Method for determining concentration of phosphite by cyclic voltammetry

A technology of cyclic voltammetry and phosphite, applied in the direction of electrochemical variables of materials, can solve problems such as long time, and achieve the effect of simple experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

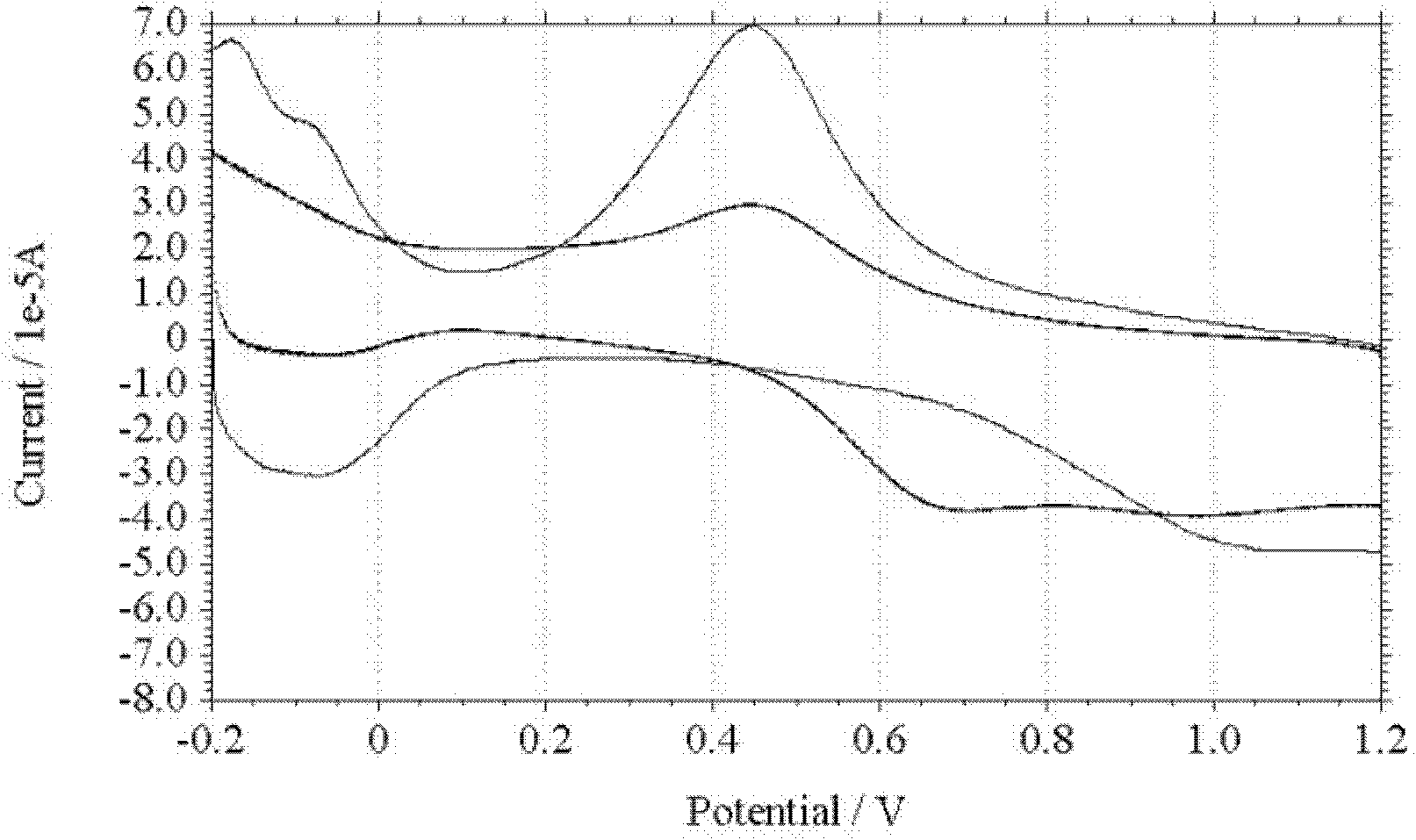

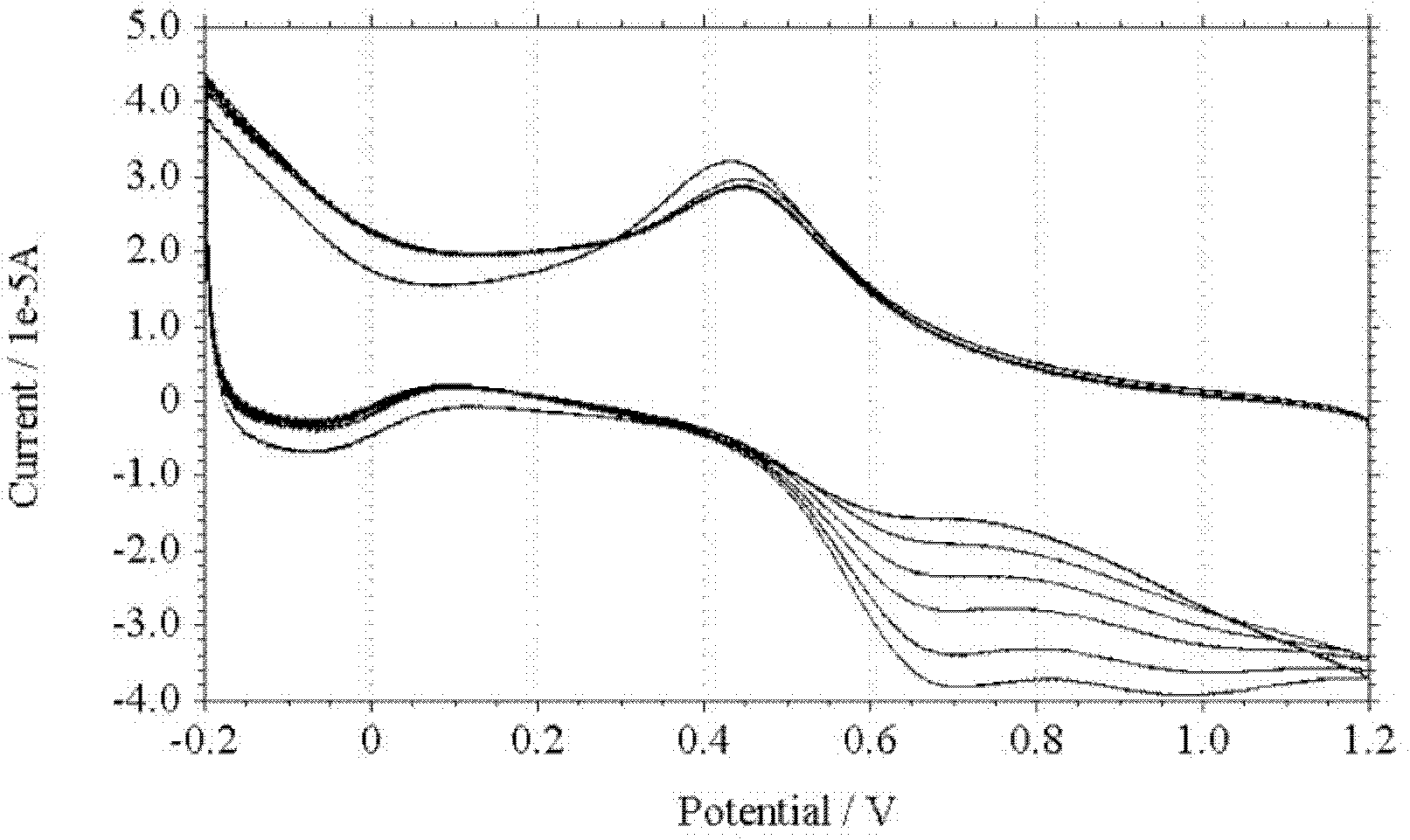

[0023] The method for determining the concentration of phosphite by cyclic voltammetry:

