Patents

Literature

111 results about "Hydrogen compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

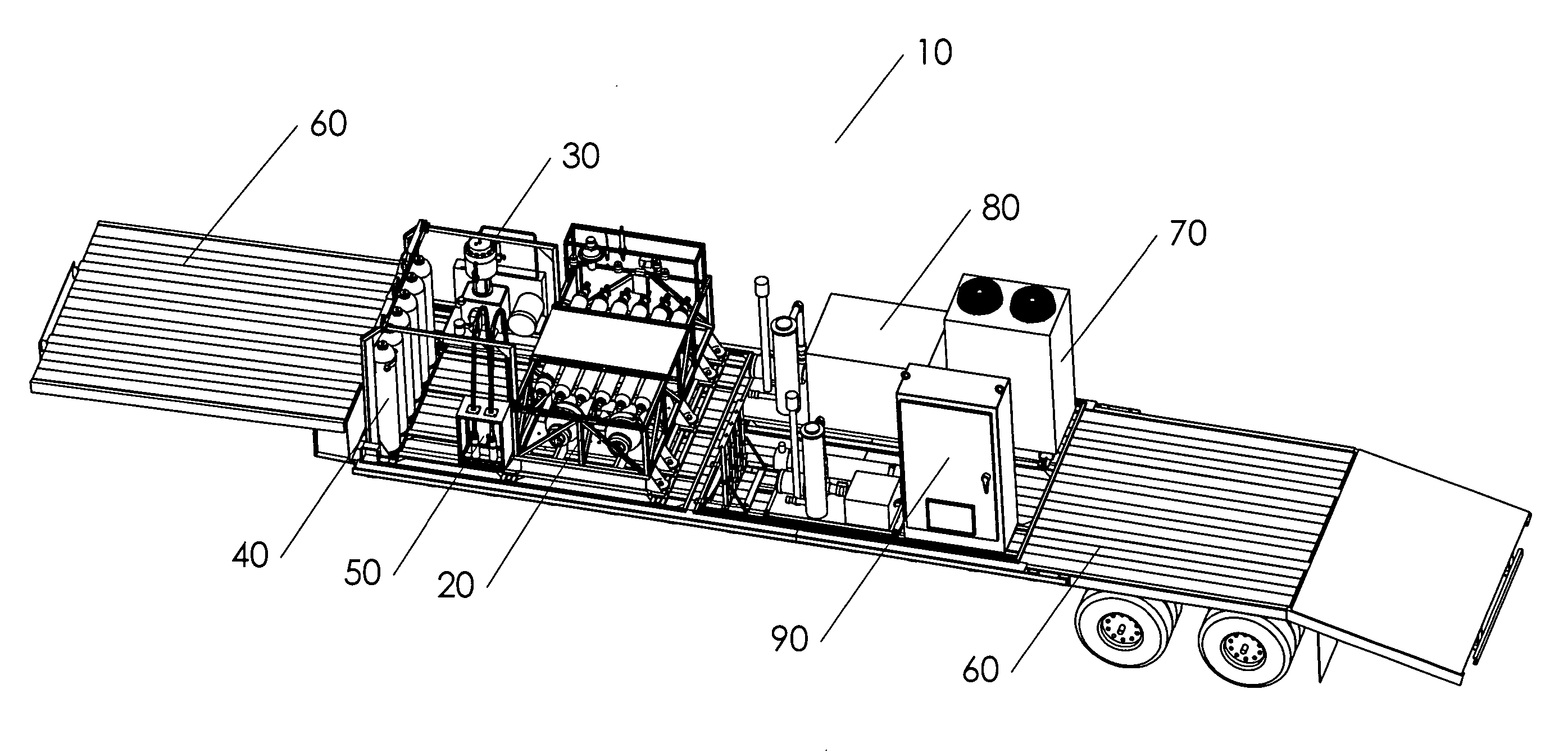

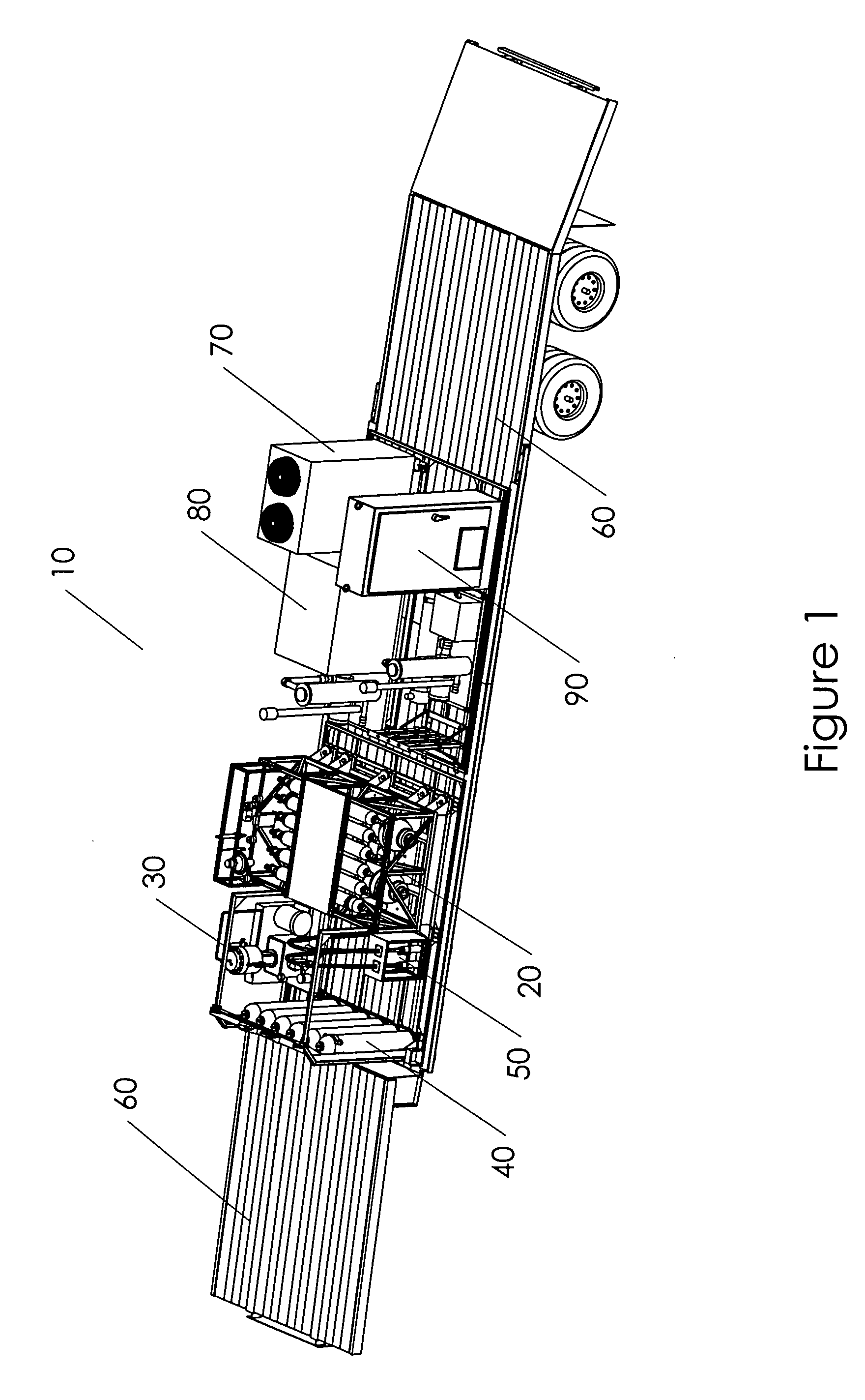

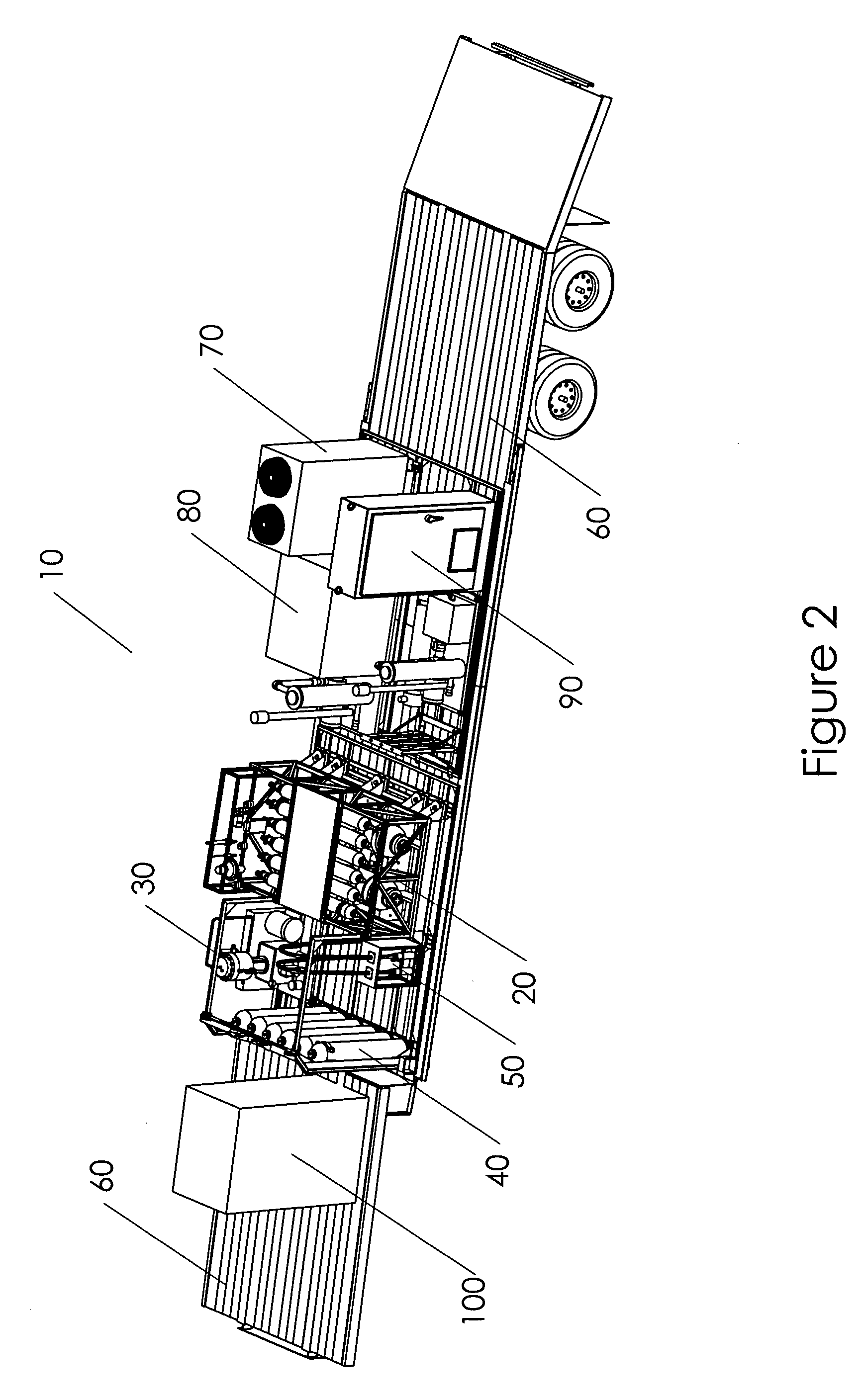

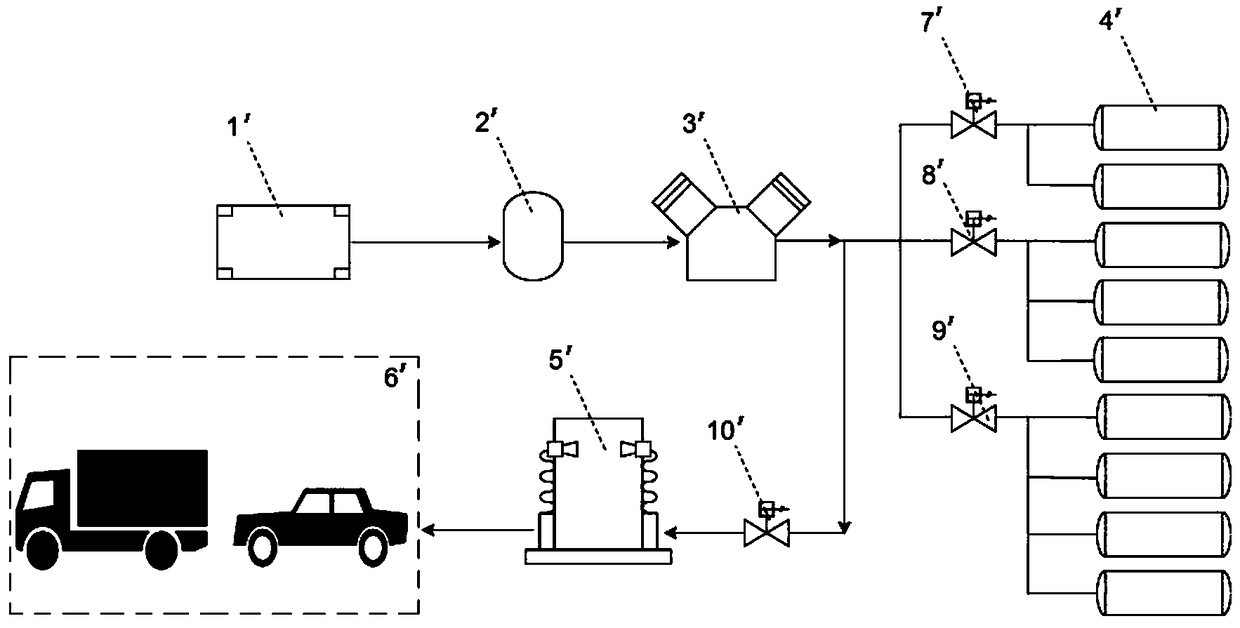

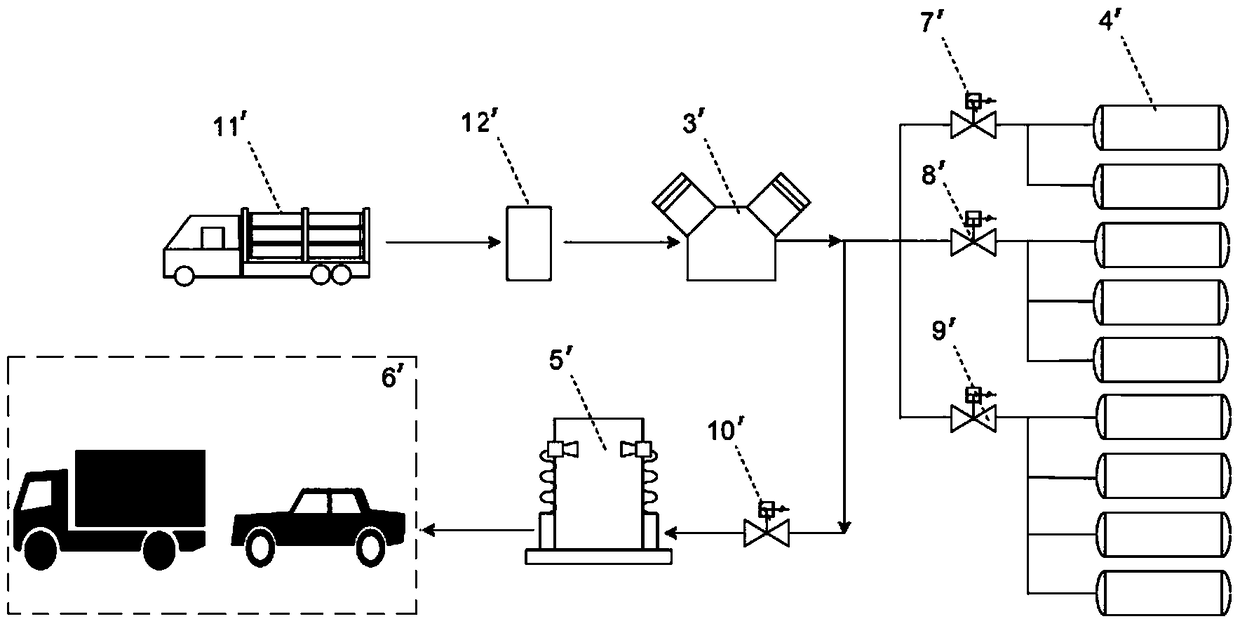

Mobile hydrogen delivery system

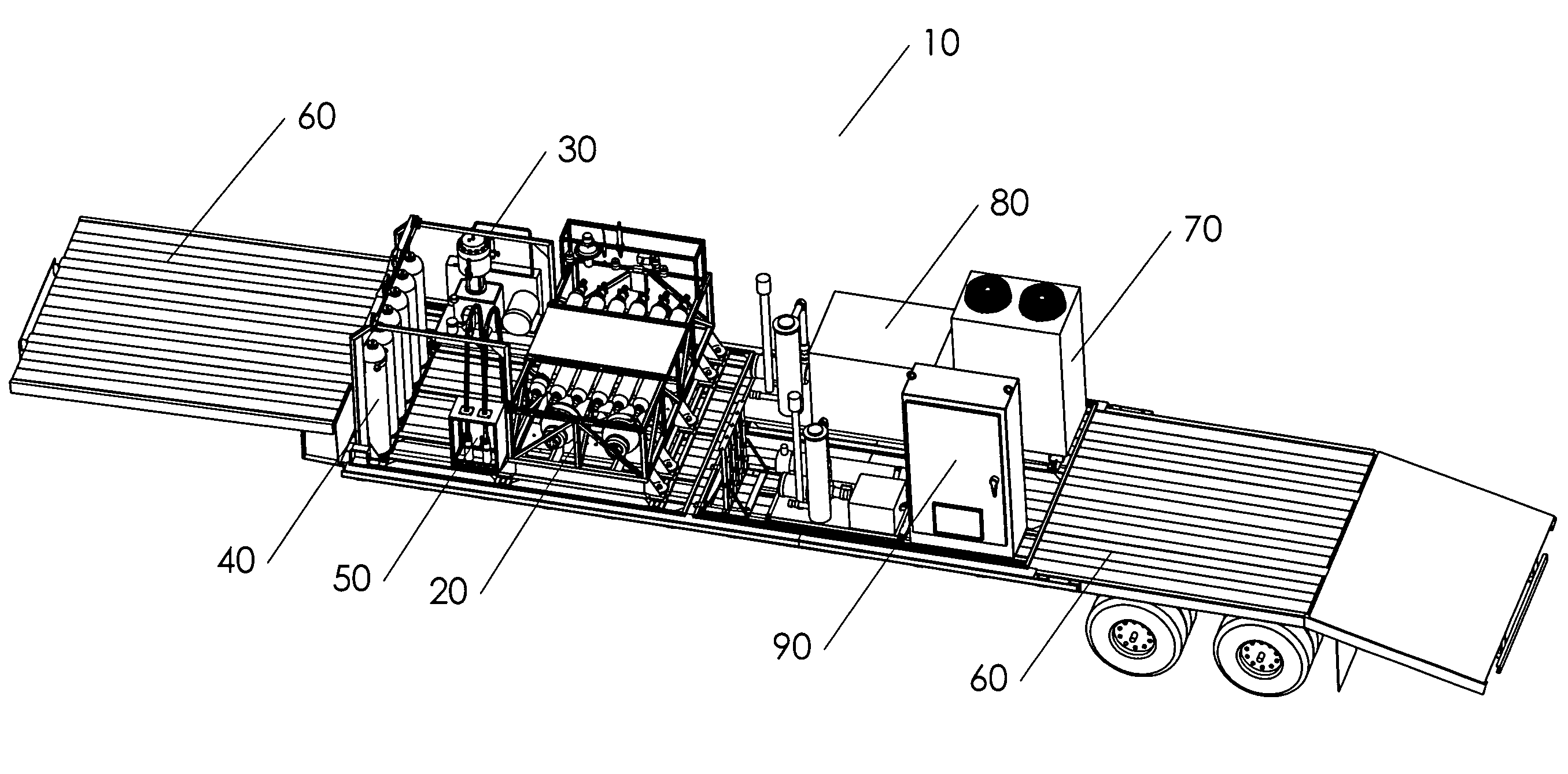

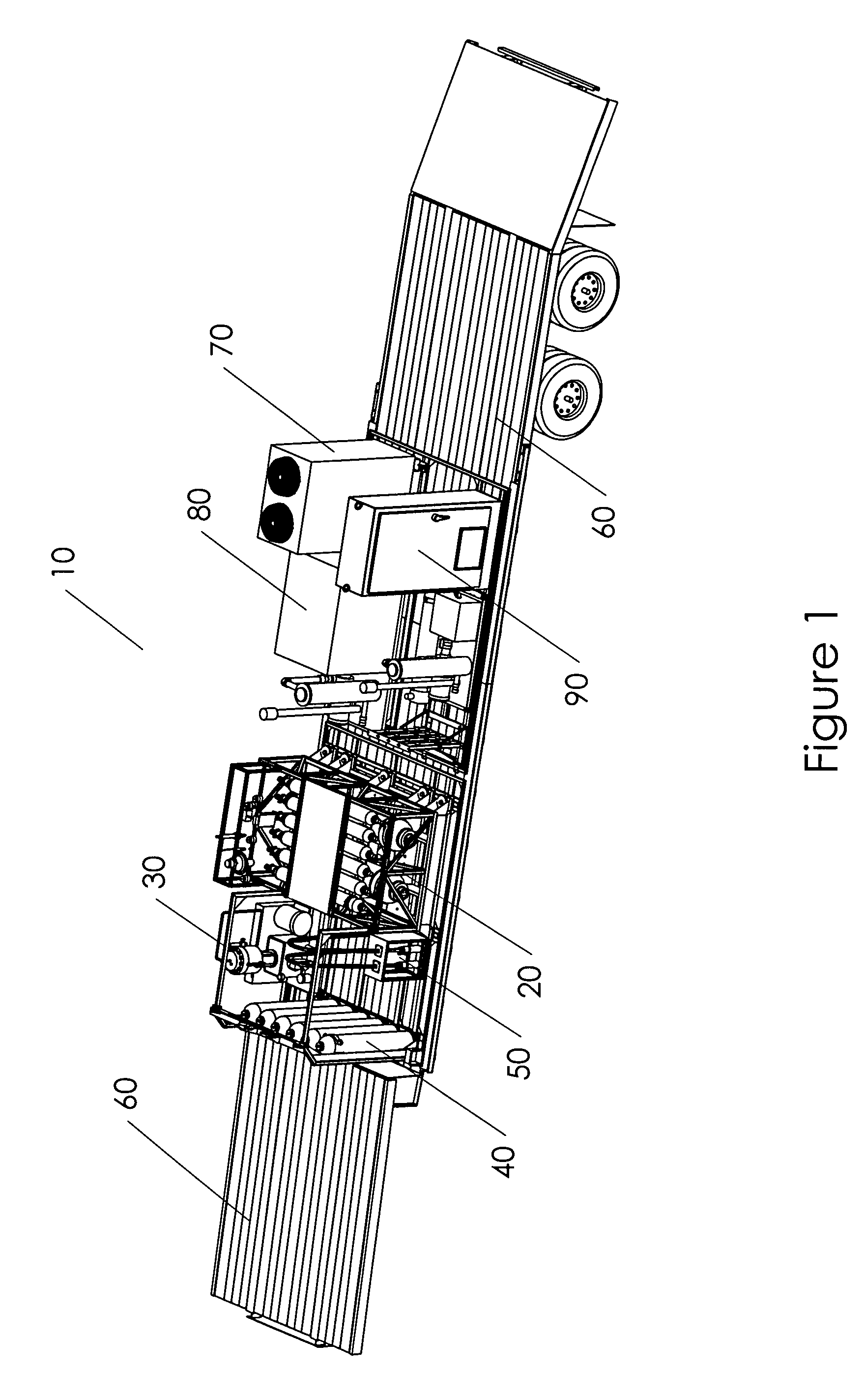

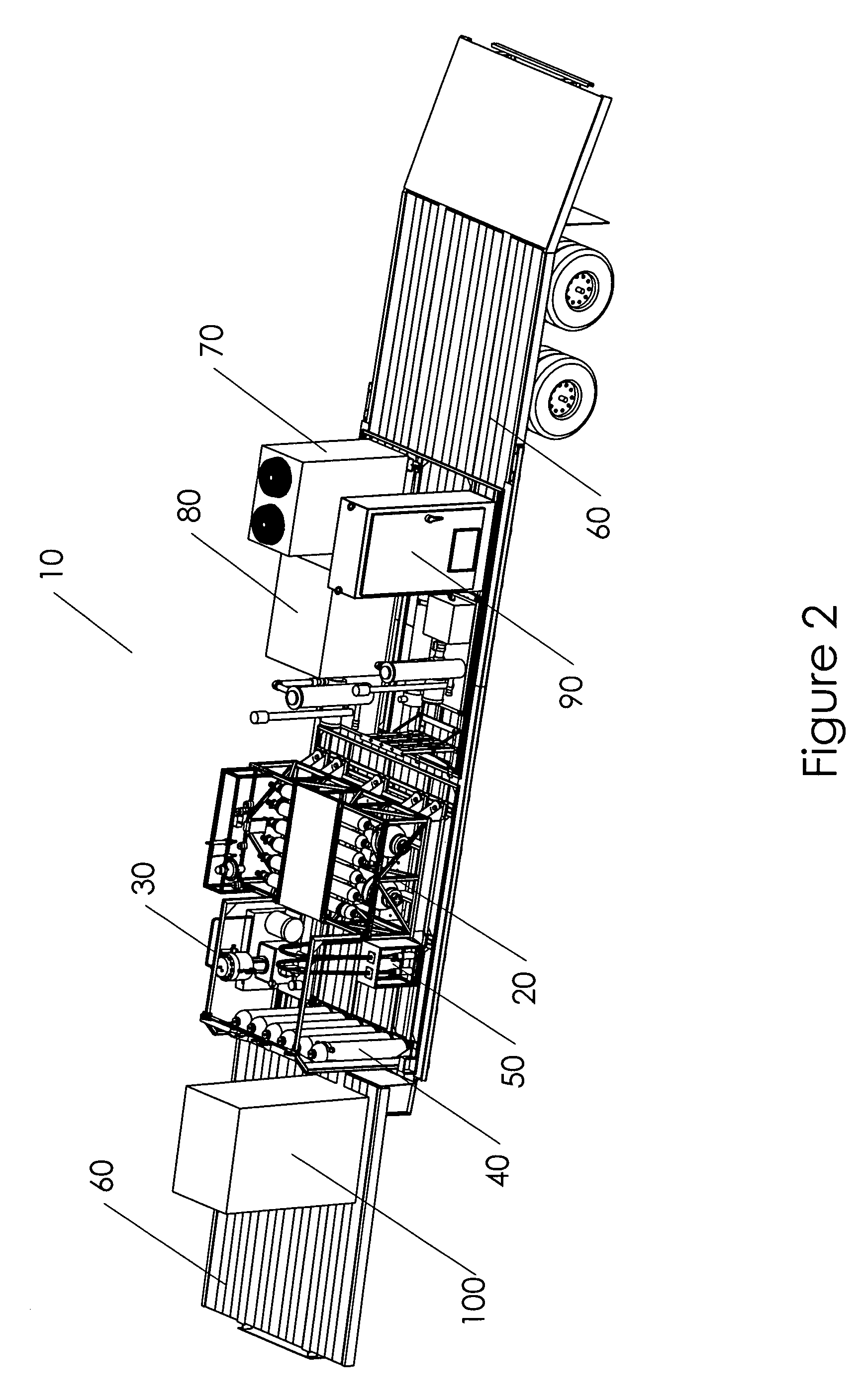

A mobile hydrogen delivery system for delivering a compressed stream of hydrogen at pressures up to 15000 psig. The mobile hydrogen delivery system includes a hydrogen compression system, a gaseous hydrogen storage system, and a delivery system for supplying hydrogen to end users. A mobile platform supports the hydrogen compression system, the gaseous hydrogen storage system, and the dispensing system. The mobile platform may be any platform, such as a trailer, capable of being pulled, pushed, or supported by any type of vehicle, such a truck, train, boat, tractor, etc.

Owner:HARNYSS IP LLC +1

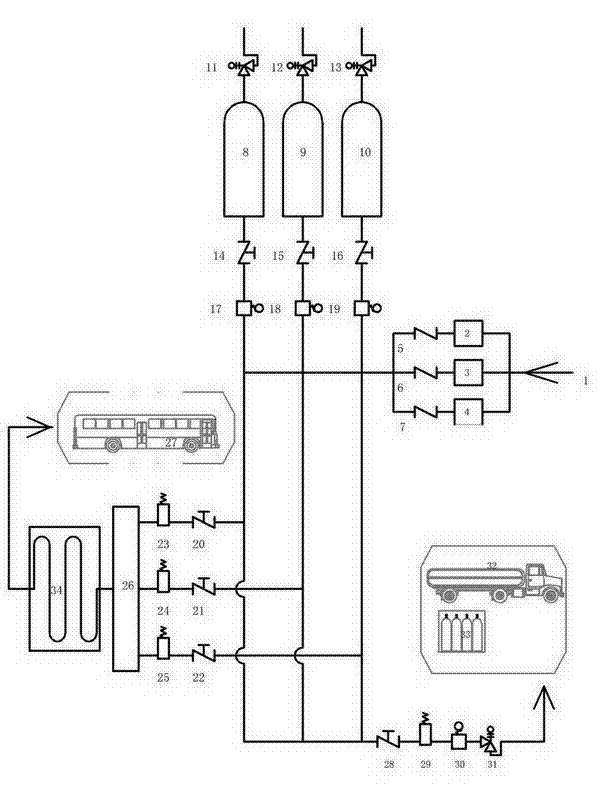

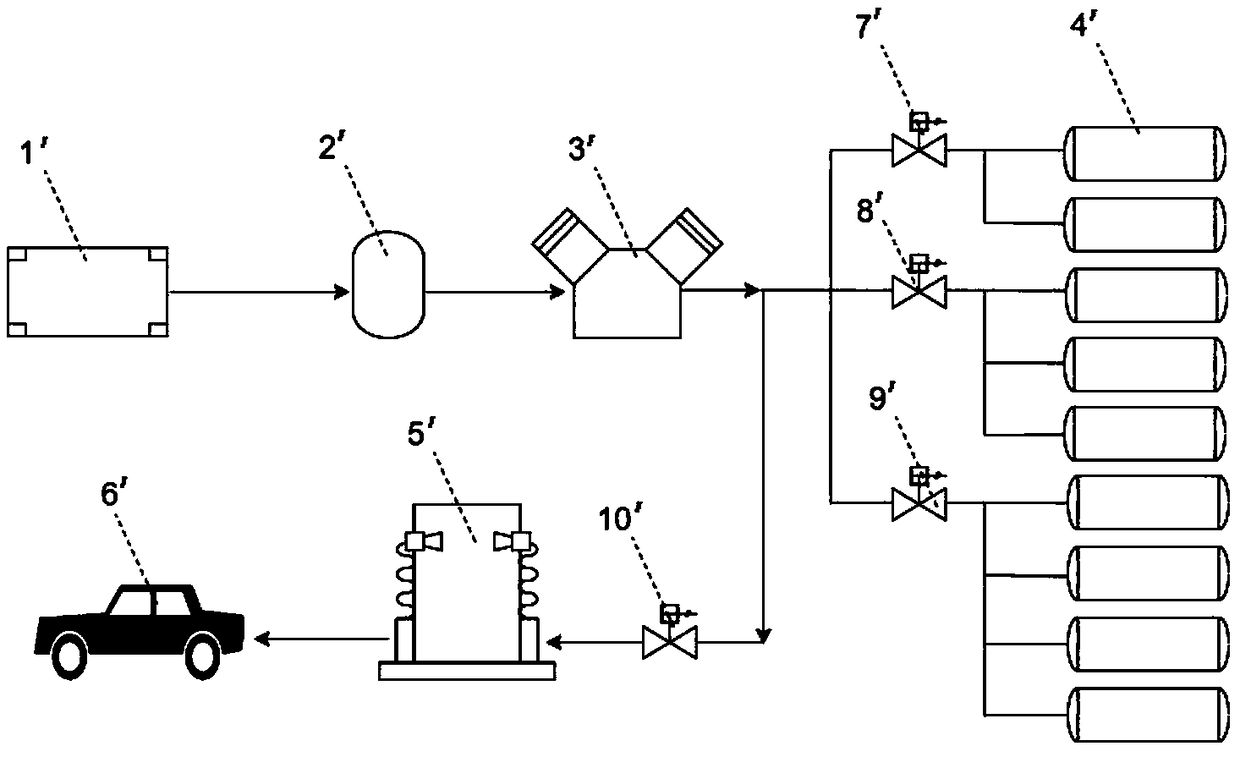

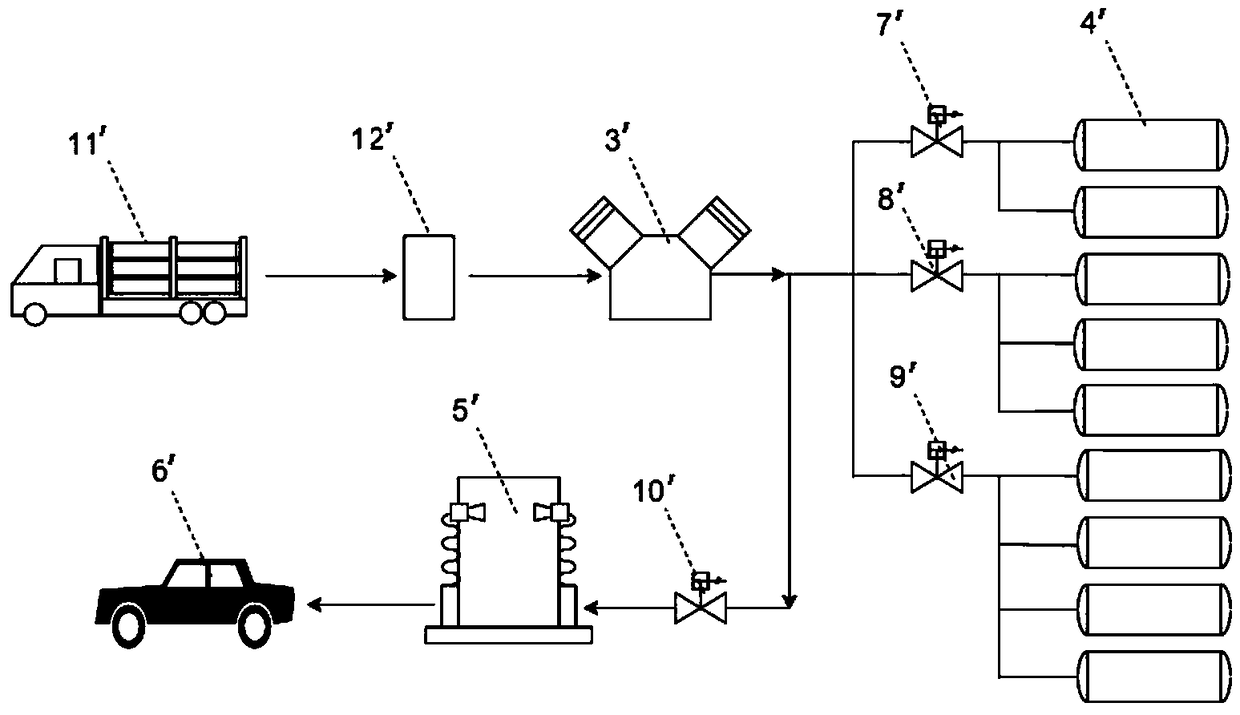

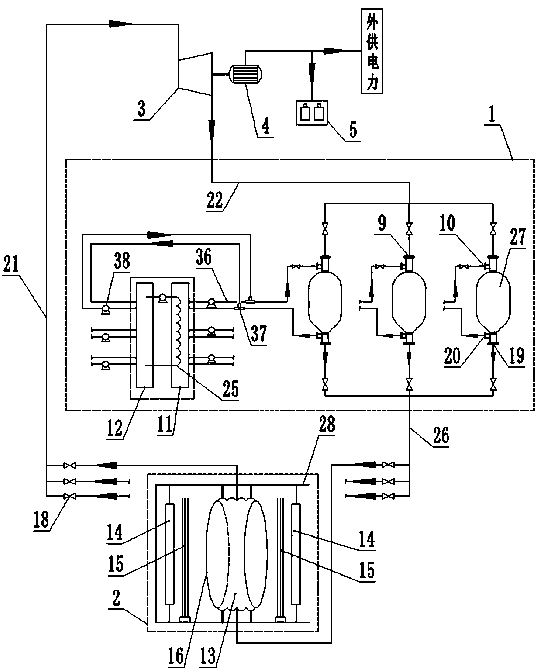

System and method for rapid hydrogen filling

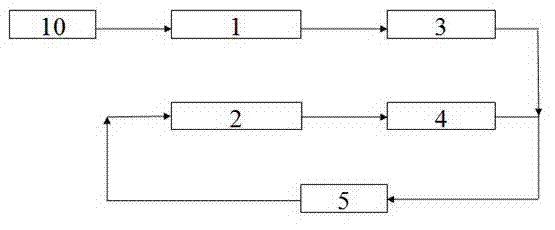

InactiveCN103244825AImprove securityReduce temperature risePipeline systemsContainer filling under pressureGas cylinderHigh pressure hydrogen

The invention provides a system and a method capable of achieving balanced pressure-reducing rapid hydrogen filling by three storage tanks with hydrogen of any sources. The system comprises a hydrogen compression device, hydrogen storage devices and a hydrogen filling device. Hydrogen prepared by any methods is compressed via the hydrogen compression device and then is stored in the high-pressure hydrogen storage devices, and a hydrogen outlet of each hydrogen storage device is directly connected to a hydrogen dispenser or an industrial hydrogen cylinder filling system. A set of pressure-reducing balanced filling system is shared during automobile hydrogen (hydrogen for the energy purpose) filling and cylinder filling (industrial hydrogen). A pressure-reducing valve is not arranged in the system, so that pipe resistance of the system is lower, and filling rate is higher. Besides, a pre-cooling device is added to the system, so that temperature rise of a filling container is lower.

