Patents

Literature

76results about How to "Improve hydrogen utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

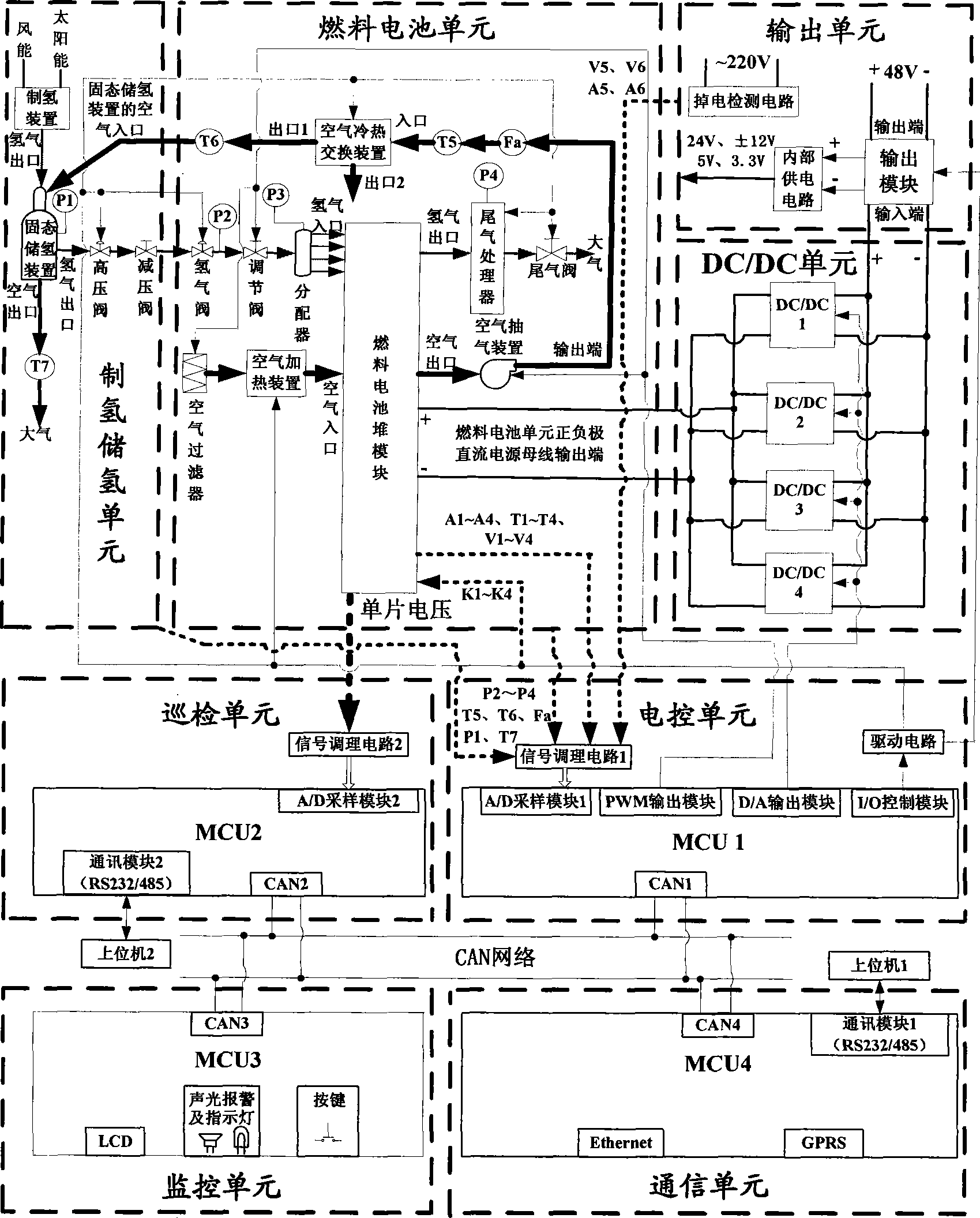

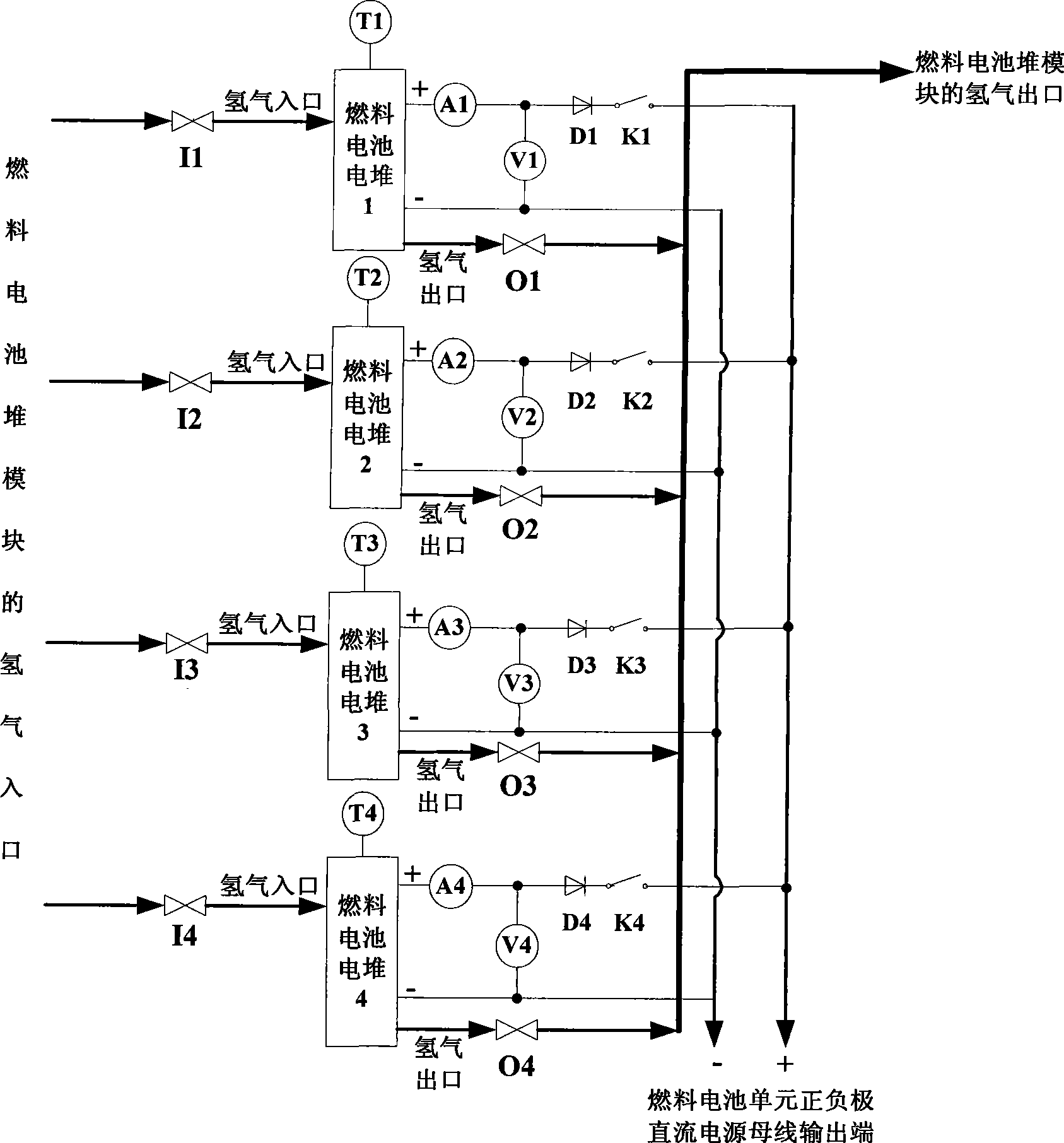

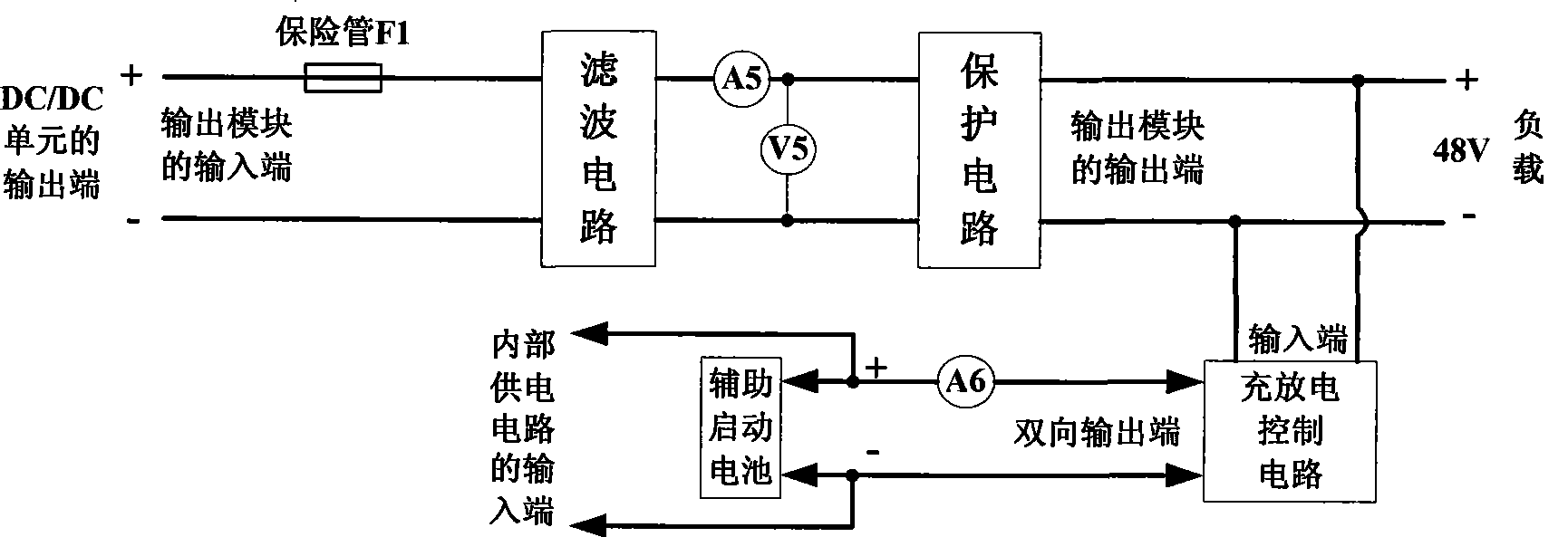

Standby electrical power system of fuel cell for communication

InactiveCN101505092AKeep aliveIncrease profitBatteries circuit arrangementsEfficient power electronics conversionElectrochemical responseEngineering

The invention relates to a communication fuel cell spare power supply system, which comprises a hydrogen generation and storage unit, a fuel cell unit, a DC / DC unit, an output unit, an electric control unit, a routing inspection unit, a monitoring unit and a communication unit, and is characterized in that: the hydrogen generation and storage unit generates hydrogen by using solar or wind energy and releases the hydrogen by absorbing the heat of the fuel cell unit; the fuel cell unit generates direct current electric energy and heat by the electrochemical reaction of the hydrogen and oxygen; the DC / DC unit adjusts and boosts the direct current electric energy and then supplies the direct current electric energy to the output unit; the output unit supplies power to a load when commercial power fails; the electric control unit acquires various data and sends control information to all units; the routing inspection unit acquires all individual cell voltage values for transmission; the monitoring unit displays various parameters and working states and realizes human-computer interaction; and the communication unit performs short-range and long-range communication and monitoring. The power supply system is clean, high efficient, reliable and applicable to various communication spare power supplies.

Owner:武汉海亿新能源科技有限公司

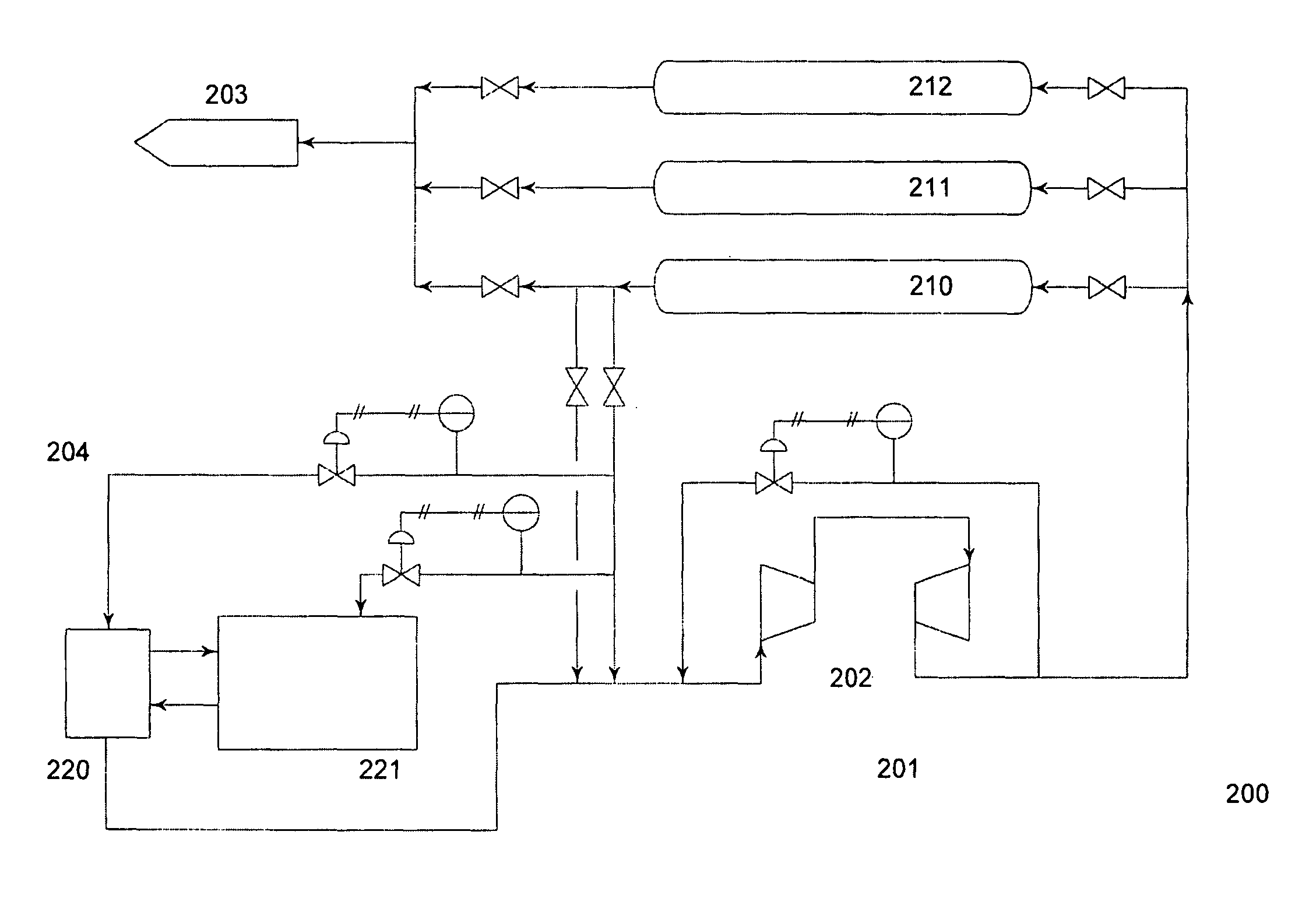

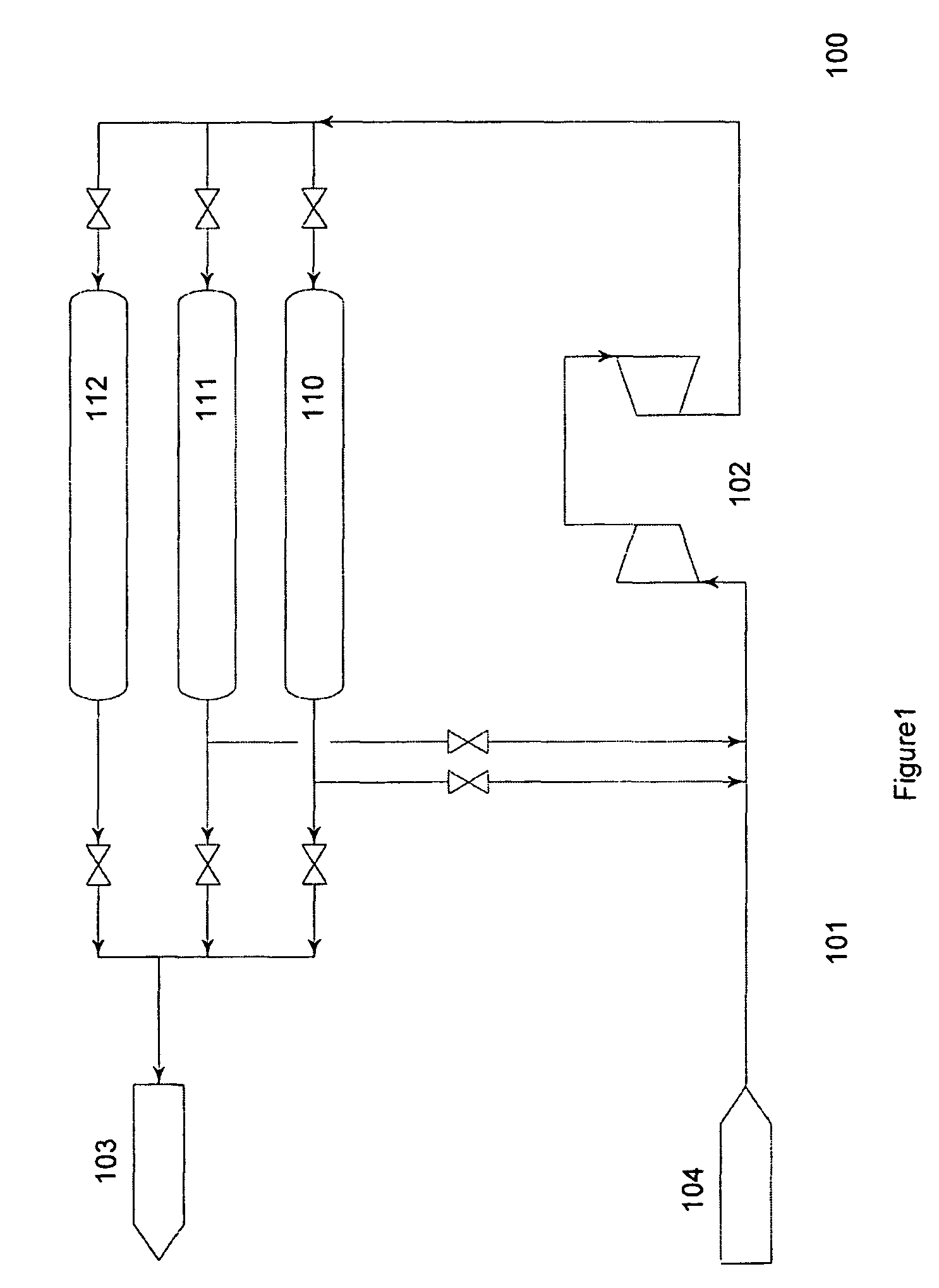

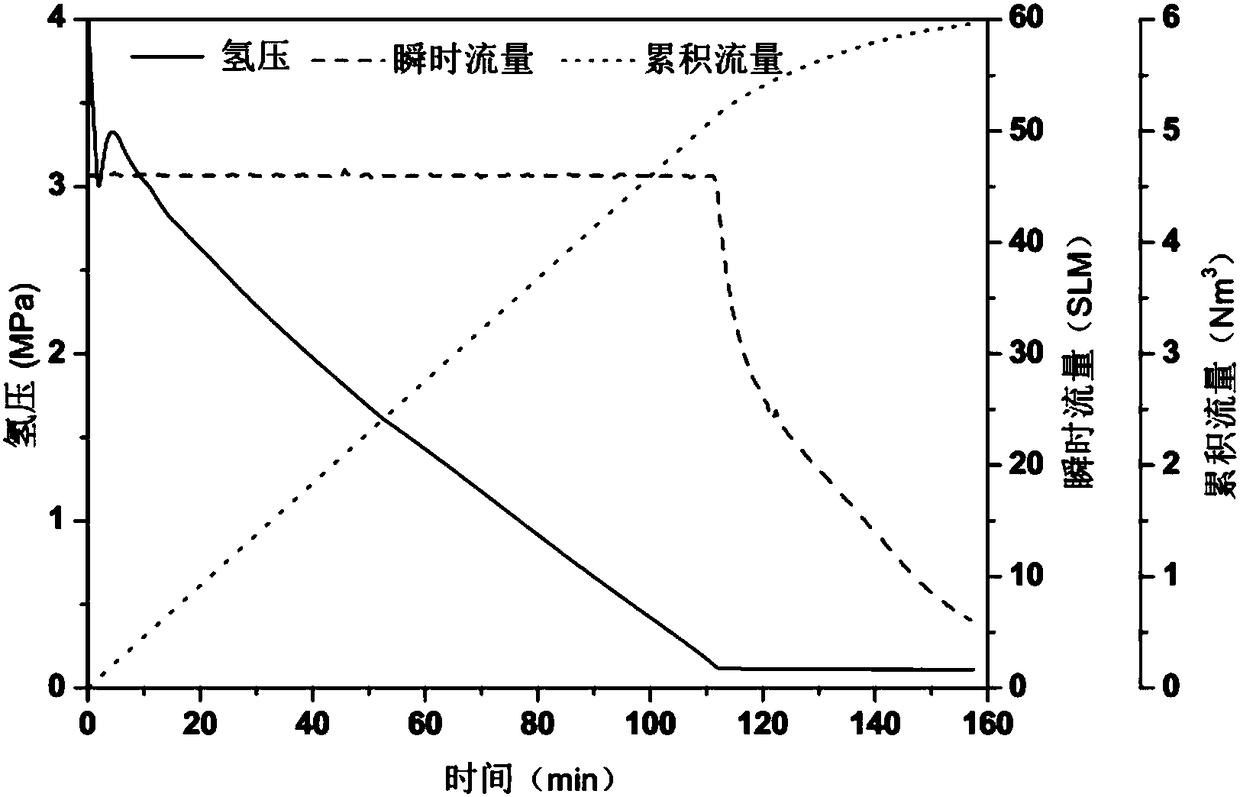

Method for managing storage of gaseous hydrogen

InactiveUS7987877B2Increase profitImprove hydrogen utilizationLiquid fillingGas handling applicationsGaseous hydrogenHydrogen vehicle

In order to increase the hydrogen utilization rate of the cascade storage system, after dispensing gaseous hydrogen to a hydrogen vehicle, gaseous hydrogen is transferred via a compressor from at least one storage vessel at a lower pressure to at least one storage vessel at a higher, dispensable pressure. The methods of the present invention economically and efficiently increase the utilization rate of gaseous hydrogen stored in a cascade storage system by managing the storage of gaseous hydrogen and increasing the utilization rate of gaseous hydrogen stored in a cascade storage system.

