Photocatalytic hydrogen production catalyst and preparation method thereof

A catalyst and photocatalysis technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as complex equipment and harsh preparation conditions, and achieve simple preparation methods, simple experimental conditions, and good photocatalysis The effect of hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

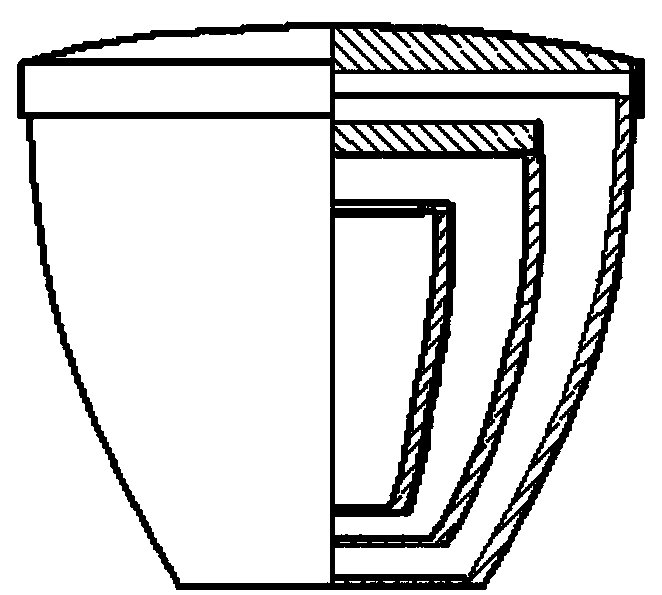

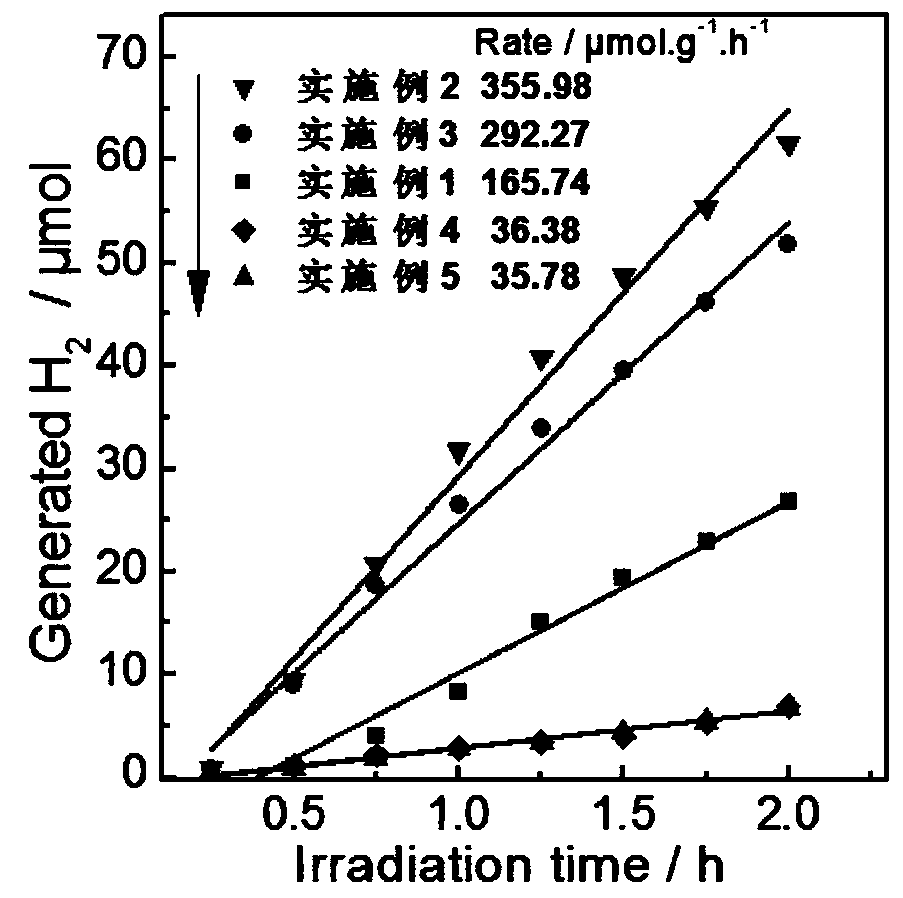

[0022] 8.64g urea and 0.370g boric acid (n 硼酸 :n 尿素 =1:24) was added to 40 ml of deionized water, stirred with a magnetic stirrer at room temperature for 30 minutes to dissolve it, and then the stirred mixture was dried in a 65°C oven for 24 hours, and then the resulting mixture was Move to a mortar and grind for 30 minutes, put the ground mixture into a 25ml alumina crucible, put it as a whole into a 50ml alumina crucible and cover it with aluminum silicate, and finally put 50ml of alumina Put the crucibles into 200ml alumina crucibles and cover them with copper oxide, set of three crucibles see figure 1 , and then heated in a microwave oven for 30 minutes to obtain hexagonal boron nitride with x being 1:24 and t being 30 minutes. Hydrogen production activity see figure 2 165.74μmol·h -1 g -1 ,and Figure 4 Compared with Comparative Example 1 and Comparative Example 2, the hydrogen production activity is obviously superior.

Embodiment 2

[0024] 8.64g urea and 0.370g boric acid (n 硼酸 :n 尿素 =1:24) was added into 40 ml of deionized water, stirred with a magnetic stirrer at room temperature for 30 minutes to dissolve it, then put the stirred mixture into an oven at 65°C for 24 hours, and then moved the resulting mixture to Grind in a mortar for 30 minutes, put the ground mixture into a 25ml alumina crucible, put it as a whole into a 50ml alumina crucible and cover it with aluminum silicate, and finally put the 50ml alumina crucible into into 200 ml alumina crucibles and cover them with copper oxide, set of three crucibles see figure 1 , and then heated in a microwave oven for 35 minutes to obtain hexagonal boron nitride with x being 1:24 and t being 35 minutes. Hydrogen production activity see figure 2 355.98μmol·h -1 g -1 ,and Figure 4 Compared with Comparative Example 1 and Comparative Example 2, the hydrogen production activity is obviously superior. XRD characterization pattern see Figure 5 , by com...

Embodiment 3

[0026] 8.64g urea and 0.370g boric acid (n 硼酸 :n 尿素 =1:24) into 40 ml of deionized water, stirred with a magnetic stirrer at room temperature for 30 minutes to dissolve, then put the stirred mixture into a 65°C oven for 24 hours, and then moved the resulting mixture to Grind in a mortar for 30 minutes, put the ground mixture into a 25ml alumina crucible, put it as a whole into a 50ml alumina crucible and cover it with aluminum silicate, and finally put the 50ml alumina crucible into into 200 ml alumina crucibles and cover them with copper oxide, set of three crucibles see figure 1 , and then heated in a microwave oven for 40 minutes to obtain hexagonal boron nitride with x being 1:24 and t being 40 minutes. Hydrogen production activity see figure 2 292.27μmol·h -1 g -1 ,and Figure 4 Compared with Comparative Example 1 and Comparative Example 2, the hydrogen production activity is obviously superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com