Owner:BEIJING JONTON HYDROGEN TECH

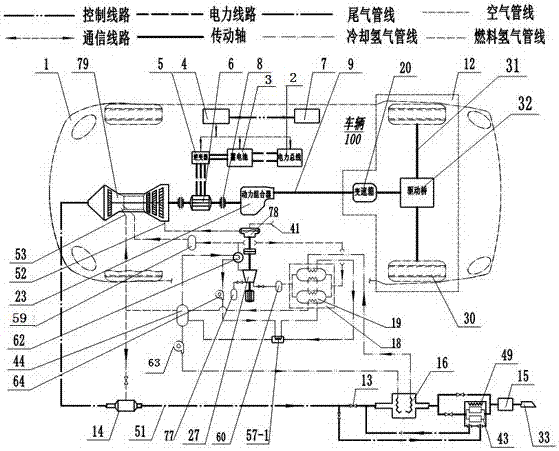

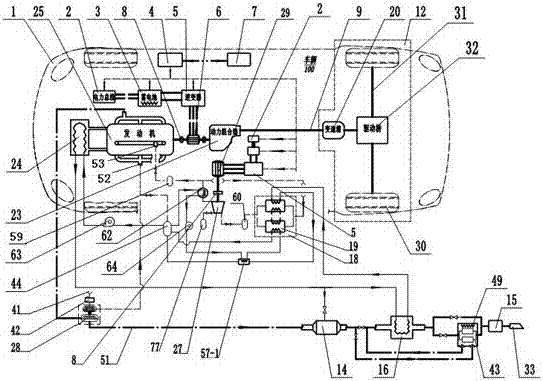

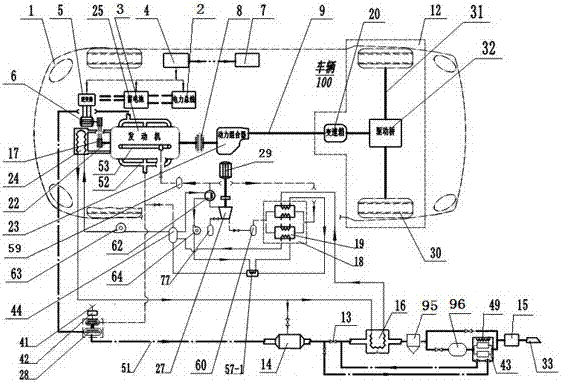

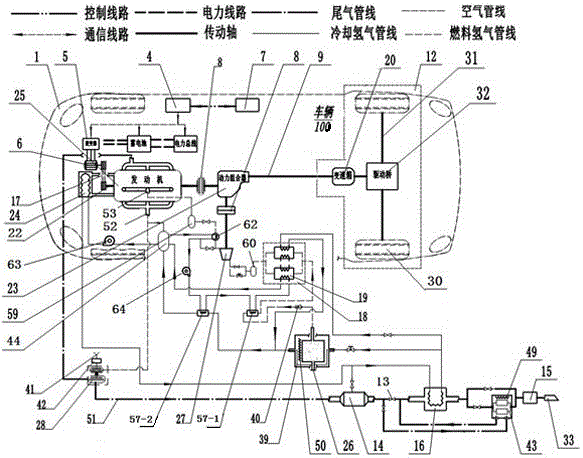

Efficient hydrogen energy vehicle power system for purifying ambient air

ActiveCN106915235AReduce consumptionIncrease motivationHybrid vehiclesInternal combustion piston enginesPower combinerEngineering

The invention relates to an efficient hydrogen energy vehicle power system with an ambient air purifying function. The efficient hydrogen energy vehicle power system comprises a drive system, a gas turbine, a high pressure hydrogen storage tank, a hydrogen compression unit, a hydrogen gas surge tank, an inverter, an electric-power generator, an expander, a storage battery and an exhaust gas treating and discharging system. The high pressure hydrogen storage tank is connected to an inlet of the expander, one path of an outlet of the expander is connected to a hydrogen inlet through a cold capacity recovery device and the hydrogen gas surge tank, and the other path is connected to the inlet of the expander through a hydrogen compression unit and an intermediate tank. A power combiner is connected with the gas turbine and / or the electric-power generator, according to the technical scheme, the gas turbine is replaced with a hydrogen fuel engine, and the power combiner is connected with the drive system through a drive shaft. According to the efficient hydrogen energy vehicle power system with the ambient air purifying function, the gas turbine is combined with the electric-power generator, so that work efficiency of the hydrogen energy vehicle power system is improved. By recycling of exhaust gas heat, air pollution is reduced, and the natural environment can be protected easily.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Mobile hydrogen delivery system

A mobile hydrogen delivery system for delivering a compressed stream of hydrogen at pressures up to 15000 psig. The mobile hydrogen delivery system includes a hydrogen compression system, a gaseous hydrogen storage system, and a delivery system for supplying hydrogen to end users. A mobile platform supports the hydrogen compression system, the gaseous hydrogen storage system, and the dispensing system. The mobile platform may be any platform, such as a trailer, capable of being pulled, pushed, or supported by any type of vehicle, such a truck, train, boat, tractor, etc.

