Fuel cell system and purging starting method thereof

A fuel cell system and stack technology, applied to fuel cells, circuits, electrical components, etc., can solve the problems of not considering the effectiveness of purging, not considering the difference between anode positive pressure or negative pressure, and reducing the life of the stack. Achieve the effect of reducing the risk of shortening the life of the stack, improving the utilization rate of hydrogen, and controlling comprehensively and finely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

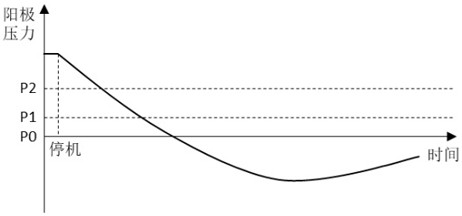

[0038] According to different working conditions when the fuel cell system is started, the present invention uses different anode purging methods to reduce hydrogen waste, avoid the appearance of anode hydrogen-air interface or shorten the existence time, thereby improving hydrogen utilization rate and ensuring the service life of the stack. like figure 2 As shown, it is the anode pressure change curve after the fuel cell system is shut down normally. After the fuel cell system shuts down, the anode hydrogen slowly permeates to the cathode, which causes the anode pressure to drop first, while the cathode nitrogen permeates to the anode, and the anode pressure gradually rises, among which: pressure P0 is the ambient pressure, pressure P1 is the pressure judgment threshold, and pressure P2 is the anode hydrogen purge pressure at startup, P2>P1>P0;

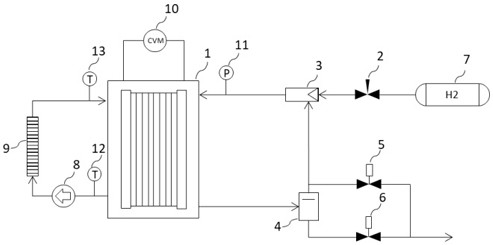

[0039] This embodiment discloses a fuel cell system, such as figure 1 As shown, it includes a stack 1, a hydrogen supply unit 7, ...

Embodiment 2

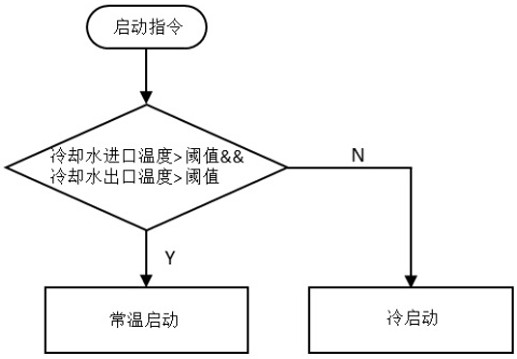

[0052] This embodiment discloses a start-up purging method for the fuel cell system on the basis of the fuel cell system in the first embodiment, such as Figure 3-Figure 5 shown, including the following steps:

[0053] After the fuel cell system receives the start-up command, it runs the water pump 8, and then detects the coolant outlet temperature and coolant inlet temperature of the stack 1. If the coolant outlet temperature and coolant inlet temperature are both greater than the specified temperature threshold, the fuel cell The system enters the normal temperature startup process, otherwise the fuel cell system enters the cold startup process;

[0054] like Figure 4 As shown, in the case of the normal temperature startup process, check whether the anode inlet pressure is greater than or equal to the pressure P1, if the anode inlet pressure is greater than or equal to the pressure P1, the fuel cell system does not perform anode purging; continue to detect whether the ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com