Stable horizontal fuel gas generator and gas generating process thereof

A gas generator, horizontal technology, applied in the direction of combustion method, liquid fuel supply/distribution, etc., can solve the problems of low gas production efficiency, large blowing power, different degree of oil mixing, etc., to reduce energy consumption and reduce pressure Demand, full effect of bubble splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

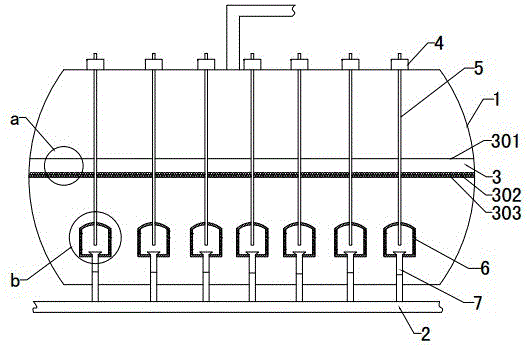

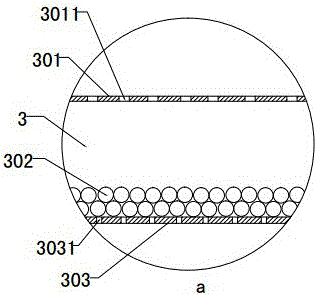

[0024] The upper partition 301 and the lower partition 303 of the bubble adjustment plate 3 are set at an interval of 12cm; the aperture of the upper mesh 3011 offered on the upper partition 301 is 1.0cm, and the aperture of the lower mesh 3031 offered on the lower partition 303 is 0.5cm ; The air bubble adjustment plate 3 is filled with activated carbon balls 302 accounting for 20% of its volume, and the diameter of the activated carbon balls 302 is 1.4 cm ~ 1.6 cm;

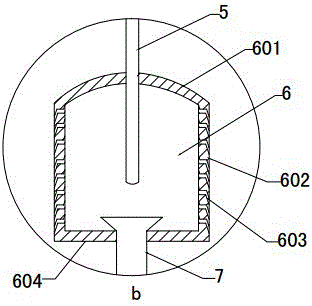

[0025] Bubbler 6 blows air bubbles at 0.46m below the oil surface during operation, and the air bubbles rise to the air bubble adjustment plate 3 and enter the air bubble adjustment plate 3 through the mesh. Extruded and collided, the air bubbles that reach the upper surface of the air bubble adjustment plate 3 escape from the mesh, rise above the oil surface and collect, and are output by the gas outlet pipe, and the gas output by the gas pipeline burns stably.

Embodiment 2

[0027] The upper partition 301 and the lower partition 303 of the air bubble adjustment plate 3 are set at an interval of 10cm; the aperture of the upper mesh 3011 offered on the upper partition 301 is 0.9cm, and the aperture of the lower mesh 3031 offered on the lower partition 303 is 0.44cm ; The air bubble adjustment plate 3 is filled with activated carbon balls 302 accounting for 20% of its volume, and the diameter of the activated carbon balls 302 is 1.4 cm ~ 1.6 cm;

[0028]Bubbler 6 blows out air bubbles 0.44m below the oil surface during operation, and the air bubbles rise to the air bubble adjustment plate 3, and enter the air bubble adjustment plate 3 through the mesh, and the incoming air bubbles drive the activated carbon balls 302 to make irregular movements and constantly interact with each other. Extruded and collided, the air bubbles that reach the upper surface of the air bubble adjustment plate 3 escape from the mesh, rise above the oil surface and collect, an...

Embodiment 3

[0030] The upper partition 301 and the lower partition 303 of the bubble adjustment plate 3 are set at an interval of 8cm; the aperture of the upper mesh 3011 offered on the upper partition 301 is 0.8 cm, and the aperture of the lower mesh 3031 offered on the lower partition 303 is 0.4 cm ; The air bubble adjustment plate 3 is filled with activated carbon balls 302 accounting for 18% to 22% of its volume, and the diameter of the activated carbon balls 302 is 1.4 cm to 1.6 cm;

[0031] Bubbler 6 blows out air bubbles 0.5m below the oil surface during operation, and the air bubbles rise to the air bubble adjustment plate 3, enter the air bubble adjustment plate 3 through the mesh, and the entered air bubbles drive the activated carbon balls 302 to make irregular movements and constantly interact with each other. Extruded and collided, the air bubbles that reach the upper surface of the air bubble adjustment plate 3 escape from the mesh, rise above the oil surface and collect, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com