Ejector unit and fuel cell hydrogen circulation system having same

A fuel cell stack and ejector technology, which is applied to fuel cells, fuel cell additives, circuits, etc., can solve the problem of insufficient ejection of the ejector, and achieve the needs of improving the hydrogen circulation capacity and reducing the hydrogen pressure. The effect of improving the utilization rate of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

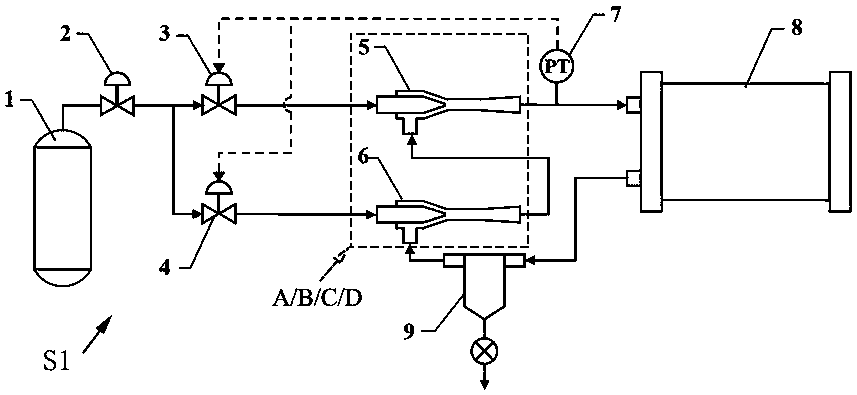

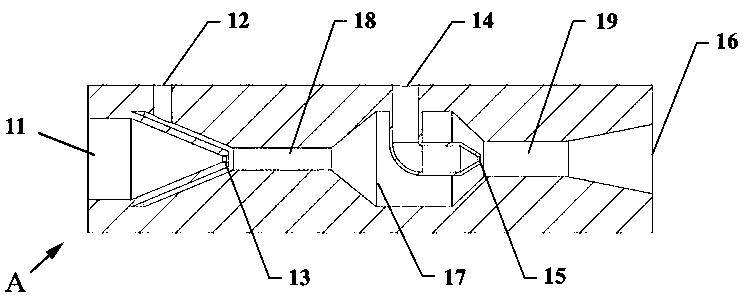

[0078] figure 1 is a sectional view of the ejector unit A according to Embodiment 1 of the present invention. Such as figure 1 As shown, the first ejector 6 and the second ejector 5 are connected in series in a coaxial form, and the first jet hole 13 and the second jet hole 15 are also located at the series axis of the ejector unit A , so that the ejector unit A is formed in the form of a center-to-center jet. Therefore, at the axial center position, the first jet inlet 11, the first jet hole 13 communicating with the first jet inlet 11, the first mixing hole 13 communicating with the first jet hole 13 and the first drainage inlet 12 are sequentially formed. Space 18, the first outlet 17 communicating with the first mixing space 18 and having the function of the second drainage inlet, the second jet hole 15 communicating with the second jet inlet 14, and the second jet hole 15 and the first outlet 17 at the same time The communicating second mixing space 19 and the second o...

Embodiment 2)

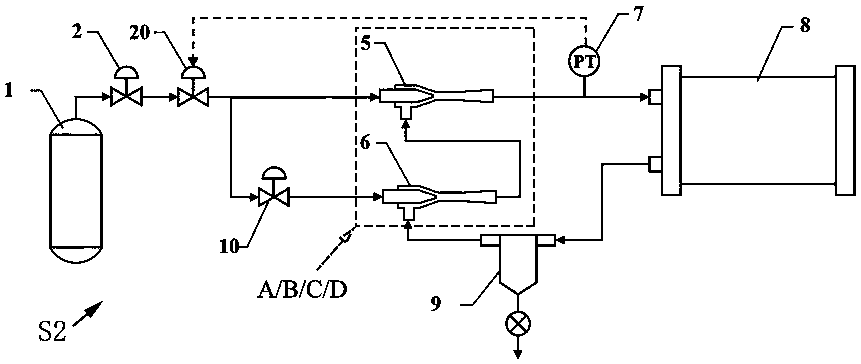

[0080] figure 2 is a sectional view of an ejector unit B according to Embodiment 2 of the present invention. Such as figure 2 As shown, the first ejector 6 and the second ejector 5 are connected in series in a coaxial form, and the first jet hole 13 is located at the center of the serial axis of the ejector unit A, while the second jet hole 15 The ejector unit B is formed in a ring form on the inner side wall portion of the ejector unit B so that the ejector unit B is formed in the form of a center-annular jet. On the series axis of the first ejector 6 and the second ejector 5, a first jet inlet 11, a first jet hole 13 communicating with the first jet inlet 11, a first jet hole 13 and a first jet hole 13 are formed in sequence. A first mixing space 18 that communicates with the first flow inlet 12 at the same time, a first outlet 17 that communicates with the first mixing space 18 and also functions as a second flow inlet, and a second outlet 17 that communicates with the ...

Embodiment 3)

[0082] image 3 is a sectional view of an ejector unit C according to Embodiment 3 of the present invention. Such as image 3As shown, the first ejector 6 and the second ejector 5 are connected in series in a coaxial form, and the first jet hole 13 and the second jet hole 15 are formed in the inner side of the ejector unit C in a ring form. The wall, and thus the ejector unit C, is formed in the form of an annular-annular jet. On the series axis of the first ejector 6 and the second ejector 5, there are sequentially formed a first drainage inlet 12, a first mixing space 18 communicating with the first jet hole 13 and directly communicating with the first drainage inlet 12 , the first outlet 17 communicating with the first mixing space 18 and having the function of the second drainage inlet, the second mixing space 19 communicating with the second jet hole 15 and directly communicating with the first outlet 17, and the second mixing space 19 The connected second outlet 16, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com