Patents

Literature

210 results about "Hydrogen technologies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen technologies are technologies that relate to the production and use of hydrogen. Hydrogen technologies are applicable for many uses. Some hydrogen technologies are carbon neutral and could have a role in preventing climate change and a possible future hydrogen economy. Hydrogen is a chemical widely used in various applications including ammonia production, oil refining and energy. Hydrogen is not a primary energy source, because it is not naturally occurring as a fuel. It is, however, widely regarded as an ideal energy storage medium, due to the ease with which electric power can convert water into its hydrogen and oxygen components through electrolysis and can be converted back to electrical power using a fuel cell. There are a wide number of different types of fuel and electrolysis cells.

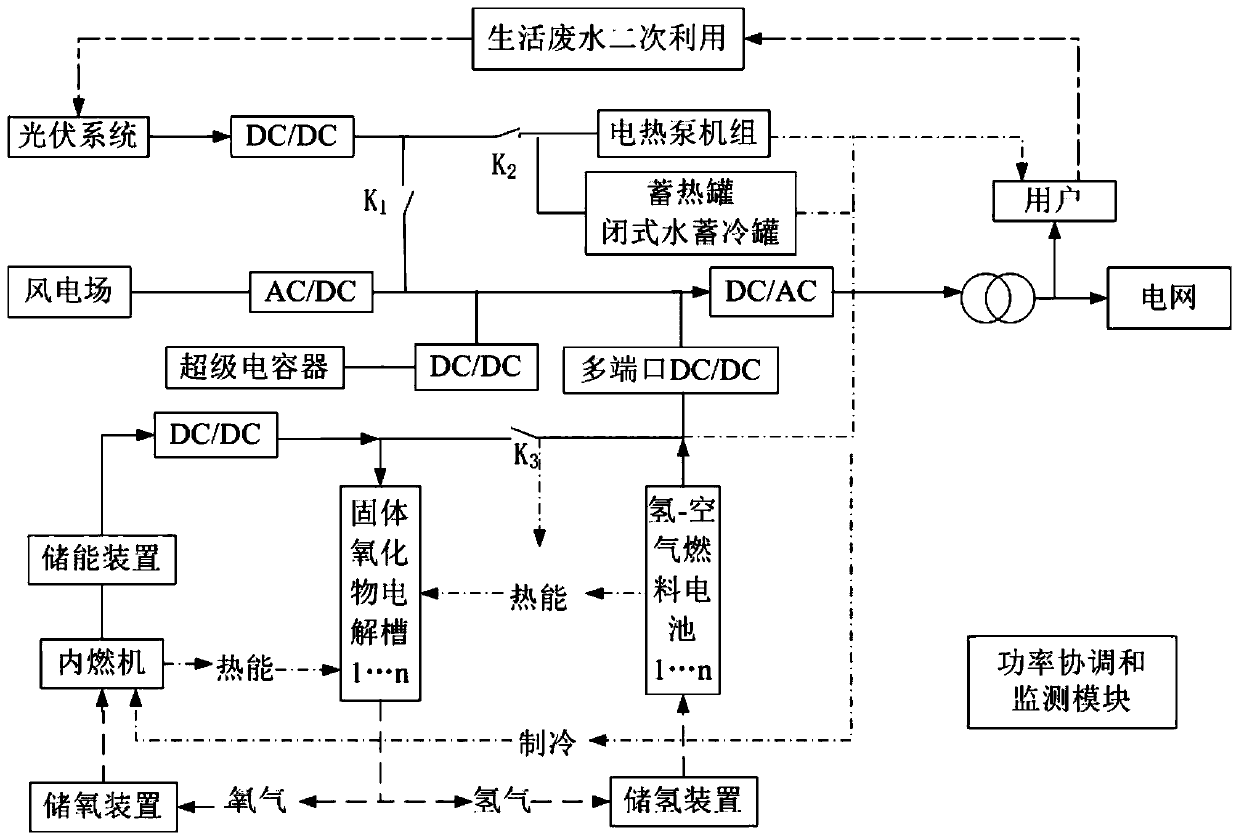

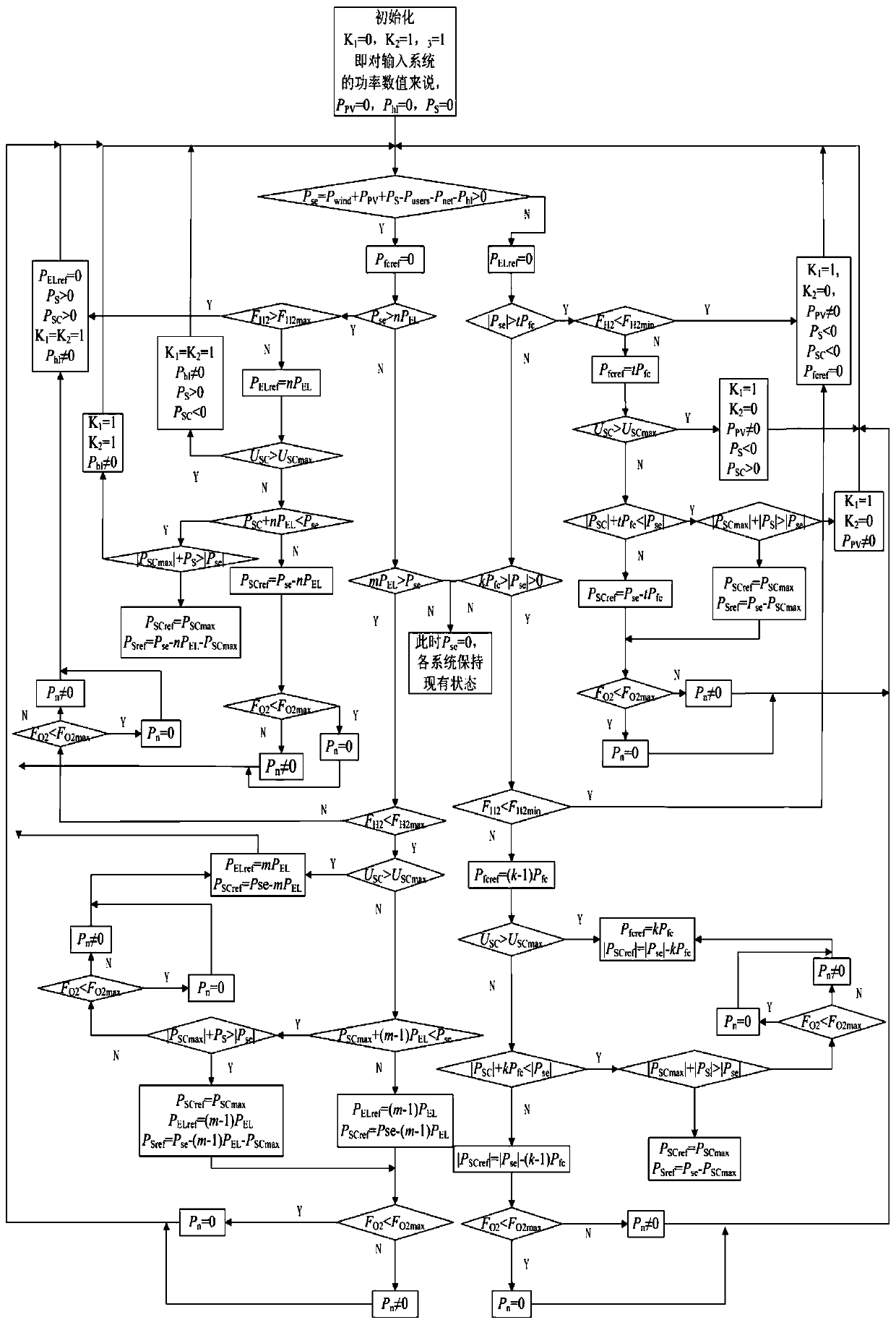

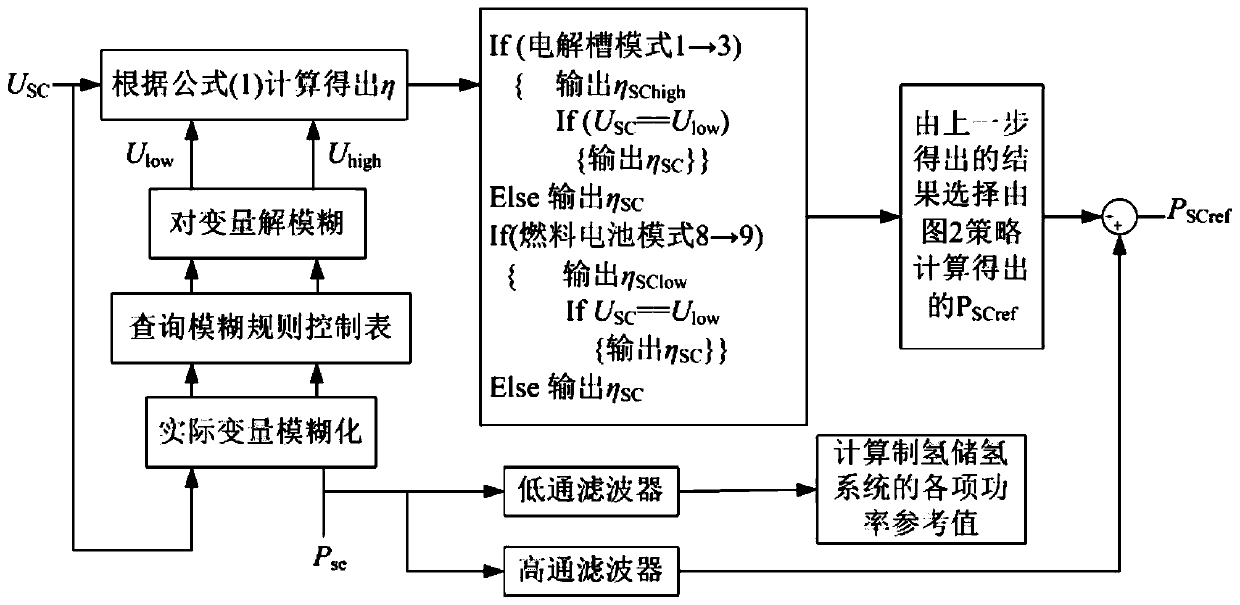

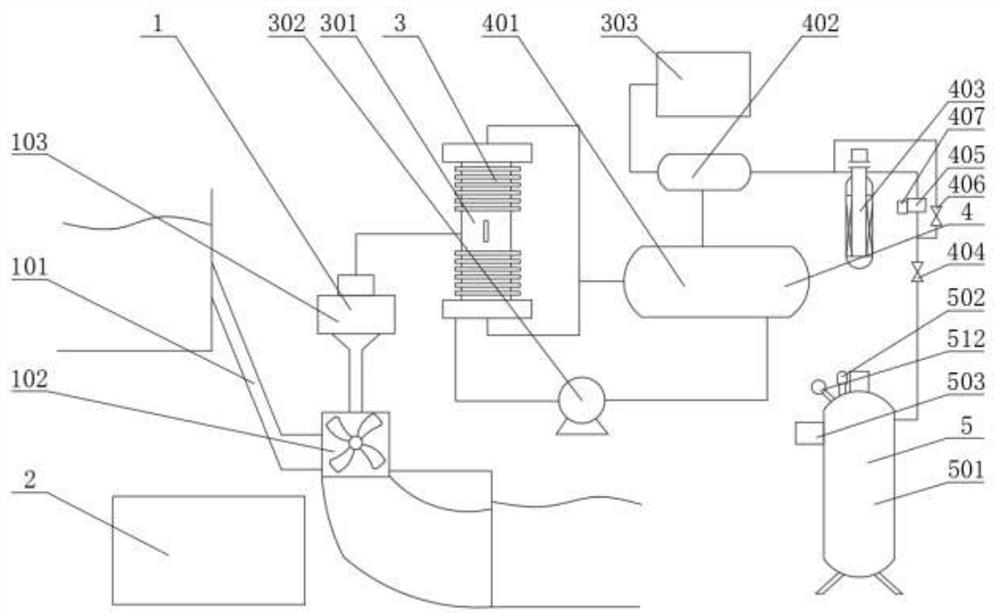

Wind-solar power generation and hydrogen-production hydrogen-storage system and operation control method thereof

ActiveCN109755965AIncrease profitSolve the requirements of evening peak loadBatteries circuit arrangementsSingle network parallel feeding arrangementsHydrogen productionGrid connection

The invention relates to a wind-solar power generation and hydrogen-production hydrogen-storage system and an operation control method thereof, and relates to the technical field of new energy wind-solar power generation and hydrogen production. According to the invention, a rectifier at a fan side of a wind power farm is connected with a grid side inverter; a DC (Direct Current) bus is connectedwith a supercapacitor of a DC / DC convertor; the rear surface of the supercapacitor is connected with a hydrogen production and hydrogen storage system; a photovoltaic system is connected with the DC bus in front of the supercapacitor by the DC / DC convertor and is used as a power compensation unit of the wind power farm; the wind-solar power generation and hydrogen-production hydrogen-storage system further comprises a power coordination control module and a monitoring module; and problems of poor peak regulation capacity, unsmooth hydrogen production, short service life of equipment and the like of a wind-solar power generation and hydrogen-production hydrogen-storage system are mainly solved. The wind-solar power generation and hydrogen-production hydrogen-storage system has the characteristics that the system is high in peak regulation capacity; the requirement of a load evening peak can be met; smooth hydrogen production can be ensured; the service life of the equipment is prolonged; flexible grid connection can be implemented in the premise of ensuring purity of produced hydrogen; and an energy utilization rate is high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

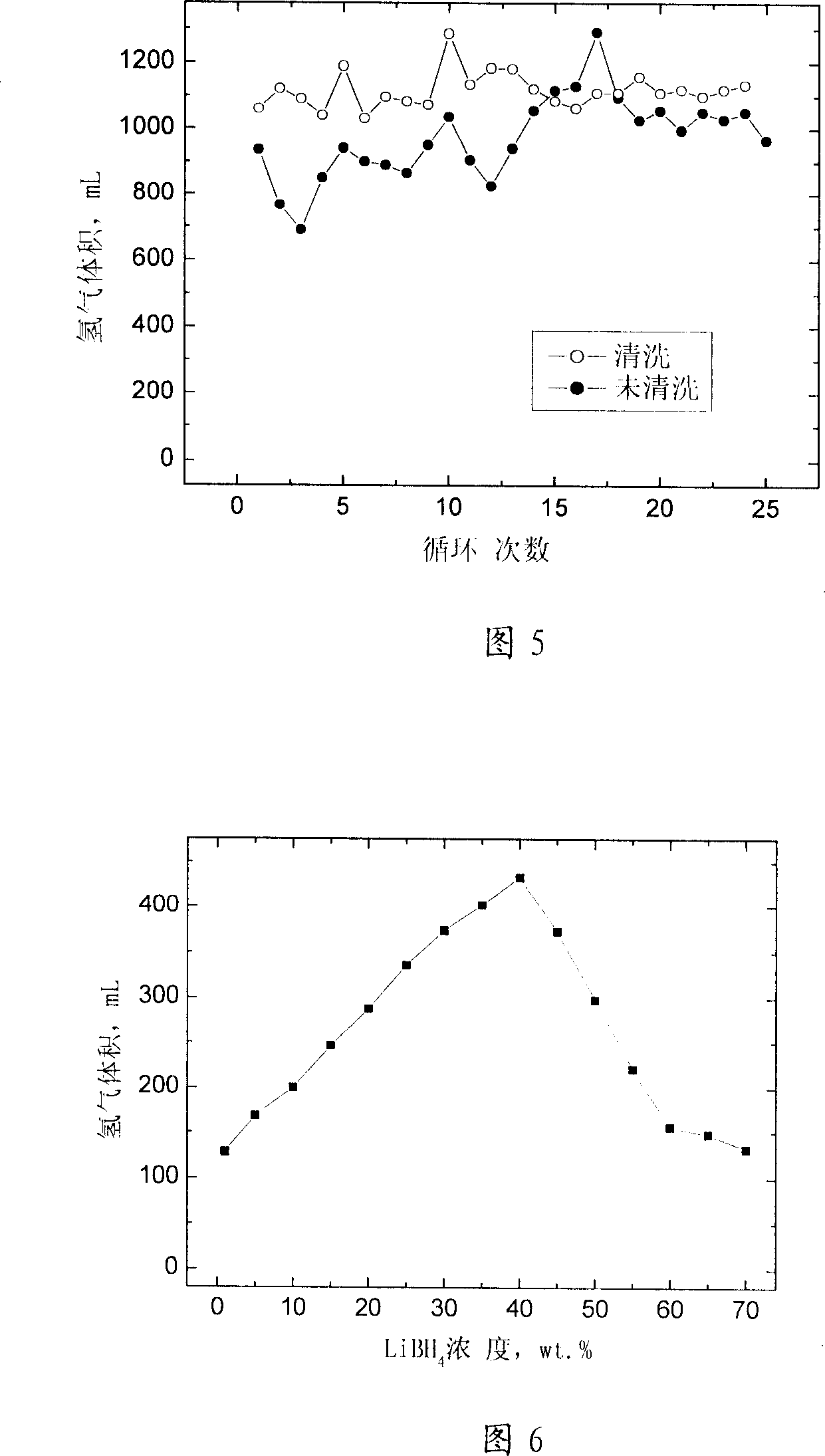

Method for generating hydrogen through lithium borohydride-porous carbon hydrolysis and reaction system

InactiveCN101841048AReduce volumeHigh hydrogen release efficiencyFuel cell detailsLiquid waterChemistry

The invention relates to a method for generating hydrogen through lithium borohydride-porous carbon hydrolysis, and a reaction system, which belongs to a hydrogen producing-storing technique for fuel cell hydrogen sources. The method is characterized in that hydrolysis material is prepared by mechanically ball-milling LiBH4 and porous carbon material, and the influent water rate of liquid water reacting with the hydrolysis material and the saturated steam pressure of steam are controlled so as to effectively control the hydrogen-releasing amount, hydrogen-releasing speed and the like of reaction. The method precisely combines hydrolysis hydrogen production with a hydrogen production system, and the hydrolysis hydrogen production system needs no catalyst for acceleration, can continuously and stably release hydrogen, and is convenient to control and higher in hydrogen-releasing efficiency than a NaBH4 hydrolysis hydrogen production system. The method completely meets the requirements of hydrogen fuel cells for hydrogen sources. The application of the technique of the invention has important and profound significance for promoting the progress of industries related to new energy, achieving the aim of saving energy and reducing emission and promoting economic development.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

