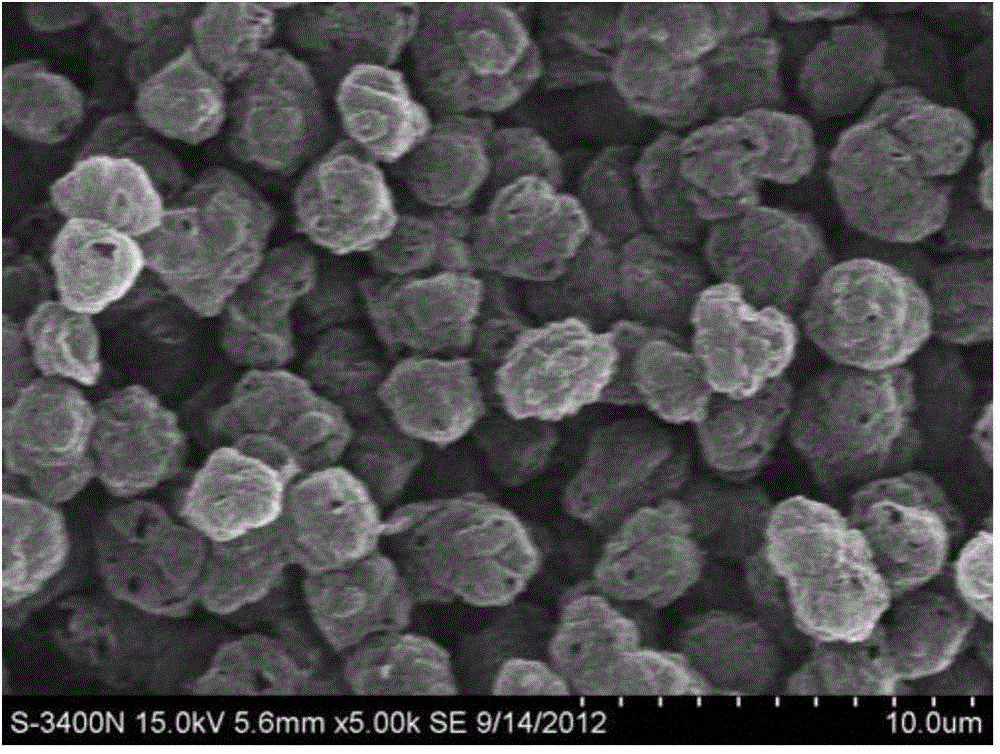

Method for uniform carbon coating on lithium iron phosphate surface

InactiveCN105655548AStabilized carbon coating effectAvoid uneven coatingCell electrodesCarbon compositesPhosphoric acid

Belonging to the technical field of lithium ion battery anode materials, the invention relates to a method for uniform carbon coating on a lithium iron phosphate surface. The method includes the steps of: (1) preparation of an emulsion: preparing an organic carbon source and water into an aqueous solution, conducting heating to 50-100DEG C, adding an additive, and performing stirring to form an emulsion; (2) coating of the lithium iron phosphate surface with the organic carbon source: adding spherical iron phosphate into the emulsion, performing mixing for 0.5-8h to obtain a rheological body, and conducting drying to obtain iron phosphate powder; and (3) preparation of a lithium iron phosphate / carbon composite cathode material: mixing iron phosphate powder with a lithium source according to a Fe-Li mole ratio of 1:1-1:1.2, placing the mixture into an argon protective atmosphere sintering furnace, conducting heat preservation at 250-400DEG C for 2-6h, then raising the temperature to 550-700DEG C and performing heat preservation for 6-16h, and carrying out furnace cooling and sieving so as to obtain the lithium iron phosphate / carbon composite cathode material. The method provided by the invention has the advantages of stable process, simplicity and easy control, low cost, safety and environmental protection, high utilization ratio of the organic carbon source, high volumetric specific energy of the material, and easy industrialization, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

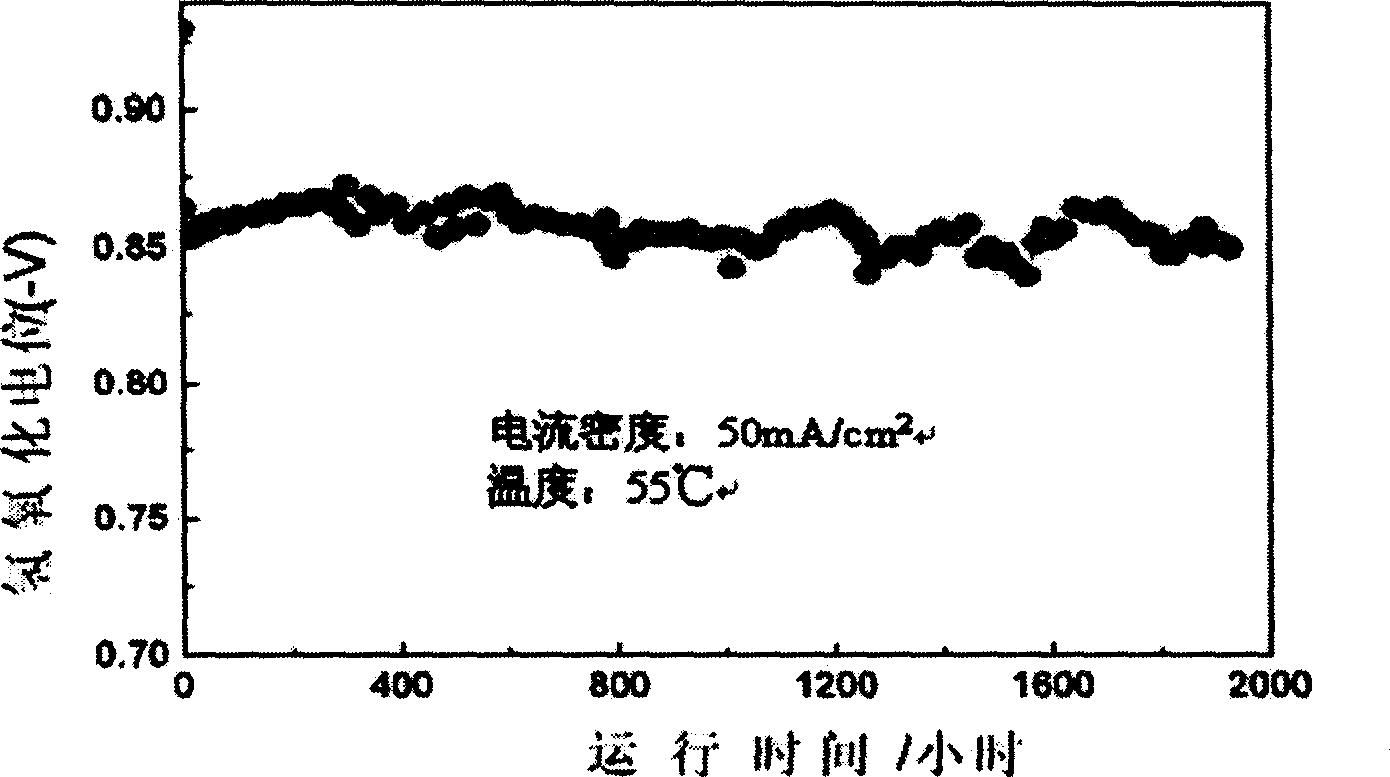

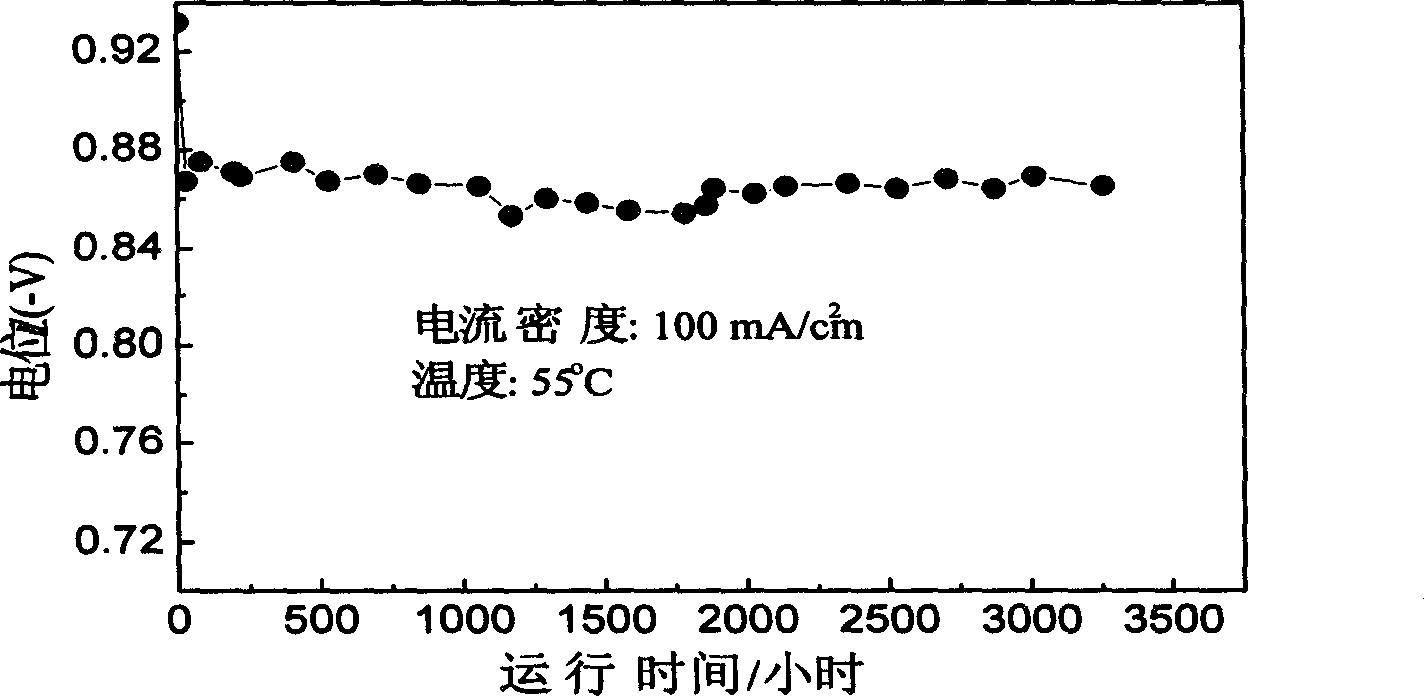

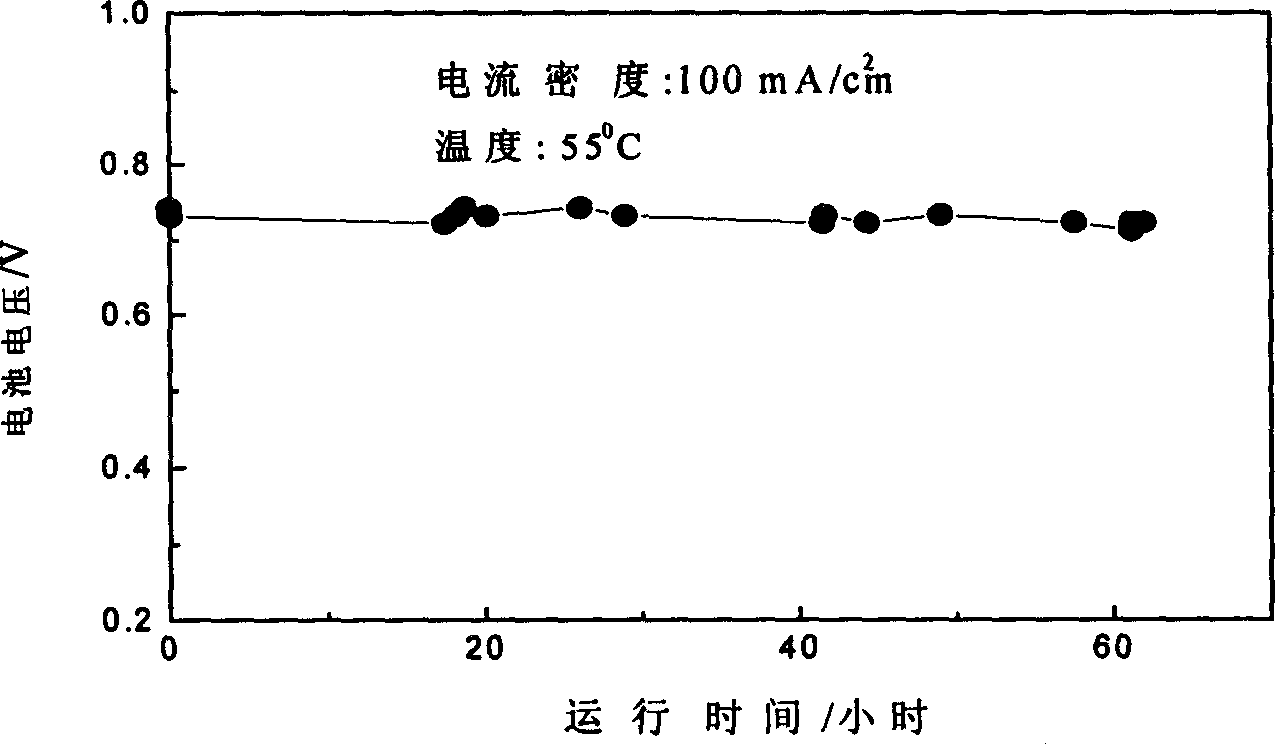

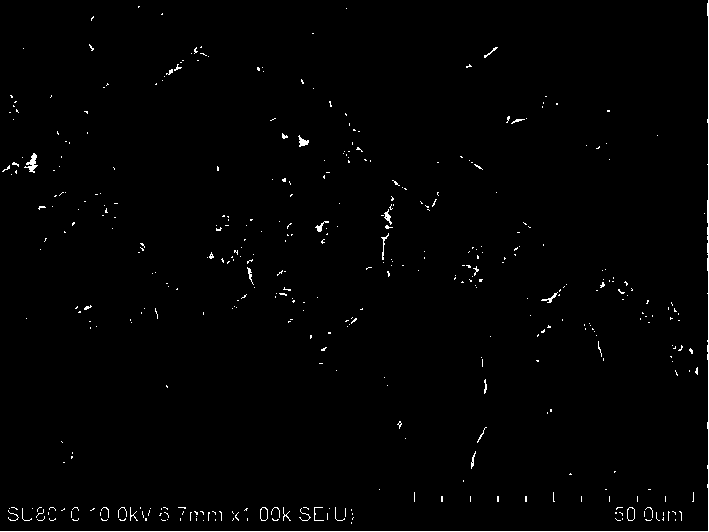

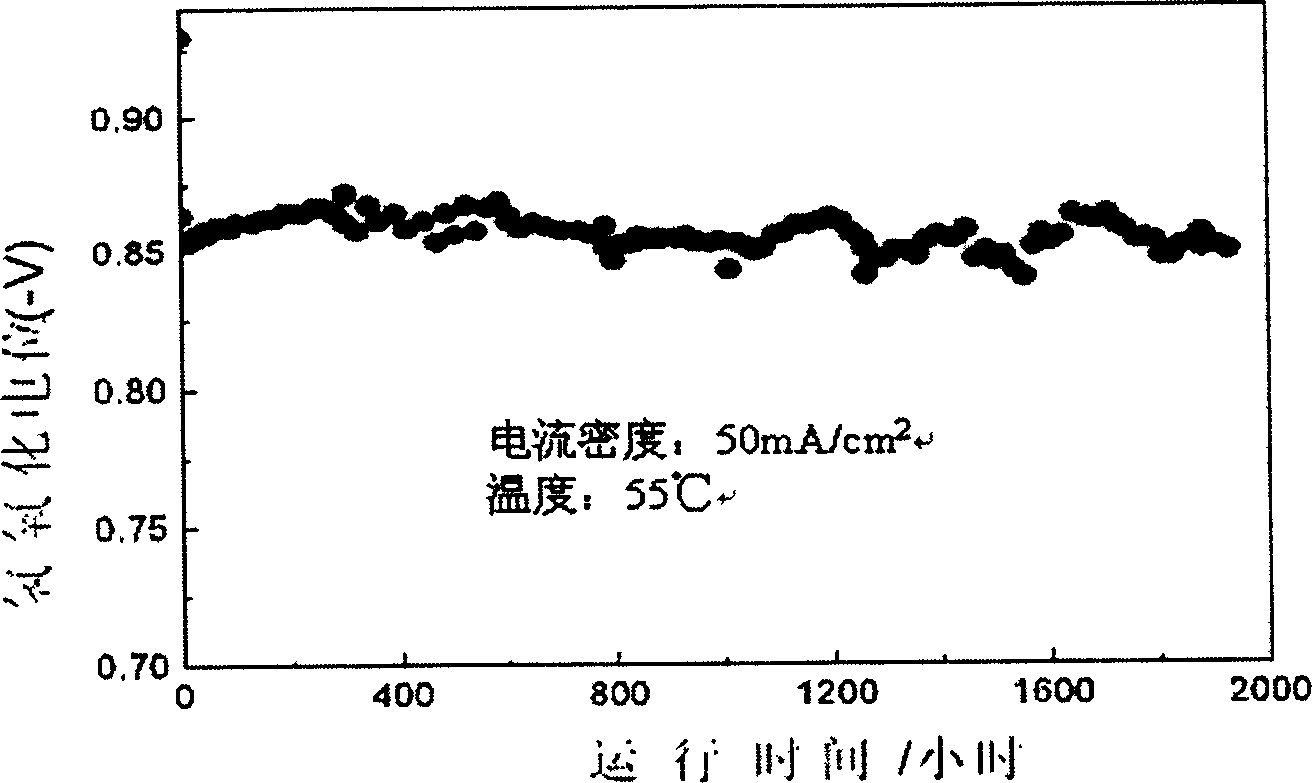

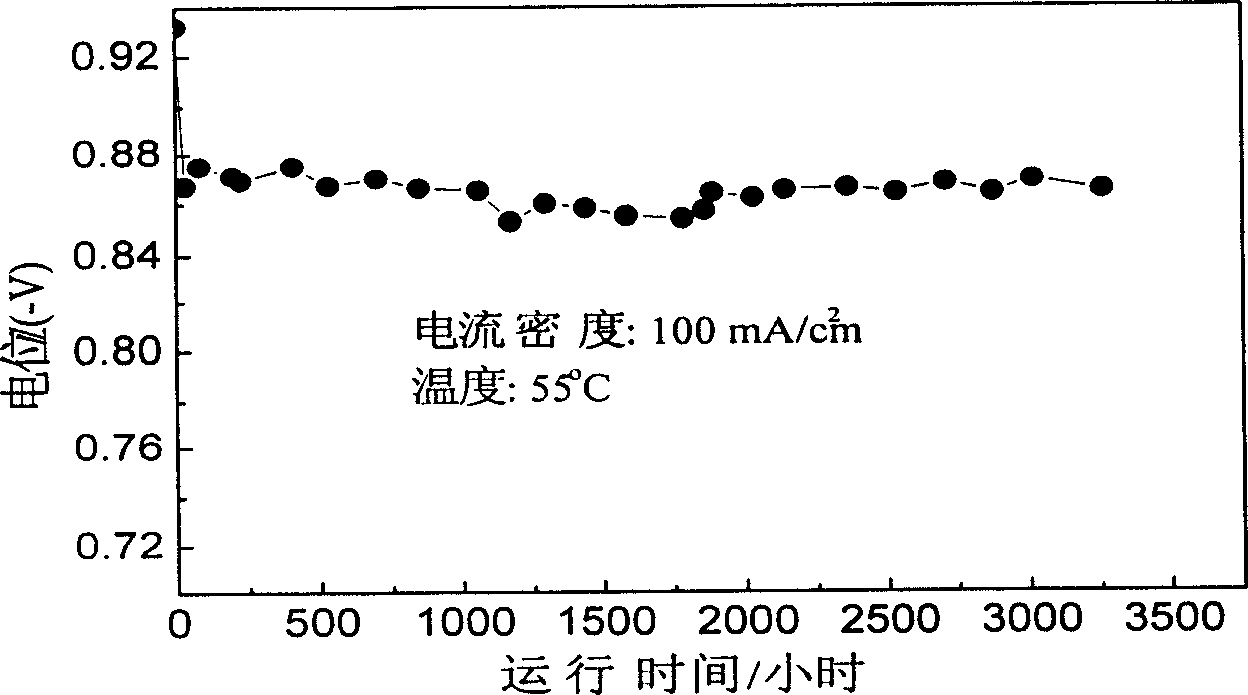

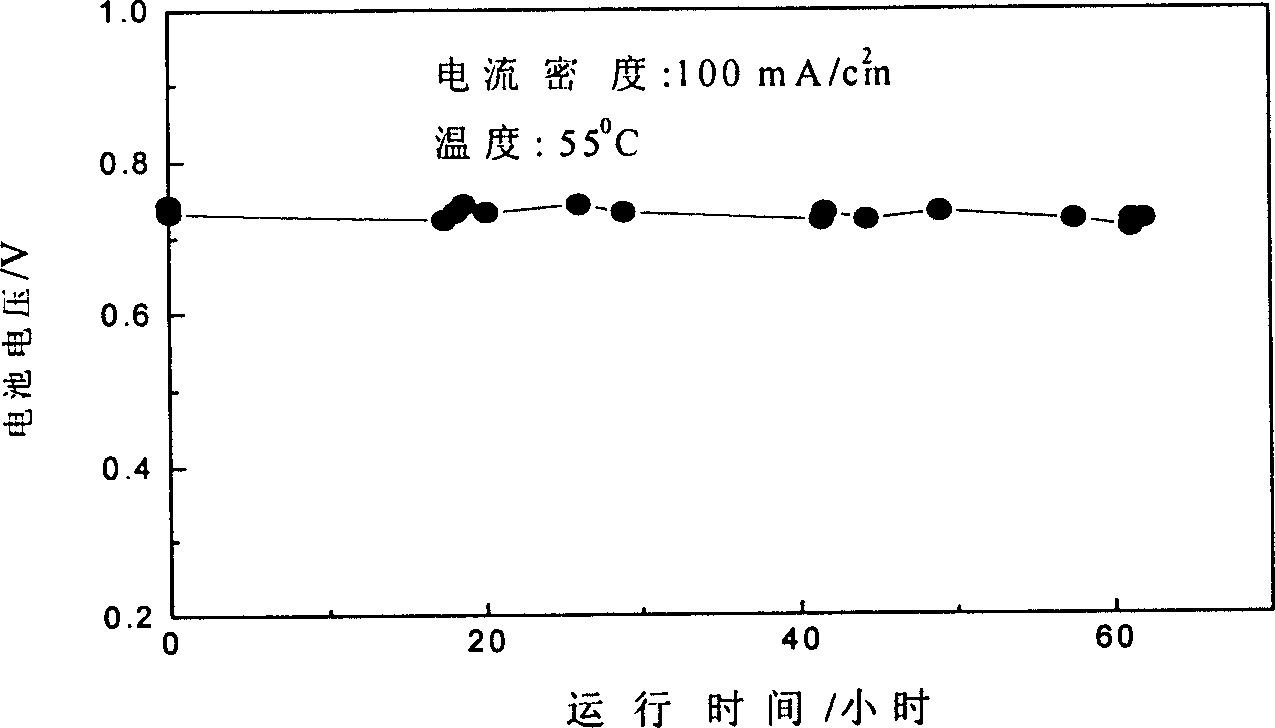

Alkaline fuel battery with hydrogen storage alloy as electric catalyst

The electrocatalyst of anode of the invented battery is alloy with hydrogen stored and without containing noble metal. The electrocatalyst of cathode of the invented battery is ABO3 type of peroviskite structure without containing noble metal and metal oxide of AB2O4 type of spinel structure. The said hydrogen stored alloy is MmNi3.3sCO0.75Mn0.4Al0.3, Mn is mixed rare earth riching in lanthanum. The metal oxide is La1-xCaxMO3, M=Co, Mn or Fe. The new type battery possesses the features of low cost, stable performances applicable to electric devices and electric vehicle etc.

