Shale compressibility comprehensive evaluation method based on uniaxial strength experiment

A comprehensive evaluation and strength technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem of complex initial damage of shale, extremely developed bedding, heterogeneous composition, nonlinear mechanics, and constraints on shale Gas exploration and development, poor volume fracturing effects, etc., to achieve the effect of convenient data processing, easy operation, simple experimental process, and intuitive and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

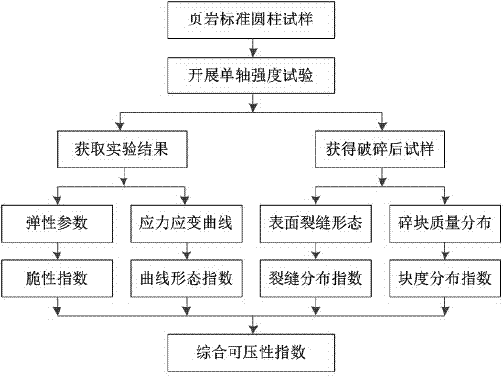

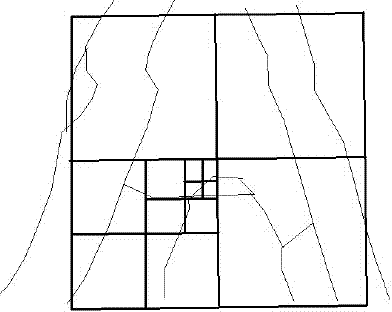

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of shale compressibility comprehensive evaluation method based on uniaxial strength experiment of the present invention, this method comprises the following steps:

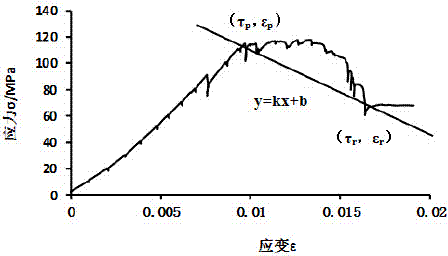

[0022] ① Take the shale core or outcrop sample of the target layer and process it into a standard cylindrical sample with a diameter of 25mm and a height of 40-50mm, grind the end surface, and place it in a servo testing machine for uniaxial compressive strength testing until the sample fails and is destroyed, and record in real time Stress and strain data, record the elastic modulus and Poisson's ratio of the sample, and draw the stress-strain curve.

[0023] ② Calculate the normalized elastic modulus E by combining the measured elastic modulus E and Poisson's ratio v with the elastic modulu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com