Owner:TEXACO INC

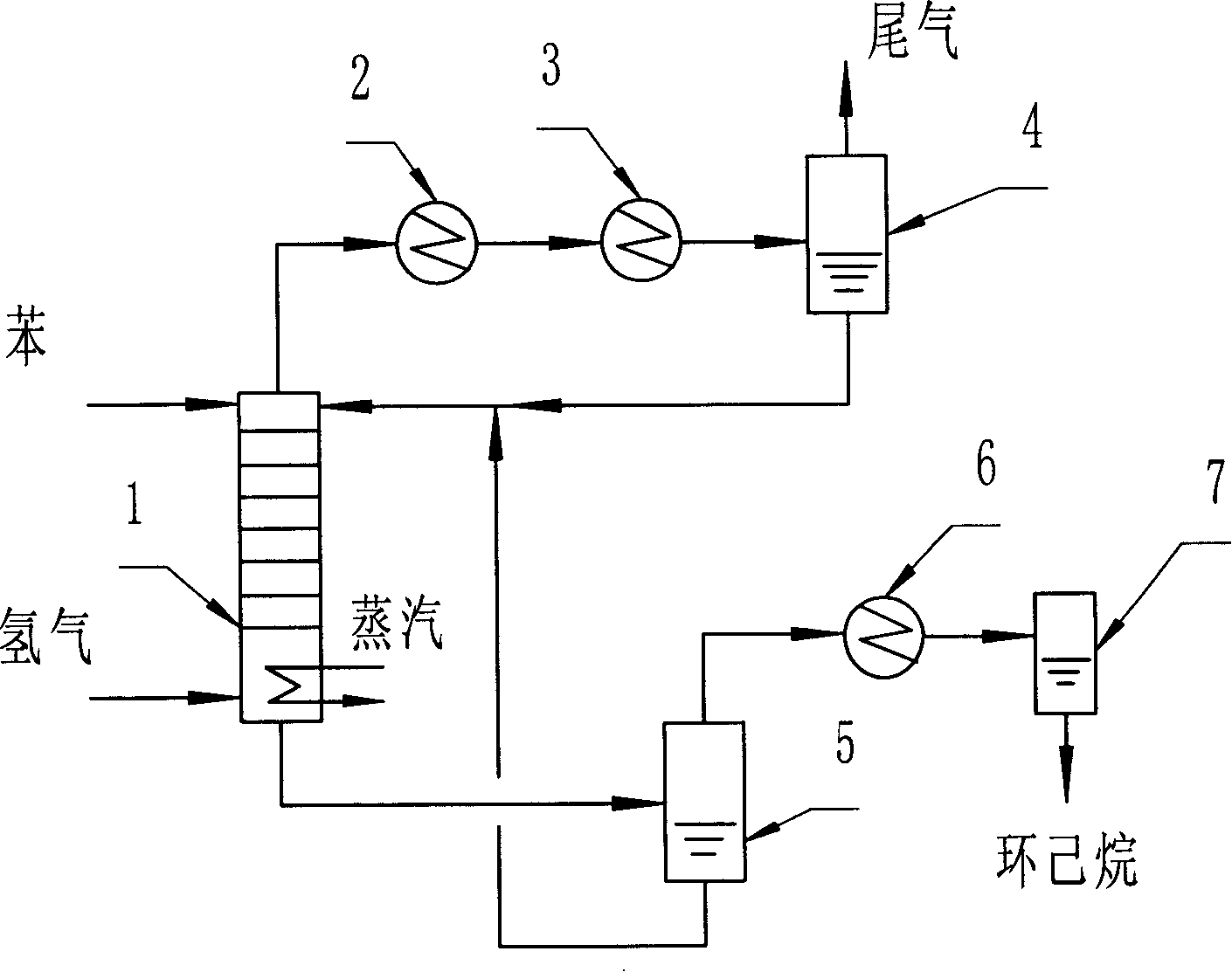

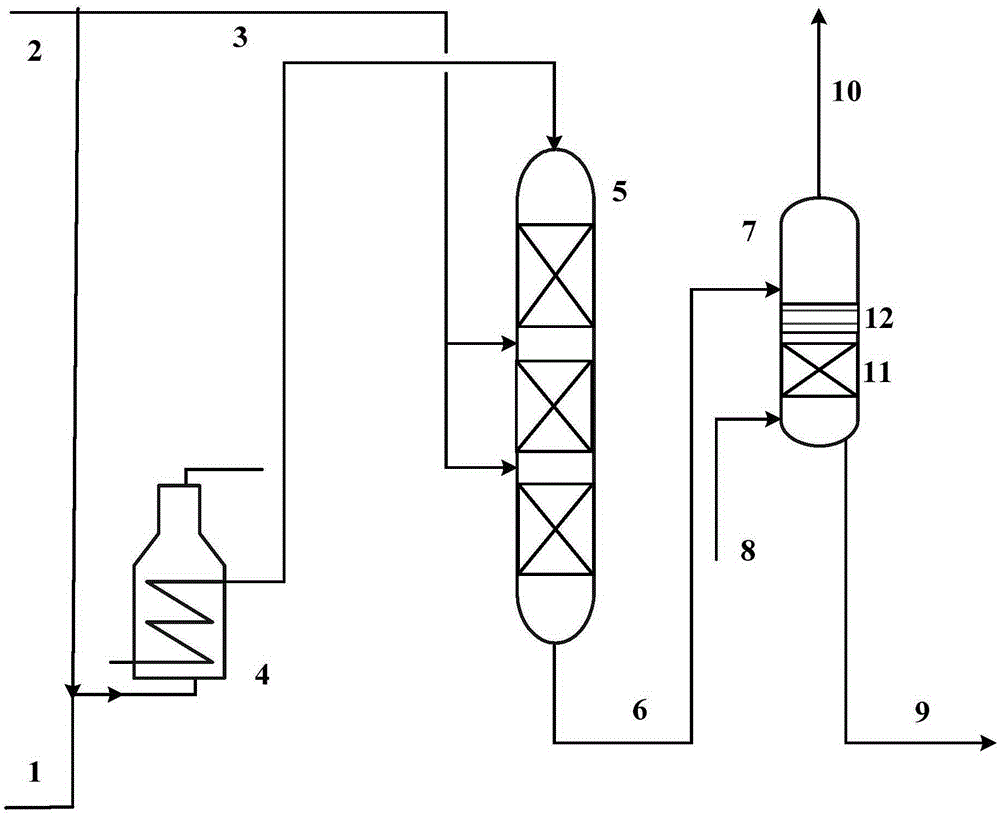

Preparation method of cyclohexane

ActiveCN101205163ASolve the problem of heat transferStable reaction temperatureHydrocarbon by hydrogenationBenzeneHydrogen

A method for preparing a cyclohexane comprises the following steps: a benzene and a hydrogenation catalyst are driven to enter a distillation tower from the tower top and the hydrogen goes into the distillation tower from the tower bottom; the tower bottom is heated by the steam and a reaction in which the benzene hydrogenation is used for generating the cyclohexane is conducted in the tower; the condensate at the tower top refluxes and the discharged materials from the tower bottom are subject to the flash separation so as to obtain the cyclohexane. The method of the invention can lower the content of the methyl cyclopentane in the products and is beneficial to the stabilized operation and the enhancement of the hydrogen utilization ratio and the effective reaction volume of the tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

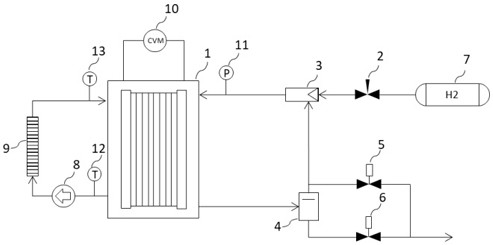

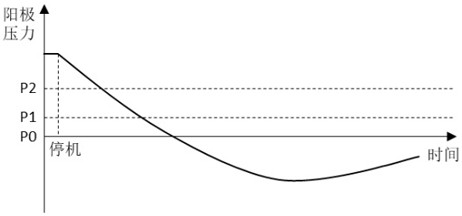

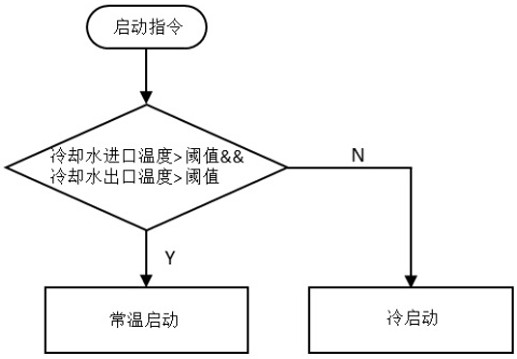

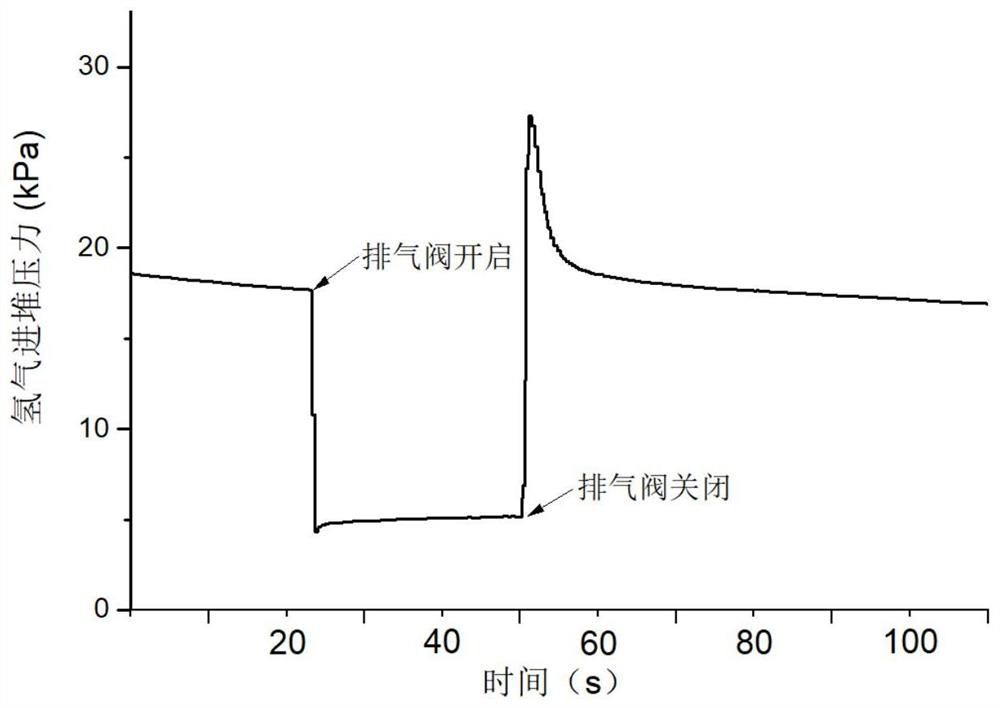

Fuel cell system and purging starting method thereof

ActiveCN114883606AImprove hydrogen utilizationReduced risk of shortened lifespanFuel cellsExhaust valveThermodynamics

The invention discloses a fuel cell system and a purging starting method thereof. The fuel cell system comprises an electric pile, a hydrogen supply unit, a hydrogen proportional valve, an ejector, a gas-water separator, an exhaust valve, a drain valve, a water pump, a radiator, a CVM voltage monitoring module, a pressure sensor, an outlet temperature sensor and an inlet temperature sensor. The starting purging method comprises the following steps: after the fuel cell system receives a starting instruction, detecting the temperature of a cooling liquid outlet and the temperature of a cooling liquid inlet of a galvanic pile, and if the temperature of the cooling liquid outlet and the temperature of the cooling liquid inlet are both greater than a specified temperature threshold, enabling the fuel cell system to enter a normal-temperature starting process; otherwise, the fuel cell system enters a cold start process. By reducing the hydrogen waste, the hydrogen-air interface of the anode is prevented from appearing or the existence time is shortened, so that the hydrogen utilization rate is improved, and the service life of the galvanic pile is ensured.

Owner:佛山市清极能源科技有限公司

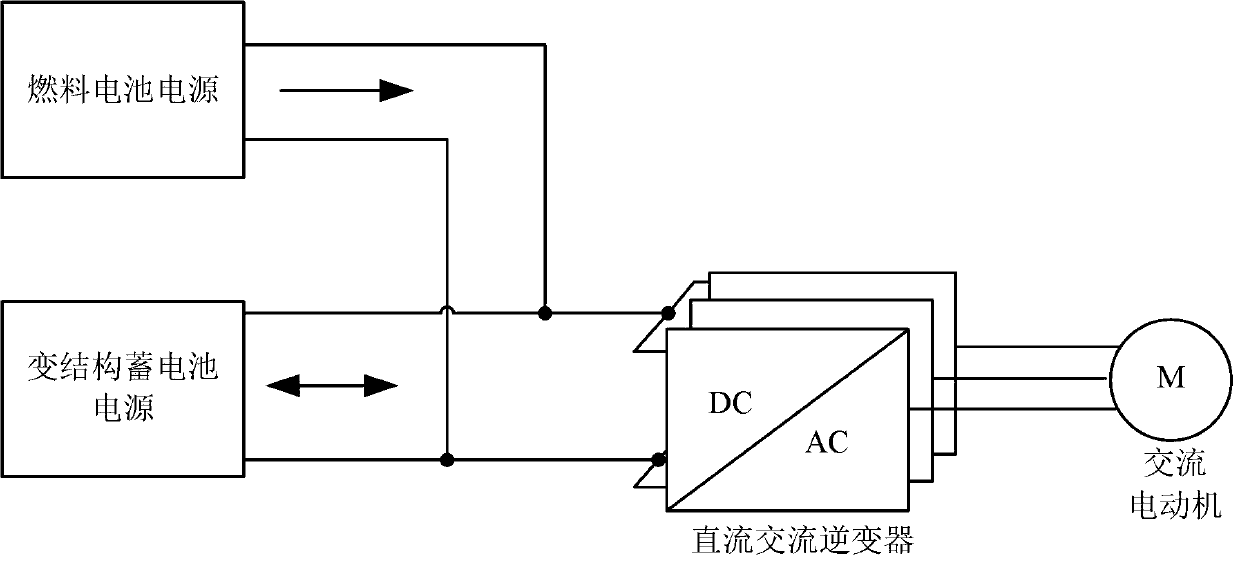

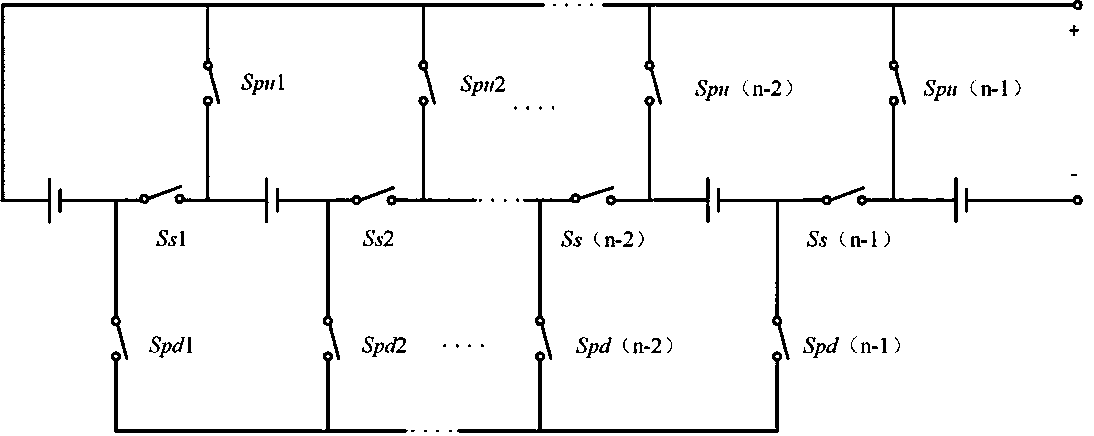

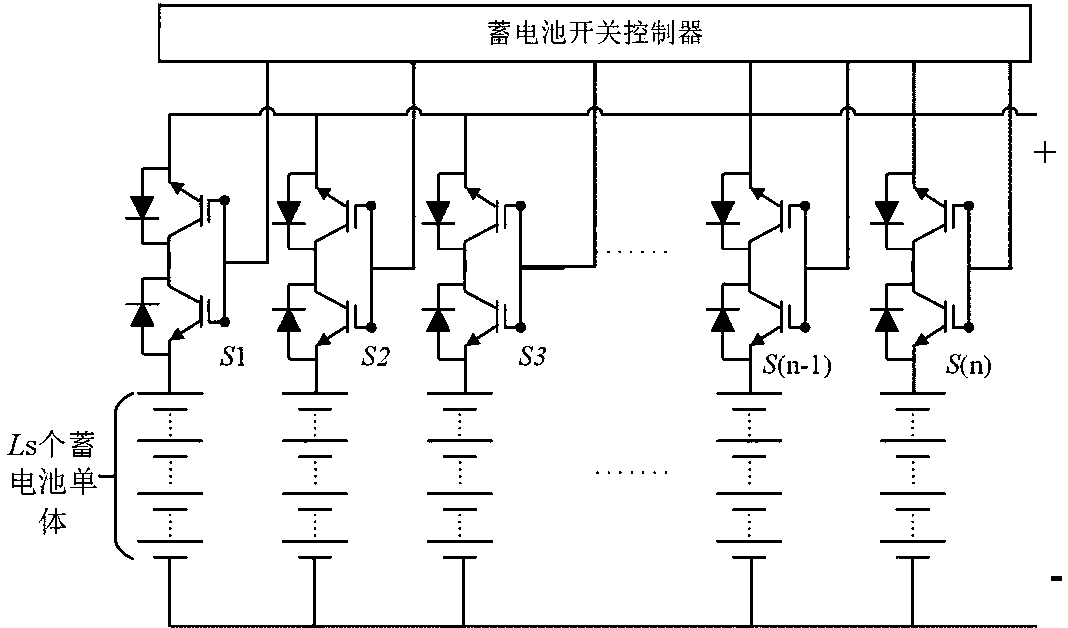

Fuel battery efficiency optimization method for electric-electric hybrid power system

ActiveCN110758122AReduce power lossIncrease profitPropulsion by batteries/cellsVehicular energy storageFuel cellsElectric machine

The invention relates to a fuel battery efficiency optimization method for an electric-electric hybrid power system and provides the electric-electric hybrid power system; a fuel battery and a variable-structure storage battery are used as a power supply and are directly connected in parallel in a bus bar and are connected with a load motor by virtue of a direct-current / alternating-current inverter; the fuel battery efficiency optimization method comprises the following steps of: step (S1) acquiring relevant parameters of each working point of a fuel battery power supply by virtue of off-linemeasurement and calculation, and acquiring a function relationship of the voltage, current, power and efficiency of the fuel battery power supply; step (S2) acquiring the voltage and power of a maximum efficiency point of the fuel battery power supply by virtue of function inverse operation; step (S3) matching serial-parallel grouped structures of the variable-structure storage battery power supply; and step (S4) calculating the amount of monomers which are to be connected in series with the variable-structure storage battery power supply and the amount of branches which are to be connected inparallel with the variable-structure storage battery power supply. The fuel battery efficiency optimization method provided by the invention can effectively increase the utilization rate of the fuelbattery by stabilizing the fuel battery to work at the maximum efficiency point.

