Patents

Literature

183results about How to "Experimental conditions are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shale compressibility comprehensive evaluation method based on uniaxial strength experiment

InactiveCN104777035AThe experimental process is simple and easyLow equipment requirementsMaterial strength using tensile/compressive forcesMass distributionElastic modulus

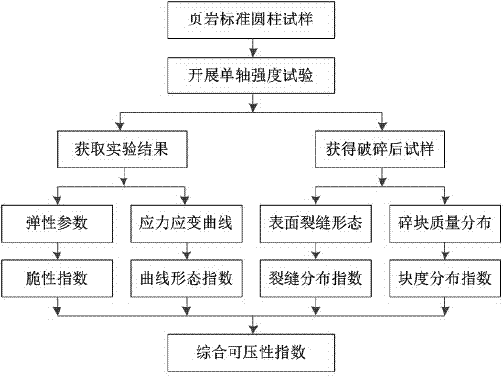

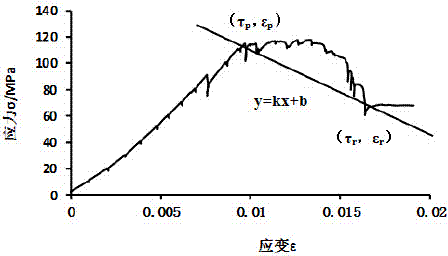

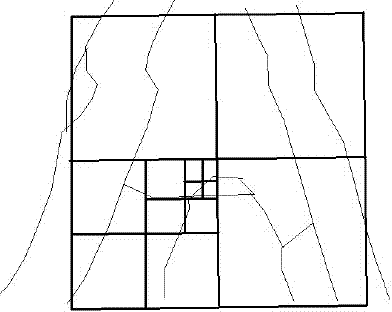

The invention provides a shale compressibility comprehensive evaluation method based on uniaxial strength experiment. The method comprises the steps of (1) taking a shale core sample for executing uniaxial compressive strength test, testing an elasticity parameter, and drawing a stress-strain curve diagram; (2) calculating normalized elasticity modulus and normalized poisson ratio to obtain a brittleness index; (3) obtaining key points on the stress-strain curve, and calculating the shape index of the stress-strain curve; (4) obtaining fracture distribution diagram of the side face of the fixed sample, and calculating a fracture distribution index through box-counting dimension method; (5) measuring spallation fragment mass distribution at different scales through a screen and a balance so as to obtain a block distribution index; and (6) calculating arithmetic mean value of the obtained brittleness index, shape index of the stress-strain curve, fracture distribution index and block distribution index of fragments to get the comprehensive compressibility index. The method provided by the invention is used for evaluating fracture net forming capability of the shale after being compressed, the experiment is simple and easy to carry out, and post treatment is visual and simple, so that the method is suitable for indoor evaluation and oilfield in-site application.

Owner:SOUTHWEST PETROLEUM UNIV

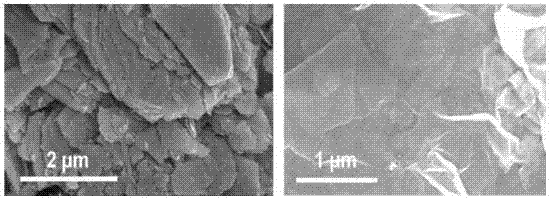

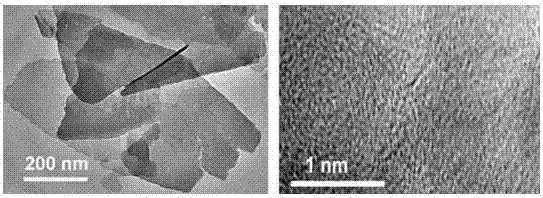

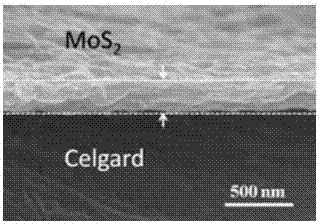

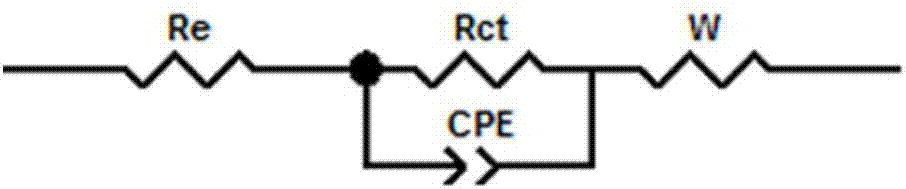

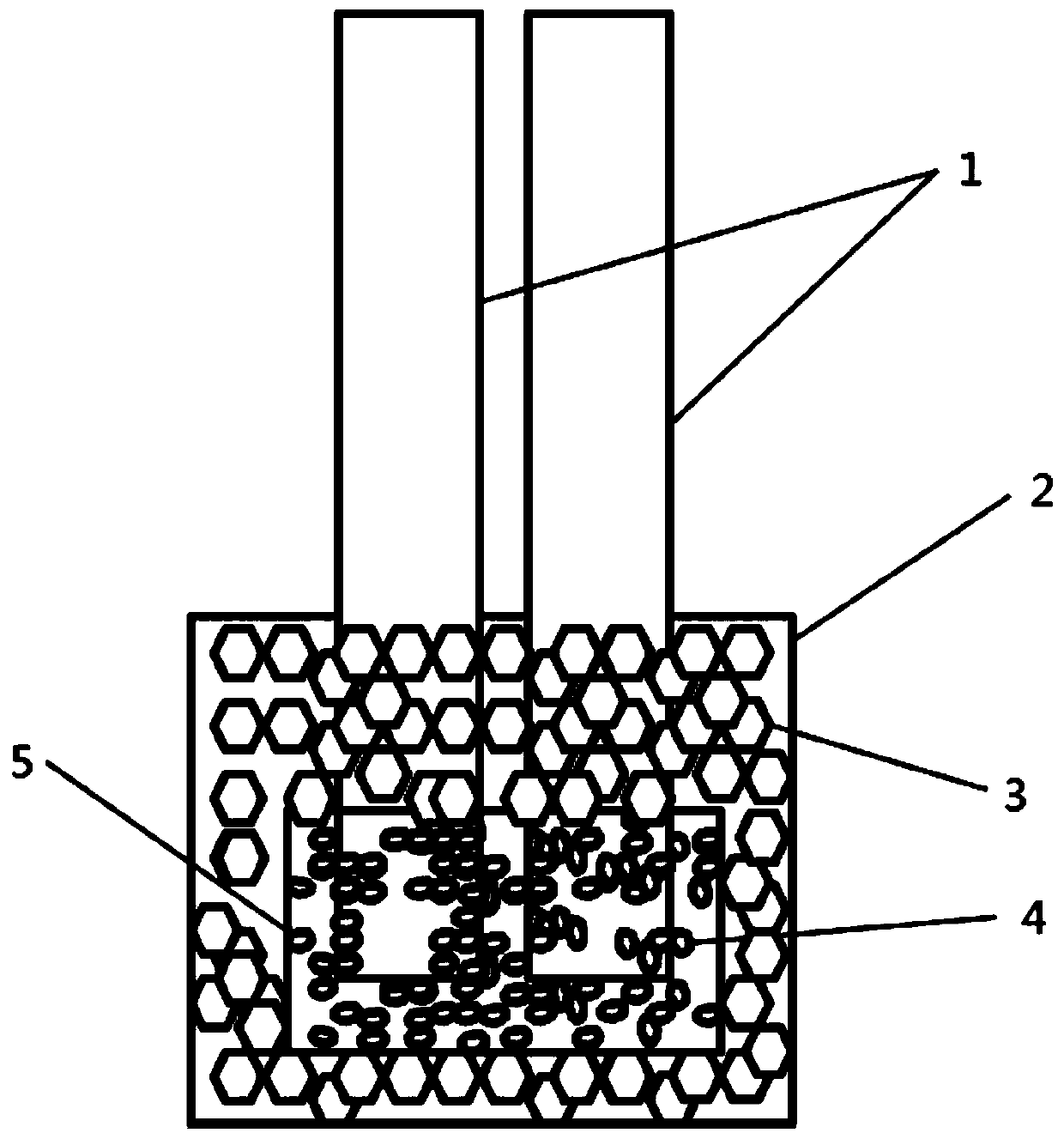

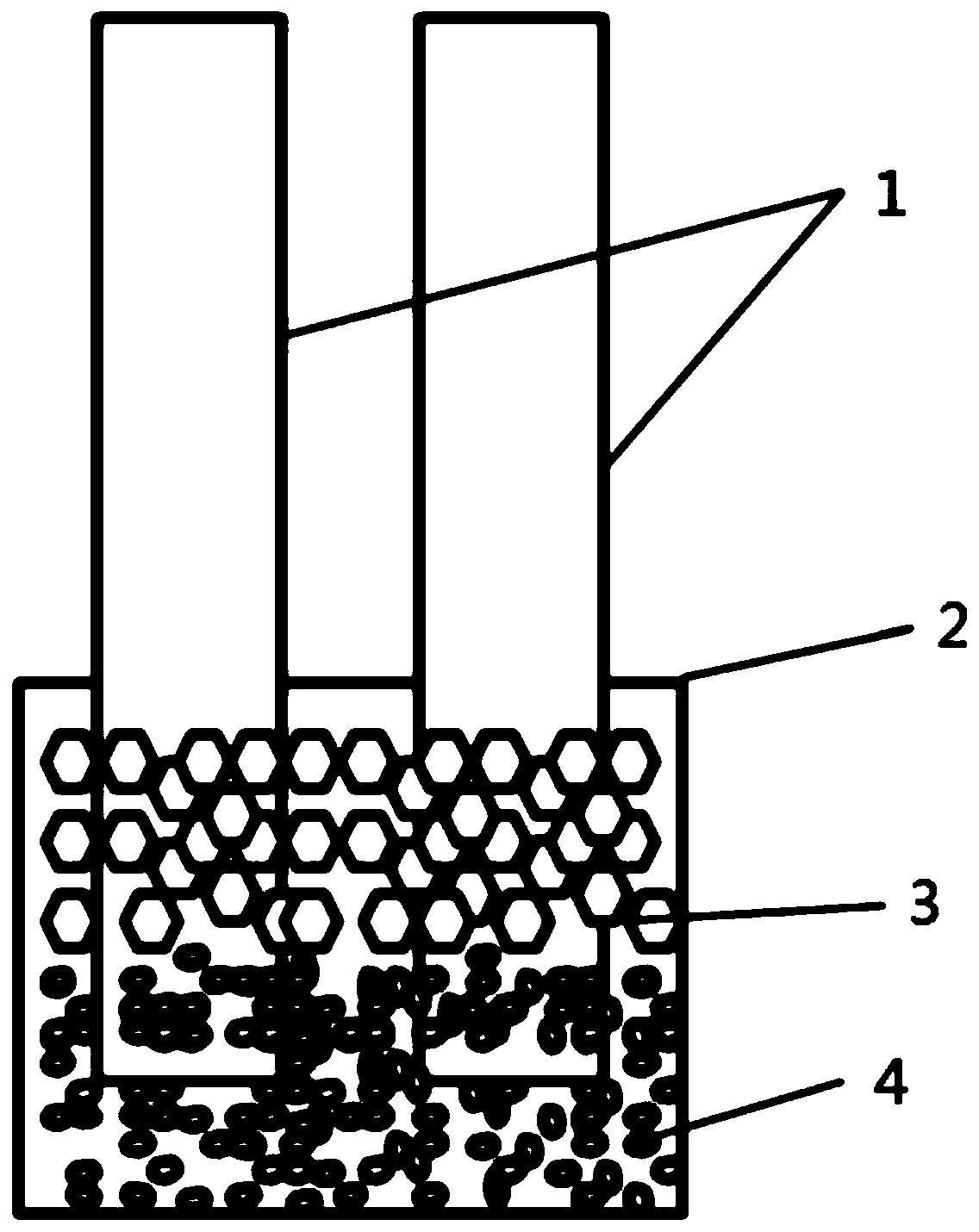

Molybdenum disulfide diaphragm of lithium-sulfur battery and preparation method therefor

InactiveCN107068944AImprove cycle lifeDoes not constitute pollutionLi-accumulatorsCell component detailsFiltrationSpectroscopy

The invention discloses a molybdenum disulfide diaphragm of a lithium-sulfur battery and a preparation method therefor, belonging to the field of lithium-sulfur batteries. According to the molybdenum disulfide diaphragm of the lithium-sulfur battery, the molybdenum disulfide diaphragm has high lithium conductivity, and is capable of inhibiting the migration of polysulfides between a positive electrode and a negative electrode so as to improve a cycle life of the lithium-sulfur battery. In addition, the high-temperature resistance of molybdenum disulfide is used to improve the overall temperature resistance of the diaphragm; a vacuum filtration method is used to deposit a molybdenum disulfide nanosheet on the surface layer of the lithium-sulfur battery diaphragm; and a relative position of pore size of a funnel on the surface of the molybdenum disulfide diaphragm is relatively small in thickness under the vacuum filtration condition, so that good air permeability can be achieved, and battery capacity is not affected. The MoS2 / Celgard prepared is applied to the lithium-sulfur battery; an electrochemical impedance spectroscopy result shows that the lithium ion conductivity of the MoS2 / Celgard diaphragm is about 2.0*10<-1> mS.cm<-1>, thereby substantially prolonging the cycle life of the lithium-sulfur battery. The whole preparation method is short in process flows, the conditions are simple, the cost is low, and no pollution is caused to the environment, so that a requirement of cleaner production can be achieved.

Owner:NORTHWEST NORMAL UNIVERSITY

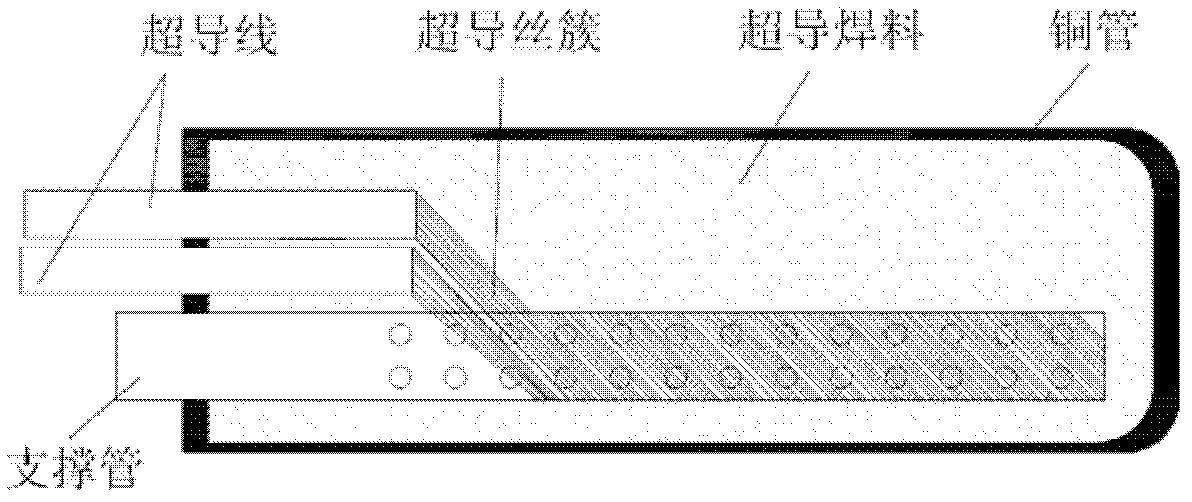

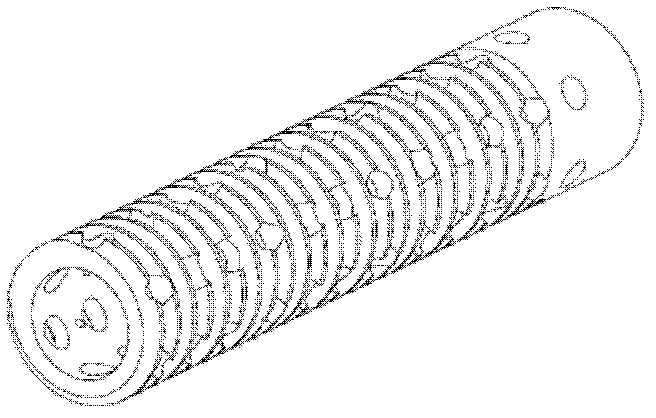

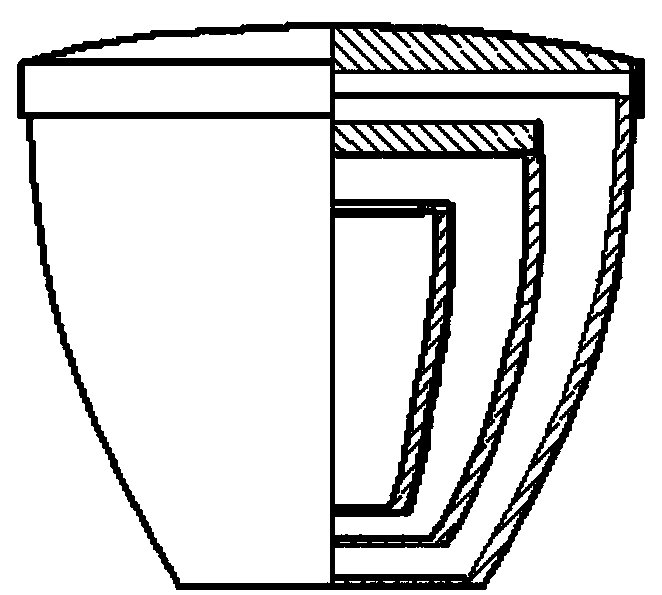

Superconducting wire joint

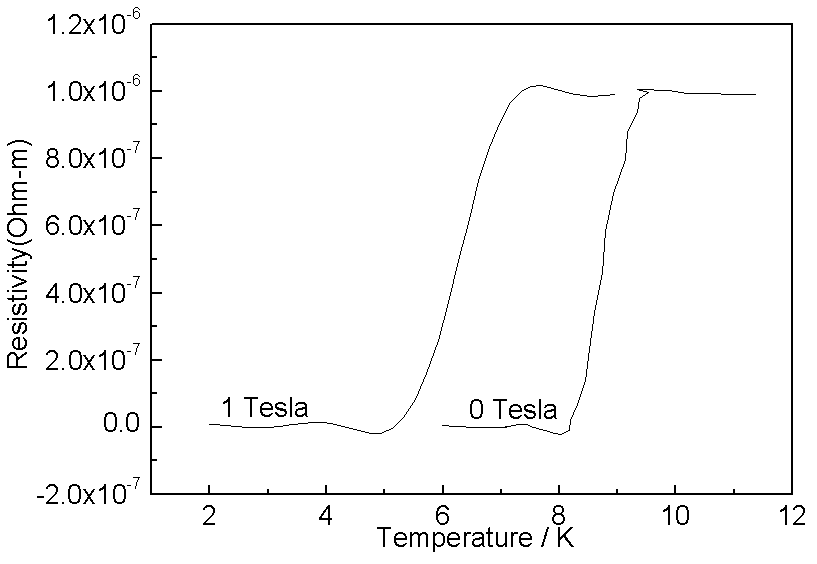

ActiveCN102593621ALower resistanceRealize superconducting direct connectionLine/current collector detailsSuperconductors/hyperconductorsEngineeringAlloy

The invention provides a superconducting wire joint which comprises a support tube, a superconductive filament cluster of a superconducting wire to be connected, a copper pipe and superconductive solder. An external cylindrical surface of the support tube is provided with a spiral groove, and both the external cylindrical surface and the groove are provided with through holes along a radial direction. After the superconductive filament cluster of the superconducting wire to be connected is twisted round the spiral groove of the support tube, the support tube which is twisted with the superconductive filament cluster is integrally inserted into the copper pipe with a segment of the superconducting wire, and other space in the copper pipe is filled with the superconductive solder. Material purity of the copper pipe is 99.999%, and in an annealing state, the support tube is NbTi superconductive alloy material. Components of the superconductive solder are Bi, Pb and Sn with the following mass ratio by weight: 53%-55% of Bi, 36% of Pb and allowance of Sn. The superconducting wire joint prepared by the invention has the advantages of low resistivity, simple preparation process, small damage and threat to superconducting wire performance and suitability for project field practical operation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Nano gold/graphene oxide composite material and preparation method thereof

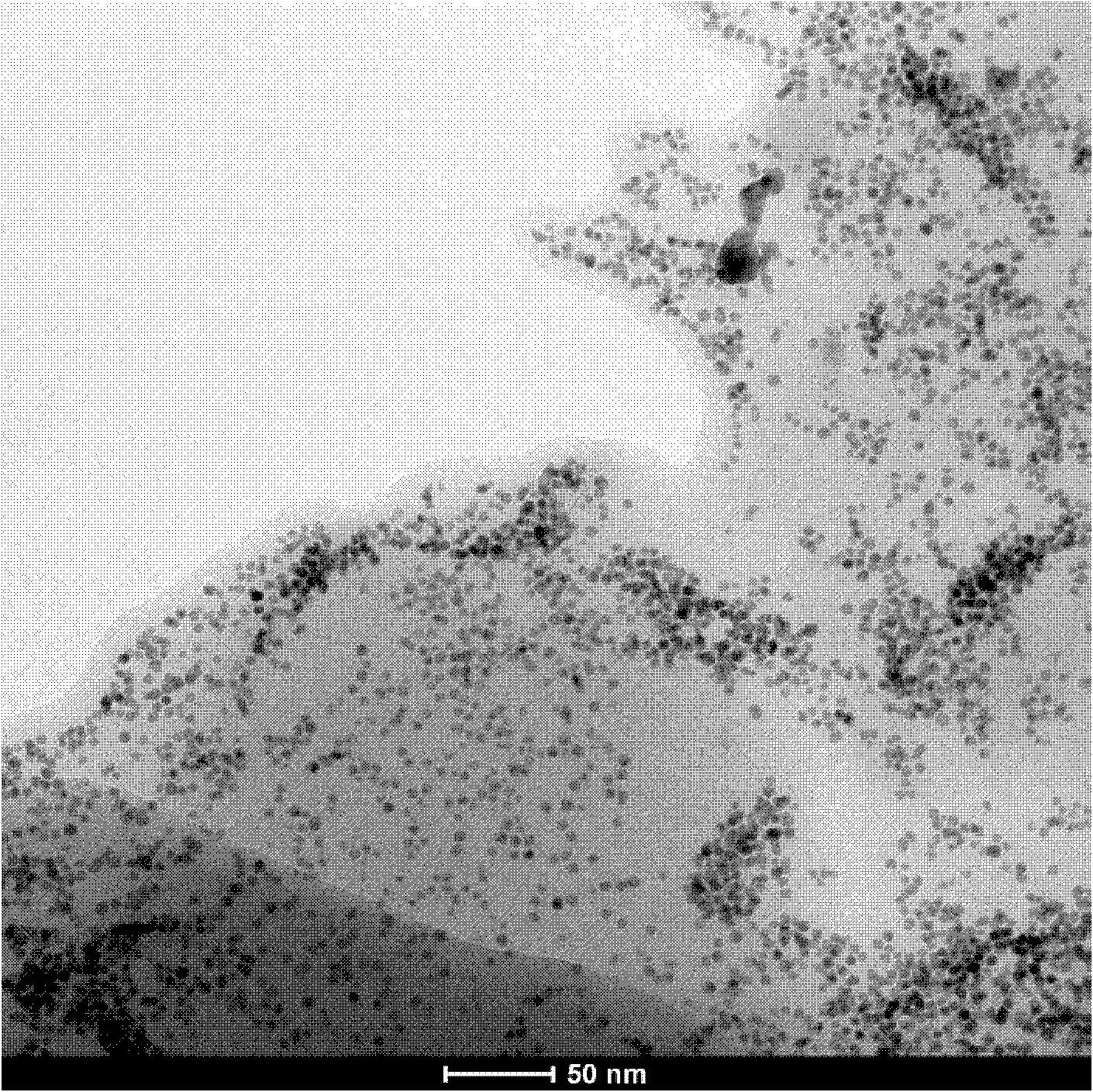

InactiveCN102211207APrompt formationImprove conductivityLiquid/solution decomposition chemical coatingGold particlesBiocompatibility Testing

The invention relates to a nano gold / graphene oxide composite material and a preparation method thereof, which are used for enhancing the conductivity of a material. The preparation method of the nano gold / graphene oxide composite material is as follows: based on graphene oxide dispersed in a water phase as a carrier, nano gold particles with even particle distribution are generated through in situ direct reduction of chloroauric acid on the surface of the carrier so as to obtain the nano gold / graphene oxide composite material; and preferably, sodium borohydride is added in a dispersion obtained by fully mixing the graphene oxide with HAuCl4 under the severe stirring condition so that HAuCl4 is reduced, so as to obtain the nano gold / graphene oxide composite material. According to the invention, experiment conditions are simple, an operation method is simple and easy, and a protective agent is not added in the experiment process; the vast majority of prepared nano gold particles are modified on the surface of graphene oxide (GO), the shape is regular, the state is stable, particle size is evenly distributed, and the conductivity and biocompatibility of GO can be enhanced by modifying the nano gold on the surface of GO.