Owner:HARNYSS IP LLC +1

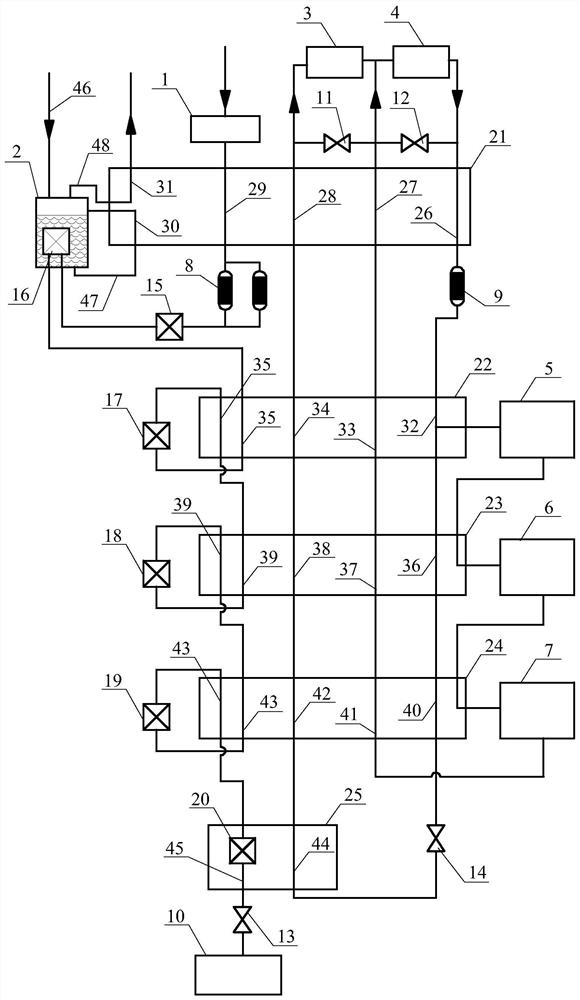

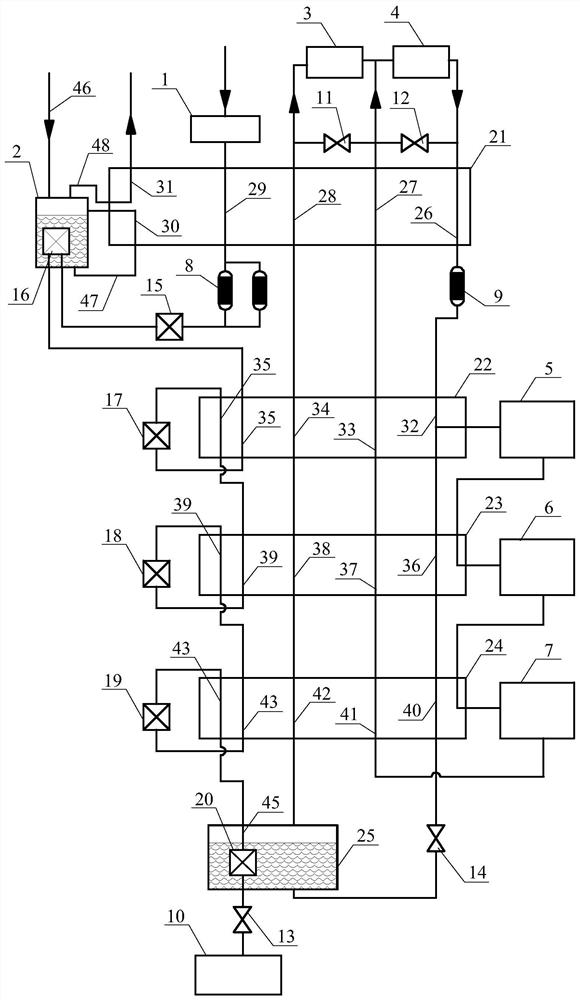

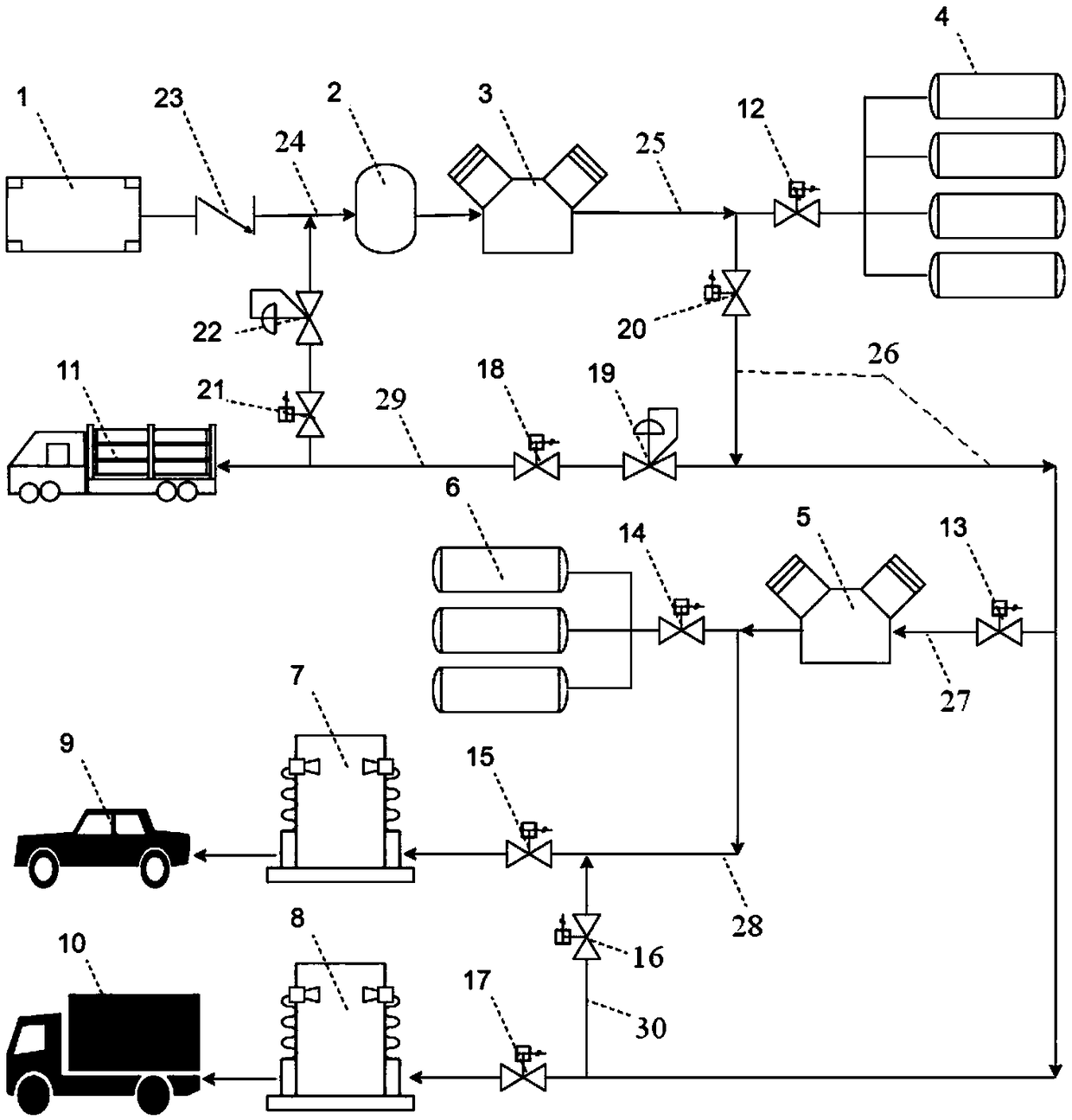

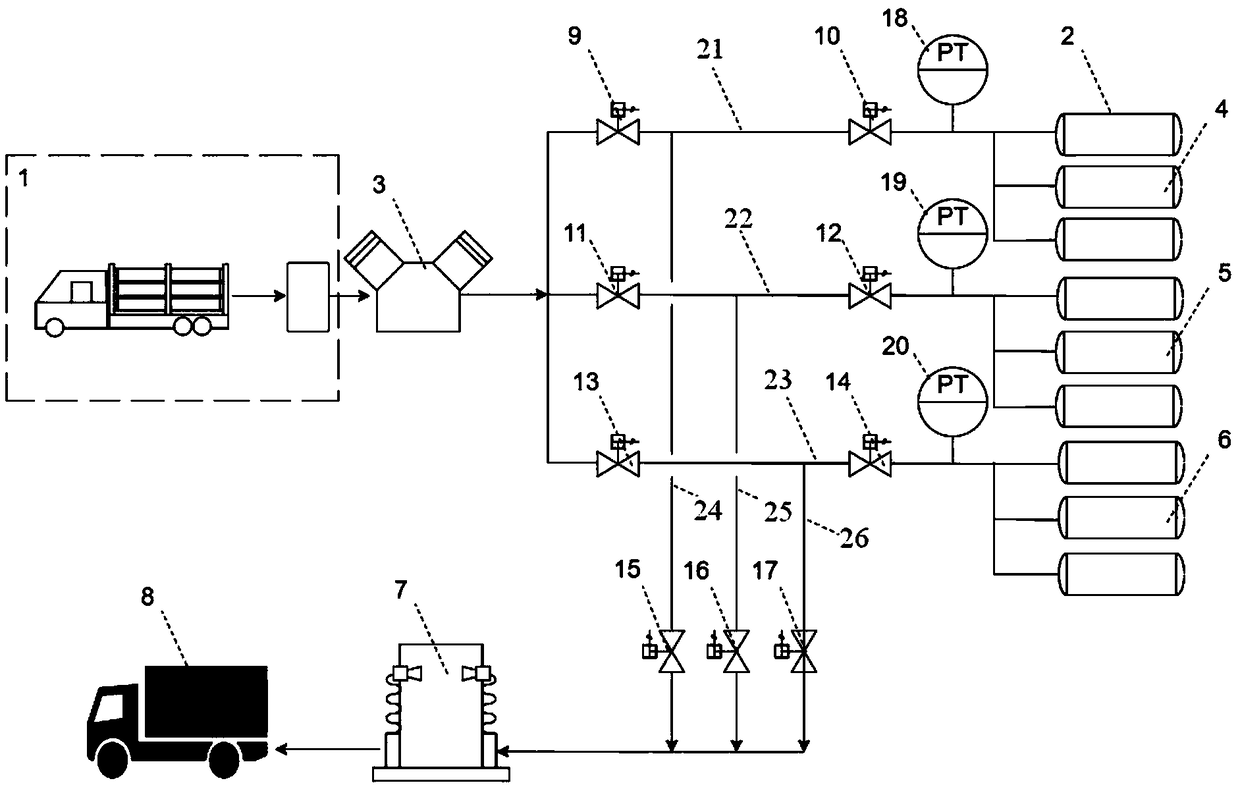

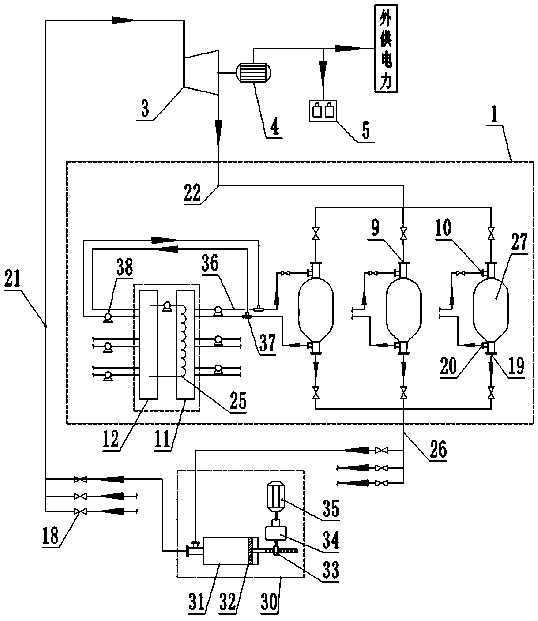

Hydrogenation method and system suitable for filling pressure of 35 or 70 MPa

ActiveCN109140226AImprove reliabilityReduce riskGas handling/storage effectsPipeline systemsHydrogen compressionHigh pressure hydrogen

The invention discloses a hydrogenation method and system suitable for a filling pressure of 35 or 70 MPa. The hydrogenation system comprises an in-station hydrogen production unit, an external hydrogen supplying unit, a buffer tank, a low-pressure hydrogen compression unit, a low-pressure hydrogen storage unit, a high-pressure hydrogen compression unit, a high-pressure hydrogen storage unit and ahydrogenation unit; and the hydrogenation method fills hydrogen by using the hydrogenation system. Compared with the prior art, a hydrogen source of the invention comprises in-station hydrogen production and external hydrogen supply, which improves the reliability of a hydrogen filling station; when in-station hydrogen production equipment is out of service or the output does not satisfy hydrogenconsumption of the hydrogen filling station, a long tube trailer is used to supply hydrogen to the hydrogen filling station for replenishment; when in-station hydrogen production capacity exceeds thehydrogen consumption of the hydrogen filling station, the empty long tube trailer can be directly filled and sold with hydrogen; two kinds of compression equipment and hydrogen storage bottle groupswith different design pressure levels are provided to reduce the number of high-pressure hydrogen storage bottles and reduce the risk of hydrogen storage; moreover, various operations can be independent of each other and do not affect each other.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

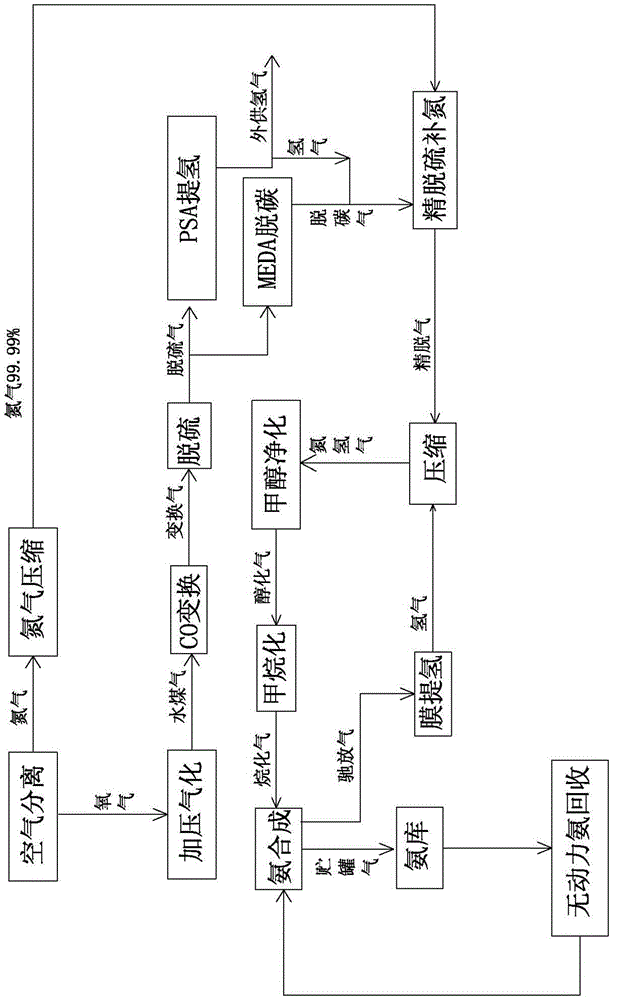

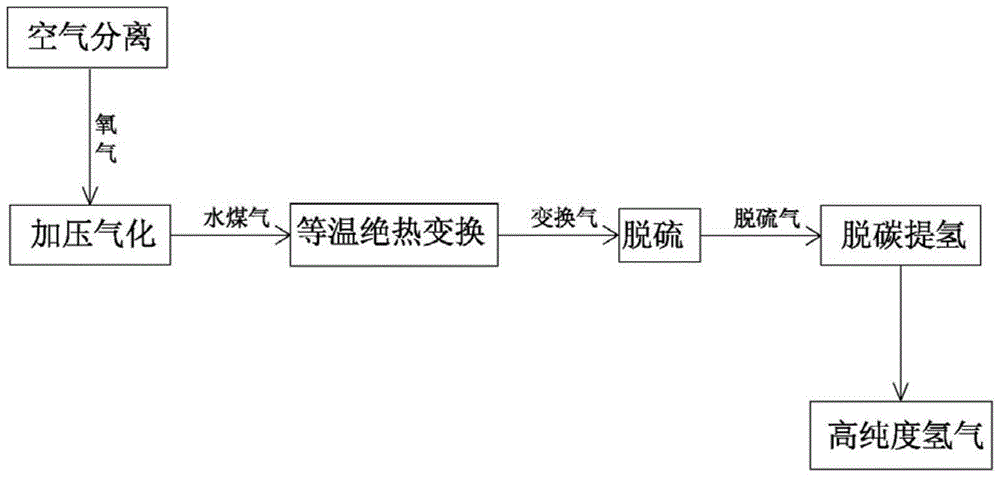

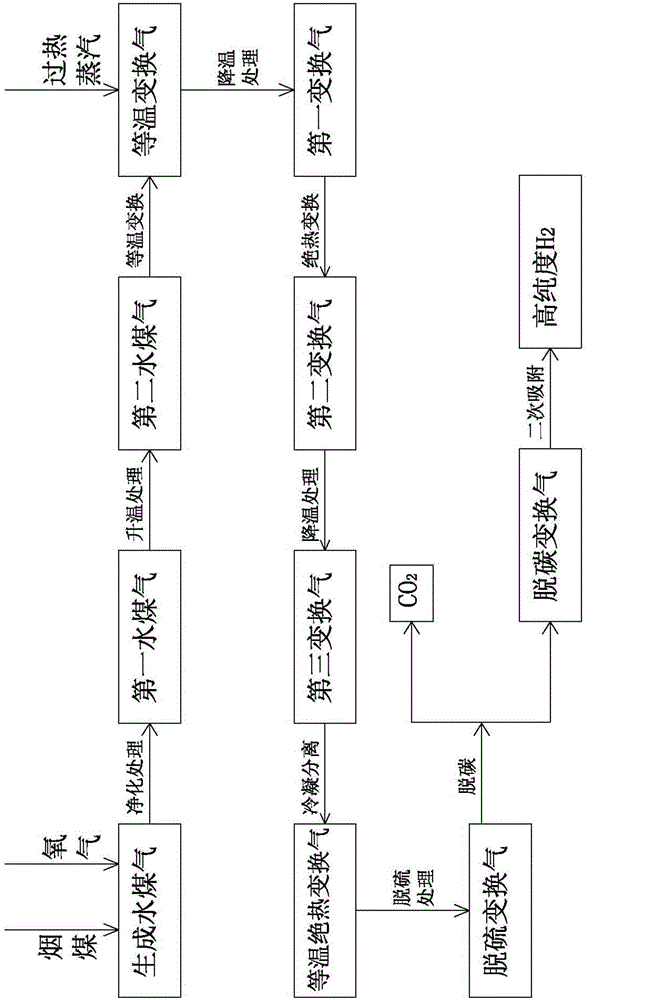

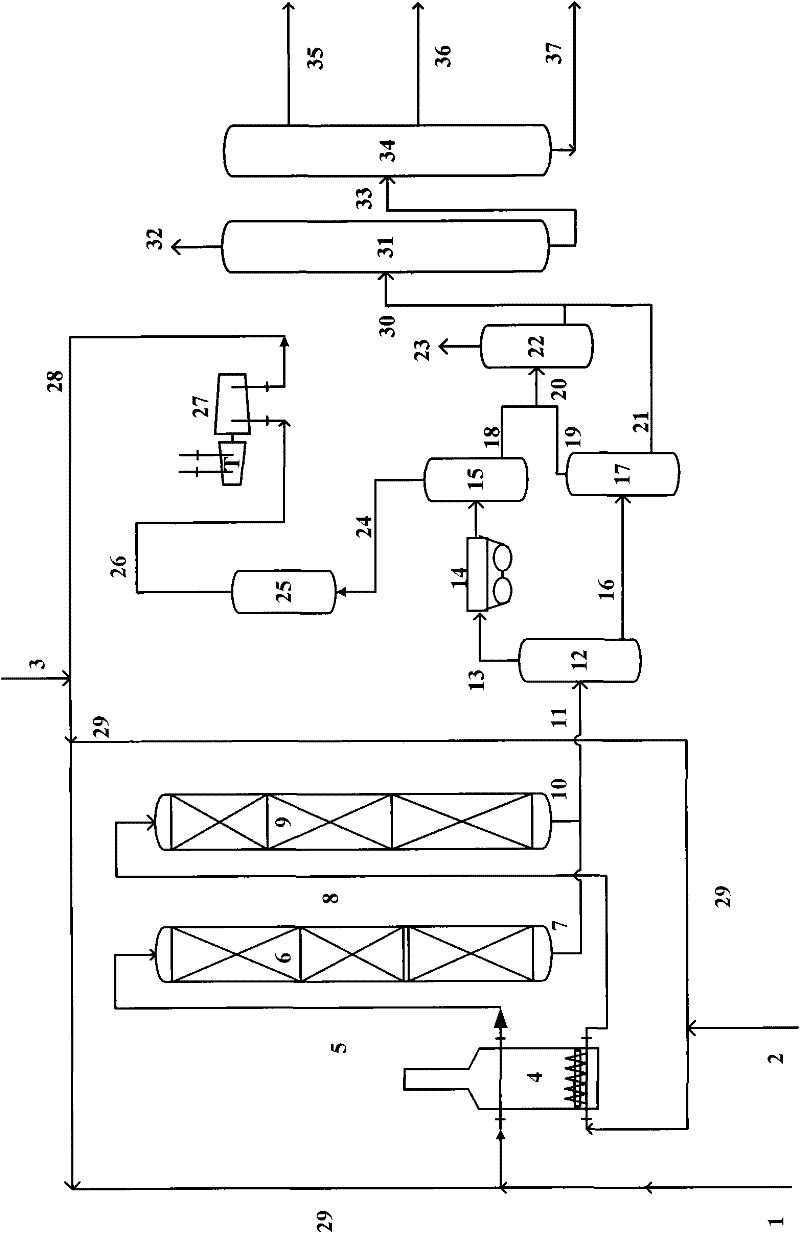

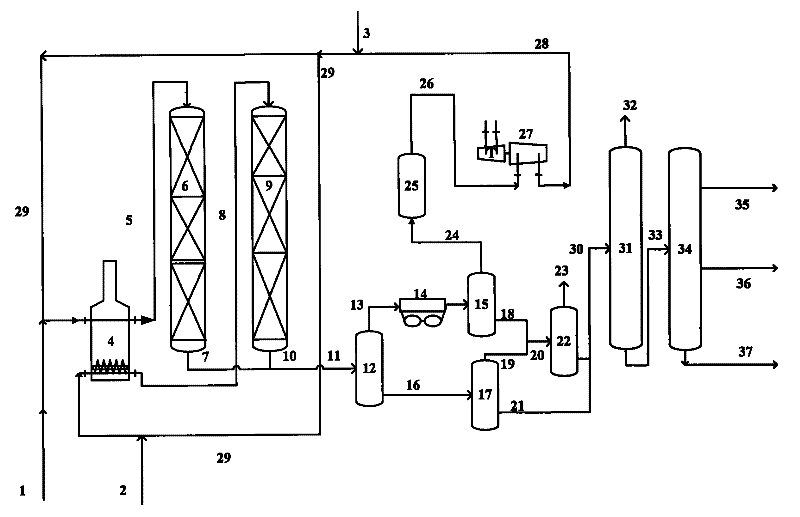

Production process and system of high-purity hydrogen and ammonia synthesis process and system

ActiveCN104560201AShort production processReduce resistanceHydrogen separation by selective and reversible uptakeHydrogen separation using solid contactOperating costOperating environment

The invention provides a production process and system of high-purity hydrogen and an ammonia synthesis process and system. The production process of high-purity hydrogen comprises the steps of generating water gas by using bituminous coal, generating shifted gas by using the water gas, desulfurizing the shifted gas, and carrying out decarbonization and hydrogen extraction on the shifted gas; the ammonia synthesis process comprises the steps of hydrogen nitrogen-feeding and deoxygenization, nitrogen-hydrogen compression and ammonia synthesis. The production system of high-purity hydrogen comprises a water gas generating part, a shifted gas generating part, a shifted gas desulfurizing part and a shifted gas decarbonization and hydrogen extraction part; and the ammonia synthesis system also comprises a hydrogen nitrogen-feeding and deoxygenization part, a nitrogen-hydrogen compression part and an ammonia synthesis part. The production process of high-purity hydrogen disclosed by the invention is short in flow, small in resistance, low in power consumption and low in operating cost; and the production system of high-purity hydrogen disclosed by the invention is high in degree of automation, less in catalyst consumption, less in species, less in operators, good in operating environment, low in operating cost and remarkable in energy saving and consumption reducing effect.