Owner:FUZHOU UNIV

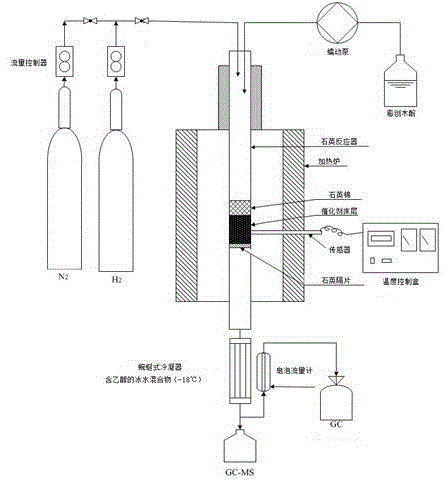

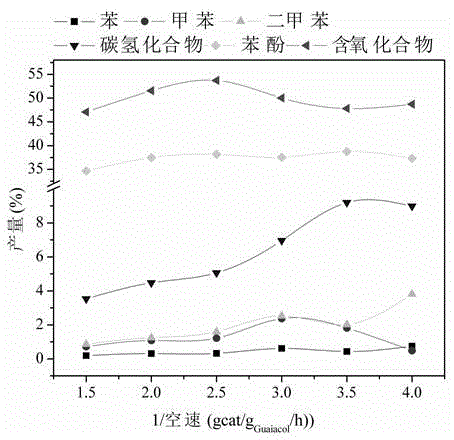

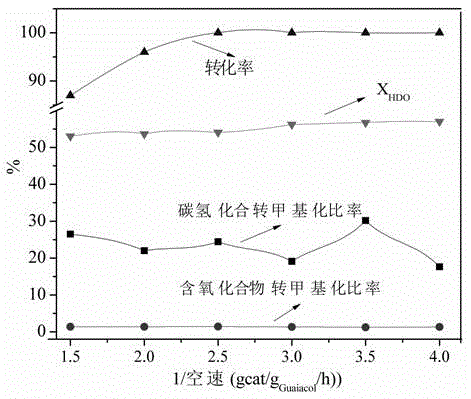

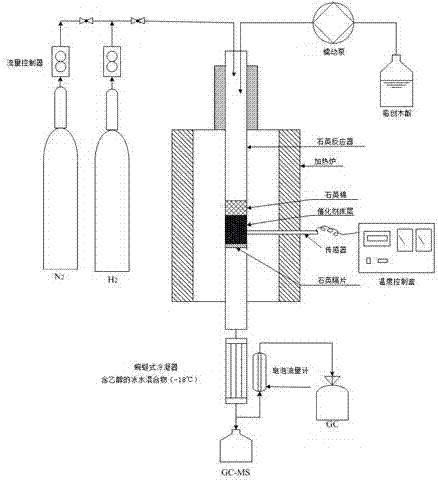

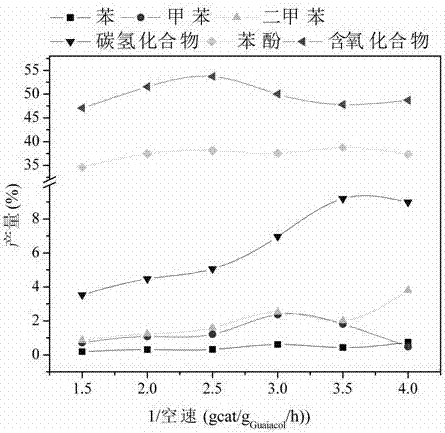

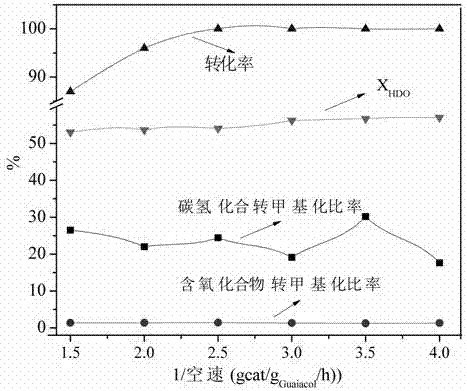

Method for increasing hydrogen utilization ratio of guaiacol during hydrodeoxygenation under normal pressure and reducing carbon atom loss

ActiveCN105461498AReduce lossesReduce consumptionMolecular sieve catalystsMolecular sieve catalystMolecular sievePhysical chemistry

The invention discloses a method for increasing the hydrogen utilization ratio of guaiacol during hydrodeoxygenation under the normal pressure and reducing carbon atom loss. The method is characterized by comprising the following steps: gasifying guaiacol, and mixing the gasifed guaiacol with hydrogen for reaction under the catalysis of an activated molecular sieve at the normal pressure with the temperature of 250-400 DEG C; while hydrodeoxygenation, allowing a methyl group on guaiacol to return to a benzene ring structure through transmethylation, so as to reduce the carbon atom loss and increase the hydrogen utilization ratio, wherein the activated molecular sieve is selected from Fe / Ni / HBeta, Fe / Ni / ZSM-5, Fe / Ni / HY, Fe / Ni / MCM-41, Fe / Ni / SiO2 or Fe / Ni / Al2O3. Through adoption of the method, the acquired BTX yield can reach up to 19.83%. In the method, an autoclave is eliminated, a transmethylation reaction is realized while hydrodeoxygenation, the carbon atom loss and hydrogen consumption are reduced, and a new way is provided for resource utilization of lignin under the normal pressure.

Owner:SOUTH CHINA AGRI UNIV

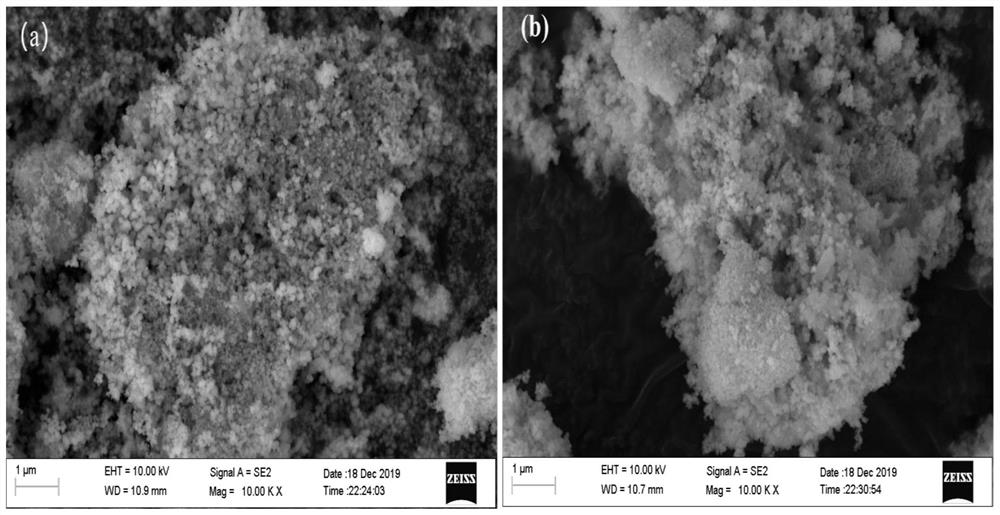

Preparation of core-shell catalyst of cyclohexene by efficient benzene hydrogenation

PendingCN109794236AHigh selectivityImprove stabilityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneMass transfer resistance

The invention discloses a preparation method of a bi-functional catalyst of a (Ru / MeOx)@MeOx core-shell structure. The method is characterized in that a center suitable for surface catalyzing is formed by core phase Ru / MeOx and shell phase m-MeOx. A ruthenium-based catalyst prepared by the method has high dispersing performance, so that benzene is dissociated and absorbed more easily at a lower temperature to improve the conversion rate of the benzene;the cyclohexene is allowed to be desorbed on a shell by a hydrophilic m-MeOx shell phase to prevent further hydrogenation and improve the selectivity of the cyclohexene, the loss of activated species can be reduced by the core-shell structure to allow the catalyst to be more stable, the mass transfer resistance can be reduced, the excellent composite performance can be applied to part of hydrogenation cyclohexene reaction of benzene, and extremely high selectivity and yield are obtained. The preparation method is simple, the conditions are mild, the repeating is easy, and the method is suitable for large-scale industrial production.

Owner:FUZHOU UNIV

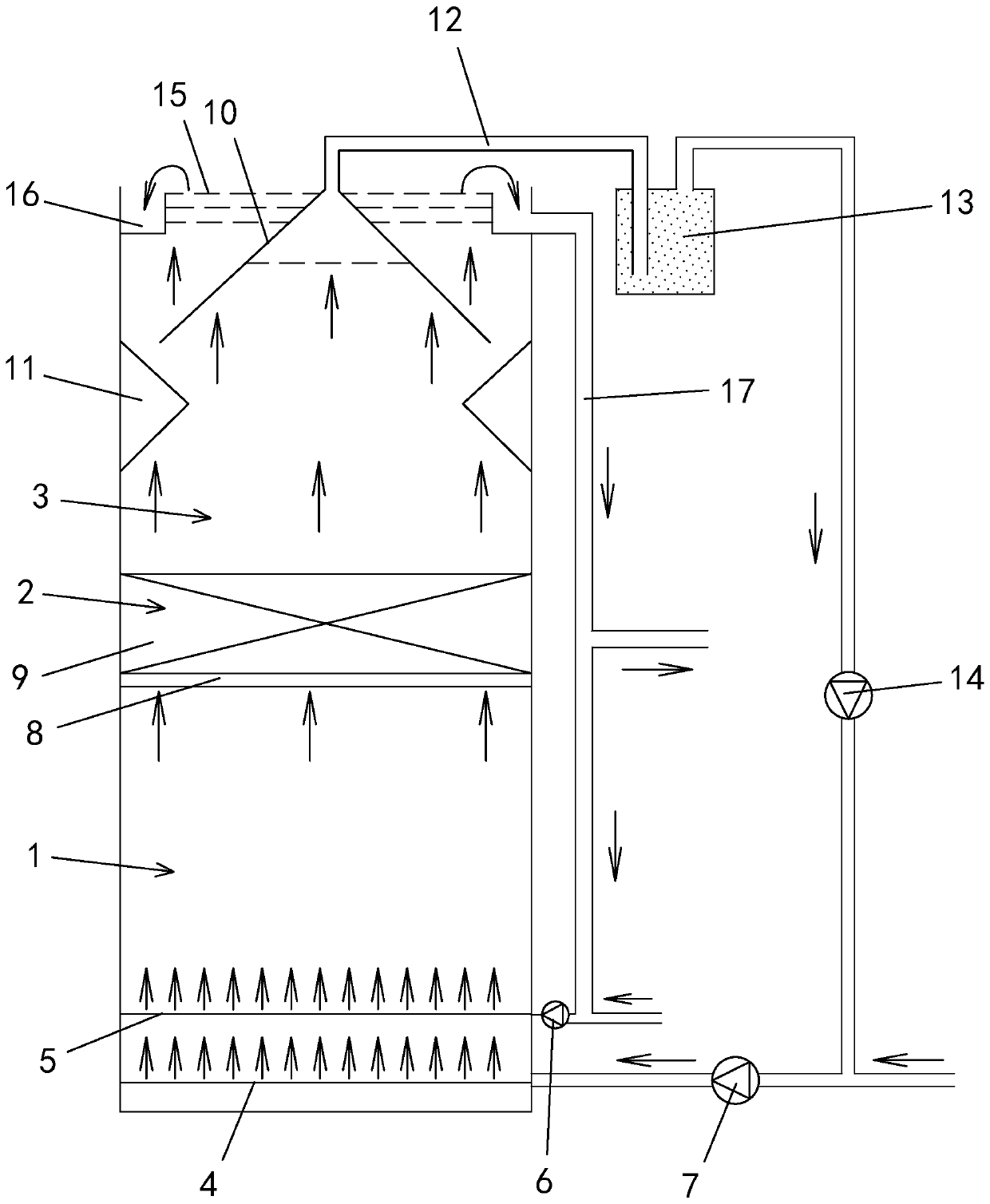

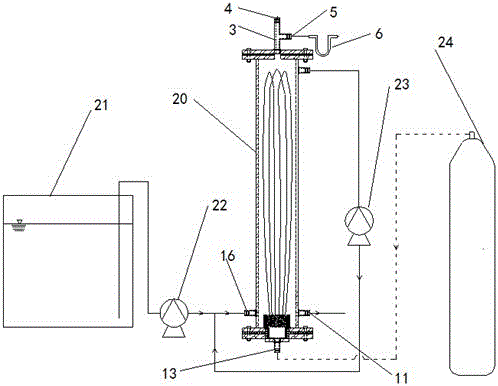

Device for advanced reduction pretreatment wastewater

ActiveCN110526376ACapable of repeated useExtended retention timeWater contaminantsWater/sewage treatment apparatusHydrogenMetal-organic framework

The invention discloses a device for advanced reduction pretreatment wastewater. The device comprises a pre-mixing zone, a reaction zone and a separation zone from bottom to top, wherein a water inletpipeline and a gas inlet pipeline are distributed inside the pre-mixing zone; a plurality of water outlet holes are formed in the water inlet pipeline; a plurality of aeration holes are formed in thegas inlet pipeline; hydrogen and polluted water are mixed in the pre-mixing zone to form a gas-water mixture; a gas-water mixing distribution plate is arranged between the reaction zone and the pre-mixing zone; a catalyst fixing bed is arranged in the reaction zone; an MOFs (metal organic framework) solid catalyst is positioned in the fixing bed; the gas-water mixture is reacted with the MOFs solid catalyst in the catalyst fixing bed to implement water body repairing on the polluted water; the separation zone is provided with a three-phase separator and comprises a gas collection cover and aguide block; the top of the gas collection cover communicates with an exhaust pipeline for discharging excessive hydrogen; and the top of the separation zone is the overflowing surface of water flowsafter reactions. When being adopted for repairing of organic polluted water bodies, the device has the advantages of being high in efficiency, free of selectivity, environment-friendly, free of secondary pollution, and the like, and is applicable to treatment of various types of organic wastewater.