Owner:SOUTHEAST UNIV

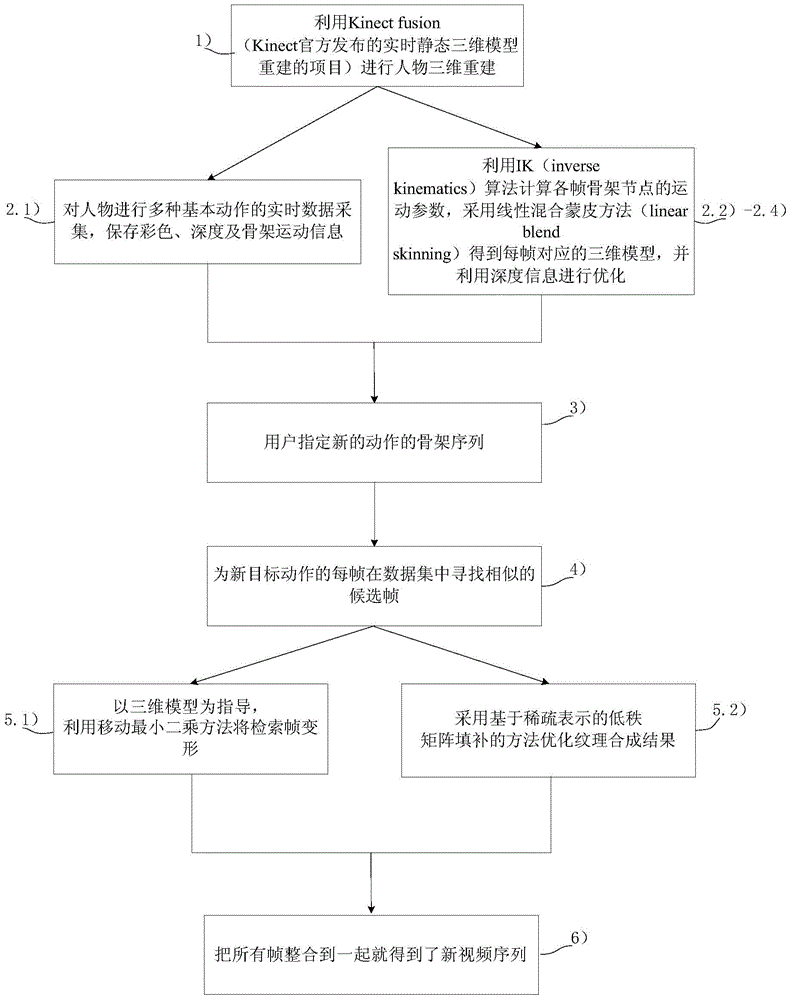

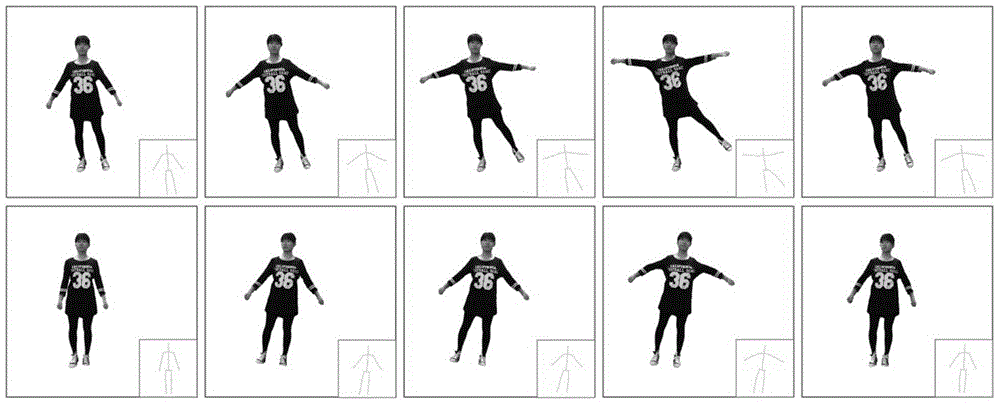

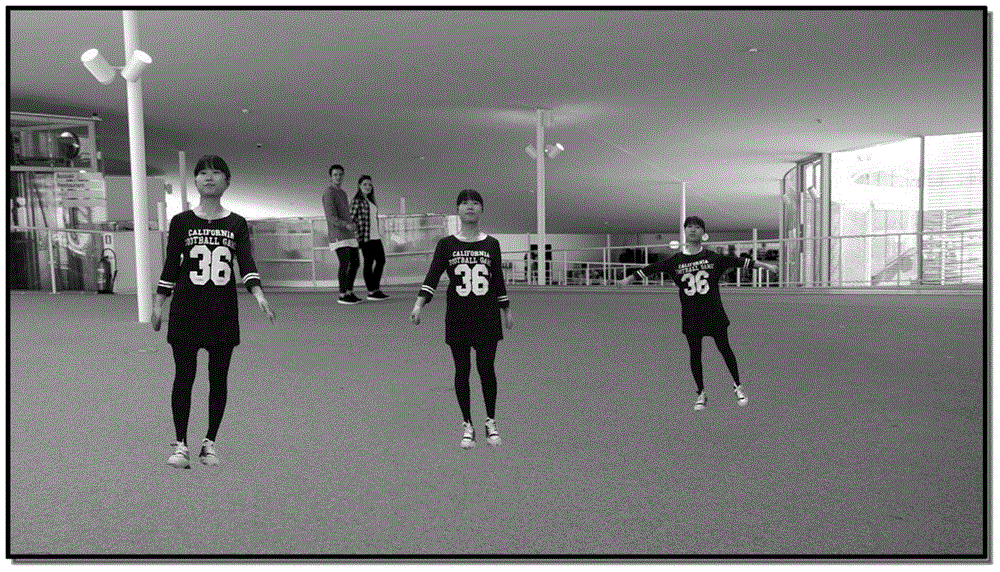

Realistic animation generation method based on Kinect

ActiveCN104915978AStrong sense of realityExperimental conditions are simpleAnimationData setSomatosensory system

The invention belongs to the field of computer vision and computer graphics, and provides a method which can ensure a newly-generated video sequence to be vivid and reliable and solve the problem of high requirements on an experimental device. According to the technical scheme adopted by the invention, the realistic animation generation method based on Kinect uses a single Kinect v2.0 to carry out static three dimensional model and color depth skeleton information acquisition on a person. A marker-free motion capture method is used, skeleton motion information of each frame and a three dimensional model after deformation are obtained. After a user designates a new action, on the basis of the built data collection, a video for the new action by the person is generated through the proposed sparse representation-based low rank matrix filling texture synthesis method. The method of the invention is mainly applied to video processing.

Owner:深圳市凌云视迅科技有限责任公司

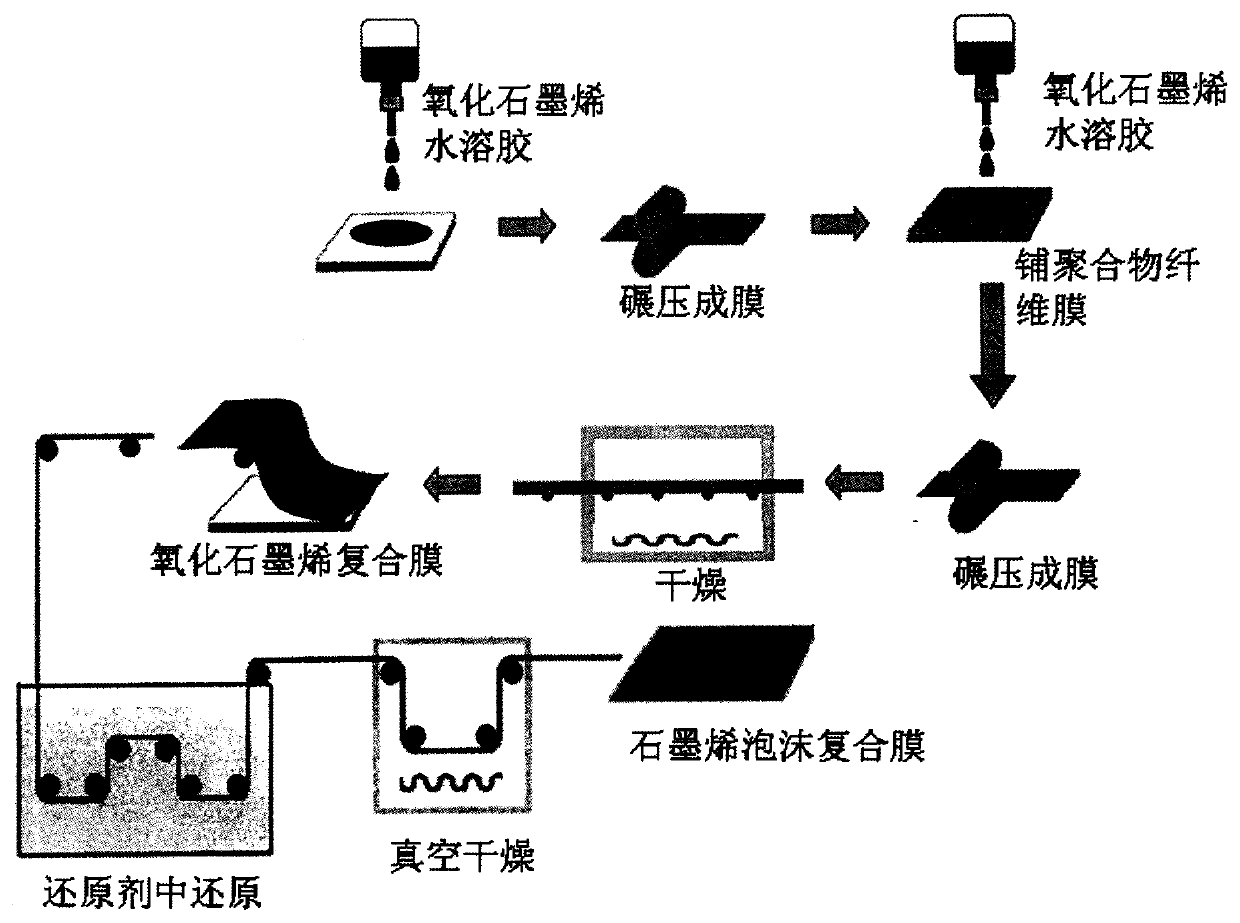

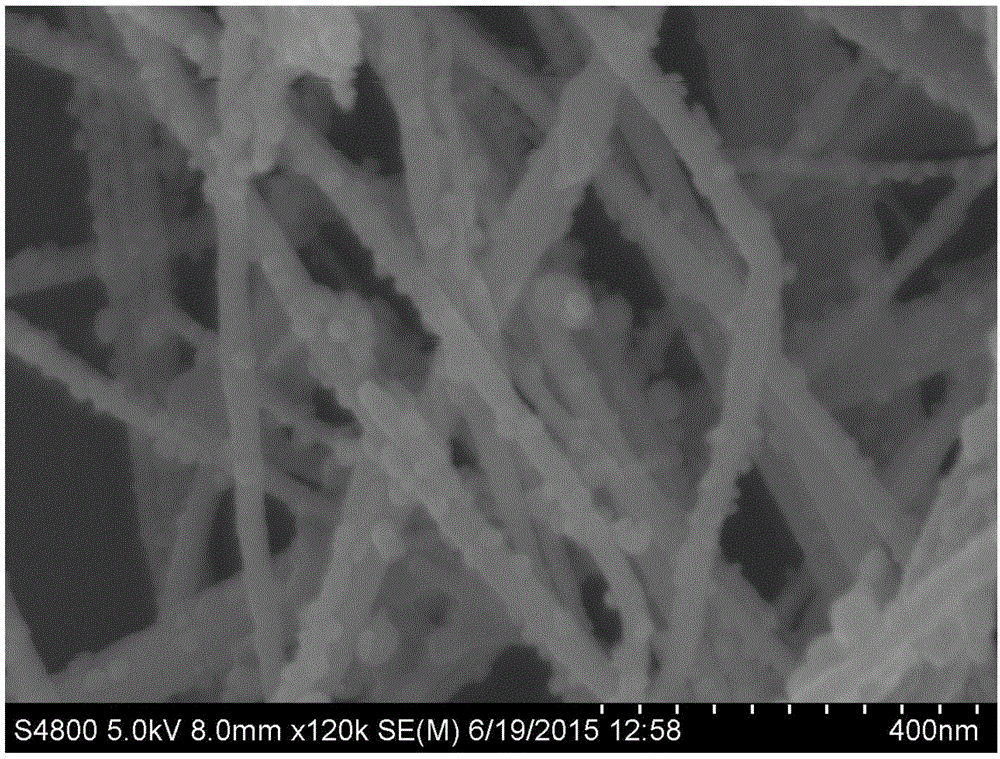

Method for quickly preparing large-area graphene foam/polymer fiber three-dimensional network composite foam film

InactiveCN103625085AHigh mechanical strengthImprove conductivitySynthetic resin layered productsGrapheneFiberPorosity

The invention relates to a method for quickly preparing a large-area graphene foam / polymer fiber three-dimensional network composite foam film. The method mainly comprises the processes of preparation of high-viscosity graphene oxide hydrosol, film formation by rolling, drying and reduction to finally obtain the large-area graphene foam / polymer fiber three-dimensional network composite foam film. The method has the technical effects that the graphene foam / polymer fiber three-dimensional network composite foam film which is controllable in thickness, large-area, high in mechanical strength, high in conductivity, light in weight and high in porosity and has certain elasticity is prepared. The composite film is similar to foam, is a self-supported flexible film, and can be bent and folded; the thickness of the composite film is 5 to 10 times that of a graphene oxide composite film prior to reduction; in the preparation process, expensive equipment and severe conditions are not needed; the composite film is easy to operate, low in cost, short in preparation period and simple in experiment condition, and industrial production can be realized.

Owner:XIANGTAN UNIV

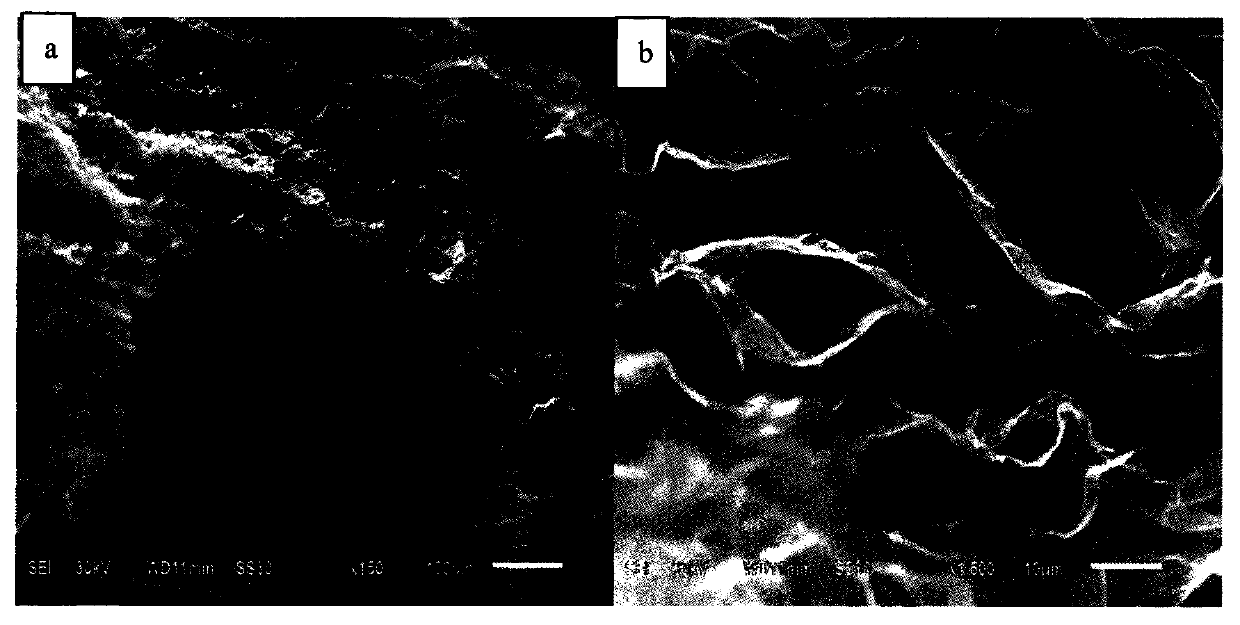

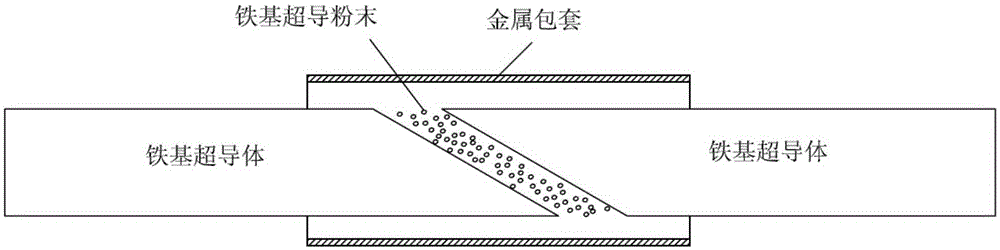

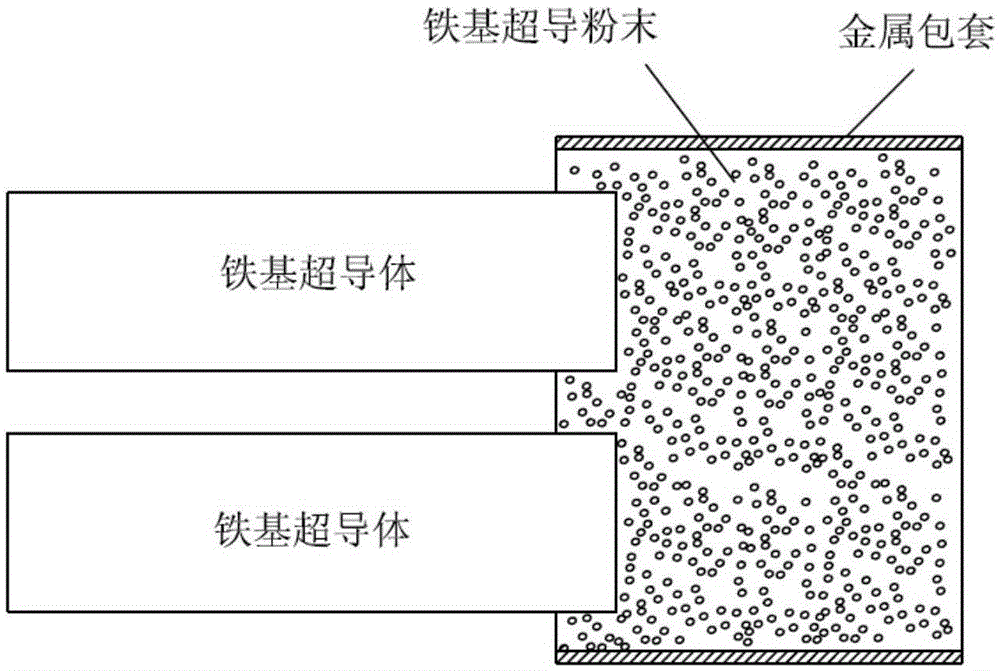

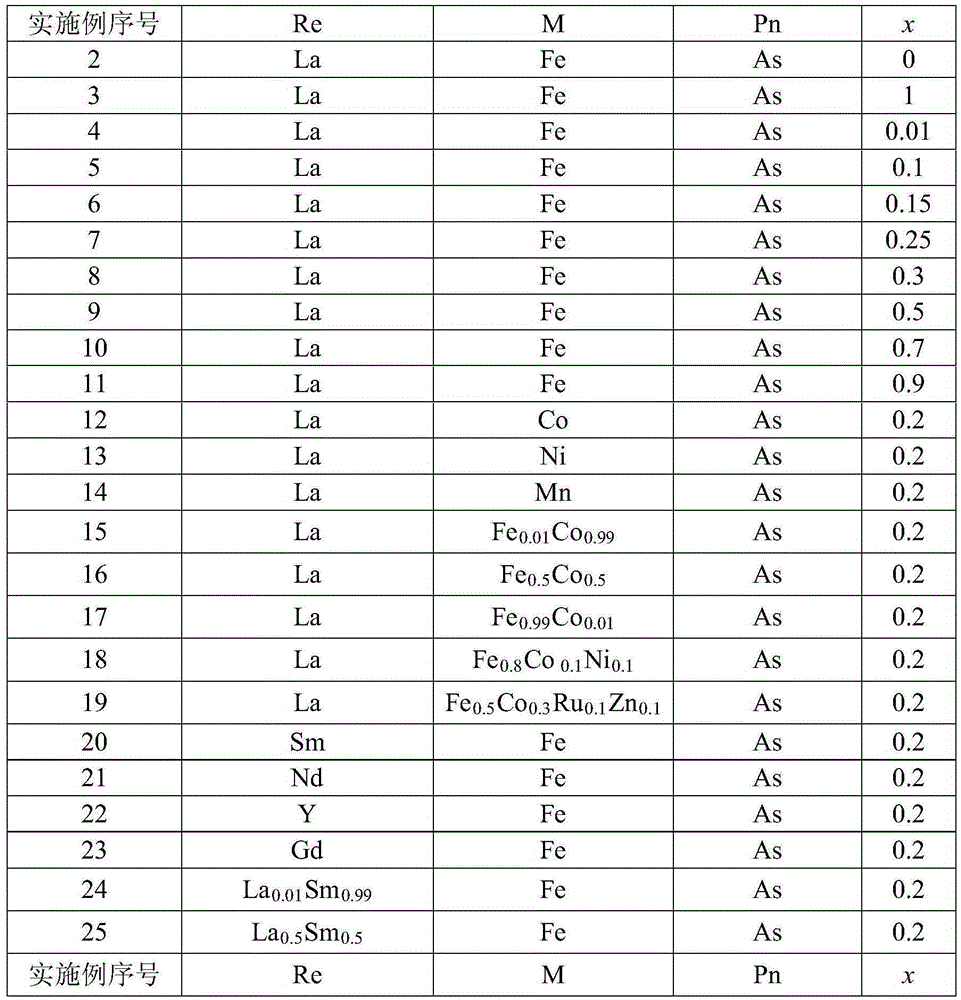

Iron-based compound superconducting joint and preparation method thereof

ActiveCN105355357AAvoid obstructionAvoid attenuationSuperconductors/hyperconductorsSuperconductor detailsHeat treatedMetal

Provided is an iron-based compound superconducting joint. The superconducting joint comprises connected iron-based superconductors, iron-based superconducting powder and a metal sheath. The position between tail ends of the connected iron-based superconductors is filled up with iron-based superconducting powder and wrapped up by a signal-layer or multi-layer metal sheath. The preparation method of the superconducting joint comprises following steps of: (1) peeling non-superconducting layers on surfaces of tail ends of the iron-based superconductors needed to be connected to expose superconducting cores; (2) filling iron-based superconducting powder between tail ends of processed tail ends of the iron-based superconductors and utilizing the multi-layer metal sheath to wrap up tail ends of the iron-based superconductors and the iron-based superconducting powder; (3) welding or not welding the metal sheath processed by the step (2); (4) applying pressure to shrink crease the cross section of the metal sheath prepared by the step (3); and (5) carrying out heat treatment on the metal sheath prepared by the step (4) during or after pressure is applied or not necessarily performing heat treatment.The invention is very suitable for making a superconducting joint in the engineering field.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