Owner:NANKAI UNIV

Self-assembling carbon nitride-TiO2/hollow structure biomass charcoal degradation ammonia nitrogen composite and preparation method thereof

InactiveCN109603888ALow costThe preparation process is controllablePhysical/chemical process catalystsWater/sewage treatment by irradiationBiomassMicrometer

The invention belongs to the technical field of composite photocatalysts, and relates to biomass charcoal degradation of ammonia nitrogen, in particular to a self-assembling carbon nitride-TiO2 / hollowstructure biomass charcoal degradation ammonia nitrogen composite. The composite is composed of hollow structure biomass charcoal (HSBC), sheet carbon nitride and TiO2 microspheres of the grading structure, wherein the HSBC is formed by adopting biomass as raw materials through smashing and carbonization, and the hollow aperture is 10-50 micrometers; the sheet carbon nitride is formed by self-assembling, and the thickness is 100-200 nanometers; the grading structure TiO2 microspheres are obtained through hydrothermal in-situ growth, the diameter of the microspheres is 1-2 micrometers, and themicrospheres are composed of dense nano-rods. The invention further discloses a preparation method of the material. The preparation conditions are simple, the high specific surface area of the HSBC and the photocatalysis performance of TiO2 and carbon nitride are combined, and ammonia nitrogen can be rapidly removed. The composite is low in cost, stable, free of secondary contamination and environmentally friendly; ammonia nitrogen wastewater is removed through experiment simulation, and the removal rate under ultraviolet irradiation reaches up to 90.3%.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Integral post insulator type lightning arrester for electrified railway

PendingCN111091941AImprove performanceImprove protectionResistor terminals/electrodesSupporting insulatorsElectrical resistance and conductanceOvervoltage

The invention discloses an integrated post insulator type lightning arrester for an electrified railway. The device comprises an insulating cylinder and a composite jacket fixedly assembled on the insulating cylinder, wherein an upper flange and a lower flange are fixedly arranged at two ends of the insulating cylinder respectively, a zinc oxide resistor disc is arranged in the insulating cylinderand separated by an aluminum backing ring, an upper electrode is arranged in the upper flange, one end of the upper electrode is hermetically connected with the upper flange, a spring is arranged between the upper electrode and the zinc oxide resistor disc, one end of the lower electrode is hermetically connected with the lower flange, and an adjusting gasket is arranged between the lower electrode and the zinc oxide resistor disc. The device is advantaged in that a locomotive of the electrified railway can be protected from being subjected to overvoltage impact, can further be used as a force-bearing insulator, realizes dual functions of integrating excellent protection characteristics of the lightning arrester and mechanical characteristics of the insulator, can reduce consumption of resources, saves cost, can enable equipment to operate stably, and is more compact in structure.

Owner:江西中南绝缘子有限公司

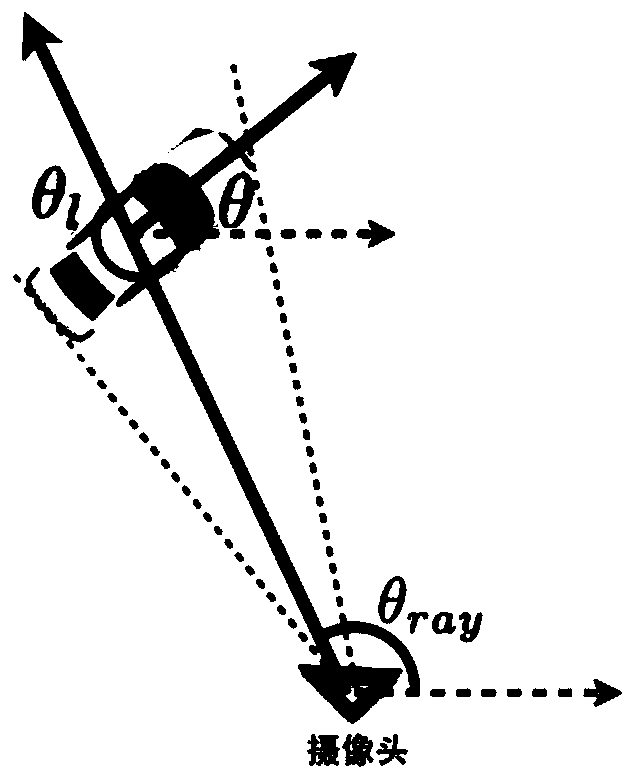

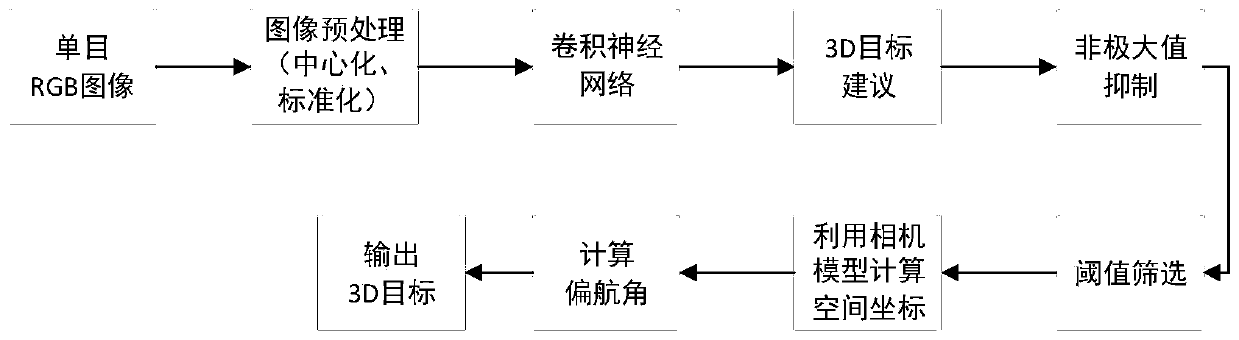

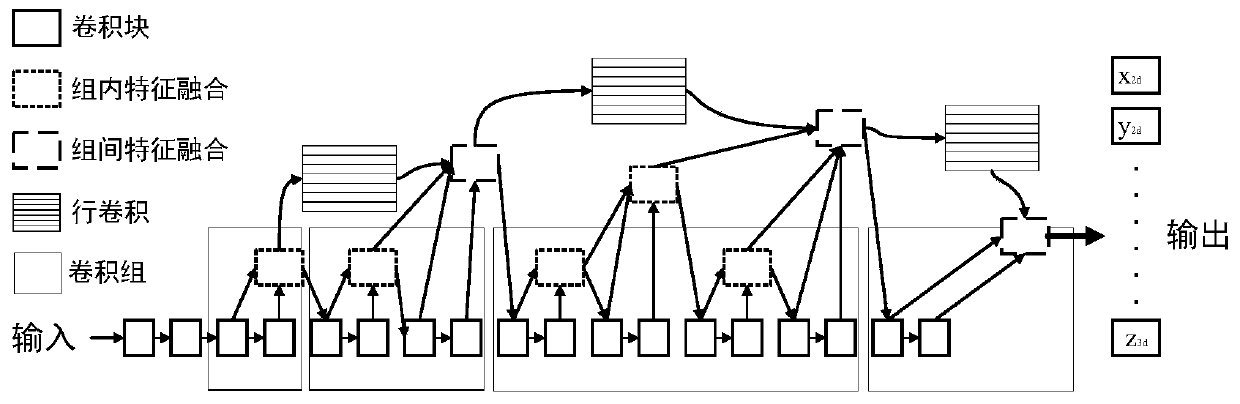

3D target detection method of monocular view based on convolutional neural network

The invention discloses a 3D target detection method of a monocular view based on a convolutional neural network. 3D targets mainly detected in an automatic driving scene include but are not limited to automobiles, pedestrians, bicycles and the like. The method mainly comprises the following steps: firstly, training network parameters by using a training set prepared in advance; secondly, in the prediction stage, a monocular image collected by a vehicle-mounted camera is preprocessed and then input into the trained convolutional neural network, and the 2D frame, the actual size and the depth of a target are predicted; and finally, solving the position of the 3D target in the 3D space through the projective geometry camera model. The 3D target detection method based on the monocular view provided by the invention has relatively high precision in a test data set, and has good accuracy and robustness.

Owner:ZHEJIANG UNIV

Welding electrode coating

ActiveCN105057924AAbundant raw ore reservesRich reservesWelding/cutting media/materialsSoldering mediaIron powderSlag

The invention discloses a welding electrode coating. The welding electrode coating comprises components of, by mass, 15-65 parts of attapulgite of medium-low grades, 0-10 parts of quartz sand, 15-20 parts of dolomite, 19-50 parts of magnesia and 1-5 parts of iron powder. According to the welding electrode coating, used attapulgite raw ore is rich in reserve and low in price and provides a stable raw material source for coating welding, and welding electrodes obtained on the basis are low in cost, stable in arc and small in spattering particle during welding, prone to slag removal after welding, smooth and attractive in formed weld joint, low in welding dust generating rate, safe and non-toxic, good in economic and environment benefit and broad in application prospect.

Owner:盱眙凹土能源环保材料研发中心 +1

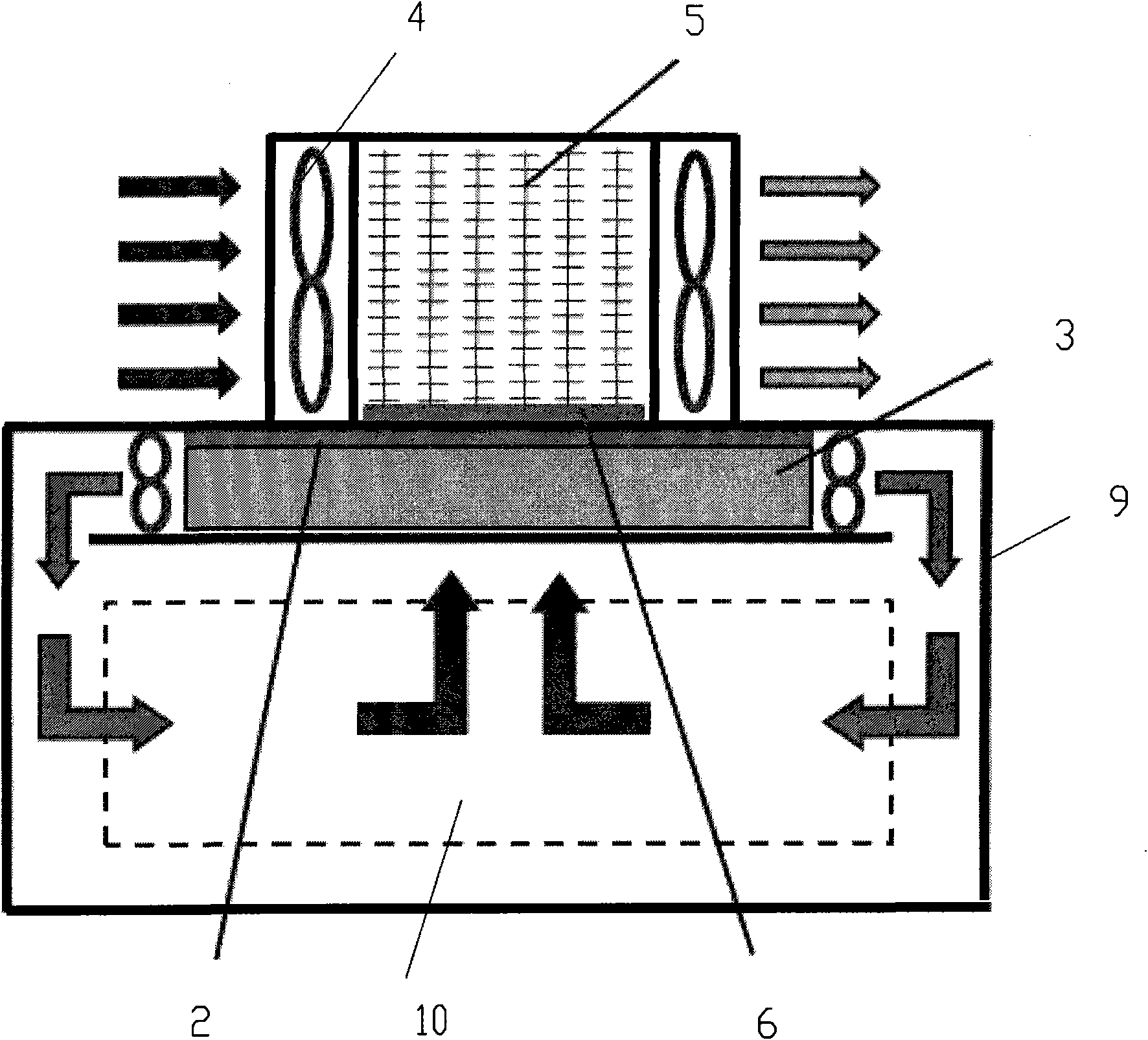

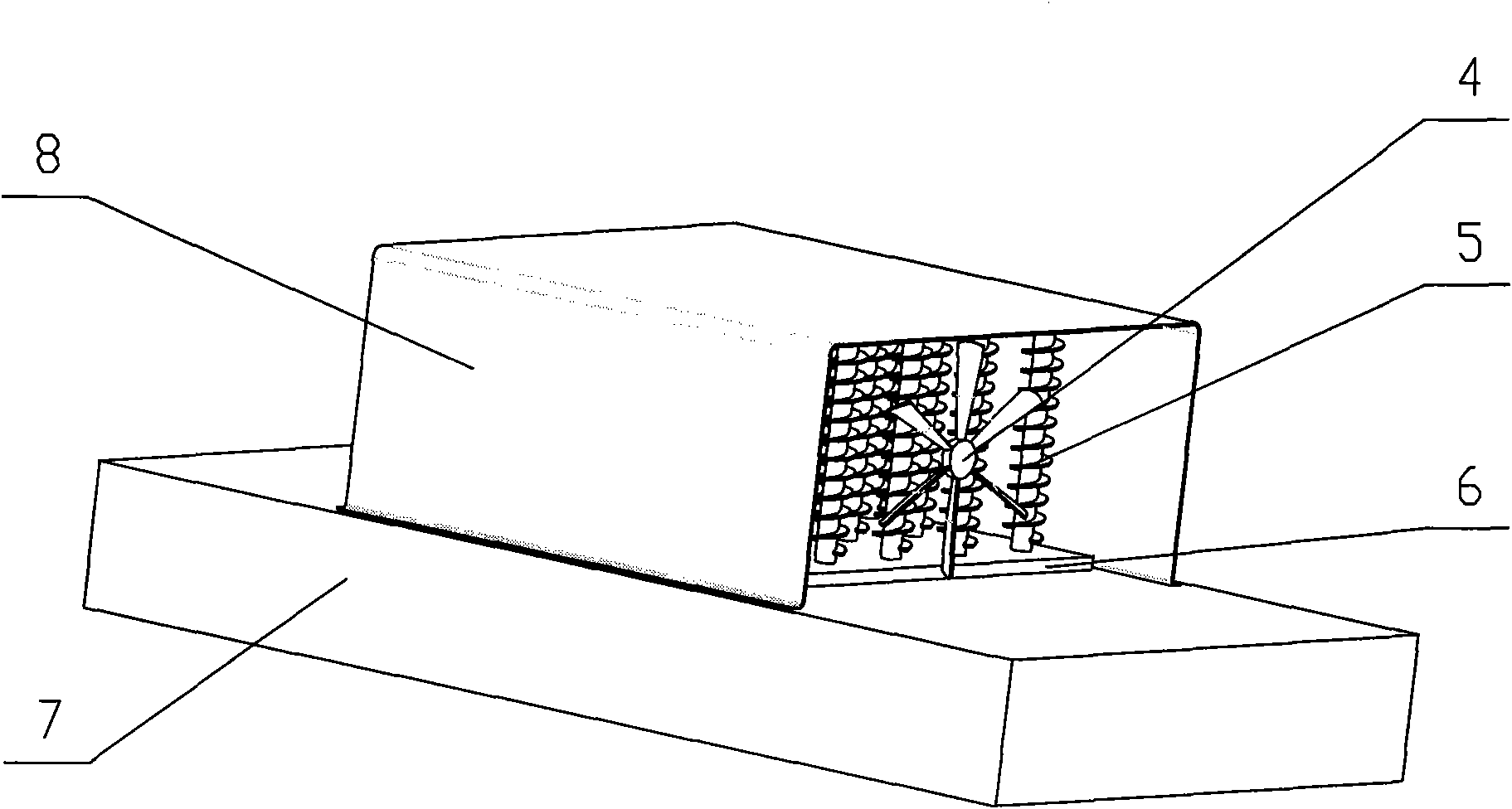

Cooler for hot plate-type wind generating set

InactiveCN101997364ALower requirementReduce the temperatureIndirect heat exchangersCooling/ventillation arrangementCold sideEngineering

The invention discloses a cooler for a hot plate-type wind generating set, which comprises a hot-side part and a cold-side part. The cooler is characterized in that the hot-side part comprises a heat absorption fin, a lower hot plate and a hot-side circulating fan which are arranged in a generator box body; the cold-side part comprises an upper hot plate, a heat tube bundle, a cold-side fan and a cold-side wind guiding cover; and the upper hot plate is arranged on the lower hot plate and is communicated with the heat tube bundle. The cooler has the advantages that 1) cooling fans in the generator box body are arranged on both sides of the heat absorption fin, the temperature is low relatively, and the requirement on a fan motor is low relatively; 2) the cooler has a compact structure, small volume and light weight; and 3) heat tubes with copper water structures and the hot plates have low cost, are stable, have no corrosive action, and can resist the low temperature of -40 DEG C.