Owner:蓝星工程有限公司

Hydrogen liquefaction equipment provided with three turbo expander units connected in series

PendingCN112361711AHigh hydrogen liquefaction efficiencyReduce energy consumptionSolidificationLiquefactionConvertersHydrogen compression

The invention discloses hydrogen liquefaction equipment provided with three turbo expander units connected in series. The hydrogen liquefaction equipment comprises a vacuum box, a hydrogen purification device, a pre-cooling device, a first hydrogen compressor unit, a second hydrogen compressor unit, a first turbo expander unit, a second turbo expander unit, a third turbo expander unit, a first low-temperature adsorber, a second low-temperature adsorber, heat exchangers, ortho-parahydrogen converters, regulating valves, throttle valves and a liquid hydrogen storage tank. According to the hydrogen liquefaction equipment, 5-10 tons of liquefied hydrogen can be produced every day, three turbo expander units are connected in series for refrigeration, a hydrogen refrigeration circulating systemconnected to high-pressure throttling refrigeration in parallel is adopted, raw material hydrogen is converted, cooled and liquefied through the multiple stages of ortho-parahydrogen converters, and the hydrogen liquefaction equipment has the advantages of being high in hydrogen liquefaction efficiency and low in energy consumption.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

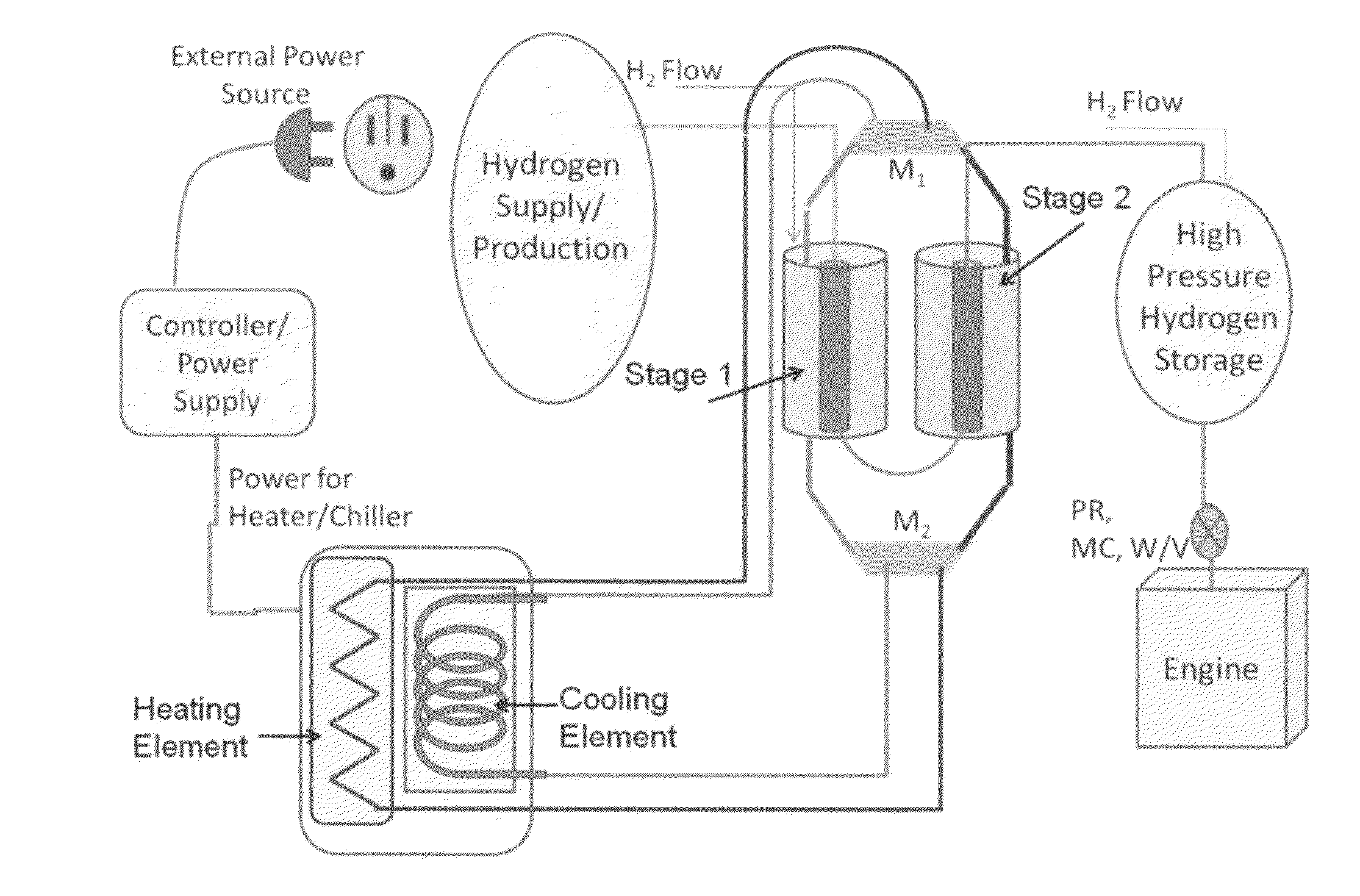

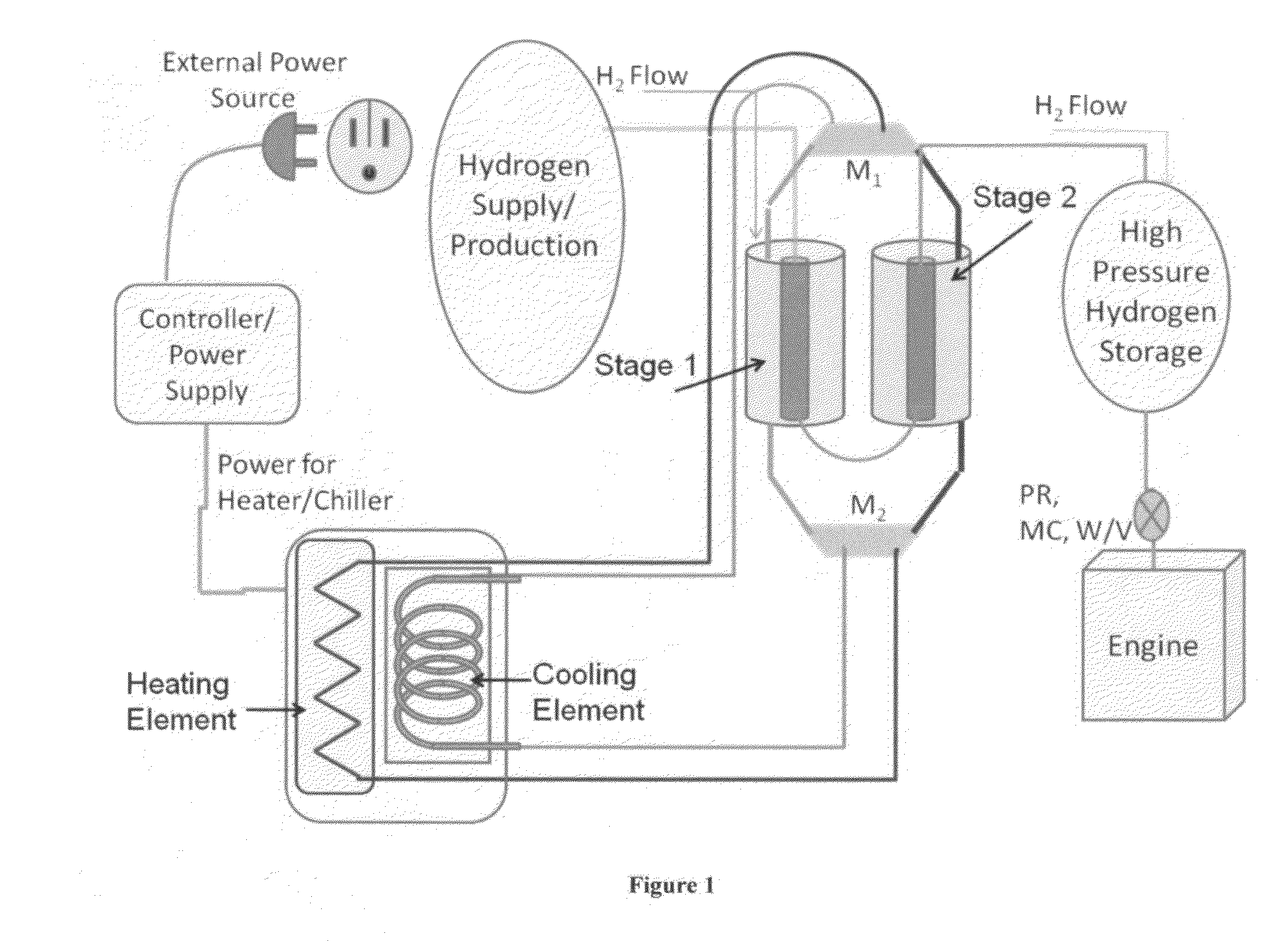

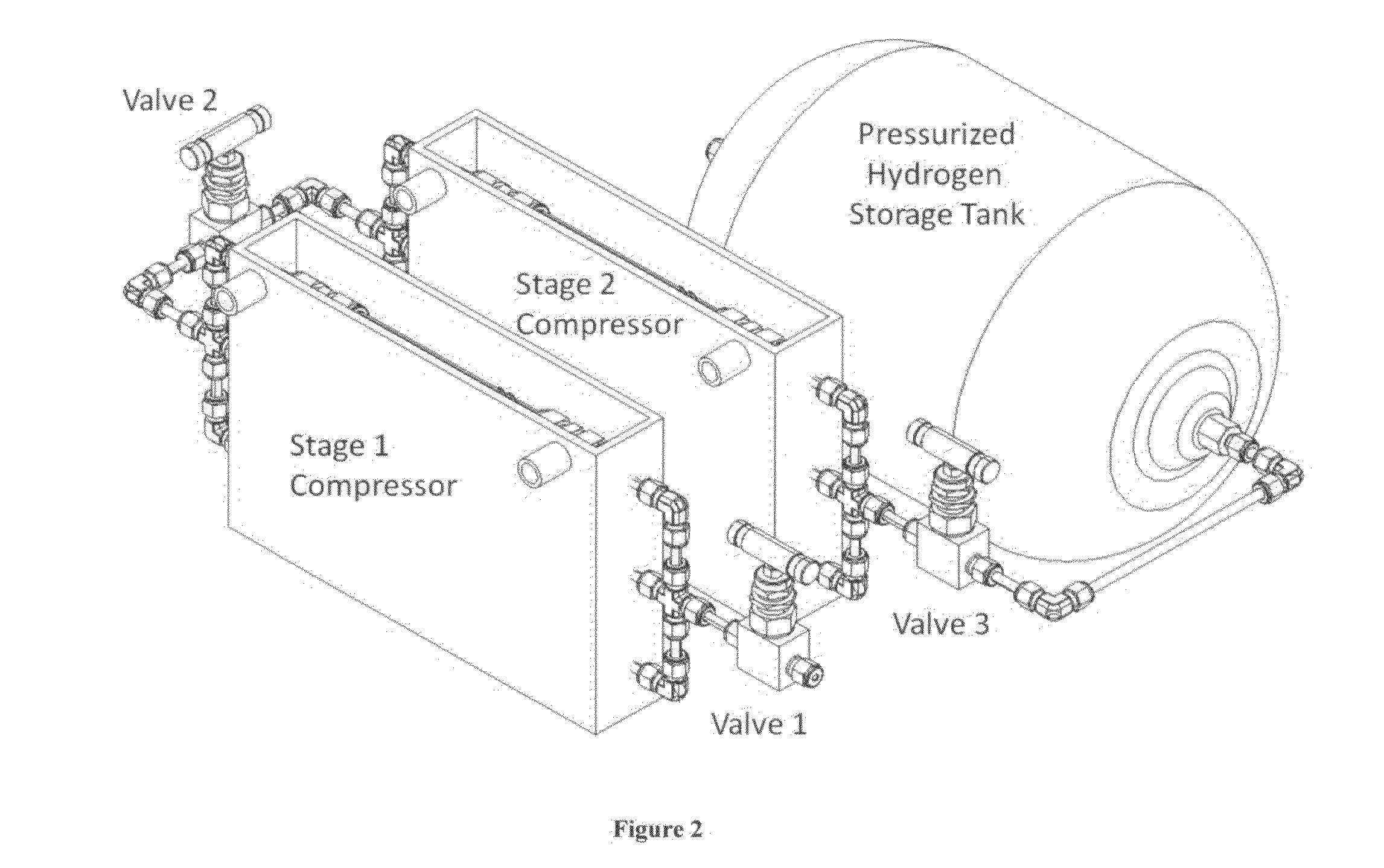

Multi Stage Hydrogen Compression & Delivery System for Internal Combustion Engines Utilizing Working Fluid

InactiveUS20110302932A1Reduce inconvenienceReduces safety issueFixed capacity gas holdersMulti-stage pumpsThermal energyWorking fluid

The multi stage hydrogen compression and delivery system for internal combustion engines utilizing a working fluid (HCDS-ICWF-Multi) consists of a thermally driven multi compression stage metal hydride hydrogen compressor in line with high pressure hydrogen storage tanks and a pressure regulating hydrogen delivery system that supplies a controlled release of hydrogen to the internal combustion engine. The working fluid carries the thermal energy needed to the metal hydride compression stages to drive the hydrogen compression. The compressor is intended to be inseparable from the storage tank to ensure safe operation.

Owner:HOPKINS RYAN REID

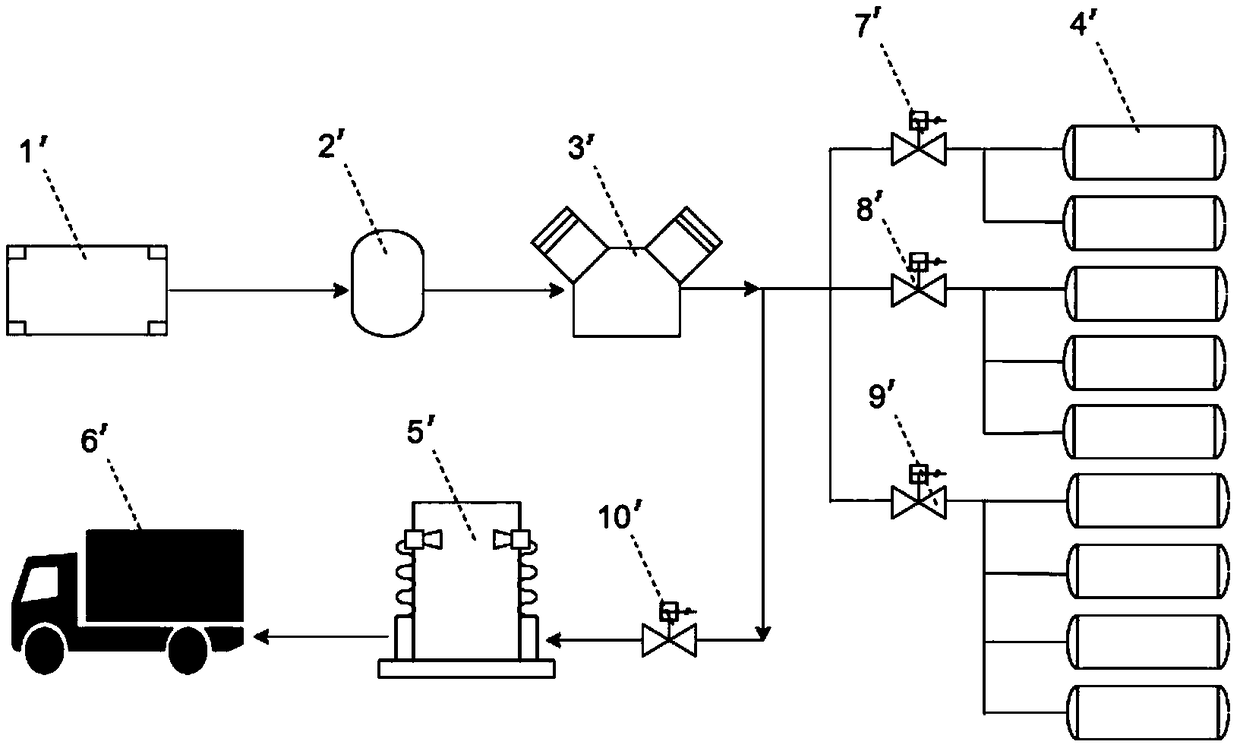

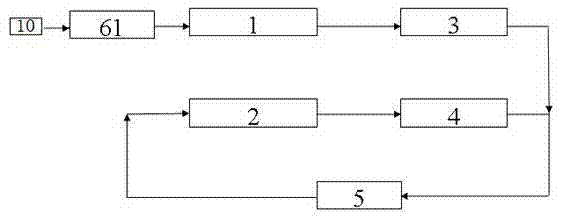

Hydrogen injection method and system simultaneously suitable for 70Mpa and 35Mpa injection pressure

ActiveCN109185699AImprove reliabilityIncrease profitGas handling/storage effectsFluid handledInjection pressureBuffer tank

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

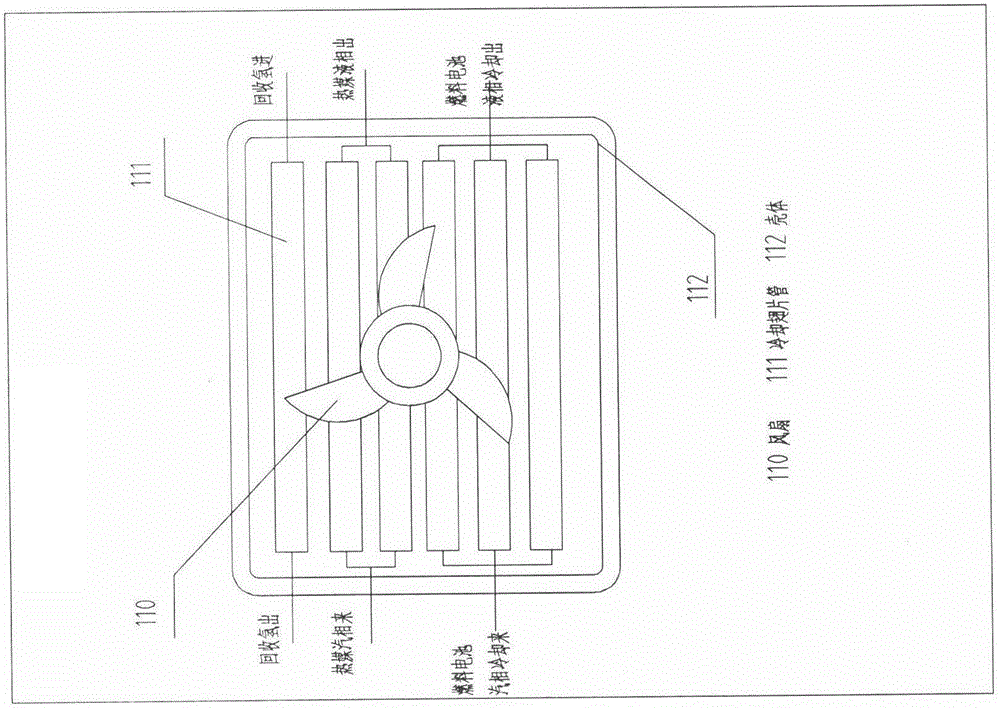

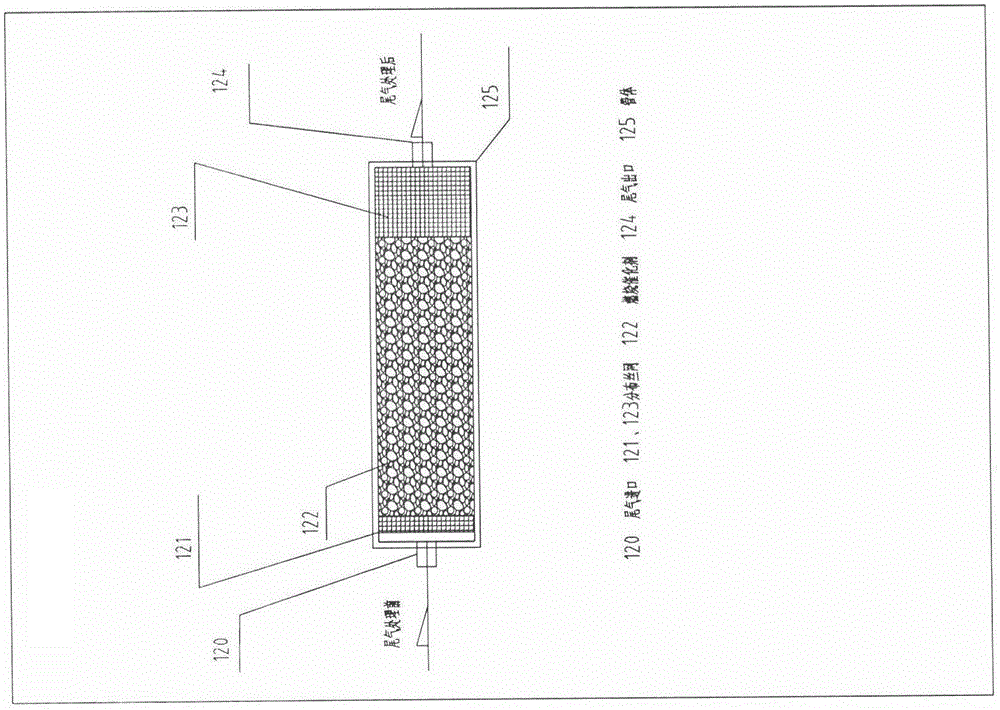

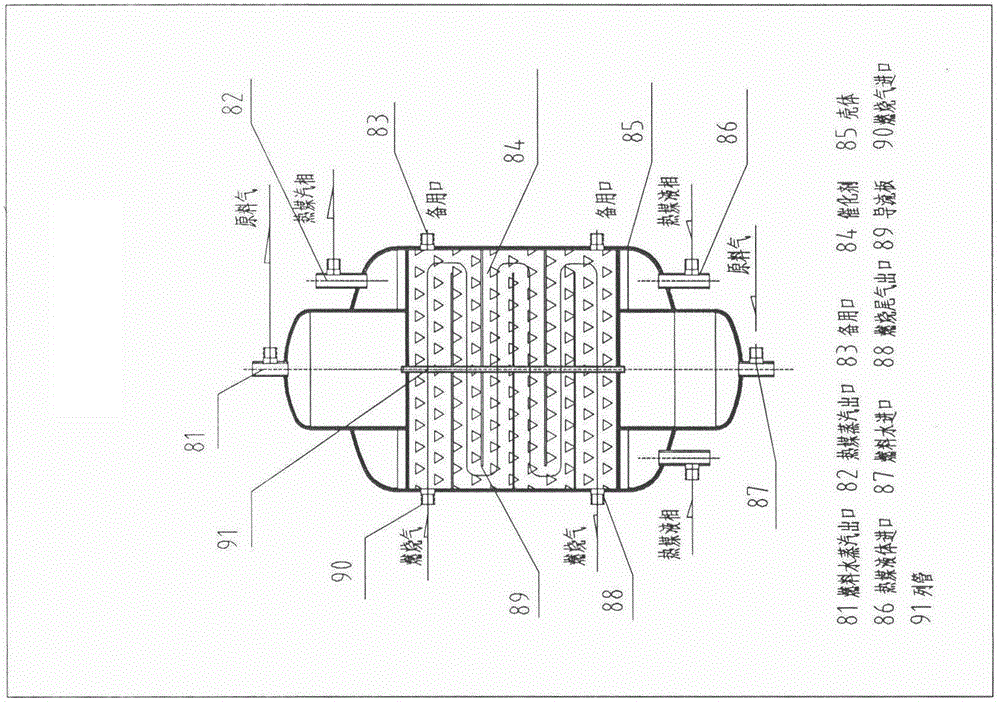

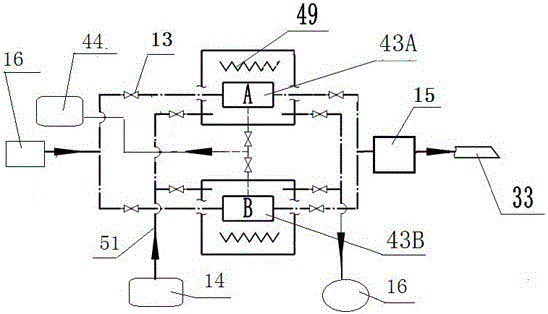

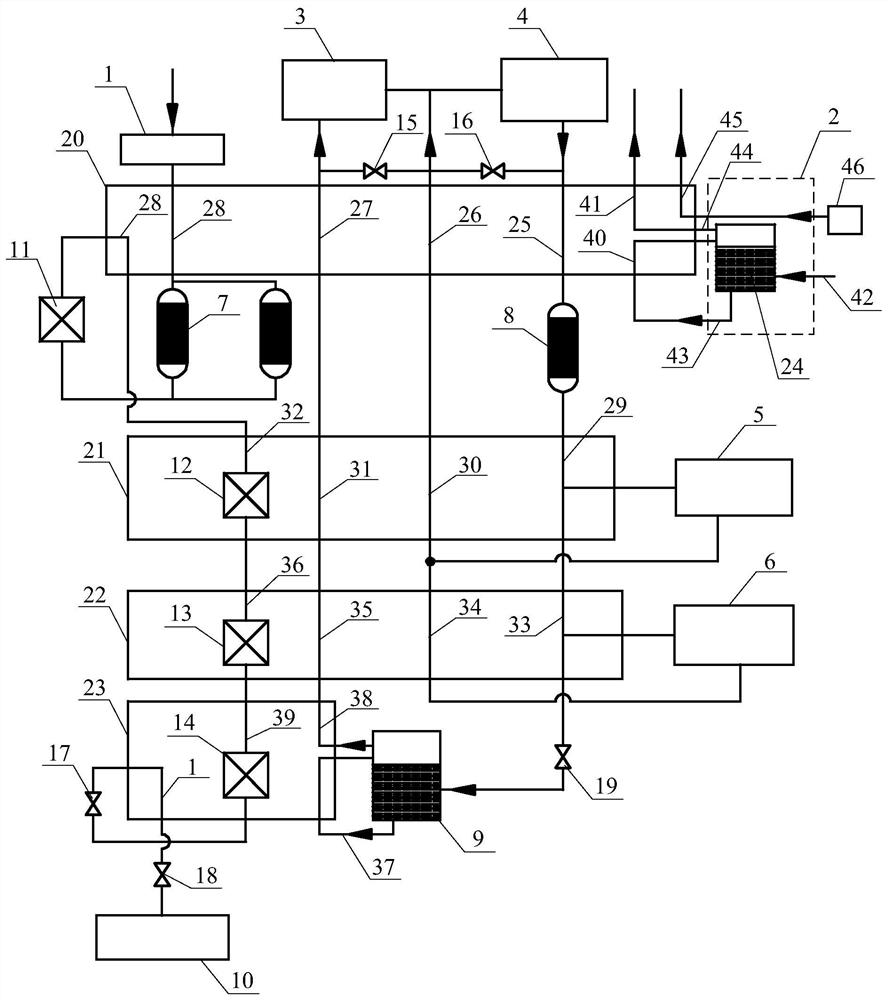

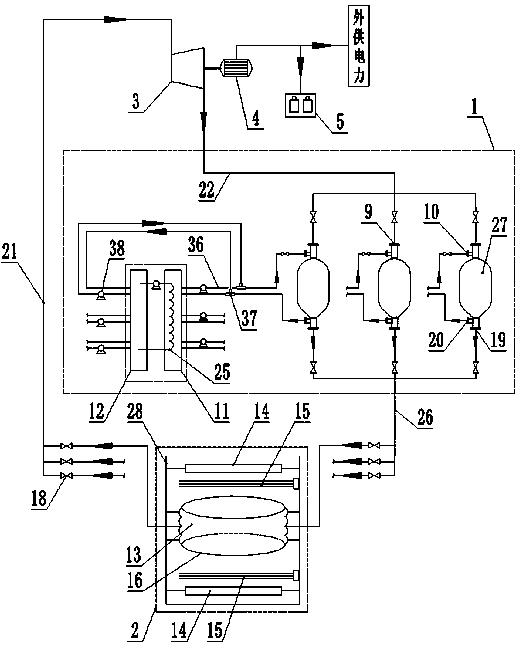

Distributed non-combustion type constant-temperature pressurized power generation system

InactiveCN105895936ASmall fluctuations in heat recoveryExtend your lifeFuel cell auxillariesFuel cell detailsCarbon monoxideVapor–liquid separator

The invention provides a distributed non-combustion type constant-temperature pressurized power generation system. The system comprises a water tank (1), a fuel storage tank (2), a fuel water proportioning pump (3), a mixer A (4), a fuel atomizer (5), a second heat exchanger (26), a first heat exchanger (25), dehydration tanks (27, 28 and 12), a carbon monoxide removal reactor (11), a catalytic combustion reactor (6), a fuel water reforming reactor (29), a composite air-cooling heat sink (22), a hydrogen-air pressure balancer (14), a fuel cell cooling liquid tank (13), a compressed air heat exchanger (23), a fuel cell cooling circulation pump (15), a recycled hydrogen compressor (21), a hydrogen-rich storage tank (19), a hydrogen recycle membrane separator (17), a hydrogen fuel cell pack (16), an exhaust purifier (7), an expansion compressor (9), a control valve (18), a (normal-pressure fuel water) vapor-liquid separator (20), a mixer B (8), a mixer C (10), a mixer D (24), a steam trap (30), a system controller (31), a one-way valve (41) and valves (42-54). By applying an energy state theory, a vapor-liquid two-phase coexistence constant-temperature condensation or evaporation principle and phase-change heat-transfer highest efficiency principle, hydrogen production by reforming and constant-temperature control on a hydrogen fuel battery are achieved.