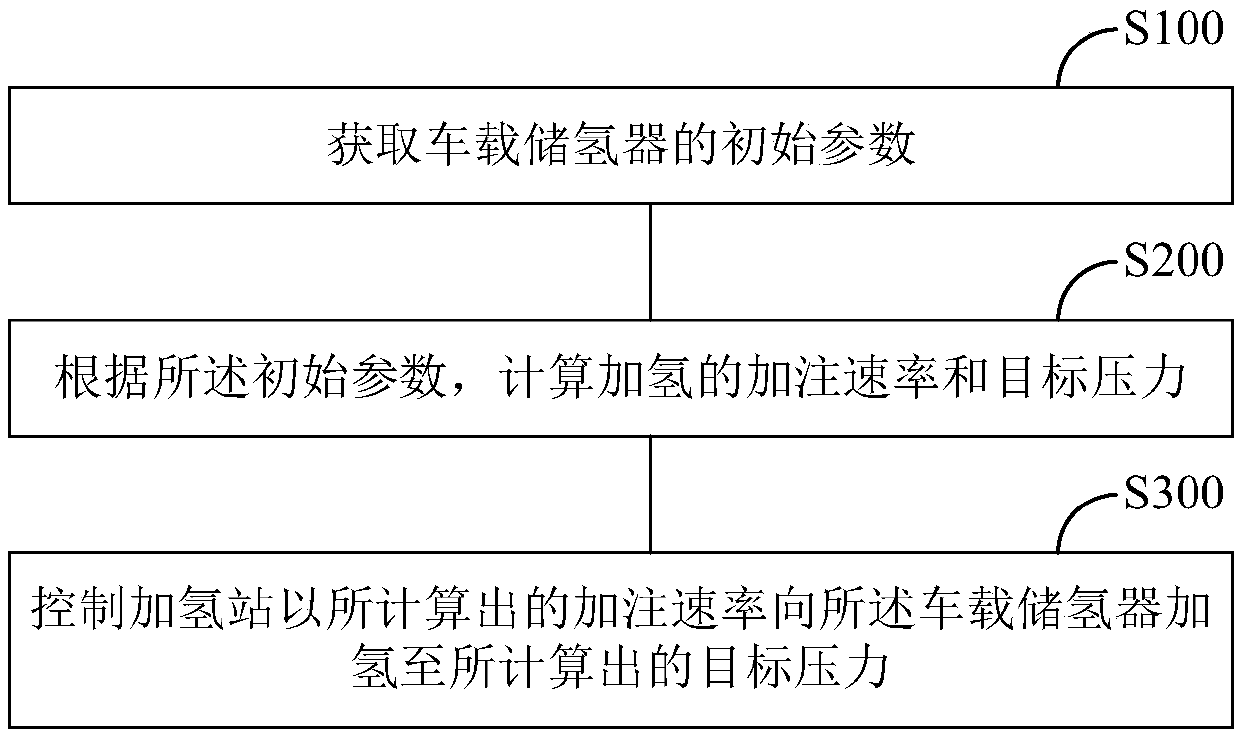

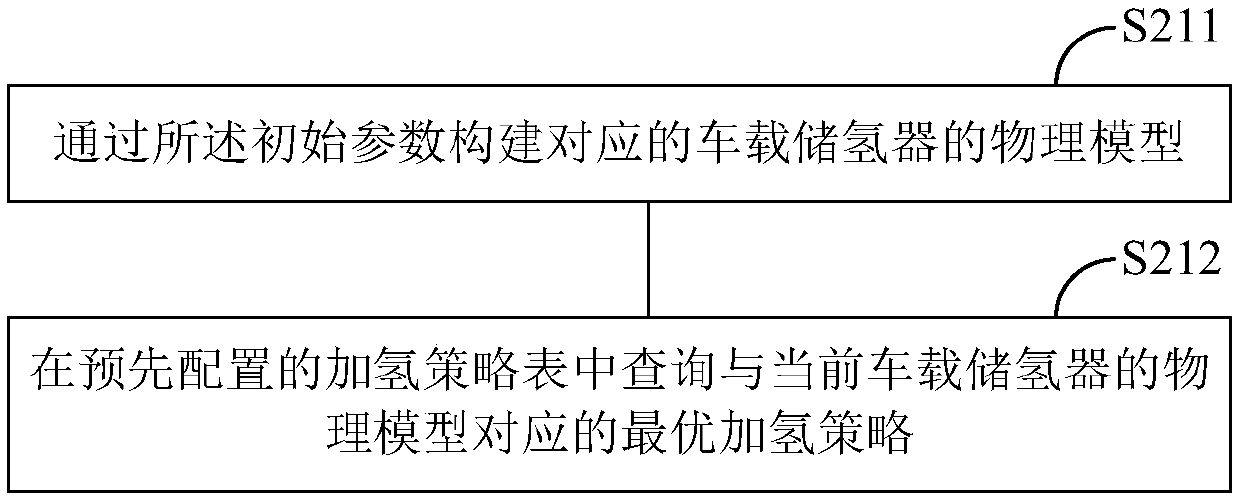

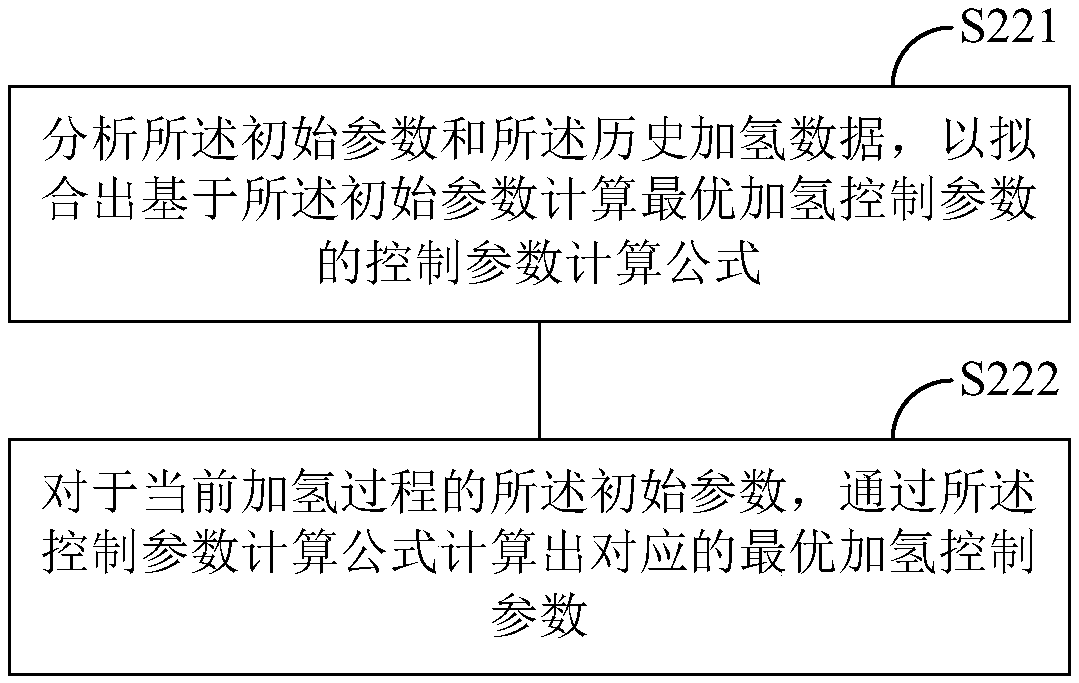

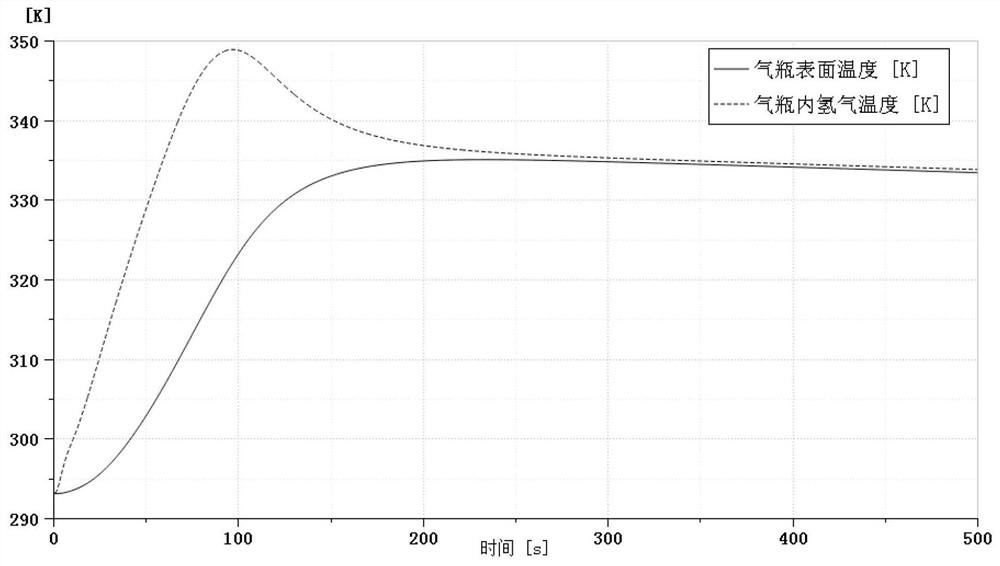

Hydrogenation control device and method

PendingCN110939859ASimple processEasy to implementVessel mounting detailsGas handling applicationsThermodynamicsIn vehicle

The invention provides a hydrogenation control device and method, and belongs to the technical field of hydrogenation. The hydrogenation control method comprises the steps of obtaining the initial parameters of a vehicle-mounted hydrogen storage device, wherein the initial parameters comprise the volume of the vehicle-mounted hydrogen storage device, initial hydrogen pressure and initial environment temperature; according to the initial parameters, calculating the filling rate and target pressure of hydrogenation, wherein the calculated filling rate and target pressure enable the hydrogen temperature in the hydrogenation pressure to be in a preset safety range; and controlling a hydrogenation station to hydrogenate the vehicle-mounted hydrogen storage device to the calculated target pressure at the calculated filling rate. The hydrogenation control device and method do not need the real-time communication between the hydrogenation station and a vehicle, and controls the filling processby obtaining the filling rate and the target pressure through the initial parameters of the vehicle-mounted hydrogen storage device measured by the hydrogenation station. The process is simple and easy to implement, and the reliability of hydrogenation process is ensured.

Owner:NAT INST OF CLEAN AND LOW CARBON ENERGY

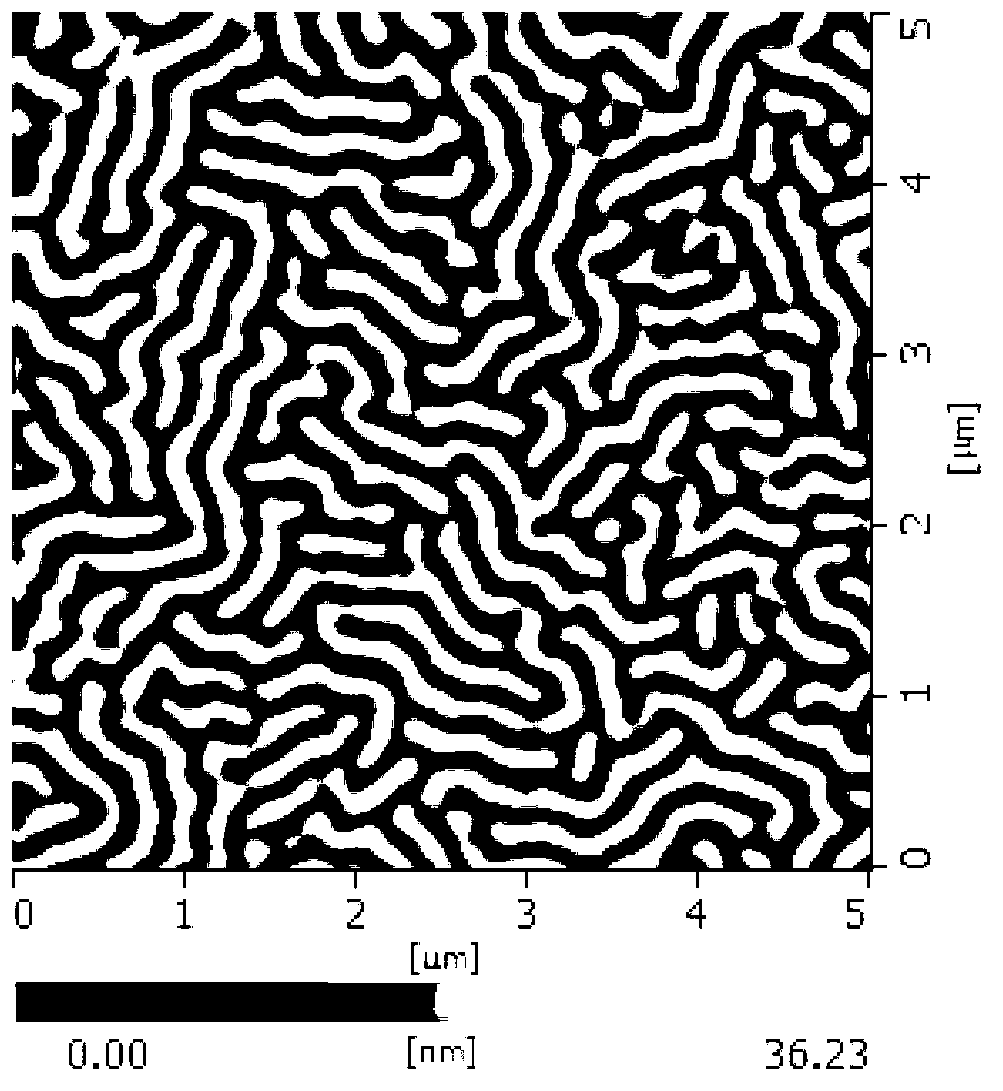

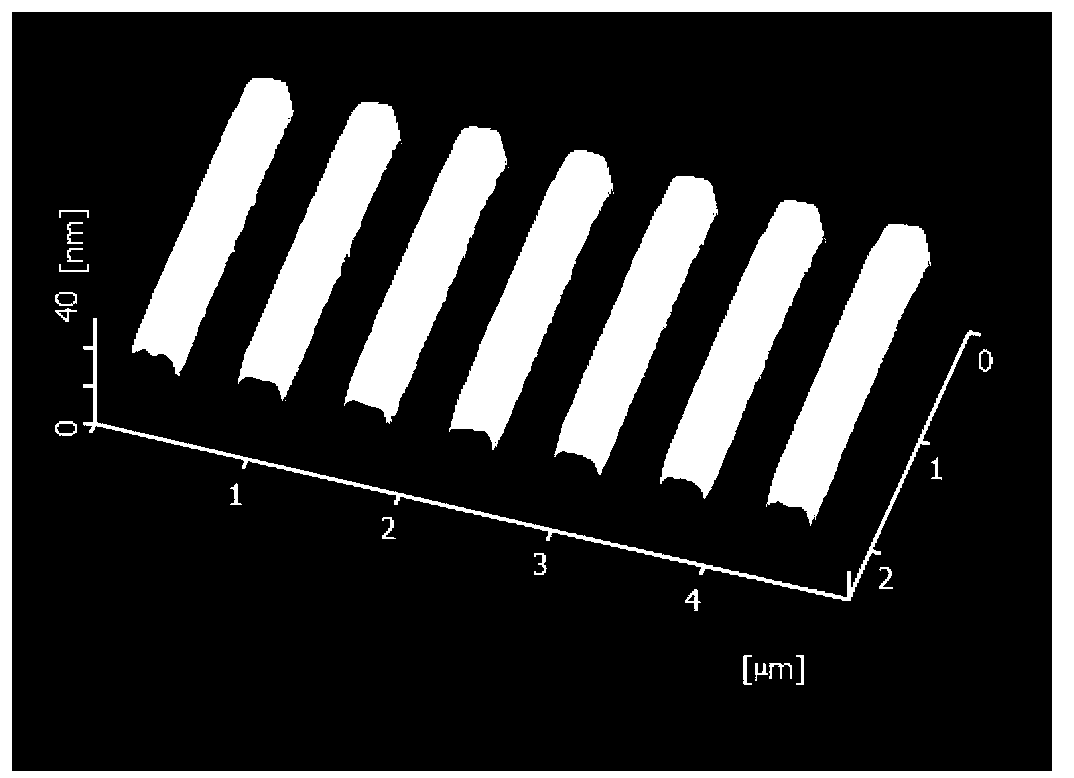

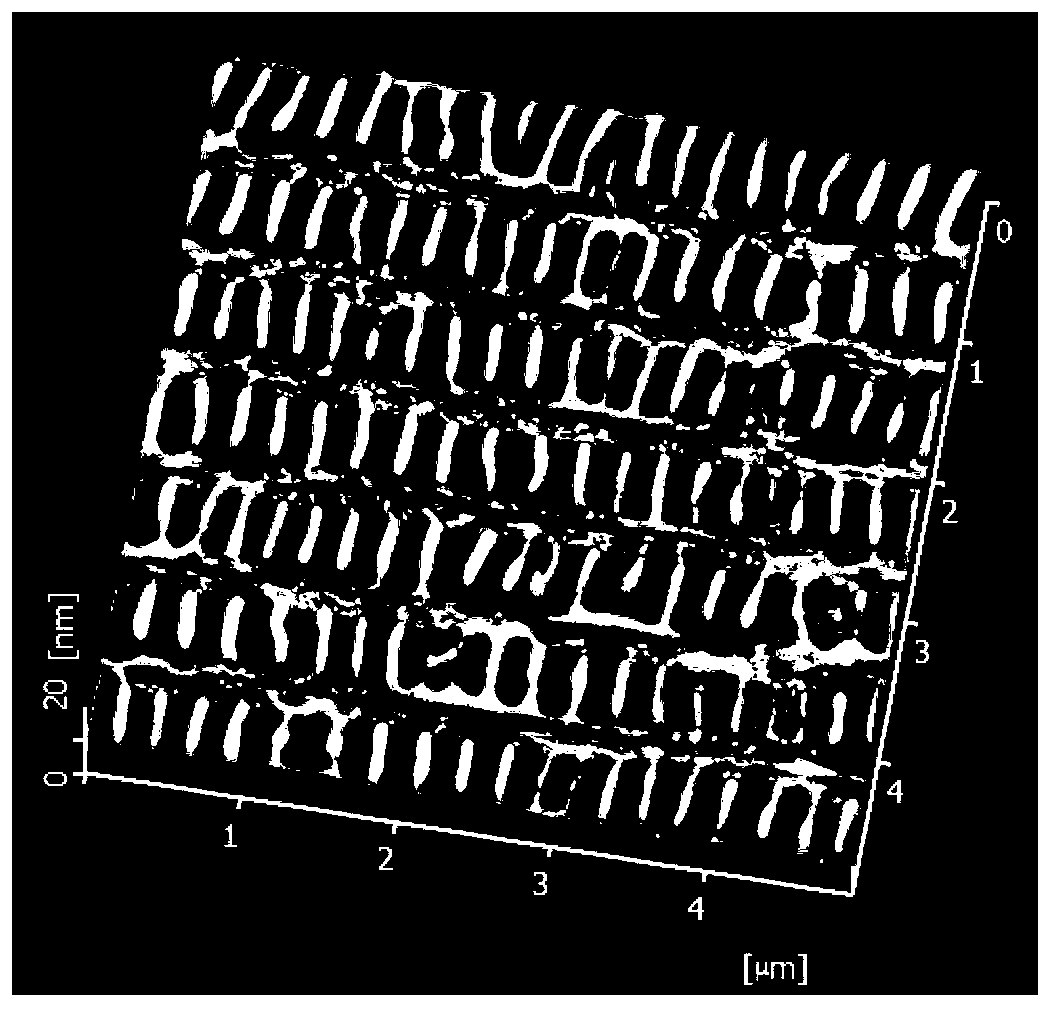

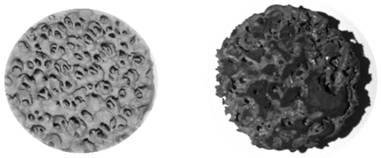

Method for preparing macromolecule ultrathin membrane nano wrinkling patterns

The invention discloses a method for preparing macromolecule ultrathin membrane nano wrinkling patterns. The method comprises the following steps of: step one, adding a corresponding solvent into a polymer to prepare a 1-4wt% solution, then performing ultrasonic treatment to accelerate dissolution, and sealing a reagent bottle for later use after completely dissolving; step two, forming a membrane by using a spin-coating method with the prepared solution, and at last, standing for 24 hours so as to completely volatilize the solvent; step three, processing the spin-coated single-layer polymer membrane by using a hyperthermal-hydrogen technology to induce the upper layer of the polymer to crosslink; step four, performing thermal annealing treatment, and taking out a sample after annealing to freely cool at a room temperature so as to obtain a wrinkling pattern. According to the method, the hyperthermal-hydrogen technology is adopted for inducing crosslinking, the method is effective on most polymer systems, only the polymer systems need to contain C-H keys, so a method for ultrathin membrane wrinkling, which is widely applicable to the polymer systems, is provided, and the method ensures that the surface functional groups of a material are not damaged.

Owner:SICHUAN UNIV

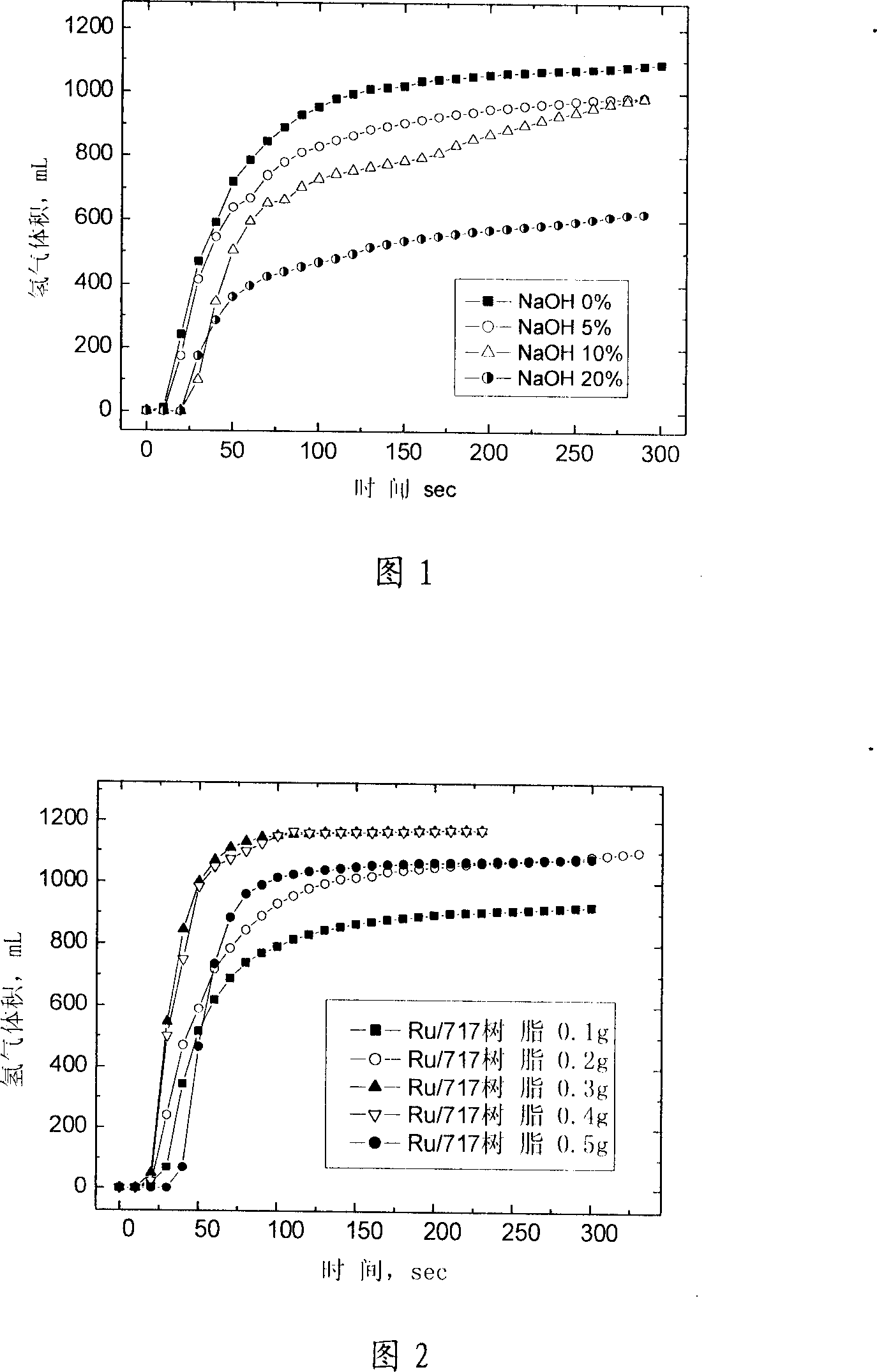

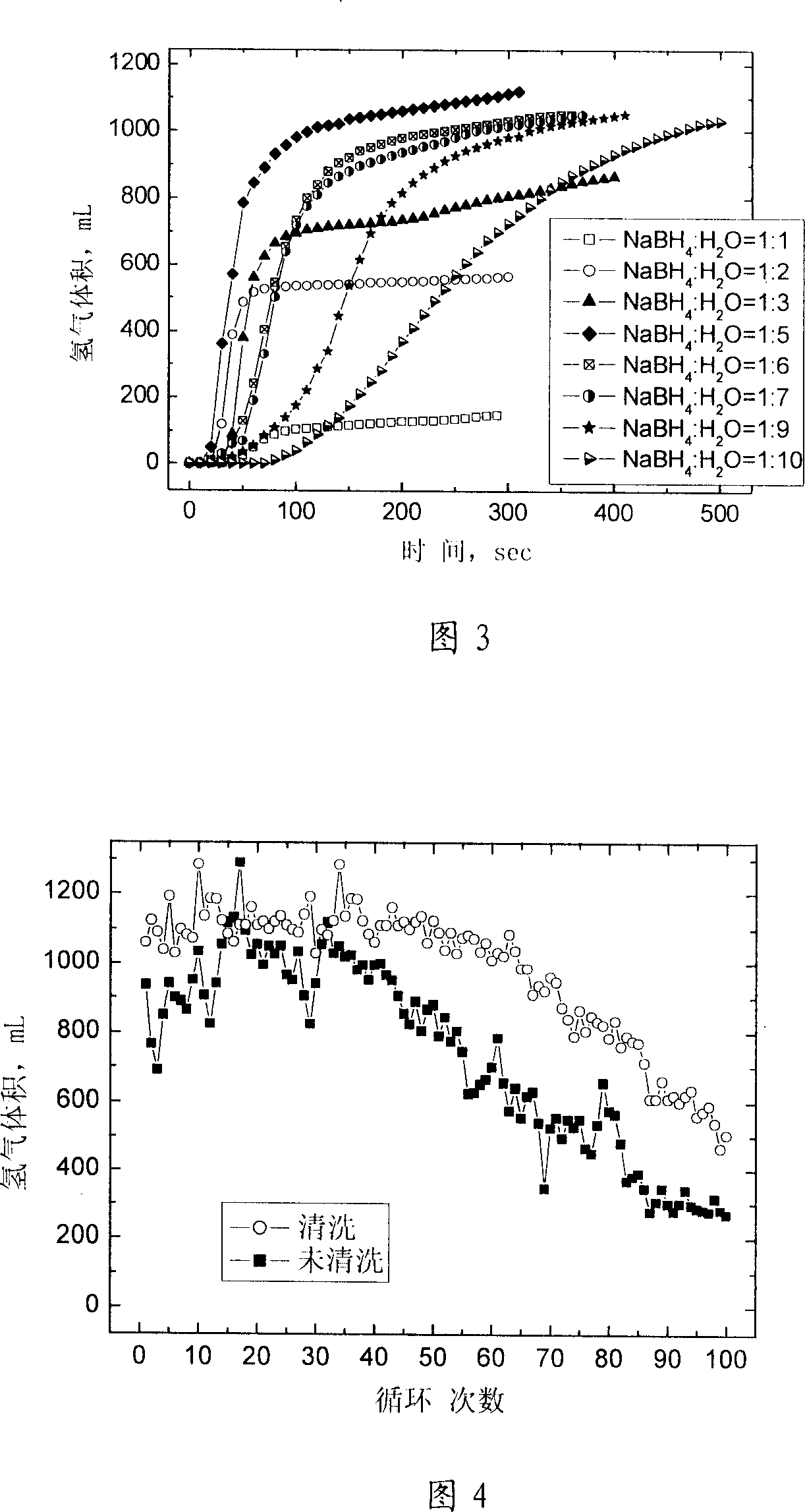

Chemical hydride hydrogen storing material system, hydrogen preparing method and hydrogen preparing device