Owner:HANGZHOU YINLUN TECH CO LTD +1

Hollow-structure biomass charcoal/TiO2 multi-wall tube/CuO photocatalyst and preparation method thereof

InactiveCN108855080ALow costStable costWater/sewage treatment by irradiationWater contaminantsAcid washingUltraviolet

The invention belongs to the technical field of water pollution photocatalysts and relates to a hollow-structure biomass charcoal / TiO2 multi-wall tube / CuO photocatalyst. The hollow-structure biomass charcoal / TiO2 multi-wall tube / CuO photocatalyst is prepared through compounding hollow-structure biomass charcoal, TiO2 multi-wall tubes and CuO nanoparticles. The invention further discloses a preparation method of the photocatalyst; the preparation method comprises the following steps: pre-treating biomasses through washing, crushing, acid washing and the like; after dissolving the biomasses intoa titanium solution, carrying out ultrasonic treatment for 20 to 40min; drying for 4 to 8h at 40 to 60 DEG C, so as to obtain a titanium source / biomasses; putting the titanium source / biomasses into amuffle furnace and carrying out high-temperature calcination for 2 to 6h; immersing into a copper solution for 3 to 6h; after washing, immersing into a copper solution and washing; after repeating for 10 to 20 times, drying for 10h at 50 to 70 DEG C; finally, carrying out high-temperature calcination for 2 to 4h under the protection of nitrogen gas and naturally cooling to obtain the photocatalyst. The preparation method disclosed by the invention is controllable and has simple reaction conditions; the high specific surface area of the hollow biomass charcoal is combined with the photocatalysis performance of TiO2 and the catalysis performance of CuO, and ammonia nitrogen is efficiently and rapidly removed. Ammonia nitrogen wastewater is removed through experimental simulation and the highest removal rate under the irradiation of ultraviolet rays reaches 99.5 percent.

Owner:JIANGSU UNIV

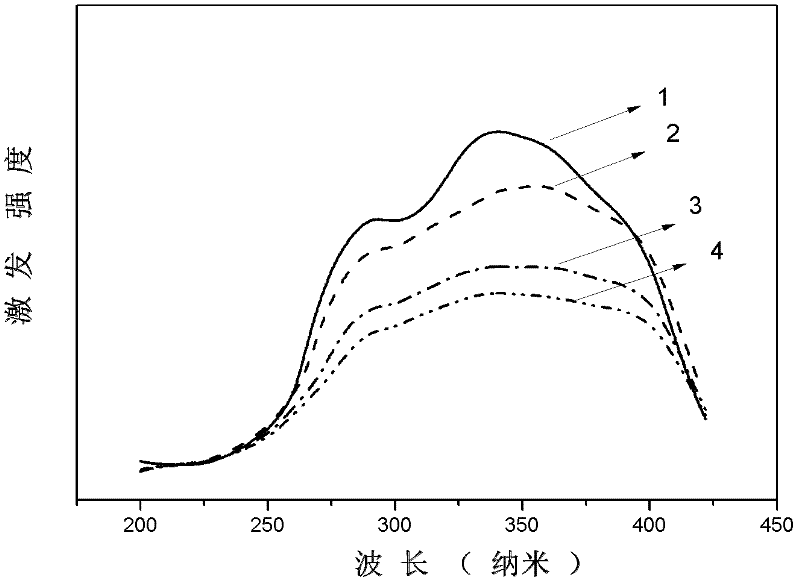

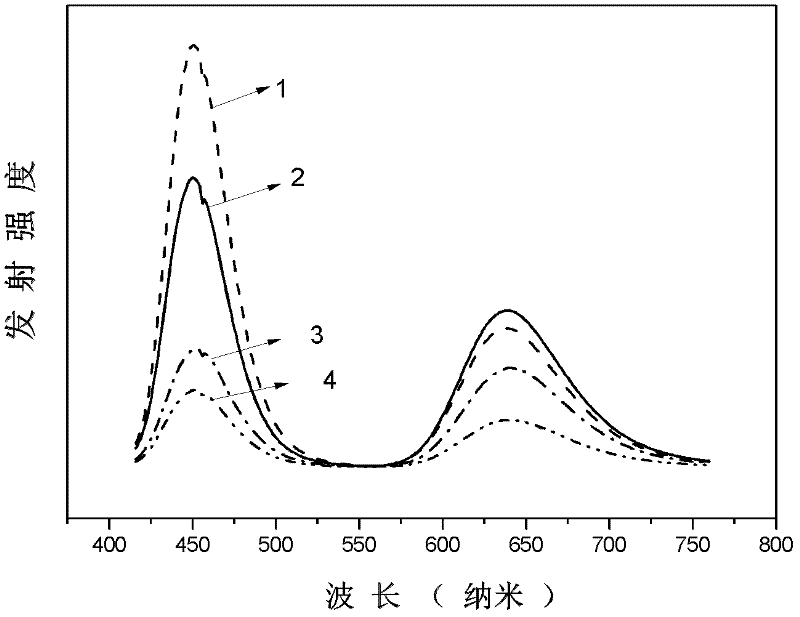

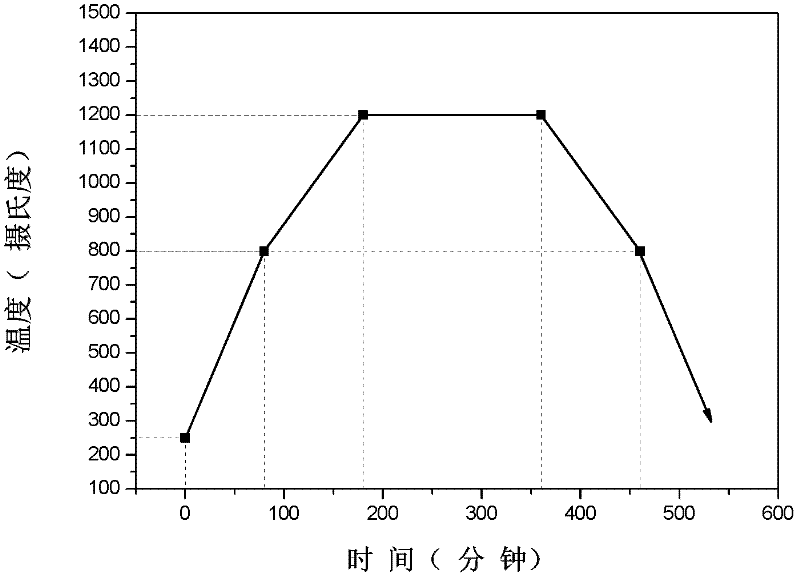

Blue-violet light excited 660-nanometer red fluorescent material and high-temperature microwave preparation method thereof

Disclosed is a blue-violet light excited 660-nanometer red fluorescent material, chemical formula Ba1.74Sr0.35Ca0.75MgSi2O8:0.06Eu2+, 0.1Mn2+, wherein the Eu2+ and the Mn2+ are luminescent central components and are 6%mol and 10%mol in doping concentration respectively. A preparation method of the blue-violet light excited 660-nanometer red fluorescent material includes: accurately weighing raw materials prior to mixing, and adding ethanol for mixing until mixed into slurry; and rising or dropping the interior temperature of a high temperature microwave oven with a frequency 2.45GHz according to set rising and dropping curved lines. The blue-violet light excited 660-nanometer red fluorescent material has the advantages that the material capable of absorbing microwave energy with the frequency 2.45GHz at high temperature is high in product purity and light efficiency, a prepared lighting system is capable of emitting 660-nanometer red light and 450-nanometerblue light, the material is used for making ecological LEDs and warm white LEDs, and the material is low in cost of raw materials, simple in process, energy-saving, environment-friendly and suitable for industrial production.

Owner:艾柯谷生态农业发展(河北)有限公司

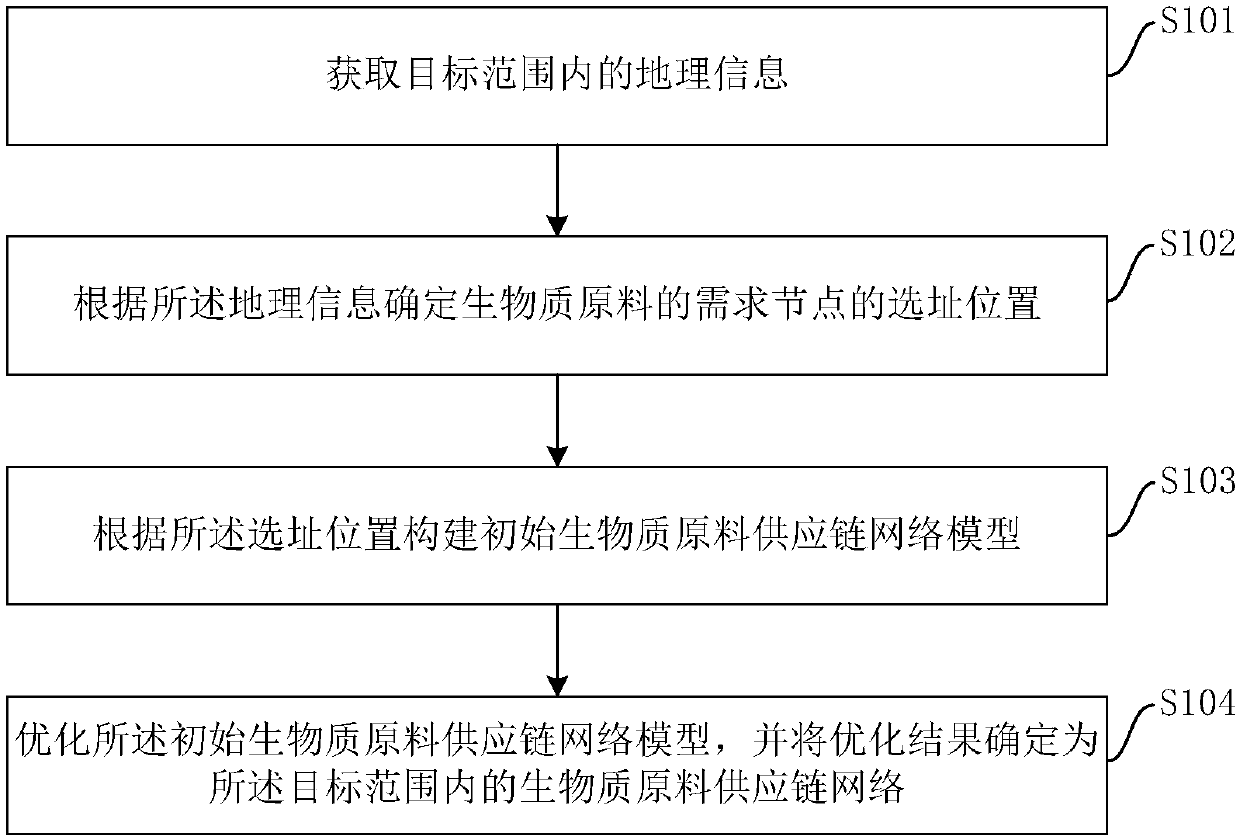

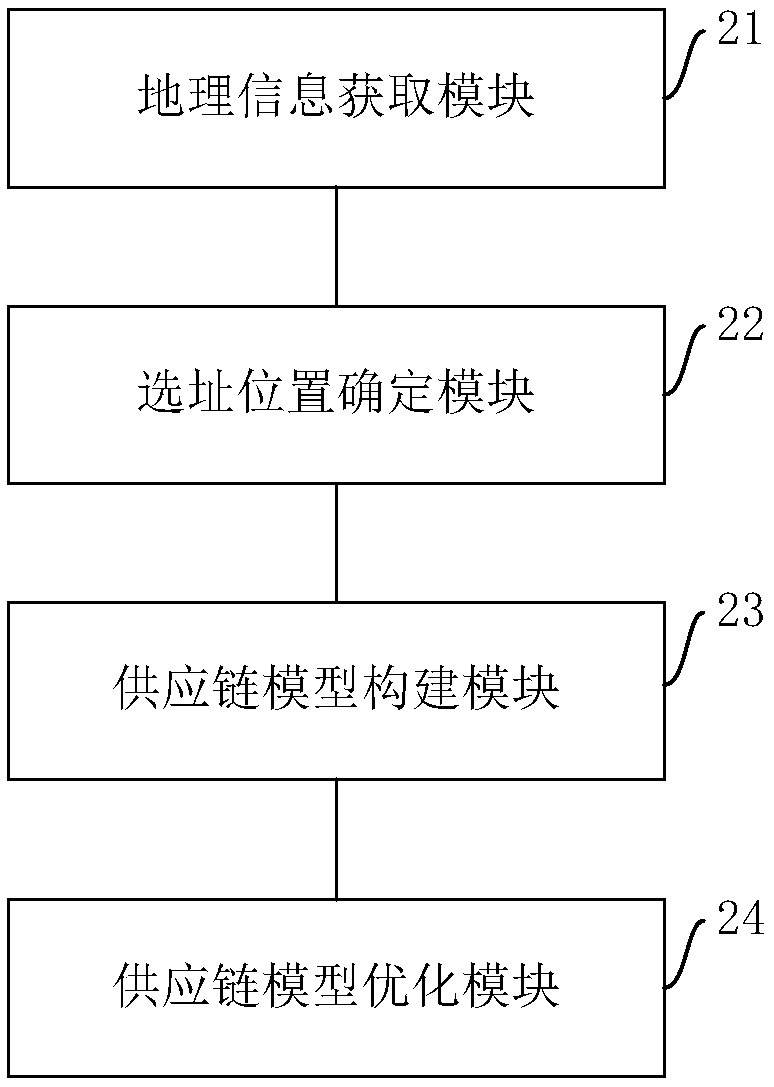

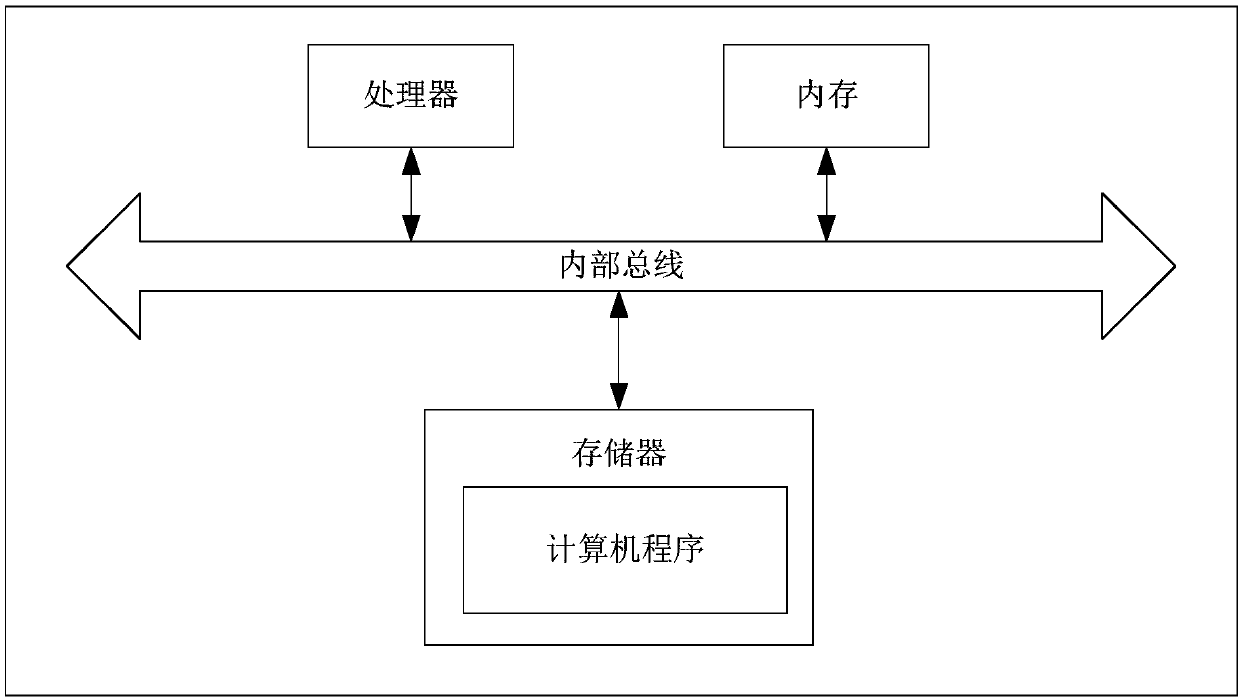

Method and apparatus for determining a biomass feedstock supply chain network

Embodiments of the present application provide a method and an apparatus for determining a biomass feedstock supply chain network. The method includes: obtaining geographic information within a targetrange; determining a location of a demand node of biomass raw materials according to the geographic information; constructing an initial biomass raw material supply chain network model according to the location selection position; optimizing the initial biomass feedstock supply chain network model, and determining the optimization result as a biomass feedstock supply chain network within the target range. The embodiments of the present application can reduce the cost of collecting, transporting, and storing biomass raw materials, and improve the economic practicability of the biomass raw material supply chain system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Natural stone binder

The invention discloses a natural stone binder. The natural stone binder comprises, by weight, 50% of P.O42.5 general portland cement, 45% of first dry quartz sands, 3.2% of second dry quartz sands, 1.5% of re-dispersible latex powder, 0.1% of starch ether and 0.2% of lignocellulose. The natural stone binder with reasonable cost and stable performances, prepared through reasonably selecting the granularity of the dry quartz sands and the weight percentage of the re-dispersible latex powder, has the advantages of firm bonding, difficulty in slipping, high flatness, convenience and fastness in construction, reduction of the labor intensity, improvement of the working environment, and low and controllable cost.

