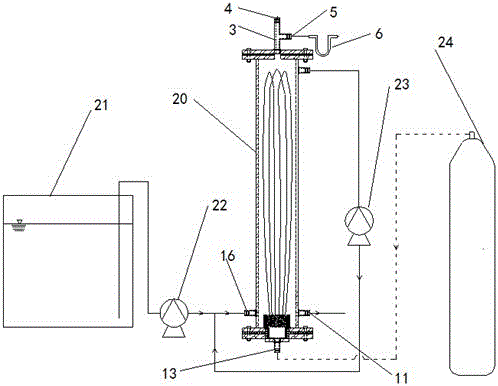

Reactor for degrading oxidative pollutants in water body by using microorganisms

A microbial degradation and reactor technology, applied in biological water/sewage treatment, polluted groundwater/leachate treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution of water bodies, increase costs, etc., and alleviate the impact load , easy to fall off, easy to buy and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

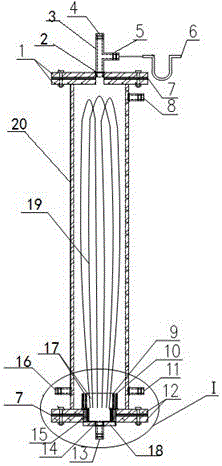

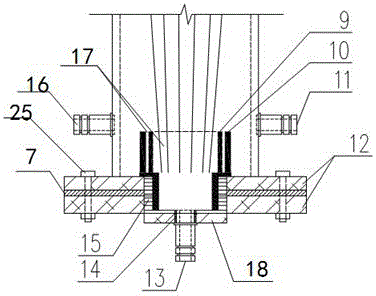

[0044] In this embodiment, a device with an effective volume of 1.8 L, an inner diameter of the reactor main body 20 of 700 mm, and a height of 500 mm is used. The hollow fiber membranes 19 are commercially available PVC hollow fiber membranes 19, with an outer diameter of 1.66 mm, an inner diameter of 1 mm, and a membrane pore diameter of 0.02 μm. There are 60 hollow fiber membranes 19 in total for each membrane module (120 are formed after bending). The aeration hydrogen partial pressure is 0.04MPa. Pump the prepared simulated wastewater (pH=7.0-7.5) containing 1mg / L Cr(Ⅵ) and inorganic carbon and nitrogen sources into the reactor main body 20 through the water inlet pump 22, when the water surface reaches the middle of the reactor main body 20 , use a sterile syringe to add 100mL of activated sludge from the anaerobic tank of the urban sewage treatment plant (sludge concentration is 2800mg / L), continue to infuse water until the main body of the reactor is filled with 20°C, ...

Embodiment 2

[0046] In this embodiment, a reactor body 20 with an effective volume of 1.8 L, an inner diameter of 700 mm, and a height of 500 mm is used. The hollow fiber membranes 19 are commercially available PVC hollow fiber membranes 19, with an outer diameter of 1.66 mm, an inner diameter of 1 mm, and a membrane pore diameter of 0.02 μm. There are 60 hollow fiber membranes 19 in total for each membrane module (120 are formed after bending). The aeration hydrogen partial pressure is 0.04MPa. The prepared simulated wastewater (pH=7.0-7.5) containing As(Ⅴ) 100μg / L and inorganic carbon source, nitrogen source and sulfate is pumped into the reactor through the inlet pump 22. When the water surface reaches the middle of the reactor, Use a sterile syringe to add 100mL of activated sludge from the anaerobic tank of the urban sewage treatment plant (the sludge concentration is 2800mg / L), continue to feed water until the reactor is full, stop the water feed, set the reflux rate to 10mL / min for ...

Embodiment 3

[0048] In this embodiment, the same reactor main body 20 as in Embodiment 1 and Embodiment 2 is used, and a similar cultivation and acclimation scheme is used to treat nitrate, and a better removal effect is obtained. When water enters NO 3 - - When N is 10mg / L, the removal rate can reach 100% after two days of domestication; when the influent depth increases to 30mgNO 3 - When -N / L, it can still be completely removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com