CdS/NiS2 block photocatalyst, preparation method and application thereof

A photocatalyst and block technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of scarcity and high cost of precious metals, and achieve a short preparation period, good cycle stability, and enhanced absorption. and utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

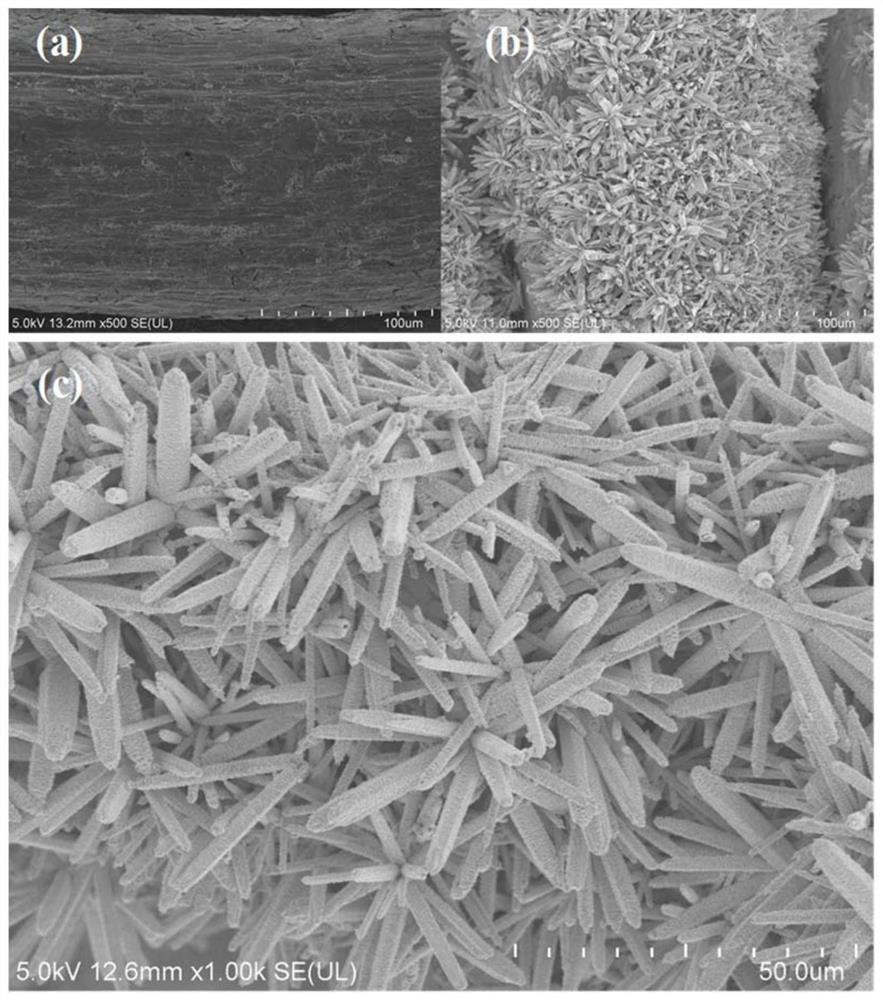

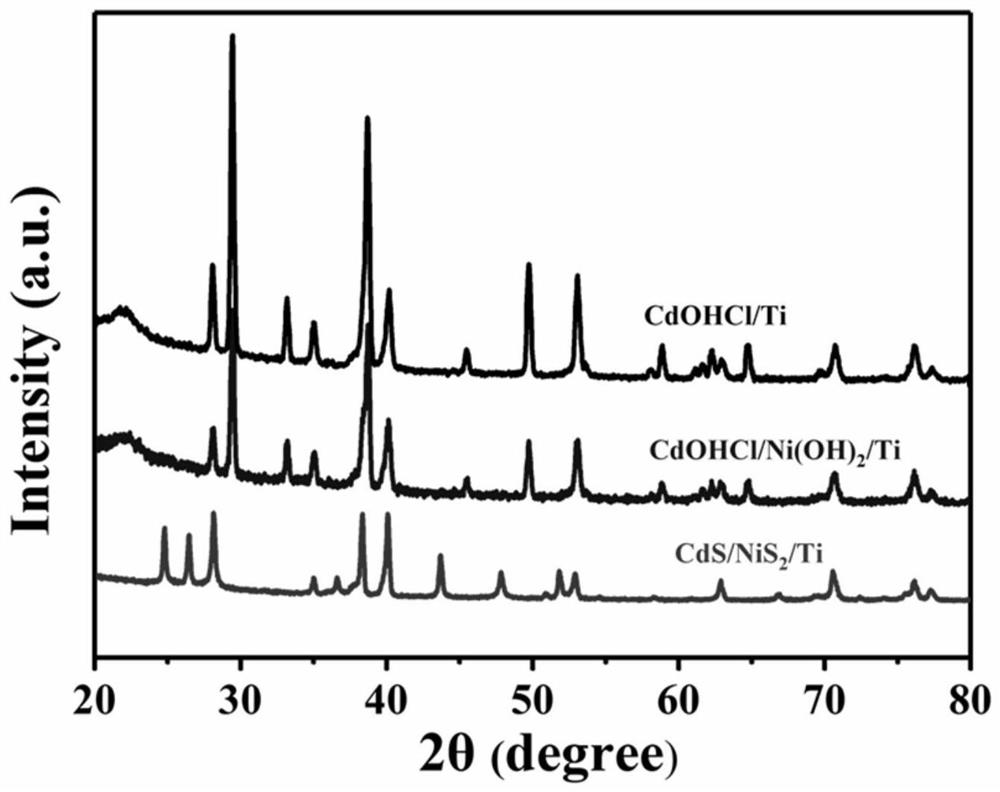

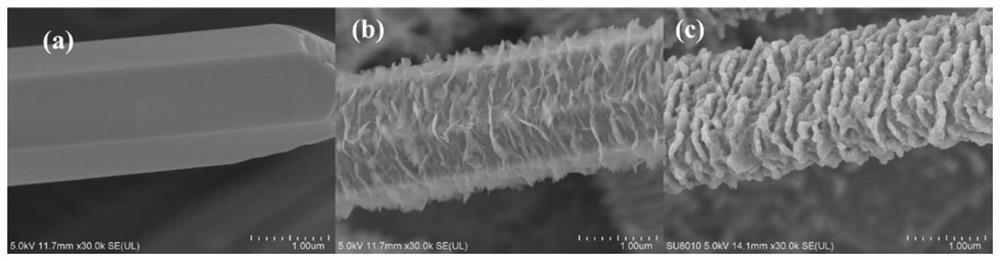

[0062] A CdS / NiS 2 A method for preparing a bulk photocatalytic material, comprising the following steps:

[0063] (1) Clean the titanium mesh with a size of 30mm*25mm (effective area 20mm*25mm) with 1mol / L hydrochloric acid, deionized water and absolute ethanol for 10 minutes respectively.

[0064] (2) Prepare 30 mL of a mixed solution of 0.1 mol / L cadmium chloride and 0.01 mol / L hexamethylenetetramine.

[0065] (3) Soak the titanium mesh in step (1) in the mixed solution in step (2), transfer it to a hydrothermal kettle with a polytetrafluoroethylene liner and seal it, and react at 100°C for 8 After cooling down to room temperature naturally, the samples were taken out, rinsed with deionized water and dried in a vacuum oven.

[0066] (4) Soak the sample in step (3) in 30mL of the aqueous solution prepared by dissolving 0.0008mol / L nickel nitrate hexahydrate and 0.01mol / L hexamethylenetetramine in deionized water, and transfer to the solution containing Packaged in a polyt...

Embodiment 2

[0069] A CdS / NiS 2 A method for preparing a bulk photocatalytic material, comprising the following steps:

[0070](1) Clean the titanium mesh with a size of 30mm*25mm (effective area 20mm*25mm) with 1mol / L hydrochloric acid, deionized water and absolute ethanol for 10 minutes respectively.