Owner:ZHENGZHOU CHUNHUI BUILDING MATERIAL TECH

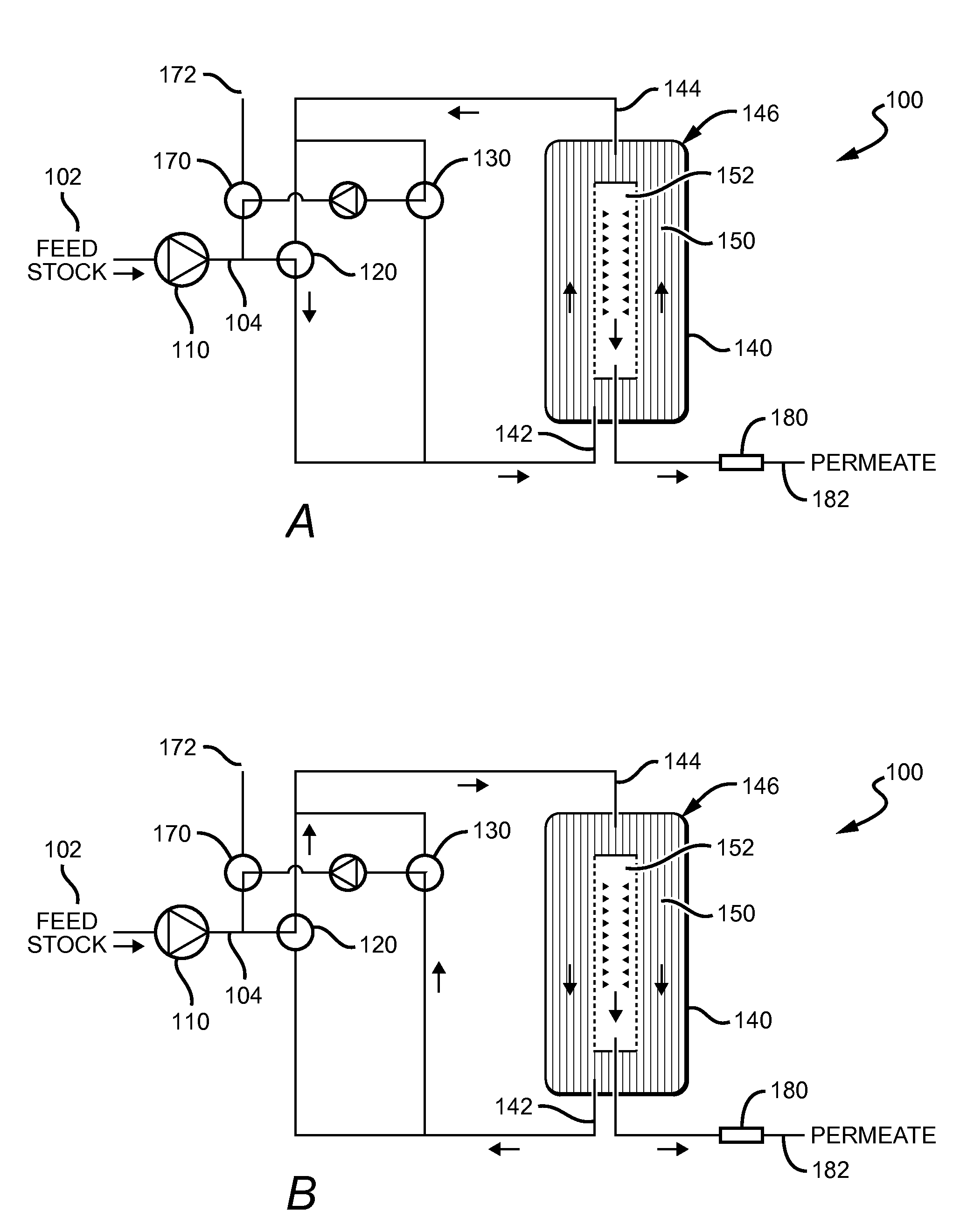

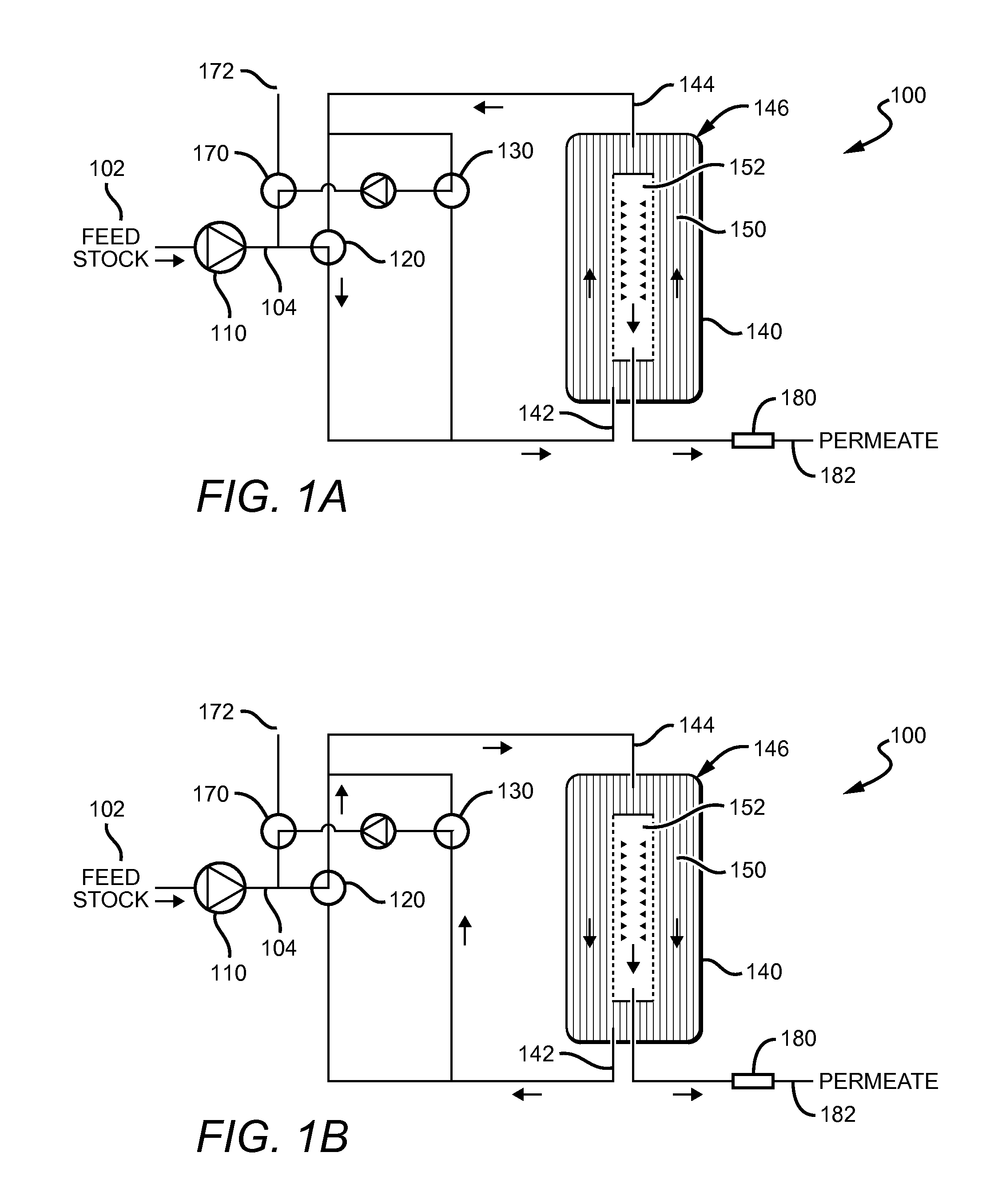

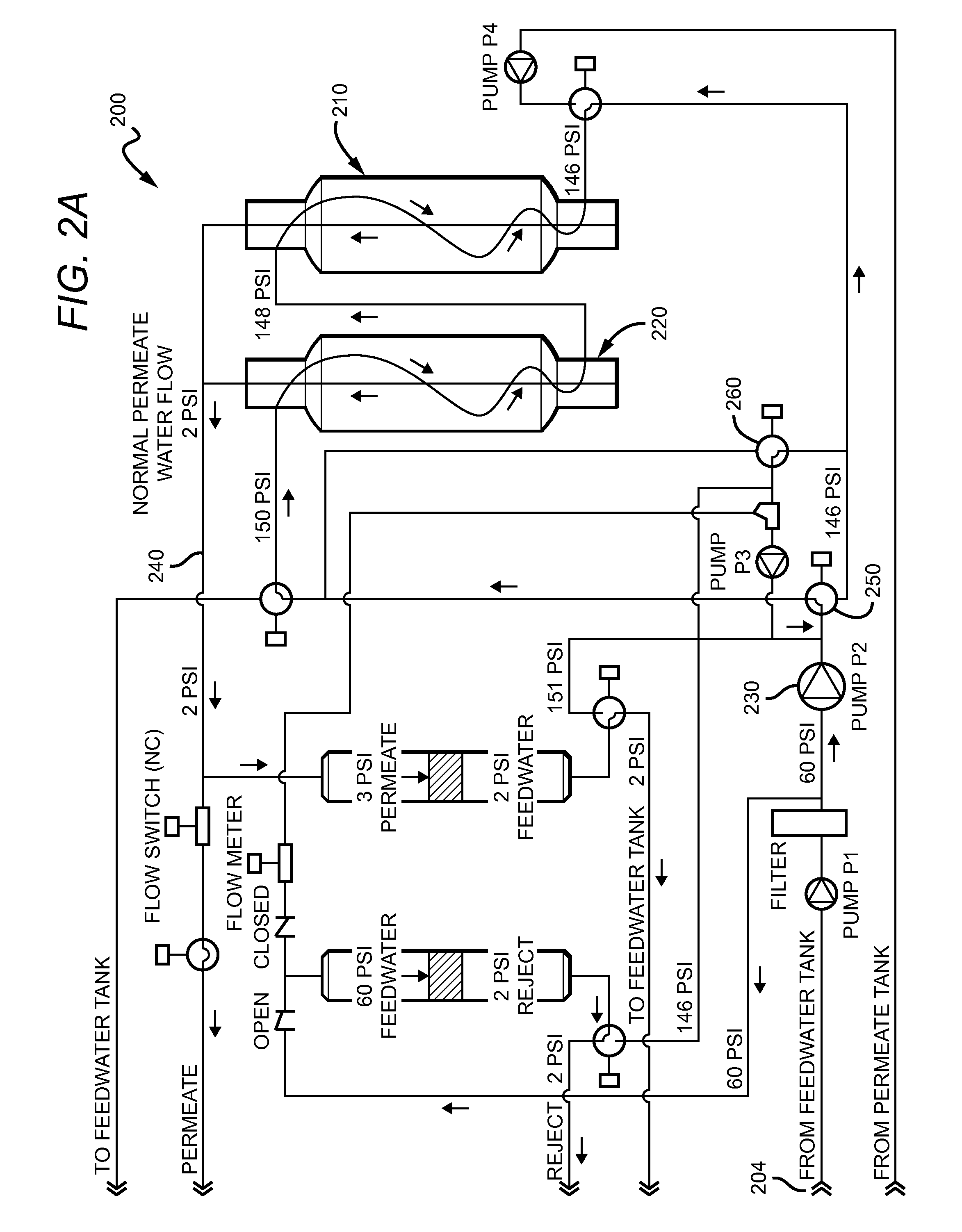

Systems and Methods for Reducing Fouling in a Filtration System

InactiveUS20140014581A1Little and down timeIncrease surface areaReverse osmosisWater/sewage treatment bu osmosis/dialysisFiltrationEngineering

A filtration system include a vessel and a filter element, a first port through which a feed stream can enter the vessel, a second port through which a reject stream can exit the vessel, and a third port through which a permeate can exit the vessel, and a valve system that can be configured to alternately pass the feed stream into the vessel through the first and second ports.

Owner:CHANCELLOR FAMILY TRUST 1996 +1

Methanol fuels for internal combustion engines

InactiveUS20160237362A1Reduce dependenceStable costOrganic chemistryInternal combustion piston enginesCombustionMethanol fuel

The common interchangeable use of a high methanol content fuel for use in all types of internal combustion engines, including cars, trucks, vehicles for transportation use (ships, boats, locomotives, airplanes, etc.), various other equipment and turbines. The engines are converted to be able to use these fuels although further vehicles can be made with components that would allow such fuels to be used. These methanol fuels are renewable and environmentally benign when produced from carbon dioxide capture and recycling of their combustion or other use.

Owner:UNIV OF SOUTHERN CALIFORNIA

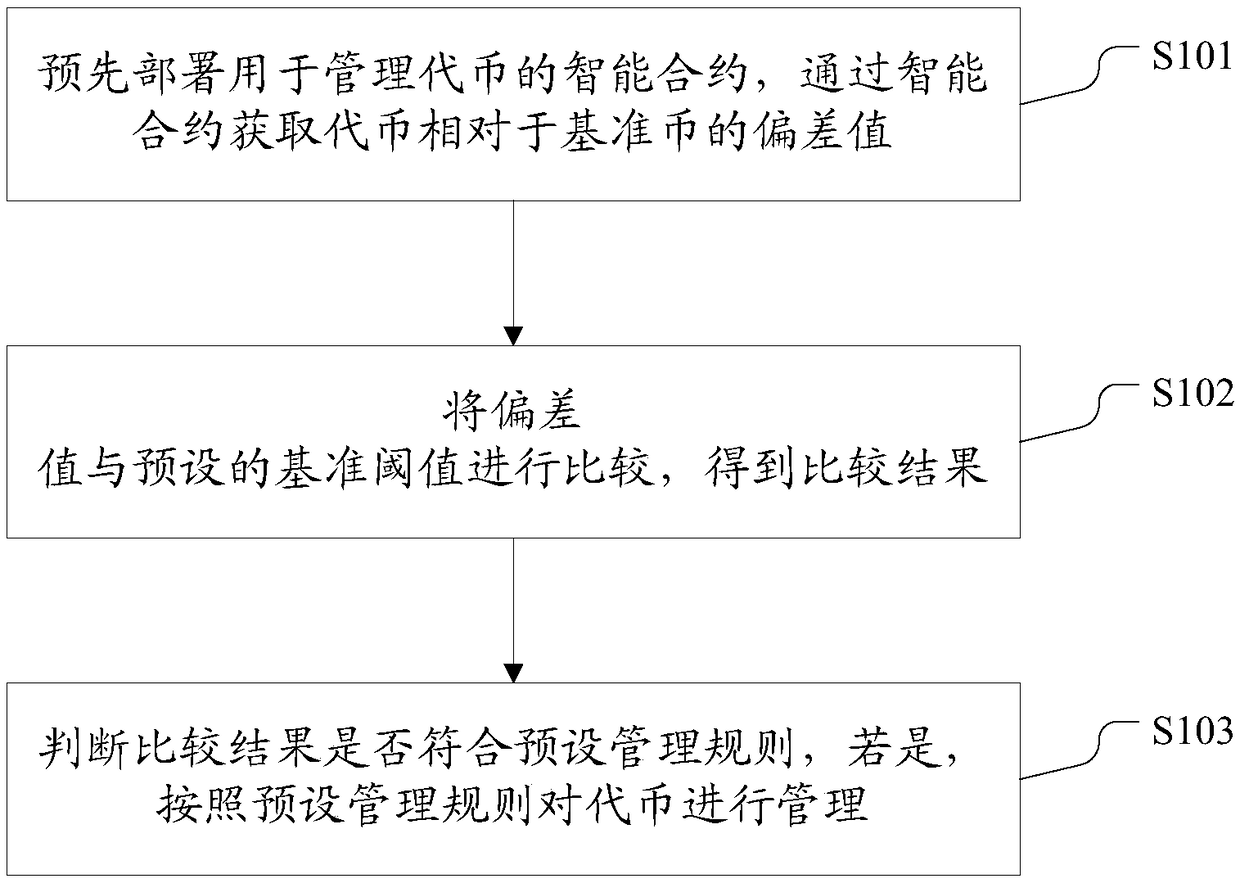

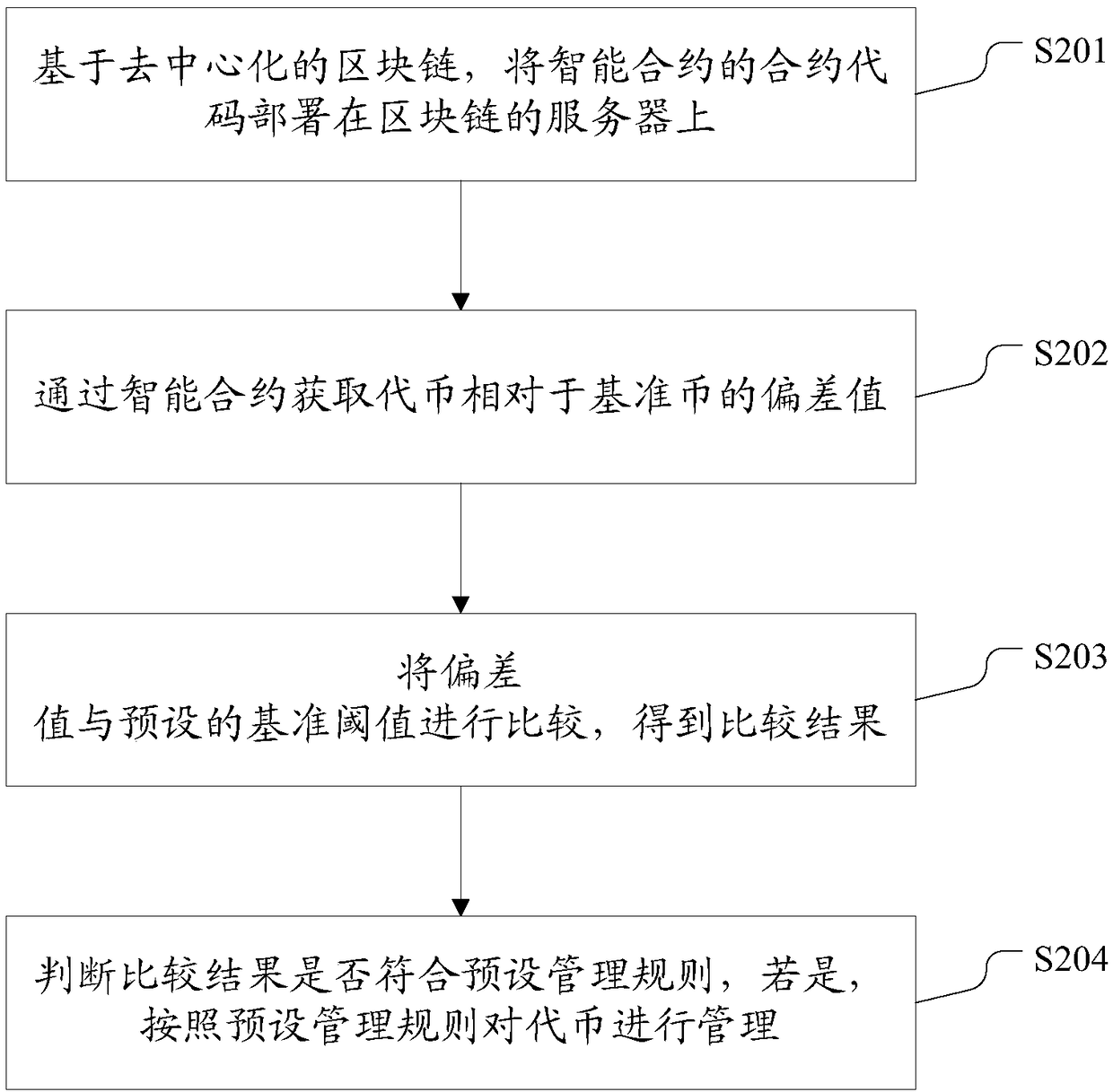

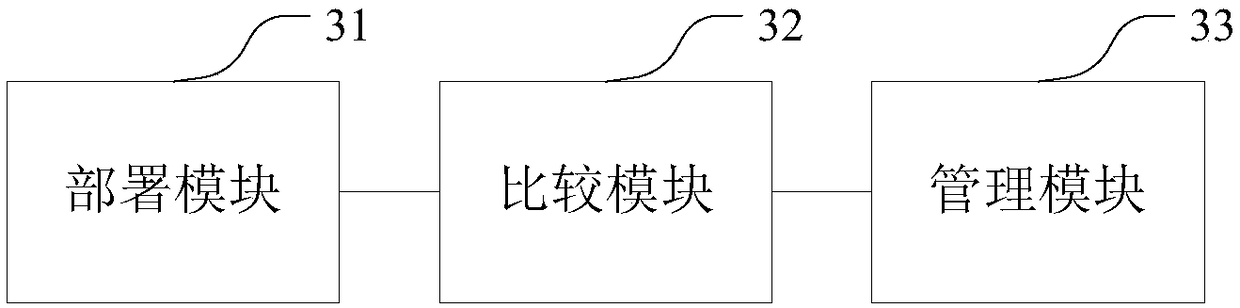

Blockchain-based token management method and device as well as computing equipment

InactiveCN108537524AStable costImprove experienceFinancePayment protocolsSmart contractComputer science

The invention discloses a blockchain-based token management method and device as well as computing equipment. The method comprises the following steps: pre-deploying an intelligent contract for managing tokens and acquiring a deviation value of each token relative to a reference coin through the intelligent contract; comparing the deviation value with a preset reference threshold value to acquirea comparison result; judging whether the comparison result meets a preset management rule or not, and if SO, managing the tokens according to the preset management rule. According to the method, currency values of the tokens can be regulated and controlled to be kept stable relative to the preset reference threshold value according to the preset management rule based on the preset reference threshold value of the reference coin, so that the cost of a user for purchasing a commodity with a token is kept stable, and the shopping experience of the user using the token is enhanced.