InactiveCN101100285AOvercome lossHigh hydrogen storage capacityMonoborane/diborane hydridesHydrogen productionAlkaline earth metalTerminal unit

This invention relates to the chemical hydrogen storage material system comprising alkali metals and alkaline-earth metals borohydrides, and the hydrolyzation of the same for producing hydrogen, and the equipment therefore. The chemical hydride hydrogen storage material system consists of: chemical hydrides, water, catalyst and the carrier. This inventive hydrogen generator consists of: raw material storage unit, water tank, mixer, pump, reactor, accumulator and collector. The hydride powder and water are mixed in the mixer, and then in the reactor equipped with catalyst, the hydrolyzation takes place and producing hydrogen. In this hydrogen storage material contains no stabilizer, so reducing the cost and increasing hydrogen production property. This invention has also advantages of: fast responsive time, fast hydrogen supply rate, automatically regulating hydrogen production process based on the requirement of terminal unit, so it is the useful technique and equipment for vehicle carried hydrogen storage and mobile electric power supply.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

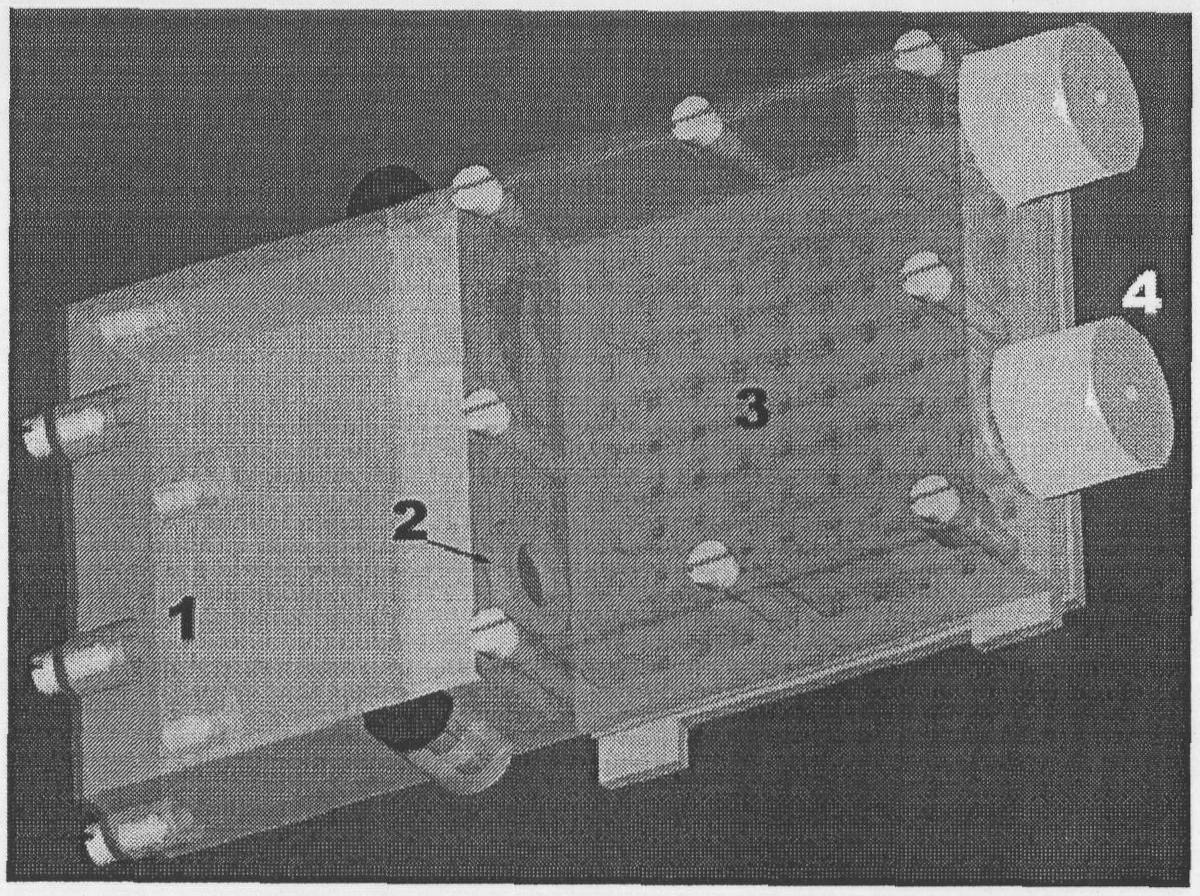

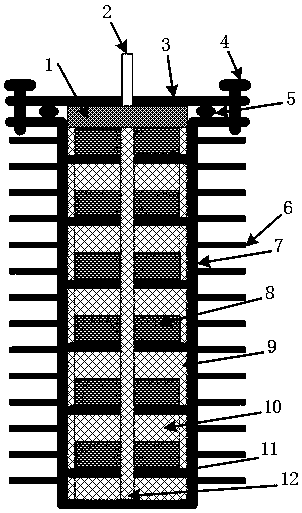

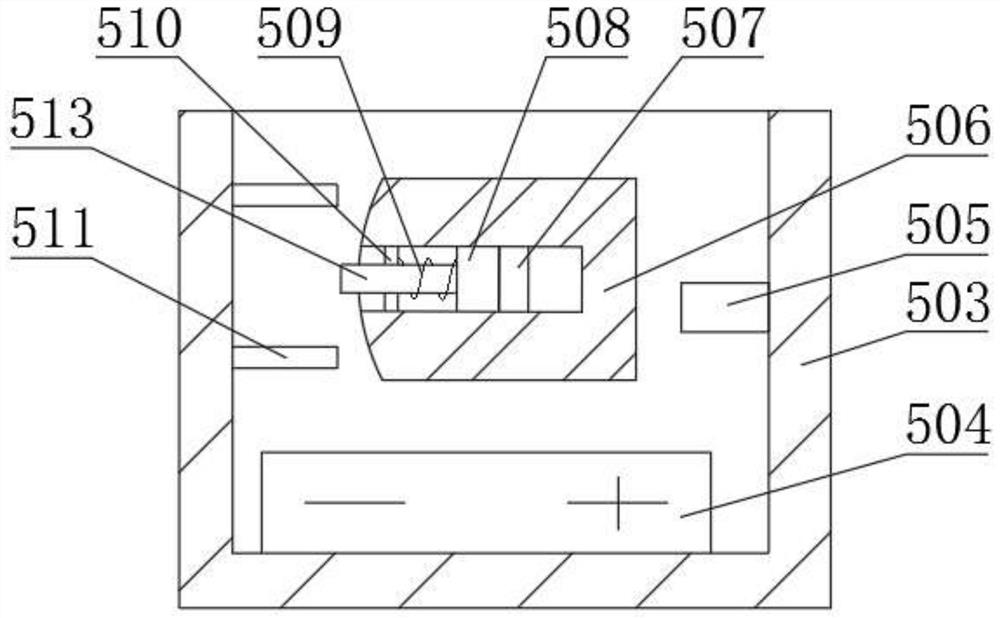

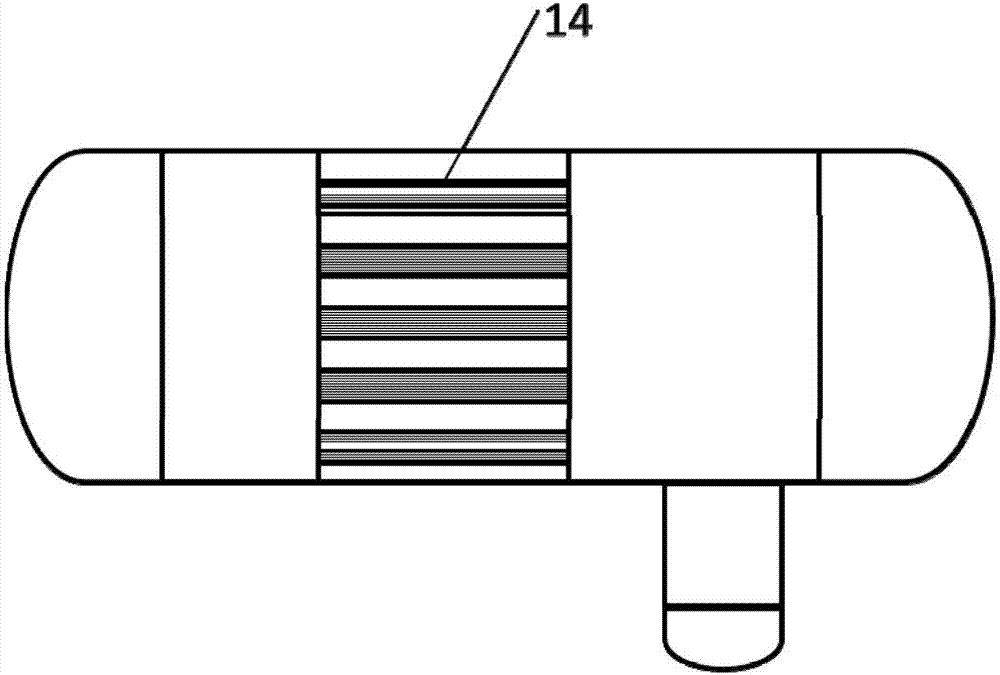

Low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank

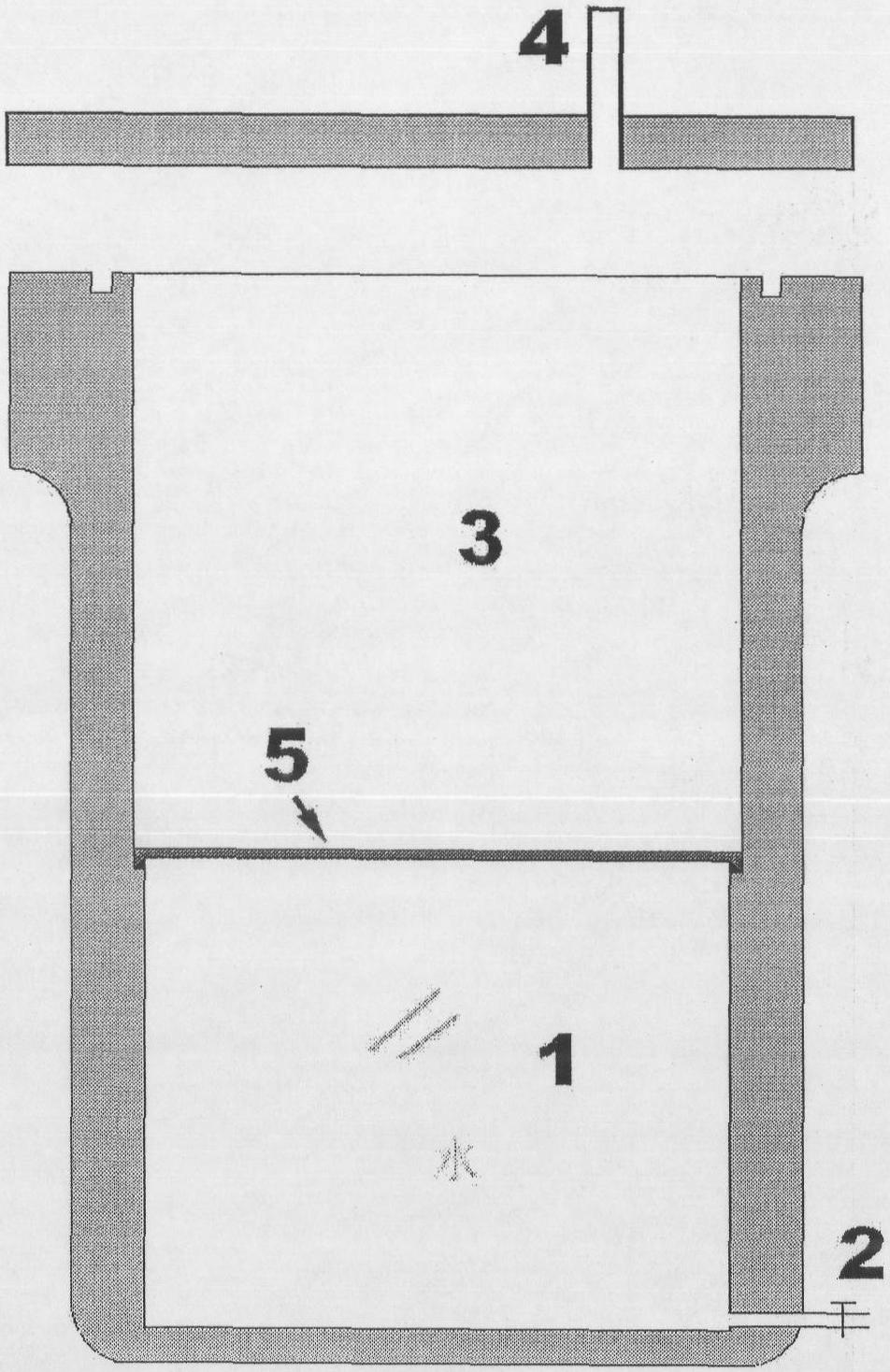

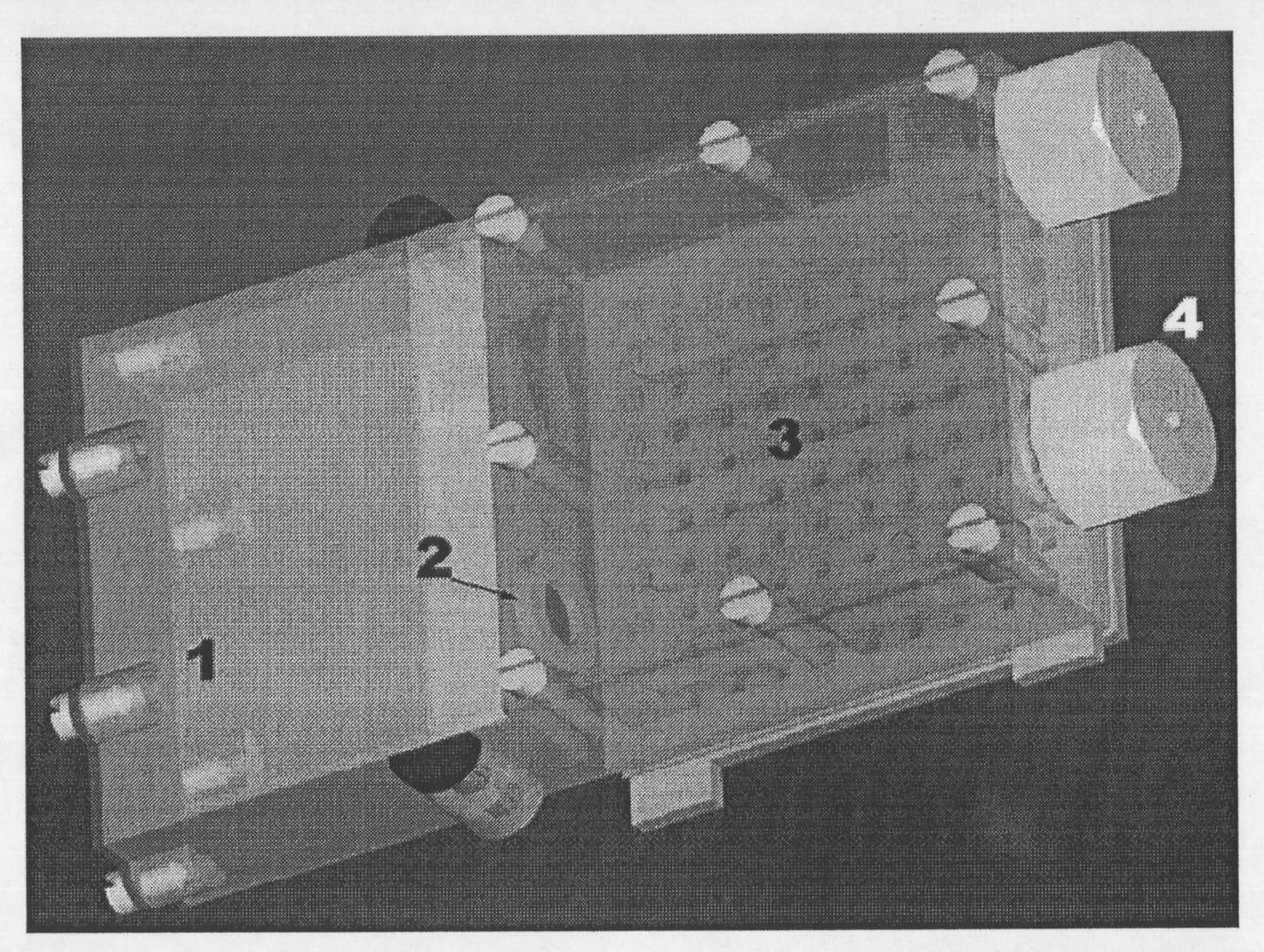

PendingCN111022912AFast hydrogen absorption and desorptionIncrease productivityVessel geometry/arrangement/sizeVessel wallsMetallurgyMetallic hydrogen

The invention relates to a hydrogen storage technology, in particular to a low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank. The hydrogen storage tank mainly comprises a round foam metal cover, a gas pipe, a flange cover, bolts, an O-shaped sealing ring, cooling fins, a tank body, hydrogen storage material powder, a round foam metal barrel, a foam metal disc, a heat pipe and a foam metal cylinder. The metal hydride hydrogen storage tank is simple in structure and easy to realize, the condition that metal hydride powder flows out of thegas pipe with the gas flow to damage downstream components can be prevented, the hydrogen storage tank has the excellent heat and mass transfer performance, and thus the hydrogen storage tank has thehigh hydrogen absorption and desorption speeds. Besides, according to the hydrogen storage tank, damage to the tank body of the hydrogen storage tank due to self-compaction and hydrogen absorption expansion of the metal hydride powder can be avoided, so that the hydrogen storage tank is high in safety and can be used repeatedly.