[0071] (2) Prepare 30 mL of a mixed solution of 0.1 mol / L cadmium chloride and 0.01 mol / L hexamethylenetetramine.

[0072] (3) Soak the titanium mesh in step (1) in the mixed solution in step (2), transfer it to a hydrothermal kettle with a polytetrafluoroethylene liner and seal it, and react at 100°C for 8 After cooling down to room temperature naturally, the samples were taken out, rinsed with deionized water and dried in a vacuum oven.

[0073] (4) Soak the sample in step (3) in 30mL of an aqueous solution prepared by dissolving 0.0002mol / L nickel nitrate hexahydrate and 0.01mol / L hexamethylenetetramine in deionized water, and transfer to the solution containing Packaged in a polytet...

Embodiment 3

[0076] A CdS / NiS 2 A method for preparing a bulk photocatalytic material, comprising the following steps:

[0077] (1) Clean the titanium mesh with a size of 30mm*25mm (effective area 20mm*25mm) with 1mol / L hydrochloric acid, deionized water and absolute ethanol for 10 minutes respectively.

[0078] (2) Prepare 30 mL of a mixed solution of 0.1 mol / L cadmium chloride and 0.01 mol / L hexamethylenetetramine.

[0079] (3) Soak the titanium mesh in step (1) in the mixed solution in step (2), transfer it to a hydrothermal kettle with a polytetrafluoroethylene liner and seal it, and react at 100°C for 8 After cooling down to room temperature naturally, the samples were taken out, rinsed with deionized water and dried in a vacuum oven.

[0080] (4) Soak the sample in step (3) in 30mL of an aqueous solution prepared by dissolving 0.0004mol / L nickel nitrate hexahydrate and 0.01mol / L hexamethylenetetramine in deionized water, and transfer to the solution containing Packaged in a polyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com