Owner:SUZHOU UNIV OF SCI & TECH

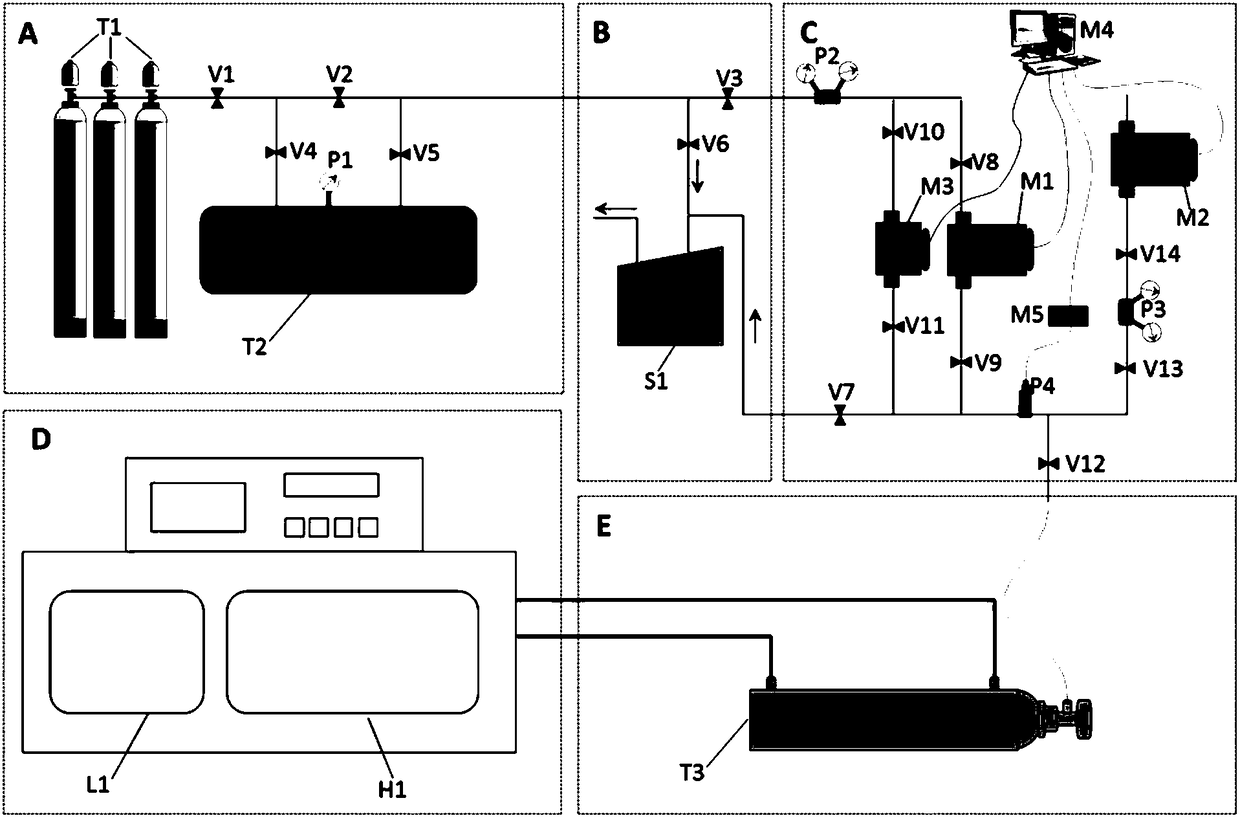

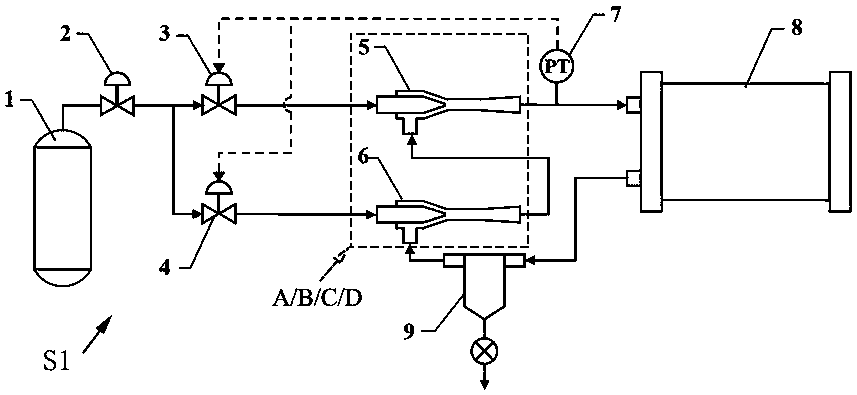

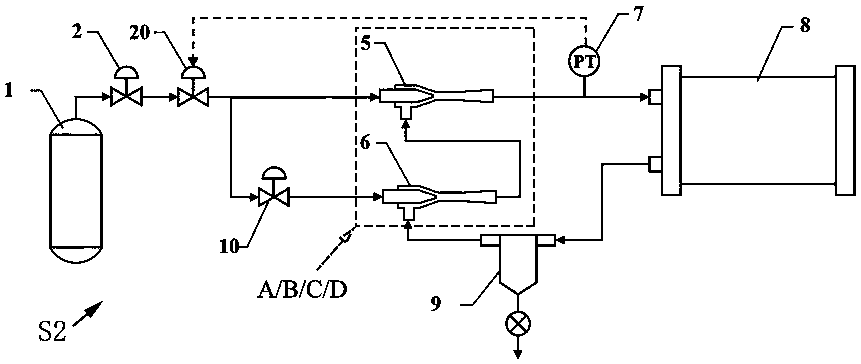

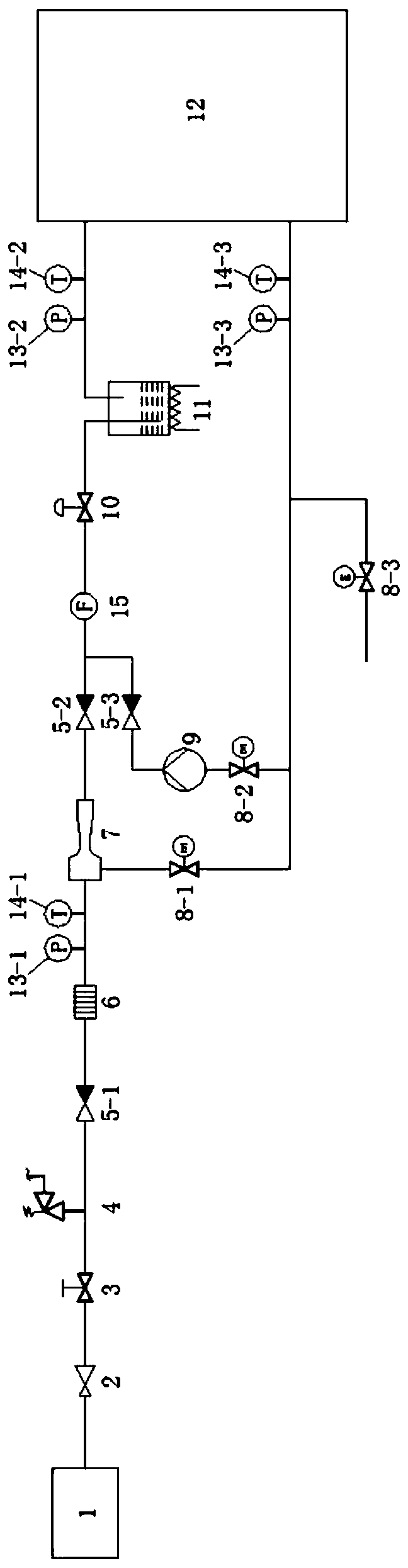

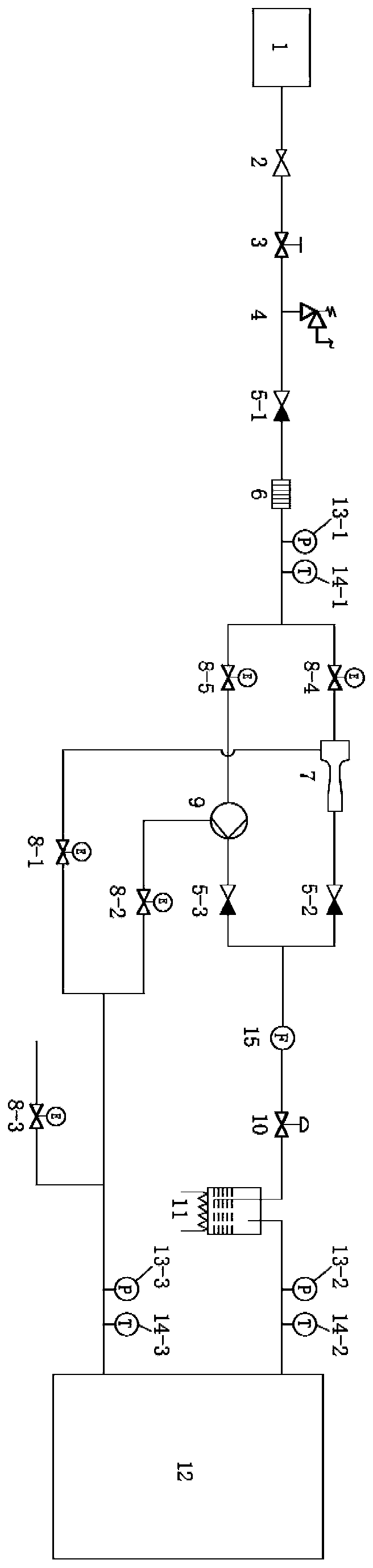

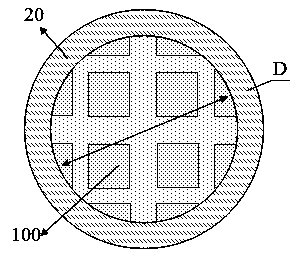

Hydrogen charging and discharging performance detection system for hydrogen storage tank

ActiveCN108730760AGood effectOvercome the disadvantages that the detection temperature range is also limitedContainer filling methodsHydrogen technologiesCharge detectionProcess engineering

The invention discloses a hydrogen charging and discharging performance detection system for a hydrogen storage tank. The hydrogen charging and discharging performance detection system comprises a hydrogen source module (A), an exhaust module (B), a measuring and recording module (C), a cold-heat source module (D) and a to-be-detected area (E). The hydrogen source module (A) is provided with a main pipeline initial segment, a main pipeline middle segment and a main pipeline tail segment, wherein the main pipeline initial segment, the main pipeline middle segment and the main pipeline tail segment are connected in the direction from the hydrogen source module (A) to the to-be-detected area (E). The hydrogen charging and discharging performance detection system for the hydrogen storage tankcan perform constant-pressure hydrogen charging and constant-flow hydrogen charging detection, and the utilization rate of steel cylinder hydrogen gas is increased; and meanwhile, the hydrogen sourcepressure can be stabilized at a high level, and the detection temperature range of the detection system can be expanded to -40-300 DEG C. The hydrogen charging and discharging performance detection system for the hydrogen storage tank provided by the invention is simple in structure, diversified in function and wide in detection temperature range, and the hydrogen utilization rate of a hydrogen source is high.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

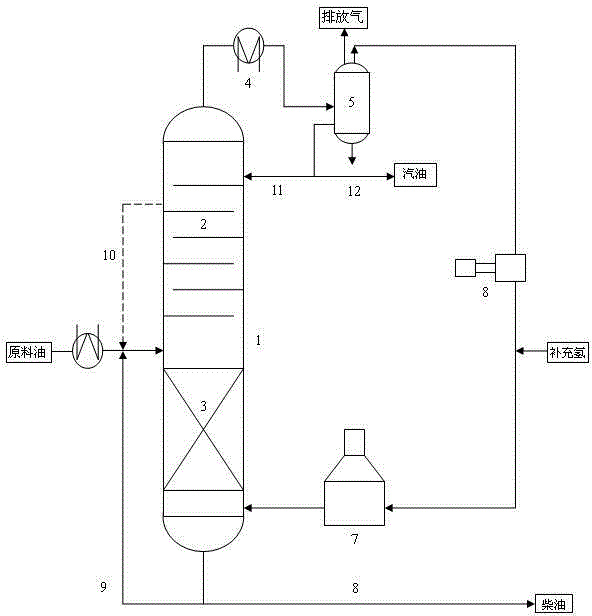

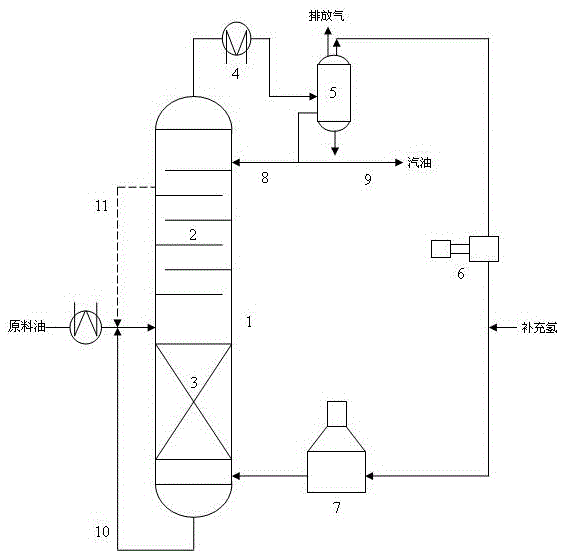

Catalytic diesel fuel reaction distillation method

ActiveCN104611049ABoost octaneIncrease cetane numberTreatment with hydrotreatment processesIsomerizationPoor quality

The present invention discloses a catalytic diesel fuel reaction distillation method. According to the method, equipment mainly comprises a reaction distillation tower and a hydrogen circulation system, the stripping section of the reaction distillation tower adopts a hydrocracking catalyst as a filler, the rectification section is provided with the rectification tower plate, the tower plate can be provided with an isomerization catalyst, one part of the tower bottom oil is circulated to the material inlet of the tower, the remaining part is discharged out from the equipment and is adopted as the product, a hydrogen circulation heating furnace is arranged, the heated hydrogen gas enters the bottom of the tower, and the gasoline distillate is obtained from the top of the tower. With the method, the characteristics of the hydrocracking and the reaction distillation process are completely utilized so as to reduce the secondary reaction of the light distillates and improve the hydrogenation reaction speed of the gasoline distillate. According to the present invention, the poor-quality cracking diesel fuel is adopted as the raw material to produce the high octane number naphtha and the high-quality diesel fuel, such that the obtained products can respectively be adopted as the blending component of the high octane number naphtha and the blending component of the high-quality diesel fuel; and compared with the conventional hydrogenation process, the method of the present invention has characteristics of simple process and energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

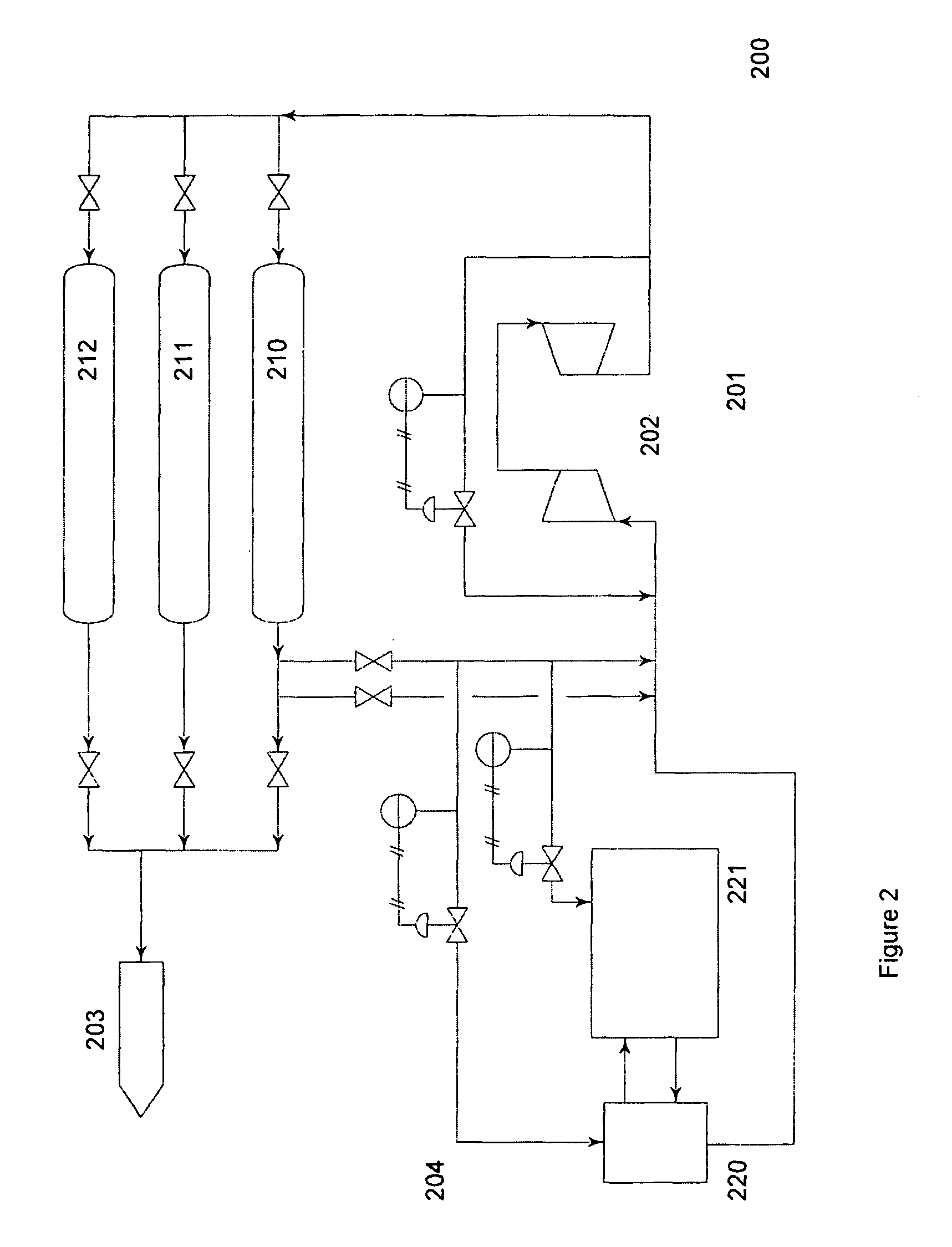

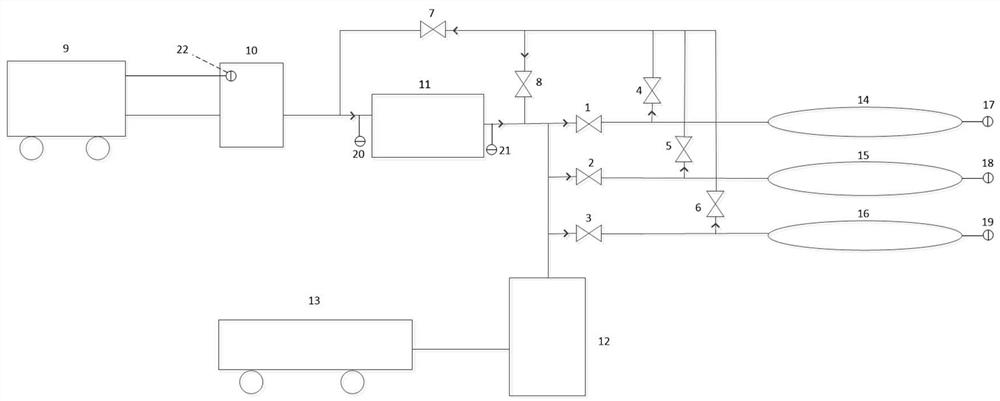

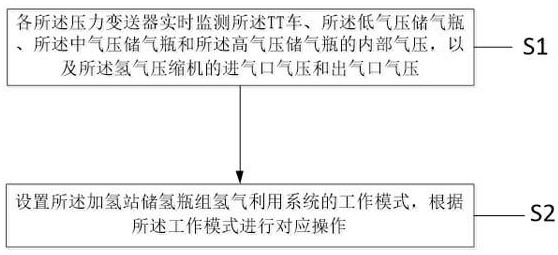

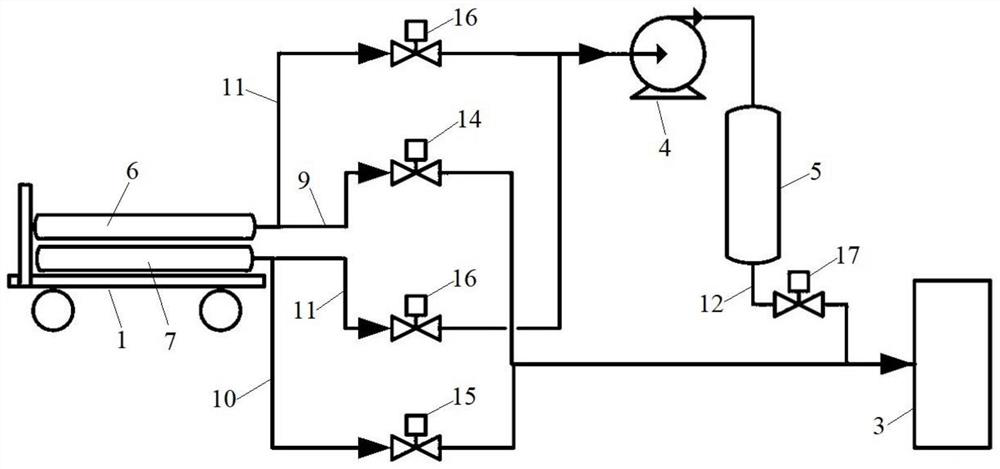

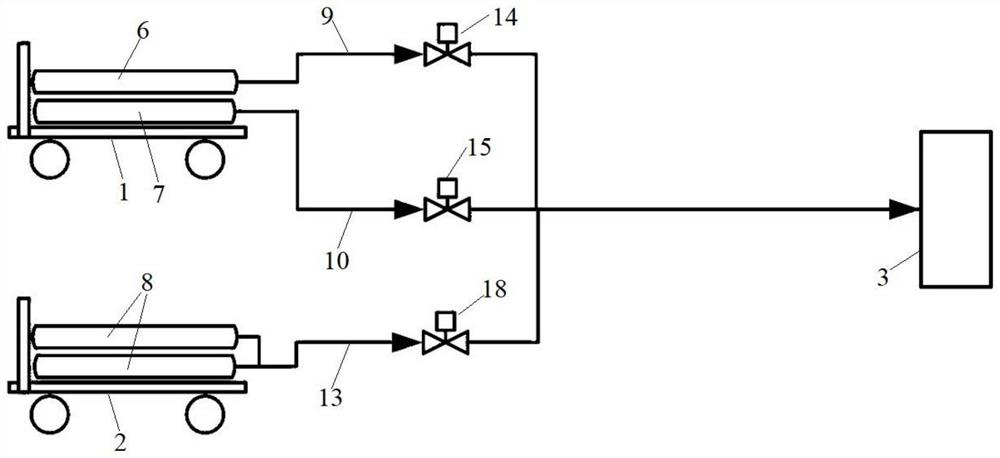

Hydrogen utilization system and method for hydrogen storage cylinder group of hydrogen refueling station

InactiveCN112594552AMeet various hydrogenation scenariosImprove hydrogen utilizationGas handling/storage effectsPipeline systemsThermodynamicsGas cylinder

The invention relates to the technical field of hydrogenation, and provides a hydrogen utilization system and method for a hydrogen storage cylinder group of a hydrogen refueling station. The hydrogenutilization system comprises a TT vehicle, a gas unloading cabinet, a hydrogen compressor, a hydrogenation machine, a low-pressure gas storage bottle, a medium-pressure gas storage bottle, a high-pressure gas storage bottle, a first gas valve, a second gas valve, a third gas valve, a fourth gas valve, a fifth gas valve, a sixth gas valve, a seventh gas valve and an eighth gas valve. According tothe hydrogen utilization system and method, multiple working modes are provided, so that the hydrogen refueling station can meet various hydrogen refueling scenes; and when the air pressure of hydrogen in the gas storage bottles is lower than a certain value and the hydrogen cannot be normally injected into a hydrogen energy automobile, the residual hydrogen in the gas storage bottles is pressurized through the hydrogen compressor, so that the residual hydrogen in the gas storage bottles can also be normally injected, and the hydrogen utilization rate of the gas storage bottles is increased.