Owner:YANGZHOU UNIV

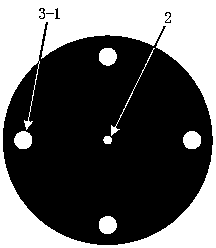

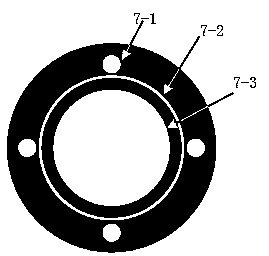

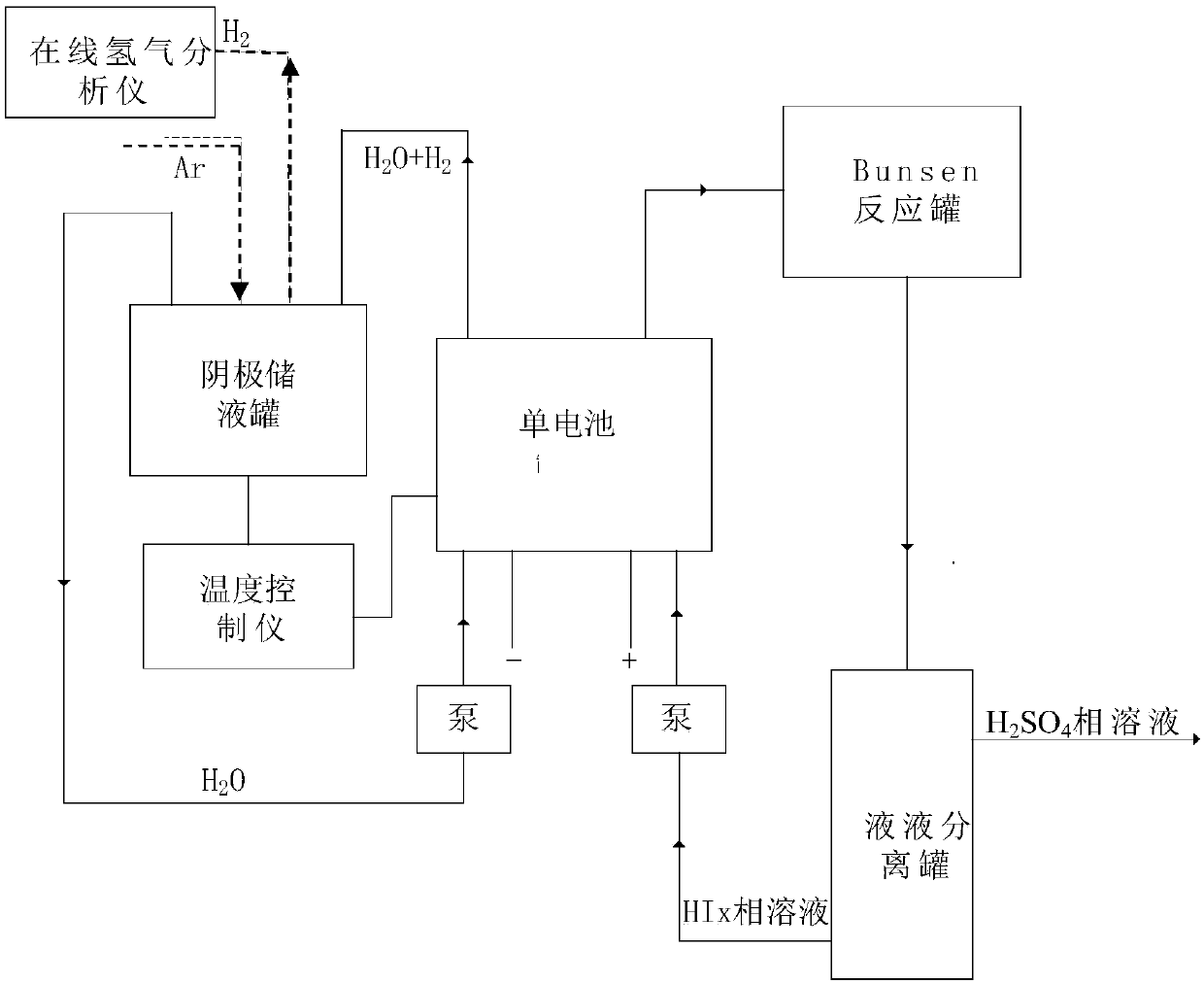

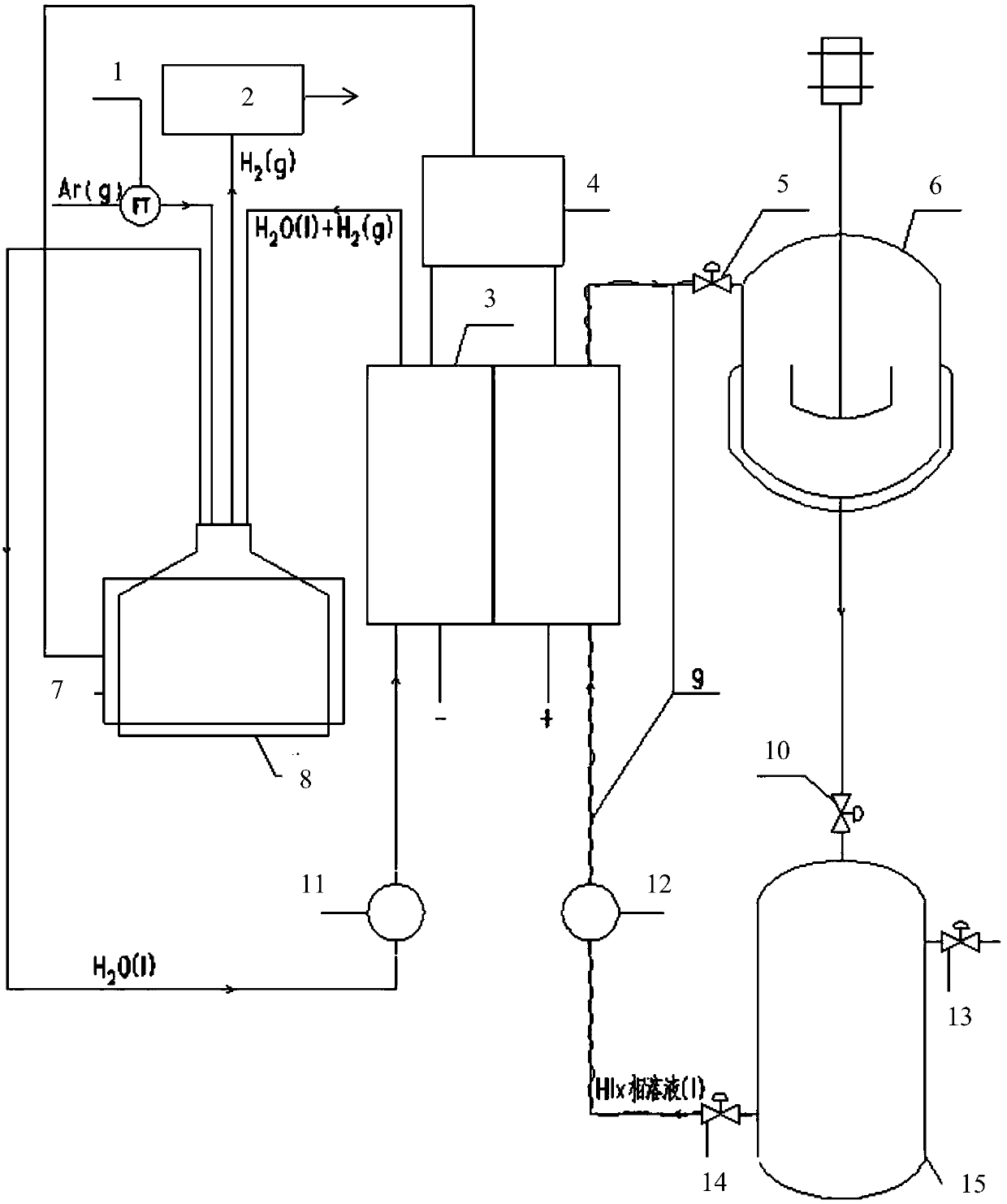

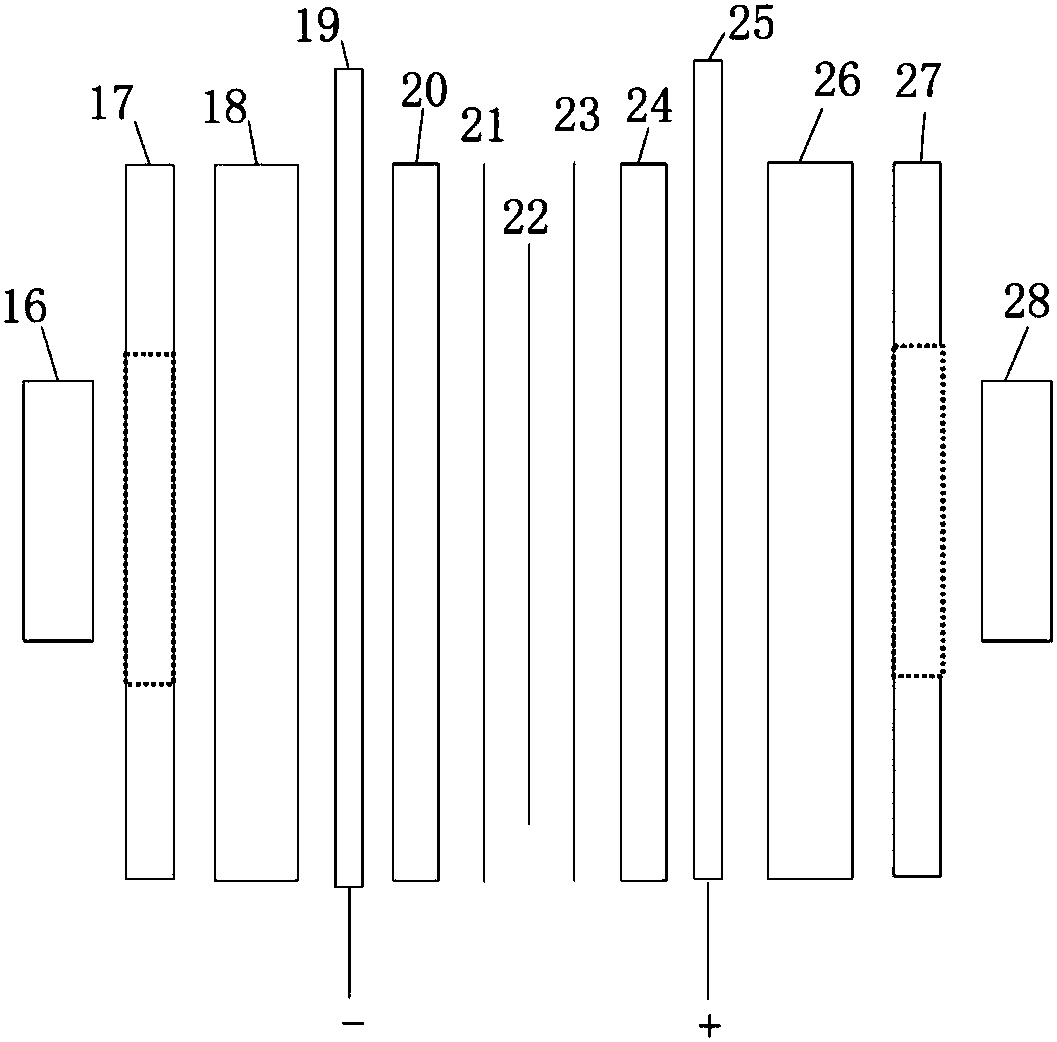

Hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and device

ActiveCN107904617AOmit enrichmentEliminate the distillation processCellsDiaphragmsElectrolysisDistillation

The invention relates to the technology of sulphur and iodine circulation hydrogen production, and particularly provides a hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and a device. The method includes the steps that a monocell is used as a reactor, the monocell has anode graphite electrode and cathode graphite electrode, and a proton exchange membrane is used as a diaphragm; HIx homogeneous solution in the sulphur and iodine circulation hydrogen production system is injected into the anode side, and deionized water is injected into the cathode side; power supply is turned on to carry out decomposition reaction, I- of the anode side HIx homogeneous solution is oxidized to I2, and generated H+ passes through proton exchange membrane to reach the cathode side and is reduced to hydrogen; HIx homogeneous solution of the anode side enters a Bunsen reactor to be Bunsen reaction raw material in a circulating modeafter electrolytic reaction, and hydrogen generated from cathode side is sent out. According to the hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production, an HIx solution is directly decomposed adopting electrochemistry method, the original process of concentration and distillation is omitted, and the process and the device are greatly simplified. Hydrogen is generated from cathode, and the separation problem with HI gas does not need to be considered.

Owner:ZHEJIANG UNIV

Reduced Cost Steel for Hydrogen Technology with High Resistance to Hydrogen-Induced Embrittlement

An austenitic steel for hydrogen technology has the following composition:0.01 to 0.4 percent by mass of carbon,≦5 percent by mass of silicon,0.3 to 30 percent by mass of manganese,10.5 to 30 percent by mass of chromium,4 to 12.5 percent by mass of nickel,≦3 percent by mass of molybdenum,≦0.2 percent by mass of nitrogen,≦5 percent by mass of aluminum,≦5 percent by mass of copper,≦5 percent by mass of tungsten,≦0.1 percent by mass of boron,≦3 percent by mass of cobalt,≦0.5 percent by mass of tantalum,≦2.0 percent by mass of at least one of the elements: niobium, titanium, vanadium, hafnium and zirconium,≦0.3 percent by mass of at least one of the elements: yttrium, scandium, lanthanum, cerium and neodymium, the remainder being iron and smelting-related steel companion elements.

Owner:BAYERISCHE MOTOREN WERKE AG

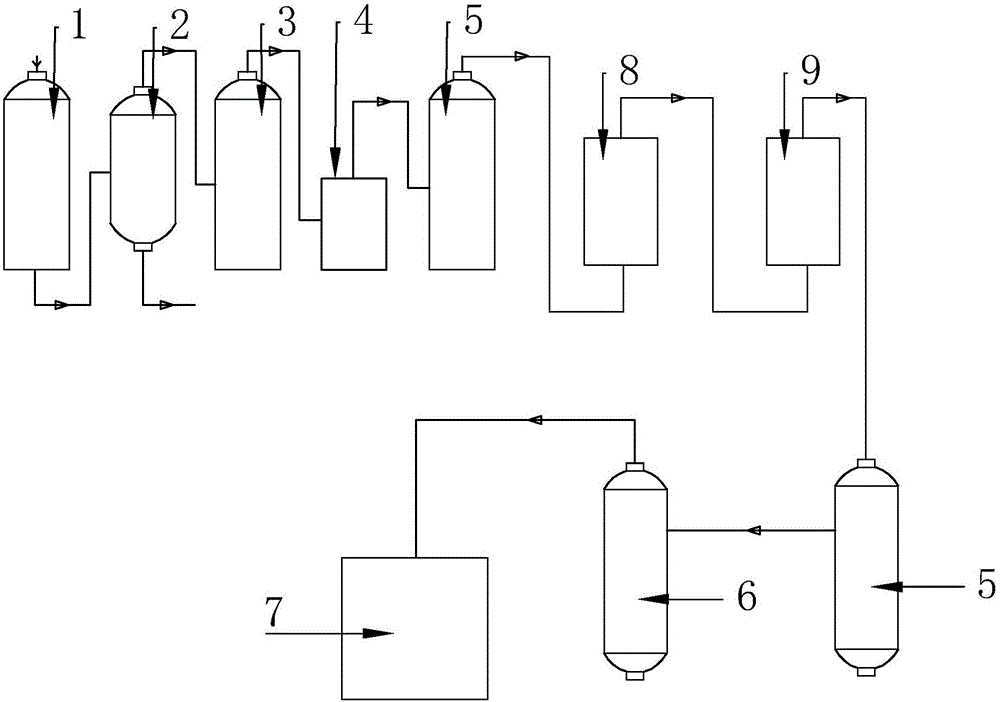

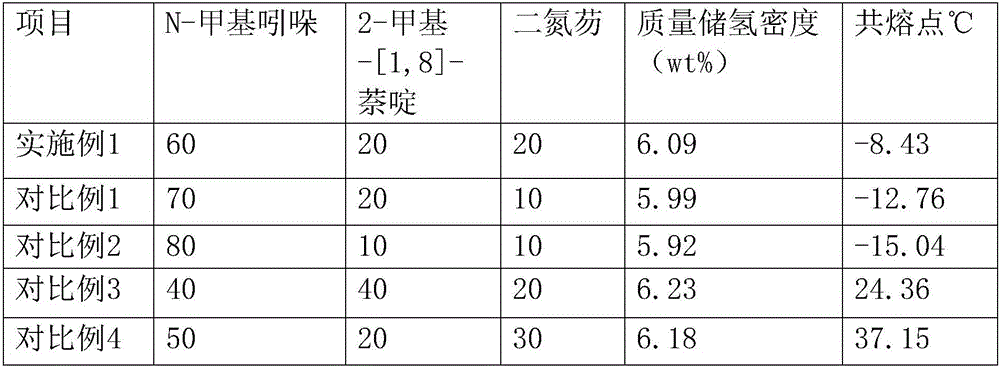

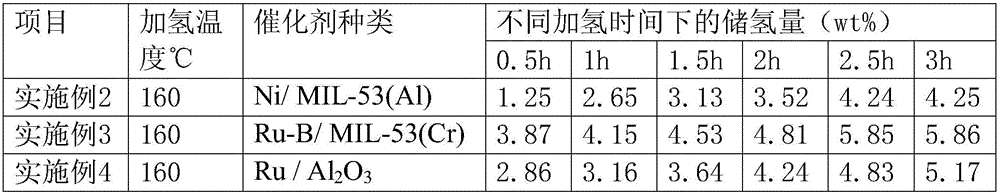

Hydrogen power generation system capable of producing and storing hydrogen

InactiveCN106252686AIncrease profitHigh purityFuel cell auxillariesDehydrogenationHydrogen fuel cell

The invention discloses a hydrogen power generation system capable of producing and storing hydrogen. Biomass resources are adopted as the raw materials, biomass thermochemical hydrogen production is utilized to decompose all agricultural straws into hydrogen-rich gas, and hydrogen in the hydrogen-rich gas is stored in an organic hydrogen storage material through an organic hydrogen storage device. The organic hydrogen storage material involved in the invention is composed of 2-methyl-[1, 8]-naphthyridine, diazafluorene and N-methylindole, has the characteristics of high hydrogen storage density and appropriate dehydrogenation temperature, the hydrogen released from the organic hydrogen storage device can be directly used for fuel cells, and hydrogen energy can be converted into electric energy or directly used for heat supply through hydrogen fuel cells, thus enhancing the economical efficiency of energy utilization. The power generation system provided by the invention is convenient and flexible, is suitable for establishment of a distributed energy system, and is applicable to energy development in areas away from the power grid and rich in biomass resources. The system combines biomass power generation technology with hydrogen technology, utilizes hydrogen energy as the biomass power generation intermediary, combines the high efficiency and flexibility of fuel cells, and realizes clean and efficient conversion of biomass to electricity.

Owner:温州集智科技有限公司

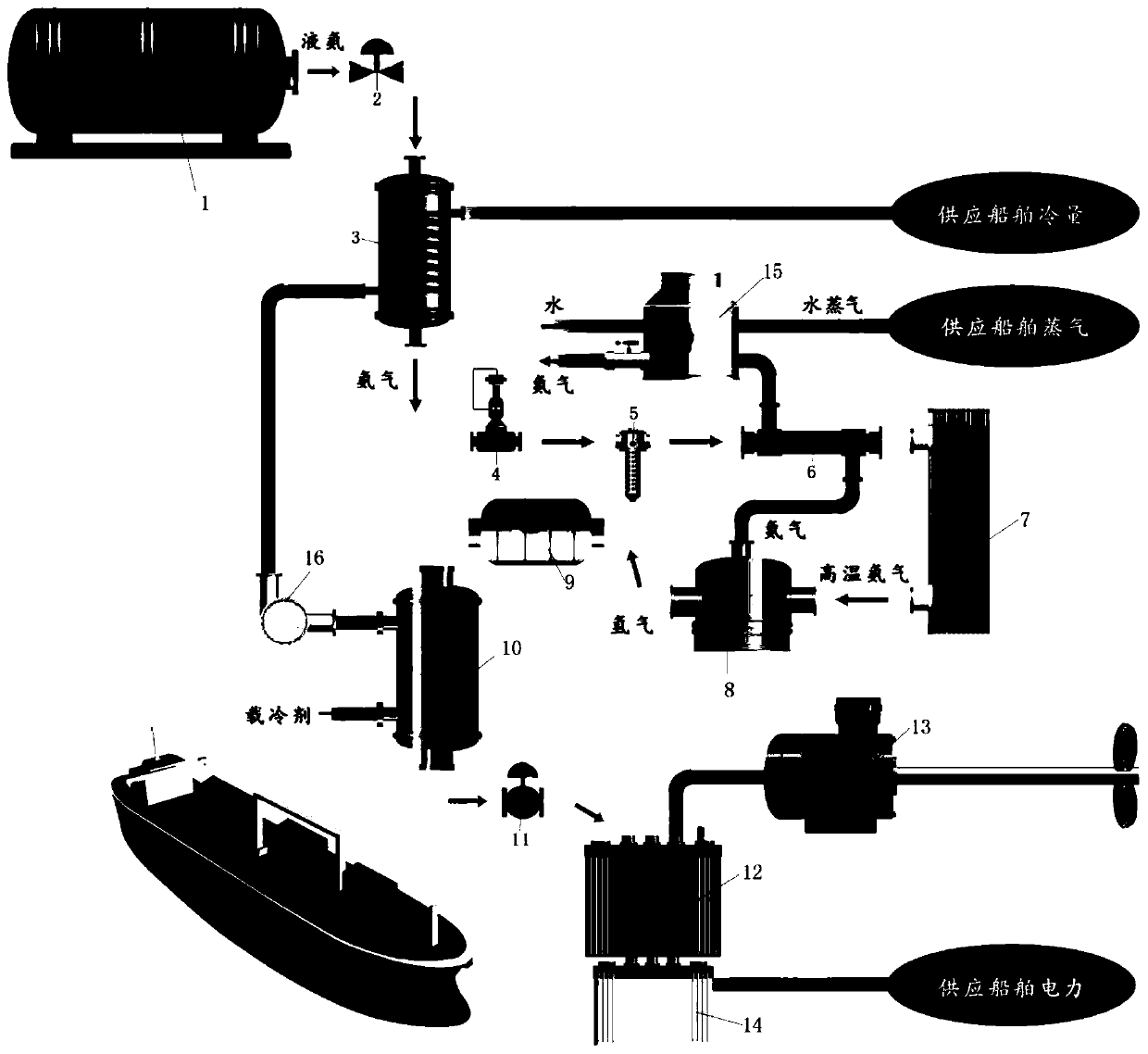

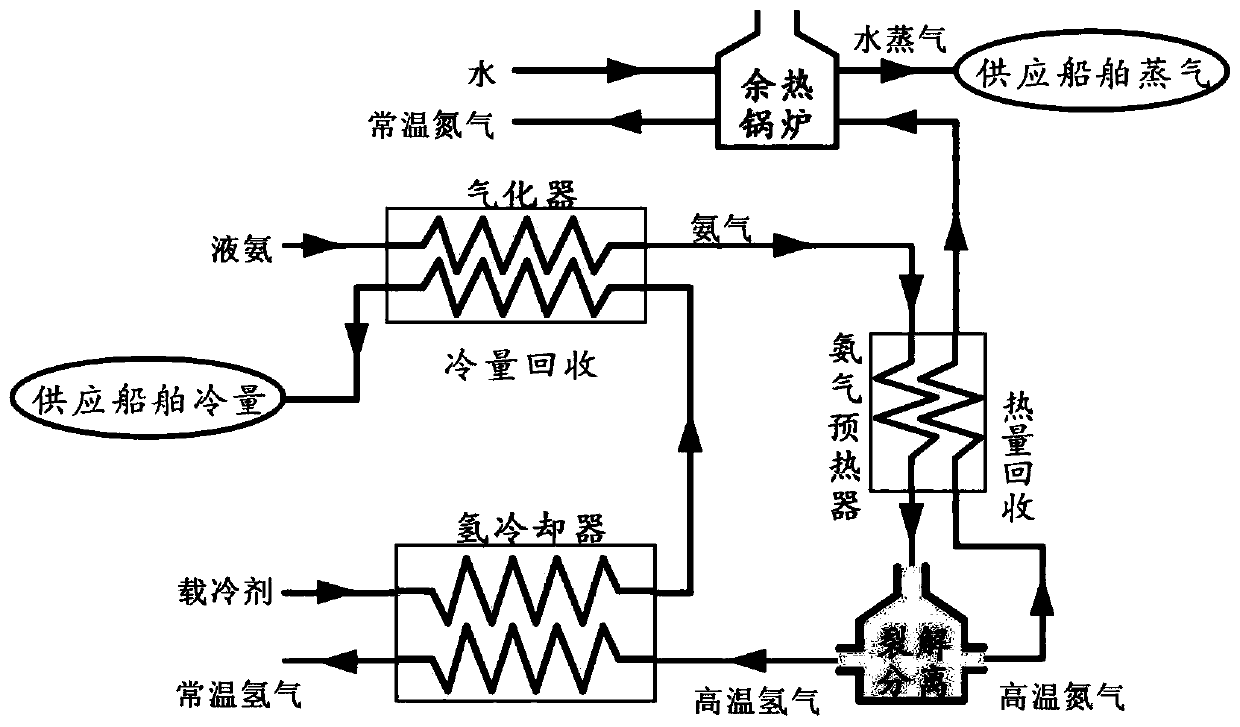

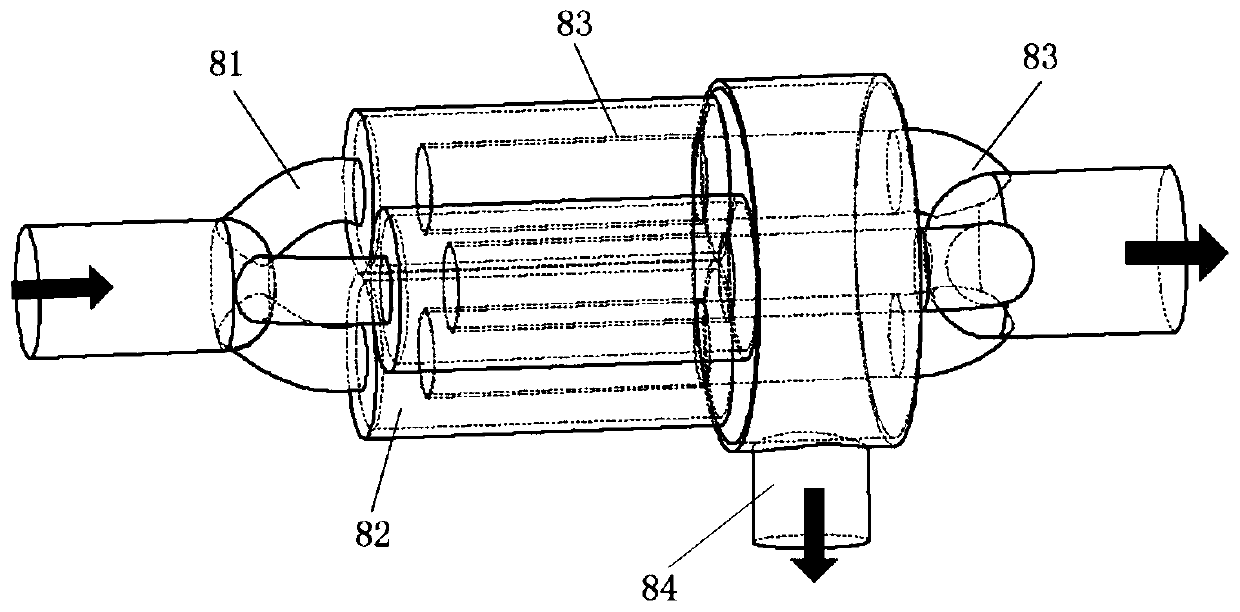

Combined cooling, heating and power composite system based on ammonia energy ship and power supply method

ActiveCN111170273AOvercome costsOvercome the shortcomings of flammable and explosiveAuxillariesHydrogen productionCatalytic decompositionHydrogen purifier

The invention provides a combined cooling, heating and power composite system based on an ammonia energy ship. The combined cooling, heating and power composite system comprises a hydrogen productionsystem, a ship power supply system and a cooling, heating and heat exchange circulating system. The hydrogen production system comprises a marine liquid ammonia storage tank, a flow regulating valve bank, a gasifier, a pressure regulating valve bank, a drying filter, an ammonia preheater, an electric heater, an ammonia catalytic decomposition hydrogen separation unit, a hydrogen purifier, a hydrogen cooler and a hydrogen pressure flow control valve bank which are communicated in sequence; the ship power supply system comprises a hydrogen-air fuel cell, a motor propeller and a storage battery.The cooling, heating and heat exchange circulating system comprises a waste heat boiler and a secondary refrigerant pump; the waste heat boiler is used for generating saturated steam to meet the heatrequirements of ship auxiliary machines and passenger cabins. The secondary refrigerant pump is used for cooling the ship equipment and supplying related cooling capacity to the ship. The problem thata large amount of energy is consumed due to the fact that an existing hydrogen production-hydrogen storage technology cuts off the hydrogen production technology and the hydrogen storage technology is solved.