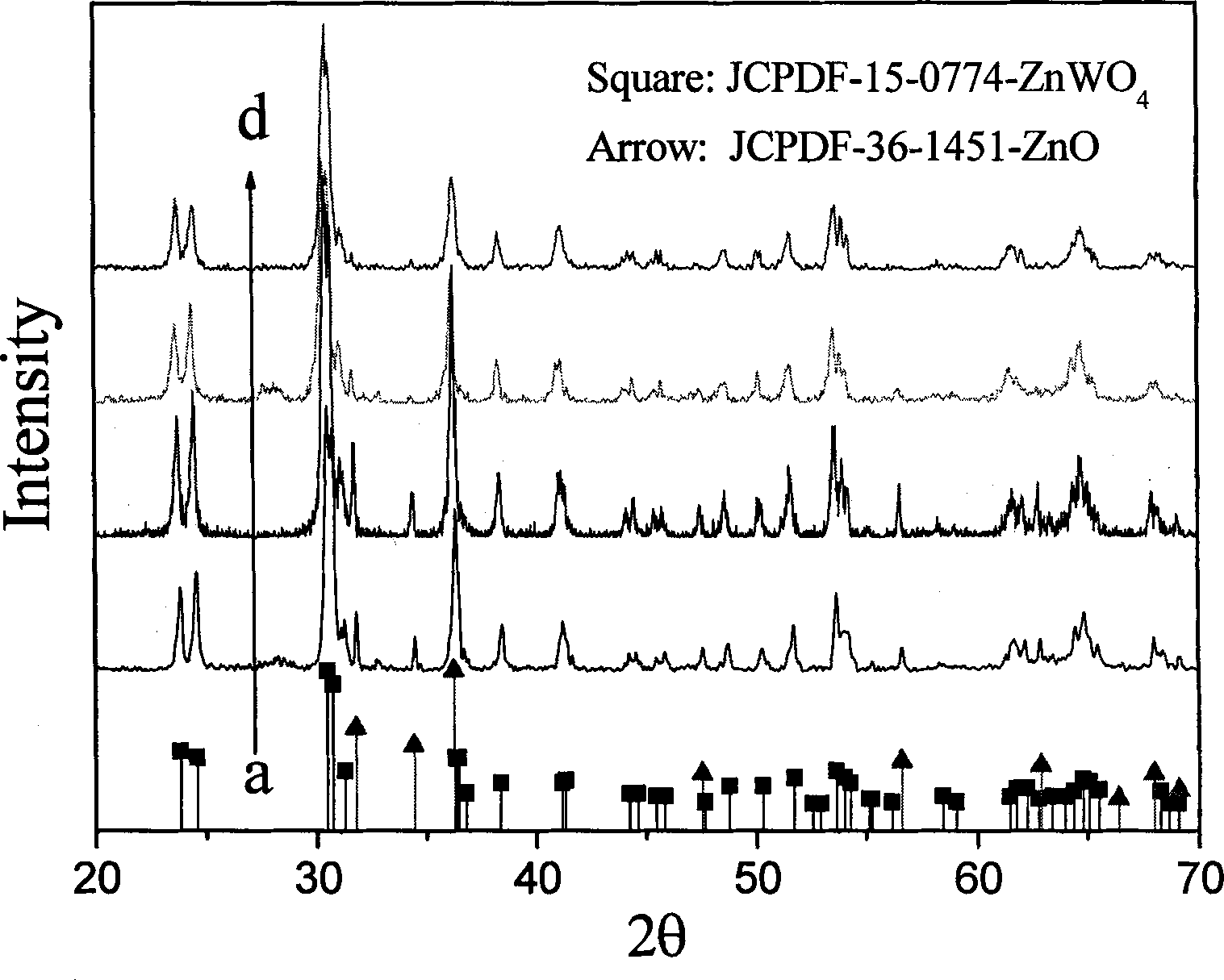

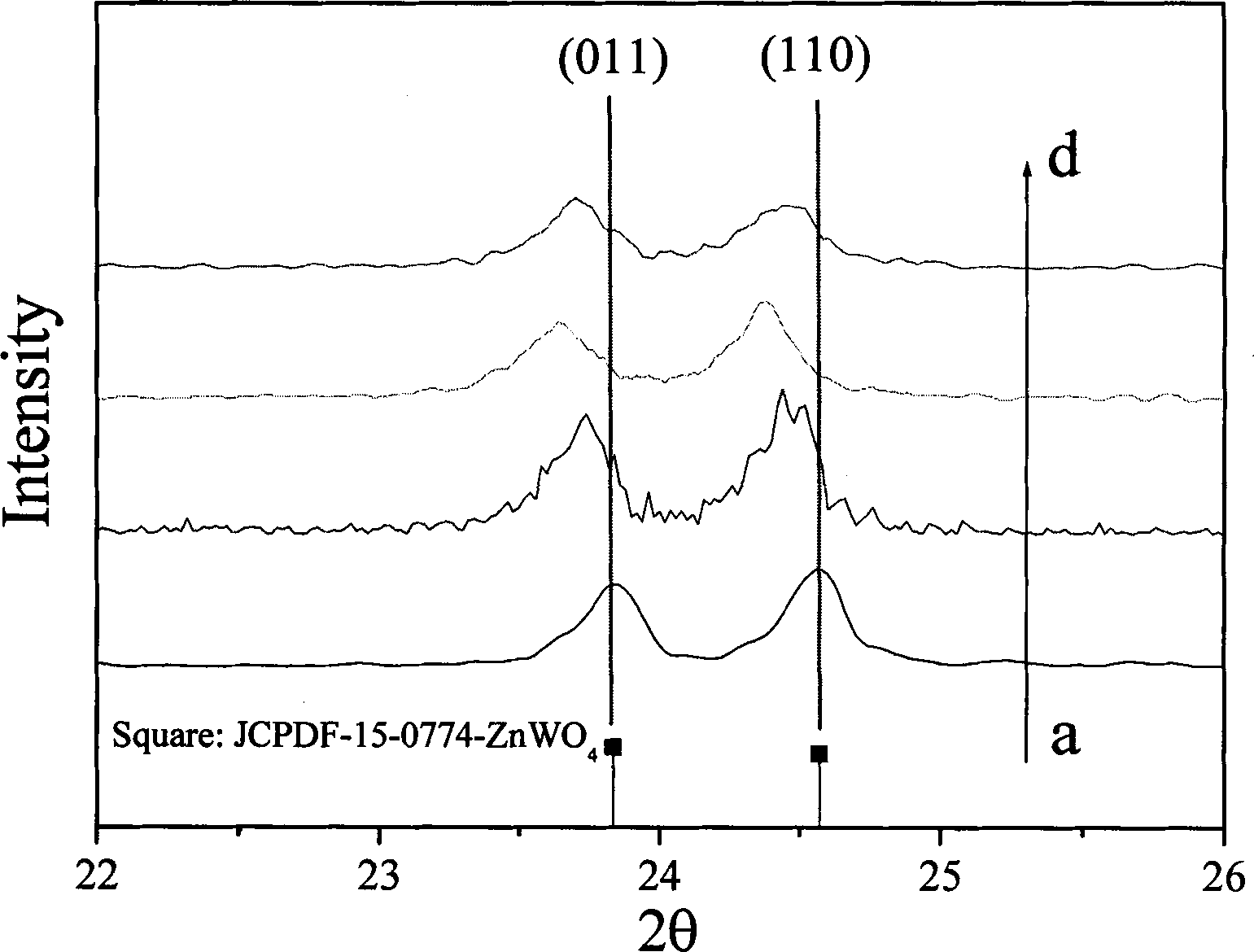

Hydrothermal method for preparing Bi-doped ZnWO4 photocatalyst

InactiveCN103846085AGuaranteed uniformityGuaranteed decentralizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc saltsEthylene glycol

The invention belongs to the technical field of photocatalyst and particularly relates to a hydrothermal method for preparing a Bi-doped ZnWO4 photocatalyst. The hydrothermal method comprises the following detail steps: adding equimolecular 1-10mmol of soluble tungstate and soluble zinc salt with deionized water and stirring; adjusting the pH value of a mixed solution to 8-12, adding 0.01-0.05% by mass of polyacrylamide and simultaneously performing magnetic stirring; preserving heat for 24-48 hours at the temperature of 150-180 DEG C for hydrothermal reaction; cooling, washing, and drying to obtain needle-shaped ZnWO4 powder; respectively dissolving bismuth nitrate pentahydrate and glucose in ethylene glycol and water to obtain two solutions, mixing the two solutions, adding a certain amount of needle-shaped ZnWO4 powder, preserving heat for 15-24 hours at the temperature of 120-150 DEG C for hydrothermal reaction; cooling, washing, and drying to obtain the Bi-doped ZnWO4 photocatalyst. Two steps of hydrothermal processes are adopted, polyacrylamide serving as a template is doped with Bi, the reaction operation and process are simple and easy to control, and the needle-shaped catalyst has good uniformity and high photocatalytic activity.

Owner:HUZHOU TEACHERS COLLEGE

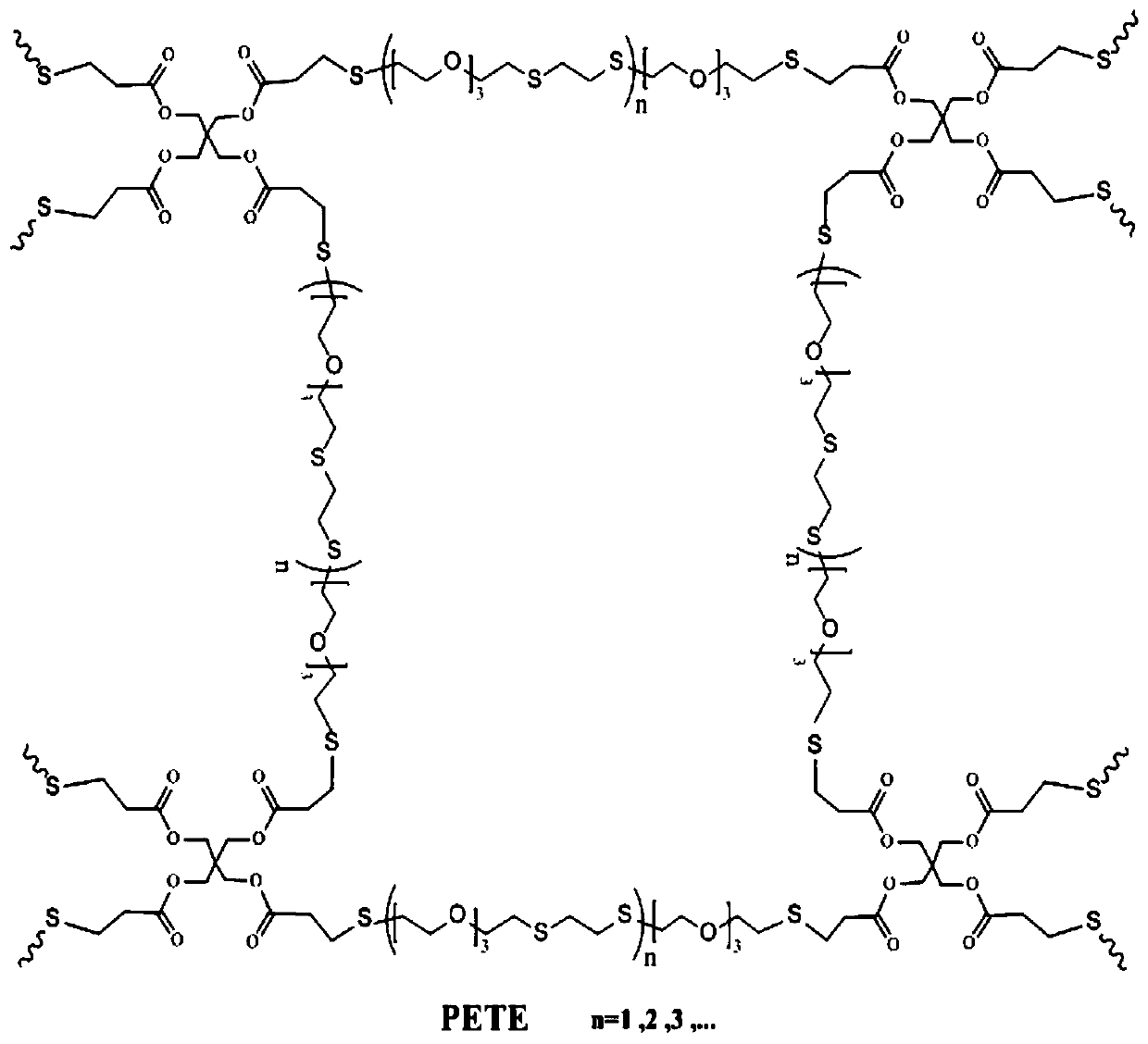

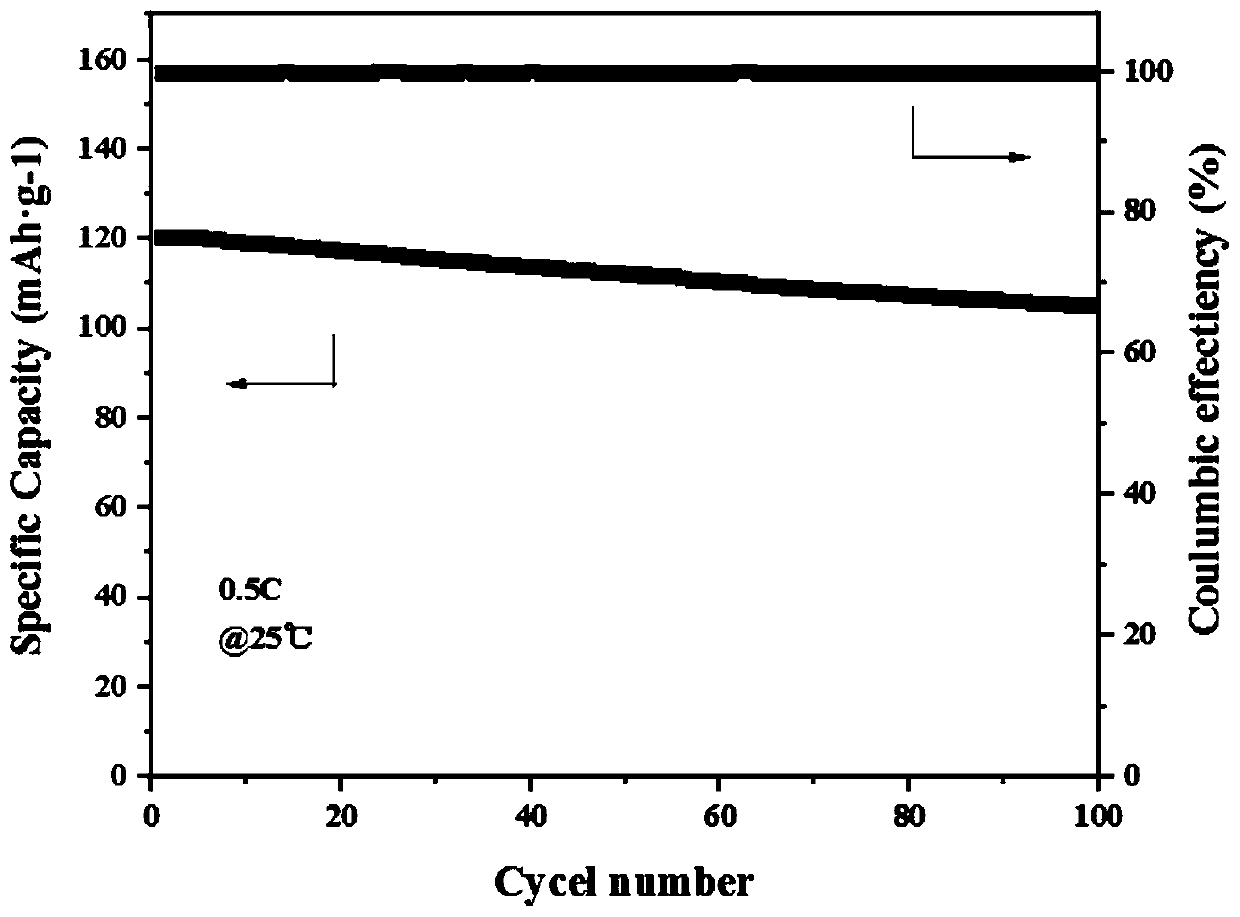

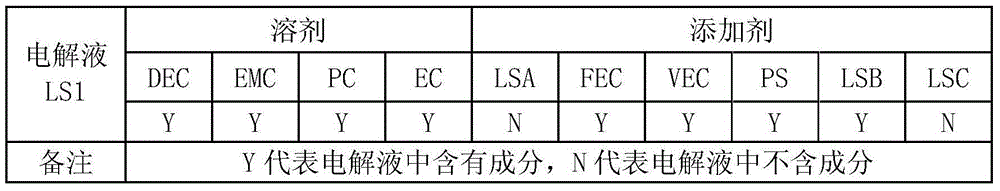

Polyether sulfur ether-based polymer electrolyte and preparation method thereof

ActiveCN110061288ALower glass transition temperatureConducive to conductionSolid electrolytesSecondary cellsChemistryPhotoinitiator

The invention discloses a polyether sulfur ether-based polymer electrolyte and a preparation method thereof. Bi-sulfydryl-containing 1, 2-dithioglycol, a diene-structure-containing diethylene glycol divinyl ether, and a tetra-sulfydryl-containing cross-linking agent tetra(3-mercaptopropionic acid) pentaerythritol are adopted, and a lithium salt, a photoinitiator and a plasticizer are added to perform an alkene-mercapto click chemistry reaction to prepare the polyether sulfur ether-based polymer electrolyte with the cross-linked network structure through a one-step method. The obtained polymerelectrolyte is high in mechanical property, high in ionic conductivity and stable in electrochemical window; and a lithium ion battery assembled by using the polymer electrolyte has the characteristics of being high in safety performance and stable in circulation.

Owner:SUN YAT SEN UNIV

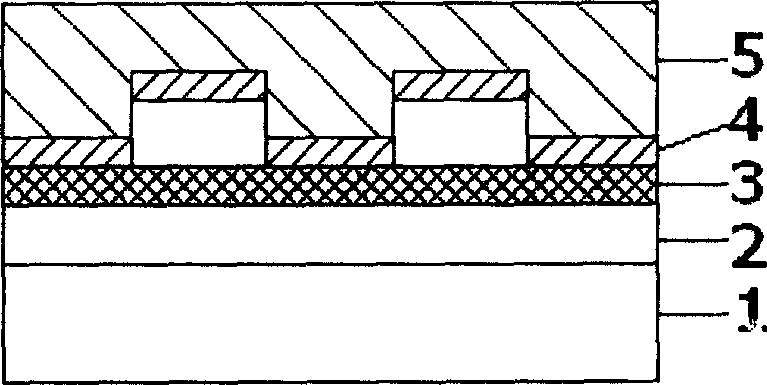

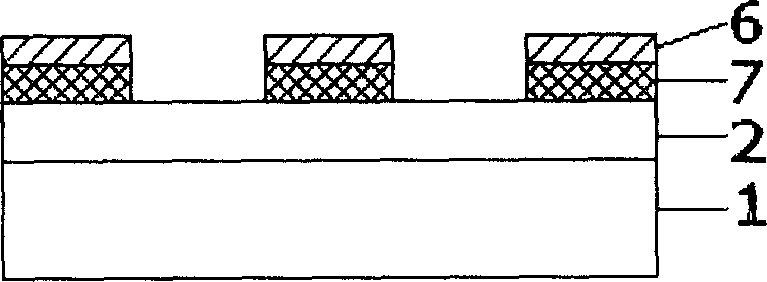

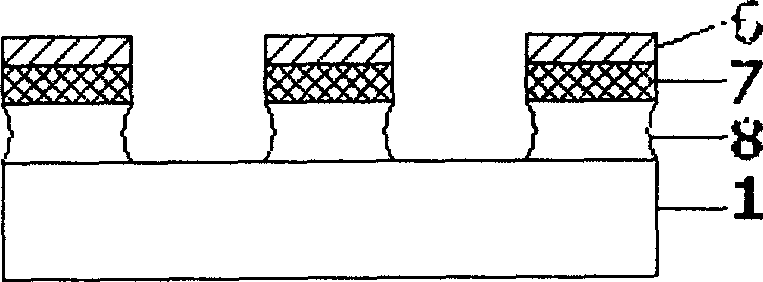

Photoetching patterning method with micro-transfer patterned graph as mask plate

InactiveCN1888978AExperimental conditions are simpleGuarantee processing qualityPhotomechanical apparatusEngineeringDesign methods

The invention is concerned with the photoetching design method that uses the micro-shift design as the covering-film board. The film structure consists of the metal film, the thermosplastic macromolecule film, the photoetching rubber film. The metal film design that is gotten by the method of the micro-shift design can be the following photoetching covering-film board, comparing with the traditional multi-layer structure photoetching design, omits once photoetching processing. The metal film design can ensure the peeling technics to get the transfer design with the matching size even the exposal time or the developing time appears windage, because the up-layer design metal film is not affect by the exposal and the developing process. The method can get the photoetching rubber sidewall structure that the edge is erect and sunken entad, therefore the photoetching design can use for the separator of the organic radiation layer and the pole layer that shows by the organic radiation matrix. The process precision is smaller than 1 micron that is higher than the design precision with the 10 micron negative photoetching rubber.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