Owner:BEIJING QIHOO TECH CO LTD

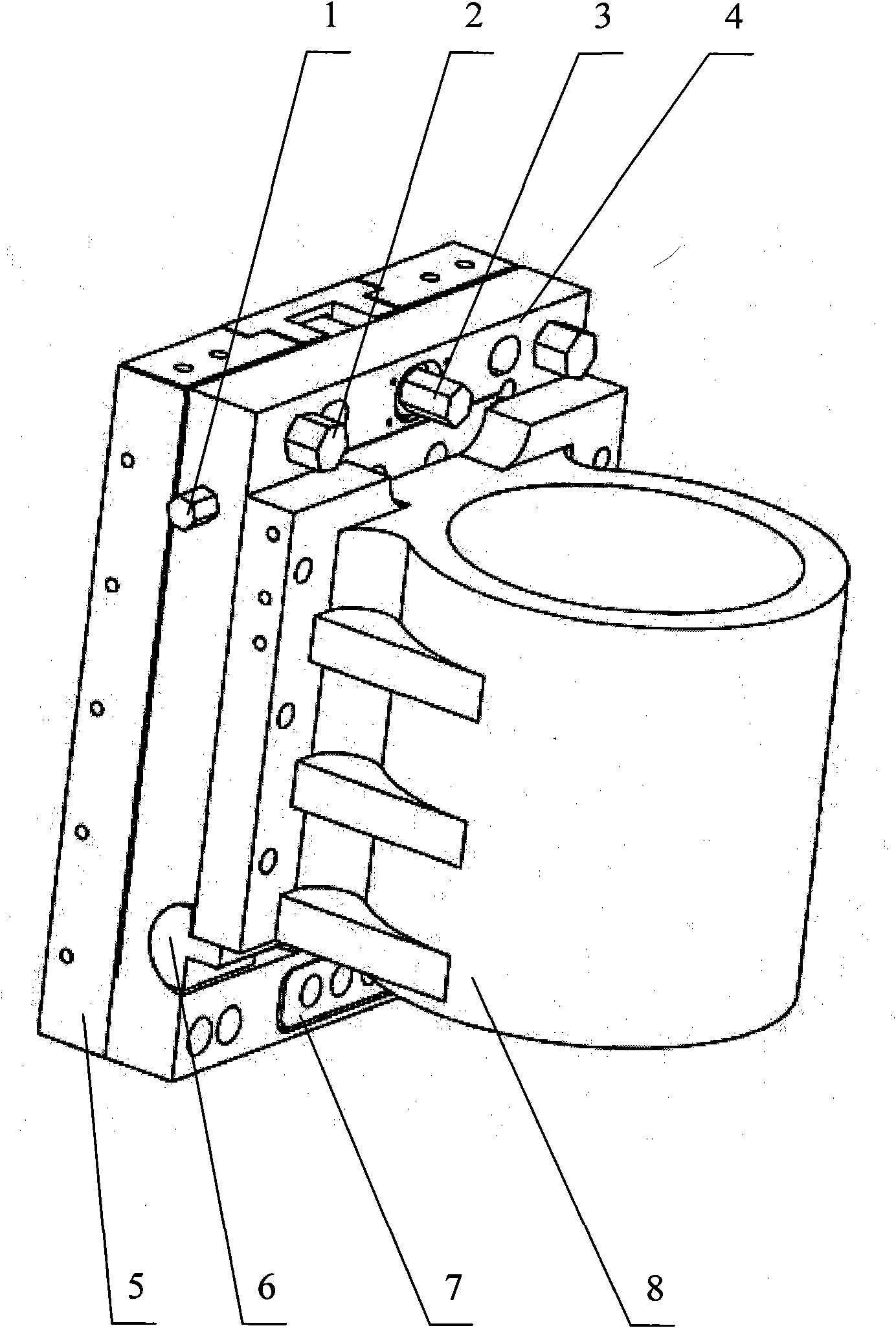

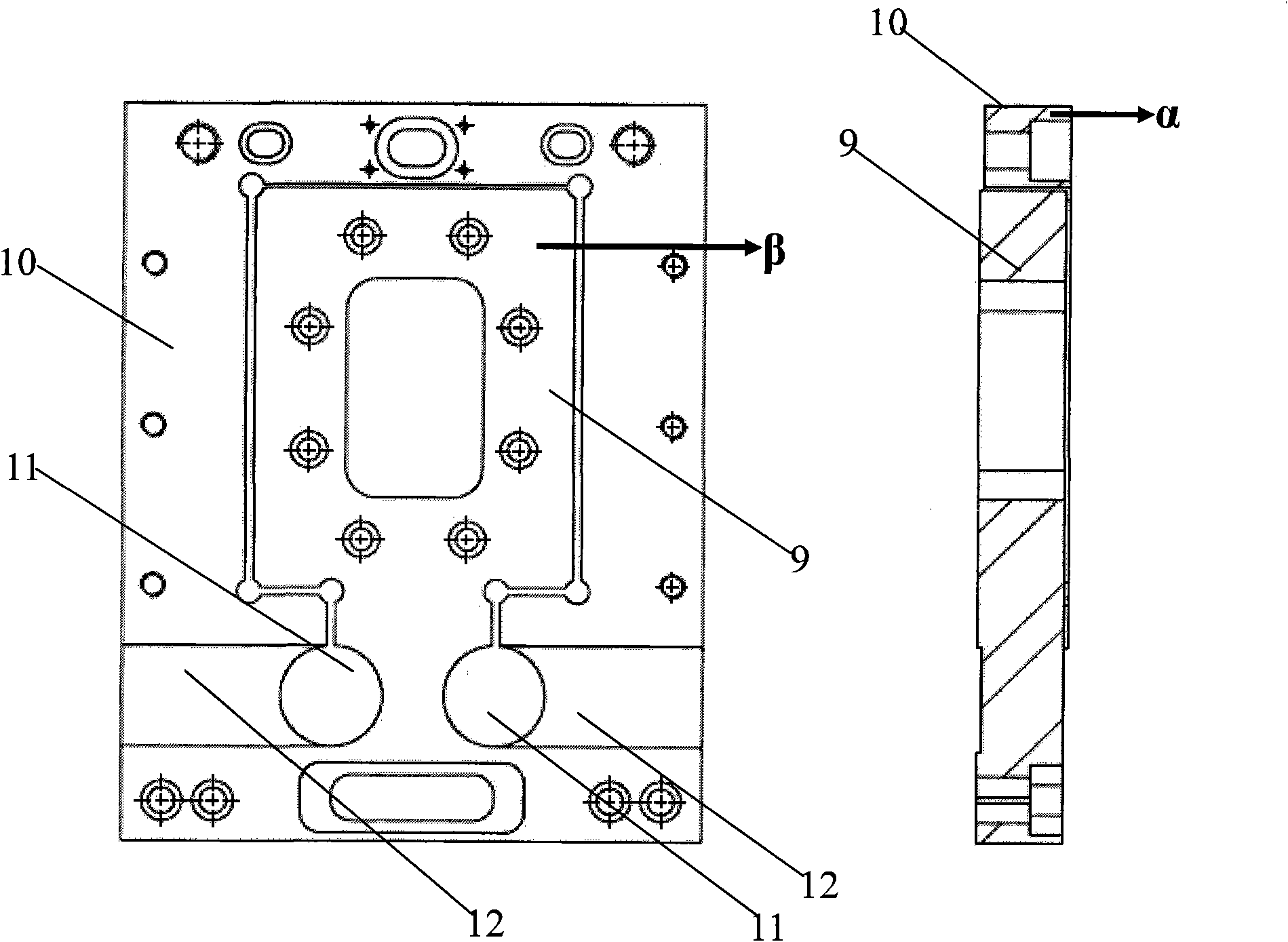

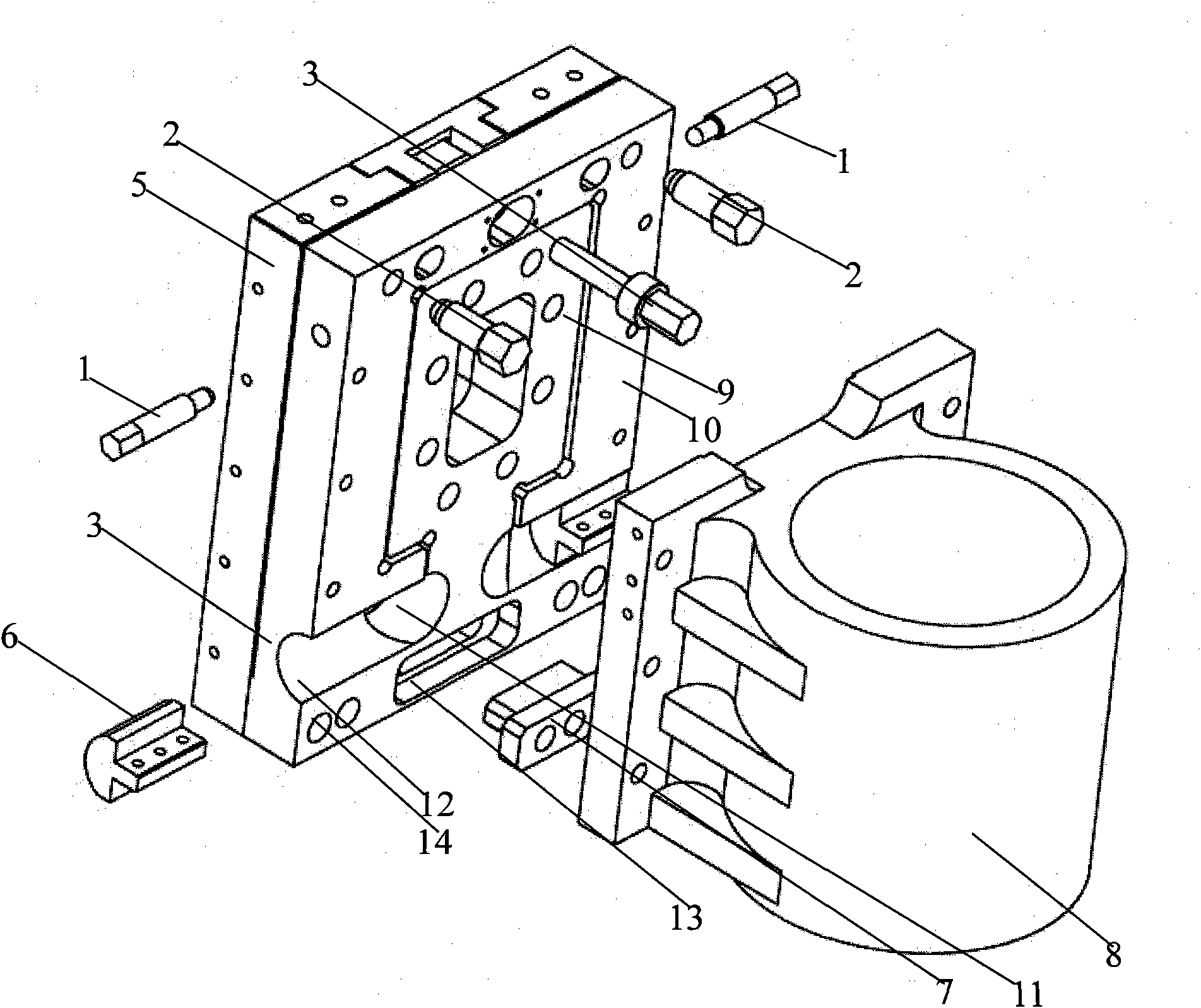

Elastic adjusting mechanism for special semiconductor device

InactiveCN101882592AAchieve regulationSimple structureSemiconductor/solid-state device manufacturingEngineeringScrew thread

The invention relates to an adjusting mechanism, and in particular to an elastic adjusting mechanism for a special semiconductor device, which comprises a track block, an elastic hinge, a knob, a press block, a shaft sleeve and a rotation chock block. An elastic hinge inner ring is fixed on the track block through a screw and an adjusting cushion block, a knob C is inserted into the elastic hinge and is connected with the track block through threads, a knob B is screwed into the elastic hinge through threads, the spherical surface on the end part of the knob B is contacted with the track block, a knob A is screwed into the elastic hinge through the threads from two sides, the spherical surface on the end part of the knob A is contacted with the elastic hinge inner ring, the rotation chock block is arranged inside a semi-circular groove of the elastic hinge and is connected with the bottom part of the shaft sleeve, and the shaft sleeve is fixed on an outer ring of the elastic hinge. The knob is used for adjusting the elastic hinge, so the micro-angle adjustment of beta in the transverse direction and alpha in the longitudinal direction can be realized in the processing technology of the wafer. The elastic adjusting mechanism has the advantages of compact structure, simple installation, convenient application and reliable adjustment, and can be widely applicable to the special semiconductor device.

Owner:CETC BEIJING ELECTRONICS EQUIP

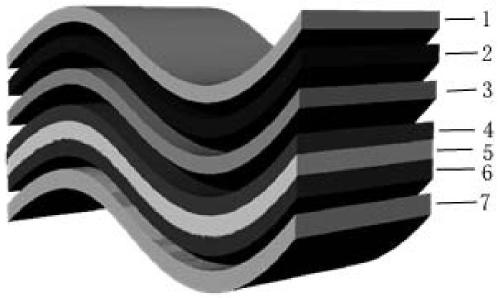

Flexible electrochromic device and preparing method thereof

ActiveCN110441970AAvoid damageImproved coefficient of thermal expansionVacuum evaporation coatingSputtering coatingScreen printingDielectric structure

The present invention relates to a flexible electrochromic device and a preparing method thereof. The preparing method mainly comprises: preparing a flexible extensible PDMS substrate, preparing a PDMS coated with a Dielectric-Metal-Dielectric structure, preparing a TCO-coated PDMS counter electrode, preparing a solid / gel electrolyte; and finally, using a silk screen printing method to print the solid / gel electrolyte onto the PDMS coated with the Dielectric-Metal-Dielectric structure, after the solid / gel electrolyte is cured and formed, placing the TCO-coated PDMS counter electrode onto the solid / gel electrolyte, and performing sealing processing around by using PVB rubber, to form ECDs of a pattern array structure. The flexible electrochromic device provided in the present invention is divided into a flexible substrate, a solid / gel electrolyte layer, an electrochromic layer of a DMD structure, and a transparent conductive layer, so that a plurality of times of circular electrochromismcan be performed, circular electrochromism is more stable, electrochromism efficiency is higher, and the device is flexible. The preparing method is simple, efficient, and low in costs, and can fastimplement industrial production. The flexible electrochromic device and the preparing method thereof are applied to an aspect of car and building intelligence systems, and can reduce energy consumed by cities and achieve an objective of energy conservation.

Owner:SHANTOU UNIV

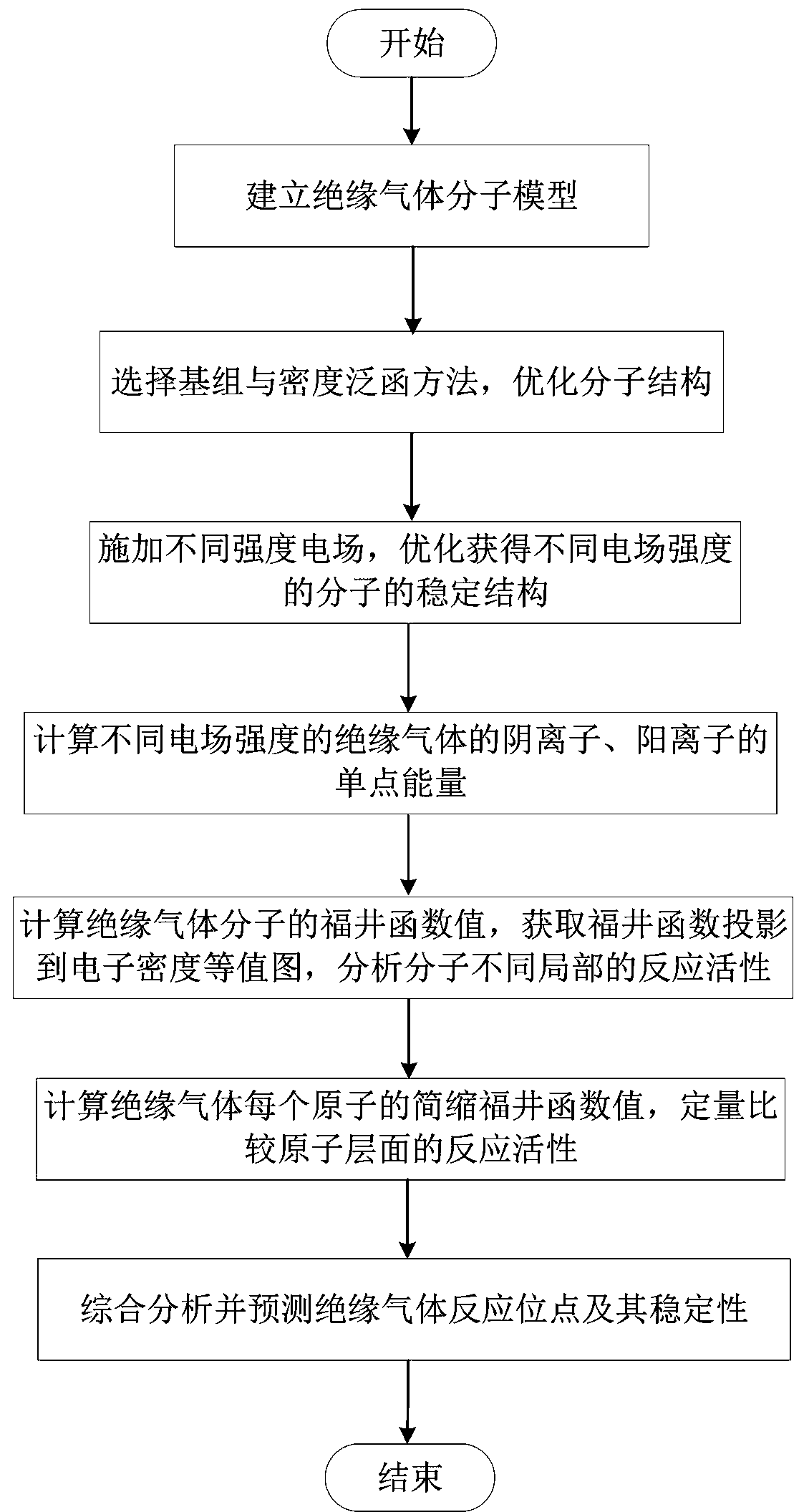

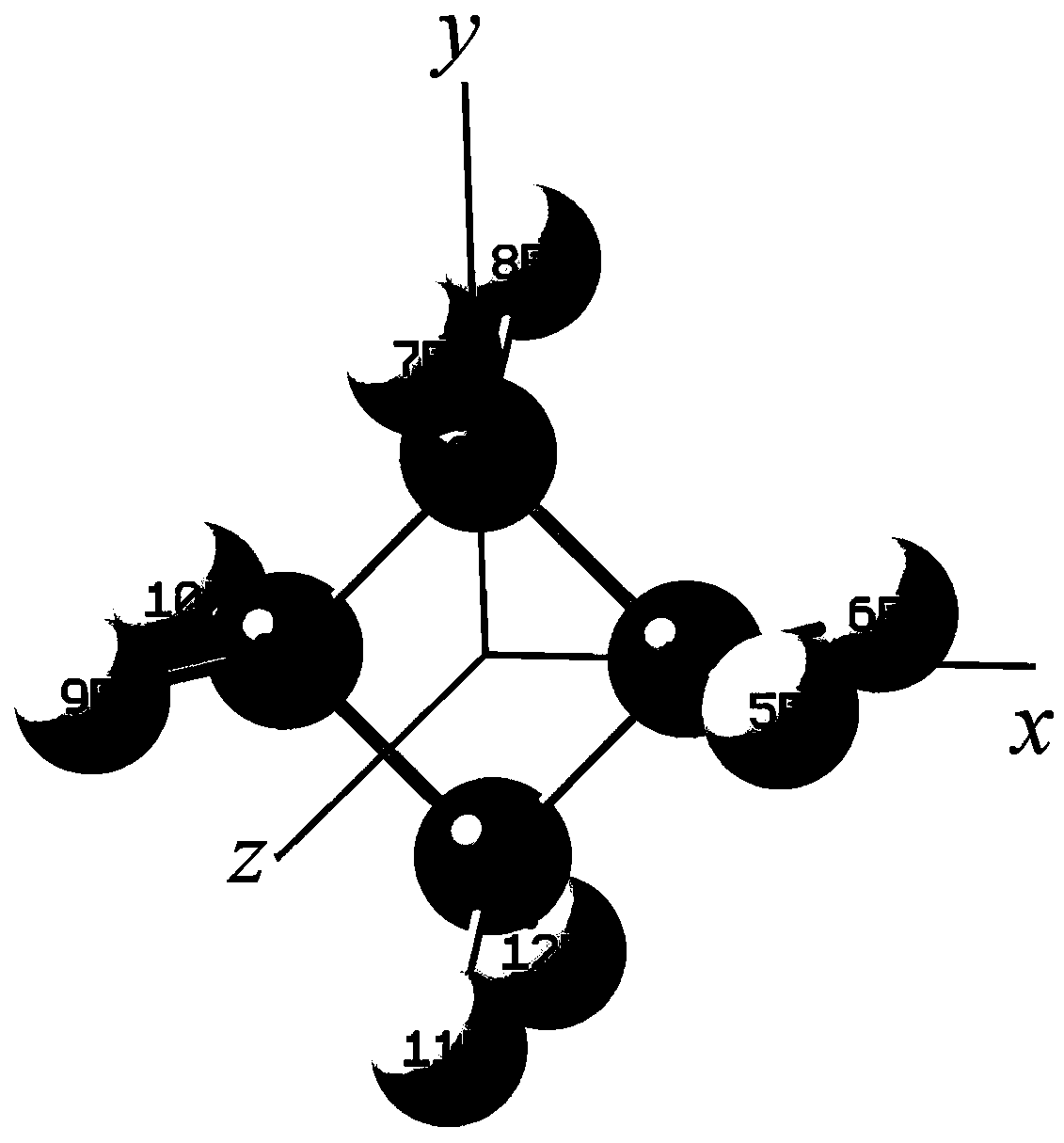

Method for quantitatively analyzing chemical stability of insulating gas molecules under external electric field

PendingCN110321608AReduce lossStable costForecastingDesign optimisation/simulationElectrical field strengthChemical stability

The invention discloses a method for quantitatively analyzing the chemical stability of insulating gas molecules under an external electric field. The method comprises steps of selecting a group and afunctional group, and optimizing a molecular structure; respectively applying electric fields with different intensities to the insulating gas molecules to obtain stable structures of the molecules with different electric field intensities; calculating single-point energy of anions and cations of the insulating gas with different electric field intensities; calculating the Fukui function value ofthe insulating gas molecule, and analyzing the reaction activity of different local parts of the insulating gas molecule; calculating a reduced Fukui function value of each atom of the insulating gas, and quantitatively comparing the reactivity of the atom level; and comprehensively analyzing and predicting the reaction sites of the insulating gas and the stability thereof. The method disclosed by the invention is low in loss, stable in cost, simple and feasible, high in repeatability and microcosmic and accurate in analysis result; the Fukui function predicts the reaction sites by considering the electronic structure characteristics of the reactants, the operation cost is low, and convenience and effectiveness are achieved.