Owner:DALIAN MARITIME UNIVERSITY

Cost Reduced Steel for Hydrogen Technology with High Resistance to Hydrogen-Induced Embrittlement

A corrosion-resistant, hot and cold formable and weldable steel for use in hydrogen-induced technology with high resistance to hydrogen embrittlement has the following composition: 0.01 to 0.4 percent by mass of carbon, ≦3.0 percent by mass of silicon, 0.3 to 30 percent by mass of manganese, 10.5 to 30 percent by mass of chromium, 4 to 12.5 percent by mass of nickel, ≦1.0 percent by mass of molybdenum, ≦0.2 percent by mass of nitrogen, 0.5 to 8.0 percent by mass of aluminum, ≦4.0 percent by mass of copper, ≦0.1 percent by mass of boron, ≦1.0 percent by mass of tungsten, ≦5.0 percent by mass of cobalt, ≦0.5 percent by mass of tantalum, ≦2.0 percent by mass of at least one of the elements: niobium, titanium, vanadium, hafnium and zirconium, ≦0.3 percent by mass of at least one of the elements: yttrium, scandium, lanthanum, cerium and neodymium, the remainder being iron and smelting-related steel companion elements.

Owner:BAYERISCHE MOTOREN WERKE AG

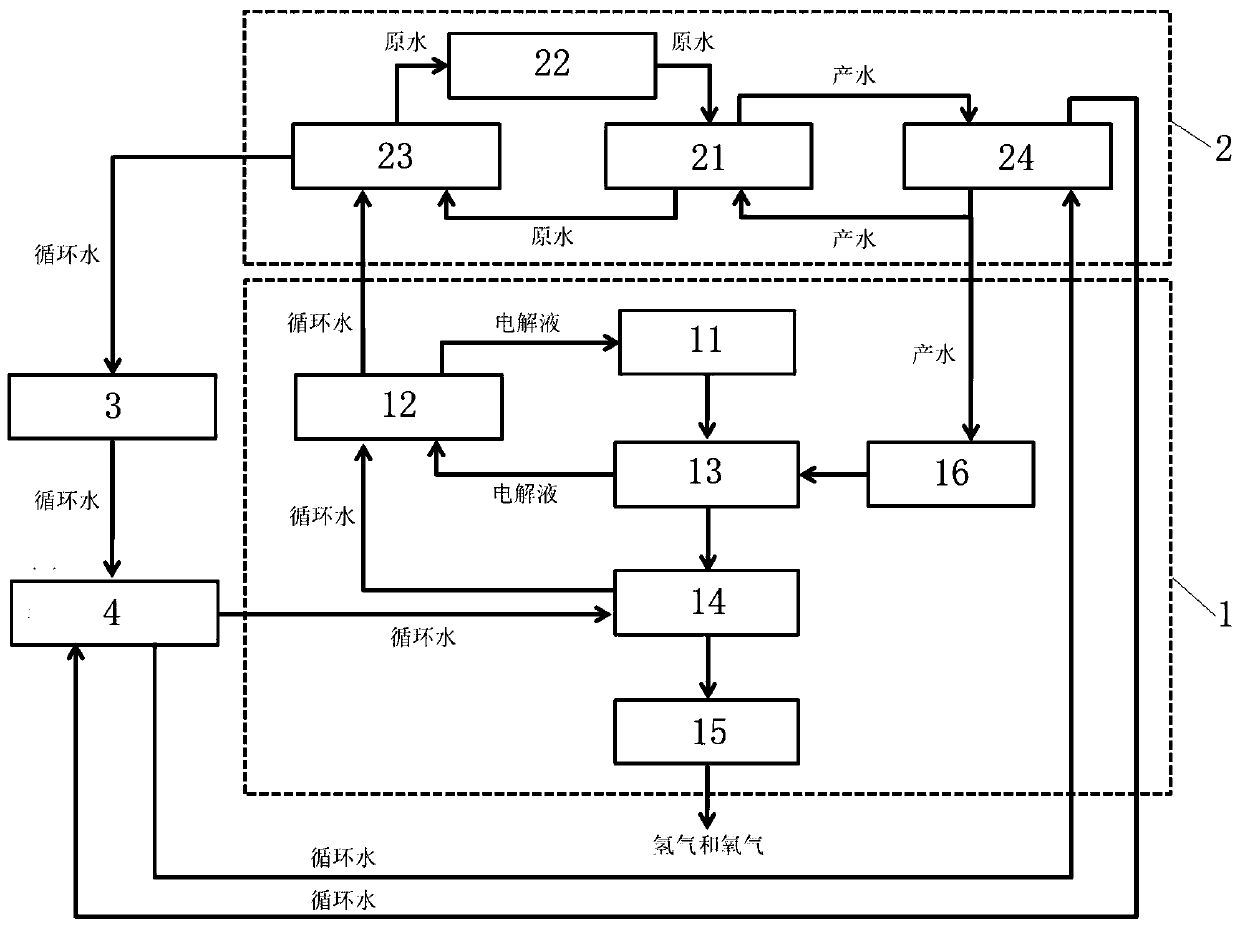

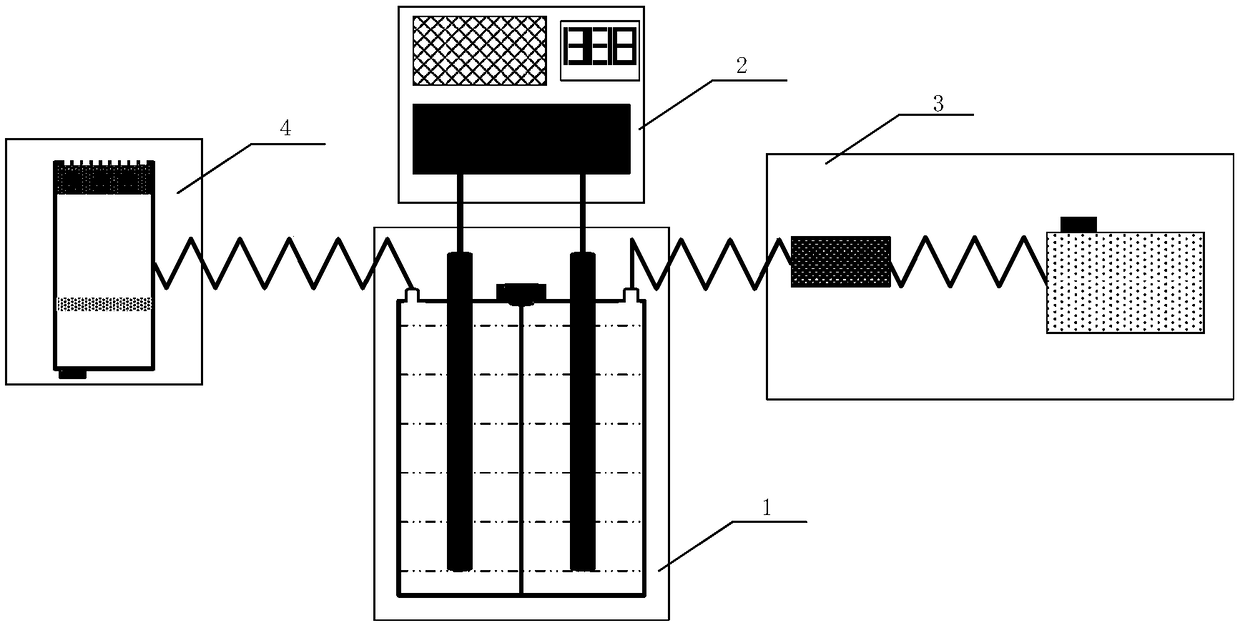

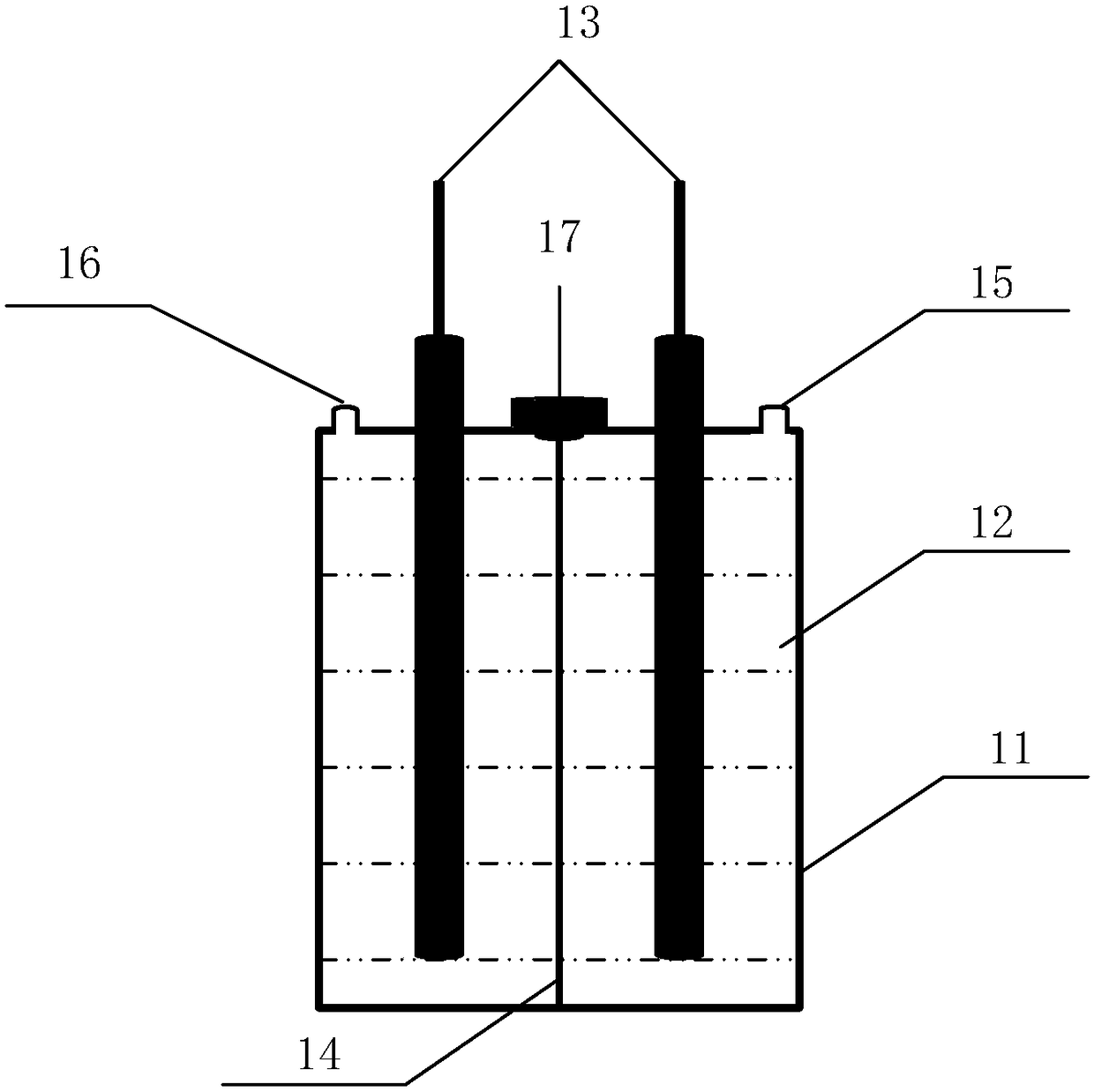

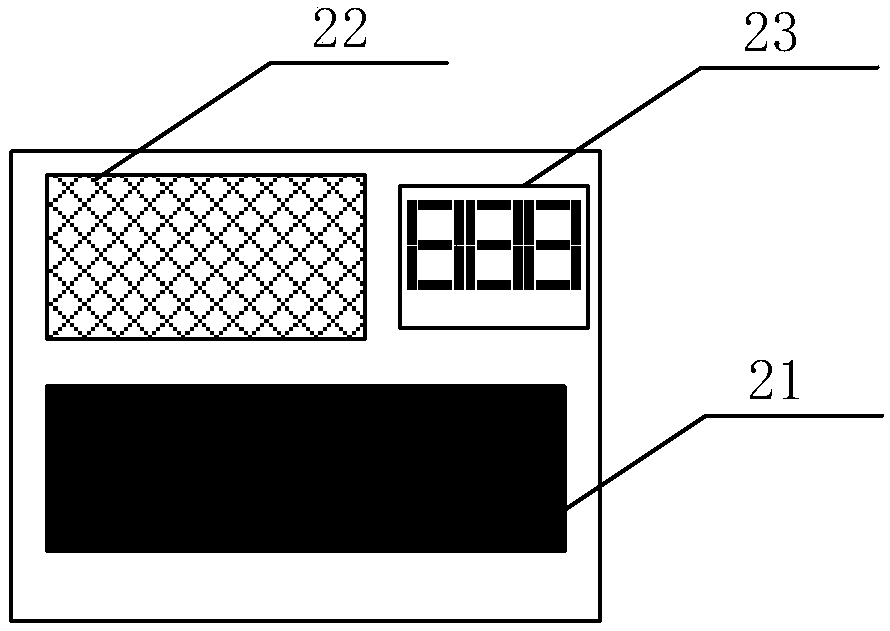

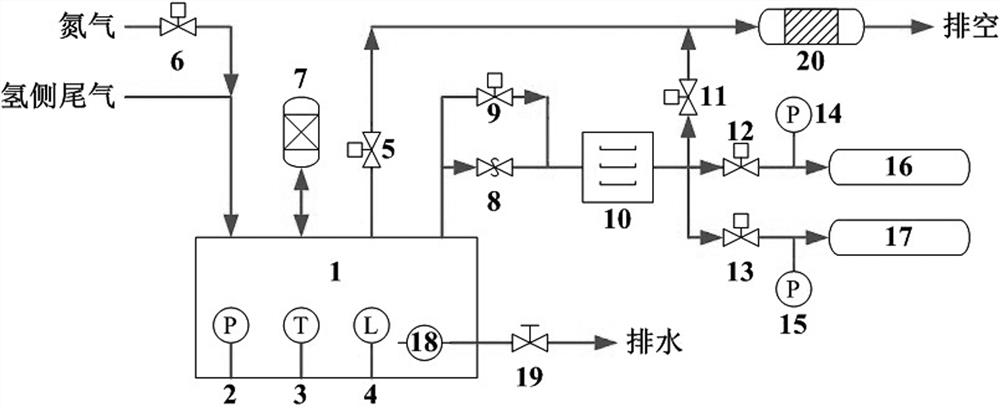

Waste heat utilization system for hydrogen production by electrolytic water and working method of waste heat utilization system

PendingCN111336571AImprove conversion efficiencyReduce heating energy consumptionElectrolysis componentsLighting and heating apparatusElectrolysed waterProcess engineering

The invention discloses a waste heat utilization system for hydrogen production by electrolytic water and a working method of the waste heat utilization system, and belongs to the technical field of hydrogen production by the electrolytic water. The waste heat utilization system comprises an electrolytic water system for the hydrogen production, a membrane distillation system, a heat user heatingsystem and a circulating cooling system. Waste heat generated in the process of the hydrogen production by the electrolytic water is used as a heat source in the membrane distillation process to prepare water supplement of the electrolytic water system for the hydrogen production, and the heating energy consumption in the membrane distillation process is saved. Compared with a traditional water preparation system, the energy consumption of water preparation of the membrane distillation system is low. Through the waste heat gradient utilization mode, waste heat still exists in circulating waterused for heating membrane distillation raw water, the waste heat can be used for winter heating for heat users such as electrolytic hydrogen production workshop or a container, the temperature requirement of the hydrogen production system in the space is met, and through the gradient utilization of the waste heat, the energy utilization efficiency of the whole electrolytic hydrogen production system is improved. The waste heat utilization system is reasonable in design, gradient and comprehensive utilization is carried out on the waste heat of the electrolytic water, the energy transferring efficiency is improved, and good application prospects are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

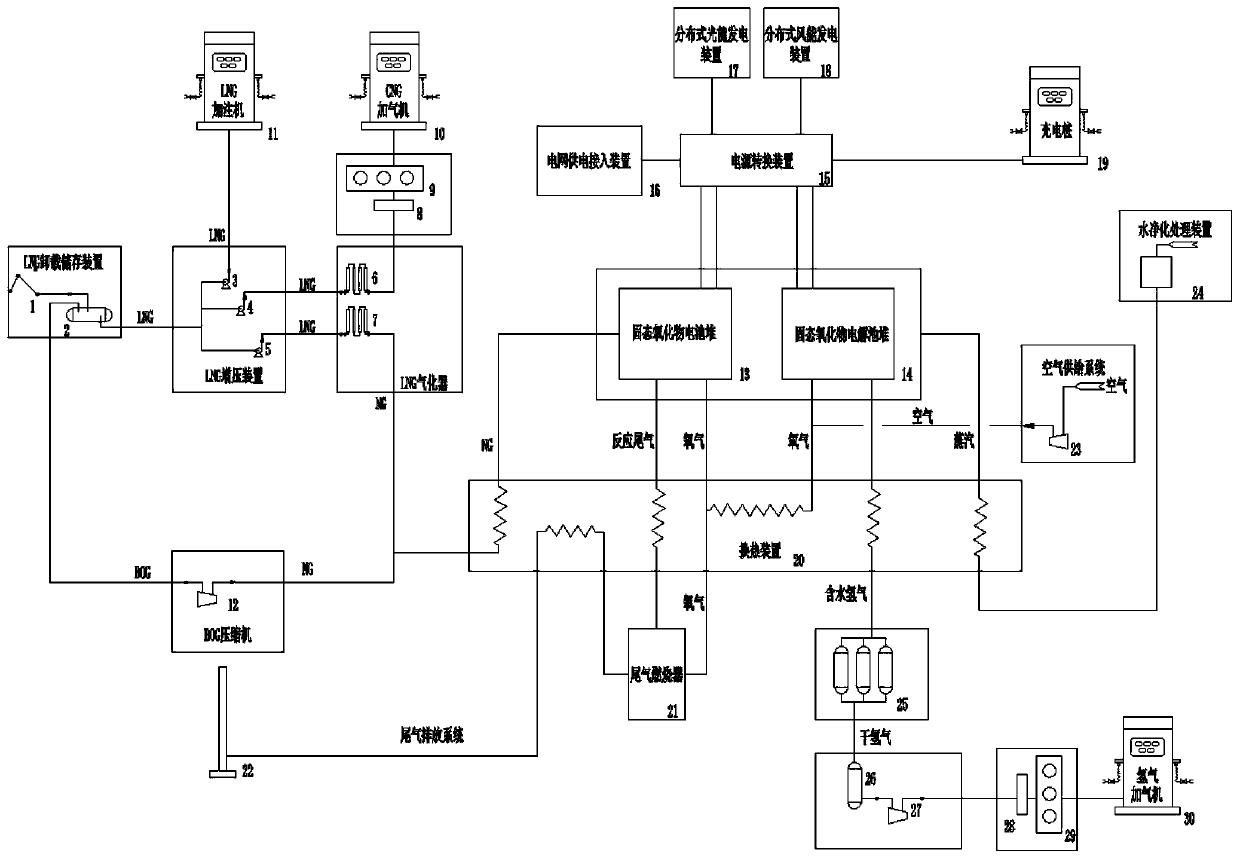

Gas-electricity-hydrogen comprehensive energy resource supplying system and method

PendingCN109882737ARealize the supplyEfficient use ofPipeline systemsPressure vesselsElectrochemical responseElectrolysis

The invention discloses a gas-electricity-hydrogen comprehensive energy resource supplying system and method. The gas-electricity-hydrogen comprehensive energy resource supplying system comprises an LNG storing and fuel supply system, an electricity supplying and storing system, an electrochemical reaction system, a heat exchanging system, an LNG filling system, a CNG filling system, a hydrogen filling system, a tail gas treating system and the like. According to the gas-electricity-hydrogen comprehensive energy resource supplying system disclosed by the invention, liquified natural gas is used as SOFC starting fuel, a stable electricity source and a stable heat source can be provided, the electricity source, the heat source, and on-site wind energy and light energy distribution type electricity generating equipment can form a coupling electric power system, and finally, hydrogen is produced through electrolyzing water with an SOEC; compared with a conventional single-energy electrolytic hydrogen technology, a technical line of relying on electricity generation by an SOFC to complement natural electric power fluctuation during electricity generation through wind energy and light energy, and maintaining reaction temperature through an electricity generation byproduct namely waste heat is provided, so that high-efficiency utilization of comprehensive energy resources is realized;and the gas-electricity-hydrogen comprehensive energy resource supplying system can realize the comprehensive supply of automobile energy resources of LNG, CNG, electricity and hydrogen, and is one of feasible construction modes of a future oil, gas electricity and hydrogen comprehensive power station.