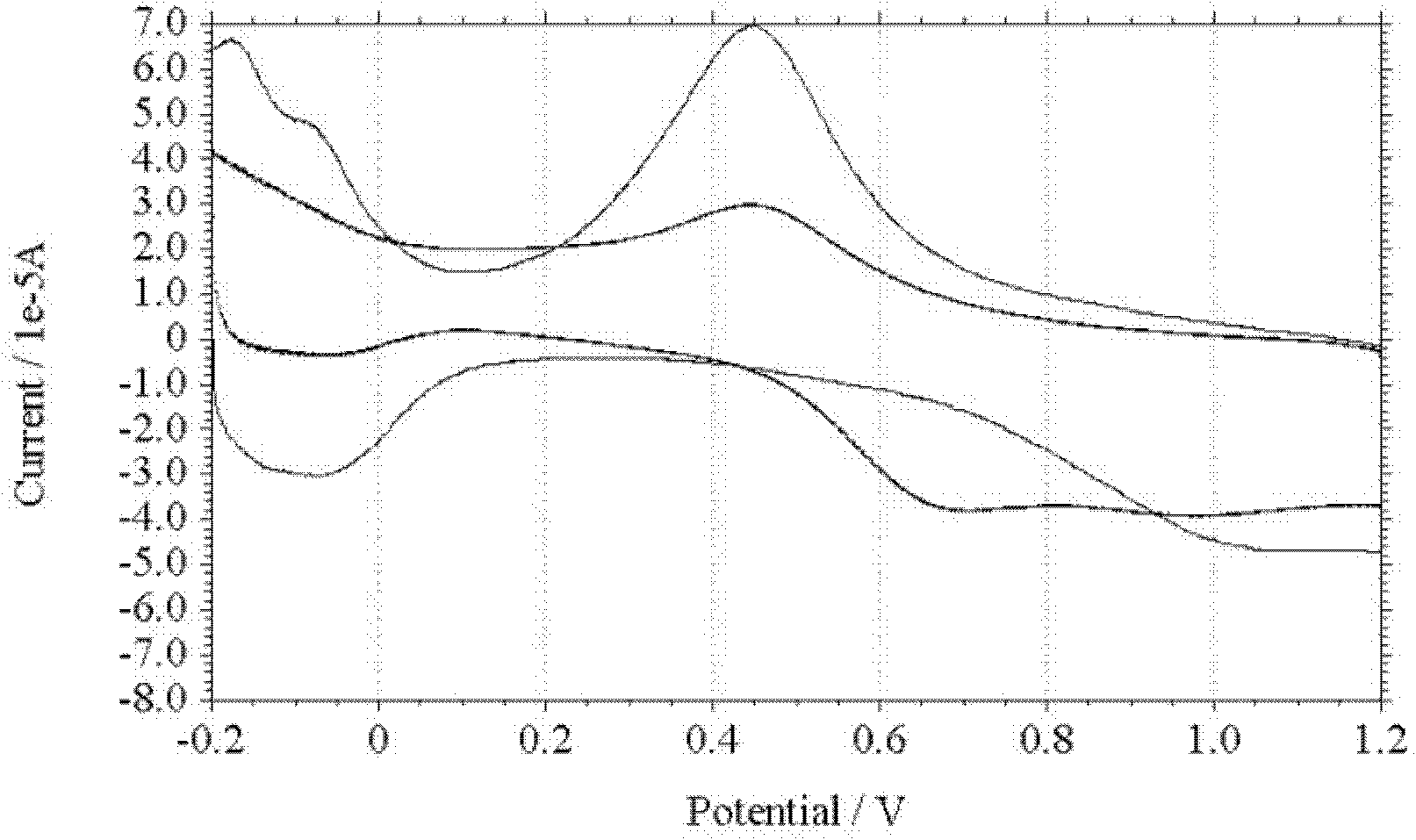

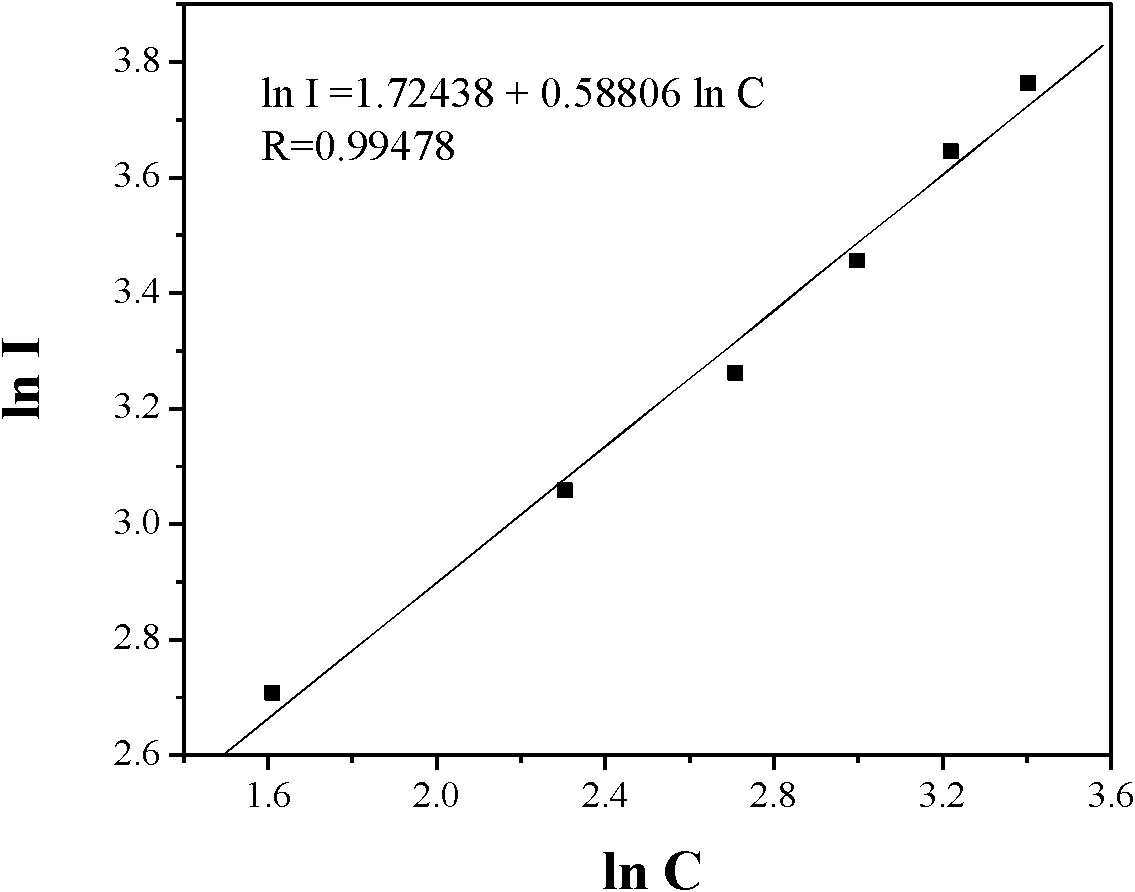

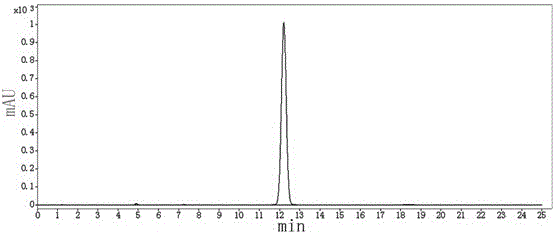

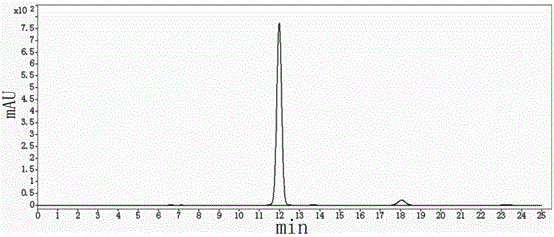

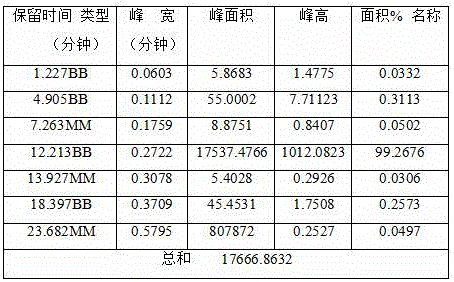

Method for determining concentration of phosphite by cyclic voltammetry

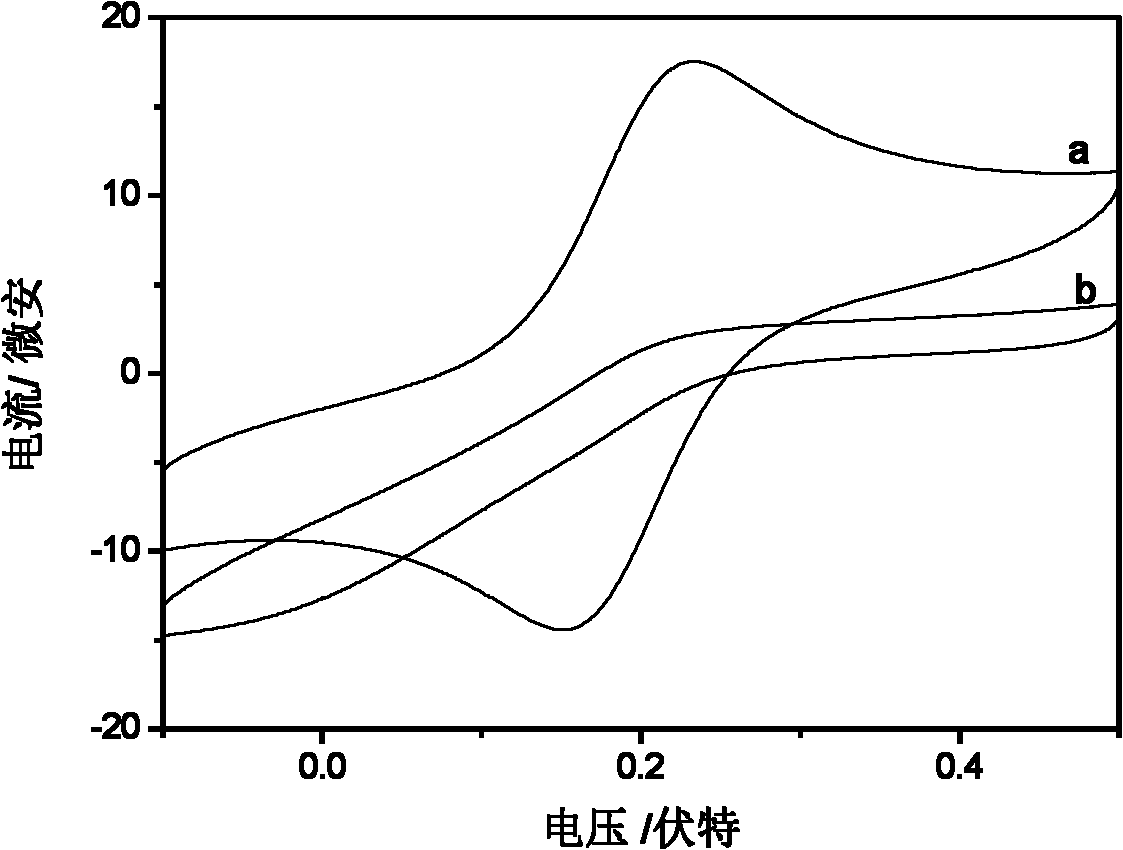

InactiveCN102141538AExperimental conditions are simpleFast experimental conditionsMaterial electrochemical variablesIon exchangePeak value

The invention discloses a method for determining the concentration of phosphite by cyclic voltammetry, which comprises the steps of: establishing a working curve by determining the quantitative proportional relation between the oxide peak current intensity of phosphite on a bare Pt electrode and the concentration of phosphite and fitting the working curve as a linear formula, and substituting theoxide peak value of a sample to be detected in the formula to obtain the concentration of phosphite. The method of the invention is accurate in detection results, has the advantages of being simple in experimental conditions, simple and convenient in operation and saving time compared with the traditional methods for determining the concentration of phosphite, such as an oxidation reduction titration method, a paper chromatography, a thin-layer chromatography and an ion exchange chromatography, and has tremendous popularization and application prospect in paint, electroplating and other fields.

Owner:SHANDONG UNIV

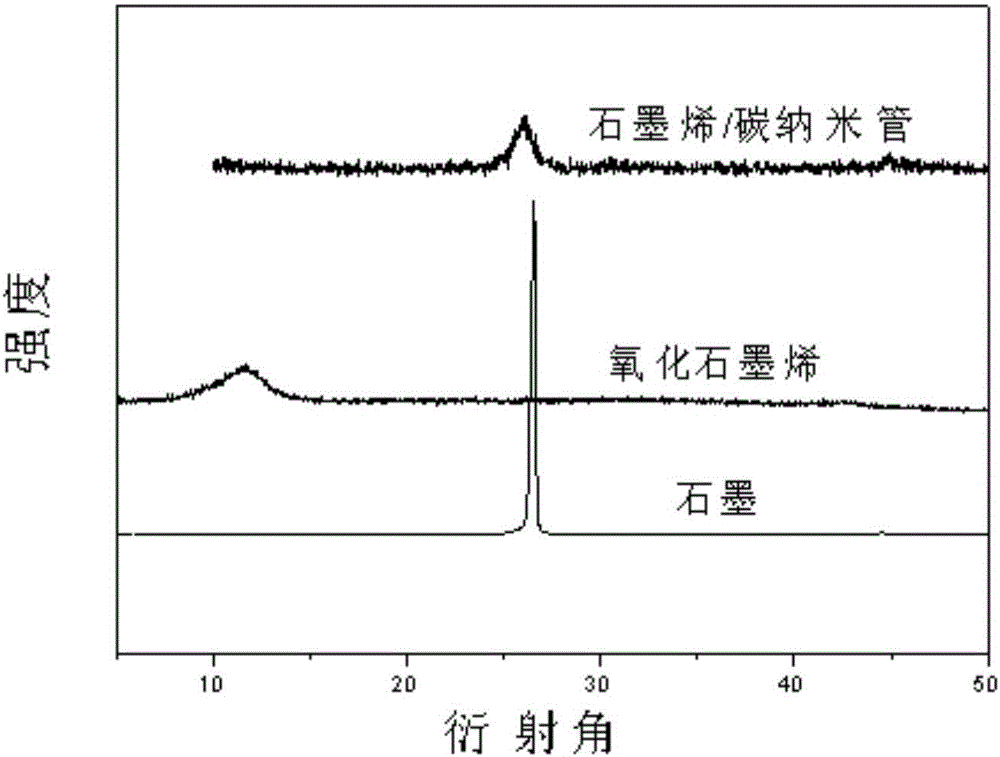

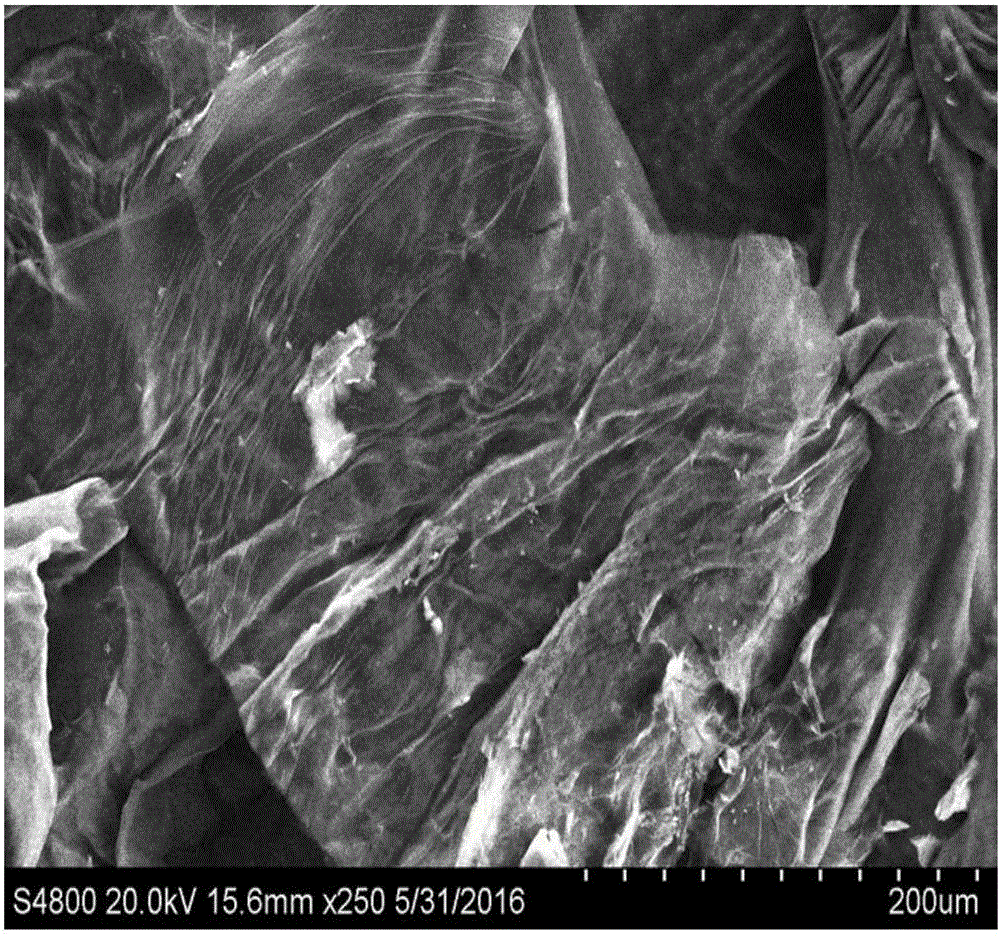

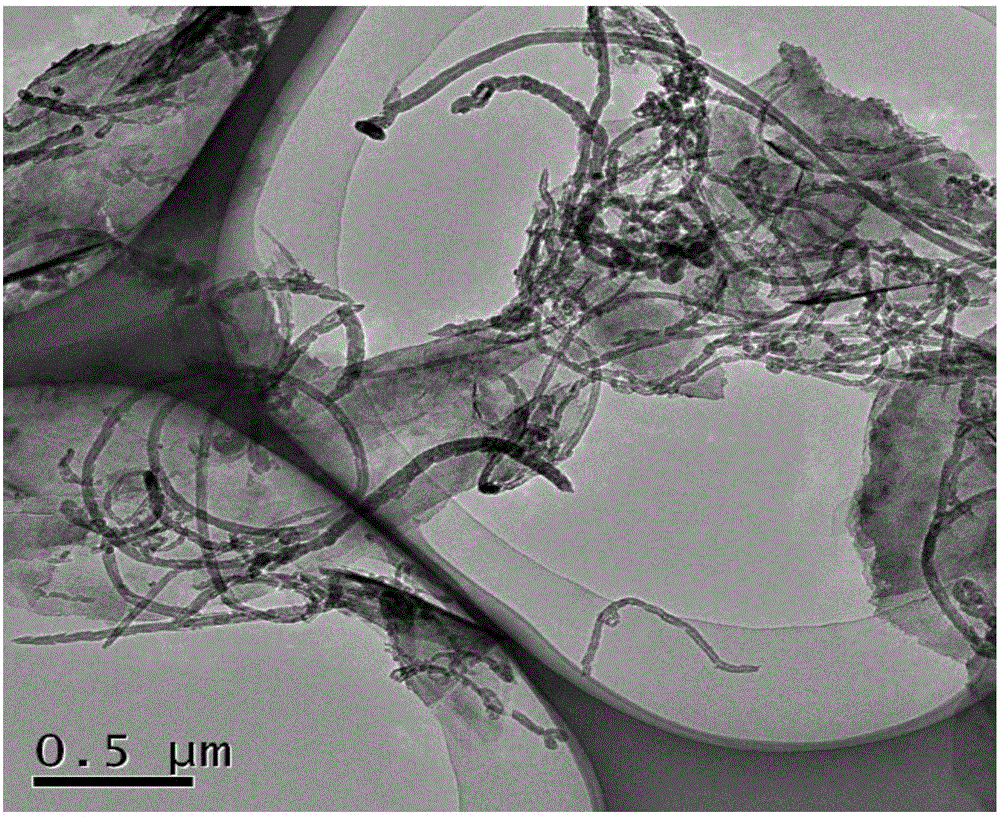

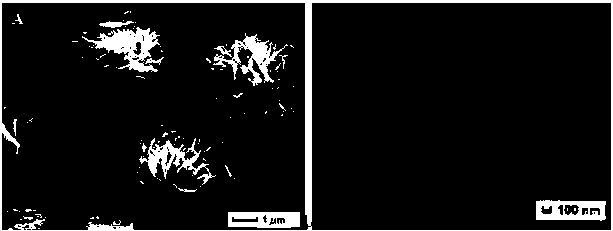

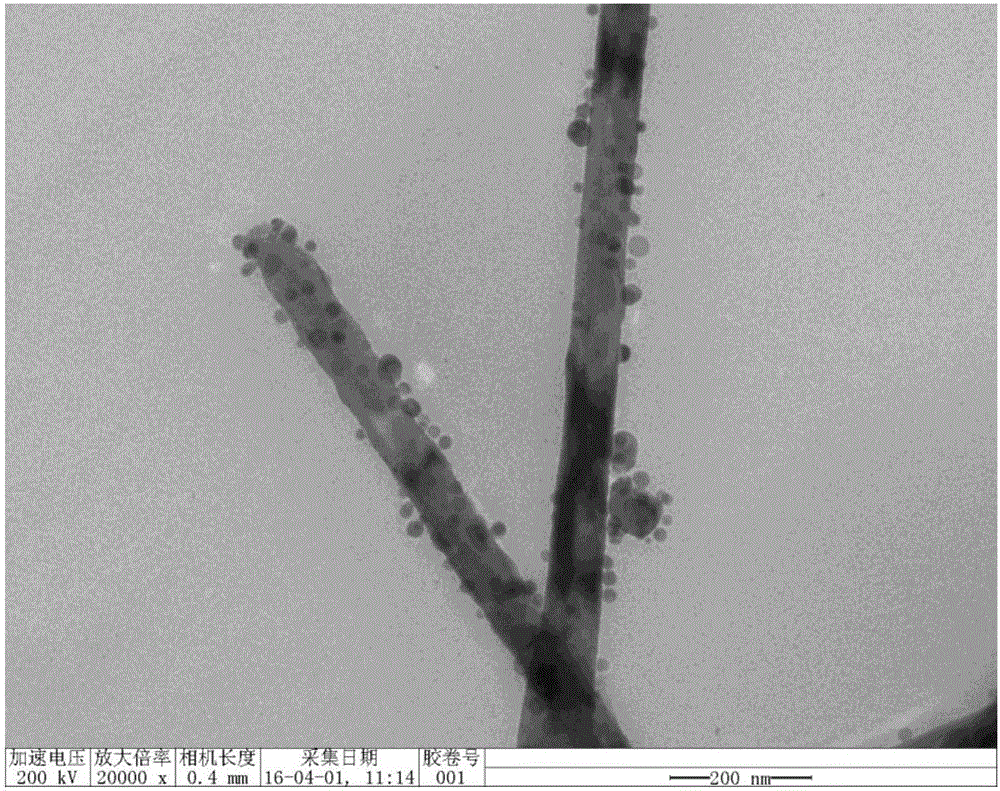

Method for preparing graphene / carbon nanotube composite material

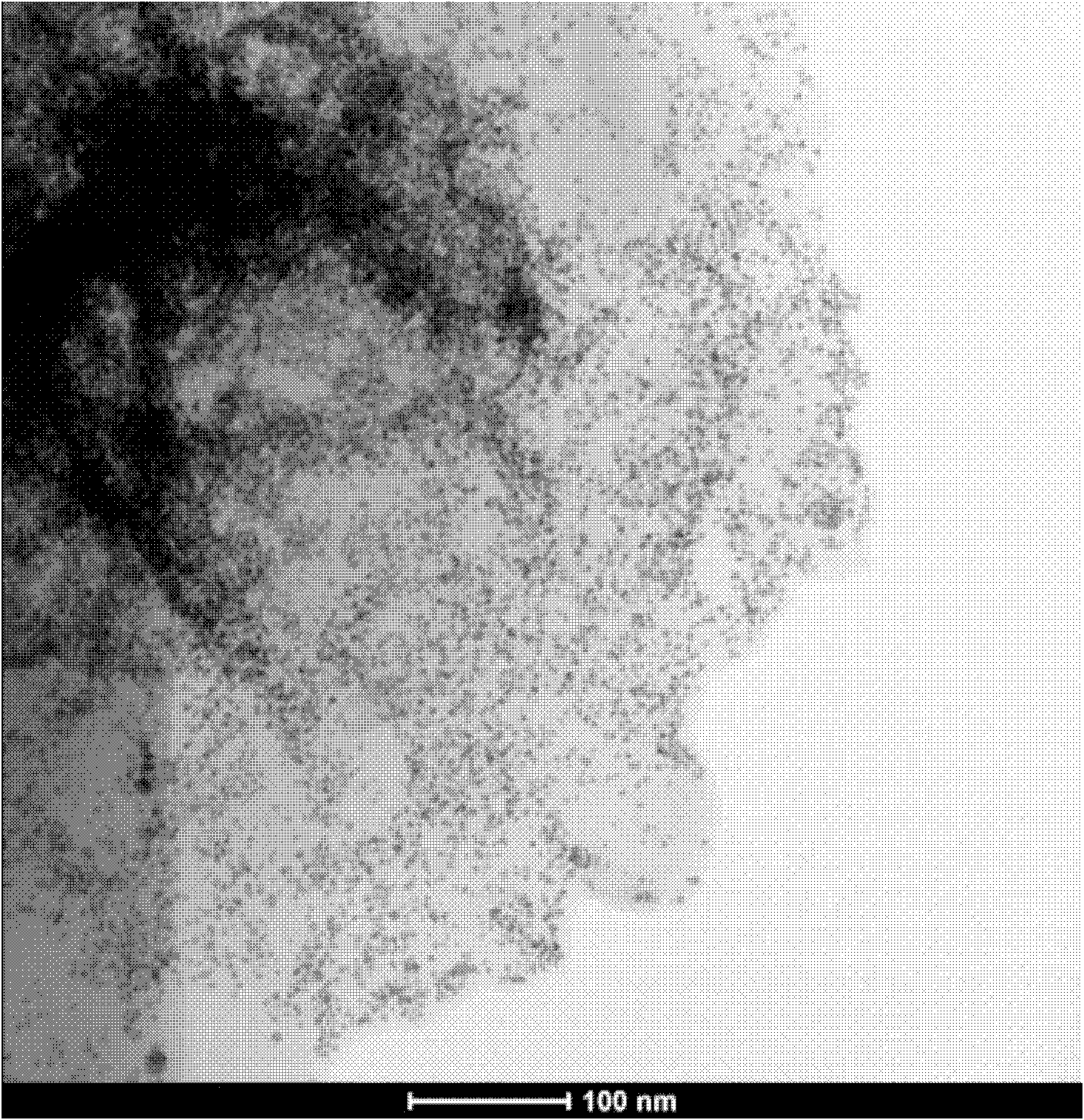

ActiveCN106241782AImprove composite uniformityControllable parametersMaterial nanotechnologyMulti-walled nanotubesIonCvd graphene

The invention discloses a method for preparing a graphene / carbon nanotube composite material. Graphene oxide can be obtained from graphite powder as a raw material by a modified Hummers method; the graphene oxide and deionized water are added into a beaker for ultrasonic dispersion, then nickel nitrate hexahydrate and hexamethylenetetramine are added and evenly fully mixed; the solution is transferred into a reaction kettle for a period of time of reaction at constant temperature, after the reaction is finished, enough hydrochloric acid with the concentration of 1mol / L is added for dissolution of nickel hydroxide, and after filteration by suction, a black solid is taken, and dried in vacuum to obtain the graphene / carbon nanotube composite material. Lens results show that the carbon nano tube size distribution is in 15-40nm, the carbon nano tube lengthis micron-scale, and the carbon nano tubes are dispersed in the system so as to realize the graphene and carbon nano tube homogeneous compounding.

Owner:ANHUI UNIV OF SCI & TECH

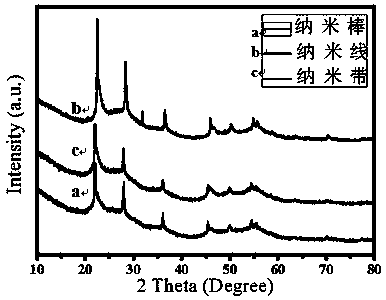

Method for controllably synthesizing different shapes of niobium pentoxide nanomaterials without template hydrothermal heat

The invention belongs to the technical field of inorganic nanomaterials, and particularly relates to a method for controllably synthesizing different shapes of niobium pentoxide nanomaterials withouttemplate hydrothermal heat. The method specifically comprises the following steps: firstly, mixing a certain amount of niobium inorganic matter ionic salt with a precipitant according to a certain ratio, and respectively dissolving into three different solvents; then performing ultrasonic treatment for 15-30 minutes, completely dissolving solid powder and evenly mixing; and finally, respectively transferring the three solutions into a reaction kettle with a polytetrafluoroethylene substrate, sealing, putting into a drying oven, controlling the temperature of the drying oven to be 180-200 DEG C, reacting for 8-12 hours, and after the reaction is over, cooling the product to be at room temperature; centrifugally separating the precipitated product, collecting solids, rinsing for multiple times with deionized water and absolute ethyl alcohol, and performing vacuum drying, to obtain the niobium pentoxide nanobars, nanowires and nanoribbon materials.

