Hydrogen charging and discharging performance detection system for hydrogen storage tank

A detection system and hydrogen storage tank technology, which is applied in the field of hydrogen storage tank hydrogen charging and discharging performance detection system, can solve problems such as the inability to realize the detection of hydrogen charging performance, the detection of constant flow hydrogen charging performance, and the limitation of the temperature range of detection. , to achieve the effect of wide detection temperature range and increased boost pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

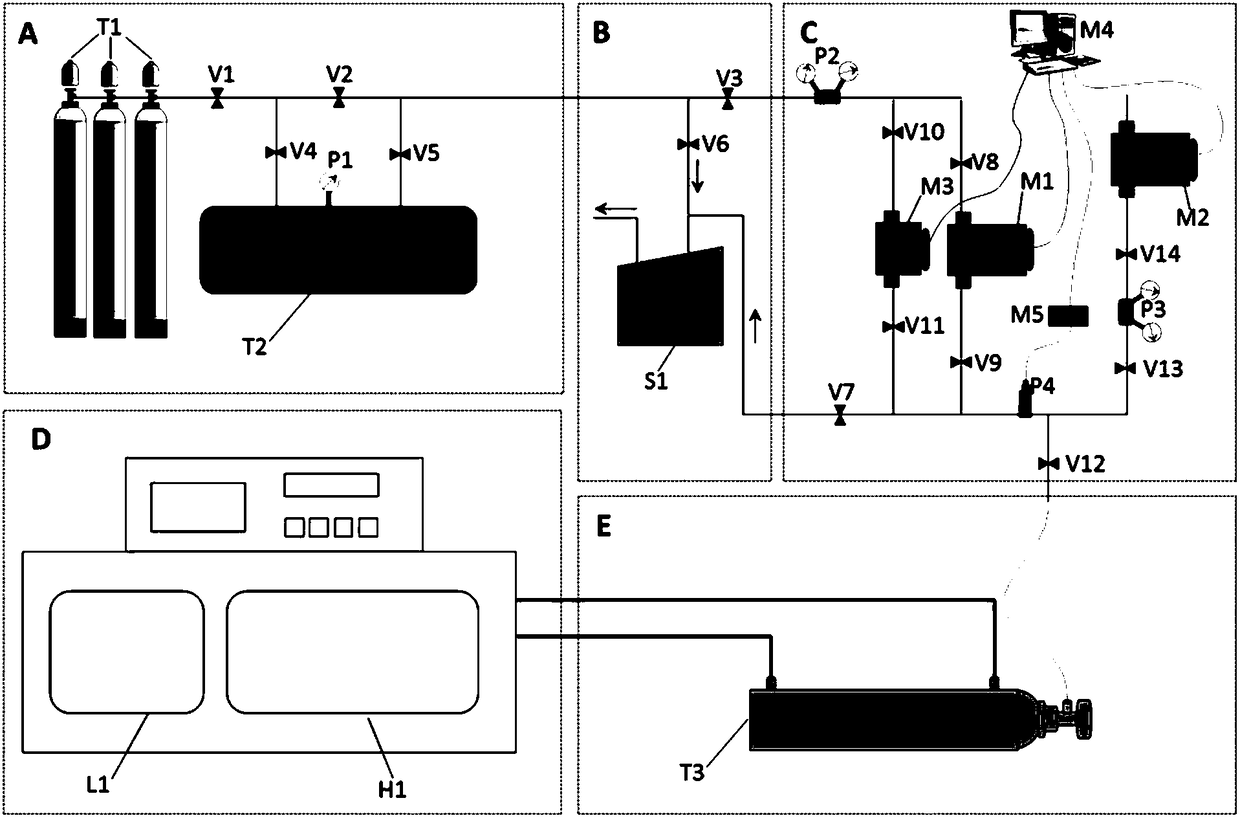

[0065] Use the static chemical hydrogen compression and storage integrated machine T2 to boost the pressure:

[0066] At room temperature, open the valves V1 and V4, close the valves V2 and V5, fill the low-pressure hydrogen in the hydrogen cylinder group T1 into the static chemical hydrogen compression and storage integrated machine T2, and close the valve V1 after the reading of the pressure gauge P1 is stable and V4, and keep the valve V5 closed, heating the static chemical hydrogen compression storage integrated machine T2, because the hydrogen plateau pressure of the metal hydride increases with the temperature, so after heating, the hydrogen in the static chemical hydrogen compression storage integrated machine T2 The pressure will rise slowly, and the boost level is related to the water temperature, hydrogen content and hydrogen storage materials.