Owner:河南氢枫能源技术有限公司 +1

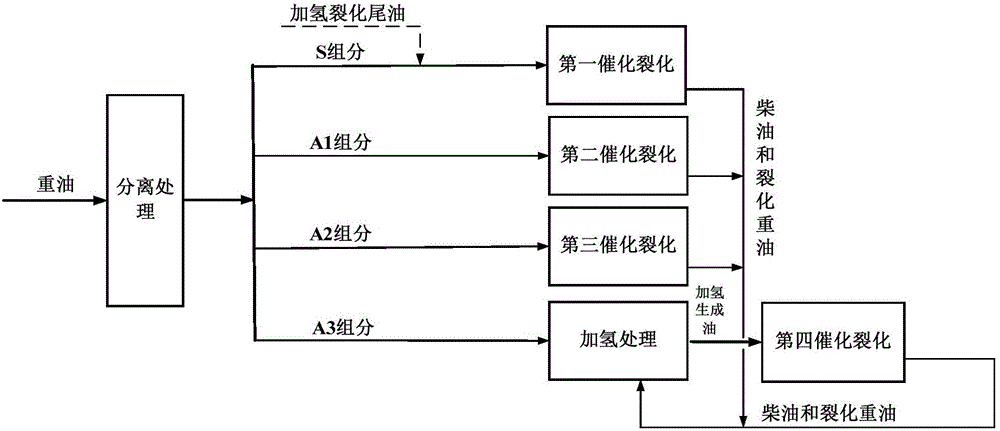

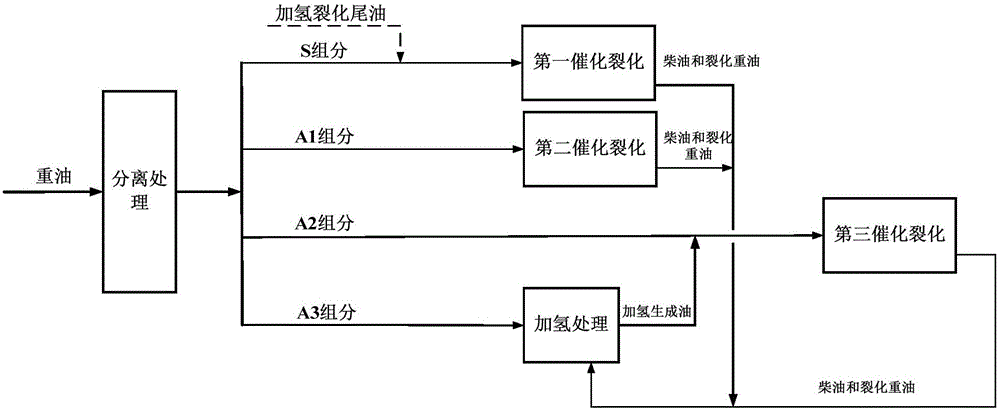

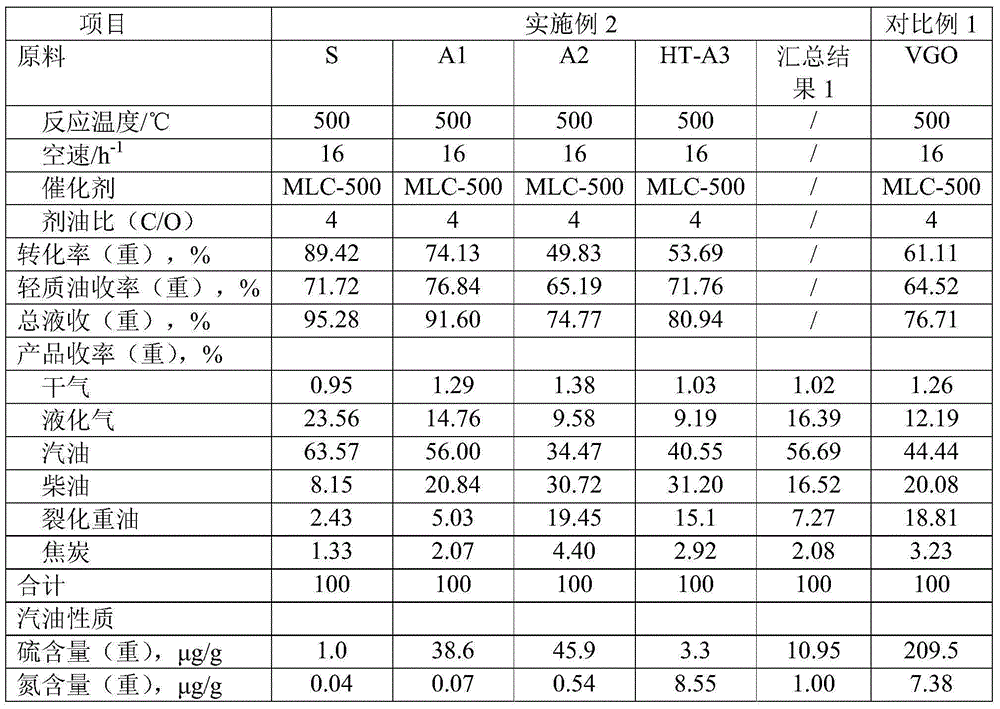

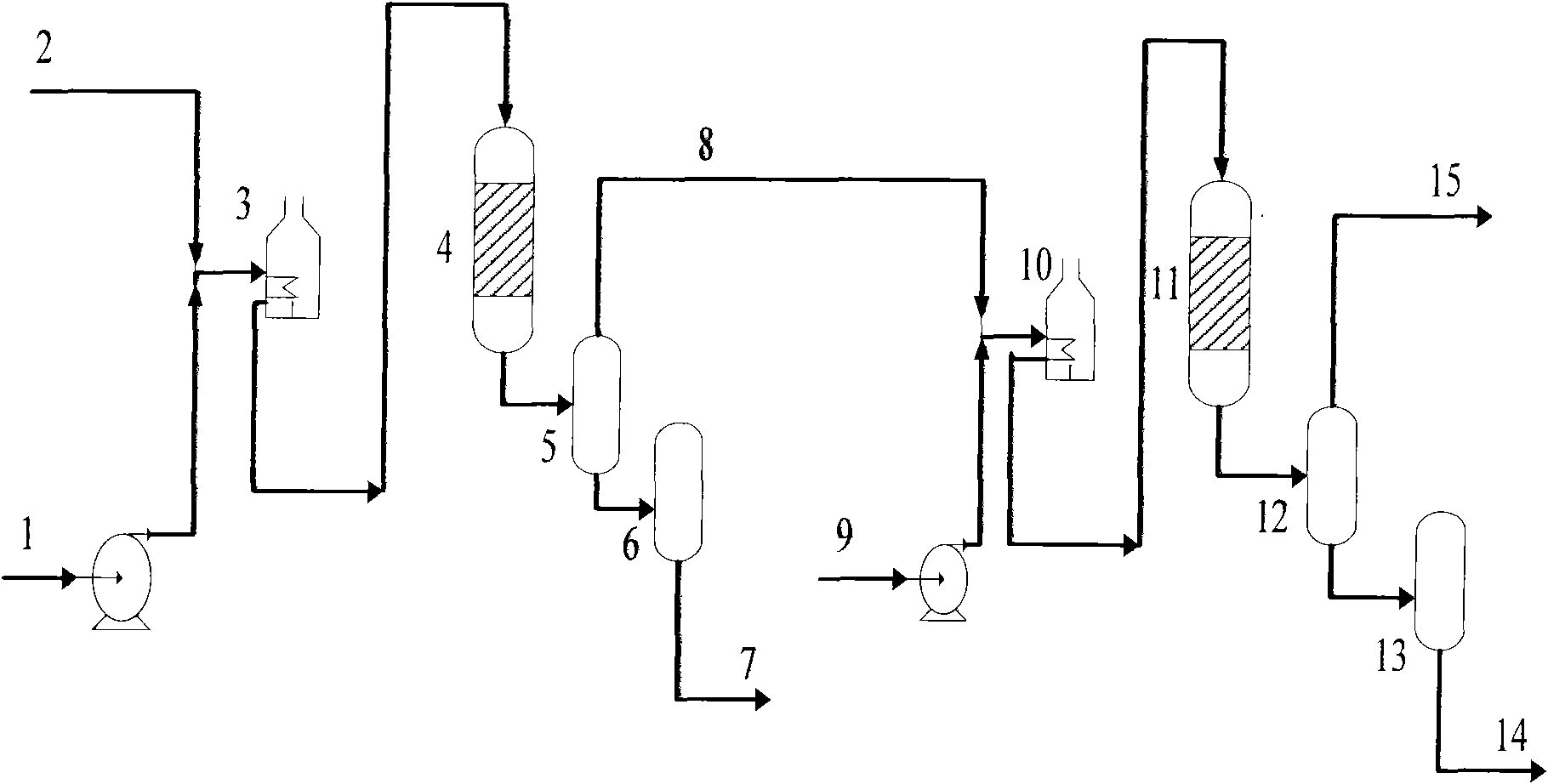

Heavy oil separation-hydrotreatment-catalytic cracking combined method

ActiveCN106467757AEliminate interactionIncrease profitTreatment with hydrotreatment processesSulfurNitrogen

The invention discloses a heavy oil separation-hydrotreatment-catalytic cracking combined method. the method comprises the following steps: a, separating heavy oil to obtain a component S, a component A1, a component A2 and a component A3; and b, carrying out a first catalytic cracking reaction on the component S obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a second catalytic cracking reaction on the component A1 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a third catalytic cracking reaction on the component A2 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; and carrying out a hydrotreatment reaction on the component A3 obtained in the step a under the action of a hydrotreating catalyst, so as to obtain hydrogenated oil. In comparison with the prior art, the method for heavy oil treatment and the subsequent catalytic cracking reactions has advantages of higher yield of gasoline and liquefied gas and lower sulfur / nitrogen content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

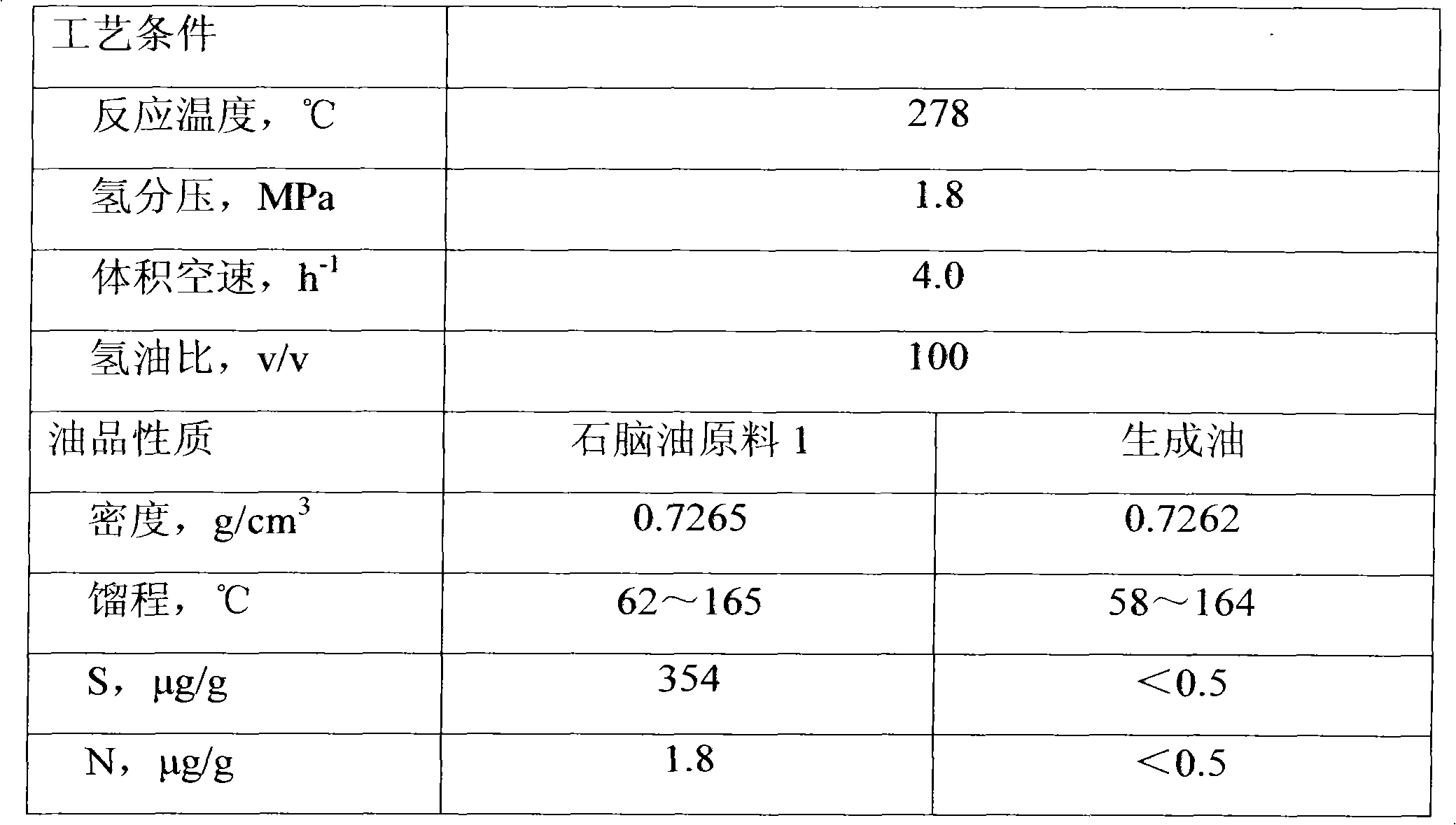

Combined hydrogenation process

ActiveCN102465016AOperating pressure matchingLow investment costTreatment with hydrotreatment processesHydrogenation reactionHydrogenation process

The invention relates to a combined hydrogenation process. The process comprises the following steps: 1, fully mixing reformed prehydrogenation raw oil with hydrogen, and carrying out a desulphurization and denitrification reaction by allowing them to go through a heating furnace and then enters a hydrogenation reactor; 2, carrying out oil-gas separation by a separator to obtain refined oil which can satisfy quality requirements of the reformed raw material; and 3, directly mixing a hydrogen-rich gas with jet fuel hydrogenation raw oil, and carrying out a hydrogenation reaction by allowing them to go through a heating furnace and then enters a reactor to obtain a product which satisfies quality index requirements of a 3# jet fuel. The method of the invention, which can simultaneously satisfy the requirements of qualified products produced with two hydrogenation devices and has the characteristics of simple process flow and no need of a cycle hydrogen compressor and a new hydrogen compressor, has the advantages of low investment and operation cost, good product property, stable operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

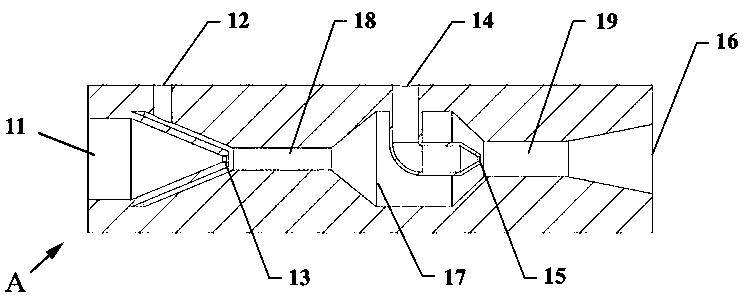

Ejector unit and fuel cell hydrogen circulation system having same

PendingCN109980249ANeed to reduce stressFlexible and diverse injection combinationsReactant parameters controlHydrogenFuel cells

The present invention provides an ejector unit and a fuel cell hydrogen circulation system having the same, wherein the ejector unit comprises a first ejector and a second ejector connected in series,the first ejector comprises: a first jet flow inlet, a first drainage inlet, a first jet flow hole communicating with the first jet flow inlet, a first mixing space communicating with the first drainage inlet and the first jet flow hole, and a first outlet communicating with the first mixing space; the second ejector includes: a second jet flow inlet, a second drainage inlet communicating with the first outlet, a second jet flow hole communicating with the second jet flow inlet, a second mixing space communicating with the second drainage inlet and the second jet flow hole, and a second outlet communicating with the second mixing space; the structure that the first jet flow inlet is connected with the second jet flow inlet in parallel and the first drainage inlet is connected with the second drainage inlet in series is formed. According to the ejector unit and the fuel cell hydrogen circulation system of the invention, flexible and various ejection combinations can be realized to meetthe requirements of hydrogen circulation volume under different power conditions.

Owner:上海楞次新能源汽车科技有限公司

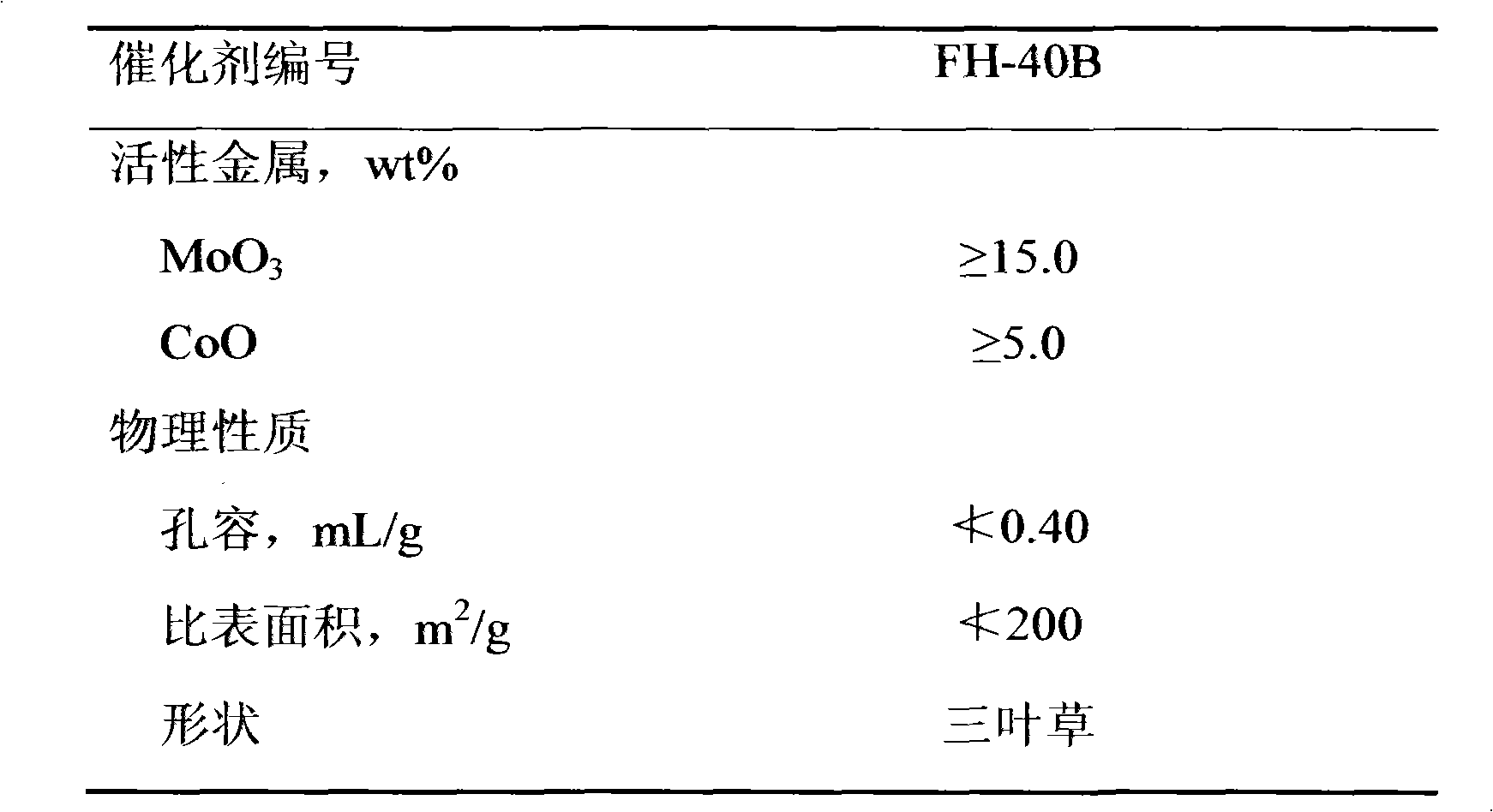

Diesel oil hydrodesulfurization and decolouring method

ActiveCN106256884AImprove hydrogen utilizationLess investmentTreatment with hydrotreatment processesHydrodesulfurizationHigh pressure

