Intermittent industrial process online quality prediction method based on JY-MKPLS

A quality prediction, industrial process technology, applied in program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as low modeling efficiency, scarcity of process data, slowing down the speed of production operation optimization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

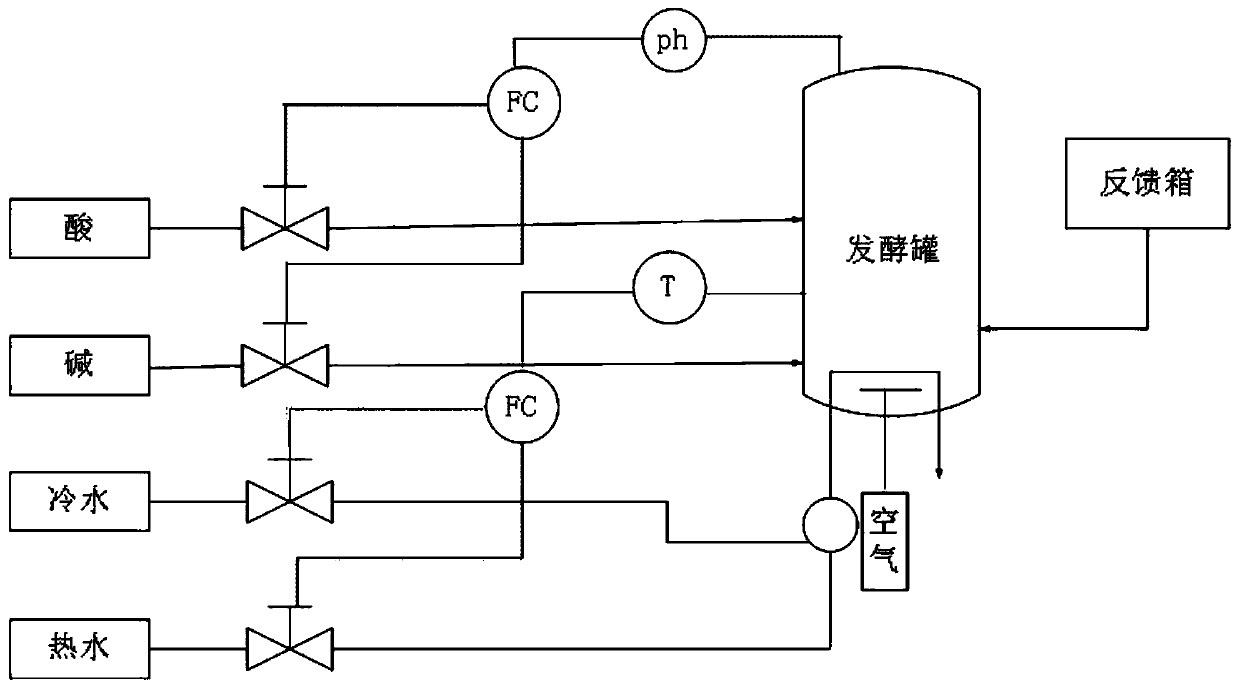

[0054] Such as Figure 5 As shown, the present invention provides a method for online quality prediction of batch industrial processes based on JY-MKPLS, including two sets of identical production equipment, and the internal parameter settings of the two sets of production equipment are different; one set is newly put into production The production equipment has the a process, and the other is the production equipment that has been put into production, which has the b process; the a process is a batch process that is newly put into production, and its production time is short and the data is less, and the b process has been put into production A similar old batch process for a period of time, with sufficient data; both process a and process b have J process variables, and there are K sampling time points in each batch; for process a and process b, I batches are collected to obtain Typical batch process 3D input data X∈R I×J×K and the output data matrix is Y∈R I×K ;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com