Owner:JIANGSU UNIV

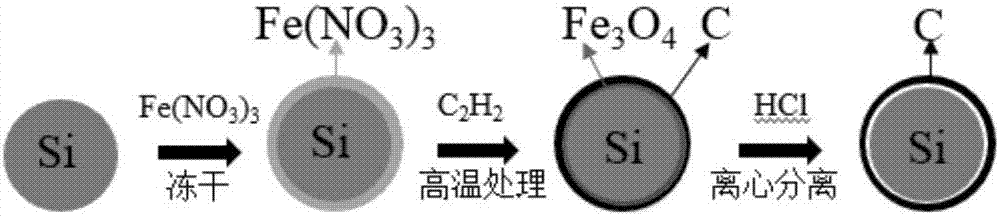

Core-shell structure Si/C material, preparation method and application

ActiveCN107248570APromote decompositionSolve the problem that it is difficult to deposit directly on the Si surfaceCell electrodesSecondary cellsCarbon coatingHigh concentration

The invention belongs to the field of lithium ion batteries and particularly relates to a preparation method of a core-shell structure Si / C material. The method comprises the following steps of (1) preparing Fe(NO3)3 solution; (2) uniformly stirring Si powder in the solution to form turbid liquid; (3) dropping liquid nitrogen into the turbid liquid to form icy Si / Fe(NO3)3; (4) carrying out vacuum freeze drying to obtain an Si / Fe(NO3)3 sample; (5) carrying out high-temperature carbon coating on the Si / Fe(NO3)3 sample to obtain Si / C powder including Fe3O4; and (6) carrying out acid pickling and drying to obtain the core-shell structure Si / C material. The invention also discloses the core-shell structure Si / C material and application thereof. The core-shell structure Si / C material prepared by the method of the invention has excellent electrochemical performance, no high-concentration acetylene and professional CVD device and higher operability and safety.

Owner:HUAZHONG UNIV OF SCI & TECH

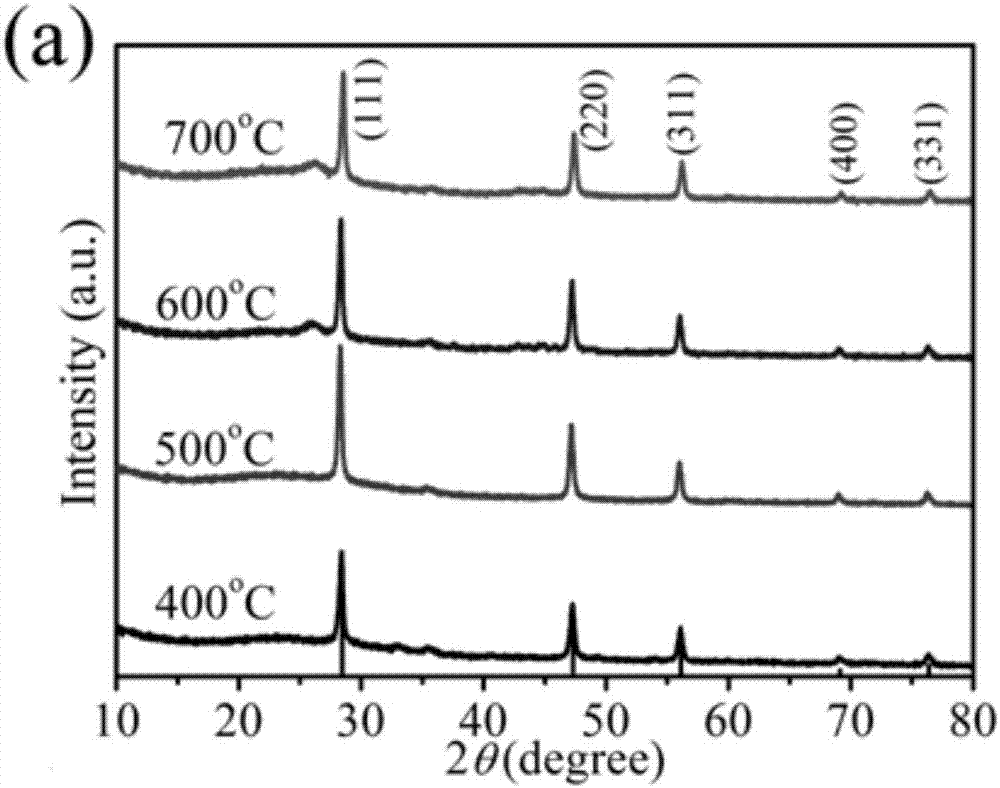

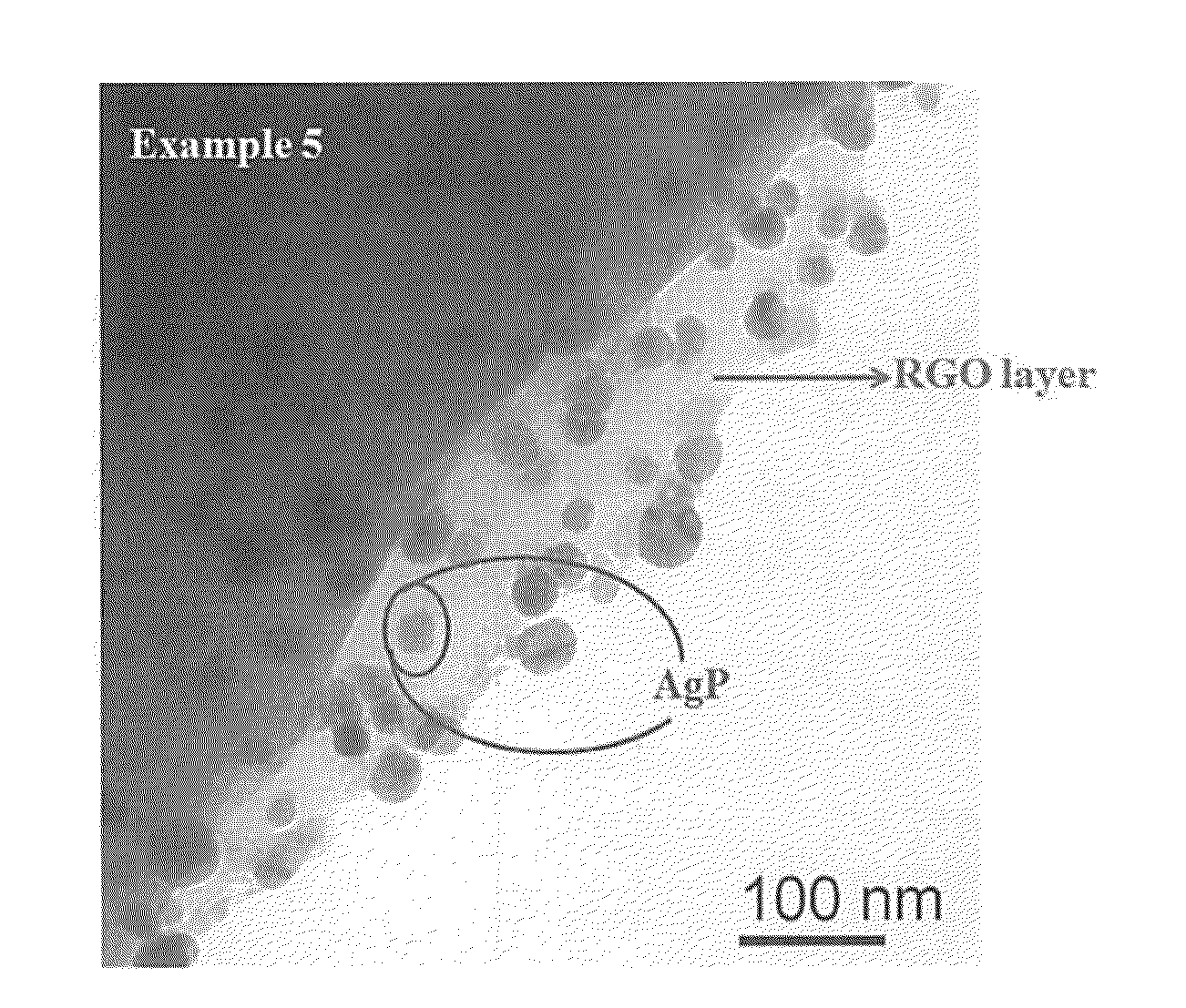

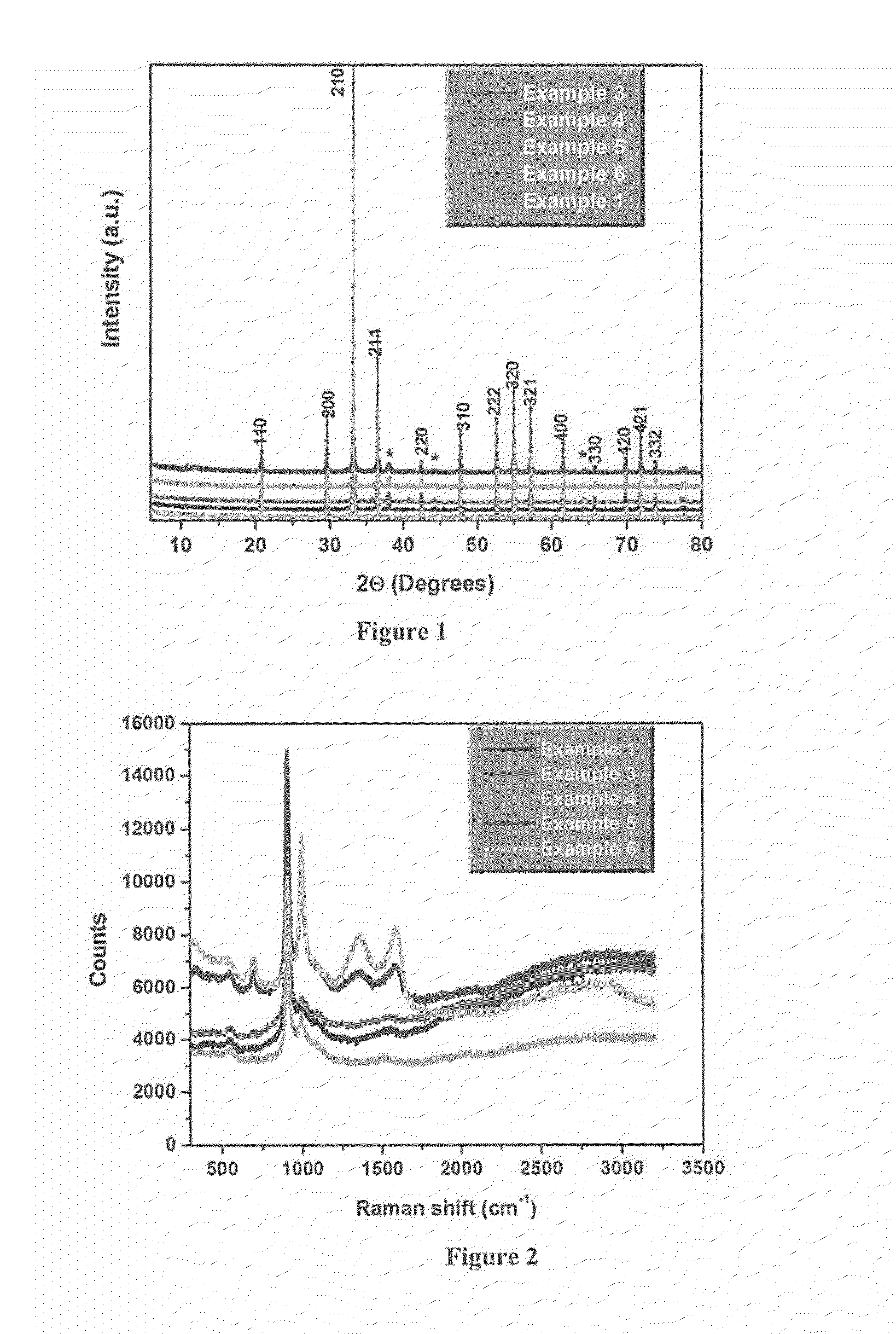

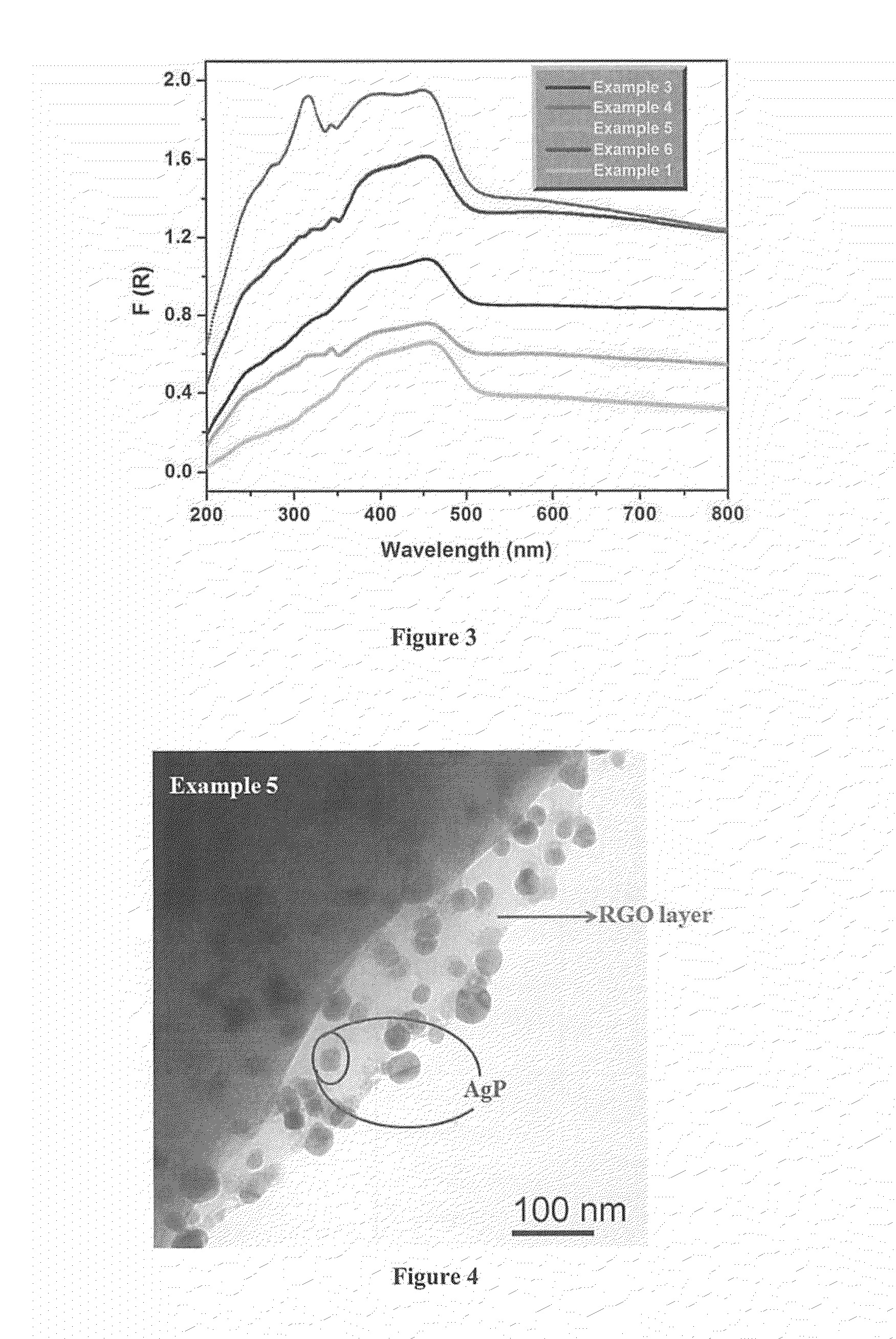

Reduced graphene oxide-silver phosphate (rgo-agp) and a process for the preparation thereof for the photodegradation of organic dyes

InactiveUS20160144349A1Easy to removeFast photodegradationWater/sewage treatment by irradiationCarbon compoundsOrganic dyeSilver phosphate

RGO is coupled with AgP in a novel one-pot photo-reduction technique in presence of a sacrificial agent like dry ethanol. Tests of the collected dirty green semiconducting towards adosoptive photodegradation of textile dyes showed that 4 wt. % RGO-AgP can degrade 100, 76, 98.57, 67.88, 69.92% of RhB, Rh6G, MB, CR and MO, respectively within only 5 min under VISL illumination over 1.5 g / L of catalyst.

Owner:COUNCIL OF SCI & IND RES

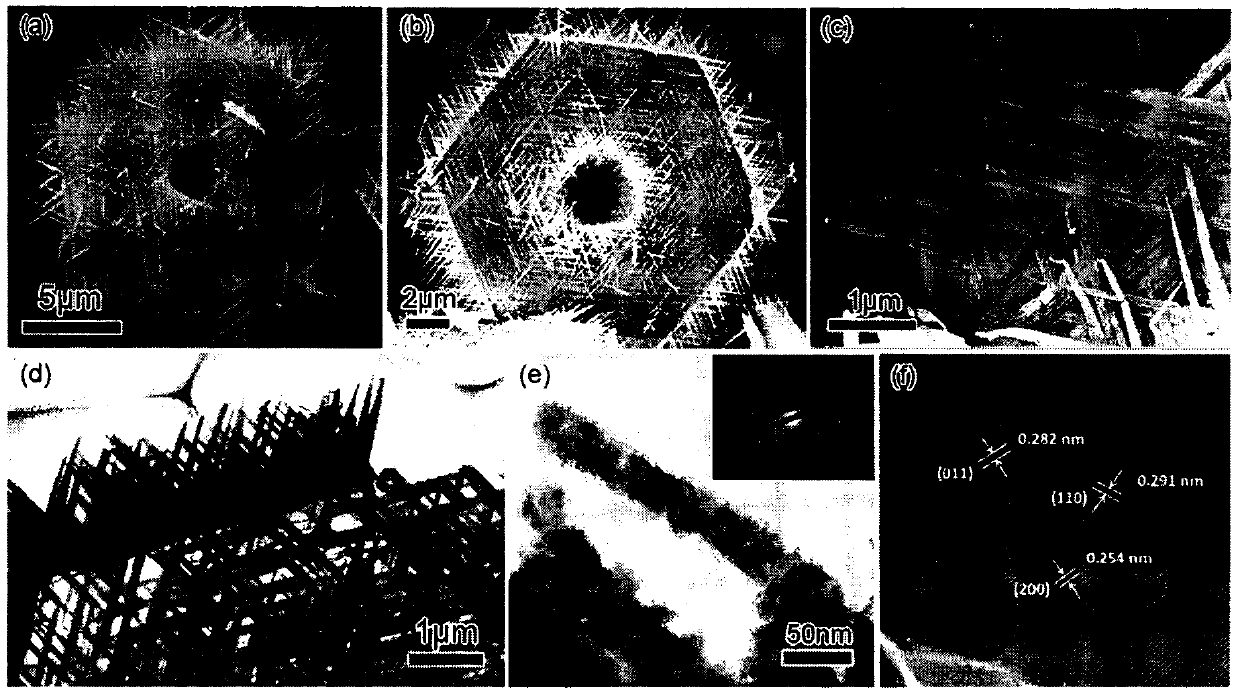

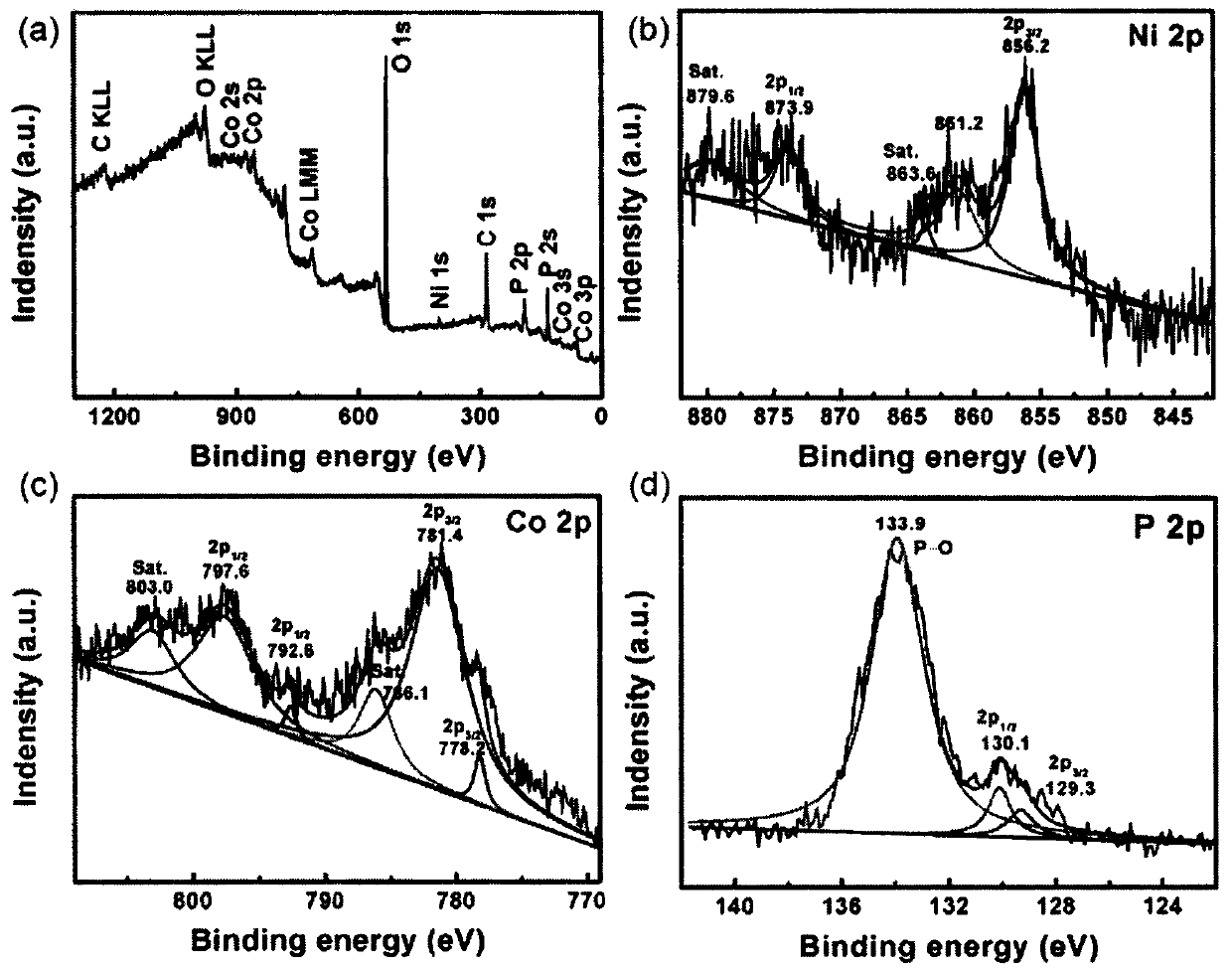

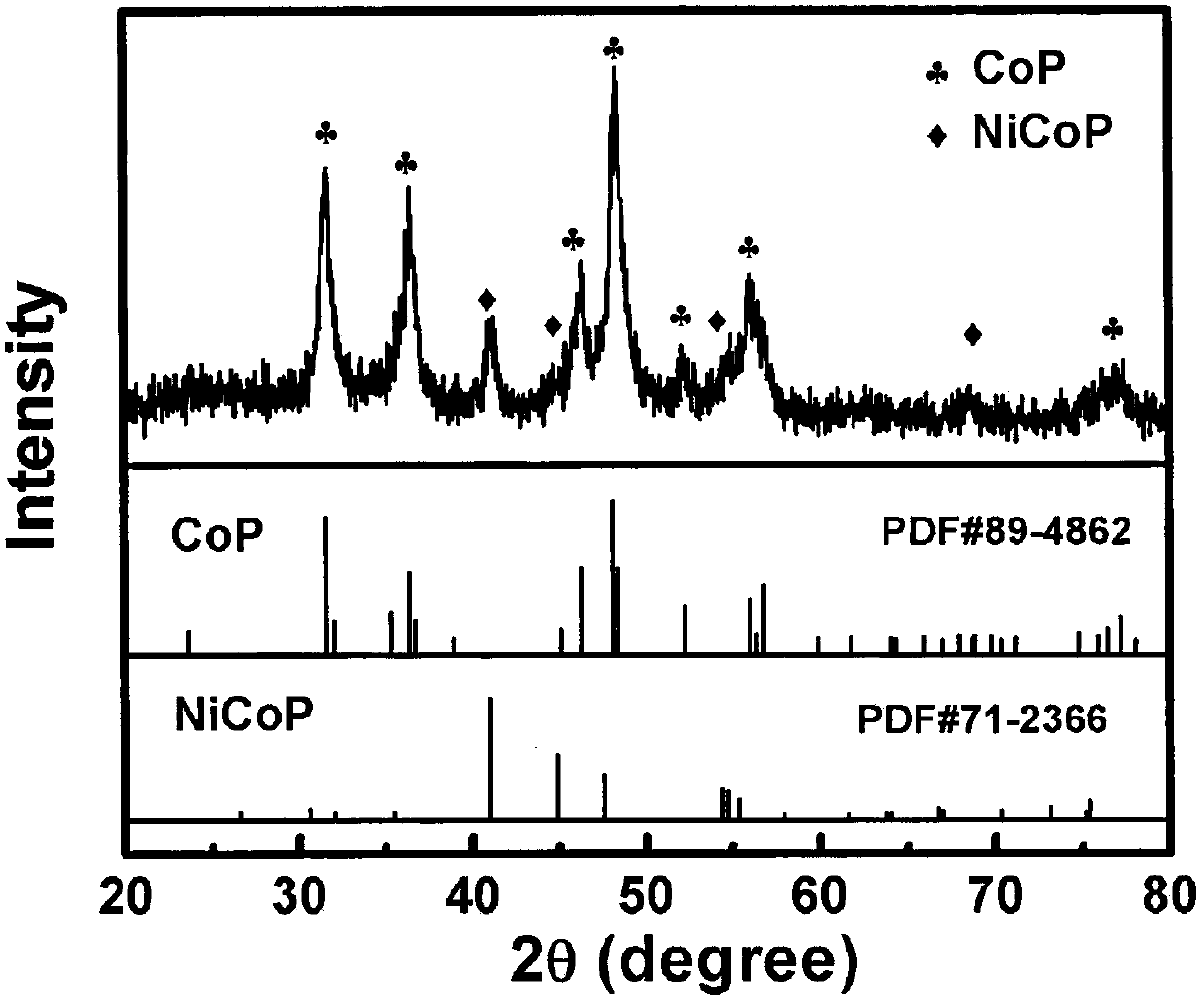

Regular hexagonal micron chip capacitor material formed by interwoven NiCoP-CoP porous nanowires and preparation method

ActiveCN109961963AImprove conductivityImprove Capacitive PerformanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceNanowire

The invention discloses a method for preparing a novel supercapacitor electrode material. The method comprises steps of using nickel nitrate, cobalt nitrate, ammonium fluoride and urea as raw materials, using a hydrothermal reaction to prepare a Ni-Co precursor formed by interwoven nanowires having a diameter of 80-100 nm, and then phosphatizing the Ni-Co precursor to obtain a material which is aregular hexagonal micron chip (having a side length of about 10[mu]m and a thickness of about 100 nm) formed by interwoven NiCoP-CoP porous (pore size 3 to 5 nm) nanowires. The material has the advantages of high specific surface area and high mechanical stability, ensures high electrochemical performance, and has a specific capacitance retention rate as high as 92% after 10000 cycles of charge and discharge. The preparation method is easy to operate, low in cost, and liable to large-scale production, and has great significance for the design and preparation of nano-micro composite electrode materials.