[0024] (1) Configure sulfuric acid solutions (5g / L, 10g / L, 15g / L, 20g / L, 25g / L, 30g / L) containing different concentrations of sodium phosphite as standard solutions, and the concentration of sulfuric acid is 0.5mol / L ;

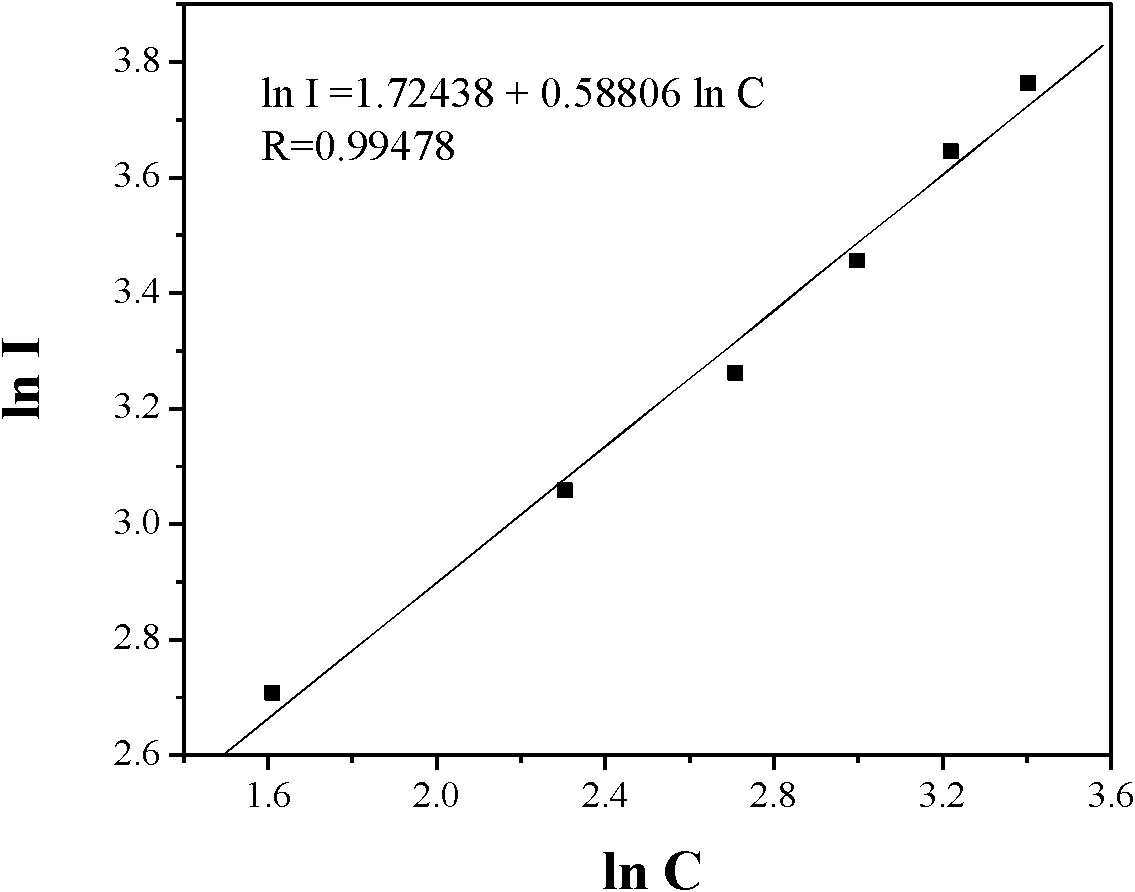

[0025] (2) Utilize the electrochemical workstation to measure the prepared standard solution, the measurement conditions are: the working electrode is a Pt electrode, the auxiliary electrode is a platinum wire, the reference electrode is a saturated calomel electrode, the scanning speed is 500mV / s, and the scanning voltage range is -0.2V~1.2V, scan forward, draw the relationship between the logarithm of the oxidation peak of the phosphite electrode and the logarithm of its concentration (ln I~ln C), establish the working curve, and obtain the linear fitting formula ln I=1.72438+ 0.58806 ln C;

[0026] (3) Dissolve the sample to be tested or its diluted sample in sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com