The invention relates to a diesel oil hydrodesulfurization and decolouring method. According to the invention, diesel oil raw oil and hydrogen are introduced into a reactor, are subjected to a hydrogenation reaction under a hydrogenation catalyst I, a reactor effluent is subjected to heat exchange and is introduced into a high-pressure hot separator, the active metal filling at the bottom of the high-pressure hot separator is a cobalt-molybdenum hydrogenation catalyst II, a liquid phase material flow obtained by the high-pressure hot separator is extracted from the bottom of the high-pressure hot separator, and the material flow is cooled and fractioned to obtain the hydrogenation gasoline and hydrogenation diesel oil. The active metal employed in the high-pressure hot separator is the cobalt-molybdenum hydrogenation catalyst II, hydrogen utilization rate of the hydrodesulfurization reaction is higher, the inhibition effect on hydrogen by H2S is less during ultra-deep hydrodesulfurization, straight-run diesel oil or inferior secondary processing diesel oil can be processed, ultra low sulfur diesel oil with sulfur content of less than 10 ppm is produced, an independent hydrogenation decolouring reactor is not required, the hydrogenation decolouring reaction can be completed, and the ASTM D1500 chroma of the product is less than 1.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

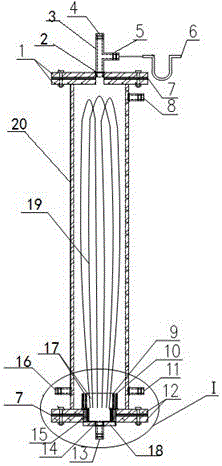

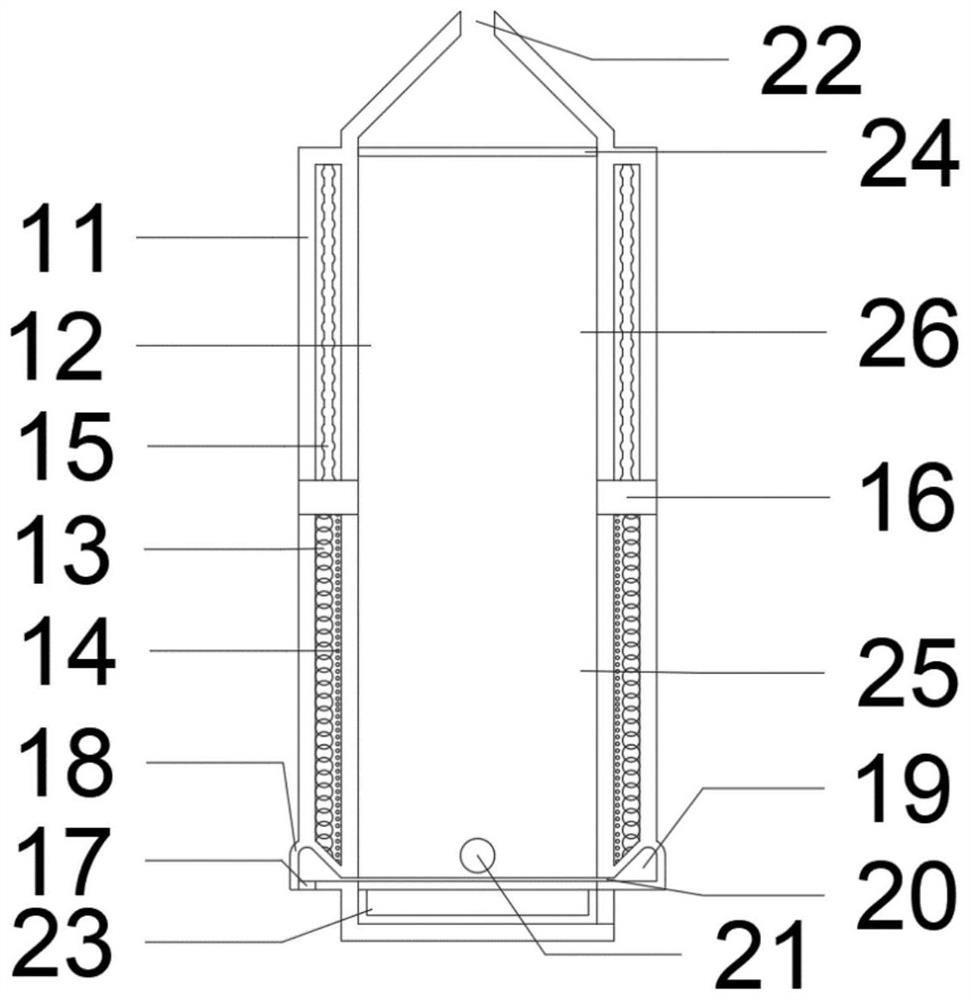

Reactor for degrading oxidative pollutants in water body by using microorganisms

InactiveCN106809959ANo biomassNo secondary pollutionContaminated groundwater/leachate treatmentBiological water/sewage treatmentMicroorganismHydrogen

The invention discloses a reactor for degrading oxidative pollutants in a water body by using microorganisms. The reactor comprises a reactor main body and a membrane module, wherein a water inlet is formed in the lower end of the reactor main body; an exhaust opening and a water outlet are formed in the top end of the reactor main body; a water inlet is formed in the bottom end of the reactor main body and is used for introducing hydrogen; the membrane module is arranged inside the reactor main body; the air inlet end of the membrane module is communicated with the gas inlet. According to the reactor for degrading the oxidative pollutants in the water body by using the microorganisms, disclosed by the invention, the hydrogen is introduced and is diffused into water from the membrane module in a foamless form for the microorganisms to utilize; the pollutants in the water and the membrane module are enabled to be in full contact; in addition, the membrane module provides a favorable attaching place for the microorganisms; quick, safe and efficient removal of the oxidative pollutants is realized by controlling the supply level of the hydrogen, hydraulic retention time and a load of pollutants entering the water.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for preparing glycol by using oxalic ester

InactiveCN101993342AImprove technical effectLow selectivityOrganic compound preparationHydroxy compound preparationHydrogenGas phase

The invention relates to a method for preparing glycol by using oxalic ester, which mainly solves the technical problems of low target product selectivity and low hydrogen utilization in the prior art. The method uses the oxalic ester as a raw material, and comprises the following steps: a) raw materials of fresh hydrogen, circulating gas I, circulating gas II and dimethyl oxalate first is fed in a reactor to be contacted with copper-containing catalyst to generate glycol-containing reactor effluent I; b) the reactor effluent I is subject to gas-liquid separation, the liquid-phase effluent is separated to obtain a glycol product, and the gas-phase effluent is separated into a gaseous phase effluent I which is used as circulating gas I and a gaseous phase effluent II; and c) the gaseous phase effluent II is fed to a hydrogen recycle system to obtain circulating gas II and analytic gas, and the circulating gas II is mixed with the fresh hydrogen for continuous recycling, wherein the molar ratio of the gaseous phase effluent I to the fresh hydrogen is 0.5-100:1, and the molar ratio of the gaseous phase effluent II to the gaseous phase effluent I is 0.01-5:1. In the invention, the technical problem is well solved, and the method can be used in the industrial production of increasing production of the glycol.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

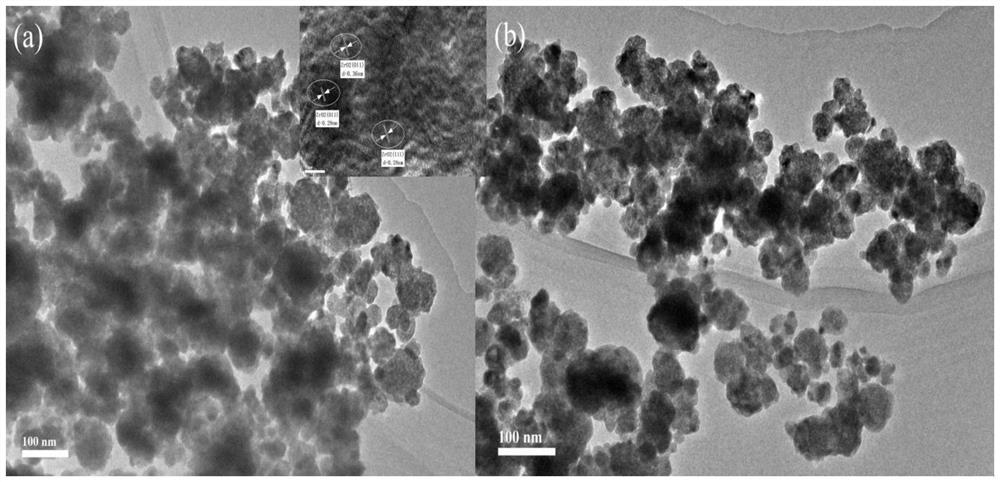

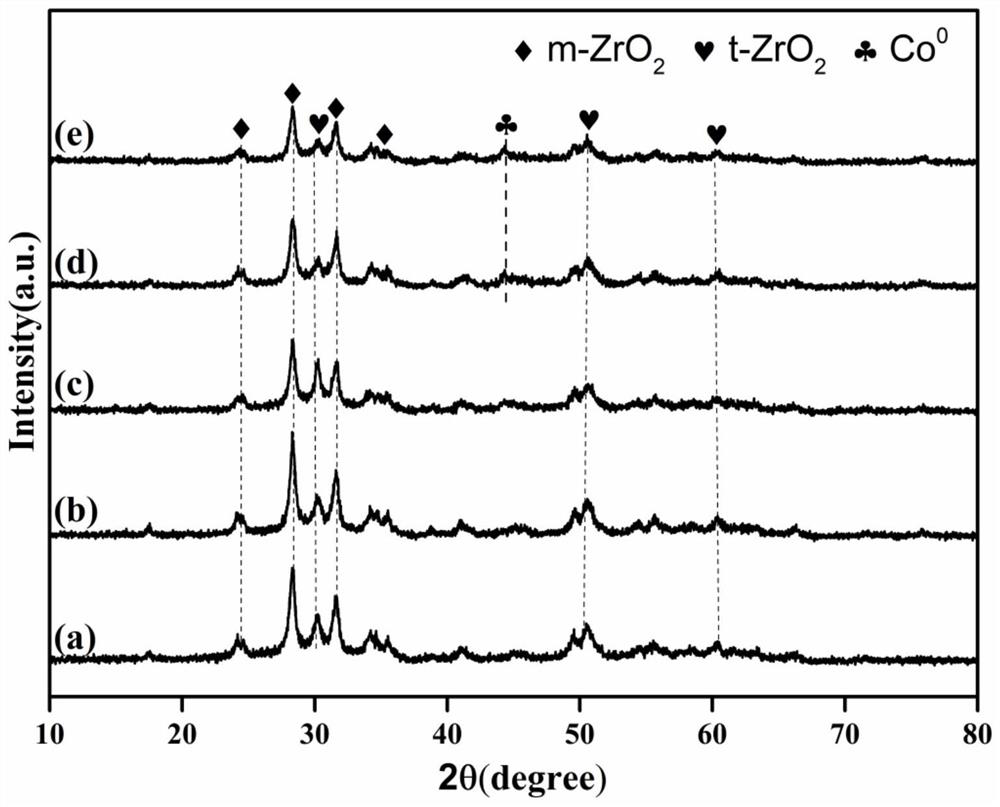

Method for catalytically synthesizing gamma-valerolactone by using cobalt-based hydrogenation catalyst

PendingCN111848553AHigh catalytic activityShort reaction timeOrganic chemistryChemical industryPtru catalystPropanoic acid

The invention discloses a method for synthesizing gamma-valerolactone through hydrogenation of methyl levulinate under the catalysis of a cobalt-based hydrogenation catalyst Co / ZrO2-Nb2O5. The catalyst has the advantages of high catalytic activity, good reusability, difficulty in loss of active components, easiness in separation from a liquid product and the like; when a mass ratio of the catalystto the reaction raw material methyl levulinate to the reaction solvent isopropanol is 0.2: 1: 20, a reaction temperature is 200 DEG C, and reaction time is 2 hours, the molar yield of the obtained hydrogenation product gamma-valerolactone is 98.32%, and the mass percent of the purity of the product is 99.01%.

Owner:XIANGTAN UNIV

Hydrogen supply system for fuel cell

ActiveCN110247082AAvoid effluxImprove hydrogen utilizationReactant parameters controlProcess engineeringHydrogen supply

The invention discloses a hydrogen supply system for a fuel cell. The system comprises a hydrogen supply subsystem and a circulation loop. The circulation loop comprises a first recovery pipeline and a second recovery pipeline, and the first recovery pipeline and the second recovery pipeline are connected in parallel to form a recovery pipeline. The circulation loop and an electric pile form a loop. The hydrogen supply subsystem is communicated with the recovery pipeline. When the hydrogen supply system is in a working state, the first recovery pipeline or the second recovery pipeline is in a working state. According to the invention, recycling of hydrogen is realized, the hydrogen utilization rate of the fuel cell is improved, and hydrogen leakage and explosion can be prevented. Only one of the first recovery pipeline and the second recovery pipeline works in a working state, and the other one can be used as a backup, so that the hydrogen supply selectivity of the fuel cell is improved, and the reliability is high.

Owner:SHANGHAI MICROPOWERS

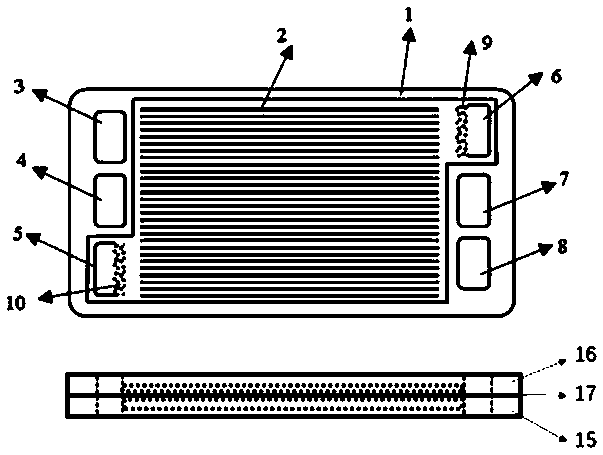

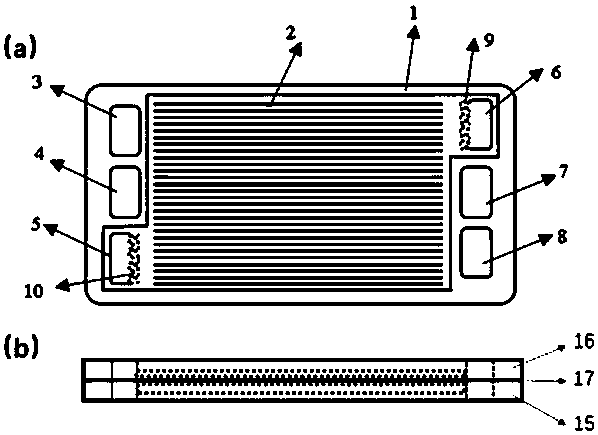

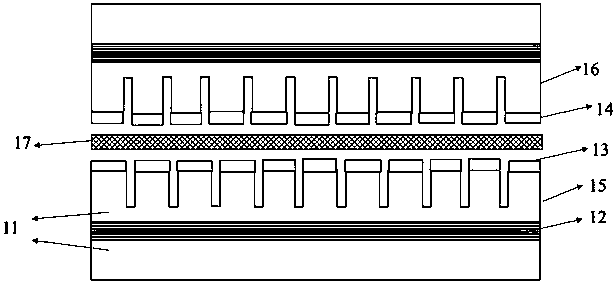

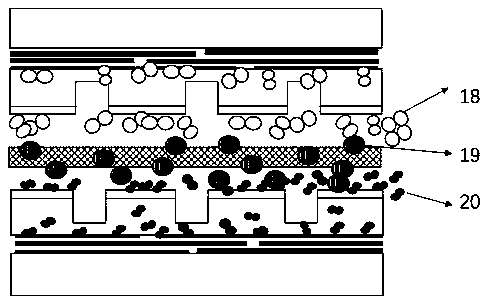

Preparation method of expanded graphite monopole plate with high gas barrier property, and hydrogen fuel cell

ActiveCN109818003AReduce wasteStop the spreadFinal product manufactureSealing/support meansOxygen utilization rateHydrogen fuel cell

The invention discloses a preparation method of an expanded graphite monopole plate with high gas barrier property, and a hydrogen fuel cell, and belongs to the technical field of hydrogen fuel cells.The method comprises the following steps: mold preparation: preparing a corresponding mold according to the shape and size of an expanded graphite monopole plate, wherein the mold is made of high-strength graphite; designing the relative positions of the graphene film and the expanded graphite powder, and prepressing and molding the expanded graphite powder; and hot-pressing sintering molding: combining the graphene film and the pre-pressed expanded graphite into a whole through hot-pressing sintering to obtain the expanded graphite monopole plate containing the graphene film. The layer of graphene film is added in the expanded graphite monopole plate, so that the hydrogen utilization rate and the oxygen utilization rate of the hydrogen fuel cell are greatly improved, gas waste is reduced, the energy conversion efficiency of the hydrogen fuel cell is further improved, and meanwhile, the safety performance of the hydrogen fuel cell can also be improved.