Owner:NANJING UNIV

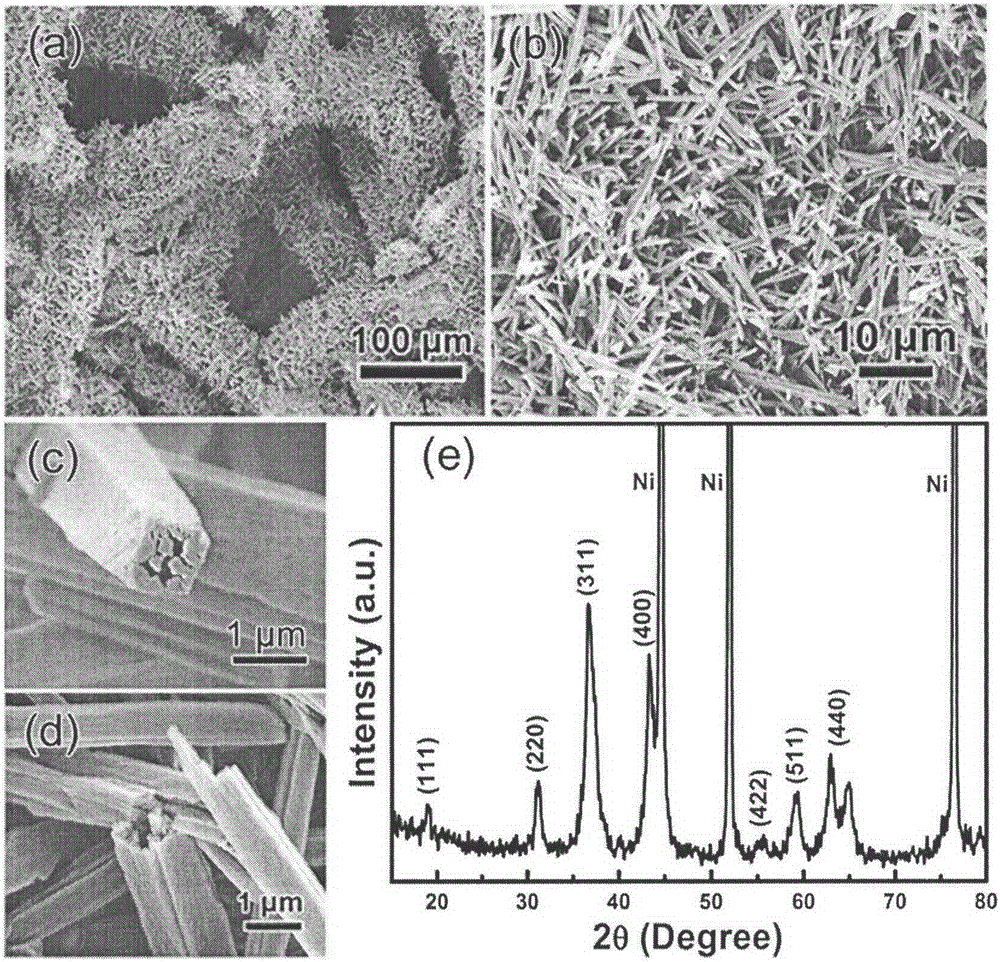

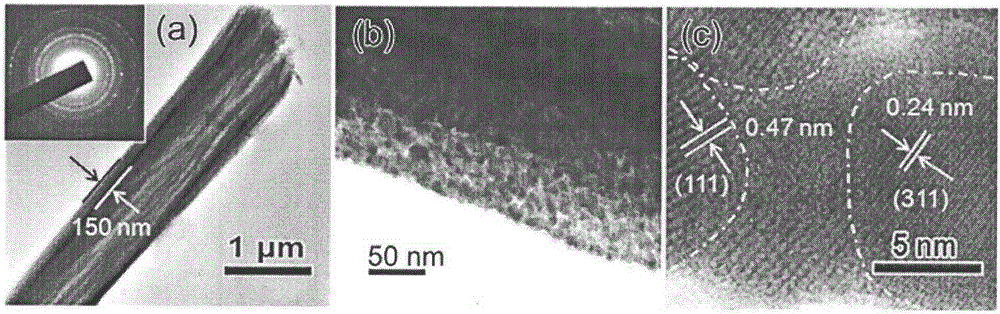

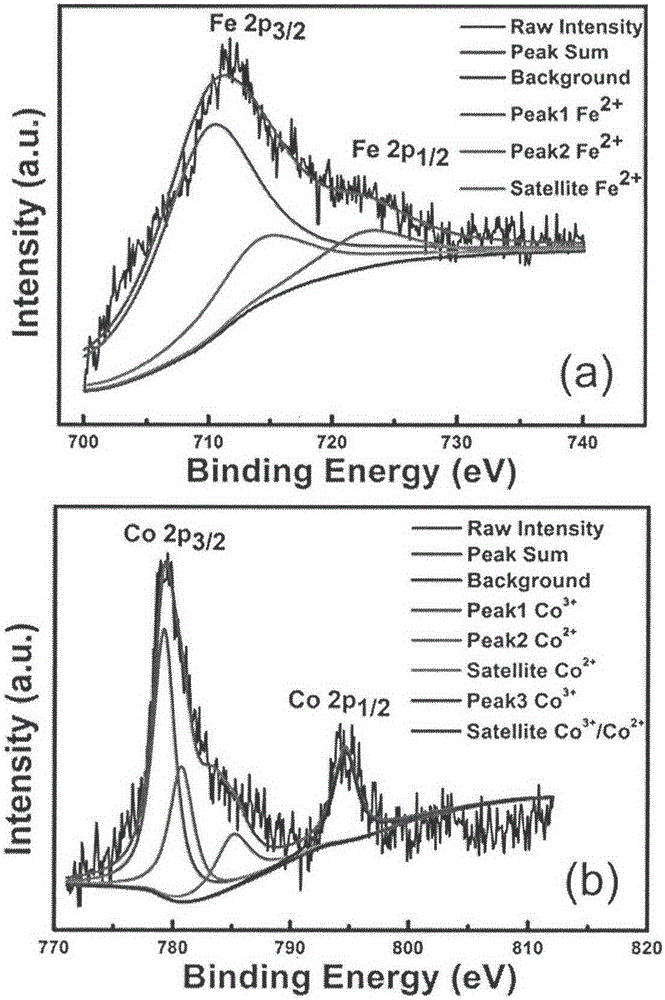

Foamed nickel-supported cobalt acid ferrous submicron tube electrode material and preparation method thereof

ActiveCN105118691AEnsure mechanical stabilityImprove Capacitive PerformanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHeat treating

The invention discloses a novel preparation method of a foamed nickel-supported cobalt acid ferrous submicron tube material and the application of the material in the electrode of a super capacitor. Ferric nitrate, cobalt nitrate and oxalic acid are adopted as raw materials, and the tubular FeCo2O4 material grows on the surface of a foamed nickel substrate through the template-free chemical sedimentation and heat treating process. The diameter of each tube is within the range of 600 to 900 nm. Based on submicron units and a stable structure thereof on the surface of a nickel substrate, the method has an important significance on the mechanical stability. Meanwhile, a tube array is uniformly distributed on the surface of a three-dimensional substrate to form a porous structure. The electrode material can be directly applied to a capacitor without the need of any binder, so that the high capacitive performance is ensured. In addition, the preparation method is simple to operate, low in cost, easy to control and large in scale.

Owner:NANJING UNIV

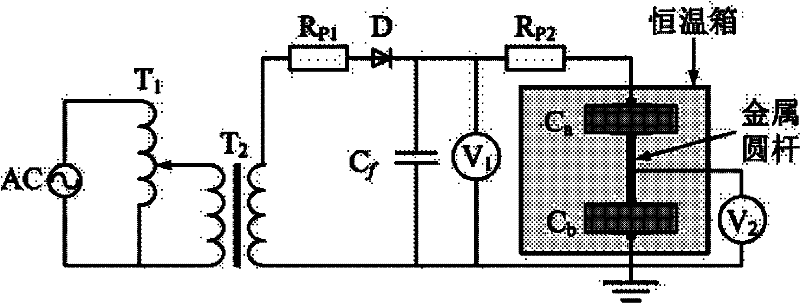

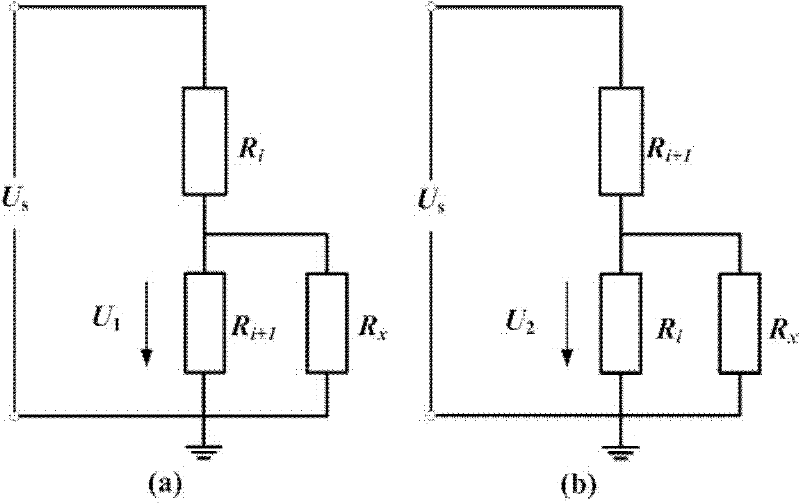

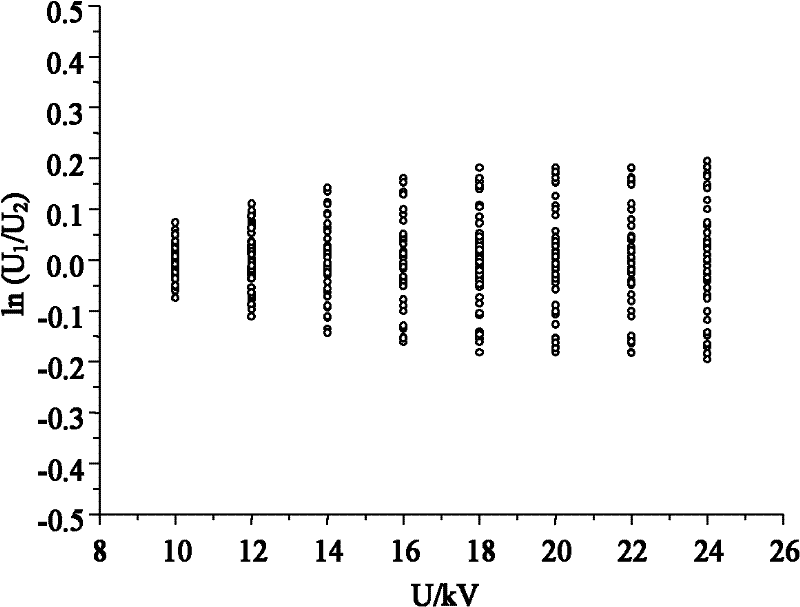

Method for nondestructively detecting and evaluating mass defect level of high-voltage ceramic capacitors

ActiveCN102253089AAccurately reflectThe method is simple and fastMaterial resistanceElectrical resistance and conductanceCeramic capacitor

The invention relates to a method for nondestructively detecting and evaluating the mass defect level of high-voltage ceramic capacitors. The method provided by the invention comprises the following steps: 1) sampling high-voltage ceramic capacitors in the same batch and numbering the extracted high-voltage ceramic capacitor samples according to a sequence from No. 1 to No. n; 2) sequentially combining the high-voltage ceramic capacitor samples pairwires, namely combining No. 1 and No. 2, combining No. 2 and No. 3, till combining No. (n-1) and No. n, and combining No. n and No. 1; 3) under the condition that the externally-applied voltage does not exceed rated voltage, carrying out a ratio test of insulation resistance on the high-voltage ceramic capacitor samples combined pairwise; 4) taking a natural logarithm of the ratio test of the insulation resistance obtained in the step 3) according to a formula and using the natural logarithm as an independent variable xi to carry out probability statistic analysis; 5) computing the obtained independent variable xi according to the formula to obtain a standard variance S; and 6) evaluating the standard variance S obtained in the step 5).

Owner:西安西交瑞力电气研究院有限公司

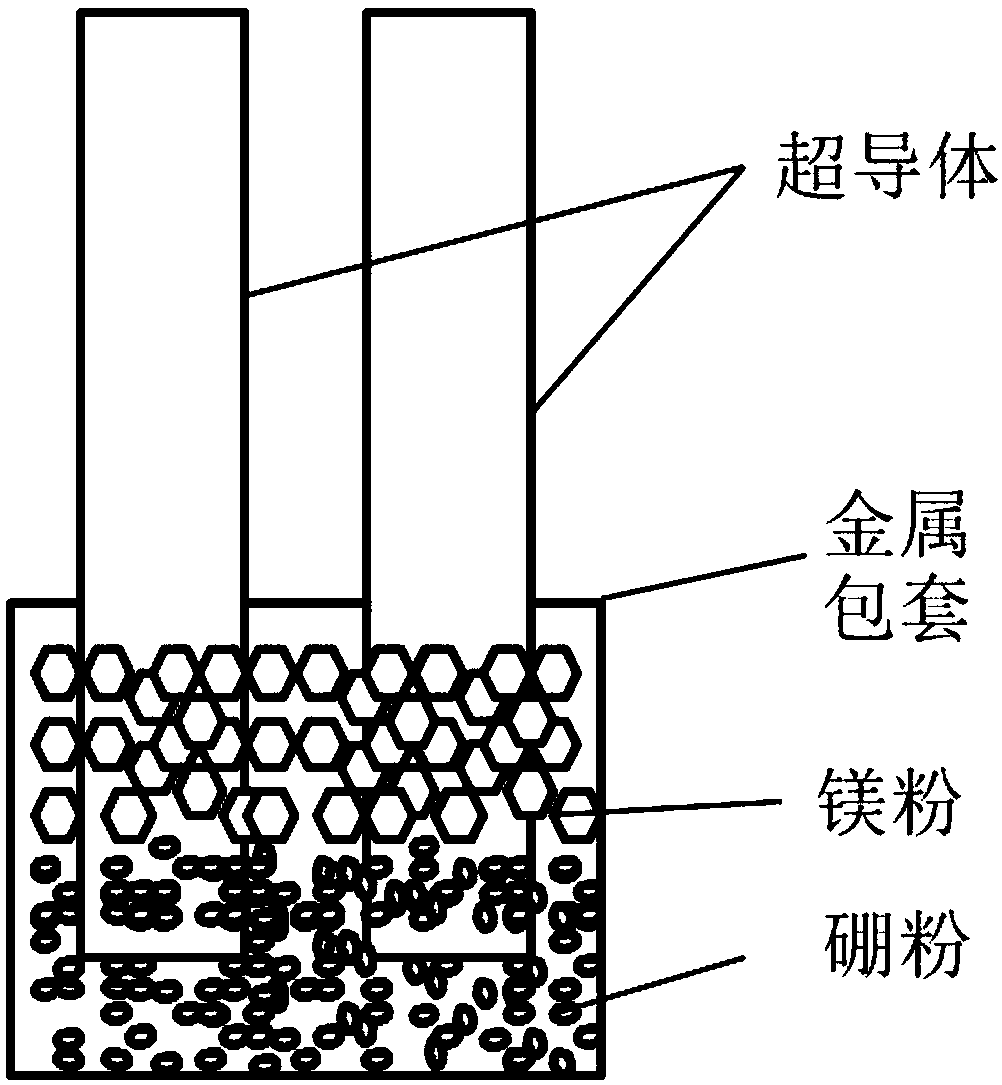

Superconductive joint and preparation method thereof

InactiveCN107863613AImprove superconductivityImprove compactnessConnection contact member materialBoronHeat treated

Provided is a superconductive joint, which comprises superconductors, boron powders, magnesium powders and a metal sleeve. The tail ends of the connected superconductors are buried in the boron powders; the surface of the boron powders is covered by the magnesium powders; and the connected superconductors, the boron powders and the magnesium powders are wrapped by the metal sleeve. The preparationmethod of the superconductive joint comprises the following steps: 1) polishing the tail ends of the connected superconductors to expose superconducting cores; 2) burying the tail ends of the processed superconductors into the boron powders, covering the magnesium powders on the surface of the boron powders, and wrapping the connected superconductors, the boron powders and the magnesium powders with the metal sleeve; 3) welding the metal sleeve processed in the step 2); and 4) carrying out heating processing on the metal sleeve prepared in the step 3).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