Owner:CHINA PETROLEUM ENG CORP LTD +2

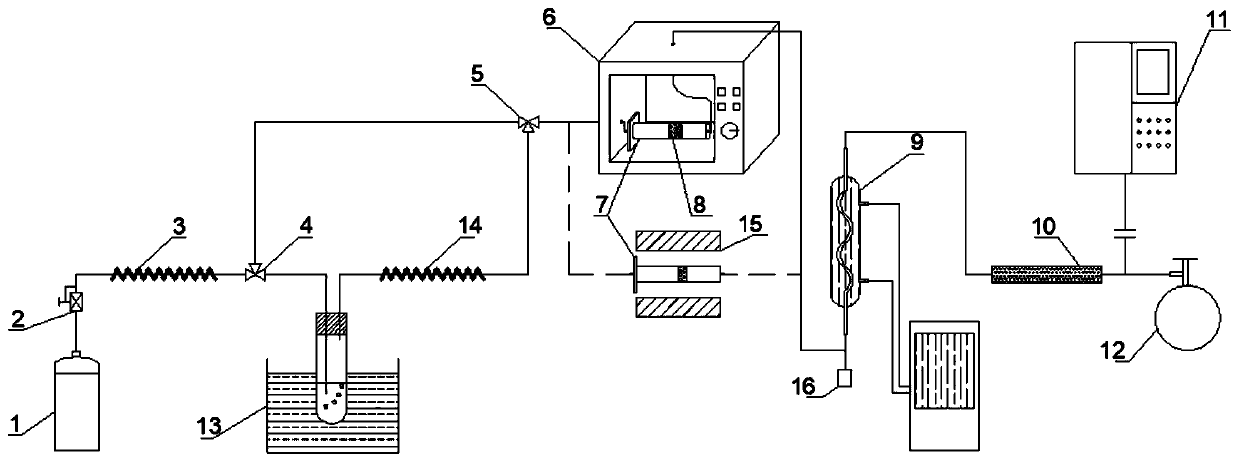

Thermochemical hydrogen production system based on microwave heating and hydrogen production method and application thereof

ActiveCN111302302ARealize continuous regenerationSolve the problem of long heat treatment timeHydrogen productionThermodynamicsMicrowave pyrolysis

The invention belongs to the technical field of thermochemical hydrogen production, and particularly relates to a thermochemical hydrogen production system based on microwave heating and a hydrogen production method and application thereof. A hydrogen production device is characterized in that an inlet of a preheater is communicated with a carrier gas storage device, a flow controller is arrangedbetween the preheater and the carrier gas storage device, an outlet of the preheater is respectively communicated with an inlet of the steam generator and one end of a second three-way valve through afirst three-way valve, the other two ports of the second three-way valve are respectively communicated with an outlet of a superheater and an inlet of the reactor, the reactor is arranged in a microwave generation device, an outlet of the steam generator is communicated with the outlet of the superheater through a pipeline, an outlet of the reactor, a condenser, a drying device and a collecting device are sequentially communicated, and a chromatographic instrument is arranged on the communicating pipeline between the drying device and the collecting device. The microwave pyrolysis of the metal oxide is short in heating time, low in power consumption and low in experiment cost, the repeated experiment period is shortened, and the effective energy utilization rate is greatly improved.

Owner:SHANDONG UNIV

Portable emergency oxygen and water production device

PendingCN108570687AIncrease the mass density of oxygen productionRespiratorsCellsLiquid waterEnvironmental resistance

The invention discloses a portable emergency oxygen and water production device, comprising an electrolysis oxygen production module, a power supply and control module, a breathing module and an active hydrogen elimination and water production module, wherein the electrolysis oxygen production module is connected with the power source and control module, the electrolysis oxygen production module is connected with the breathing module through an oxygen outlet, and the electrolysis oxygen production module is connected with the active hydrogen elimination and water production module through a hydrogen outlet. The device provided by the invention adopts an electrolysis water and active hydrogen elimination technology, so that both oxygen and water are produced; liquid water stores oxygen, sothat the mass density of oxygen produced by the device is effectively improved, and liquid can be fed during operation; the device can be recycled, and is safe and environmentally friendly.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Hydrogen elimination device for hydrogen fuel cell and hydrogen elimination method in closed environment

ActiveCN111799489AHigh volume hydrogen storage densityImprove securityReactant parameters controlHydrogen fuel cellNitrogen gas

The invention discloses a hydrogen elimination device for a hydrogen fuel cell. The hydrogen elimination device comprises main parts such as a hydrogen side product water tank, a pressure sensor, a temperature sensor, a liquid level sensor, an electromagnetic valve, an oxygen concentration analyzer, a dryer, an alloy hydrogen storage tank, a water pump, a manual valve and a catalytic combustion type hydrogen eliminator. The invention further discloses a hydrogen elimination method of the hydrogen fuel cell in the closed environment. In the hydrogen elimination process, the oxygen concentrationin the hydrogen side product water tank needs to be detected to judge the state of the fuel cell and ensure safety. When the liquid level is too high, water is drained through the water pump. In caseof emergency, nitrogen is introduced for purging protection. According to the hydrogen elimination method, the characteristics of the alloy hydrogen storage technology are fully utilized, the hydrogen elimination capacity per unit volume is high, safety is good, and it is guaranteed that replenishment is convenient.

Owner:武汉氢能与燃料电池产业技术研究院有限公司

On-line hydrogen supply fuel cell system based on water self-circulation

PendingCN110556555AReduce raw water requirementsReduce the size and weight of the deviceFuel cellsChemistryRaw water

The invention discloses an on-line hydrogen supply fuel cell system based on water self-circulation. The fuel cell system comprises an on-line hydrogen supply unit which is used for contacting reactant blocks to be hydrolyzed for hydrogen production with water to carry out hydrolysis hydrogen production reaction to provide hydrogen; a fuel cell unit which is used for using the hydrogen from the on-line hydrogen supply unit as fuel and converting chemical energy of hydrogen and oxygen reaction into electric energy; and a water circulation unit which is used for recovering at least part of the water in the gas-water mixture discharged after the fuel cell unit generates electricity and sending the water as hydrolysis hydrogen production reaction water to the on-line hydrogen supply unit for recycling. According to the fuel cell system, the product water generated after electricity generation of the fuel cell through the hydrogen is recovered by the water circulation system and can participate in the hydrogen supply reaction again, thus reducing the raw water demand of the on-line hydrogen supply technology, reducing the volume and weight of the device and greatly improving the practicability and the portability of the on-line hydrogen supply power supply power system.

Owner:JILIN UNIV

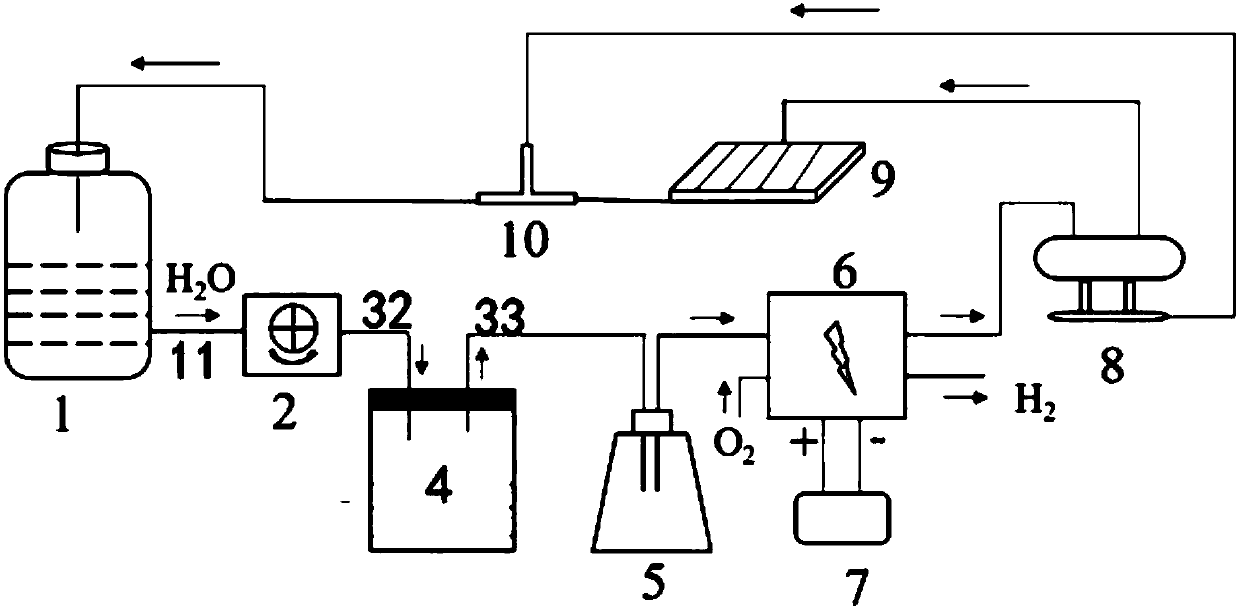

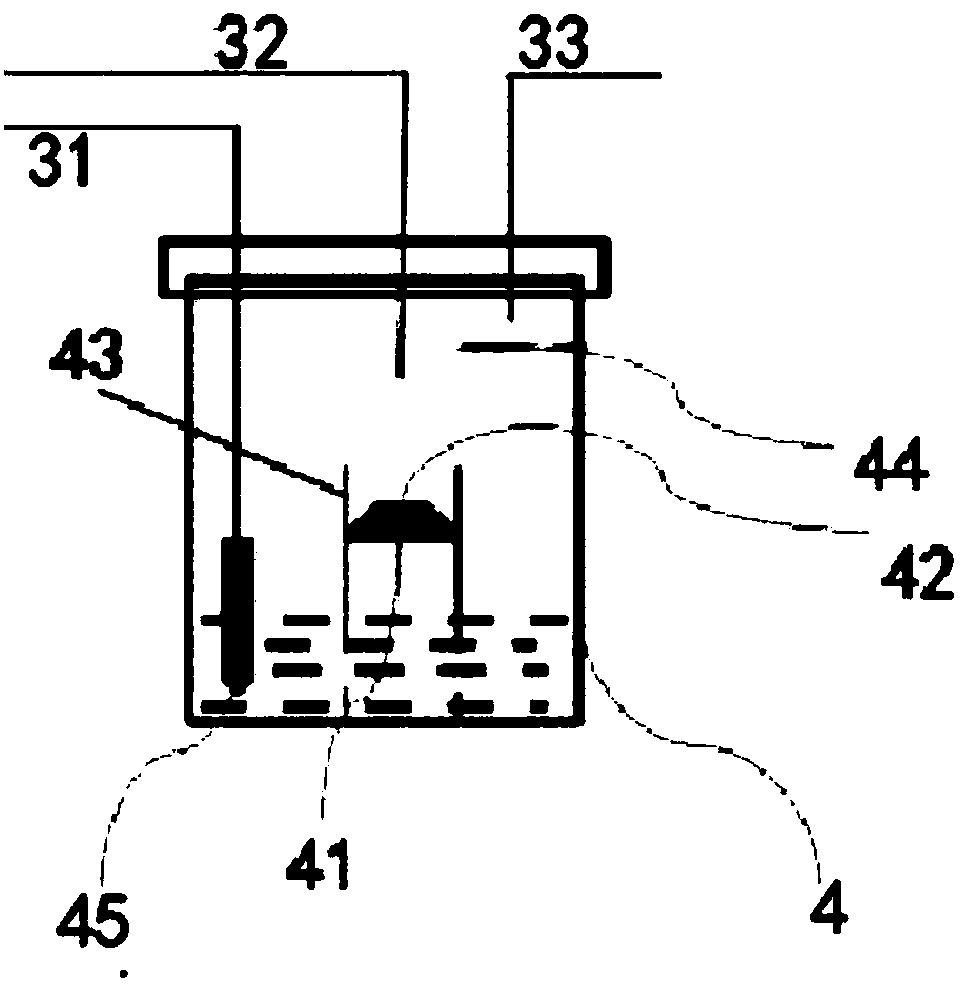

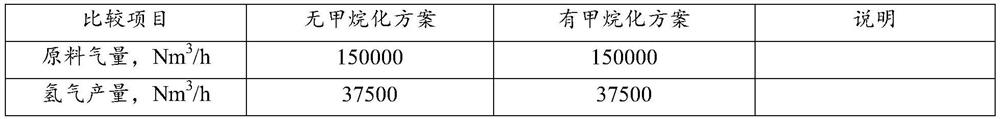

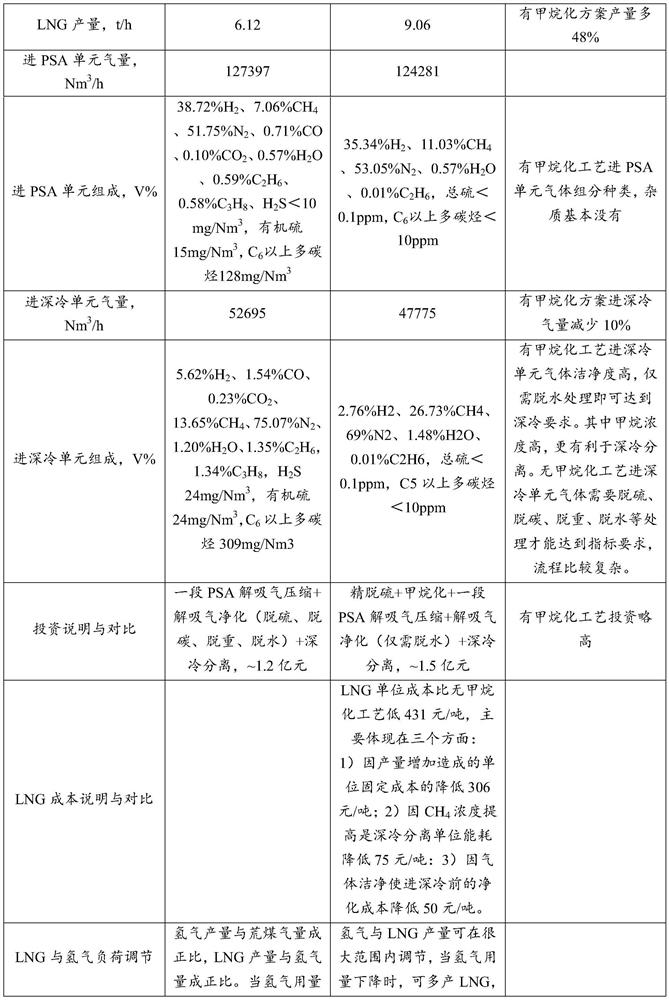

Process for hydrogen production and co-production of LNG from raw gas with methanation

ActiveCN112897464AOptimize the purification processEfficient removalHydrogen separationGaseous fuelsMethanationProcess engineering

The invention provides a process for hydrogen production and co-production of LNG from raw gas with methanation, and belongs to the technical field of hydrogen production from raw gas. According to the process, raw gas obtained by pyrolysis of low-rank coal is used as a raw material, and high-purity hydrogen and LNG products are obtained through pretreatment, compression purification, conversion hydrogenation, desulfurization and decarburization, methanation, pressure swing adsorption and cryogenic separation. According to the invention, a tar and naphthalene multi-stage removal system is arranged in the process of hydrogen production and co-production of LNG from raw gas, and through optimal combination of all purification processes, impurities such as tar, naphthalene, ammonia and sulfur in the raw gas can be effectively removed under the condition that the impurities fluctuate in a relatively large range. According to the process, methanation is set, and the LNG productivity can be increased by 40%-60% under the condition of the same raw gas volume and hydrogen yield. Meanwhile, the concentration of methane in the raw gas is increased to 11-24% from about 6% through methanation, and is further concentrated to 24-60% through PSA, so that the amount of gas entering cryogenic separation is greatly reduced, and the investment and energy consumption of cryogenic separation are greatly reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

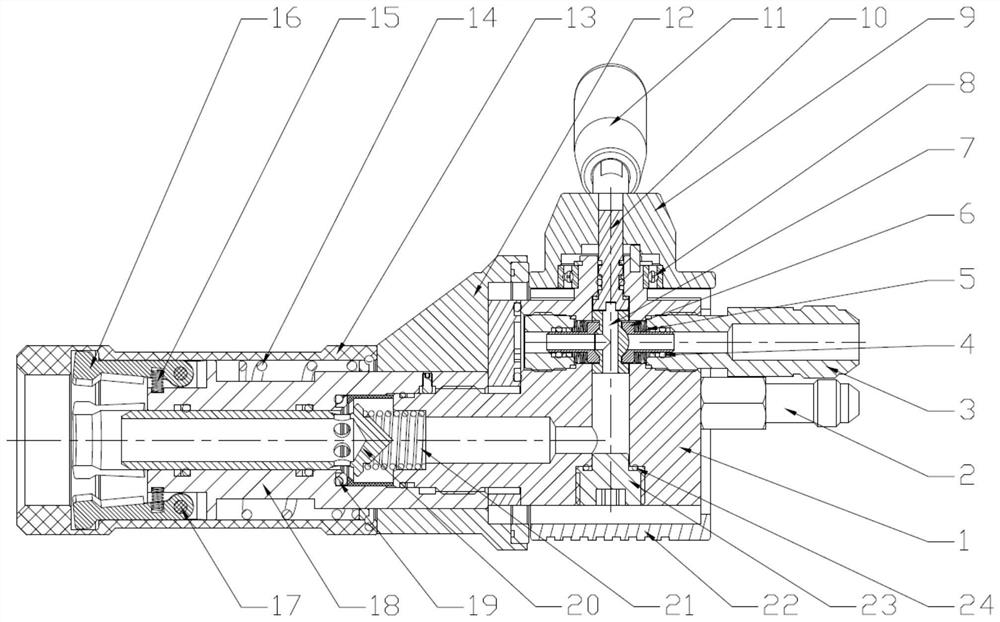

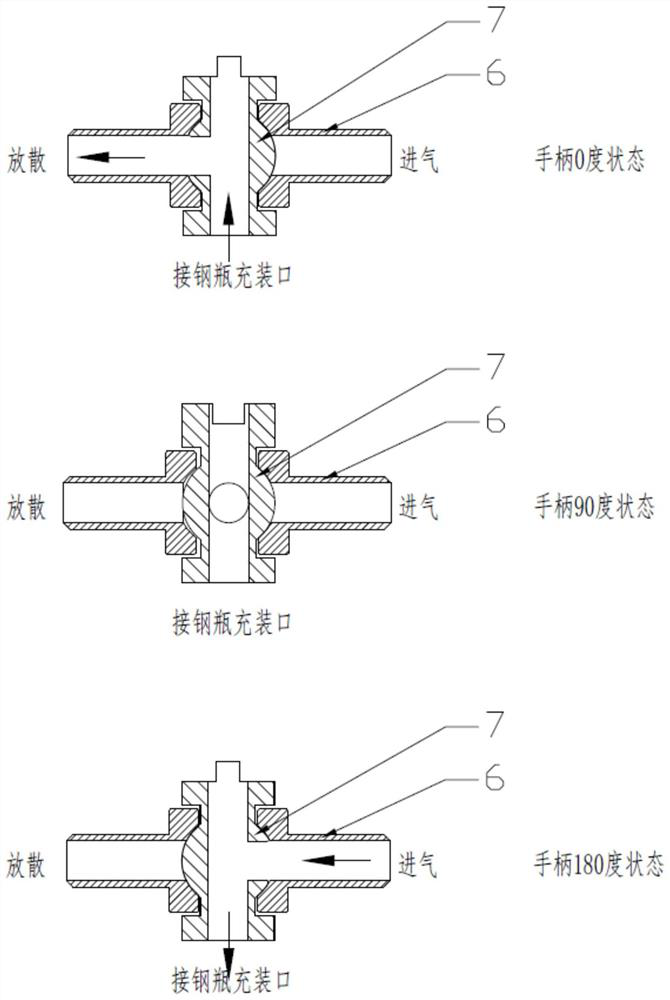

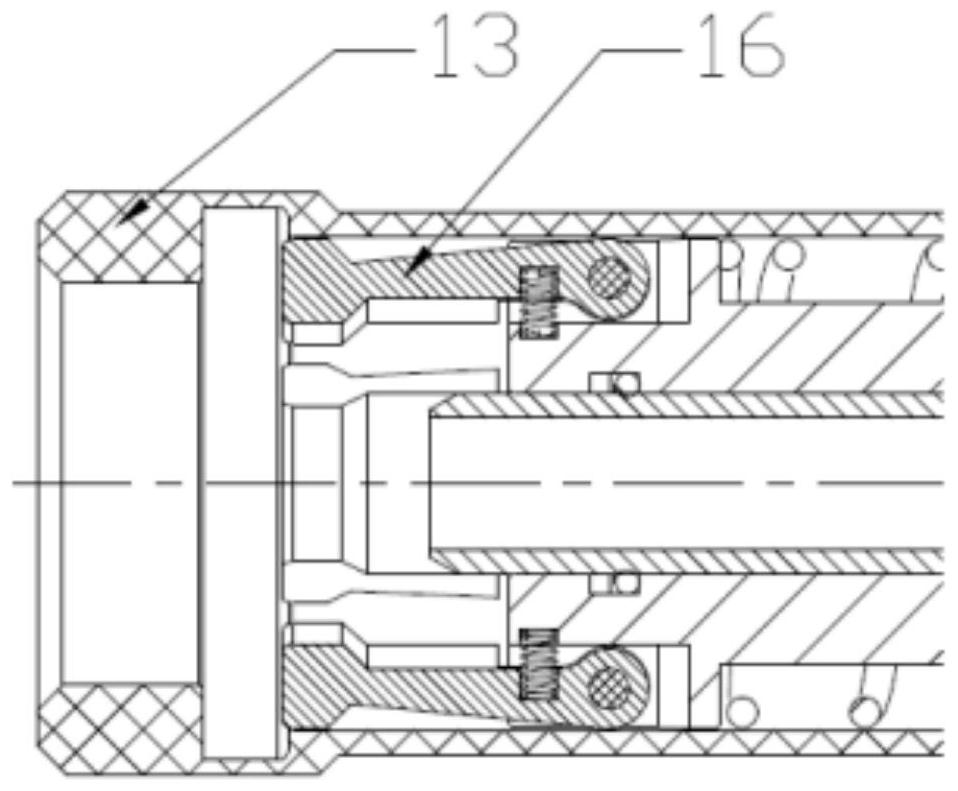

Hydrogenation gun

PendingCN114738666ARealize switchingOperating means/releasing devices for valvesGas handling applicationsEngineeringHydrogen fuel

The invention relates to the technical field of automobile hydrogenation, in particular to a hydrogenation gun which comprises a valve body, a gas return connector and a gas inlet connector are formed in the valve body, a shell is arranged on the outer wall of the valve body, a handle is arranged on the valve body, and the handle drives a cam, a valve rod and a bearing to rotate by 180 degrees around the valve body. When the valve rod rotates, the three-way ball is indirectly driven to rotate by 180 degrees at the same time. The hydrogenation gun is used for being connected with a hydrogen fuel automobile steel cylinder, hydrogen is injected into the steel cylinder, and the hydrogen enters the hydrogenation gun from the gas inlet connector, enters the valve body through the valve clack and the three-way ball and then is injected into the automobile steel cylinder through the valve element. After filling is completed, residual hydrogen in the gun is controlled by the three-way ball to enter the gas return connector to be discharged; and the three-way ball body is controlled by a valve rod driven by the handle to rotate by 180 degrees, so that the switching of the connection between the steel cylinder and the air inlet interface and the connection between the steel cylinder and the air return interface is realized.