Owner:日照市烯创新材料科技有限公司

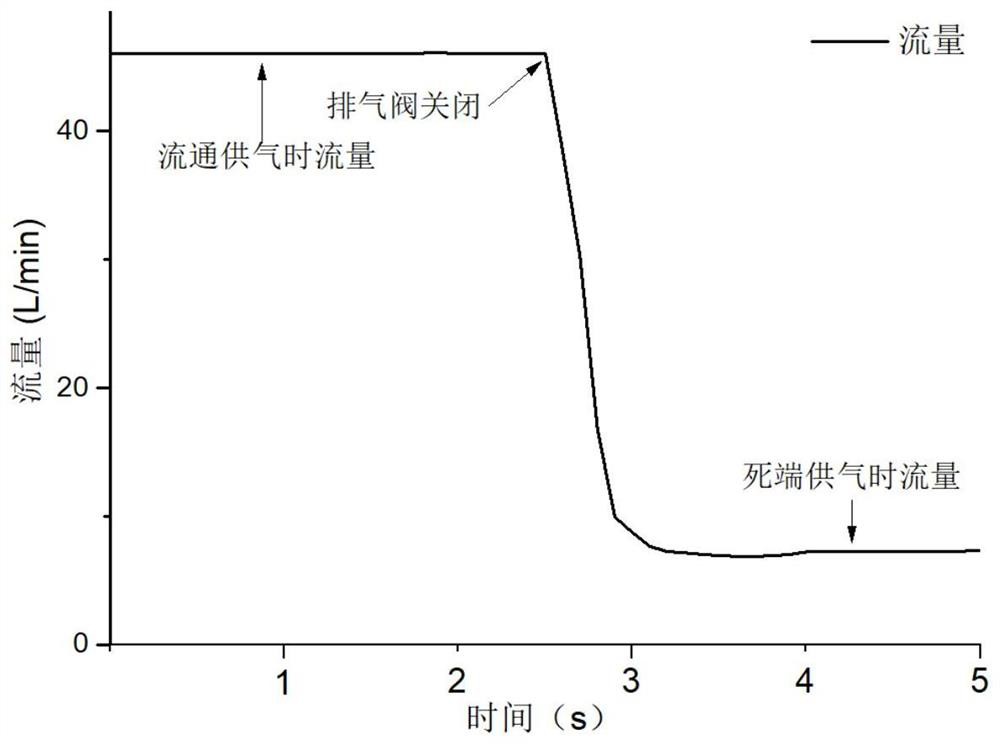

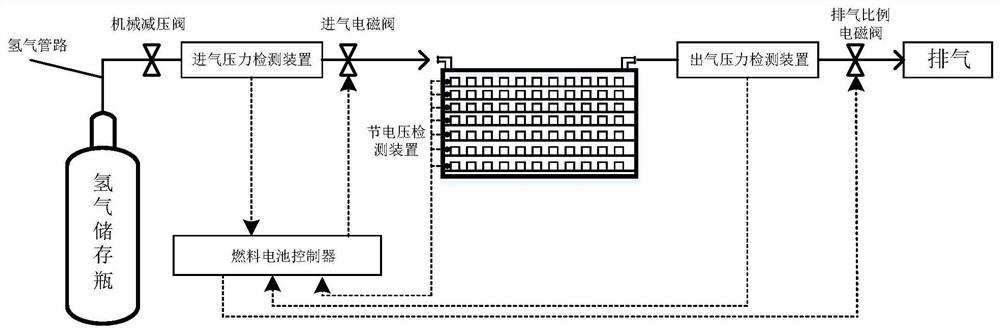

Air-cooled fuel cell hydrogen supply system and control method

ActiveCN112909299AImprove energy utilizationImprove hydrogen utilizationMotive system fuel cellsNew energyElectrical battery

The invention discloses an air-cooled fuel cell hydrogen supply system and a control method, and belongs to the technical field of new energy power generation. The hydrogen supply system comprises a hydrogen storage bottle, a hydrogen pipeline, a mechanical pressure reducing valve, an air inlet valve, an exhaust proportional electromagnetic valve, a fuel cell controller, an air inlet pressure detection device, an air outlet pressure detection device and a power saving voltage detection device. The control method comprises the steps that the mechanical pressure reducing valve and the air inlet valve are opened, the exhaust proportional electromagnetic valve is closed, the battery begins to output electric energy, when the average power saving voltage is reduced to U1, the inlet pressure of the exhaust proportional electromagnetic valve is controlled to be PB or the exhaust proportional electromagnetic valve is opened to the opening degree tau1, and when the average power saving voltage is recovered to U2, the inlet pressure P is controlled to be gradually increased to PA or the opening tau is controlled to be gradually reduced to 0, and the process is continuously repeated in the working process of the cell, so that intelligent emission of redundant hydrogen in the air-cooled fuel cell stack is realized, and the working performance of the cell and the hydrogen utilization rate are improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

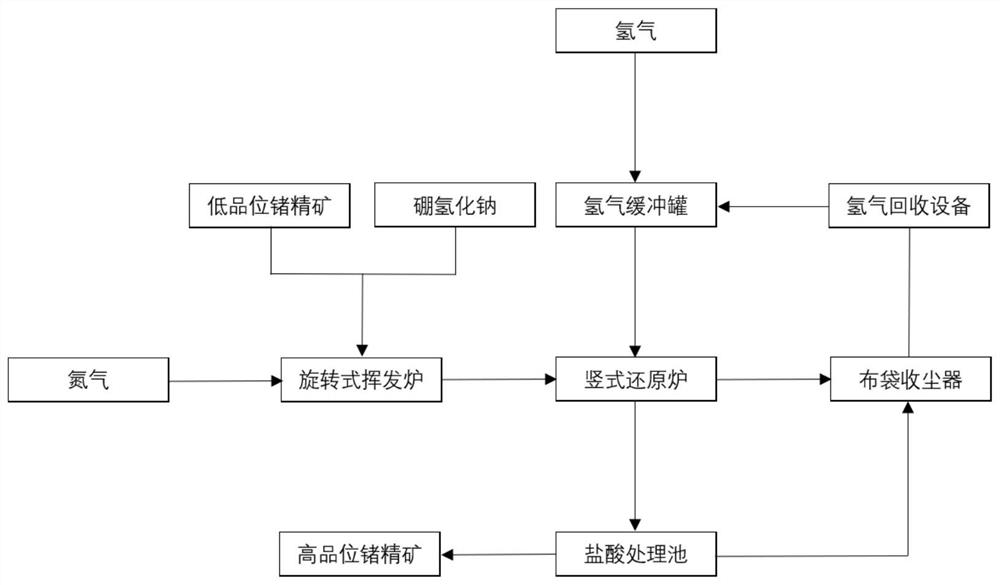

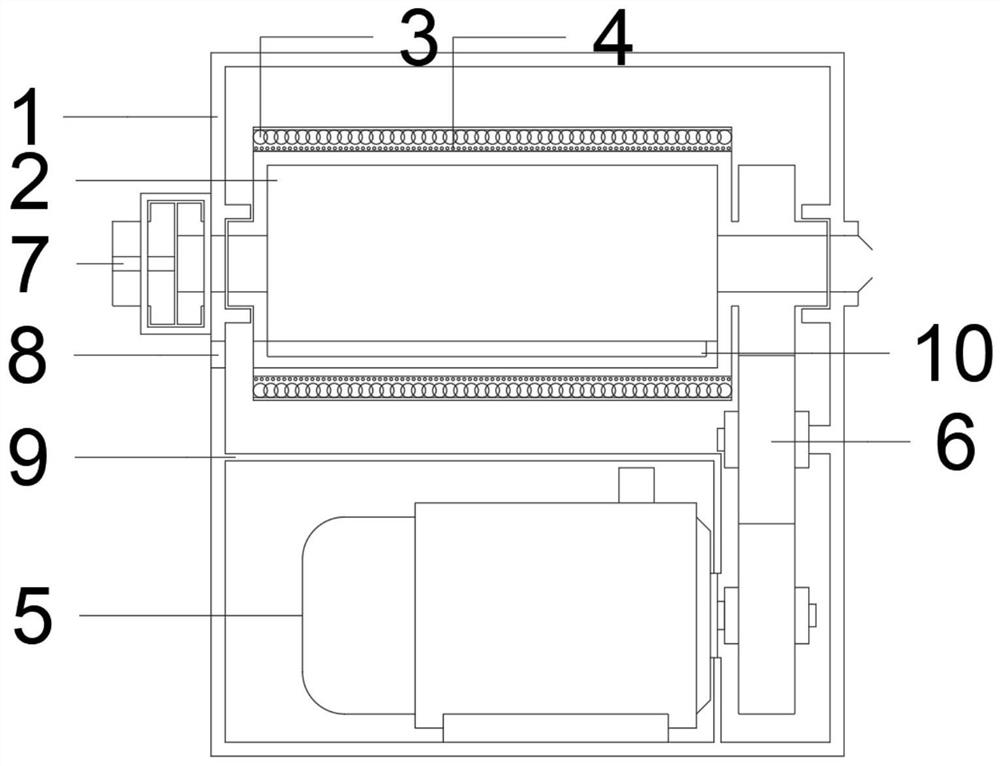

Equipment and method for enriching germanium in low-grade germanium concentrate through two-stage reduction volatilization

The invention relates to the technical field of germanium recovery and extraction, and particularly discloses equipment and method for enriching germanium in low-grade germanium concentrate through two-stage reduction volatilization. The equipment comprises nitrogen supply equipment, a rotary volatilization furnace, a vertical reduction furnace and a bag collector which are connected in sequence, wherein the vertical reduction furnace is further connected with a hydrogen supply device and a hydrochloric acid treatment pond. The method comprises the following steps: crushing low-grade germanium concentrate, then adding a reducing agent, uniformly mixing, and then putting into a rotary volatilization furnace; firstly carrying out oxidizing roasting volatilization in the rotary volatilization furnace to remove substances being volatile at a low temperature; then heating the rotary volatilization furnace, and carrying out first-stage reduction volatilization on germanium; feeding the volatilized germanium into a vertical reduction furnace, and introducing hydrogen for reduction to obtain germanium-containing solid particles; and adding hydrochloric acid for reacting to obtain germanium metal. The two-stage germanium enrichment process is adopted, so that the enrichment multiple of secondary enrichment of the germanium concentrate and the grade of the germanium concentrate are improved, and the problems that the recovery rate is reduced, the cost is high, and the environmental influence is large in the subsequent process of germanium extraction through chlorination are solved.

Owner:YUNNAN UNIV +1

A kind of high-octane gasoline production method

ActiveCN104611062BBoost octaneQuick responseTreatment with hydrotreatment processesIsomerizationHydrogenation process

The present invention discloses a high octane number gasoline production method, which is used for processing catalytic diesel fuel so as to produce the high octane number gasoline distillate, wherein the process mainly adopts a reaction distillation tower and a hydrogen circulation system, the stripping section of the reaction distillation tower adopts a hydrocracking catalyst as a filler, the rectification section is provided with the rectification tower plate, the tower plate is provided with an isomerization catalyst, the tower bottom oil is circulated to the material inlet of the tower, a hydrogen circulation heating furnace is arranged, the heated hydrogen gas enters the bottom portion of the tower, the gasoline distillate is obtained from the top of the tower, and a small amount (less than 2%) of the diesel fuel distillate is periodically discharged from the bottom of the tower. According to the method of the present invention, the characteristics of the hydrocracking and the reaction distillation process are completely utilized, such that the secondary cracking reaction of the light distillate is reduced, the liquid yield is increased, and the gasoline distillate yield is more than 90%. With the method of the present invention, the catalytic diesel fuel is completely catalyzed, the octane number of the produced is high, and compared with the conventional hydrogenation process, the method of the present invention has characteristics of simple process and energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

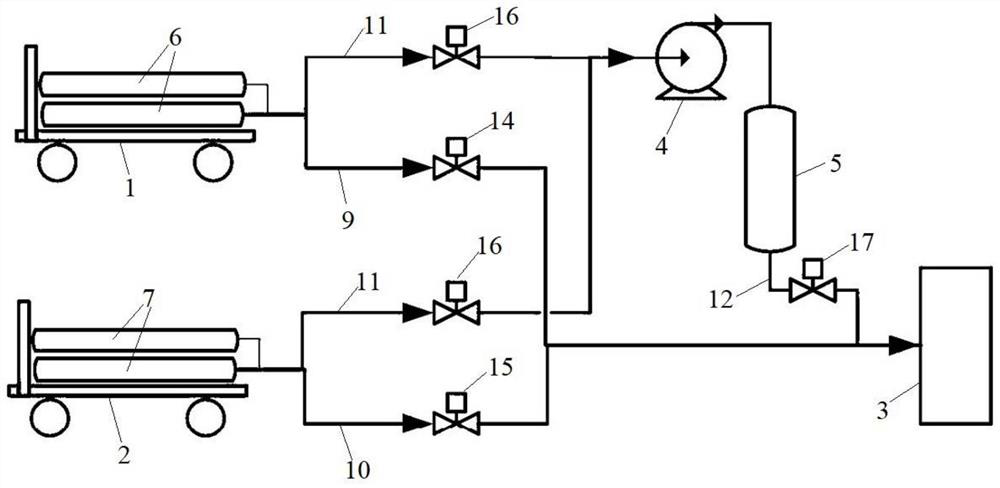

Hydrogenation system and hydrogenation method

PendingCN113531381AImprove hydrogen utilizationImprove daily filling capacitySecondary cellsPipeline systemsAutomotive engineeringProcess engineering

The invention relates to the technical field of hydrogenation, and discloses a hydrogenation system and a hydrogenation method. The hydrogenation system comprises a tube bundle vehicle set serving as a gas source and a hydrogenation machine used for hydrogenation of equipment to be subjected to hydrogenation, and the tube bundle vehicle set comprises at least one tube bundle vehicle and at least two groups of hydrogen supply tube bundles arranged on the at least one tube bundle vehicle; and hydrogen is stored in the hydrogen supply tube bundles, the initial pressure of the hydrogen is greater than the highest hydrogen storage pressure of the equipment to be subjected to hydrogenation, gas outlets of at least two groups of hydrogen supply tube bundles are respectively communicated with a gas inlet of the hydrogenation machine, and the hydrogenation system further comprises valves which are respectively used for controlling connection and disconnection between each group of hydrogen supply tube bundles and the hydrogenation machine. According to the hydrogenation system, gradient utilization of the hydrogen can be achieved, and the hydrogen utilization rate and daily filling capacity are effectively improved; and in addition, the hydrogenation system can not be provided with a storage tank or a compressor, so that the investment and energy consumption of fixed equipment can be remarkably reduced, and the hydrogen supply cost can be reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

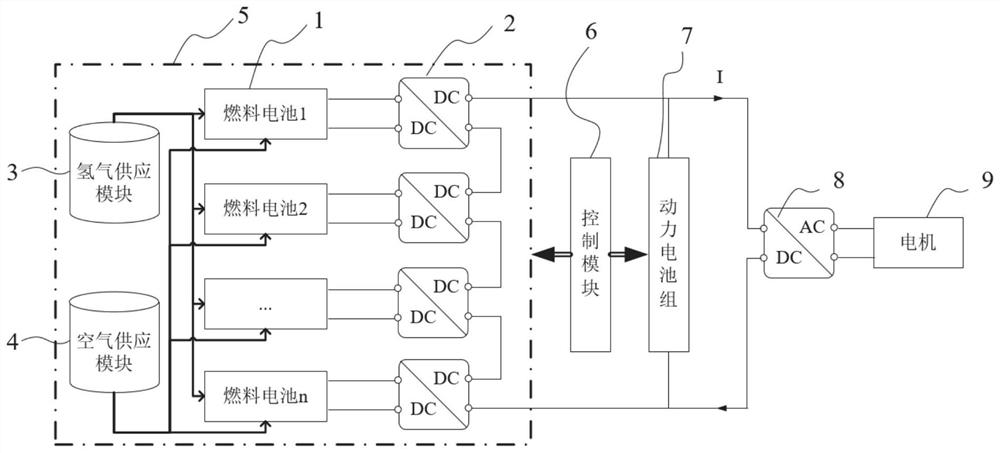

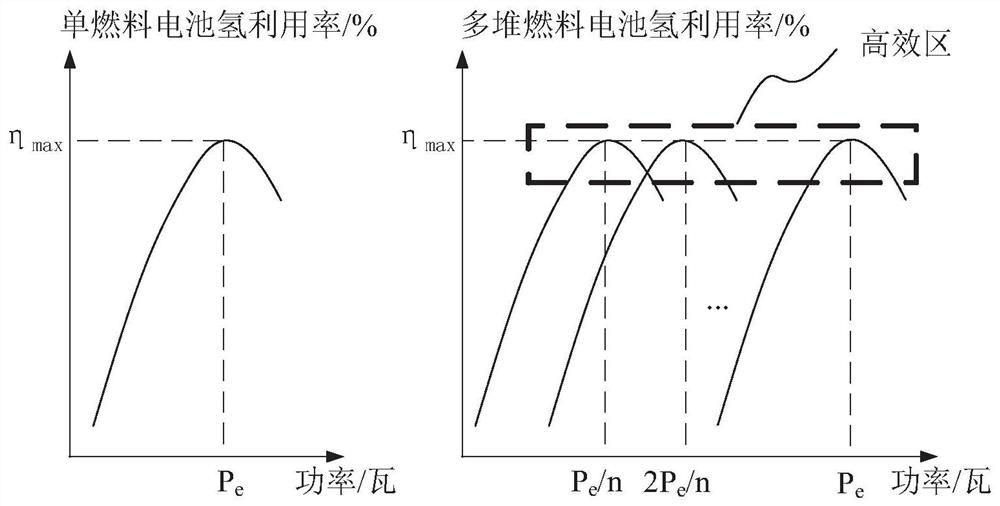

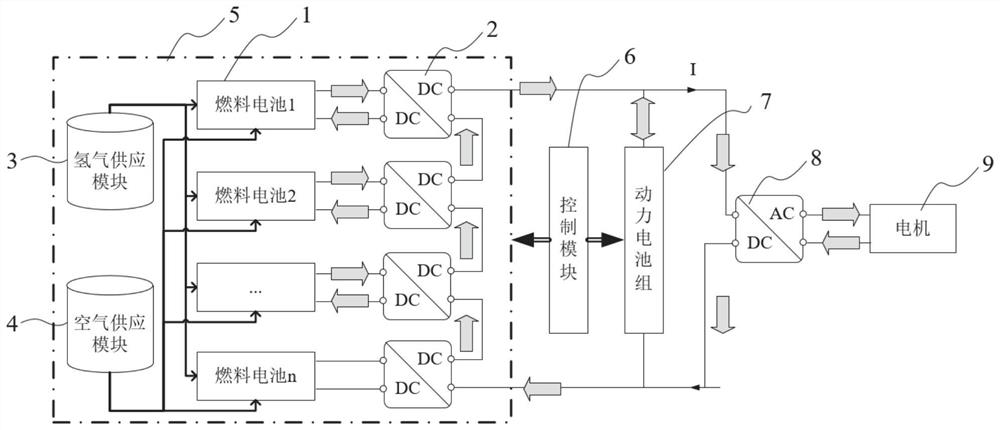

Electric vehicle power system based on multi-stack fuel cells

PendingCN113386632ALower requirementLow costPropulsion by batteries/cellsVehicular energy storageAutomotive engineeringElectric vehicle

The invention relates to an electric vehicle power system based on multi-stack fuel cells. The electric vehicle power system comprises a plurality of fuel cell stacks. The fuel cell stacks are sequentially connected in series through a one-way DC / DC converter to form a multi-stack fuel cell system; the multi-stack fuel cell system is connected in parallel with the power battery pack and then connected in series with the motor through the DC / AC converter; the system further comprises a control module which is connected with the multi-stack fuel cell system and the power battery pack through control wires, and the control module is used for controlling the output power of the corresponding fuel cell stacks through the one-way DC / DC converter. Compared with the existing parallel structure, the multi-stack fuel cell system has the advantages that the bus voltage can be distributed among different fuel cell stacks, the requirement on the one-way DC / DC converter is low, and the cost is low.

Owner:SOUTHEAST UNIV

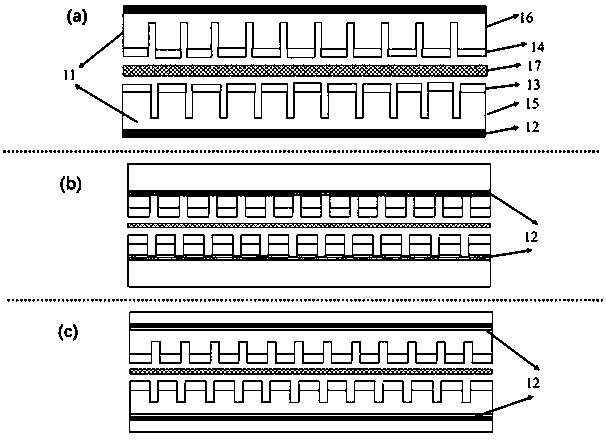

Monopole plate for hydrogen fuel cell, preparation method thereof and hydrogen fuel cell

ActiveCN109817990AImprove thermal conductivityImprove conductivityCell electrodesFuel cellsHigh densityHeat conducting

The invention discloses a monopole plate for a hydrogen fuel cell, a preparation method of the monopole plate and the hydrogen fuel cell, and belongs to the technical field of hydrogen fuel cell research. The monopole plate is prepared from expanded graphite and graphene. According to the preparation method, a graphene layer is added into the monopole plate, and the high-density (2-2.1 g / cm<-3>) monopole plate with an expanded graphite / graphene / expanded graphite sandwich structure is obtained by combining an in-situ densification means. Compared with a traditional monopole plate for the hydrogen fuel cell, the monopole plate provided by the invention has the advantages that due to the fact that the electrical conductivity (8 * 10<5>S / m) and the thermal conductivity (as high as 1500 Wm <-1>K<-1>) of the middle graphene layer are very high, the thermal conductivity and the electrical conductivity of the monopole plate are also greatly improved. And the conductivity of the monopole plateis improved, so that the electron transmission speed of the bipolar plate can be greatly improved, and the use efficiency of the whole hydrogen fuel cell is improved. And the service life of the hydrogen fuel cell can be prolonged by improving the heat-conducting property.

