Self-assembling carbon nitride-TiO2/hollow structure biomass charcoal degradation ammonia nitrogen composite and preparation method thereof

A biochar and ammonia nitrogen degradation technology, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve the problems of high management input and cost, harsh treatment conditions, etc., and achieve low cost and good experimental conditions Simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

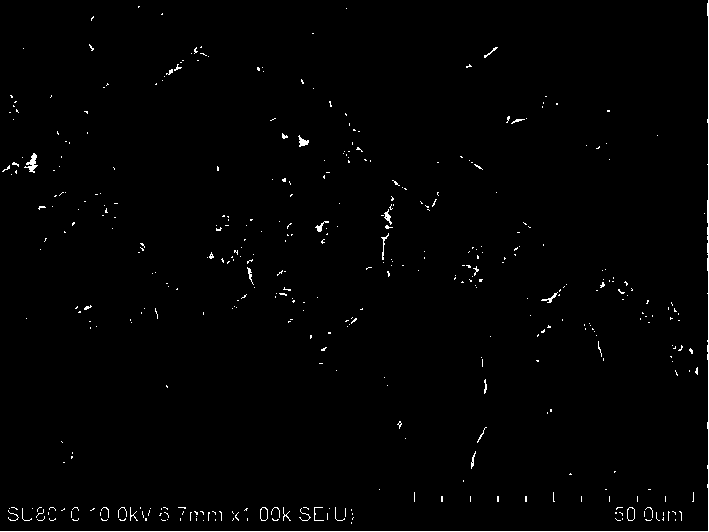

Image

Examples

Embodiment 1

[0029] a) Cut the cannabis into small pieces (1.5mm~2mm) with a pulverizer, wash it with ethanol, dry it in a 50°C oven for 6 hours, take out the sample and place it in a tube furnace, and heat it up to 450°C under nitrogen protection, Obtain biomass charcoal for 2 hours;

[0030] b) Soak 80 mg of biomass charcoal in 60 mL of glacial acetic acid, stir magnetically for 10 min to obtain a uniform suspension, 4 mL of sodium dodecylbenzene sulfonate and 4 mL of dimethyl sulfoxide are added to the suspension to fully dissolve Slowly drop 4 mL of titanium isopropoxide into the suspension and stir magnetically for 30 min to obtain a uniform suspension;

[0031] c) Transfer the homogeneous suspension to a suitable size reactor, hydrothermally react at 120 °C for 11 h, filter with suction, wash with ethanol for three times, and then dry it in an oven at 75 °C for 6 h to obtain TiO 2 / HSBC;

[0032] d) According to the mass ratio of melamine:cyanuric acid is 1:1.02, they are respectiv...

Embodiment 2

[0036] a) Cut the cannabis into small pieces (1.5mm~2mm) with a pulverizer, wash it with ethanol, dry it in a 50°C oven for 6 hours, take out the sample and place it in a tube furnace, and heat it up to 500°C under nitrogen protection, Obtain biomass charcoal for 2 hours;

[0037] b) Soak 80 mg of biomass charcoal in 60 mL of glacial acetic acid, stir magnetically for 10 min to obtain a uniform suspension, 4 mL of sodium dodecylbenzene sulfonate and 4 mL of dimethyl sulfoxide are added to the suspension to fully dissolve Slowly drop 4 mL of titanium isopropoxide into the suspension and stir magnetically for 30 min to obtain a uniform suspension;

[0038] c) Transfer the homogeneous suspension to a suitable size reactor, hydrothermally react at 120 °C for 11 h, filter with suction, wash with ethanol for three times, and then dry it in an oven at 75 °C for 6 h to obtain TiO 2 / HSBC;

[0039] d) Dissolve equal volumes in dimethyl sulfoxide solution according to the mass ratio o...

Embodiment 3

[0043] a) Cut the cannabis into small pieces (1.5mm~2mm) with a pulverizer, wash it with ethanol, dry it in a 50°C oven for 6 hours, take out the sample and place it in a tube furnace, and heat it up to 500°C under nitrogen protection, The biomass charcoal was obtained for 3 hours;

[0044] b) Soak 80 mg biomass charcoal in 60 mL glacial acetic acid, stir magnetically for 10 min to obtain a uniform suspension, 4 mL N,N,N',N'-tetramethyldiamine and 4 mL dimethyl sulfoxide are added to the suspension After fully dissolving in the liquid, slowly drop 4 mL of titanium isopropoxide into the suspension, and stir magnetically for 30 minutes to obtain a uniform suspension;

[0045] c) Transfer the homogeneous suspension to a suitable size reactor, conduct hydrothermal reaction at 120 °C for 12 h, filter with suction, wash with ethanol for three times, and then dry it in an oven at 75 °C for 6 h to obtain TiO 2 / HSBC;

[0046] d) Dissolve in an equal volume of dimethyl sulfoxide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com