Owner:四川天成氢洁能源技术有限公司

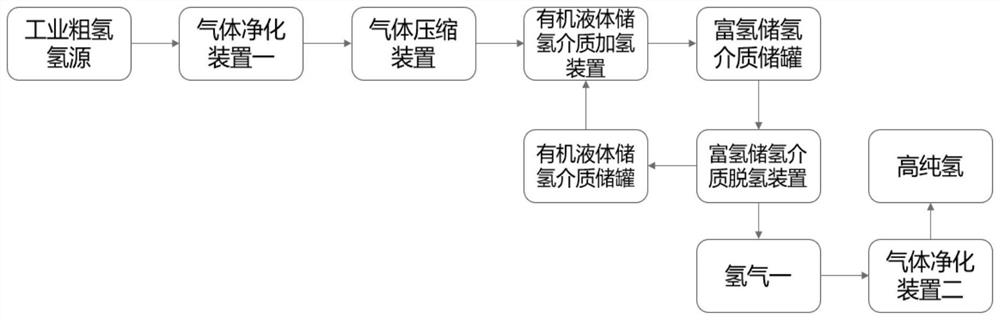

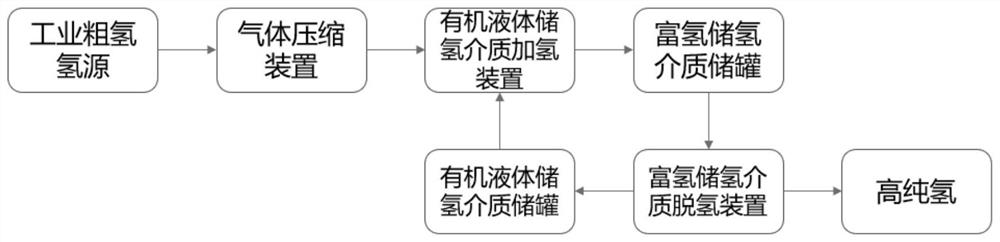

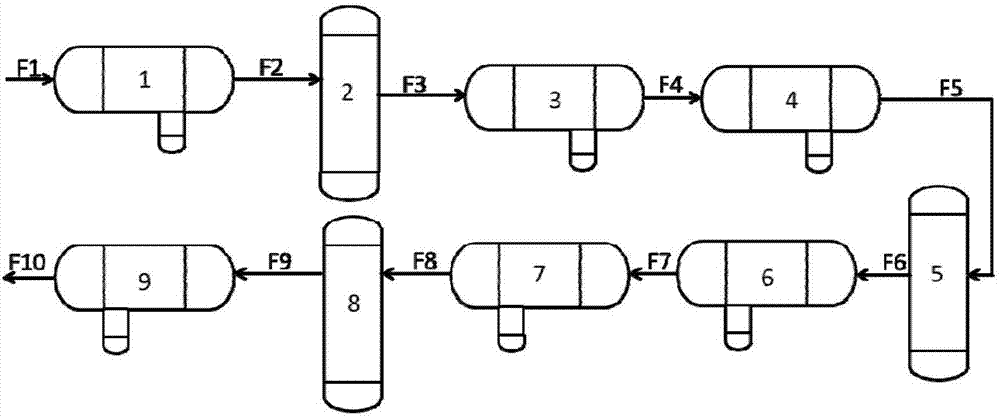

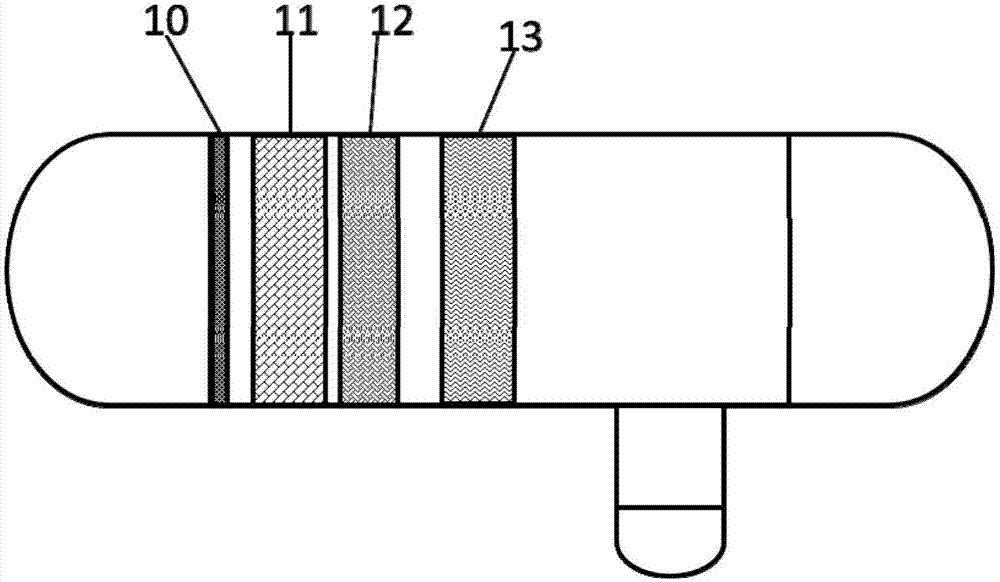

Hydrogen storage and release system and method for organic liquid hydrogen storage medium and industrial crude hydrogen source

PendingCN112093775AAchieve purificationFix security issuesHydrogen separationOrganic liquidsDehydrogenation

The invention discloses a hydrogen storage and release system and method for an organic liquid hydrogen storage medium and an industrial crude hydrogen source, and belongs to the technical field of organic liquid hydrogen storage. The system comprises a first gas purification device, a gas compression device, an organic liquid hydrogen storage medium hydrogenation device, an organic liquid hydrogen storage medium storage tank, a hydrogen-rich hydrogen storage medium storage tank, a hydrogen-rich hydrogen storage medium dehydrogenation device and a second gas purification device, an industrialcrude hydrogen source is introduced into the first gas purification device, is purified, then introduced into the gas compression device and is compressed, the compressed hydrogen source enters the organic liquid hydrogen storage medium hydrogenation device, is subjected to catalytic hydrogenation, is fed into a hydrogen-rich hydrogen storage medium storage tank, then is fed into the hydrogen-richhydrogen storage medium dehydrogenation device, and is subjected to dehydrogenation, and hydrogen obtained after passing through the hydrogen-rich hydrogen storage medium dehydrogenation device enters the second gas purification device and is purified again to obtain high-purity hydrogen. The high-purity hydrogen is obtained, and meanwhile, the problems of purification of an industrial crude hydrogen source and safe storage and transportation of hydrogen can be effectively solved.

Owner:陕西氢易能源科技有限公司

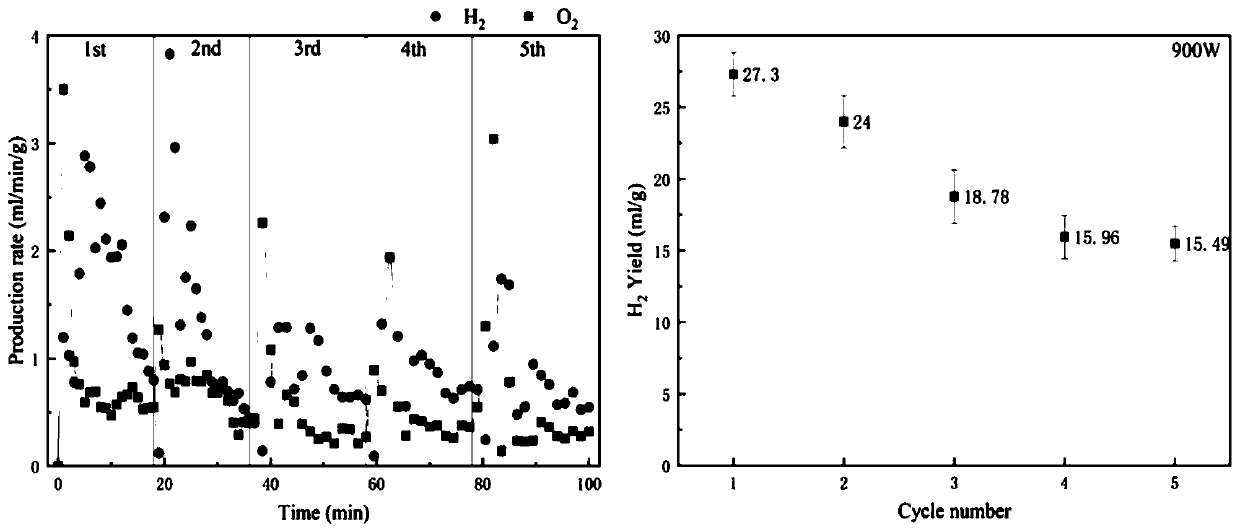

Hydrogen production composite material base on sulfide-based photo-electric bifunctional catalysis and preparation method thereof

InactiveCN110665518AImprove electrochemical stabilityImprove conductivityPhysical/chemical process catalystsNanotechnologyHeterojunctionOptical radiation

The invention relates to that technical field of photo-electrocatalytic hydrogen production, and discloses a sulfide-based photo-electric bifunctional catalytic hydrogen production composite materialand a preparation method thereof. The composite material comprises the following formula raw materials: nano MOS2 sheets, CD (CH3COO) 2.2H2O, thiourea, carbon nanotubes and Ni-doped Co9S8. According to the sulfide-based photo-electric bifunctional catalytic hydrogen-production composite material and the preparation method thereof, Ni doping enhance the conductivity of Co9S8, accelerates the transmission and diffusion process of electrons. The Ni-doped Co9S8 is coated by the carbon nanotubes; the side reaction between Co9S8 and an electrolyte is avoided; holes generated by CdS under optical radiation enter the valence band of MoS2; the recombination efficiency of photo-induced electrons and holes of CdS is reduced; the nano MoS2 has a good carrier mobility to inhibit the recombination of CdS photon-generated carriers; according to the preparation method disclosed by the invention, the electrocatalyst Ni-doped Co9S8 with is tightly coated by the carboxylated carbon nano tubes, and meanwhile, the photocatalyst CdS-MoS2 heterojunction is uniformly attached, so that the dual functionalization of photolysis-electrolysis of water to produce hydrogen of the composite material is realized.

Owner:广州市涂屋信息科技有限公司

Water electrolysis hydrogen production system

PendingCN112144071AAvoid wastingEasy to storeCellsHydrogen separationHydrogen storage systemClean energy

The invention relates to the technical field of clean energy and water electrolysis hydrogen production, in particular to a water electrolysis hydrogen production system, which comprises a hydroelectric generation system, an electric power storage system, a water electrolysis hydrogen production system, a hydrogen purification system and a hydrogen storage system, wherein the lower side of the hydroelectric generation system is provided with the electric power storage system; the water electrolysis hydrogen production system is arranged on one side of the hydroelectric generation system, the hydrogen purification system is arranged at one end of the water electrolysis hydrogen production system, and the hydrogen storage system is arranged at one end of the hydrogen purification system. Inthe invention, by arranging the hydroelectric generation system, the hydrogen storage system, the water electrolysis hydrogen production system and the hydrogen purification system, waste water is used for power generation, energy waste is avoided, the electricity price is low, on-site hydrogen production is achieved, and energy storage is facilitated.

Owner:南通安思卓新能源有限公司

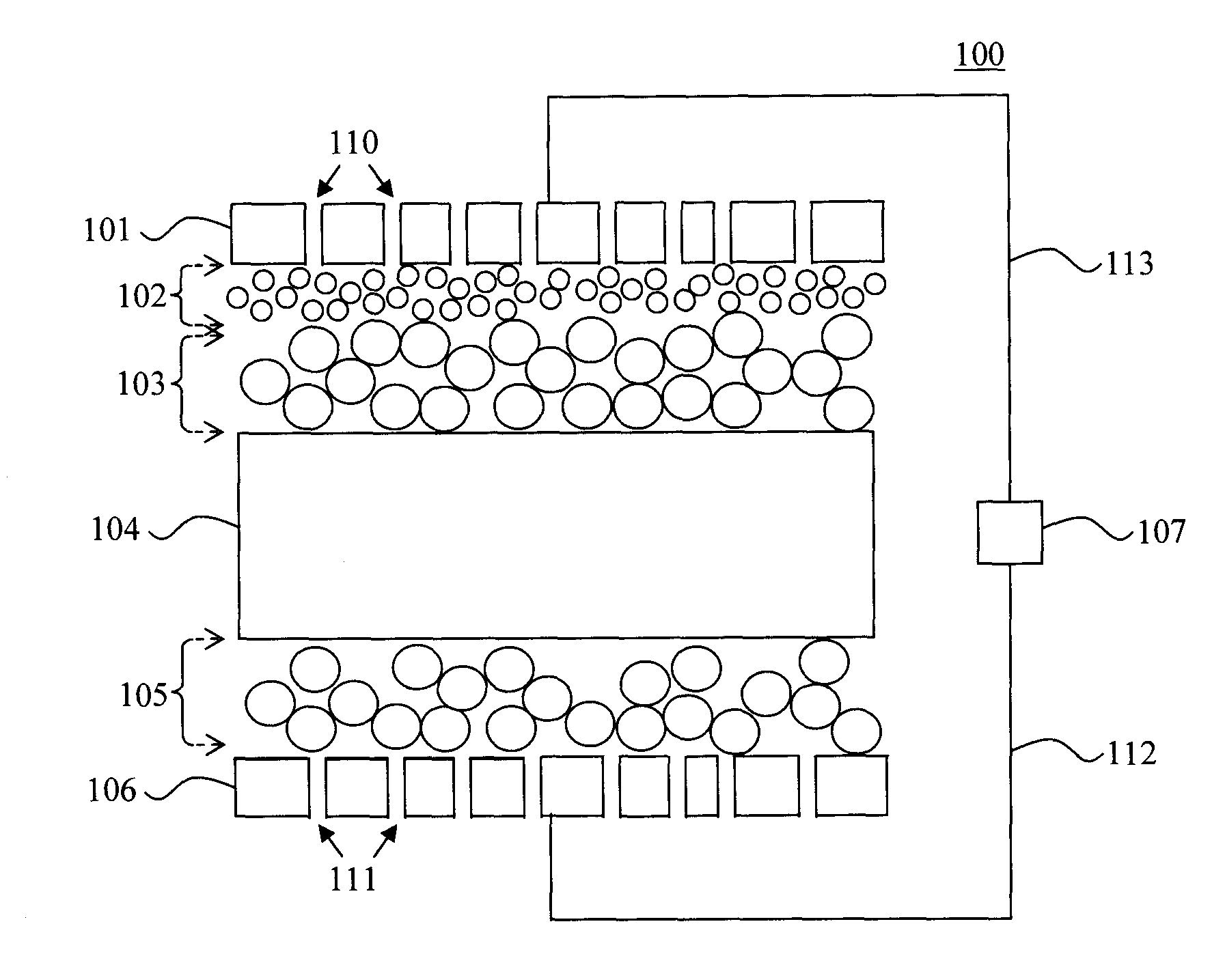

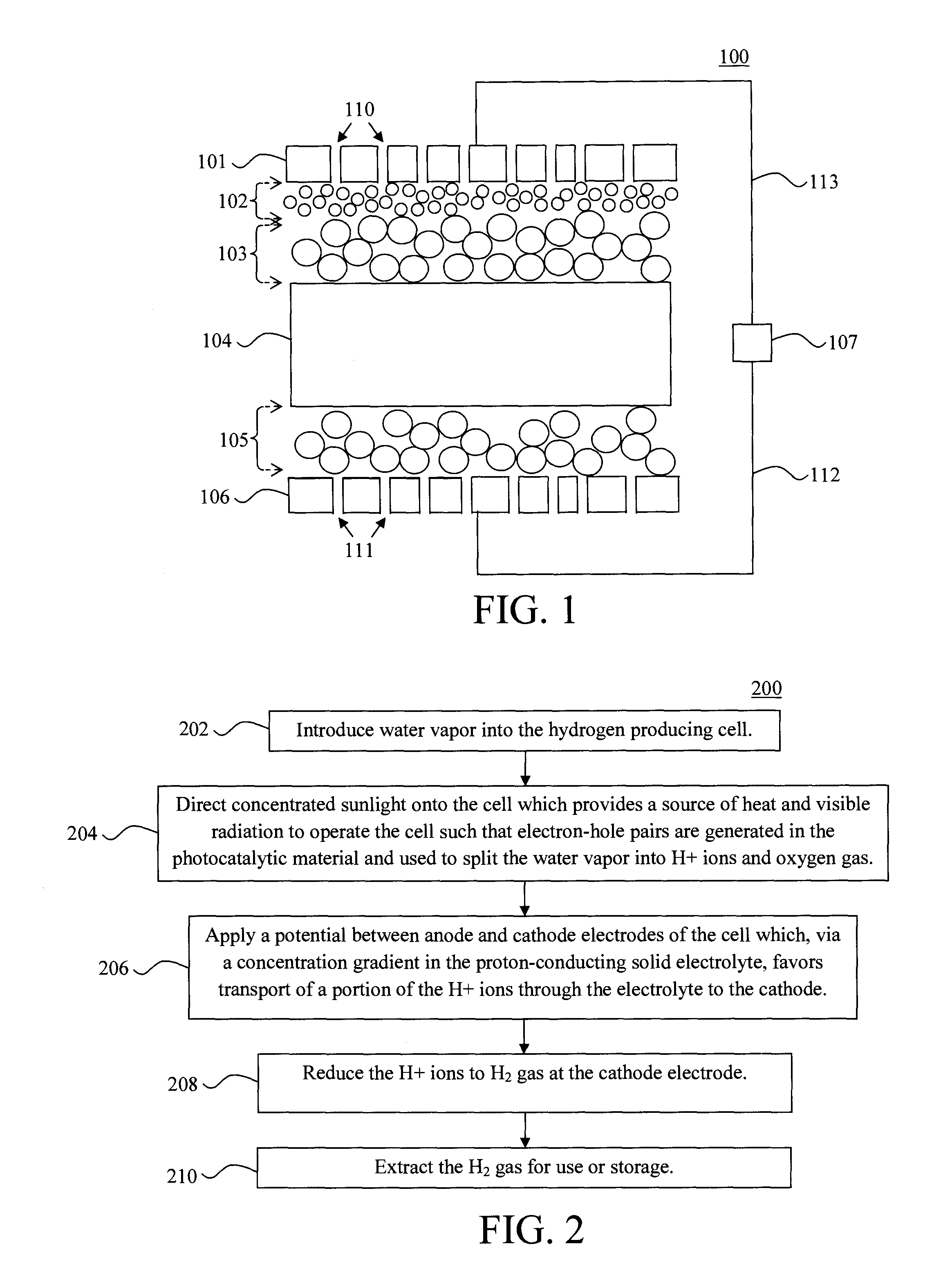

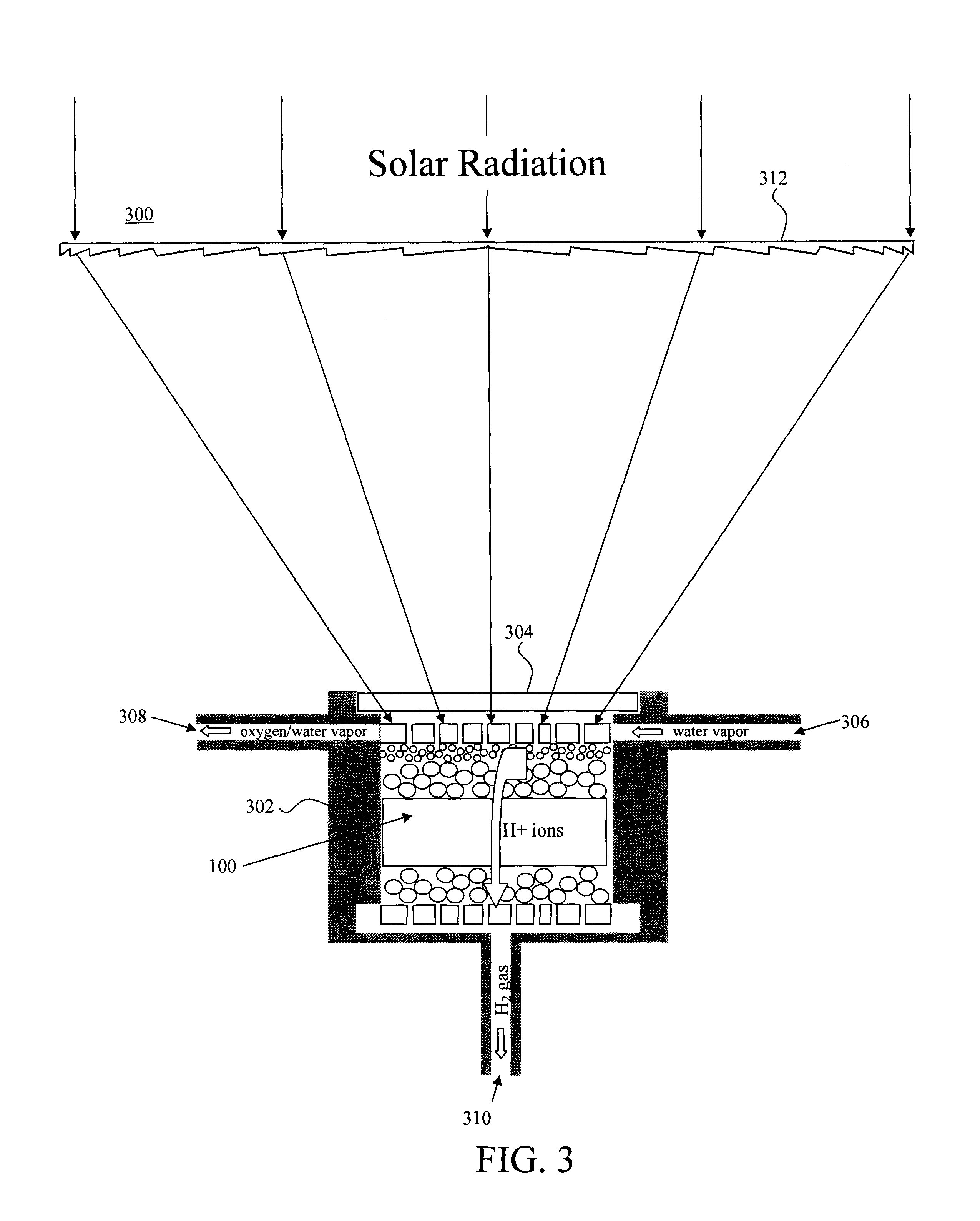

Techniques for Photocatalytic Hydrogen Generation

Techniques for photocatalytic hydrogen generation are provided. In one aspect, a hydrogen producing cell is provided. The hydrogen producing cell includes an anode electrode; a photocatalytic material adjacent to the anode electrode; a solid electrolyte adjacent to a side of the photocatalytic material opposite the anode electrode; and a cathode electrode adjacent to a side of the solid electrolyte opposite the photocatalytic material. A solar hydrogen producing system including at least one solar concentrating assembly having the hydrogen producing cell, and a method for producing hydrogen using the hydrogen producing cell are also provided.