Owner:YANGZHOU SANYE NEW ENERGY SCI & TECH CO LTD

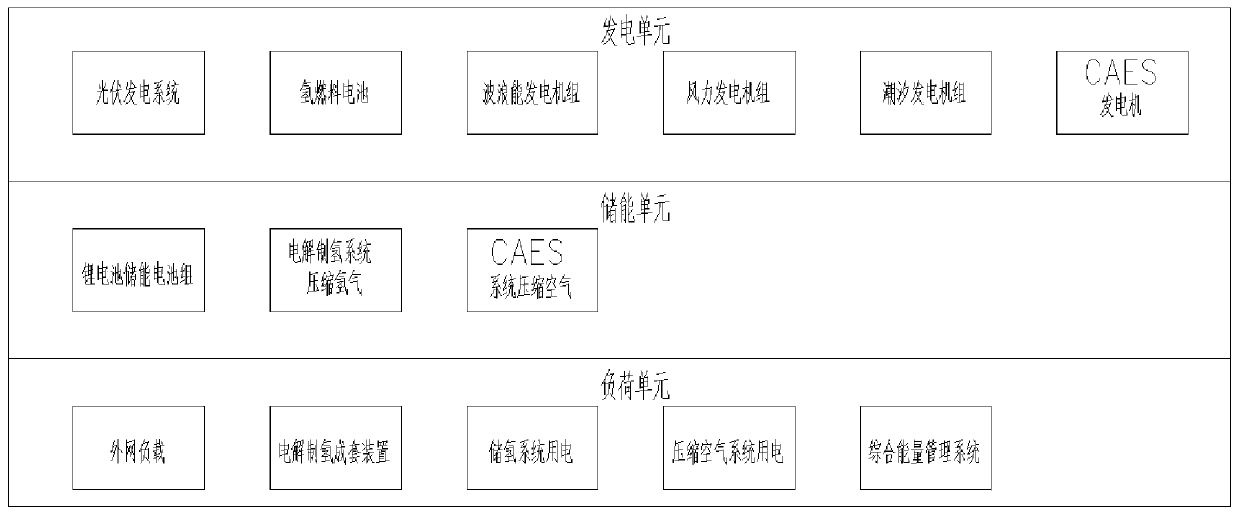

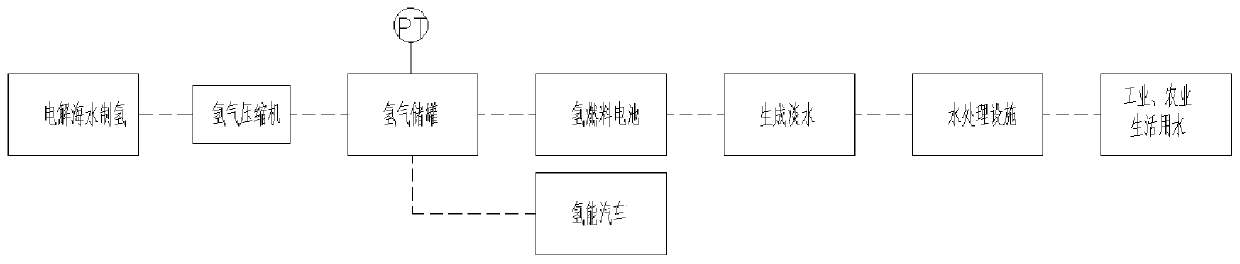

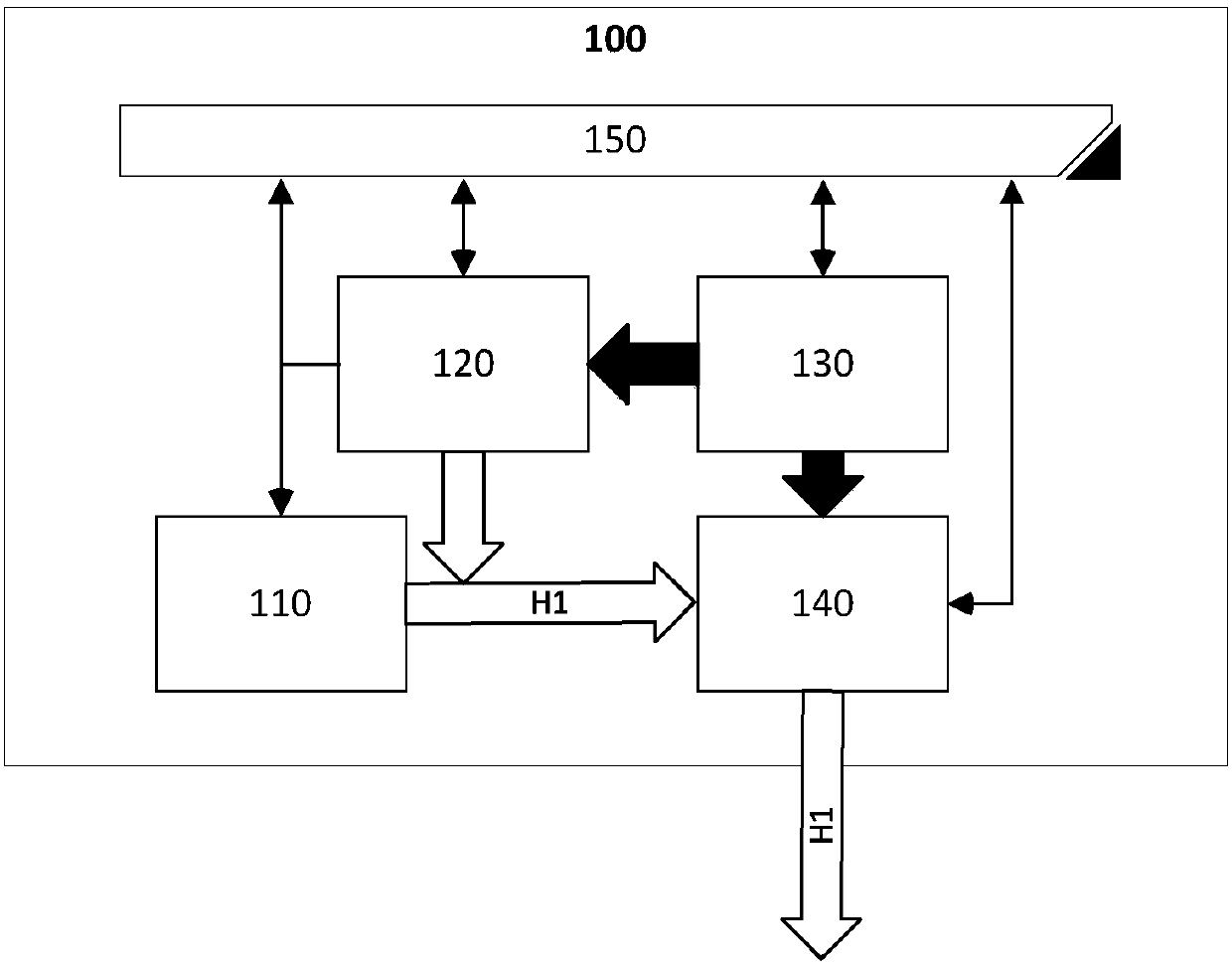

Island comprehensive energy system based on hydrogen fuel cell and control method thereof

PendingCN110190629AAutogenous primingAchieve clean and low carbonDc network circuit arrangementsBatteries circuit arrangementsHydrogen fuel cellEngineering

The invention discloses an island comprehensive energy system based on a hydrogen fuel cell. The system comprises a power generation unit for providing energy power supply, an energy storage unit forstoring energy and a load unit for consuming energy by an offshore island; and the power generation unit comprises a hydrogen fuel cell, the energy storage unit comprises a hydrogen compression moduleof an electrolytic hydrogen production system, and the load unit comprises an electrolytic hydrogen production system complete device and a hydrogen storage system power utilization module. The powergeneration unit also comprises a photovoltaic power generation system, a wave energy generator set, a wind generator set and a tidal generator set; the photovoltaic power generation system is configured and distributed on the roof of a building on an island and a wide region on the island, the wave energy generation device is arranged in a sea area around the island, the wind generator set is arranged on an offshore tidal flat and a high-altitude mountain top on the island, and the tidal generator set is arranged at a high-altitude valley by the sea; and the load unit also comprises an external network load.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Hydrogen energy vehicle power system for ambient air purification

ActiveCN106837529AOvercome wasteOvercome environmental pollutionInternal combustion piston enginesFuel supply apparatusPower combinerEngineering

The invention relates to a hydrogen energy vehicle power system for ambient air purification. The hydrogen energy vehicle power system comprises a transmission system, a hydrogen fuel engine, a metal hydride storage tank, a hydrogen compression unit, a hydrogen stabilized tank, an inverter, a, electric-generator, an expansion machine, a storage battery and an exhaust gas disposal system. The storage battery is electrically connected with a power bus and the inverter, and the inverter is electrically connected with the electric-generator; the metal hydraulic storage tank is connected with the hydrogen fuel engine through the hydrogen compression unit and the hydrogen stabilized tank, and an exhaust outlet of the hydrogen fuel engine is connected with the exhaust gas disposal system through a turbo charger; the hydraulic fuel engine or / and the number one electric-generator is / are connected with a power combiner, the expansion machine is connected with the power combiner, and the power combiner is connected with the transmission system through a transmission shaft. By the combination of the hydrogen fuel engine with the electric-generator, operation efficiency of the hydrogen energy vehicle power system is improved; by recycling exhaust heat, atmospheric pollution is reduced, and natural environment is favorably protected.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

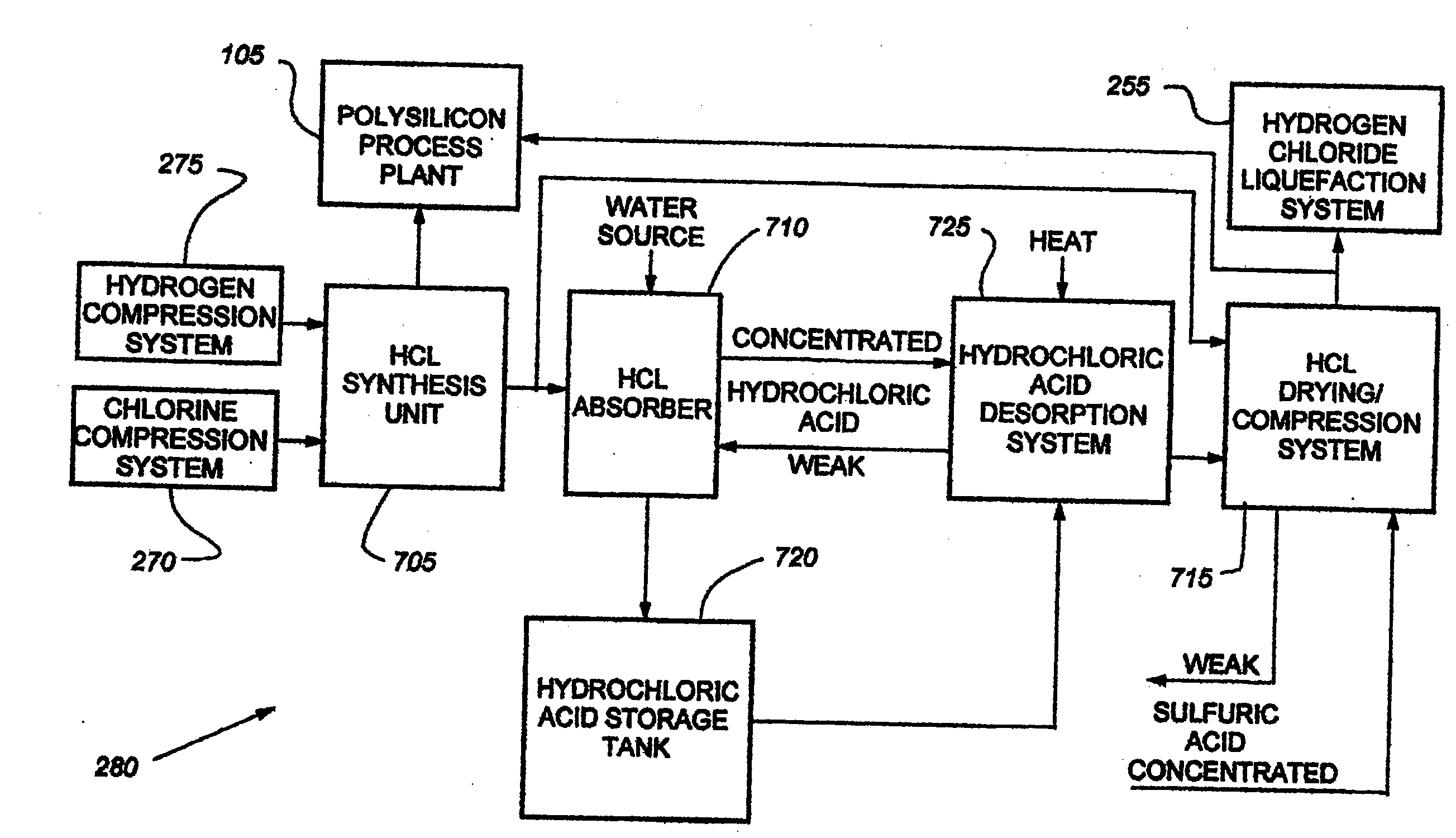

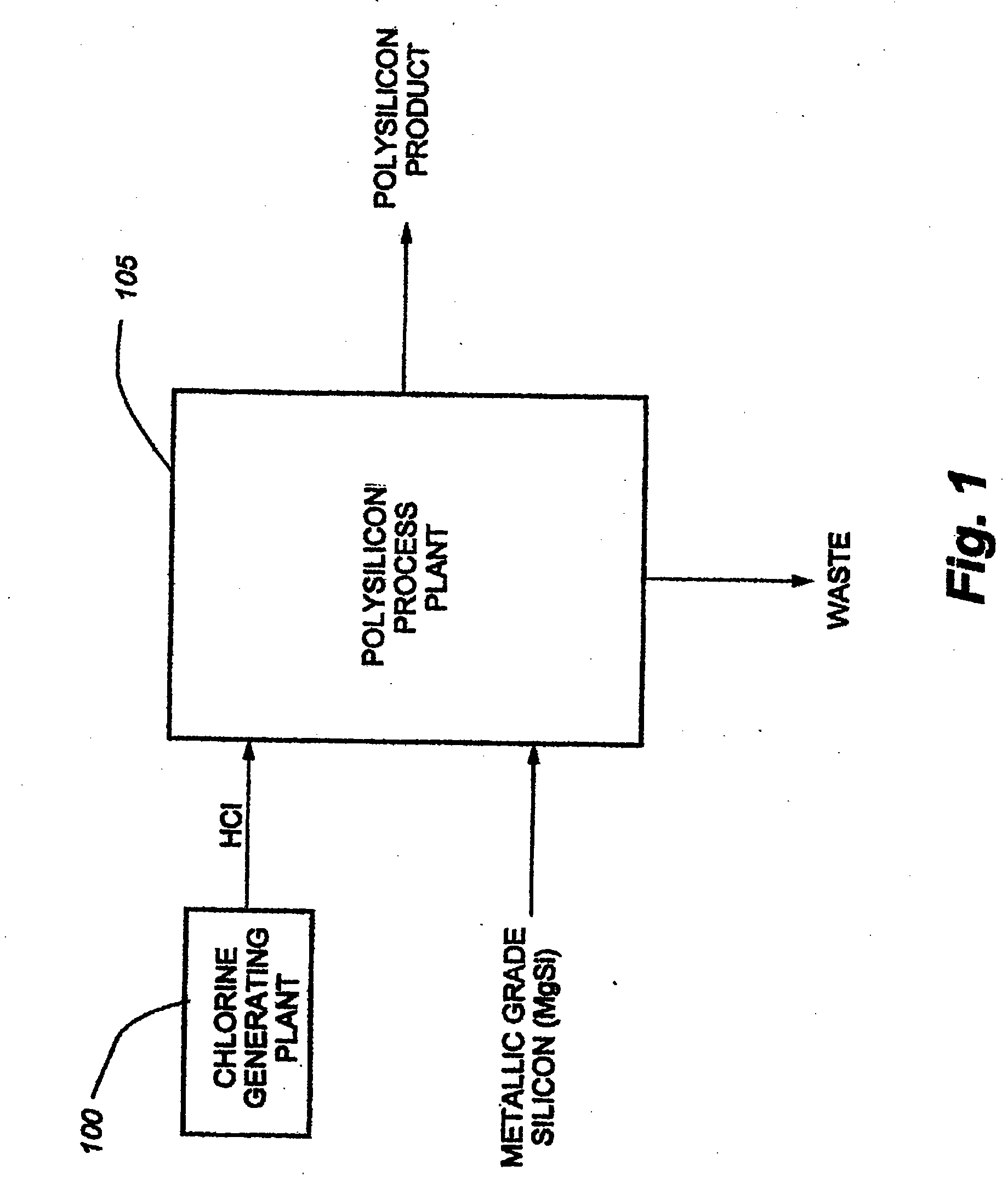

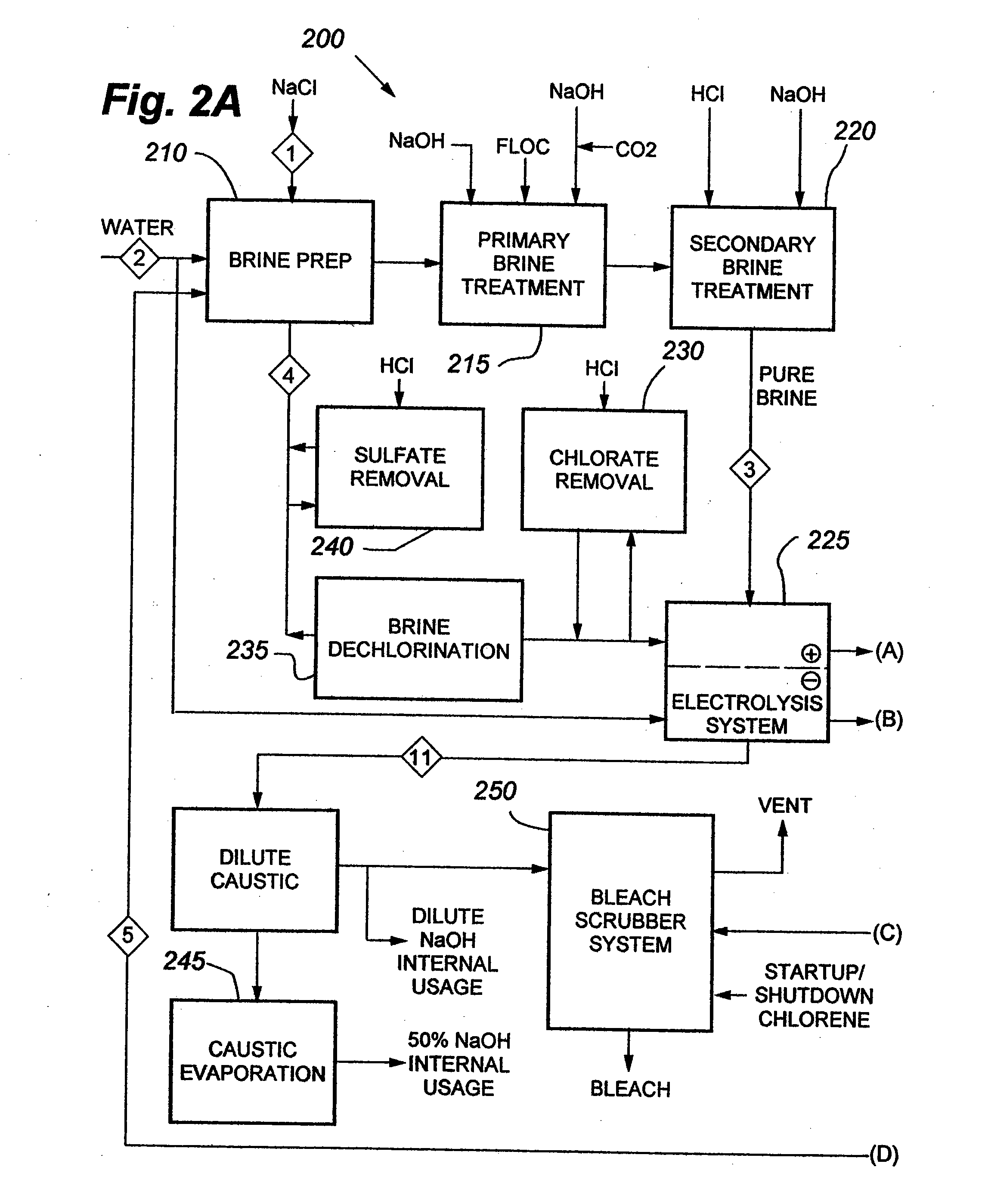

Systems and methods for supplying chlorine to and recovering chlorine from a polysilicon plant

A system for supplying chlorine to and recovering chlorine from a polysilicon plant may include a brine treatment system, at least one membrane cell, a chlorine drying system, a chlorine compression system, a hydrogen drying system, a hydrogen compression system, a hydrogen chloride synthesis / desorption system, a hydrogen chloride liquefaction system, a liquefied hydrogen chloride storage system, a hydrogen chloride vaporizer, and a waste conversion and filtration system. These systems may be operatively joined to generate hydrogen chloride gas for delivery to the polysilicon plant. A method for supplying chlorine to the polysilicon plant may include generating hydrogen gas and chlorine gas from recovered and raw salt, converting at least a portion of the hydrogen gas and at least a portion of the chlorine gas to hydrogen chloride, passing the hydrogen chloride through a cryogenic column, vaporizing the hydrogen chloride, and providing the vaporized hydrogen chloride to the polysilicon plant.