Owner:山东国烯新材料创新中心有限公司

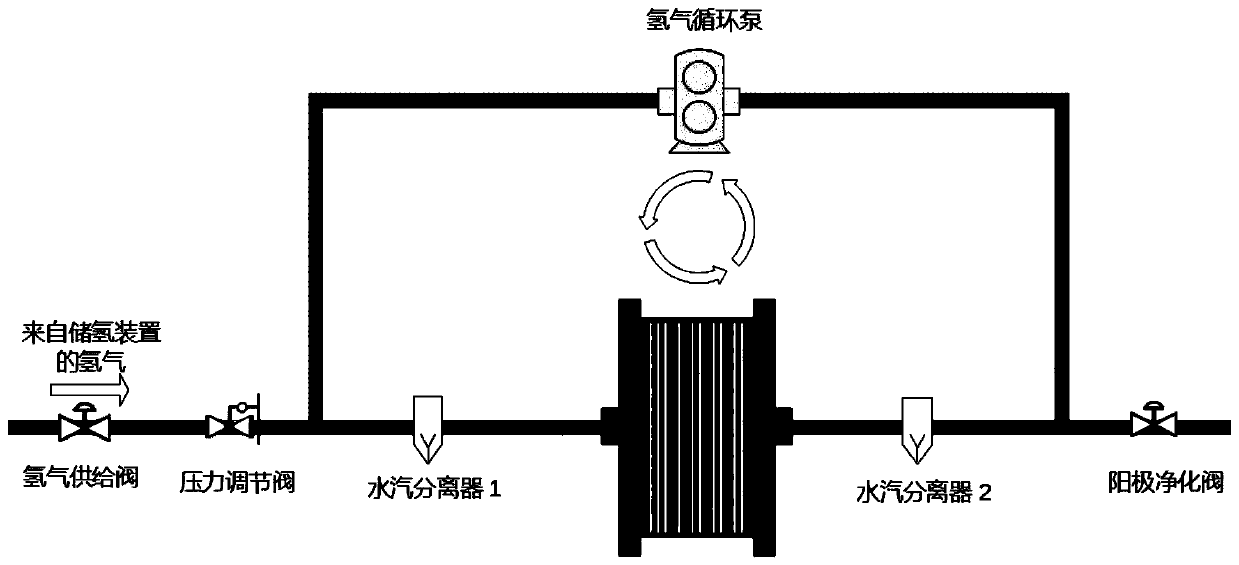

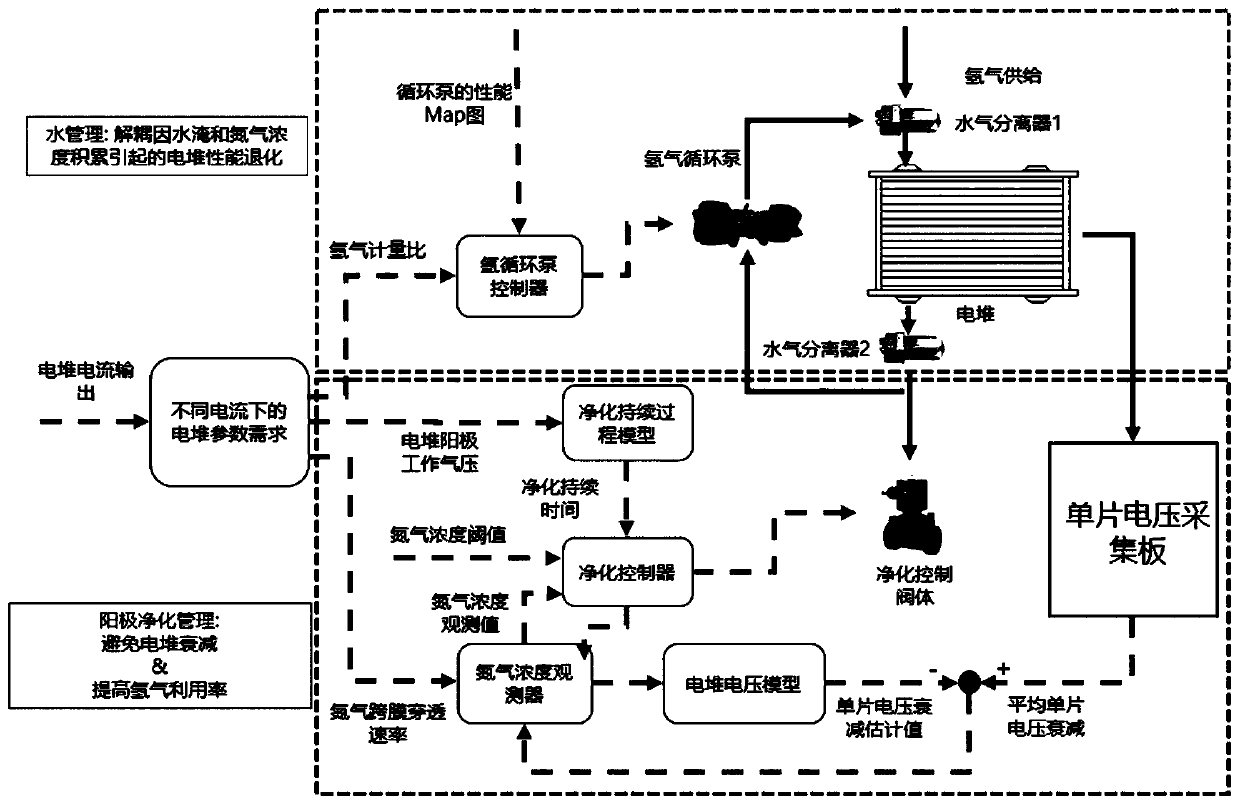

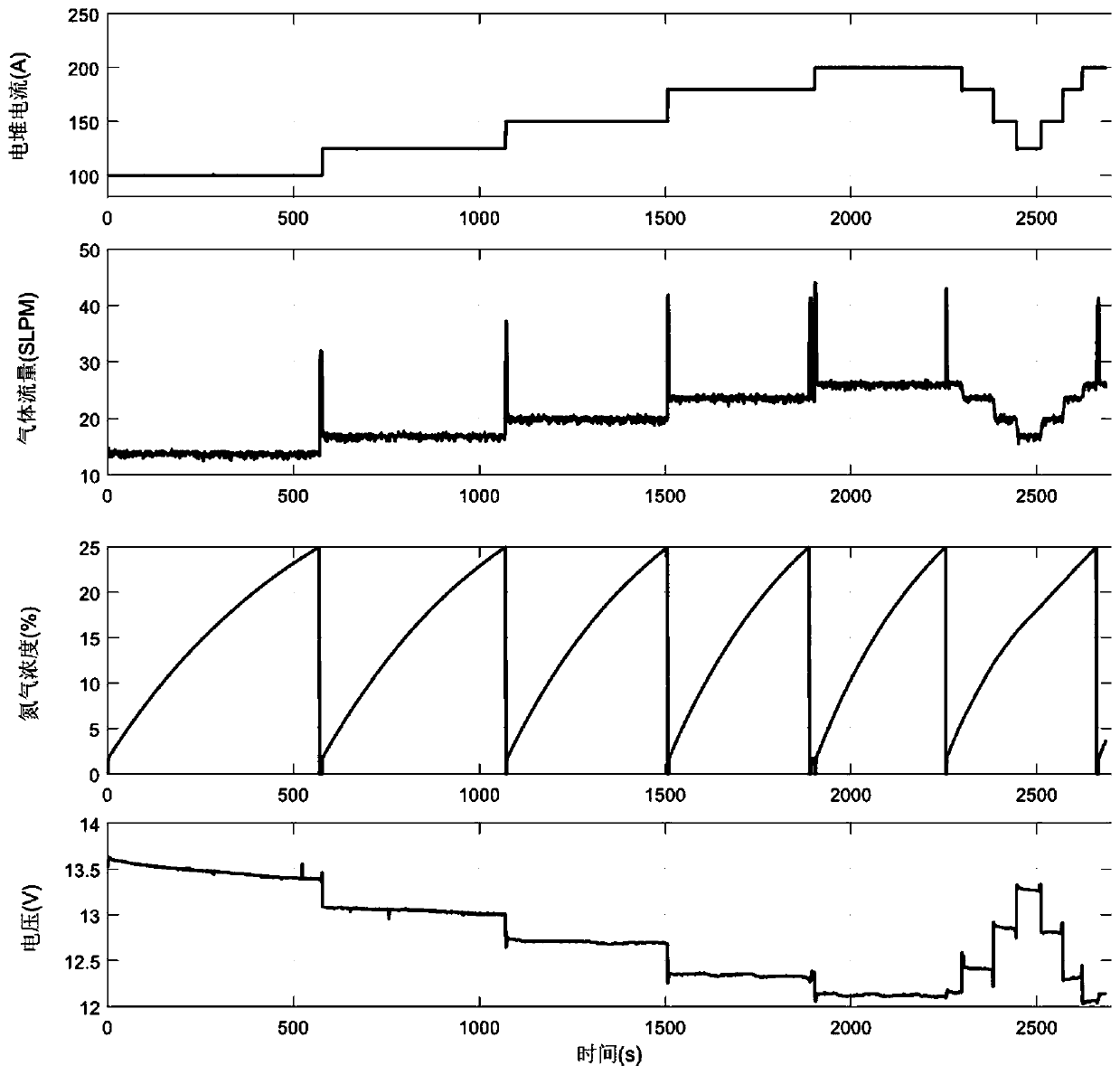

Anode gas purification control method for proton exchange membrane fuel cell

ActiveCN111313055AImprove hydrogen utilizationDecoupling stack performance degradationWater management in fuel cellsPhysicsChemistry

The invention discloses an anode gas purification control method for a proton exchange membrane fuel cell. The method comprises the steps of constructing an anode water management structure, and controlling the anode water management structure to work by utilizing an anode nitrogen concentration observer; controlling the hydrogen flow through a hydrogen circulating pump to take away liquid water contained in gas in a fuel cell stack and remove the liquid water through a second water-vapor separator, and removing the liquid water condensed and separated from gas through a first water-vapor separator; adopting an anode nitrogen concentration observer to process to obtain a nitrogen concentration observation value, using a purification duration process model to obtain purification duration time, when the nitrogen concentration observation value reaches a nitrogen concentration threshold value, opening a purification valve, and discharging nitrogen; and closing the purification valve afterthe purification duration, and entering the next period. The optimization problem of the gas purification process of an anode loop of a proton exchange membrane fuel cell engine system is solved, andthe hydrogen utilization rate of the fuel cell system can be greatly improved on the basis of ensuring the service life of an electric pile.

Owner:ZHEJIANG UNIV

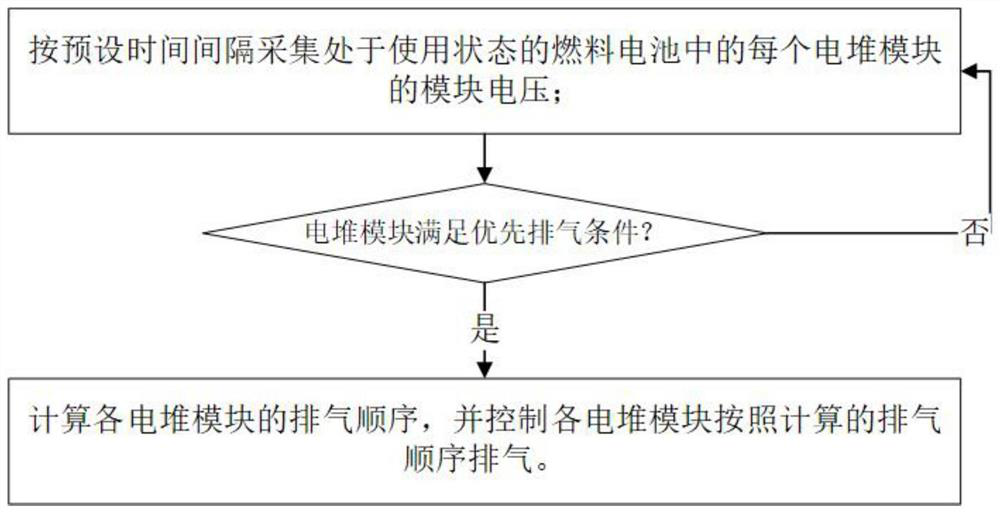

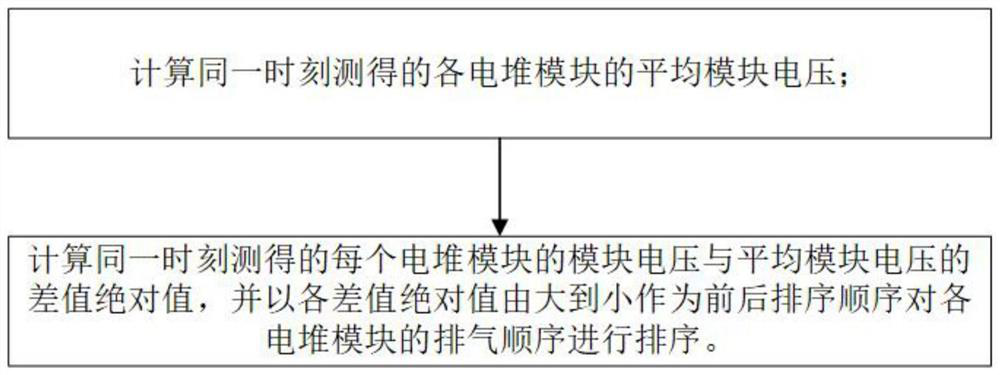

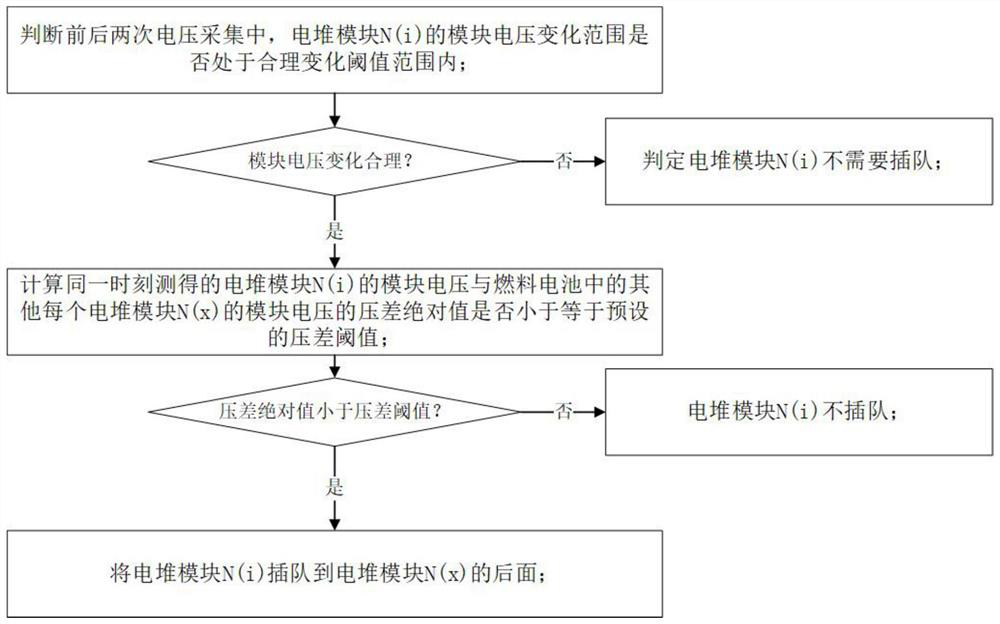

Sequential exhaust control method for fuel cell

ActiveCN113851676AImprove hydrogen utilizationExtended service lifeReactant parameters controlFuel cell controlFuel cellsElectrical battery

The invention discloses a sequential exhaust control method for a fuel cell. The sequential exhaust control method comprises the following steps: 1) acquiring module voltage of each electric pile module in the fuel cell in a use state according to a preset time interval; 2) according to the measured module voltage, judging whether each galvanic pile module reaches a preferential exhaust condition, if at least one galvanic pile module reaches the preferential exhaust condition, calculating the exhaust sequence of each galvanic pile module, and controlling each galvanic pile module to exhaust according to the calculated exhaust sequence; and if all the stack modules do not meet the preferential exhaust condition, returning to the step 1). According to the invention, reasonable control of the exhaust sequence of each single battery (or an electric pile module formed by at least one single battery) in the fuel cell is realized, and improvement of the hydrogen utilization rate of the fuel cell, reduction of the difference among the single batteries, improvement of the durability of the single batteries and prolonging of the service life of the fuel cell are facilitated.

Owner:南京氢创能源科技有限公司 +1

A method for improving the hydrogen utilization rate of the hydrodeoxygenation reaction of guaiacol under normal pressure and reducing the loss of carbon atoms

ActiveCN105461498BReduce lossesReduce consumptionMolecular sieve catalystsMolecular sieve catalystResource utilizationGuaiacol

The invention discloses a method for increasing the hydrogen utilization ratio of guaiacol during hydrodeoxygenation under the normal pressure and reducing carbon atom loss. The method is characterized by comprising the following steps: gasifying guaiacol, and mixing the gasifed guaiacol with hydrogen for reaction under the catalysis of an activated molecular sieve at the normal pressure with the temperature of 250-400 DEG C; while hydrodeoxygenation, allowing a methyl group on guaiacol to return to a benzene ring structure through transmethylation, so as to reduce the carbon atom loss and increase the hydrogen utilization ratio, wherein the activated molecular sieve is selected from Fe / Ni / HBeta, Fe / Ni / ZSM-5, Fe / Ni / HY, Fe / Ni / MCM-41, Fe / Ni / SiO2 or Fe / Ni / Al2O3. Through adoption of the method, the acquired BTX yield can reach up to 19.83%. In the method, an autoclave is eliminated, a transmethylation reaction is realized while hydrodeoxygenation, the carbon atom loss and hydrogen consumption are reduced, and a new way is provided for resource utilization of lignin under the normal pressure.

Owner:SOUTH CHINA AGRI UNIV

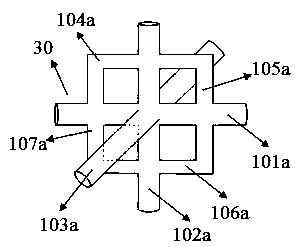

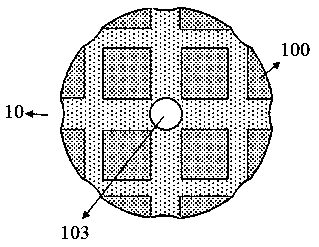

Hydrotreating method of heavy hydrocarbon raw material

InactiveCN111100693AReasonable temperature distributionIncrease profitTreatment with hydrotreatment processesChemical/physical processesPtru catalystFixed bed

The invention discloses a hydrotreating method of a heavy hydrocarbon raw material. The method comprises the following steps: at least one up-flow reactor and at least one down-flow fixed bed reactorare connected in series, a heavy hydrocarbon raw material is sequentially enable to pass through the up-flow reactor and the down-flow fixed bed reactor, and effluent of the down-flow fixed bed reactor is separated to obtain products; wherein the up-flow reactor is at least filled with a hydrotreating catalyst provided by the invention, a hydrotreating catalyst carrier at least comprises seven channels penetrating through the carrier; the first channel, the second channel and the third channel penetrate through the sphere center of the catalyst carrier and are communicated with one another, every two channels are perpendicular to each other, the fourth channel, the fifth channel, the sixth channel and the seventh channel are connected end to end and communicated, and the total volume of the channels accounts for 20%-60% of the volume of the spherical carrier. According to the method, the overall performance of the catalyst can be improved, the catalytic performance synchronization of the up-flow catalyst and the fixed bed catalyst is realized, the catalytic activity is improved, and the operation period is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com