Owner:IBM CORP

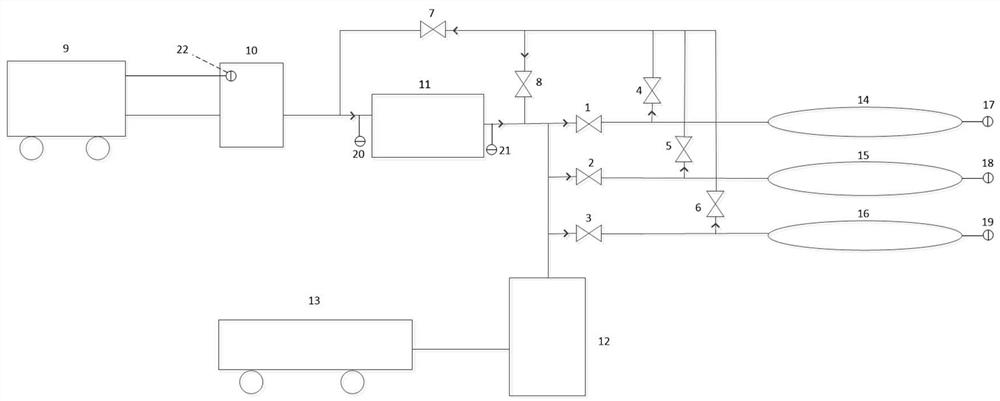

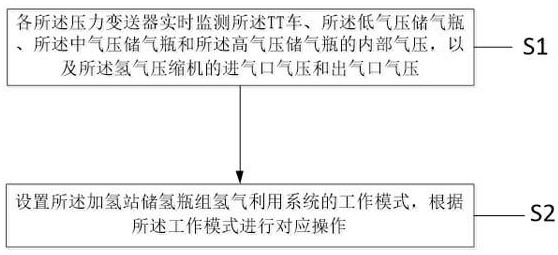

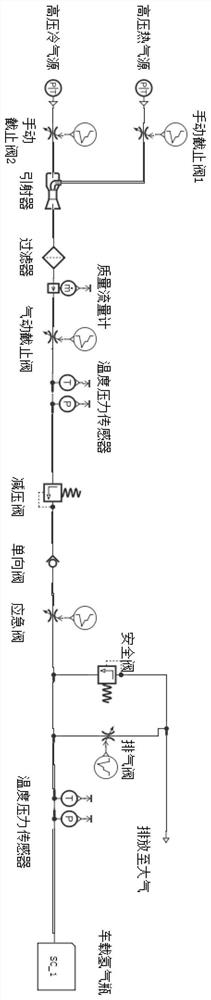

Hydrogen utilization system and method for hydrogen storage cylinder group of hydrogen refueling station

InactiveCN112594552AMeet various hydrogenation scenariosImprove hydrogen utilizationGas handling/storage effectsPipeline systemsThermodynamicsGas cylinder

The invention relates to the technical field of hydrogenation, and provides a hydrogen utilization system and method for a hydrogen storage cylinder group of a hydrogen refueling station. The hydrogenutilization system comprises a TT vehicle, a gas unloading cabinet, a hydrogen compressor, a hydrogenation machine, a low-pressure gas storage bottle, a medium-pressure gas storage bottle, a high-pressure gas storage bottle, a first gas valve, a second gas valve, a third gas valve, a fourth gas valve, a fifth gas valve, a sixth gas valve, a seventh gas valve and an eighth gas valve. According tothe hydrogen utilization system and method, multiple working modes are provided, so that the hydrogen refueling station can meet various hydrogen refueling scenes; and when the air pressure of hydrogen in the gas storage bottles is lower than a certain value and the hydrogen cannot be normally injected into a hydrogen energy automobile, the residual hydrogen in the gas storage bottles is pressurized through the hydrogen compressor, so that the residual hydrogen in the gas storage bottles can also be normally injected, and the hydrogen utilization rate of the gas storage bottles is increased.

Owner:河南氢枫能源技术有限公司 +1

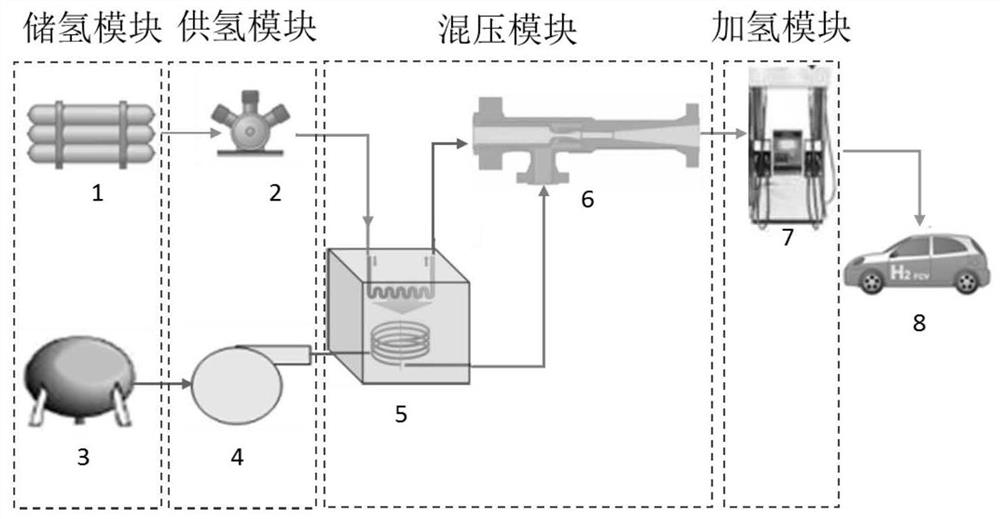

Liquid hydrogen and high-pressure gaseous hydrogen combined hydrogen refueling system based on ejection mixed pressure

ActiveCN112344207ASolve the problem of mixing different pressuresReduce complexityVessel mounting detailsContainer filling methodsHigh pressure hydrogenLiquid hydrogen

The invention belongs to the technical field of hydrogenation of hydrogen refueling station, and discloses a liquid hydrogen and high-pressure gaseous hydrogen combined hydrogen refueling system basedon ejection mixed pressure. The system comprises a high-pressure hydrogen storage tank (1), a liquid hydrogen tank (3), a compressor (2), a liquid hydrogen pump (4), a heat exchanger (5) and an ejector (6), wherein the heat exchanger is used for heat exchange treatment to enable high-pressure gaseous hydrogen to release heat so as to obtain gaseous first hydrogen and enable liquid hydrogen to absorb heat so as to obtain gaseous second hydrogen; and the ejector is used for mixing the first hydrogen and the second hydrogen to obtain mixed hydrogen. According to the system, by improving the composition of all components in the system and the matching working mode of the components, high-pressure hydrogen and low-pressure hydrogen are obtained through heat exchange and precooling of the high-pressure gaseous hydrogen and the liquid hydrogen respectively, and mixed pressure of the high-pressure hydrogen and the low-pressure hydrogen is achieved through the ejector; a traditional precoolingunit is saved while the reliability is guaranteed, so that investment, operation and maintenance cost of pre-cooling equipment of the hydrogen refueling station is reduced; and the system is suitablefor the large hydrogen refueling stations for liquid hydrogen and gas hydrogen combined storage.

Owner:HUAZHONG UNIV OF SCI & TECH

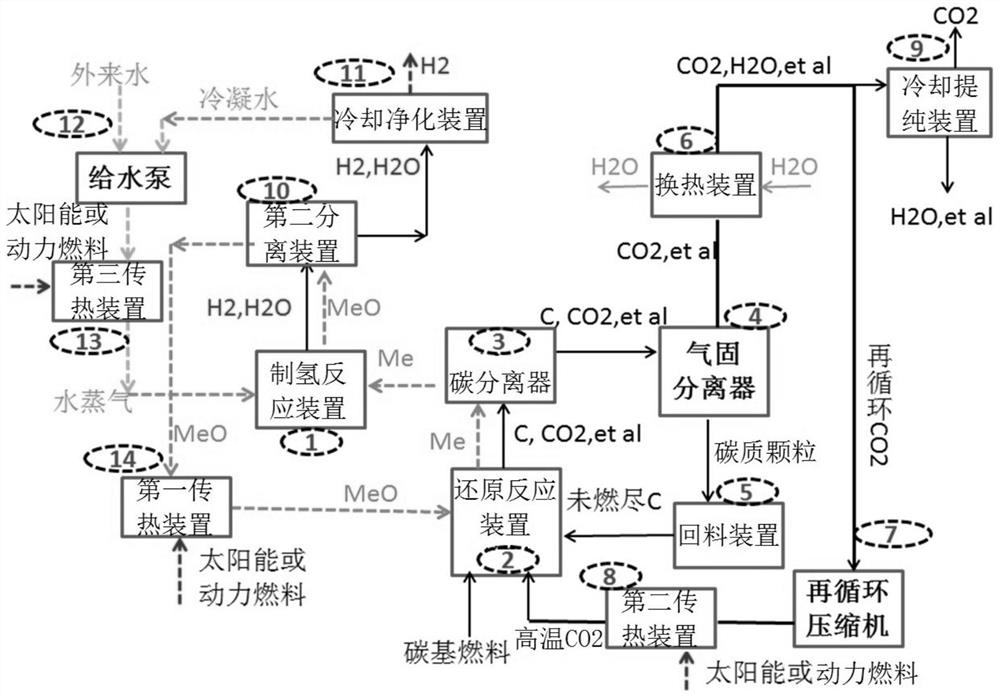

Chain reaction hydrogen production system and hydrogen production method

ActiveCN112079333AReduce water consumptionReduce energy consumptionHydrogen separation using solid contactGasification processes detailsChemical reactionCarbon-based fuel

The invention discloses a chain reaction hydrogen production system and a hydrogen production method, and the system comprises a reduction reaction device, a first separation device, a hydrogen production reaction device, a second separation device, a first heat transfer device and a cooling purification device. The invention starts from the chain combustion reaction mechanism, MeO / Me circularly flows between the hydrogen production reaction device and the reduction reaction device to respectively generate reduction / oxidation chemical reaction, and the traditional carbon-based solid fuel is converted into high-purity clean hydrogen energy. According to the method, the system is used for preparing hydrogen. Compared with the traditional water gas shift synthesis gas hydrogen production technology, the water consumption, the energy consumption and the environmental pollution of the hydrogen production process can be reduced; renewable energy sources such as solar energy can be utilized,traditional carbon-based fuel is converted into clean hydrogen energy, and the efficient capture and storage of CO2 gas are achieved; the metal oxide can be recycled through a chain reaction, and thelow-cost, sustainable and stable production of hydrogen is achieved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

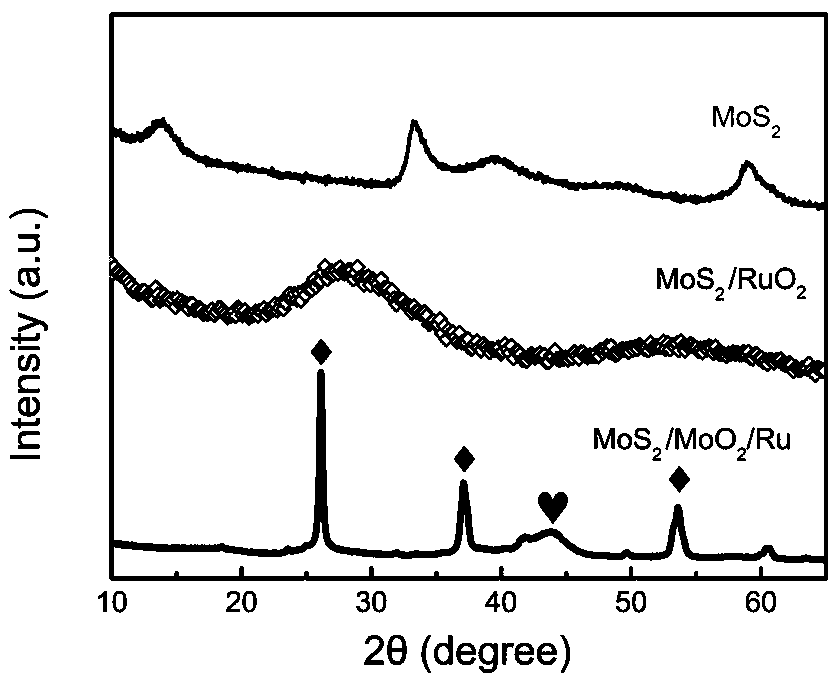

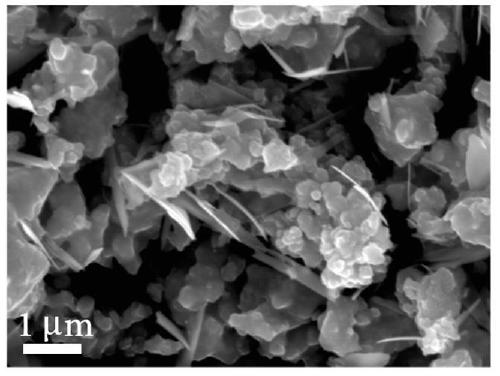

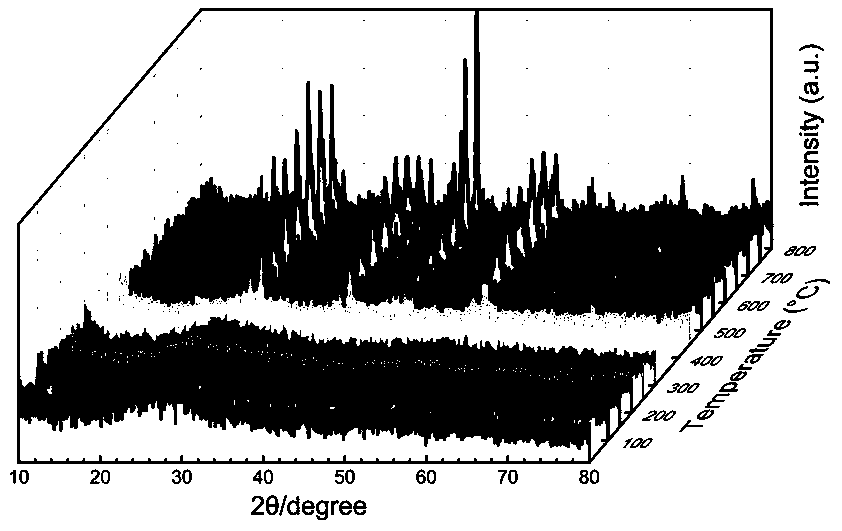

MoS2/MoO2/Ru composite material as well as preparation method and application thereof

ActiveCN111468144AUniform shapeImprove electrocatalytic performancePhysical/chemical process catalystsElectrodesPtru catalystHydrogen evolution

The invention belongs to the technical field of electrocatalytic hydrogen production, and discloses a MoS2 / MoO2 / Ru composite material as well as a preparation method and application thereof. The method comprises: adding nano MoS2 into water, ultrasonically dispersing uniformly under an ice bath condition, and then putting the ultrasonically dispersed mixed solution into a cell disruptor for ultrasonic treatment for at least 30 minutes; sequentially adding water-soluble Ru salt and H2O2 with the concentration of 4-6 wt% into the obtained mixed solution, uniformly stirring, controlling the temperature to be 80-95 DEG C, reacting for 4-6 hours, centrifuging, washing and drying to obtain a MoS2 / RuO2 composite material; and fully and uniformly grinding the prepared MoS2 / RuO2 composite material,calcining the MoS2 / RuO2 composite material for 3-6 hours at 400-800 DEG C in N2 gas or inert atmosphere, and naturally cooling to room temperature to obtain the MoS2 / MoO2 / Ru composite material. The disclosed composite material is used as a catalyst for an electrocatalytic hydrogen evolution reaction. The MoS2 / MoO2 / Ru composite material prepared by the method disclosed by the invention has uniformmorphology and excellent electrocatalytic performance, and meanwhile, in the preparation process, the reaction conditions are simple, the operation is easy, the yield is high, and the industrial production is easy.

Owner:ZHENGZHOU UNIV

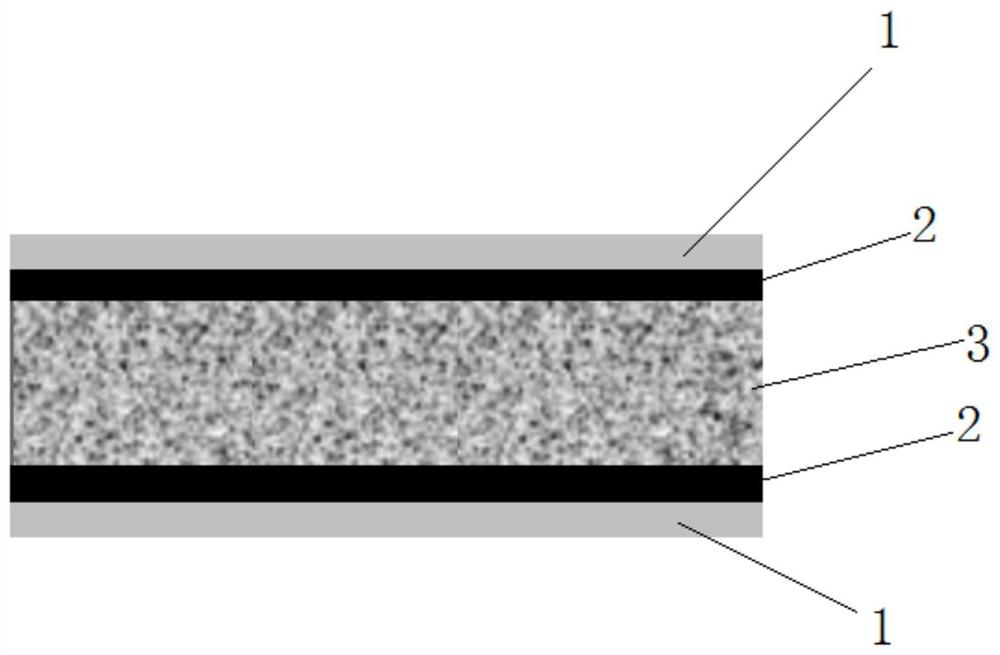

Multilayer selective hydrogen permeation composite membrane, and preparation method and application thereof

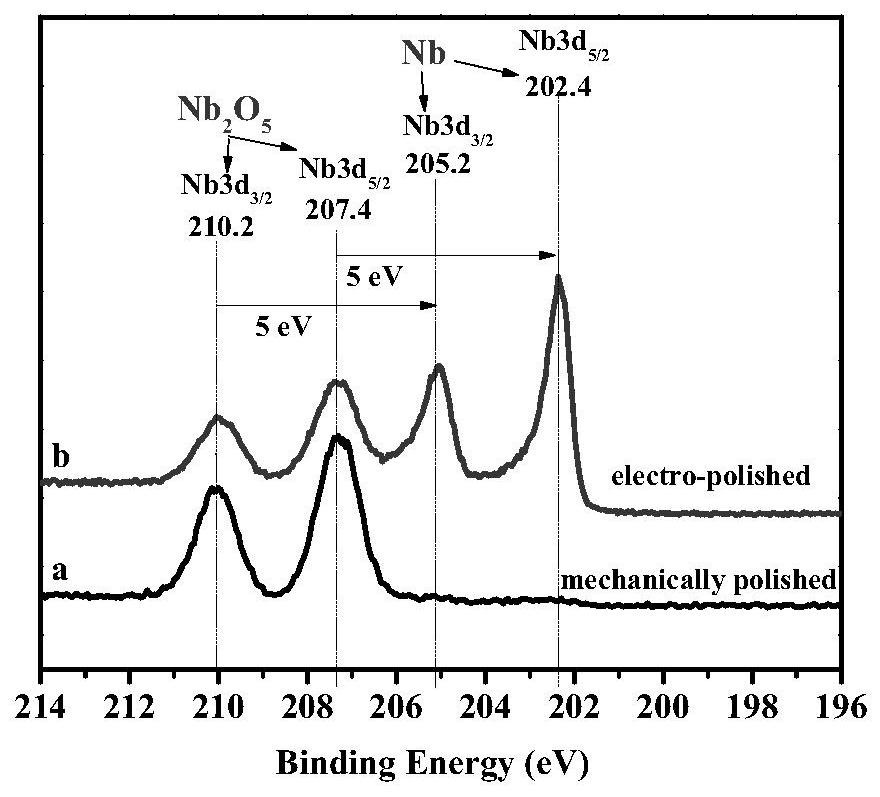

ActiveCN112957912ADoes not affect hydrogen permeabilityExtended service lifeSemi-permeable membranesGas treatmentMetal alloyPhysical chemistry

The invention provides a multilayer selective hydrogen permeation composite membrane, and belongs to the technical field of hydrogen permeation. The composite membrane comprises a metal base material layer with high hydrogen permeability, a metal layer with catalytic activity and permeability to hydrogen and a single-layer graphene film with selective permeability to proton hydrogen, wherein the metal base material layer is made of niobium or a metal alloy composed of niobium and other metal elements, and the metal layer is made of palladium or a metal alloy composed of palladium and other elements. The invention also provides a preparation method of the multilayer selective hydrogen permeation composite membrane. According to the multilayer selective hydrogen permeation composite membrane, high-temperature mutual diffusion of metal atoms in the metal layer and metal atoms in a metal substrate layer can be effectively prevented, meanwhile, the hydrogen permeation rate of the composite membrane is not affected, and the service life of the composite membrane can be prolonged. The multilayer selective hydrogen permeation composite membrane material is particularly suitable for separating hydrogen from a gas mixture through selective diffusion.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Industrial crude hydrogen purification and hydrogen storage and release system and method based on organic liquid hydrogen storage medium

PendingCN112028018AReduce complexityEfficient production capacityHydrogen separation using liquid contactHydrogen/synthetic gas productionOrganic liquidsDehydrogenation

The invention discloses an industrial crude hydrogen purification and hydrogen storage and release system and method for an organic liquid hydrogen storage medium, and belongs to the technical field of organic liquid hydrogen storage. The system comprises a gas compression device, an organic liquid hydrogen storage medium hydrogenation device, an organic liquid hydrogen storage medium storage tank, a hydrogen-rich hydrogen storage medium dehydrogenation device and a hydrogen-rich hydrogen storage medium storage tank. The method comprises the steps of firstly, introducing an industrial crude hydrogen source into the gas compression device to compress the industrial crude hydrogen source, then introducing the compressed crude hydrogen source into the organic liquid hydrogen storage medium hydrogenation device to carry out catalytic hydrogenation, feeding a material subjected to catalytic hydrogenation into the hydrogen-rich hydrogen storage medium storage tank, feeding the material in the hydrogen-rich hydrogen storage medium storage tank into the hydrogen-rich hydrogen storage medium dehydrogenation device for dehydrogenation, and finally, discharging high-purity hydrogen from one outlet after passing through the hydrogen-rich hydrogen storage medium dehydrogenation device. Additional gas purification equipment is not needed, the purification problem of an impurity-containing industrial crude hydrogen source is solved, and high-purity hydrogen meeting the use standard can be output.

Owner:陕西氢易能源科技有限公司

Step-by-step dehydration method for wood tar hydrogenation integration device

InactiveCN107353935ATechnical requirements to ensure process dehydrationReduce design costTreatment with hydrotreatment processesNaphthaEconomic benefits

The invention discloses a step-by-step dehydration method of a wood tar hydrogenation combined device in the technical field of wood tar hydrogenation. The method comprises the following steps: (1) the wood tar raw material of the wood tar hydrodeoxygenation device first passes through a deep dehydration unit; (2) The reaction product of the BDO unit enters the modified BDO cold high-pressure separator for preliminary dehydration treatment; (3) The reaction product of the OTM unit enters the modified OTM cold high-pressure separator for preliminary dehydration treatment; (4) Naphtha and light diesel oil The product is finally processed by a deep dehydration device before leaving the factory. Using the technological process proposed by the method, the raw materials, intermediate products and final products of the wood tar hydrogenation complex are dehydrated step by step. After the step-by-step dehydration treatment process, the energy consumption of the combined wood tar hydrogenation unit has been greatly reduced, the product quality has been greatly improved, the stable operation time of the unit has been greatly increased, and the economic benefits of the entire unit have been improved.

Owner:SHANGHAI MISU ENVIRONMENTAL PROTECTION TECHCO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com