Owner:CHINA THREE GORGES UNIV

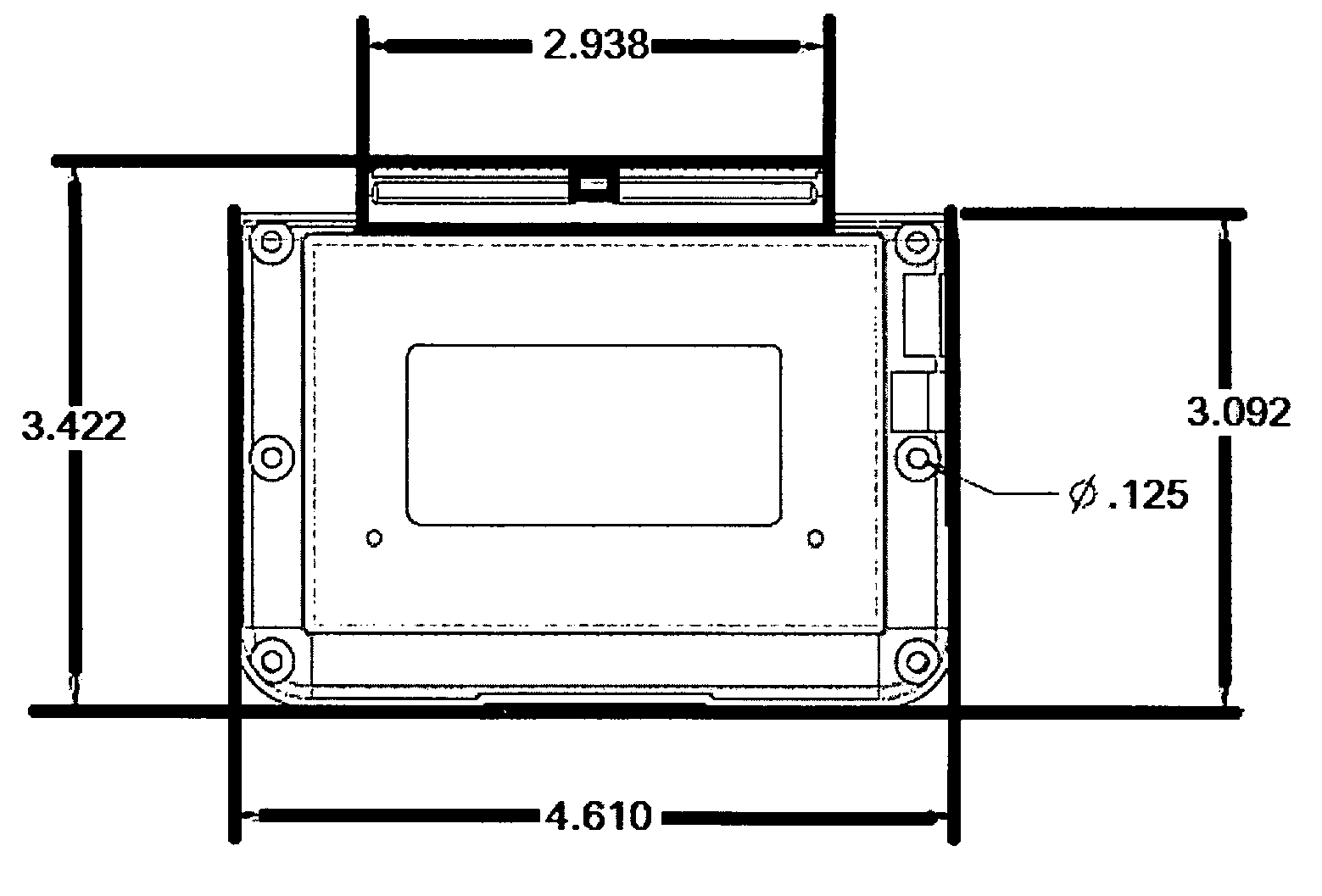

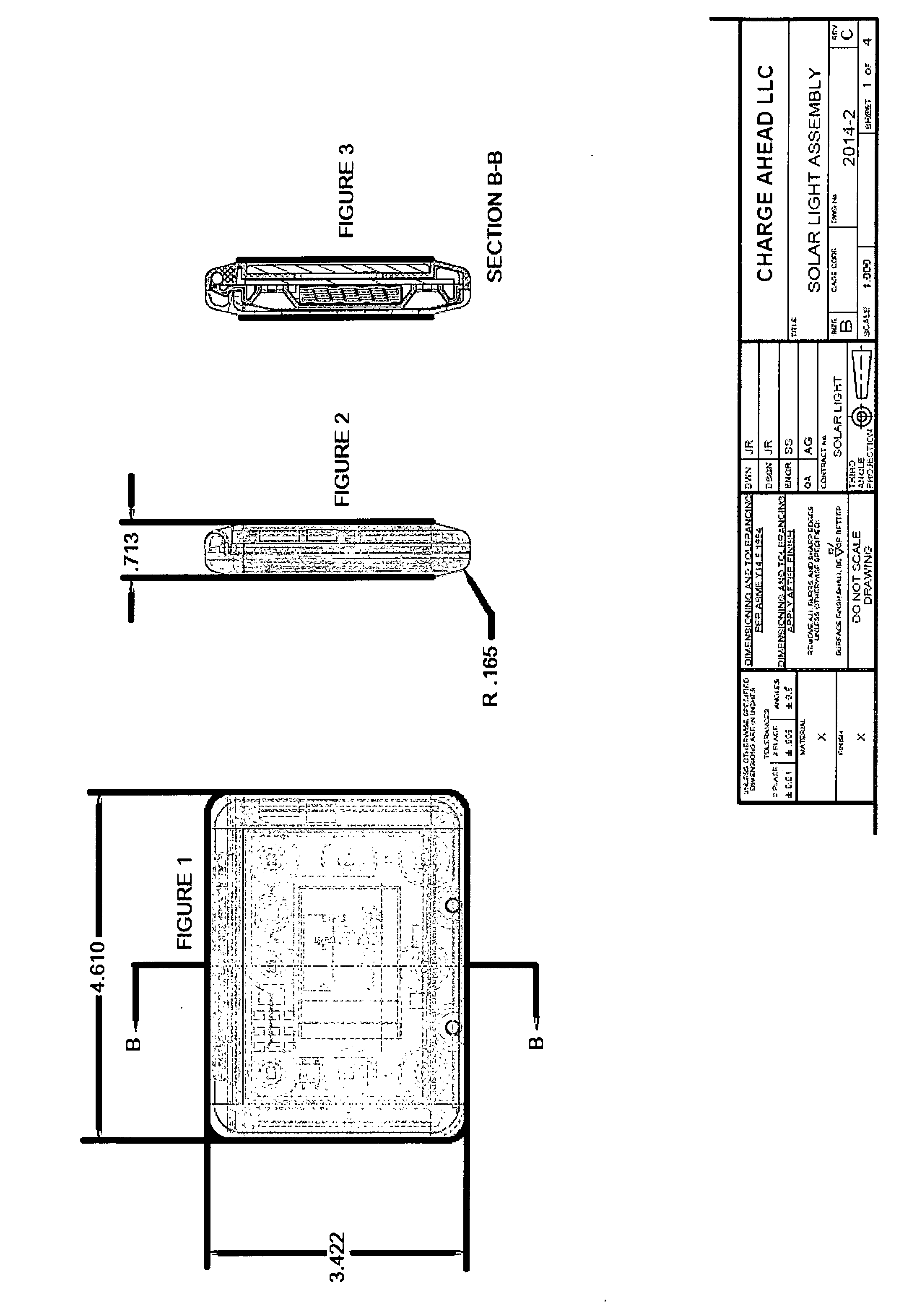

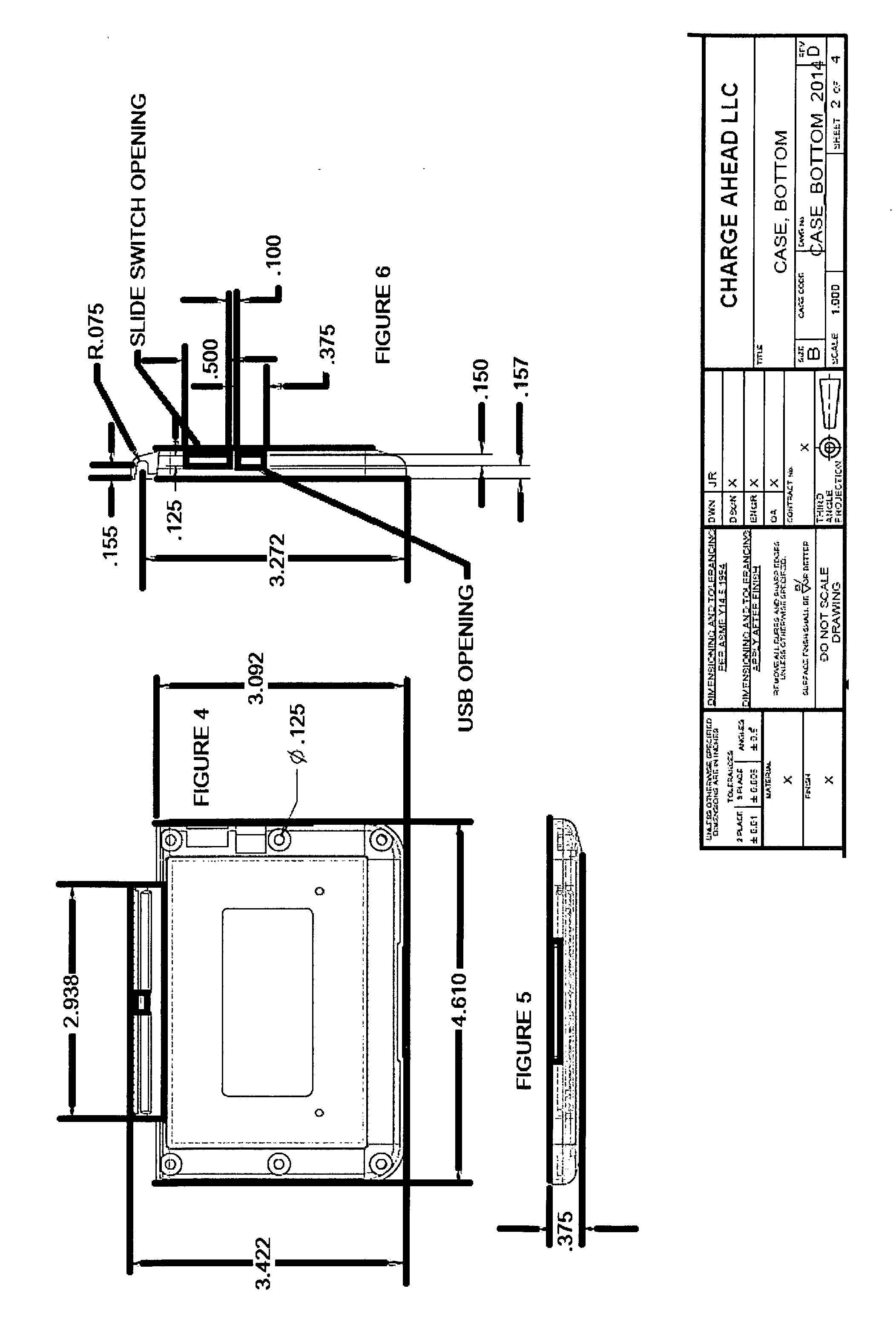

Self-powered solar illumination device with self-contained power system

InactiveUS20160123548A1Stable costBig roomPlanar light sourcesBatteries circuit arrangementsLight equipmentEffect light

The quest for efficient lighting has been around for generations. LED (light emitting diode) is an efficient way to illuminate. Predecessors like the florescent light and standard incandescent light sources proved to only generate a fraction of the light source provided by a LED. Florescent light only provides a ¼ of a LED's illumination, and a standard incandescent light provides 1 / 20th of a LED's illumination. The self-powered device provides a compact, durable solution for efficient lighting through utilizing energy from the sun, as well as the potential to transfer solar energy to other small portable devices.

Owner:GRIFFIN ANNE MARIE +1

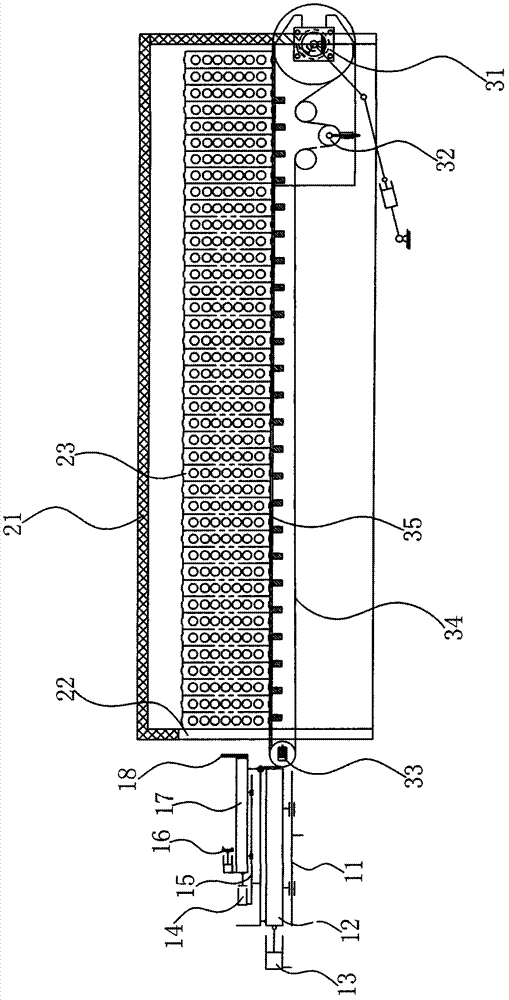

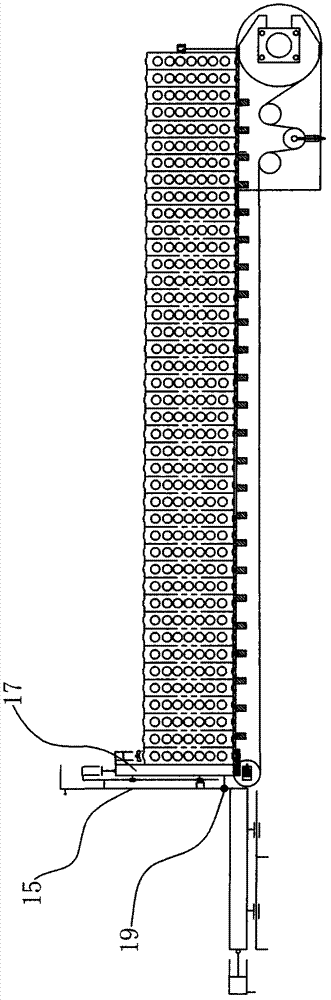

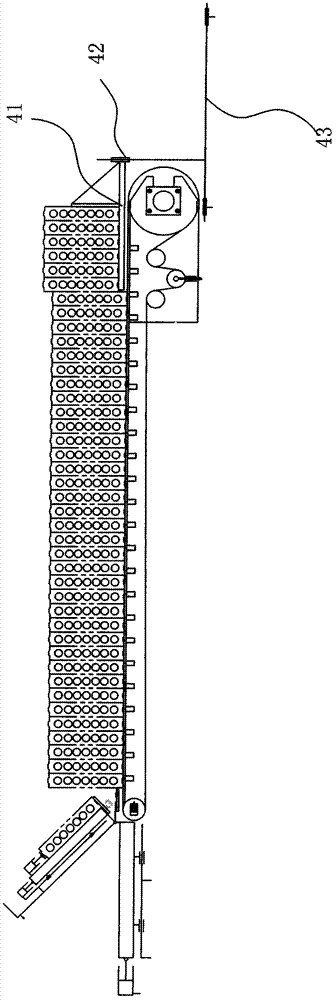

Flow line production method and device for construction partition wall board

InactiveCN102211349BReduce distortionEliminate deformationConstruction materialCeramic shaping plantsEngineeringKiln

The invention discloses a flow line production method and a flow line production device for a construction partition wall board. The flow line production method comprises the following steps of: overturning a molded construction partition wall board to a maintenance conveying mechanism by using a partition wall board moving and overturning mechanism, wherein the partition wall board moving and overturning mechanism comprises an overturning frame, one end of the overturning frame is rotationally arranged, and a partition wall board fixing board is slidably arranged on the overturning frame; placing the molded construction partition wall board on the partition wall board fixing board, and then overturning the construction partition wall board to the maintenance conveying mechanism by using the rotated and overturned overturning frame; and performing molding maintenance on the arranged construction partition wall board in a maintenance conveying kiln when the construction partition wall board is conveyed in a translation way through the maintenance conveying mechanism which is positioned in the maintenance conveying kiln. By the method and the device, defects in the prior art are overcome, a large number of transport supporting boards, supporting frames and kiln vehicles are prevented from being used, and processes are simple.