Owner:CH2M HILL ENGINEERS

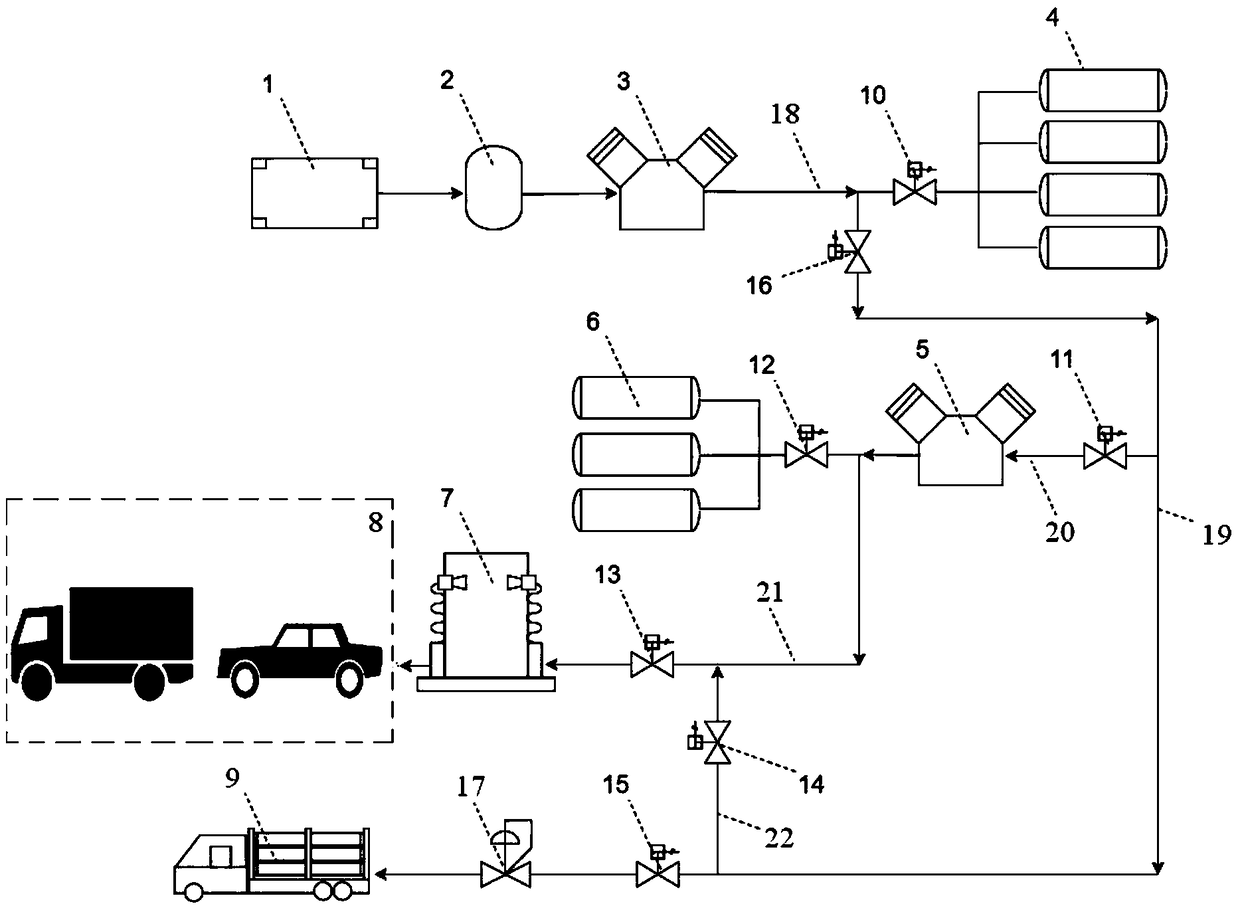

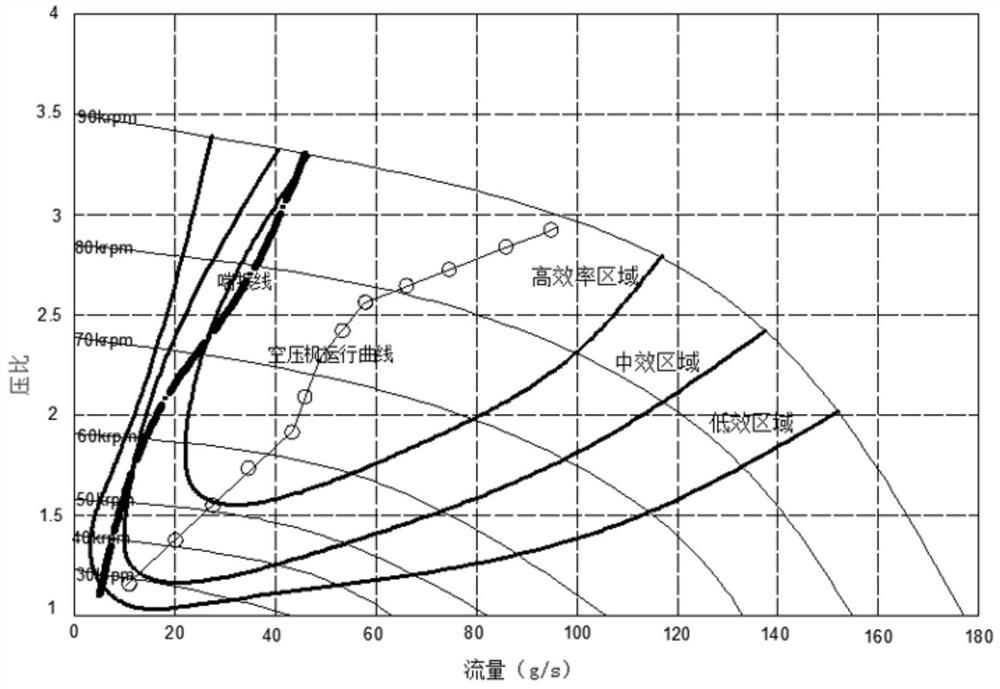

Mobile designed hydrogen refueling station

InactiveCN108045354AAchieving a modular designAchieve standardizationVehicle servicing/repairingHydrogenHydrogen compression

The invention provides a mobile designed hydrogen refueling station. The mobile designed hydrogen refueling station comprises a plurality of subsystem modules, hydrogen gas pipelines and electric wire / control pipelines, and each of the subsystem modules is separately sealed and packaged in a standardized module box body. The invention further provides a design method and a use method of the hydrogen refueling station. The standardization and the mobilization deployment of the hydrogen refueling station design and construction are realized. A mobile hydrogen refueling station system of the mobile designed hydrogen refueling station is sealed and packaged in a standardized container for convenient transportation, installation and maintenance. According to the mobile hydrogen refueling station, a hydrogen compression subsystem is eliminated, and the completion of refueling hydrogen with the pressure of 35 MPa or 70 MPa is finally achieved without a hydrogen compressor or cascade compression in series, thereby reducing the cost and improving the system reliability.

Owner:湖南行知聚能源科技发展有限公司

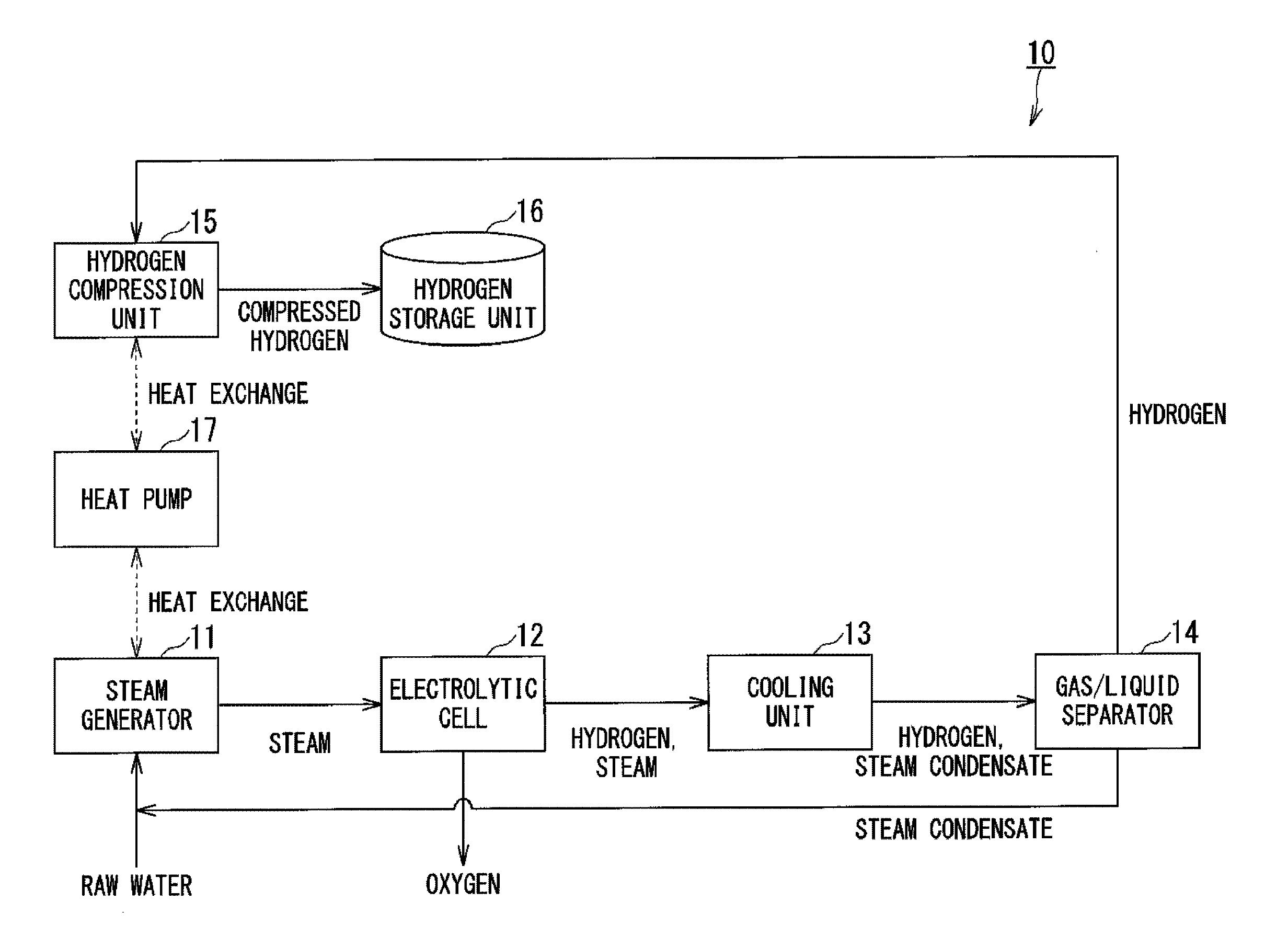

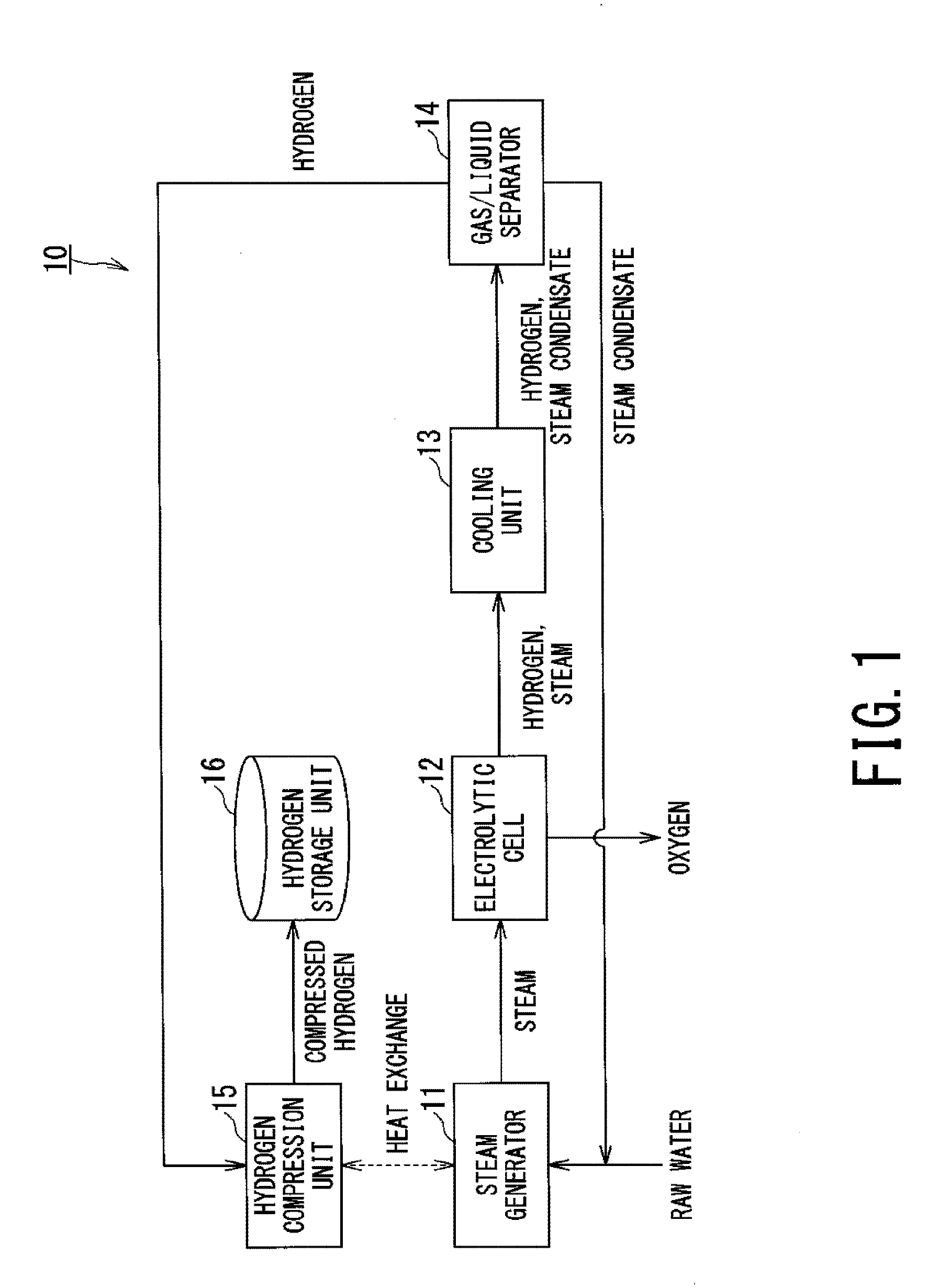

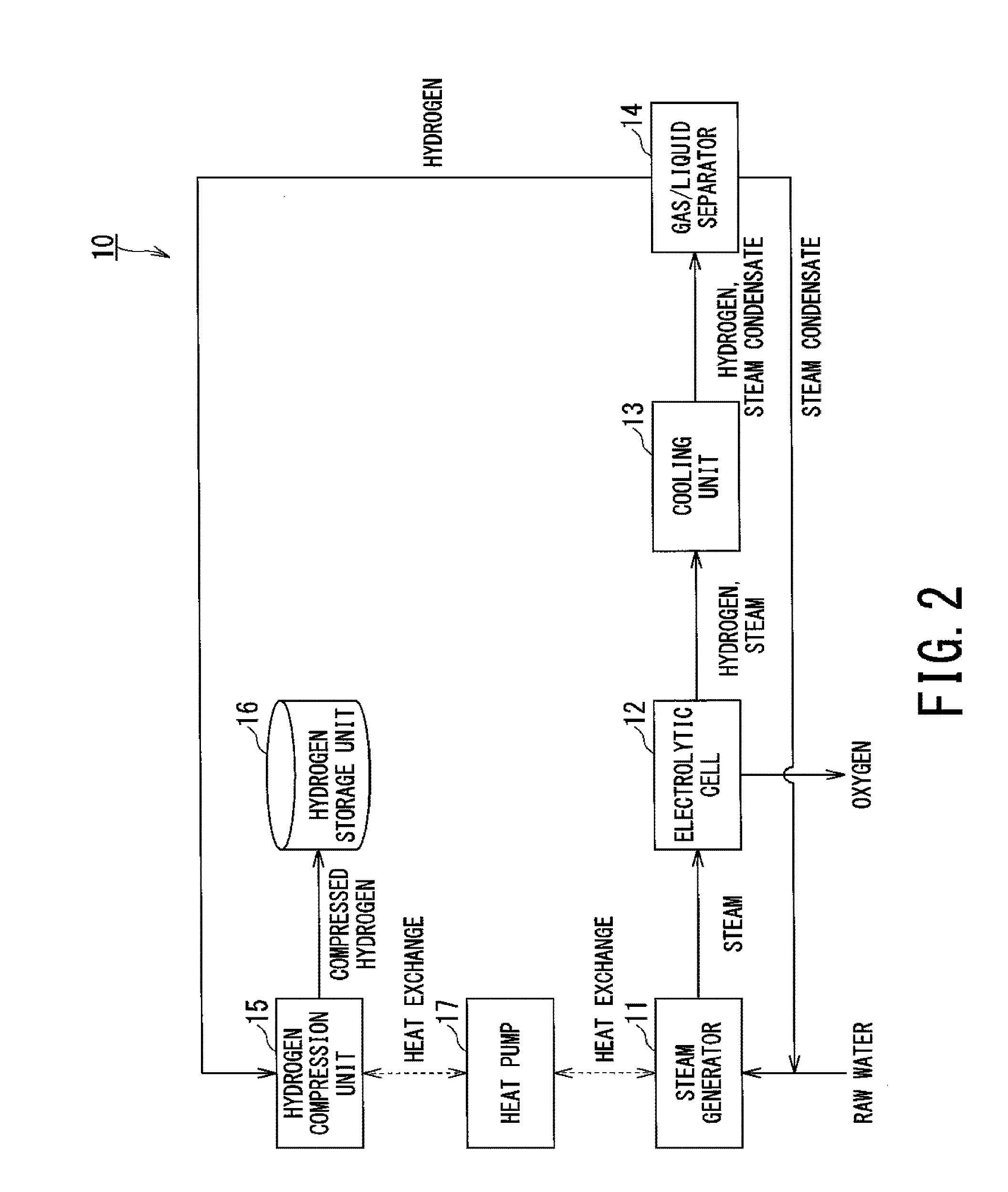

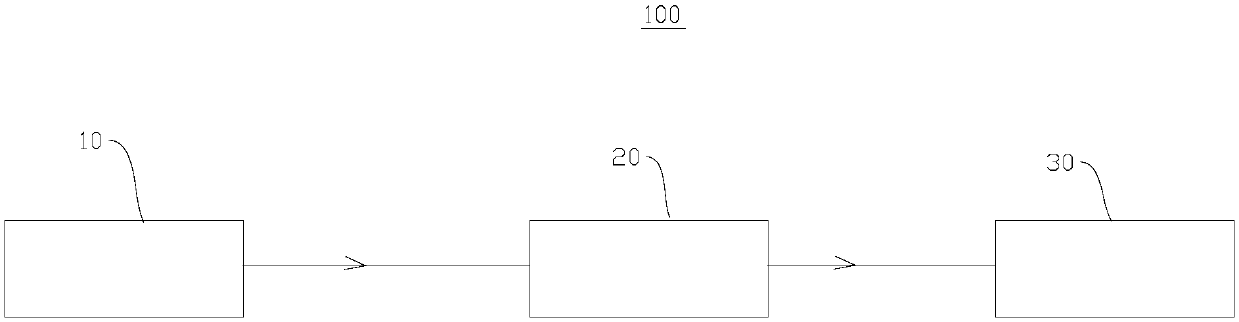

Hydrogen production system and method for producing hydrogen

ActiveUS20160122882A1Reduce heatImprove hydrogen production efficiencyCellsEnergy inputThermal energyHydrogen compression

A hydrogen production system includes: a steam generator heating supplied raw water and generating steam; an electrolytic cell receiving the steam and generating hydrogen and oxygen through a high temperature electrolysis; a cooling unit cooling an unreacted part of the steam in the high temperature electrolysis and changing the unreacted part of the steam into steam condensate; a gas / liquid separator performing gas / liquid separation on the generated hydrogen and the generated steam condensate; a hydrogen compression unit compressing the separated hydrogen and transmitting thermal energy generated when the hydrogen is compressed, to the raw water; and a hydrogen storage unit storing the compressed hydrogen.

Owner:KK TOSHIBA

Hydrogen liquefaction equipment provided with parallel-connection turbo expander units

PendingCN112361713ALarge hydrogen liquefaction efficiencyHigh hydrogen liquefaction efficiencySolidificationLiquefactionHydrogen compressionHydrogen content

The invention discloses hydrogen liquefaction equipment provided with parallel-connection turbo expander units. The hydrogen liquefaction equipment comprises a vacuum box, a hydrogen purification device, a pre-cooling device, a first hydrogen compressor unit, a second hydrogen compressor unit, a first turbo expander unit, a second turbo expander unit, a first low-temperature adsorber, a second low-temperature adsorber, a heat exchanger, an orthohydrogen-to-parahydrogen converter, an adjusting valve, a throttling valve, a liquid hydrogen tank and a liquid hydrogen storage tank. According to thehydrogen liquefaction equipment, the two turbo expander units are adopted for parallel-connection refrigeration, a hydrogen refrigeration circulation system in parallel connection with high-pressurethrottling refrigeration is adopted, raw material hydrogen is converted, cooled and liquefied through the multi-stage orthohydrogen-to-parahydrogen converter, hydrogen can be liquefied by 100%, the parahydrogen content reaches 99% or above, and the advantages of being high in hydrogen liquefaction efficiency and low in energy consumption are achieved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Combined hydrogenation method for producing catalytic raw material and high-quality diesel oil

ActiveCN102344826AAdaptableLow investment costTreatment with hydrotreatment processesFractionationRaw material

The invention relates to a combined hydrogenation method for producing catalytic raw material and high-quality diesel oil. The method arranges two parallel feedstock hydrogenation reaction zones, a shared hydrogen system and a shared post-separation system, wherein, the feedstock of the first hydrogenation reaction zone is a wax oil raw material, the feedstock of the second hydrogenation reaction zone is diesel oil raw material, and the hydrogen partial pressure at the inlets of the two reaction zones is 5.0-11.0MPa. The method of the invention can realize the two reaction processes of wax oil hydrotreatment and diesel oil hydro-upgrading on one instrument, and arranges only one system of new hydrogen supplementation, circulating hydrogen desulphurization and circulating hydrogen compression. And the reaction products are subjected to separation in one gas-liquid separation and fractionation system so as to obtain the target products. The method provided in the invention can effectively reduce equipment investment and operation cost, and improve the economic benefits to the maximum in an oil refining process.