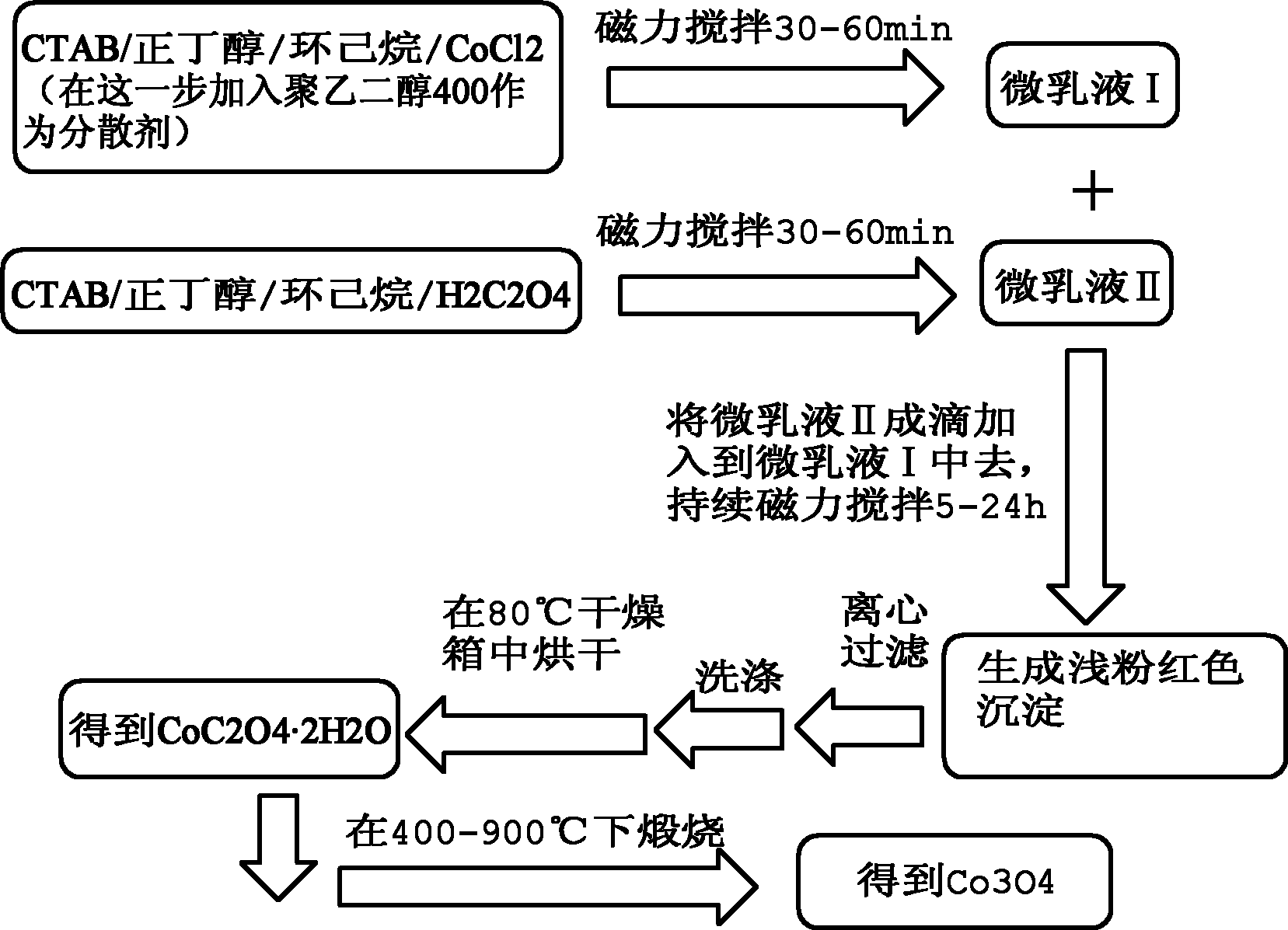

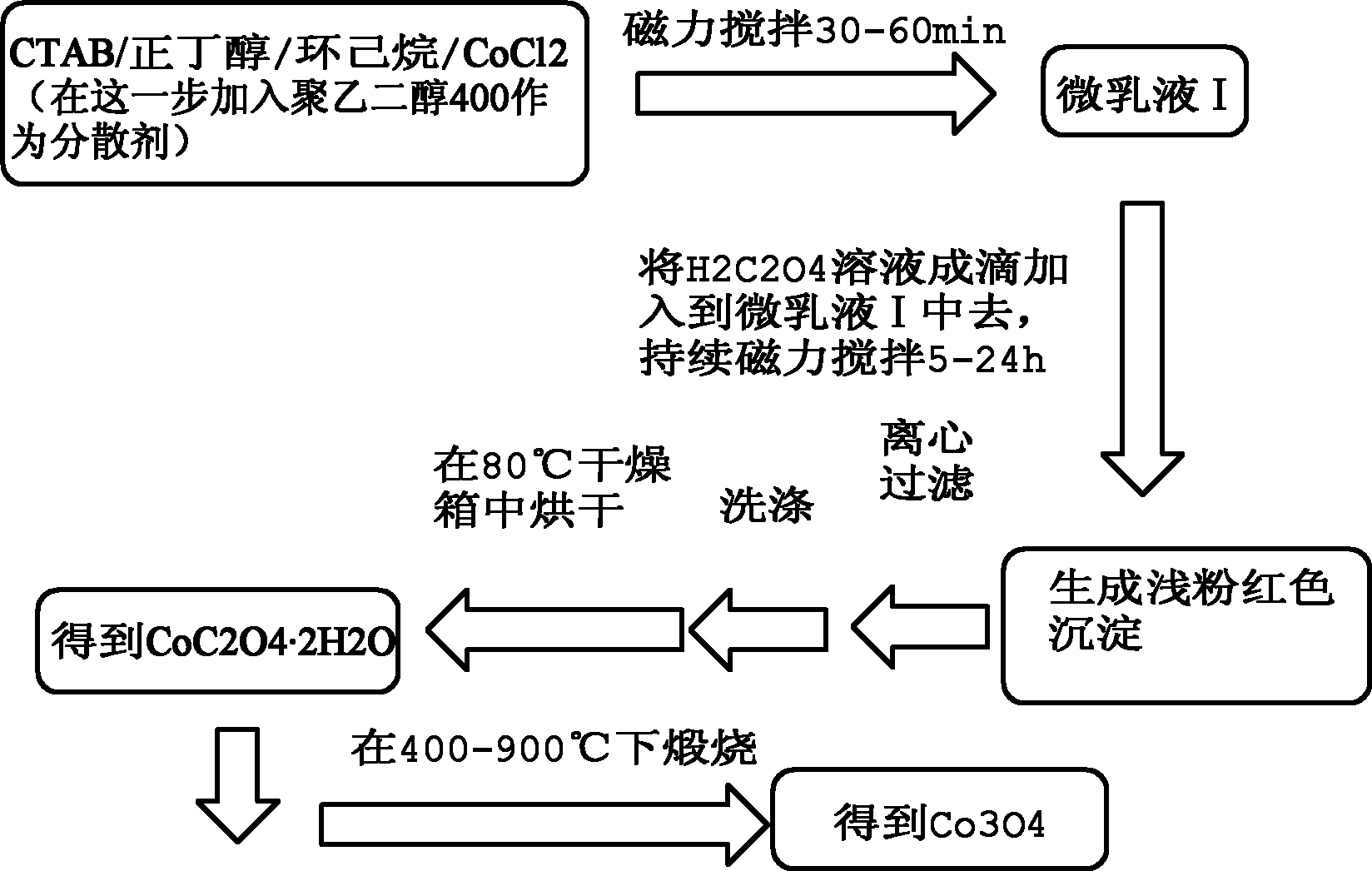

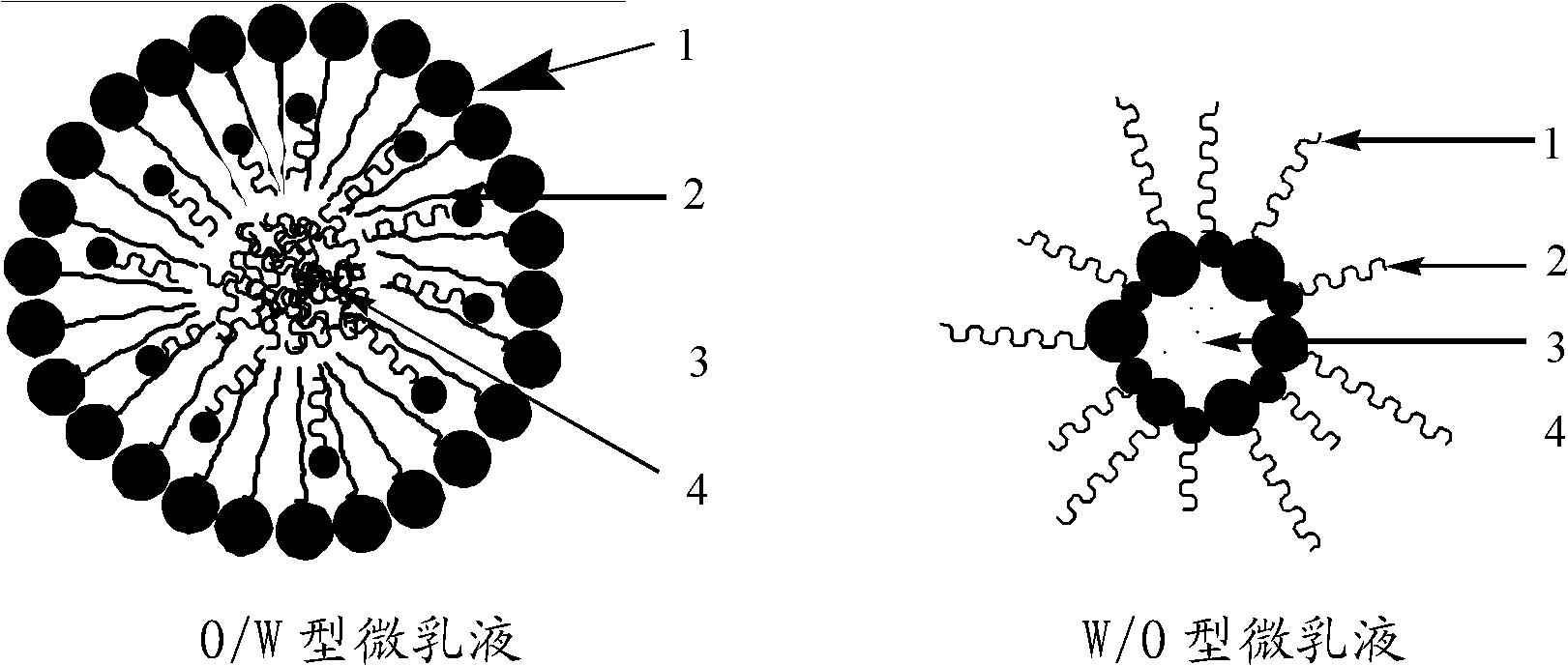

Method for preparing cobaltosic oxide nanorod by using microemulsion

InactiveCN102115213AExperimental raw materials are cheapAvoid pollutionCatalyst carriersNanotechnologyChemistrySolution composition

The invention discloses a method for preparing a cobaltosic oxide nanorod by using microemulsion. A double microemulsion system and a single emulsion system are provided, wherein the double microemulsion system consists of a microemulsion I and a microemulsion II; each of the microemulsion I and the microemulsion II consists of CTAB (Cetyltrimethyl Ammonium Bromide) serving as a surfactant, normal butanol serving as a cosurfactant, oil phase cyclohexane and a water phase; the mass ratio of the oil phase to the water phase is 1:20-20:1; and in the microemulsion I, the water phase is a CoCl2 aqueous solution; in the microemulsion II, the water phase is an H2C2O4 solution. Polyethylene glycol serving as a dispersant is added into the system, wherein the polyethylene glycol accounts for 10-80 percent by mass of the entire microemulsion system (the double microemulsions comprise the microemulsion I and the microemulsion II, the single microemulsion comprises the microemulsion I, and the double microemulsions and the single microemulsion do not comprise the polyethylene glycol). The single microemulsion system consists of the microemulsion I and the H2C2O4 aqueous solution, and the composition of the microemulsion I is the same as that of the microemulsion I in the double microemulsions. By adopting the method, the diameter of the obtained nanorod is between 70 nanometers and 150 nanometers, and the length is between 1 mu m and 3 mu m.

Owner:BEIJING UNIV OF CHEM TECH +1

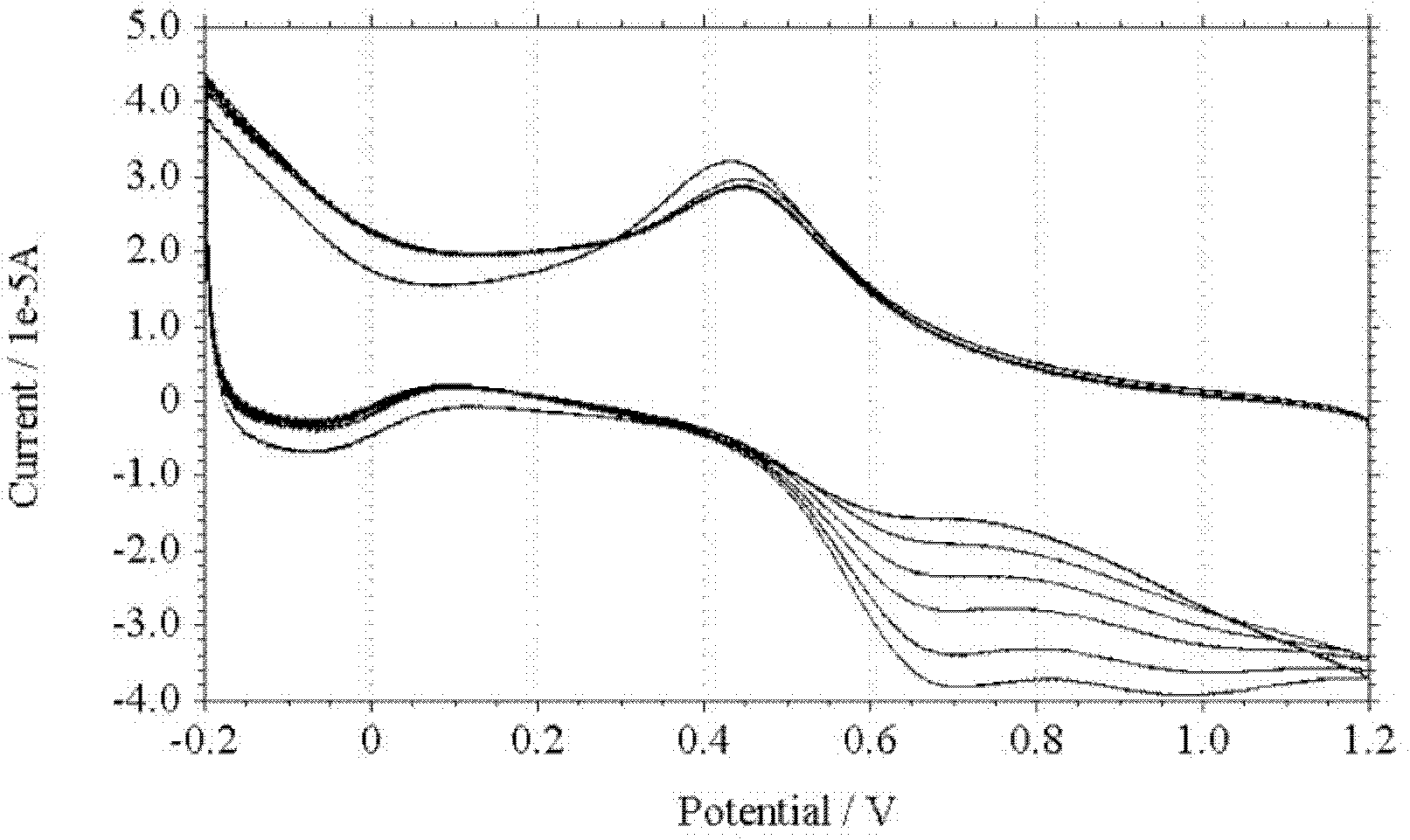

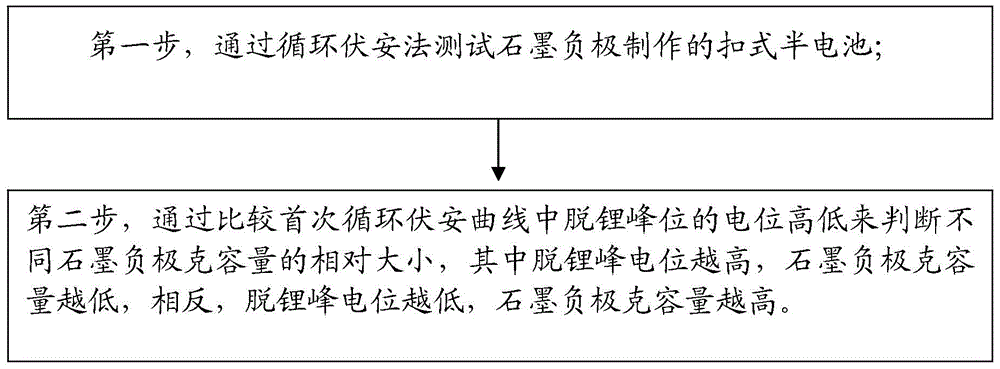

Evaluation method for gram volume of graphite cathode material

InactiveCN104614433AExperimental conditions are simpleImprove efficiencyMaterial electrochemical variablesGramVoltage

The invention discloses an evaluation method for gram volume of a graphite cathode material. The method comprises the following steps: firstly, testing a button half cell made from a graphite cathode through cyclic voltammetry, and then, judging relative size of gram volume of different graphite cathodes by comparing voltage at a lithium deintercalation peak position in a first cyclic voltammetry curve. The higher the electric potential at the lithium deintercalation peak position, the lower the gram volume of graphite cathode. As a relative value comparison method, the evaluation method can compare and evaluate advantages and disadvantages of gram volume of different graphite cathodes more conveniently in comparison with the conventional method for testing the gram volume of graphite by relative values, and can better adapt to the demand of rapid evaluation in actual production research and development.

Owner:TIANJIN LISHEN BATTERY

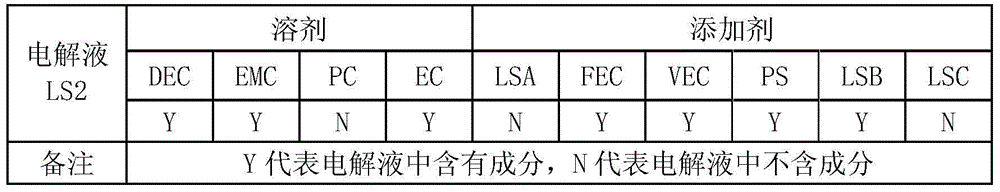

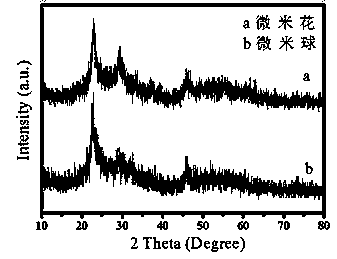

Method for controllably synthesizing niobium pentoxide microspheres and microflowers without template solvent heat

The invention belongs to the technical field of inorganic nanomaterials, and particularly relates to a method for controllably synthesizing niobium pentoxide microspheres and microflowers without template solvent heat. The method comprises the following steps: firstly, mixing a certain amount of niobium inorganic matter ionic salt with a precipitant according to a certain ratio, and respectively dissolving into two different organic solvents; then performing ultrasonic treatment for 15-30 minutes, completely dissolving solid powder and evenly mixing; and finally, respectively transferring thetwo solutions into a reaction kettle with a polytetrafluoroethylene substrate, sealing, putting into a drying oven, controlling the temperature of the drying oven to be 180-200 DEG C, reacting for 8-12 hours, and after the reaction is over, cooling the product to be at room temperature; centrifugally separating the precipitated product, collecting solids, rinsing for multiple times with deionizedwater and absolute ethyl alcohol, and performing vacuum drying, to obtain the niobium pentoxide microspheres and microflowers.

Owner:JIANGSU UNIV

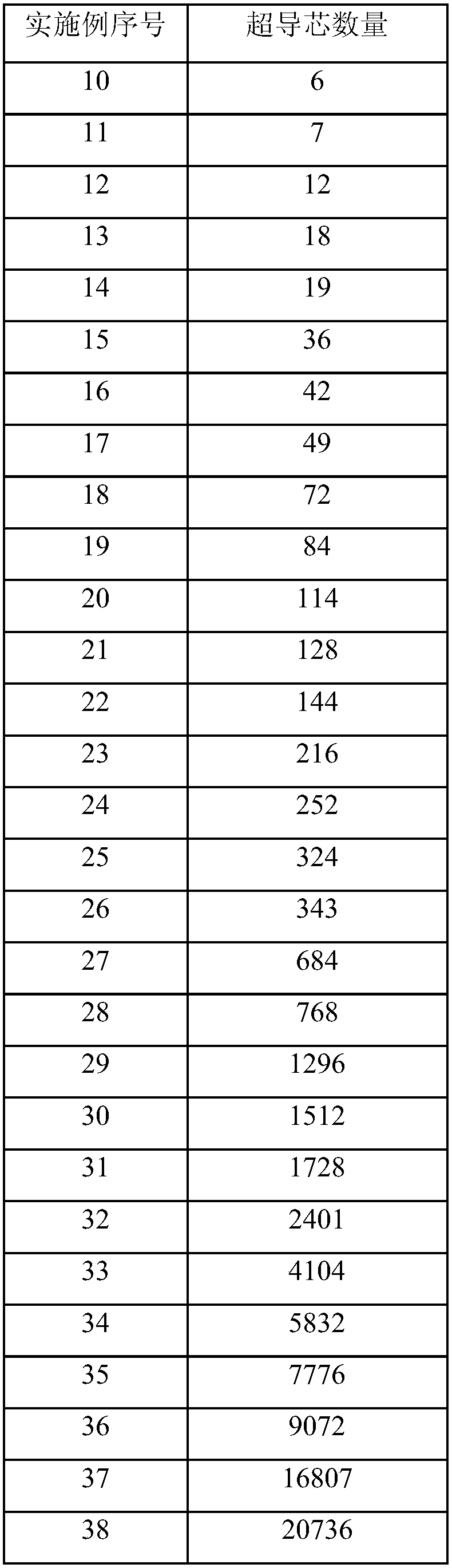

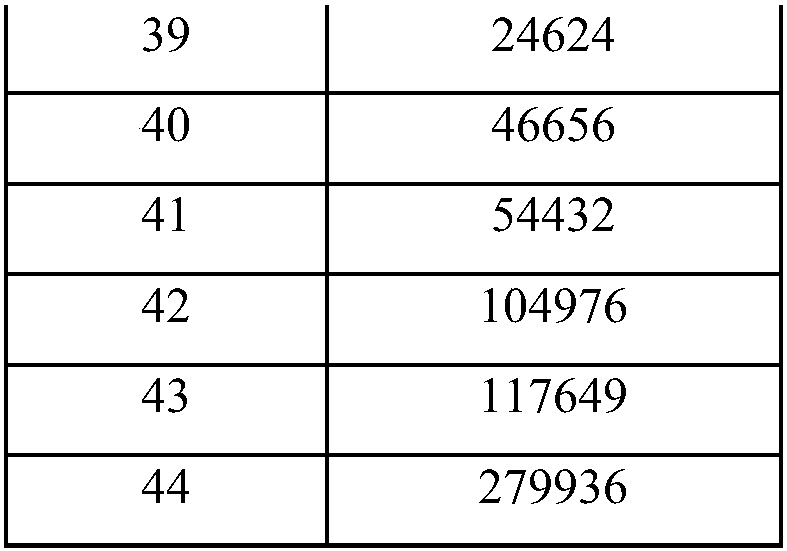

Superconducting joint and preparation method thereof

ActiveCN109802247AConnection Efficiency LimitSmall grain sizeContact member manufacturingCoupling contact membersElectrical conductorReaction rate

The invention belongs to the technical field of superconductor preparation, and specifically relates to a superconducting joint and a preparation method thereof. The superconducting joint comprises boron powder, magnesium powder, superconductors, an outer metal sheath and an inner metal sheath, wherein the superconductors and boron powder are coated by the inner metal sheath, a low-melting-point alloy phase is formed at the junction of the inner metal sheath and the magnesium powder when heat treatment is carried out, a liquid phase can be formed when the temperature is lower than 600 DEG C, and the diffusion rate and reaction rate of magnesium for entering the boron powder are accelerated, so that the reaction of the boron powder and the magnesium powder can be conducted at a temperaturelower than 600 DEG C, the crystal grain size of a product MgB2 is reduced, the crystal boundary area is increased, and thus the pinning ability of MgB2 is improved. In addition, the setting of the inner metal sheath can enable the connection efficiency of the superconducting joint not to be limited by the shape of the superconductors.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Graphitized carbon coated manganese-fluorine oxide material and preparation method thereof

InactiveCN105514374AParticle size controllableIncrease speedMaterial nanotechnologyCell electrodesCarbonizationLithium-ion battery

The invention discloses a graphitized carbon coated manganese-fluorine oxide material, prepared by mixing manganese source and perfluorinated sulfonic acid resin solution and carbonizing the mixture. A preparation method of the graphitized carbon coated manganese-fluorine oxide material comprises the concrete steps of mixing the manganese source solution and perfluorinated sulfonic acid resin, and evenly stirring; then, adjusting a pH of the mixed solution; after a stirring reaction, sequentially drying and carrying out roasting carbonization to obtain the graphitized carbon coated manganese-fluorine oxide material. The carbon in the graphitized carbon coated manganese-fluorine oxide material is in a graphitized state, so that an ion and electron transport rate of the material can be greatly improved; the graphitized carbon coated manganese-fluorine oxide material can be taken as a high cycle stability lithium ion battery cathode material; furthermore, the preparation technology is simple and short in synthesizing time, thus being suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