Owner:吴振军

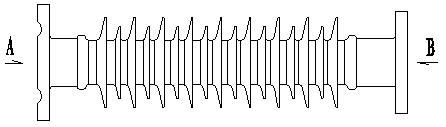

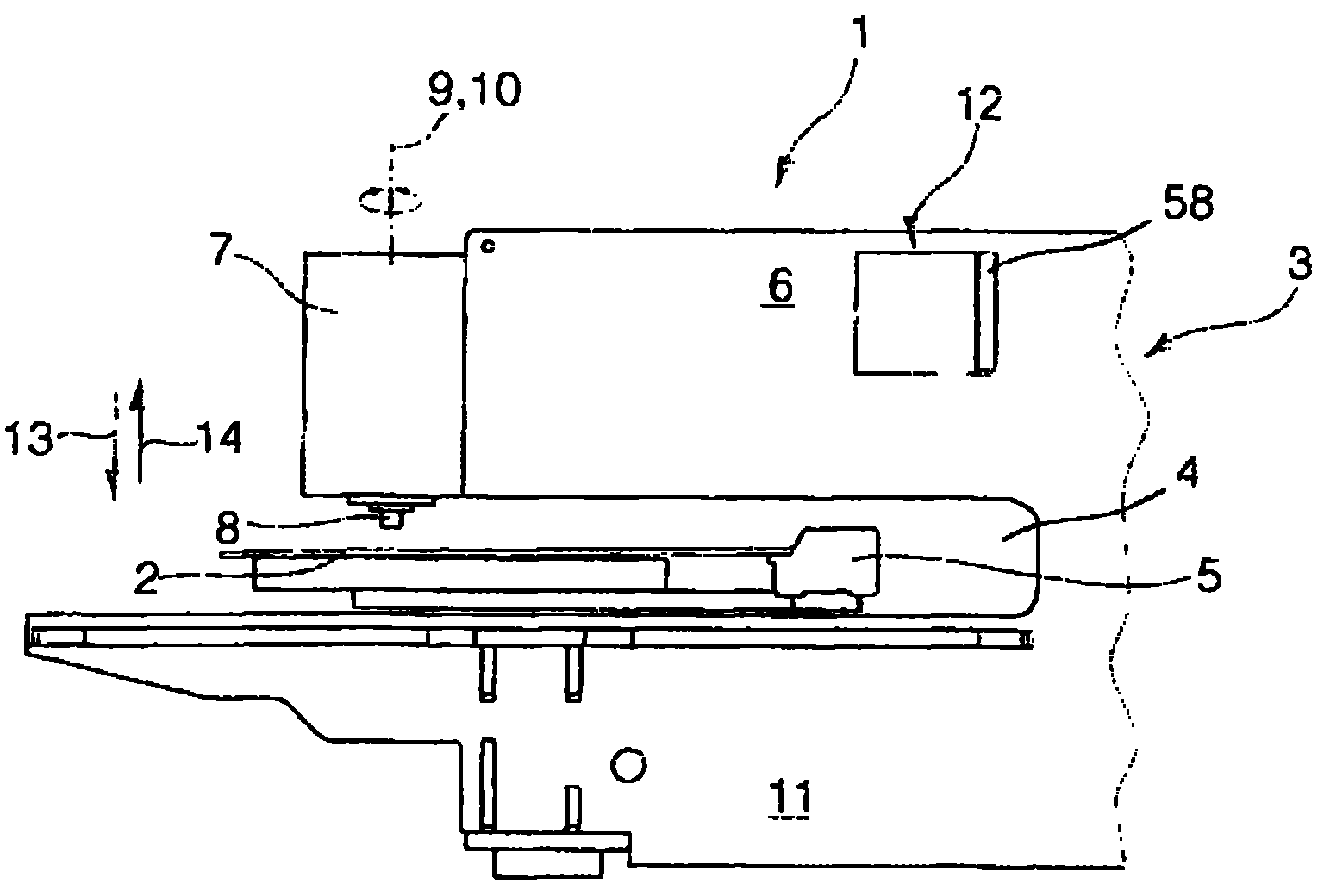

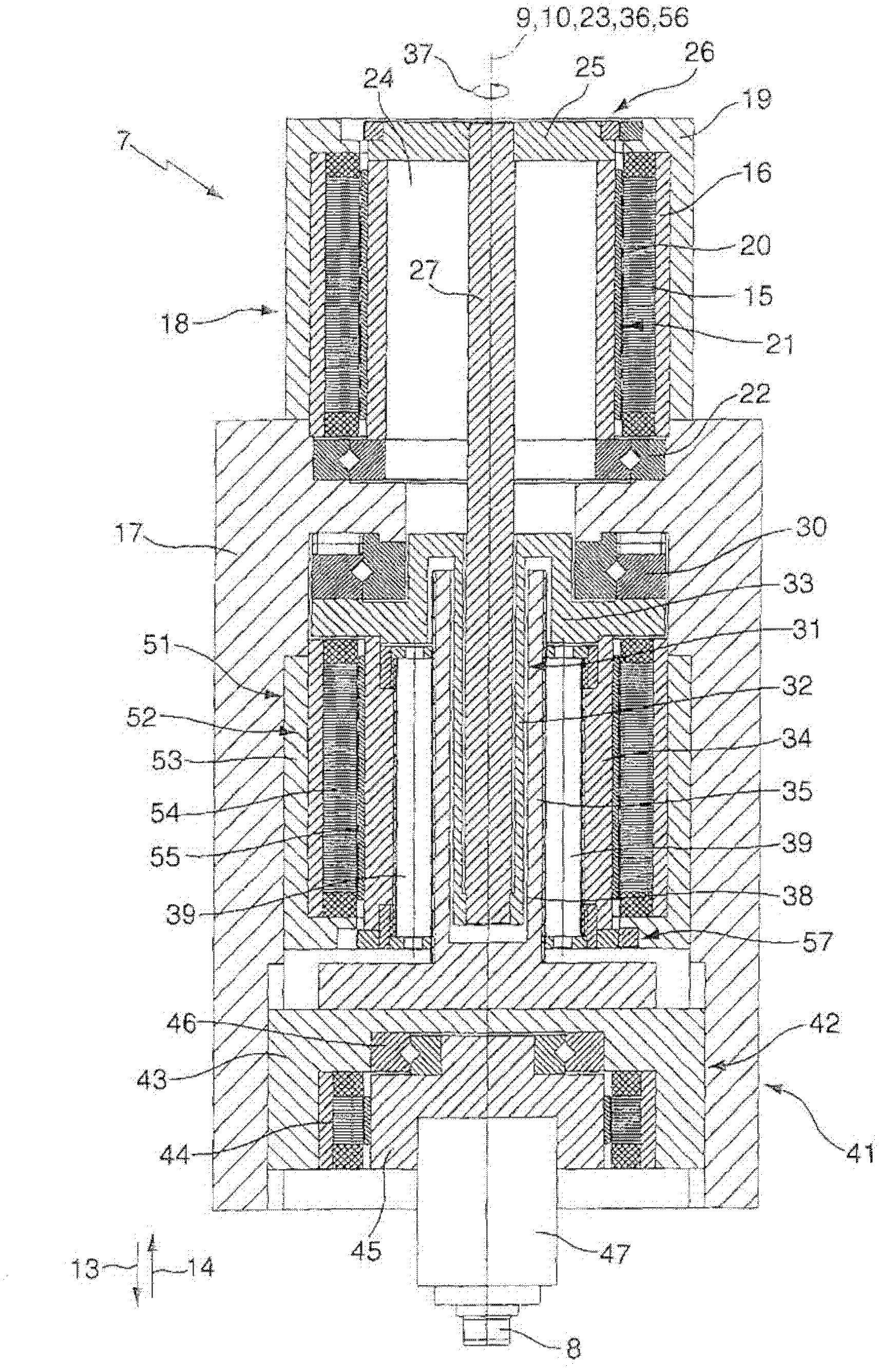

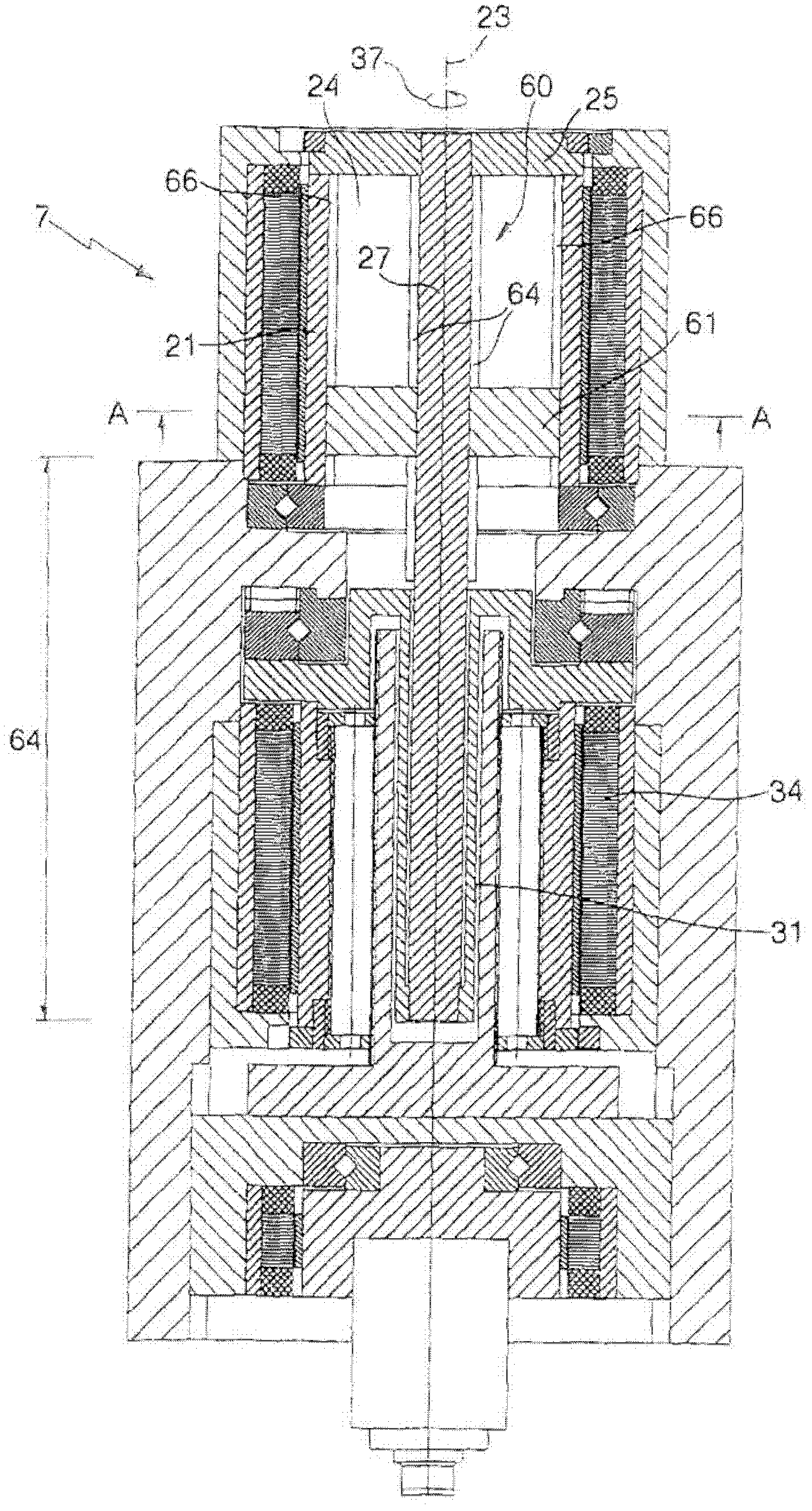

Press drive and method for generating a stroke motion of a tool mounting by means of a press drive

The invention relates to a press drive (7) comprising a press drive motor (18) drivingly connected to a tool mounting (47) by means of a coupling having a coupling element (25, 34) on the motor side and on the tool mounting side. In order for a press drive (7) to have high dynamic performance, an elastic connecting element (27, 31) is connected between the coupling element (25) on the motor side and the coupling element (34) on the tool mounting side, and a controllable delay device (51) engages with the coupling element (34) on the tool mounting side. A change in motion of the coupling element (34) on the tool mounting side introduced by means of the press drive motor (18) can be at least partially delayed by means of the delay device (51) in a controlled manner by deforming the elastic connecting element (27, 31).

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

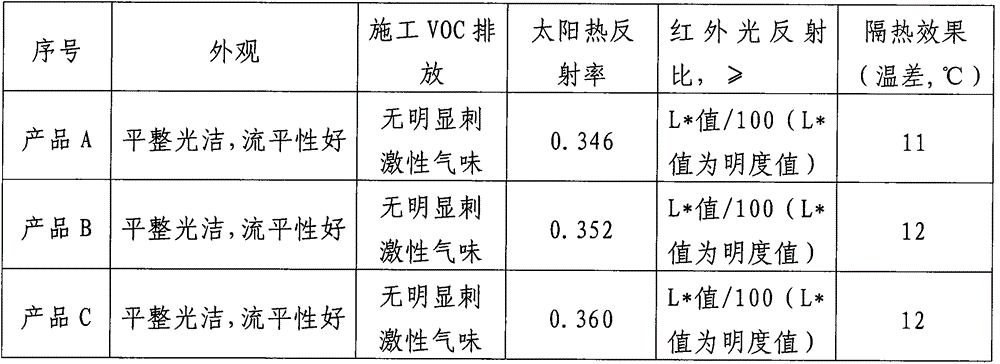

Waterborne building heat-insulation environment-friendly coating and preparation method thereof

InactiveCN104830131AAvoid performance degradationReduce performance degradationCoatingsMethacrylateEnvironmental resistance

Waterborne building heat-insulation environment-friendly coating comprises, by weight, 20-30 parts of hexafluorobutyl methacrylate, 20-30 parts of methyl methacrylate, 250-280 parts of styrene-acrylic emulsion, 180-200 parts of water, 3-6 parts of defoamer, 1-2 parts of mildew preventive, 3-6 parts of dispersant, 1-2 parts of wetting agent, 200-400 parts of Luzhao soil, 100-160 parts of coal ash, 150-180 parts of titanium dioxide, 80-120 parts of talcum powder, 50-60 parts of expanded perlite, 30-40 parts of N-dodecanethiol, 20-30 parts of butyl cellosolve, 20-30 parts of thickener, 6-8 parts of flatting agent, 6-10 parts of water repellent agent and 1-2 parts of tributyl phosphate. The waterborne building heat-insulation environment-friendly coating is low in VOC (volatile organic compound) emission, simple in production and construction process, environment friendly and excellent in performance. Meanwhile, functional filler with specific components replace commonly used glass beads, and the waterborne building heat-insulation environment-friendly coating is stable in performance and has wide application in building coating in the industrial and decoration fields.

Owner:杨秀莲

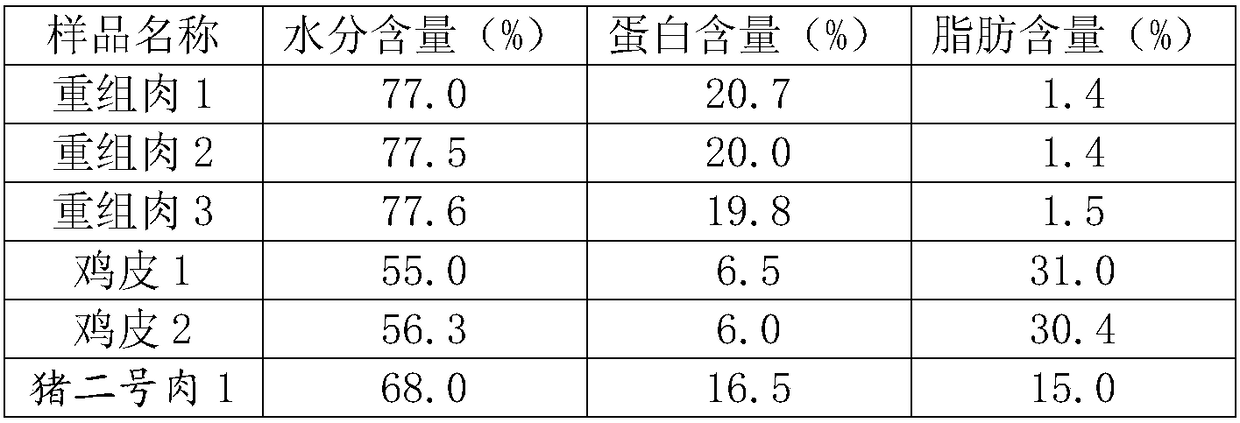

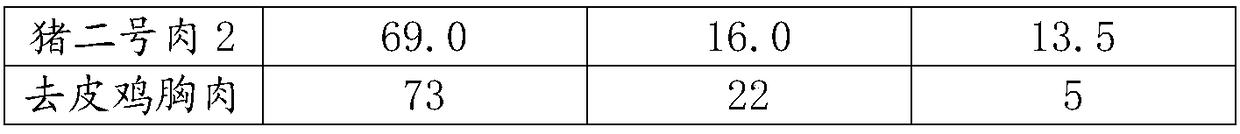

Restructured meat and processing method thereof

PendingCN108783261ASame sensualitySame experienceFood ingredient as mouthfeel improving agentAnimal proteinChicken breast

The invention discloses restructured meat and a processing method thereof. The restructured meat consists of the following raw materials in percentage by weight: 17%-19% of soy protein isolate, 14%-18% of peeled chicken breast meat, 0.2%-0.4% of anhydrous sodium carbonate, 0.25%-0.45% of sodium pyrophosphate, 0.02% of transglutaminase and 64%-67% of water. The restructured meat disclosed by the invention is provided for meat product processing to be used for replacing raw material meat, the situation that the restructured meat has the same meat feeling and experience as meat can be guaranteed,the situation that the restructured meat contains animal protein and vegetable protein at the same time can be guaranteed, the protein source is rich, and the restructured meat has obvious advantageson the cost.