Owner:CHINA PETROLEUM & CHEM CORP +1

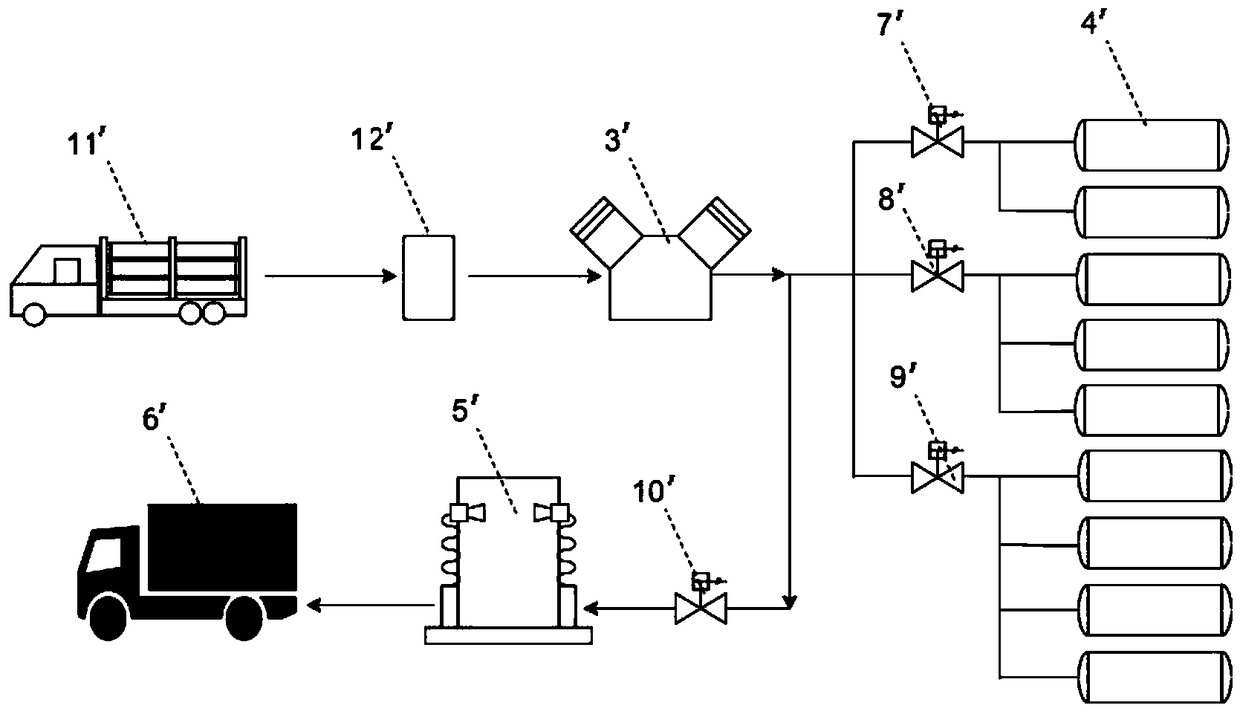

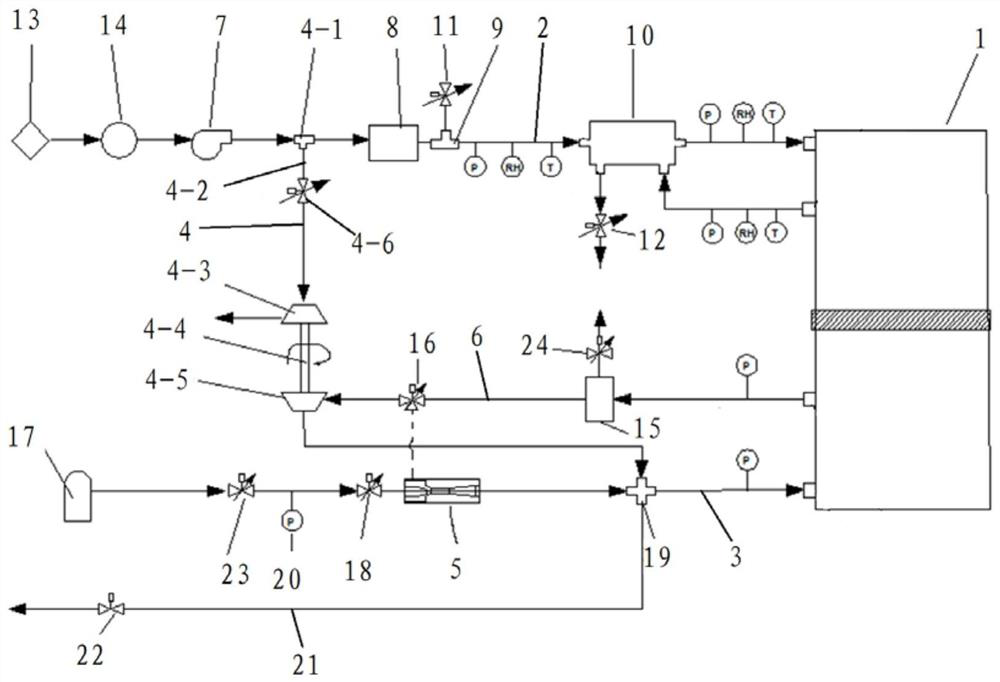

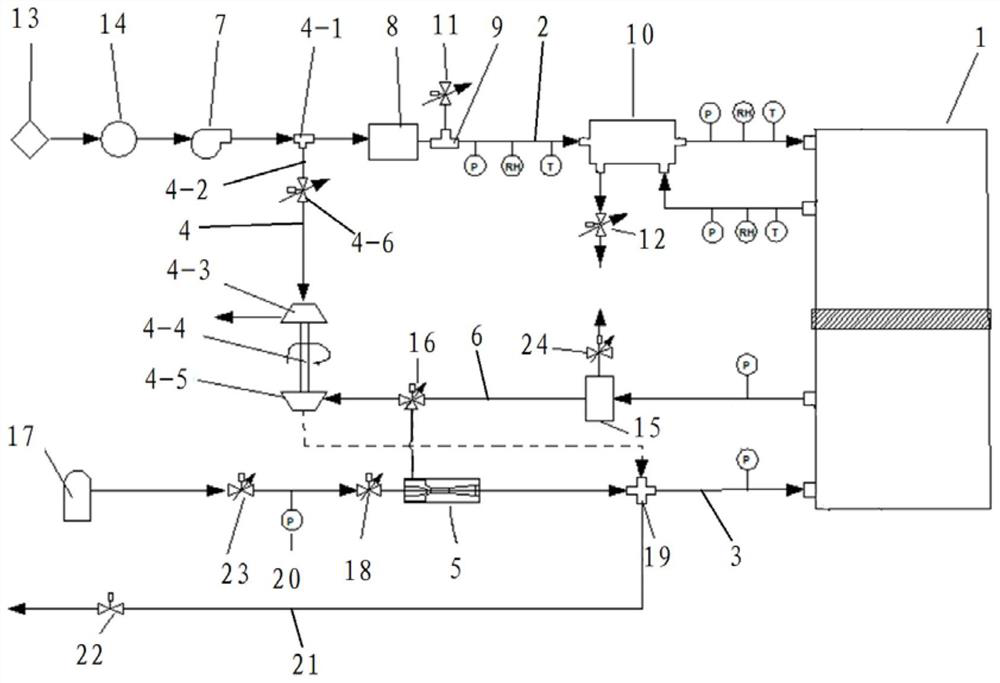

Efficient hydrogen filling method and system

PendingCN109185698AEfficient hydrogenationIncrease profitHydrogen technologiesContainer discharging methodsHydrogen pressureHydrogen compression

The invention discloses an efficient hydrogen filling method and system. The efficient hydrogen filling system comprises a hydrogen supply unit, a hydrogen compression unit, a hydrogen filling unit and at least two sets of hydrogen storage units arranged in a parallel connection manner, the hydrogen supply unit is connected with the hydrogen compression unit, the hydrogen compression unit is connected with the hydrogen storage units through hydrogen storage branches, and the hydrogen storage units are connected with the hydrogen filling unit through hydrogen conveying branches connected with the hydrogen storage units. According to the efficient hydrogen filling method, the efficient hydrogen filling system is used for filing hydrogen to a terminal user. Hydrogen supplementing of compression equipment to the other hydrogen storage units is not affected when a certain hydrogen storage unit supplies hydrogen to the terminal user, the use rate of the compression equipment is improved, inthe running process of a hydrogen filling station, the hydrogen pressure of hydrogen storage bottles of the hydrogen storage units is kept within the higher pressure range all the time, efficient hydrogen filling of the terminal user can be achieved through the higher hydrogen pressure, and meanwhile, the use rates of the hydrogen storage bottles in the hydrogen storage bottle sets are kept relatively consistent.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

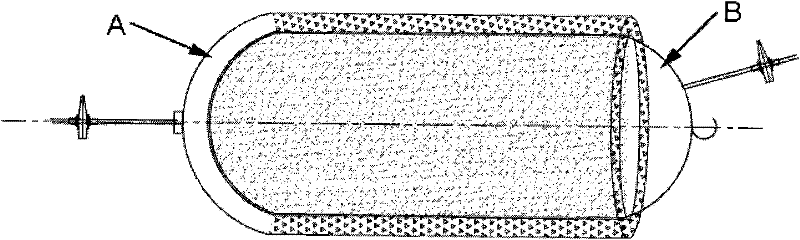

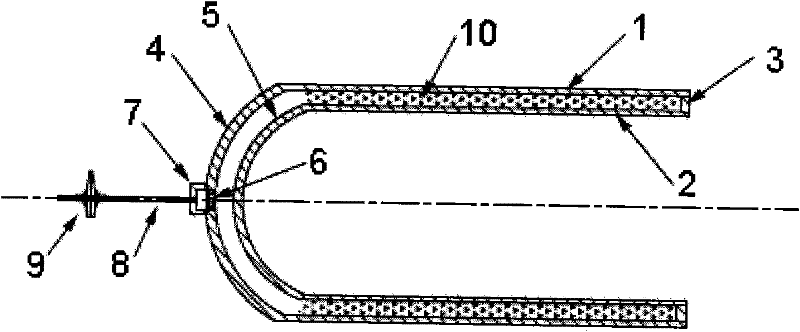

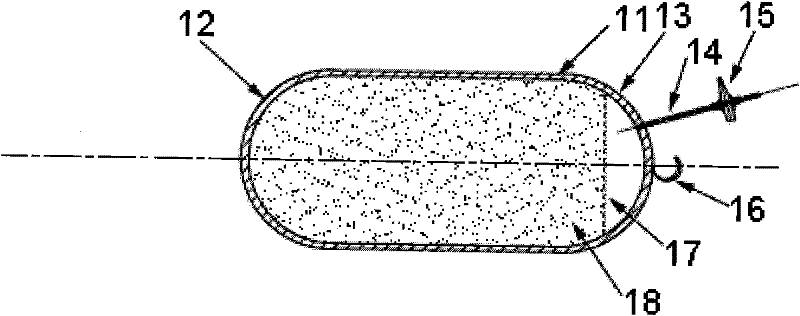

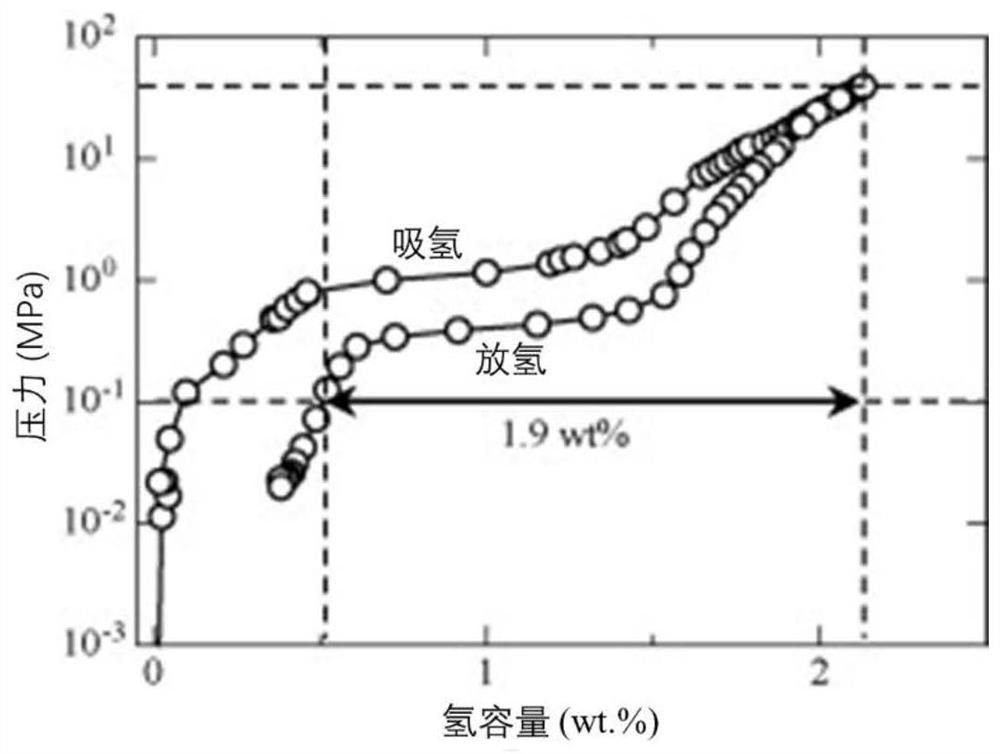

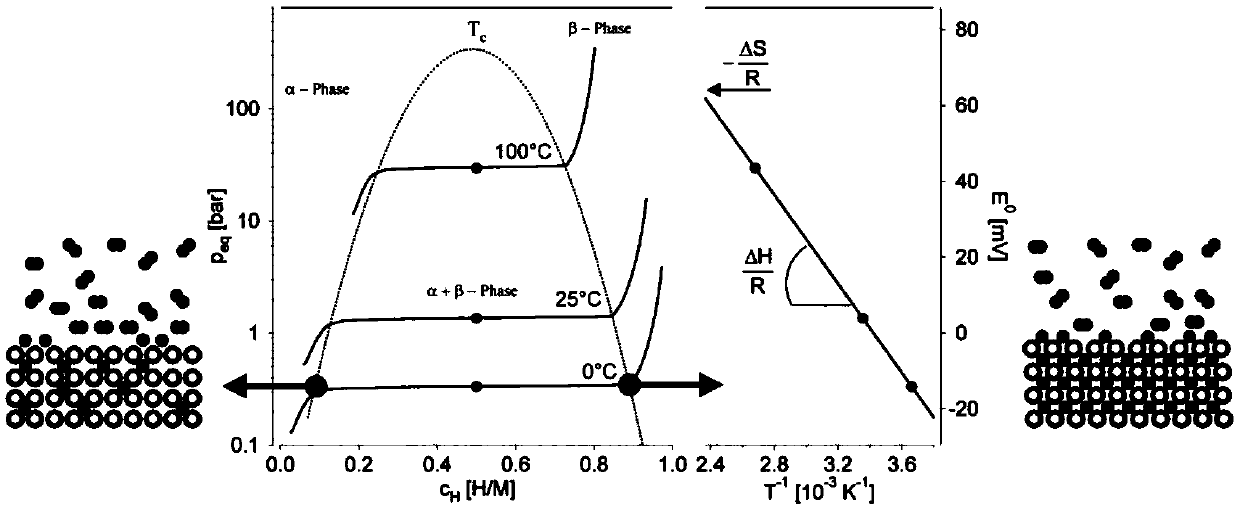

Metal hydride hydrogen compression device with heat source and manufacture method thereof

ActiveCN102530860AAchieve superchargingSimple structureHydrogen productionHydrogen compressionRoom temperature

The invention relates to a metal hydride hydrogen compression device with a heat source and a manufacture method thereof. The manufacture method is characterized in that the metal hydride hydrogen compression device is heated by self under the condition of no additional heat sources, and then the metal hydride hydrogen compression device adsorbs hydrogen at the room temperature and discharges high-voltage hydrogen at high temperature. The device comprises a hydrogen compression part with metal hydride and a heat source part, wherein a phase change energy storage material in the heat source part is subjected to temperature raising and phase change and stores heat under the heating condition, and heat is provided for the metal hydride in the hydrogen compression part; then, the metal hydride releases hydrogen at a certain temperature range of 50-300DEG C in more than two hours; and the hydrogen release pressure is between 10MPa and 100MPa.

Owner:GRIMAT ENG INST CO LTD

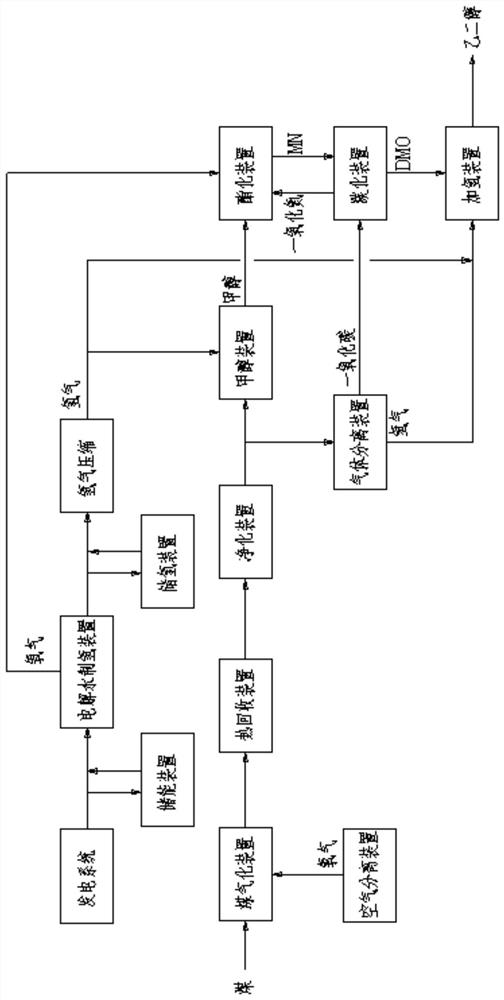

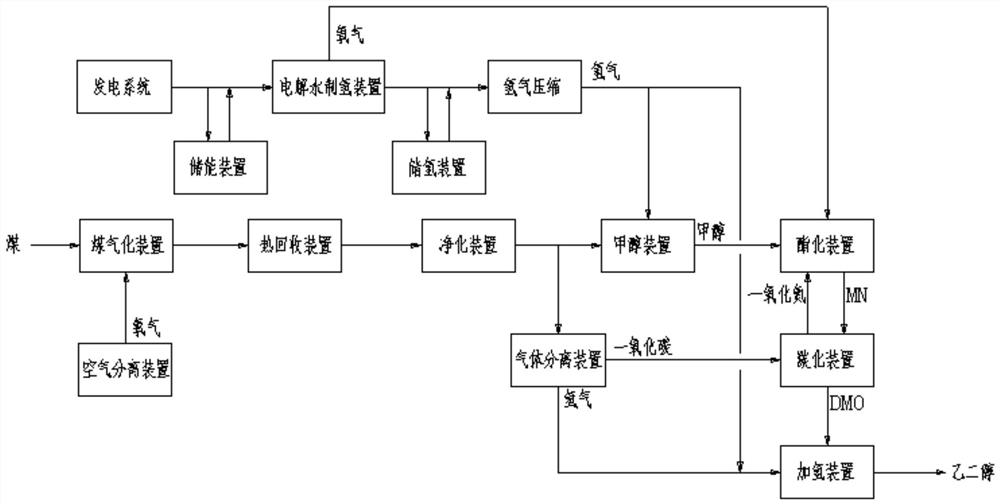

Method for realizing methanol/ethylene glycol co-production through coal chemical industry and green hydrogen coupling

PendingCN113956131AReduce coal consumptionEmission reductionElectrolysis componentsHydrogen separationGlycol synthesisHydrogen production

The invention relates to the field of carbon neutralization energy conservation and emission reduction, and particularly discloses a method for realizing methanol / ethylene glycol co-production through coal chemical industry and green hydrogen coupling. A device comprises a power generation system, an energy storage device, a water electrolysis hydrogen production device, a hydrogen storage device, a hydrogen compression device, a coal gasification device, an air separation device, a heat recovery device, a purification device, a gas separation device, a methanol device, an esterification device, a carbonylation device and a hydrogenation device. Through comprehensive utilization of a power generation system, the energy storage device, the water electrolysis hydrogen production device and the hydrogen storage device, green production and reliable supply of hydrogen are achieved, hydrogen generated by coal gasification is replaced, the carbon emission of coal-to-methanol and ethylene glycol is reduced, and the effective utilization rate of carbon elements in coal is increased.