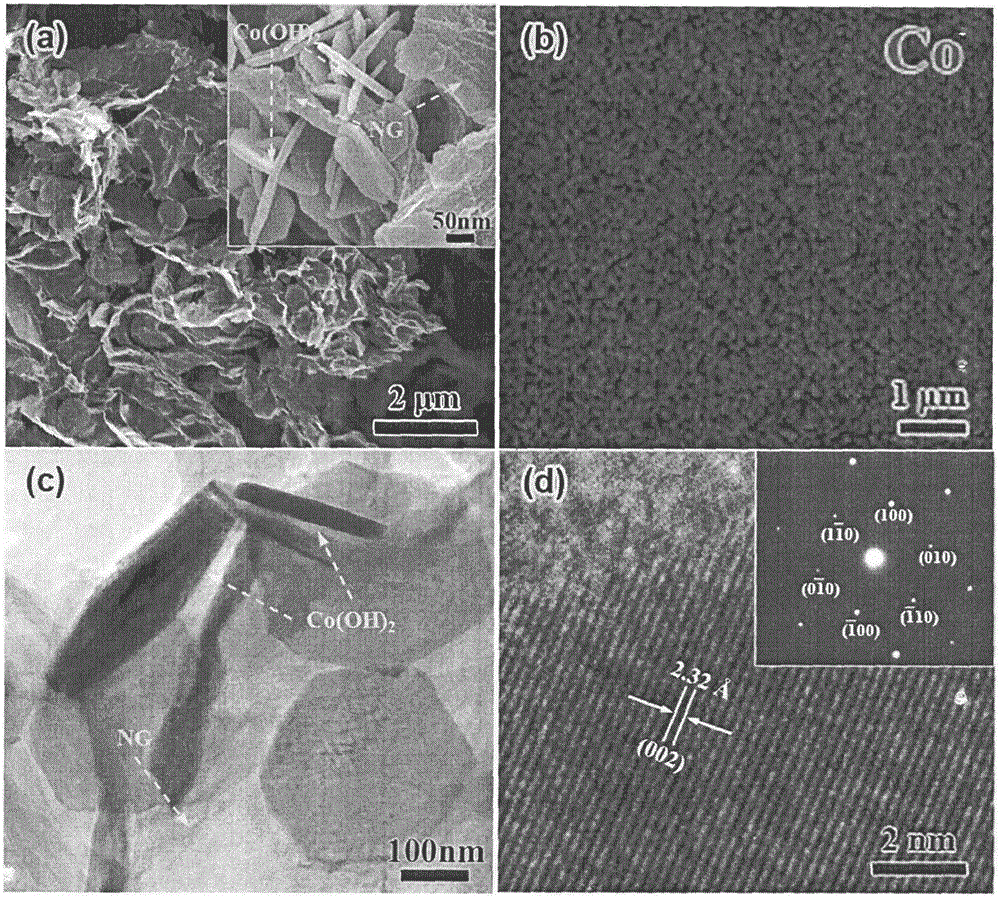

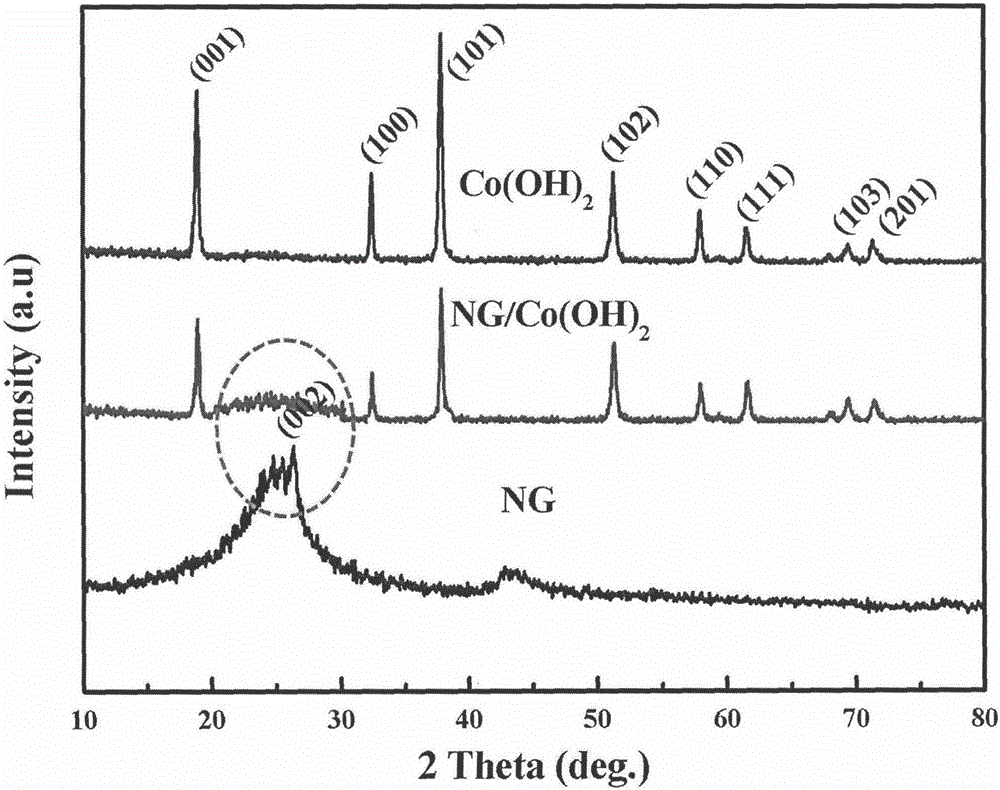

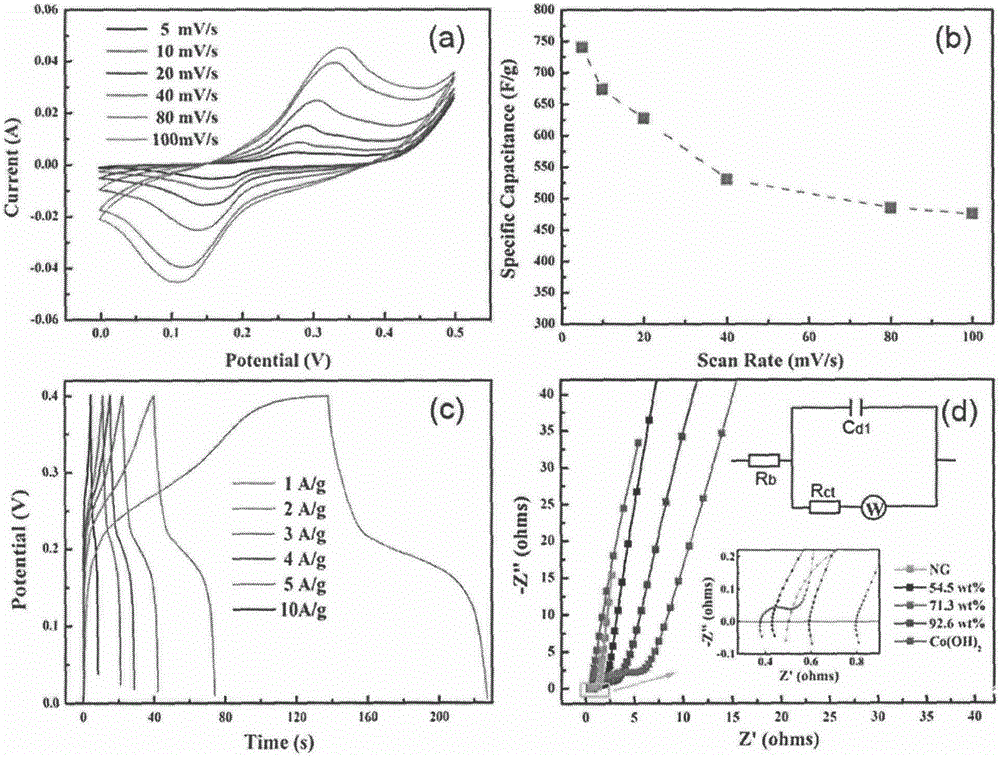

Preparation method for three-dimensional reticular nitrogen-doped graphene composite cobalt hydroxide hexagonal nano-sheet electrode material

InactiveCN105118693AGuaranteed specific surface areaHigh specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneCobalt hydroxide

The invention discloses a preparation method for a three-dimensional reticular nitrogen-doped graphene composite cobalt hydroxide hexagonal nano-sheet electrode material. In order to overcome the problem that the pseudocapacitance material is poor in electrical conductivity and low in specific surface area, the simple and economical one-step hydrothermal route is conducted. During the formation process of three-dimensional reticular nitrogen-doped graphene, the graphene three-dimensional network skeleton-supported Co(OH)2 composite electrode material is prepared through the in-situ growth of Co(OH)2 hexagonal nano-sheets. Each edge of one hexagonal nano-sheet is about 100-300 nm, and the thickness of the hexagonal nano-sheet is 10-15 nm. The material is good in capacitive performance, wherein the capacitive value of the material is 740.4F / g at the scanning speed of 5mV / s and is up to 952.4F / g at the current density of 1.0A / g. therefore, the method has a considerable advantage in preparing electrode materials for super capacitors.

Owner:NANJING UNIV

Method for simply synthesizing pyraclostrobin

The invention discloses a method for simply synthesizing pyraclostrobin. The method comprises steps as follows: N-hydroxyl-N-2-[1-(4-chlorophenyl)-3-pyrazoloxy methyl]phenyl carbamate and a phase transfer catalyst are dissolved in an organic solvent, dimethyl sulfate is added, an acid-binding agent is dropwise added at the system temperature kept in a range of 5-70 DEG C, the components react for 1-5 h, and pyraclostrobin is obtained. Under the condition of reasonable control of feeding sequence of reaction raw materials and the system temperature, the problems of many reaction by-products as well as potential safety hazard and the like due to the many reaction by-products in an existing pyraclostrobin synthesis process are effectively solved, and a plurality of advantages such as reduction of production cost, reduction of wastewater quantity in a production process and the like can be provided for industrial production, so that the method is beneficial to energy conservation, emission reduction and environment protection of pesticide chemical enterprises and is more suitable for large-scale industrial production.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

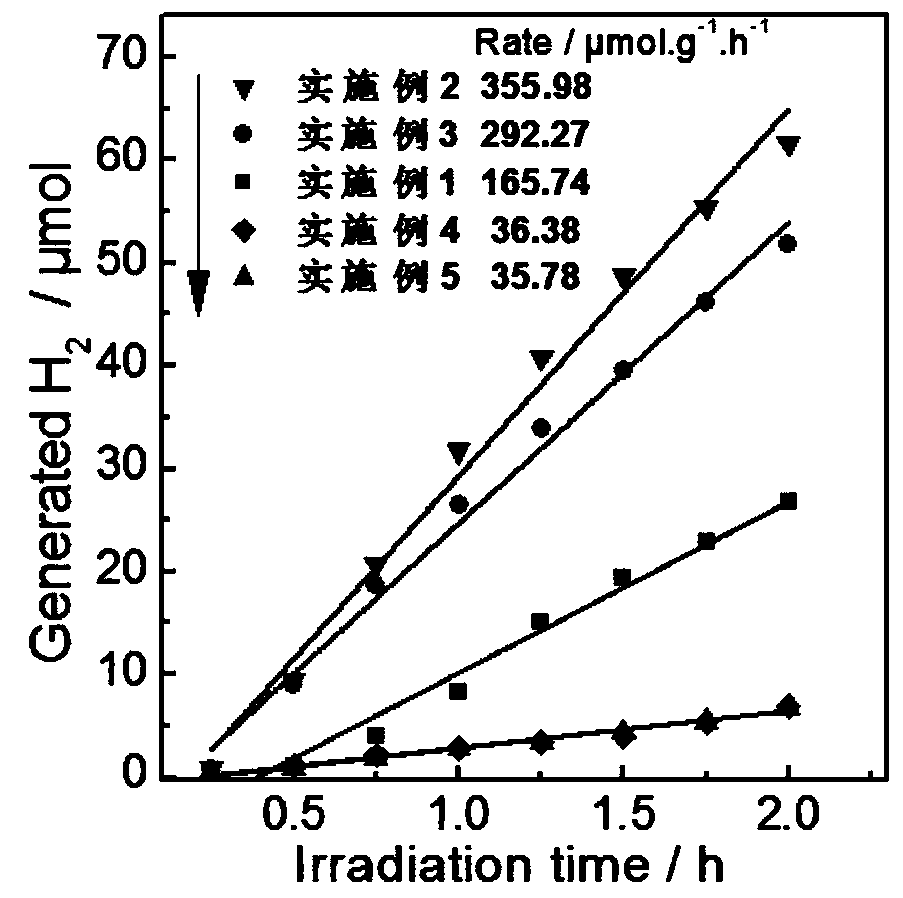

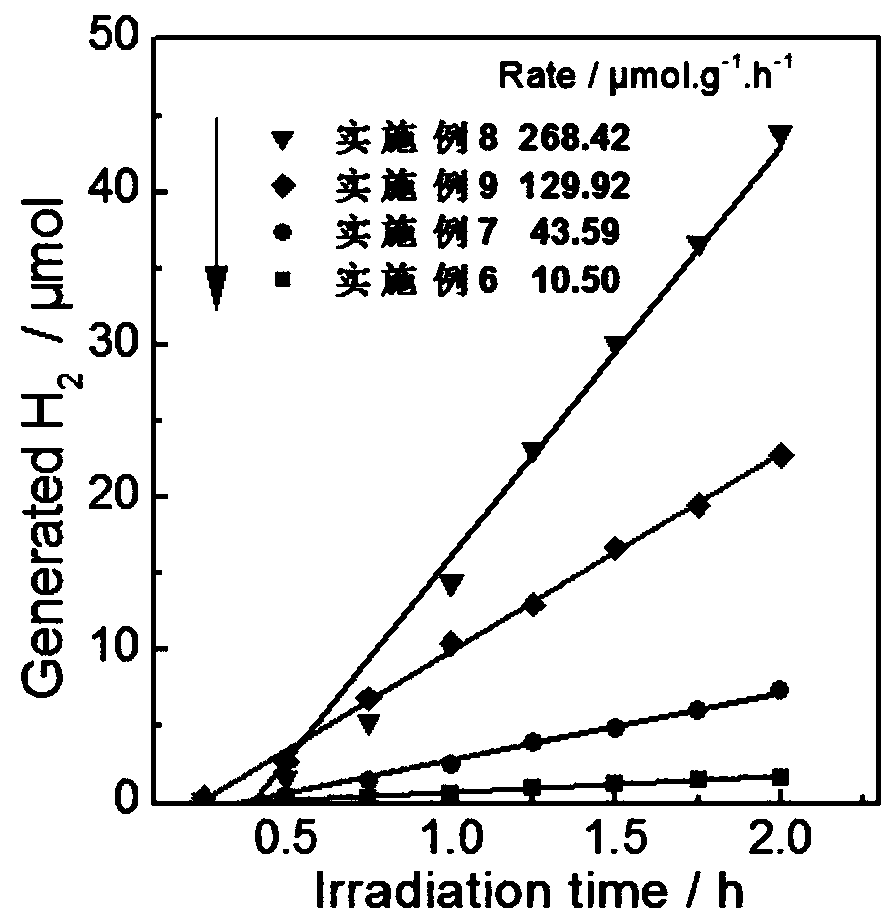

Photocatalytic hydrogen production catalyst and preparation method thereof

ActiveCN108714432AExcellent photocatalytic hydrogen production performanceThe method is simplePhysical/chemical process catalystsNitrogen compoundsMicrowaveMicrowave oven

The invention discloses a photocatalytic hydrogen production catalyst and a preparation method thereof. The catalyst is h-BN(x, t), 1 / 6<=x<=1 / 48, 30min<=t<=50min, x is the proportion of boric acid tourea, and t is microwave heating time. The preparation method includes the steps: sufficiently dissolving the boric acid to the urea by the aid of deionized water, drying mixture into a drying oven, and transferring steamed samples into a mortar to grind the samples; transferring the grinded samples into an aluminum oxide crucible with the volume of 25 milliliters, placing the whole samples into an aluminum oxide crucible with the volume of 50 milliliters, covering the samples by aluminum silicate, placing the samples into an aluminum oxide crucible with the volume of 200 milliliters, coveringthe samples with copper oxide, transferring the samples into a microwave oven to heat the samples for 30-50 minutes to obtain a finished product. The catalyst has good photocatalytic hydrogen production activity and practical application prospects.

Owner:ZHEJIANG NORMAL UNIVERSITY

Cellulose solution prepared with low energy consumption and novel preparation thereof

Owner:DONGHUA UNIV

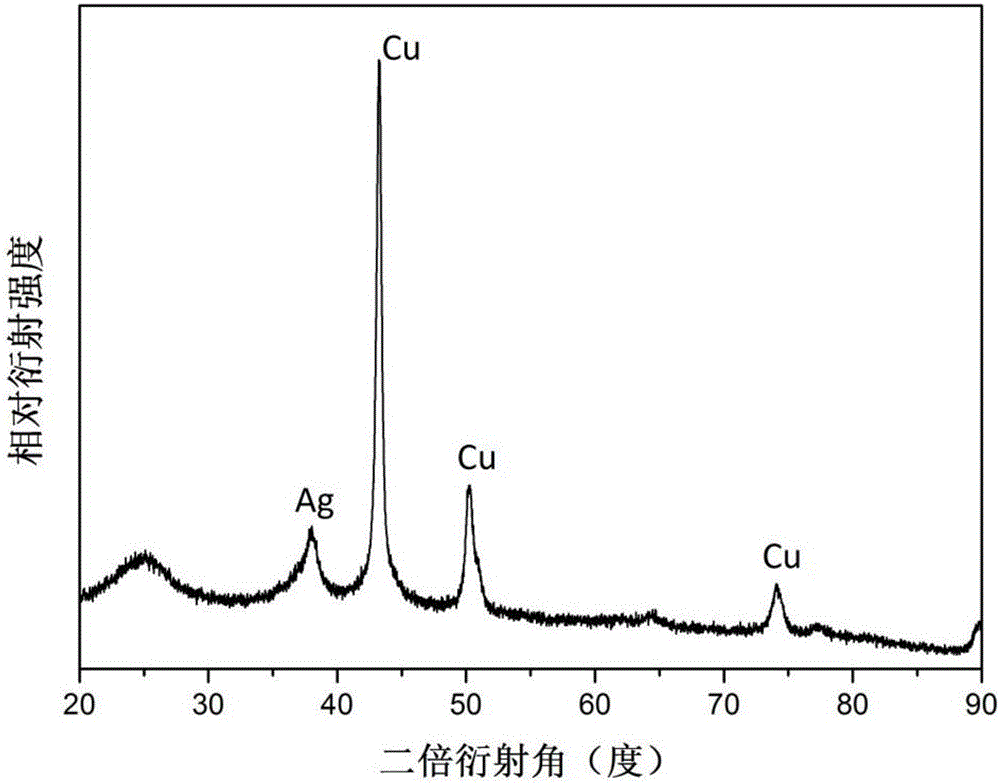

Method for preparing zero-dimension and one-dimension composite material with copper nanowires loaded with silver nanoparticles

ActiveCN106825604AAvoid uneven loadFully exposedMaterial nanotechnologyTransportation and packagingOrganic solventUltrasonic dispersion

The invention discloses a method for preparing a zero-dimension and one-dimension composite material with copper nanowires loaded with silver nanoparticles, and relates to the field of metal nanomaterial preparation. The method includes the following steps that the copper nanowires are subjected to ultrasonic dispersion into organic solvent H so that mixed liquor A can be obtained; a silver source is dissolved into organic solvent O to obtain a solution B; the mixed liquor A is added into the solution B at a normal temperature, ventilation protecting begins, and stirring lasts for 1-20h to obtain mixed liquor C; the mixed liquor C is continuously heated to 50-150 DEG C, and the temperature is kept for 0.5-6h; then the temperature of the mixed liquor C is lowered to an indoor temperature, and ventilation protecting is ended; and afterwards, the mixed liquor C is subjected to centrifugal treatment, products are washed and vacuum-dried, and accordingly the zero-dimension and one-dimension composite material with the copper nanowires loaded with the silver nanoparticles can be obtained. By the adoption of the method, a copper nanowire loaded silver nanoparticle material of the zero-dimension and one-dimension composite structure can be obtained at a normal pressure and at a low temperature, the sizes of the loaded silver nanoparticles are uniform, and the silver nanoparticles are uniformly dispersed onto the surfaces of the copper nanowires so that a heterostructure can be formed.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

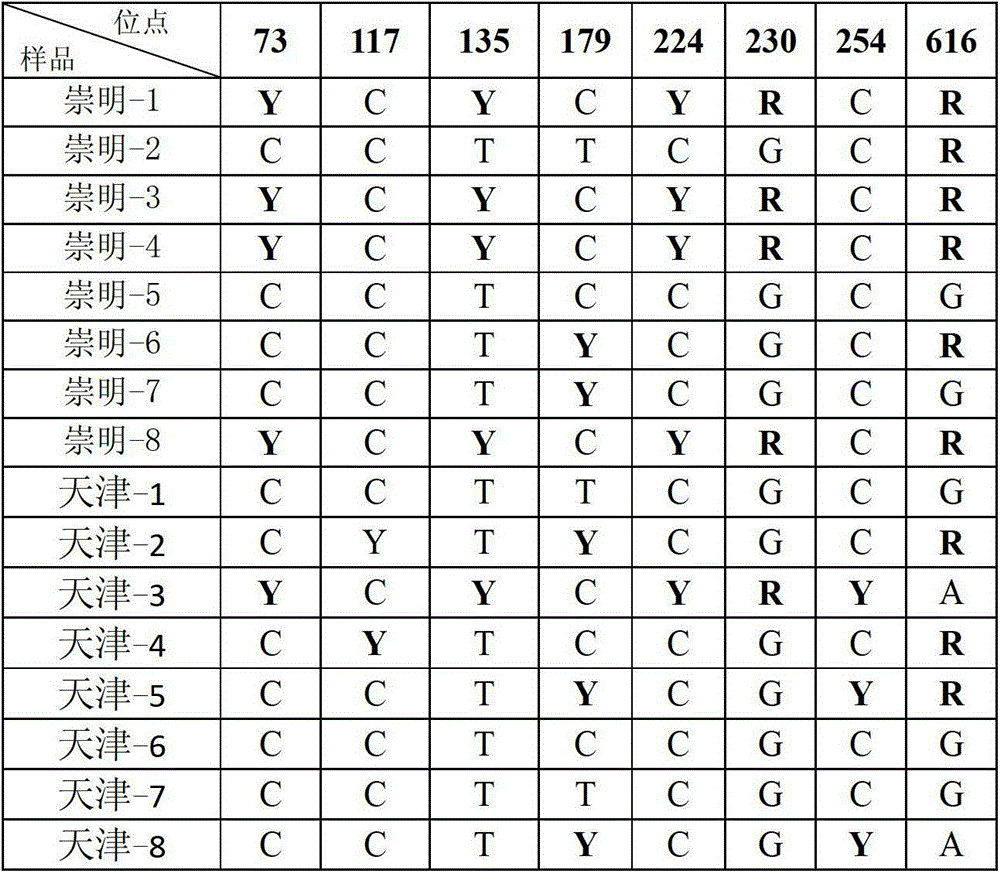

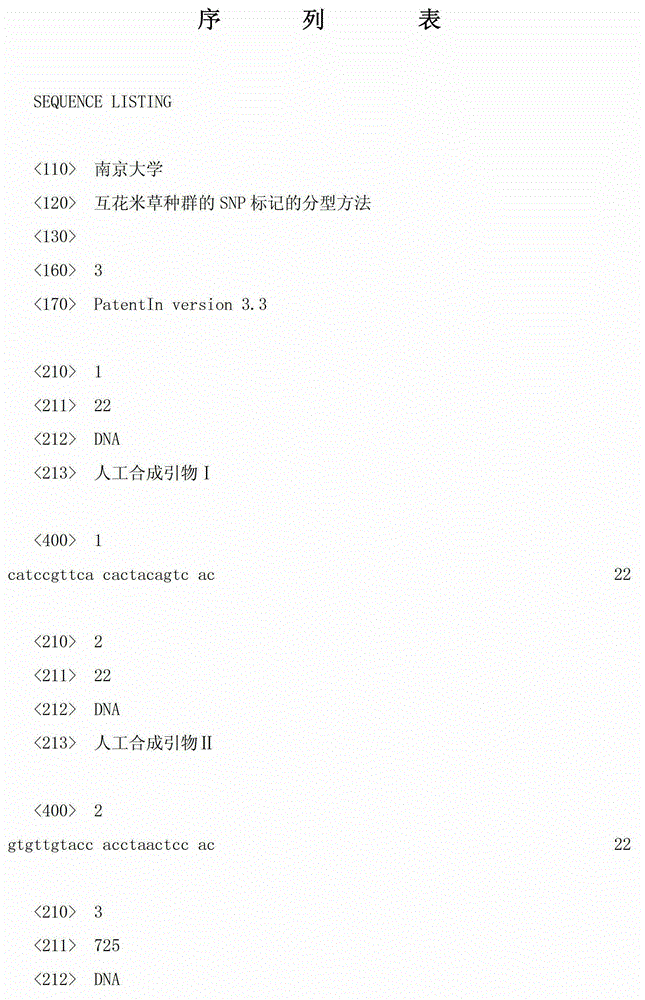

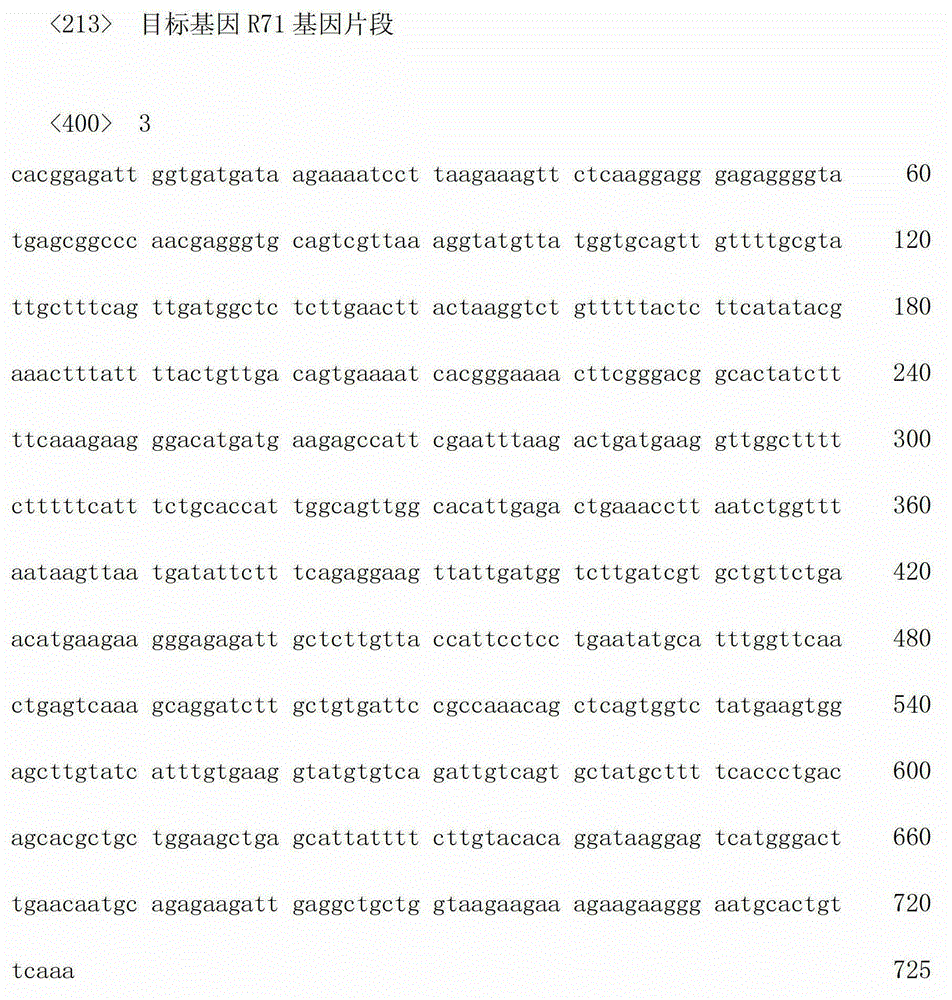

SNP marker based typing method for spartina alterniflora population

InactiveCN103146817AExperimental conditions are simpleIncrease success rateMicrobiological testing/measurementInvasive species monitoringPopulationTyping methods

The invention relates to an SNP (single nucleotide polymorphism) marker based typing method for a spartina alterniflora population. According to the method, a target gene can be screened based on high-throughput transcriptome sequencing, and then by means of a PCR reaction, PCR product sequencing, multiple SNP loci can be obtained. Then, all valid SNP loci compose a haplotype to be used for molecular markers, thus achieving genetic typing. According to the method disclosed in the invention, abundant polymorphic information can be acquired in one experiment. The method provided in the invention has the advantages of genetic stability of SNP markers and simple operation, thus being suitable for species origin tracing.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com