Owner:临沂金锣文瑞食品有限公司

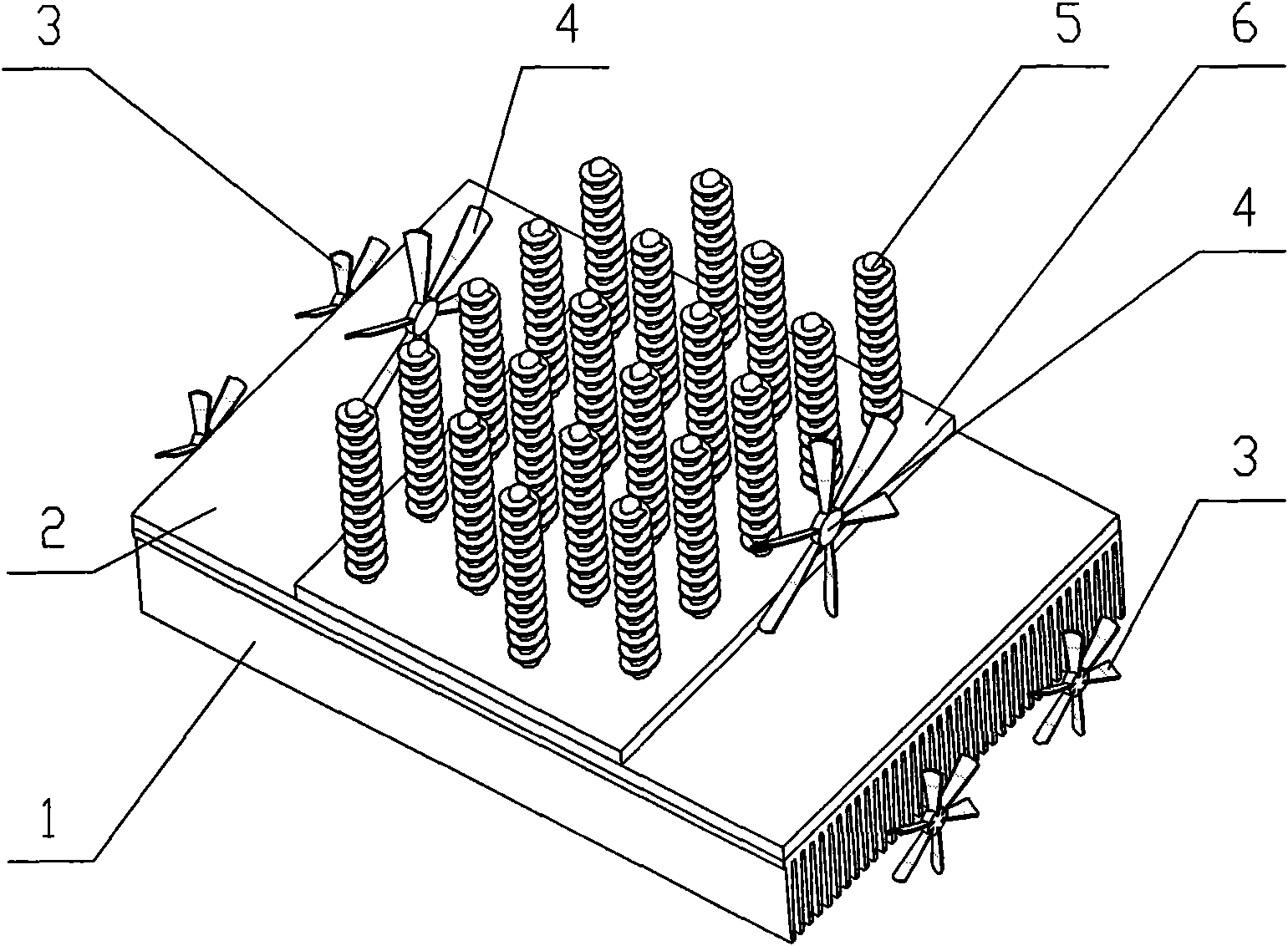

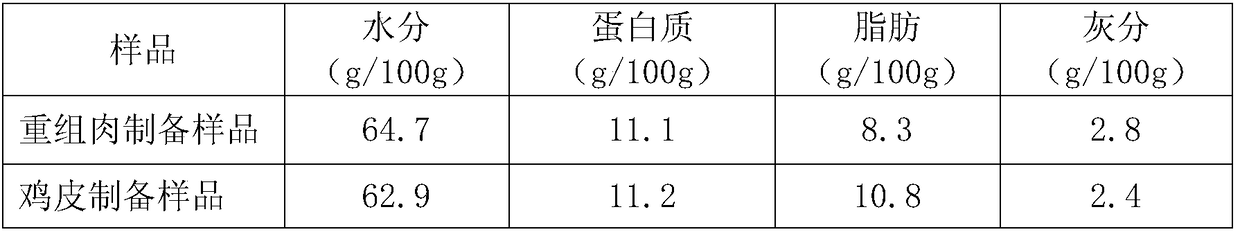

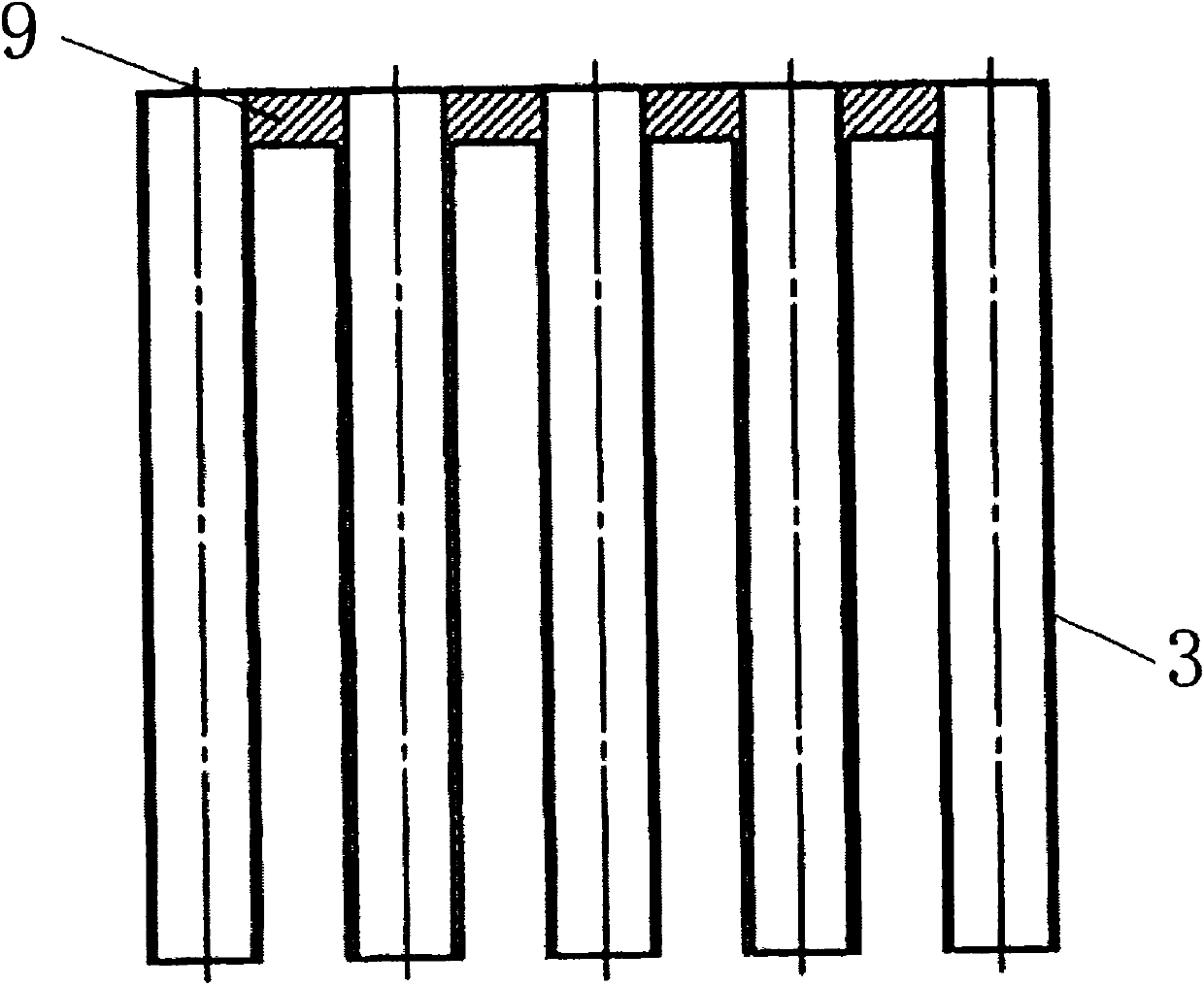

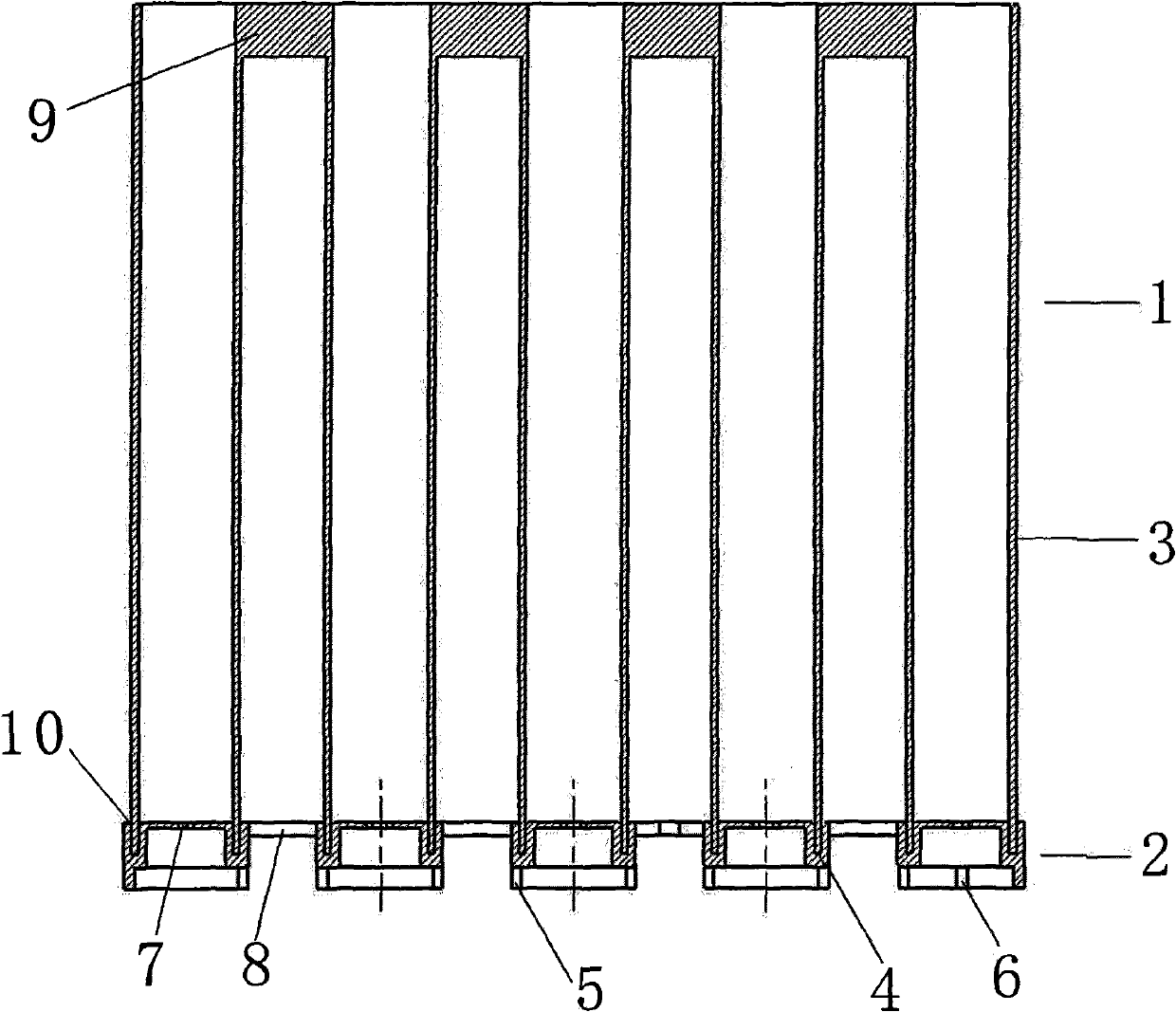

Automatic forming combined firework barrel

The invention discloses an automatic forming combined firework barrel, which is characterized in that: the firework barrel (1) mainly comprises two independent components, namely a firework barrel seat (2) and a barrel tube (3) which are connected by inserting; the firework barrel seat (2) mainly comprises a barrel tube socket (4) and a barrel tube socket connector (8); and the barrel tube socket(4) is provided with a circle of groove (10) for inserting the barrel tube (3), the bottom of the barrel tube socket (4) is provided with a serial fire hole (7), and the lower part of the tube wall of the barrel tube socket (4) is provided with serial fire lead slots (5 and 6). The firework barrel has the advantages that: 1, because the firework barrel mainly comprises the two independent components, namely the firework barrel seat and the barrel tube which are connected by inserting, the firework barrel is convenient to assemble a lead; a space is formed between the barrel tubes, so the firework barrel has light weight, is suitable for manufacturing large-sized fireworks of various specifications and is also convenient for transportation; and 2, the firework barrel can be formed by one-time injection molding, is convenient for automatic production, and overcomes the defects that the hand-made bundled combined fireworks have complex process, high labor intensity, low production efficiency, high cost and the like.

Owner:项友健

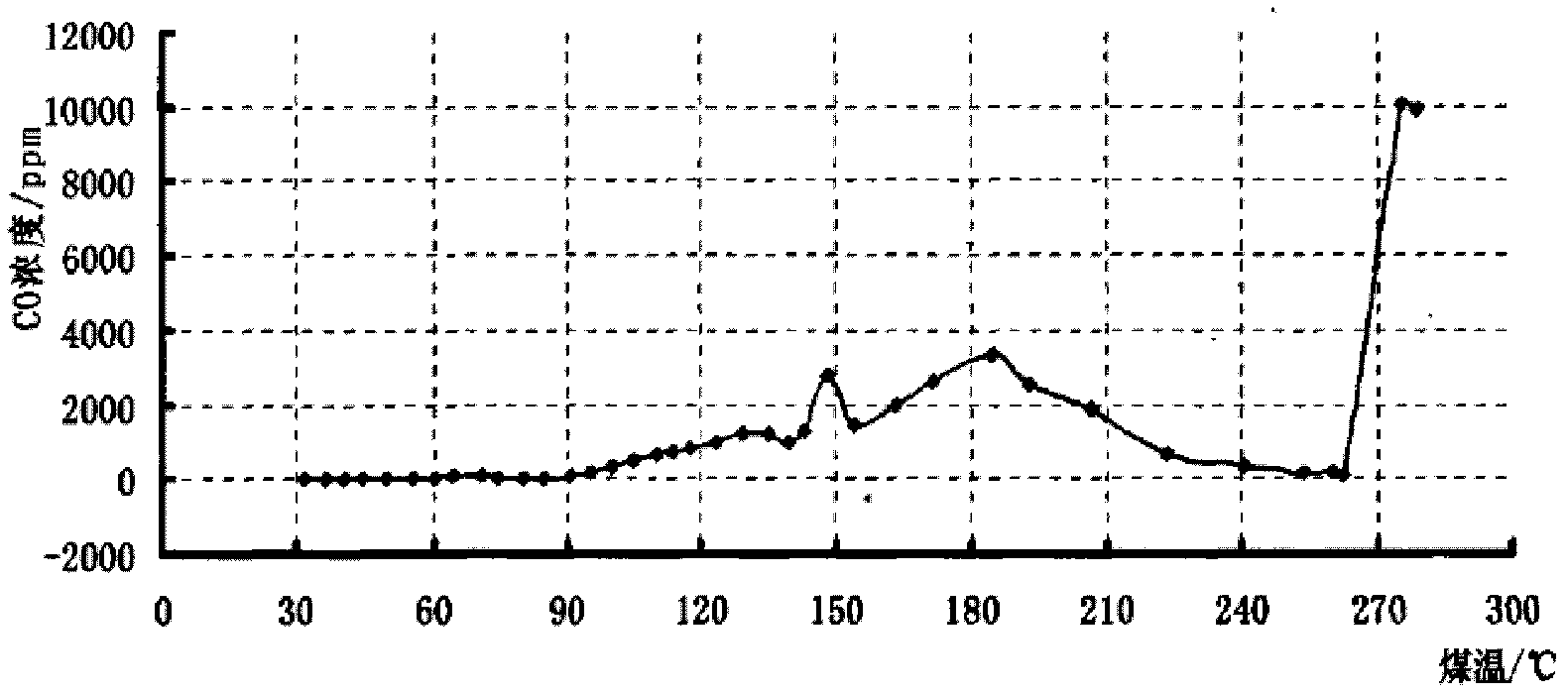

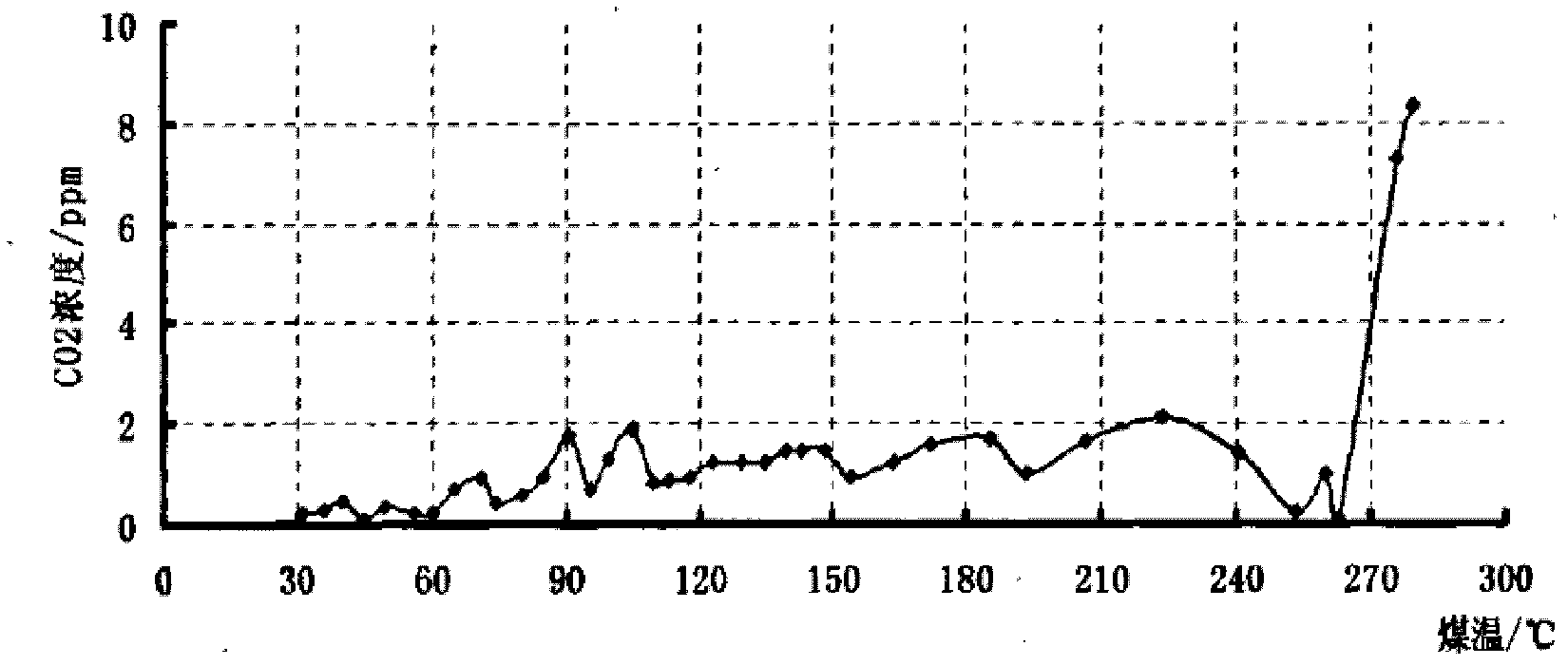

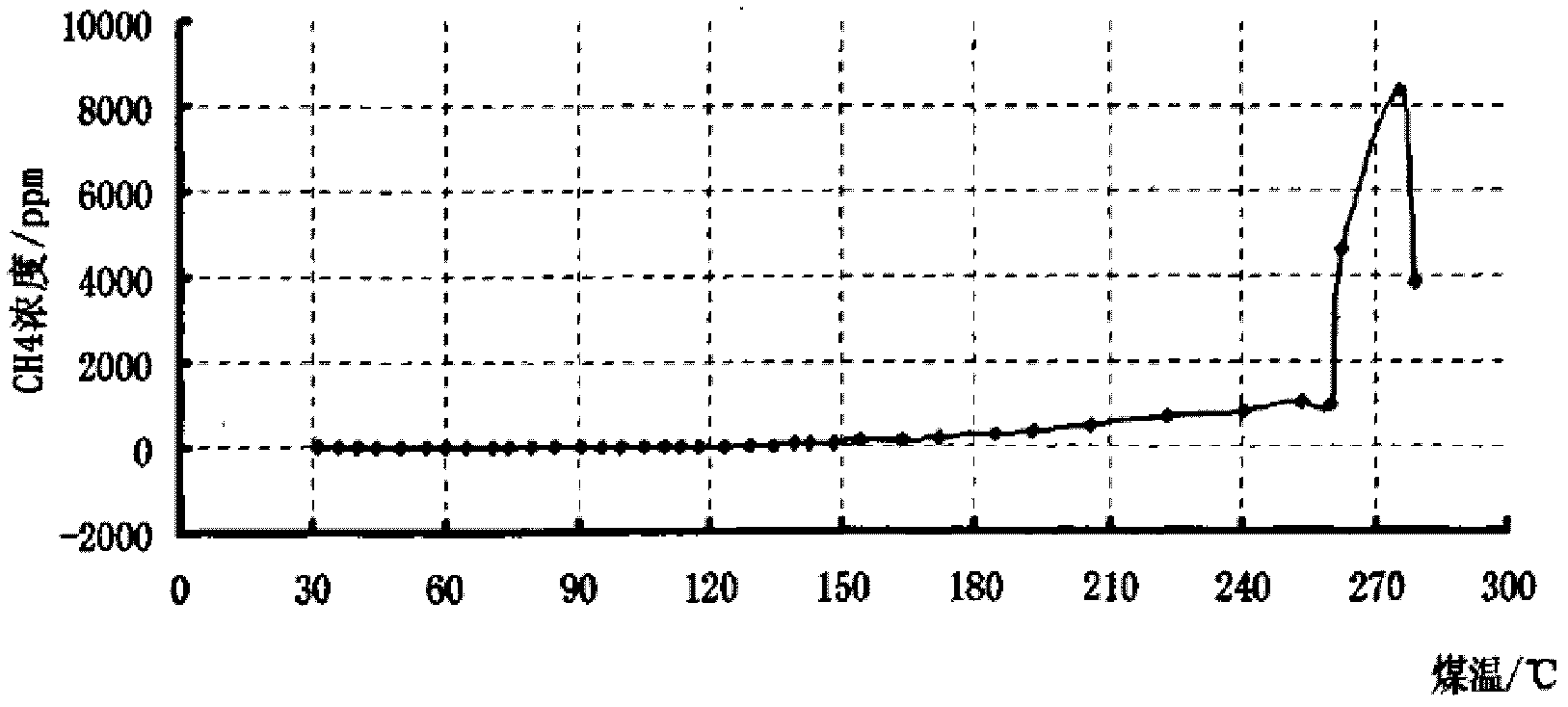

Coal mine down-hole fire monitoring system based on wireless sensor network

InactiveCN102269014BAccurate monitoring of underground fire functionsExtended service lifeMining devicesLine sensorWireless mesh network

The invention provides a coal mine down-hole fire monitoring system based on a wireless sensor network. The system comprises a monitoring host, a communication master station and the wireless sensor network, wherein the wireless sensor network communicates with the monitoring host through the communication master station, is a ZigBee wireless self-organized network and comprises a wireless sensorand a wireless gateway; and the wireless sensor is used for acquiring coal mine safety data and wirelessly transmitting the coal mine safety data and comprises a wireless carbon monoxide sensor, a wireless wind pressure sensor and a wireless temperature sensor. Therefore, according to the coal mine down-hole fire monitoring system based on the wireless sensor network provided by the embodiment ofthe invention, coal mine down-hole fire conditions can be timely and accurately monitored, the energy consumption of a wireless sensor network node can be effectively controlled, and the service lifeof the wireless sensor network can be prolonged.

Owner:CCTEG CHINA COAL RES INST

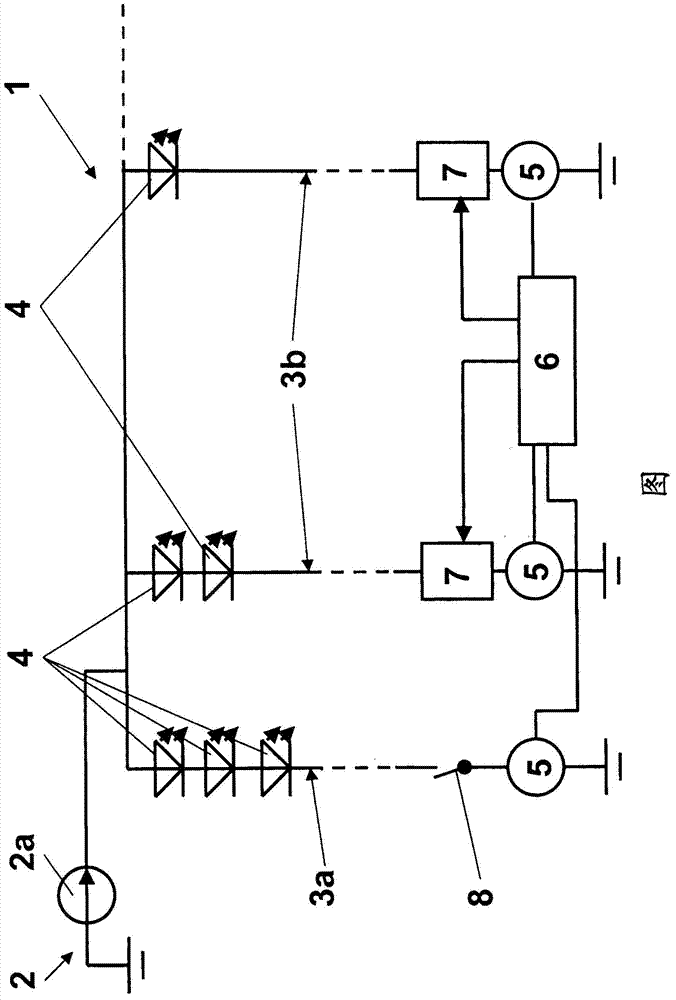

Method for supplying current to an LED array and circuit arrangement for carrying out the method

ActiveCN102771185ALow costStable costElectrical apparatusElectroluminescent light sourcesControl electronicsCurrent source

The invention relates to a method for supplying current to an LED array, which comprises at least two LED branches connected in parallel, in each of which at least one LED is arranged. The LED array is supplied with a predetermined current from a current source connected in series, wherein currents in the LED branches are measured, wherein the measured currents are compared in control electronics, and wherein the currents are controlled in some of the LED branches in such a way that the currents in the LED branches have a defined relationship with each other. The method should be improved in such a way that the method can be performed inexpensively and using simple means. This is achieved in that one of the LED branches is selected as a master, the current of which is used as a target specification for the other LED branches. The invention further relates to a circuit arrangement for carrying out the method according to the invention and to a lighting unit having such a circuit arrangement.

Owner:海拉有限双合股份公司

Alkaline fuel battery with hydrogen storage alloy as electric catalyst

The electrocatalyst of anode of the invented battery is alloy with hydrogen stored and without containing noble metal. The electrocatalyst of cathode of the invented battery is ABO3 type of peroviskite structure without containing noble metal and metal oxide of AB2O4 type of spinel structure. The said hydrogen stored alloy is MmNi3.3sCO0.75Mn0.4Al0.3, Mn is mixed rare earth riching in lanthanum. The metal oxide is La1-xCaxMO3, M=Co, Mn or Fe. The new type battery possesses the features of low cost, stable performances applicable to electric devices and electric vehicle etc.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com