Embodiment 2

[0068] Use the mechanical vacuum pump S1 to exhaust the hydrogen pipeline:

[0069] When the hydrogen cylinder T1 is replaced, close the valves V4, V5, V3 and V7, open the valves V1, V2 and V6, and turn on the mechanical vacuum pump S1 at the same time to remove the miscellaneous gas in the gas circuit; when the hydrogen storage tank T3 to be tested is replaced , then close the valves V11, V9, V13 and V6, open the valves V7 and V12, and at the same time turn on the mechanical vacuum pump S1 to remove the miscellaneous gas in the gas circuit.

Embodiment 3

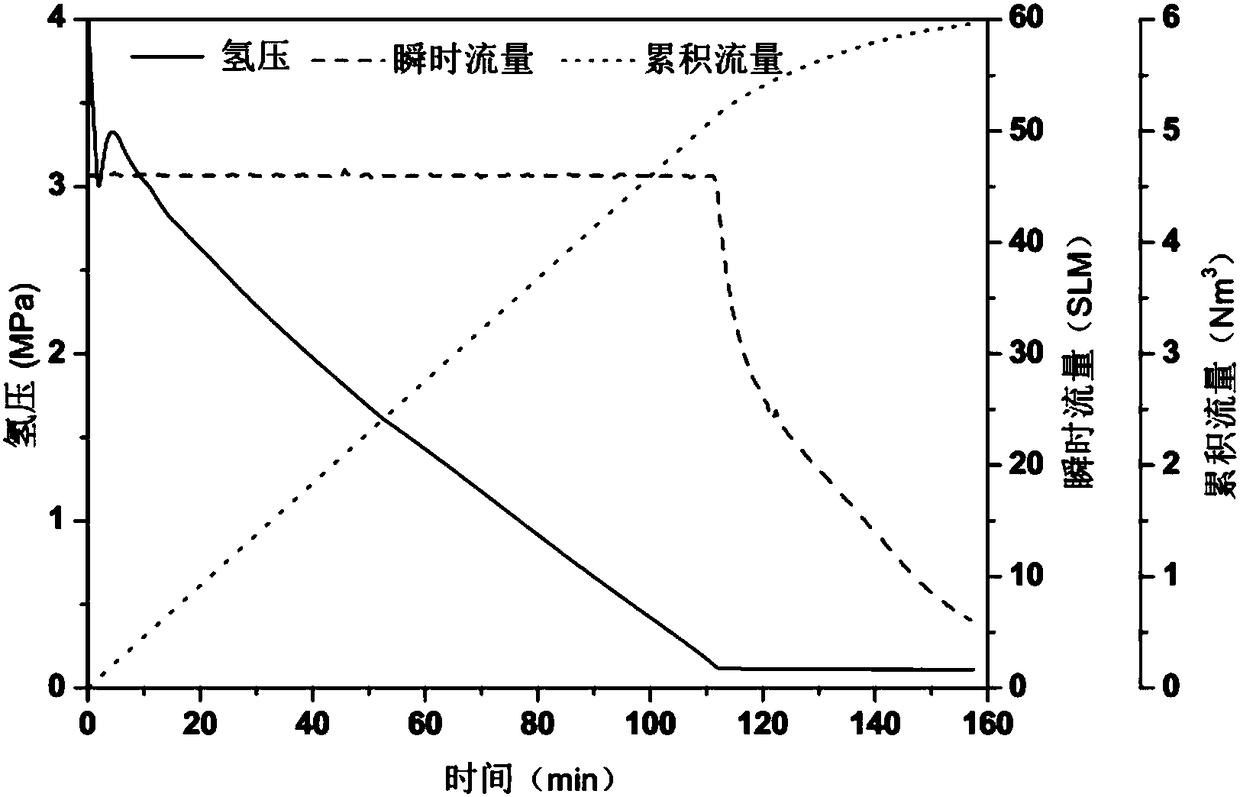

[0071] Test the hydrogen charging and discharging performance of a hydrogen storage tank T3 to be tested:

[0072] The rated hydrogen storage capacity of the hydrogen storage tank T3 to be tested is 5Nm 3 , the rated hydrogen filling pressure is 4MPa, and the heat exchange is carried out by means of external heat exchange.

[0073] 1. Test preparation.

[0074] Connect the hydrogen storage tank T3 to be tested to the test system, close the valves V11, V9, V13 and V6, open the valves V12 and V7, and at the same time turn on the mechanical vacuum pump S1 to vacuum the gas path to discharge impurity gases. After the exhaust is completed, close each Valves and mechanical vacuum pump S1.

[0075] Connect the cylinder T1 filled with hydrogen to the test system, close the valves V4, V5, V3 and V7, open the valves V1, V2 and V6, and at the same time turn on the mechanical vacuum pump S1 to evacuate the gas path to discharge impurity gases. After the exhaust is completed, Close all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com