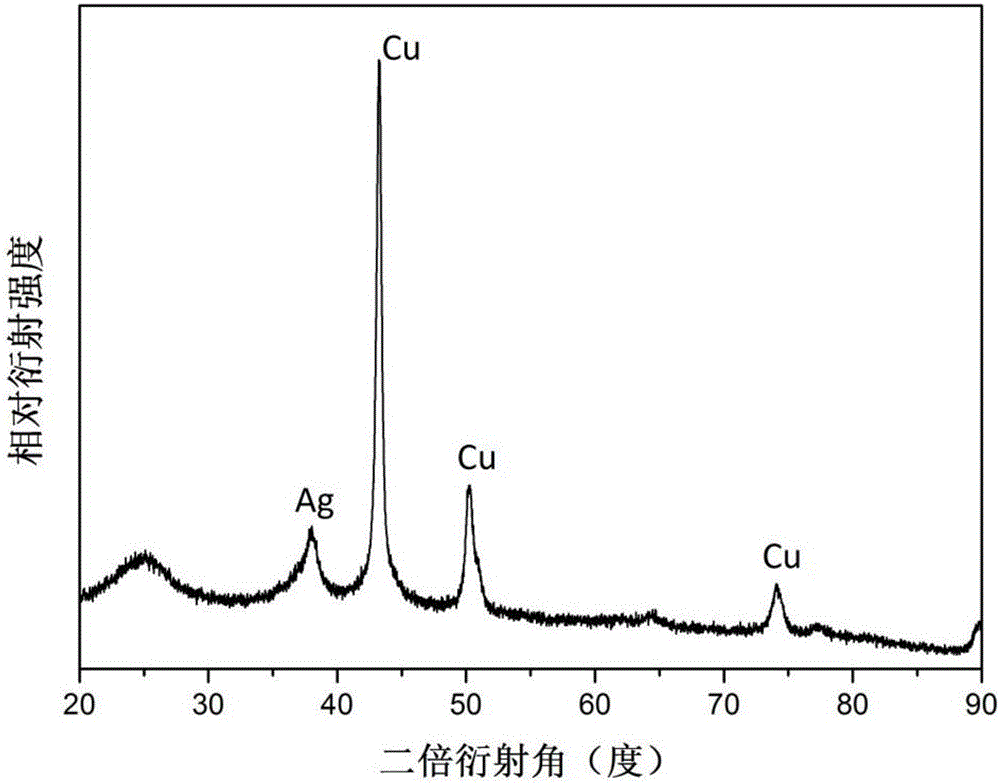

Method for preparing zero-dimension and one-dimension composite material with copper nanowires loaded with silver nanoparticles

A technology of silver nanoparticles and copper nanowires, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of insufficient exposure of the effective catalytic surface and the increase in the amount of precious metal silver, and achieve savings The effect of drugs, good morphology and large effective surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

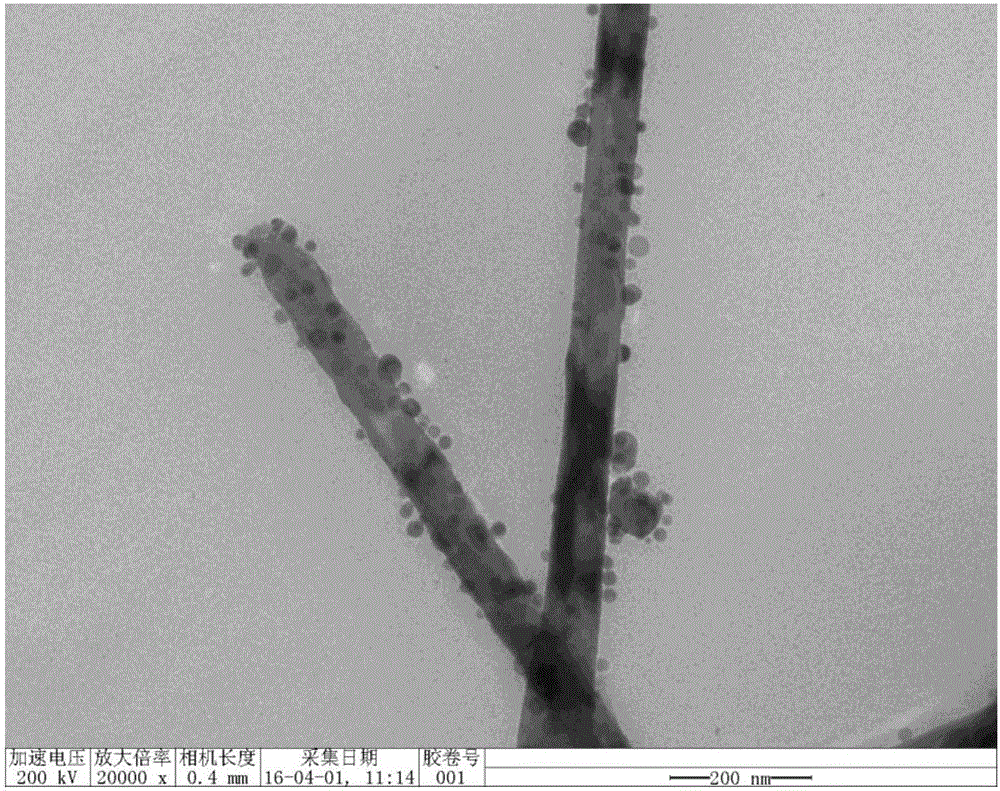

[0032] A method for preparing a zero-dimensional one-dimensional composite material of copper nanowires loaded with silver nanoparticles, comprising the steps of:

[0033] 1) Ultrasonic dispersion of 16 mg of copper nanowires in 6.4 ml of n-hexane to obtain mixed solution A;

[0034] 2) Dissolve 42.47mg of silver nitrate in 8ml of oleylamine under appropriate heating and stirring conditions and then lower it to room temperature to obtain solution B;

[0035] 3) Add the mixed solution A to the solution B at normal temperature, start nitrogen protection, stir for 6 hours, and obtain the mixed solution C;;

[0036] 4) Continue to raise the temperature of the mixed solution C to 80°C, maintain it for 2h, then bring it to room temperature, end the nitrogen protection, then centrifuge the mixed solution C, pour the supernatant liquid, wash the bottom product with n-hexane at least three times, and dry it in vacuum at room temperature, that is A zero-dimensional and one-dimensional ...

Embodiment 2

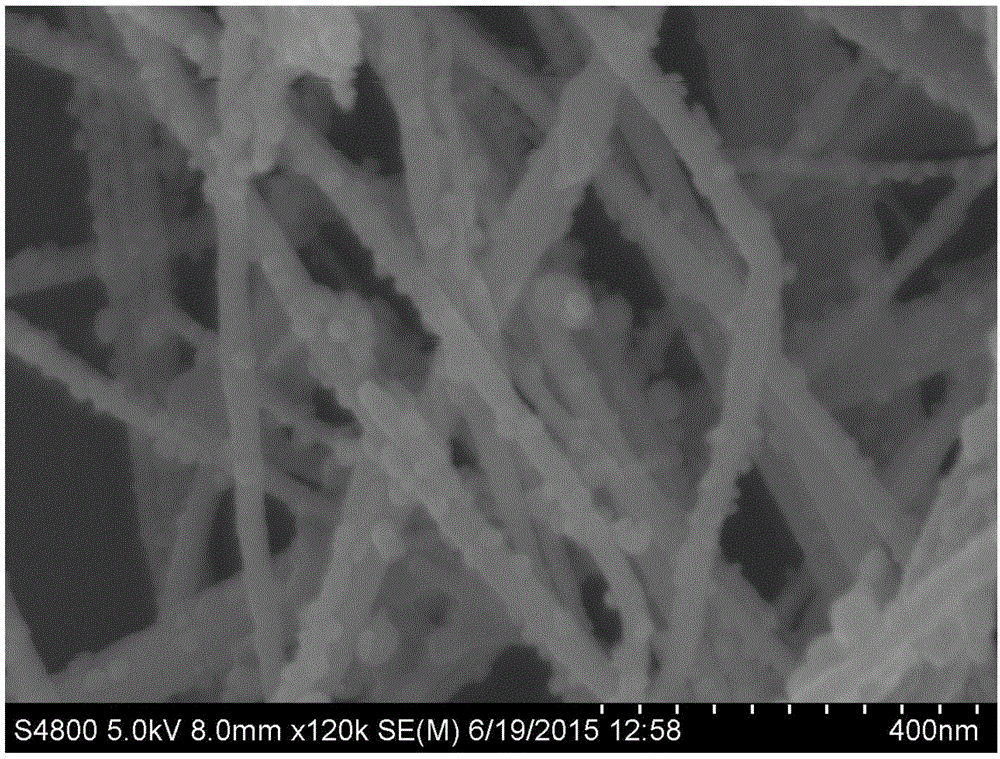

[0041] A method for preparing a zero-dimensional one-dimensional composite material of copper nanowires loaded with silver nanoparticles, comprising the steps of:

[0042] 1) Ultrasonic dispersion of 16 mg of copper nanowires in 6.4 ml of n-hexane to obtain mixed solution A;

[0043] 2) Dissolve 10.61mg of silver nitrate in 8ml of oleylamine under appropriate heating and stirring conditions and then lower it to room temperature to obtain solution B;

[0044]3) Add the mixed solution A to the solution B at normal temperature, start nitrogen protection, stir for 4 hours, and obtain the mixed solution C;;

[0045] 4) Continue to raise the temperature of the mixed solution C to 80°C, maintain it for 2h, then bring it to room temperature, end the nitrogen protection, then centrifuge the mixed solution C, pour the supernatant liquid, wash the bottom product with n-hexane at least three times, and dry it in vacuum at room temperature, that is A zero-dimensional and one-dimensional c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com