Owner:HUALU ENG & TECH

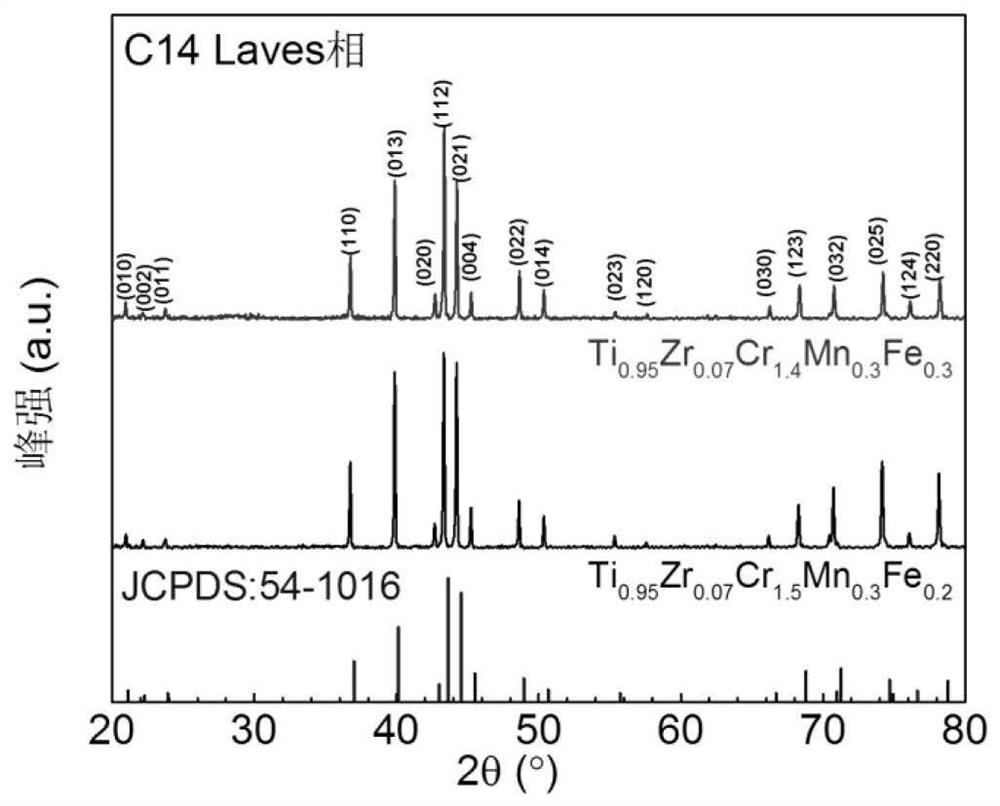

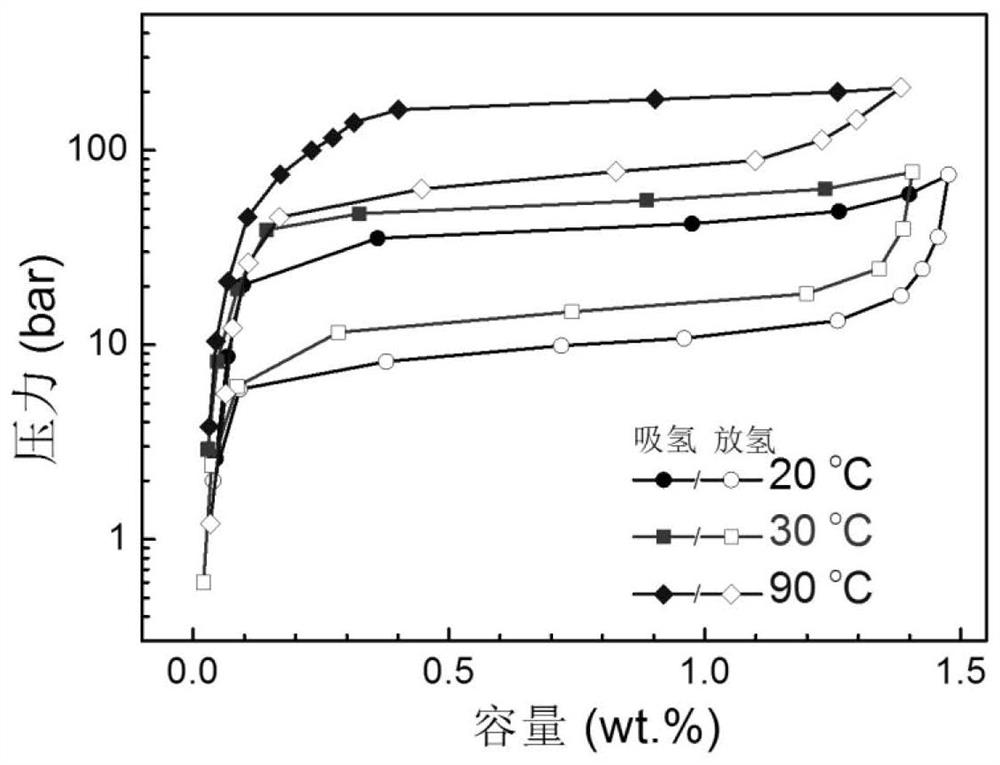

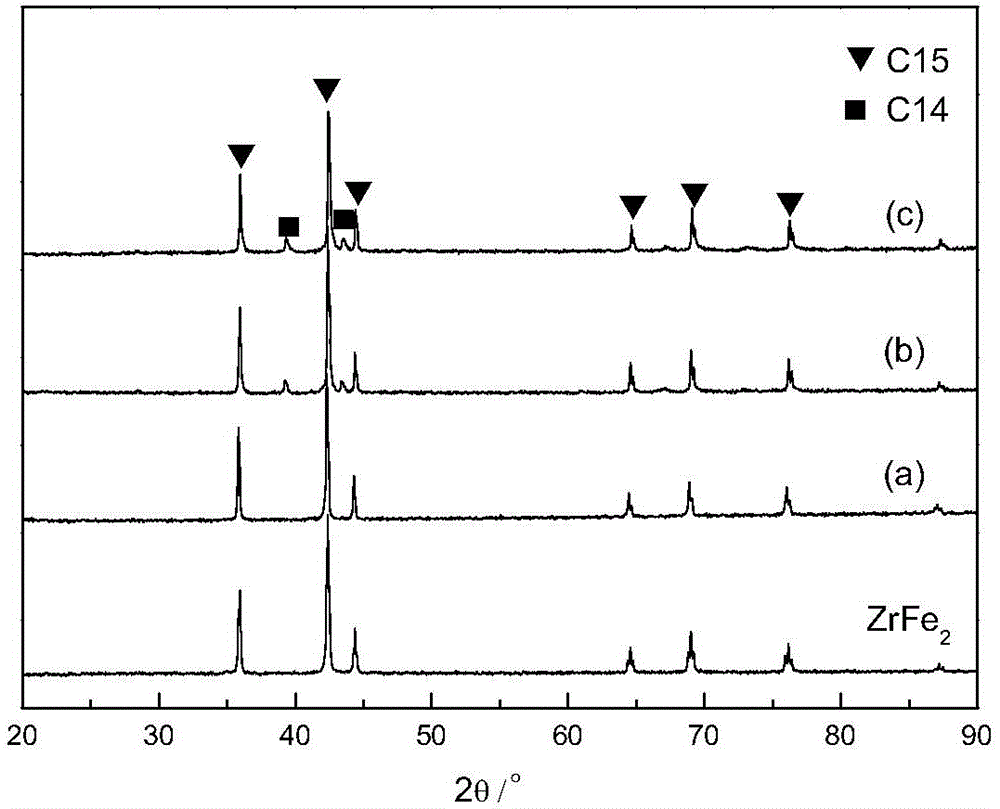

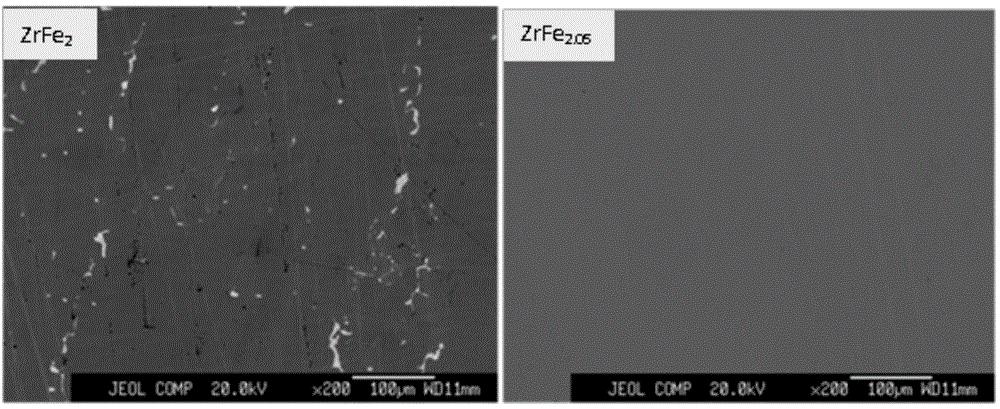

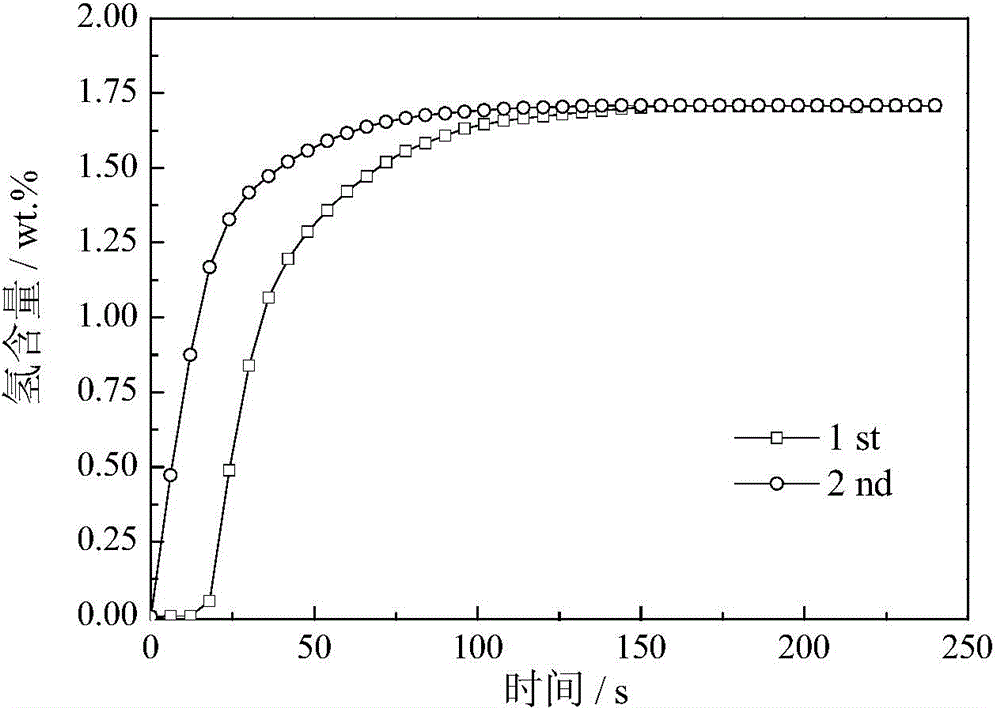

Solid hydrogen storage material for hydrogen refueling station and preparation method and application thereof

ActiveCN113215467AExcellent hydrogen absorption and desorption performance at room temperatureImprove cycle stabilityHydrogenMetallurgyHydrogen compression

The invention discloses a solid hydrogen storage material for a hydrogen refueling station, a preparation method of the solid hydrogen storage material and application of the solid hydrogen storage material in the hydrogen refueling station with static hydrogen compression. The solid hydrogen storage material for the hydrogen refueling station is a TiCr-based high-entropy intermetallic compound with a stable C14 Laves phase, and the chemical general formula of the solid hydrogen storage material is Ti < 1-x > Zr < x > Cr < 2-x > Mn < x > Fe < x >, wherein x is greater than or equal to 0.1 and less than 0.2. The preparation method comprises the steps that a Ti < 1-x > Zr < x > Cr < 2-x > Mn < x > Fe < x > high-entropy intermetallic compound cast ingot is prepared, and hydrogen absorption state powder can be obtained through room-temperature hydrogen absorption activation.

Owner:ZHEJIANG UNIV

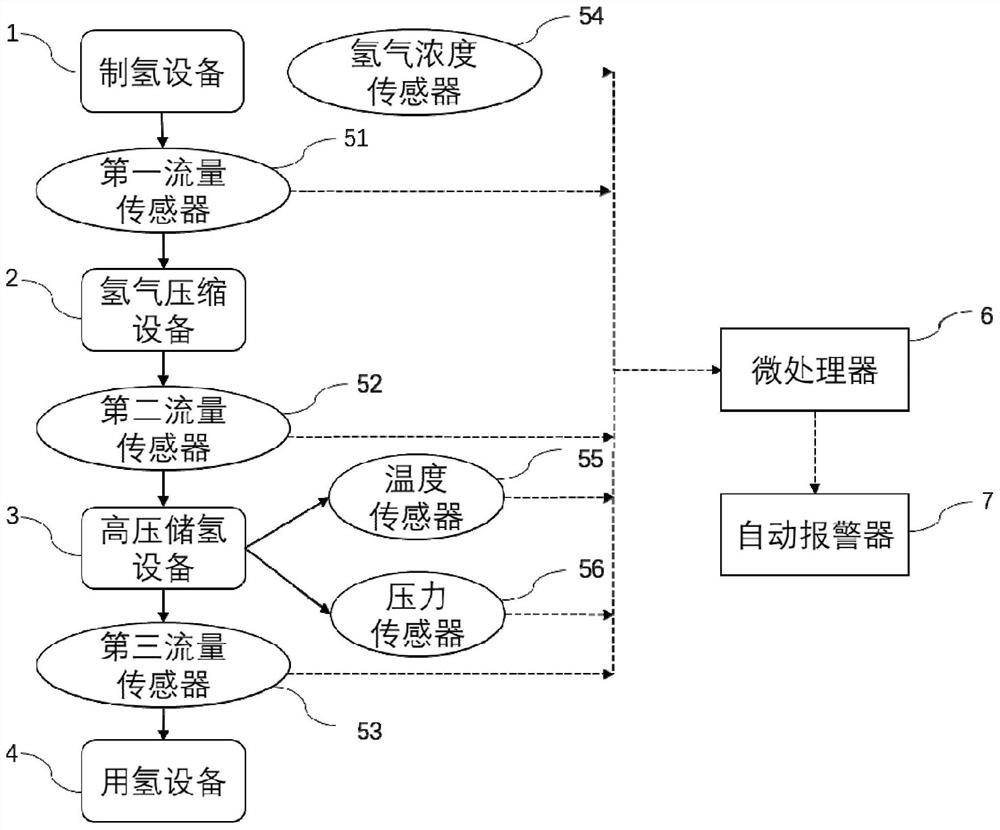

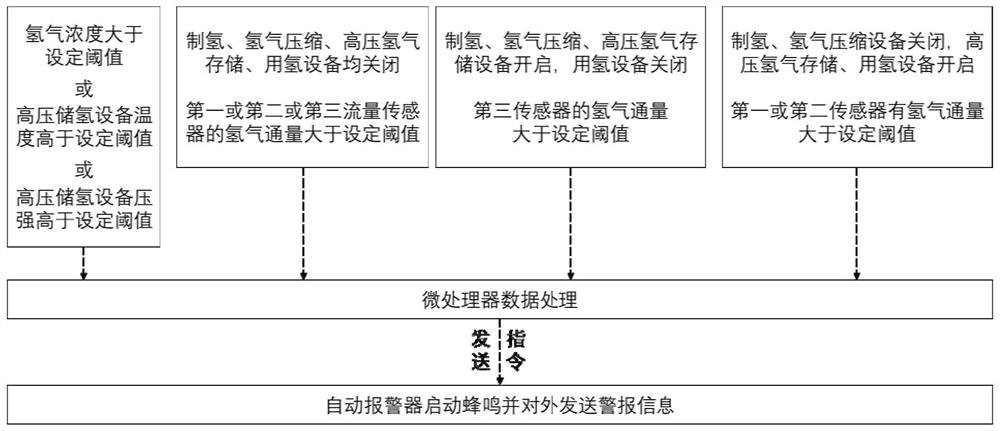

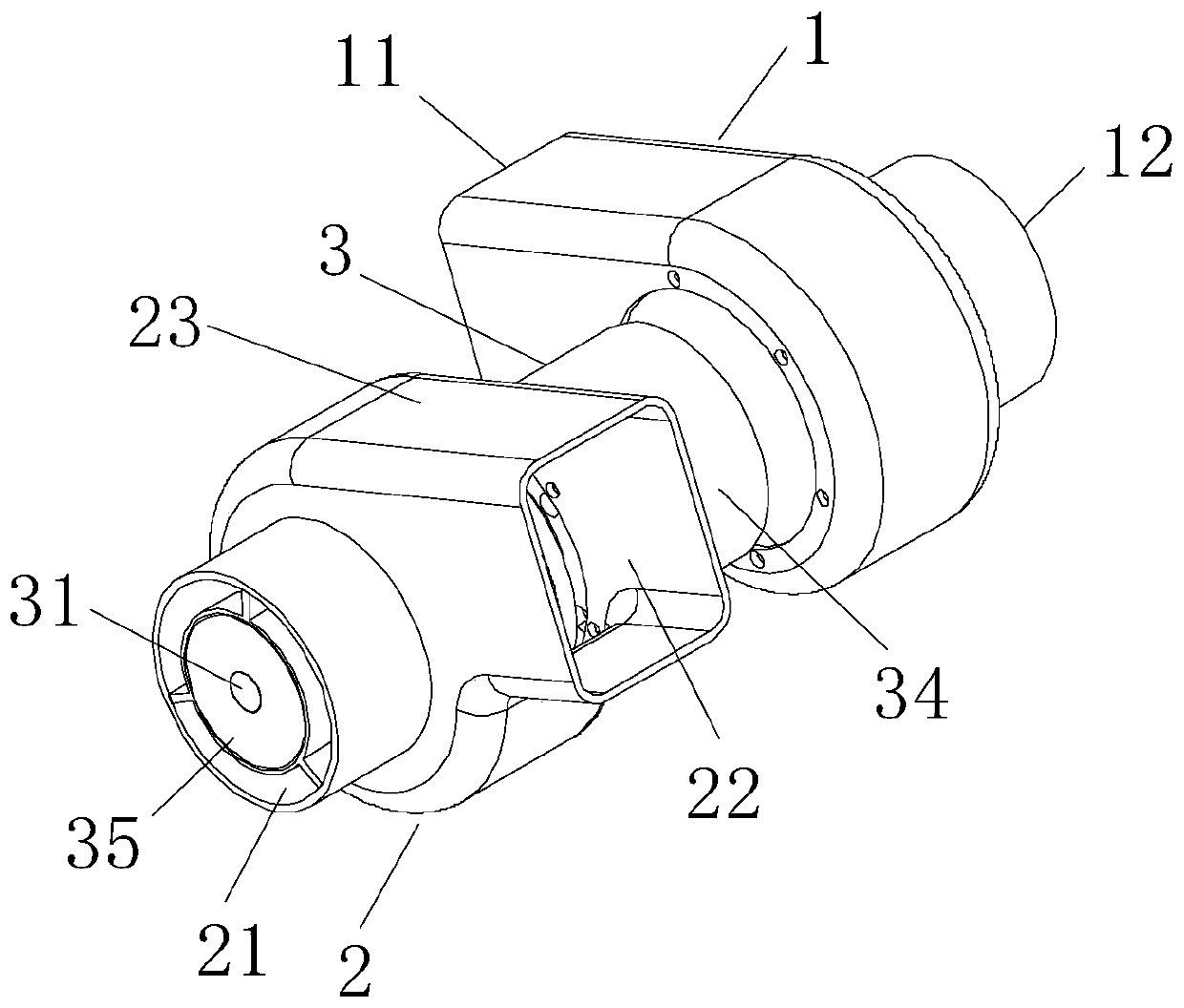

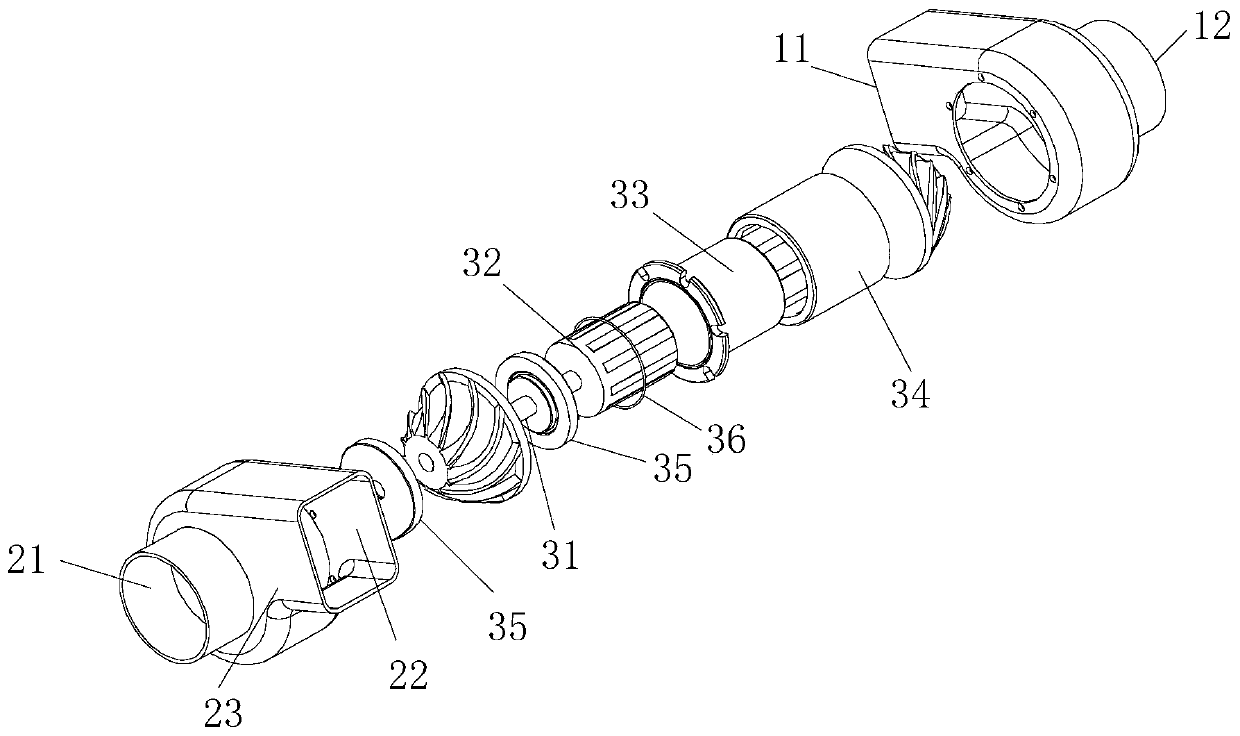

Alarm system and method for detecting hydrogen leakage

InactiveCN111915850AEfficient detectionReasonable designDetection of fluid at leakage pointMeasurement of fluid loss/gain rateInformation processingAlarm message

The invention discloses an alarm system and method for detecting hydrogen leakage, and the system comprises a hydrogen production device which is used for producing hydrogen; a hydrogen compression device which is used for compressing and storing the hydrogen prepared by the hydrogen production device into a high-pressure hydrogen storage device; the high-pressure hydrogen storage device which isused for storing the hydrogen compressed by the hydrogen compression device and conveying the hydrogen to a hydrogen utilization device when the hydrogen utilization device needs to use the hydrogen;the hydrogen utilization device which is used for utilizing hydrogen; a hydrogen safety detection device which is used for detecting the hydrogen leakage condition and transmitting the detection information to an information processing and alarming device; and the information processing and alarming device which is used for processing the detection information and judging whether to give an alarmor not. According to the invention, the hydrogen leakage position can be simply, rapidly and effectively positioned, the alarm information can be conveniently and timely reported to the outside, the possibility that hydrogen leakage is gathered to reach an explosion limit is reduced, and major accidents can be effectively prevented.

Owner:XI AN JIAOTONG UNIV

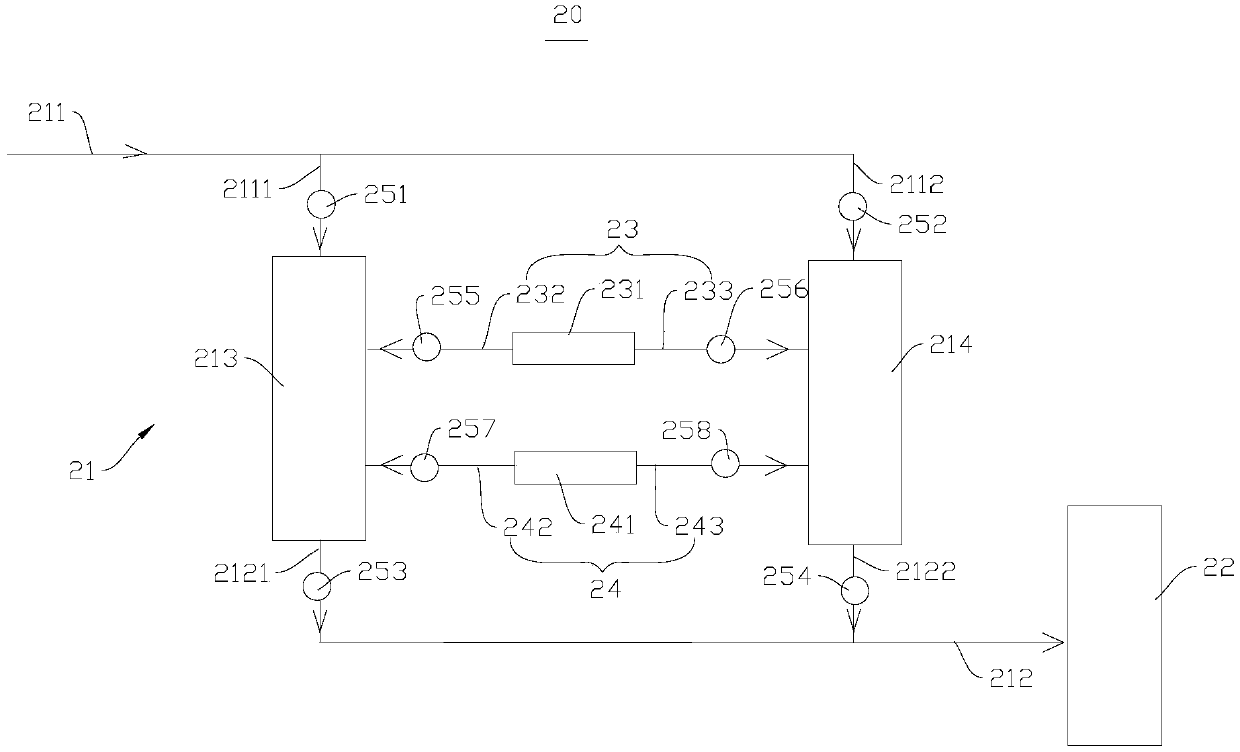

Hydrogen recovery device of fuel cell system

PendingCN110459788AReduce self-consumption powerIncreased net power outputReactant parameters controlFuel cellsHydrogen

A hydrogen recovery device for a fuel cell system includes a turbine driving device provided with an air input port; a hydrogen compression device in driving connection with the turbine driving deviceand provided with a hydrogen inlet and a hydrogen outlet; and a fuel cell provided with a hydrogen input end, a hydrogen output end, an air input end and an air output end, wherein the hydrogen inputend of the fuel cell is communicated to the hydrogen outlet of the hydrogen compression device, the hydrogen output end of the fuel cell is communicated to the hydrogen inlet of the hydrogen compression device, and the air output end of the fuel cell is communicated to the air input port of the turbine driving device. By adopting the hydrogen recovery device of the fuel cell system, the self power consumption of the fuel cell engine is reduced. The power density of the fuel cell engine system is increased, and the net power output of the fuel cell is increased.

Owner:苏州久安通氢能源科技有限公司

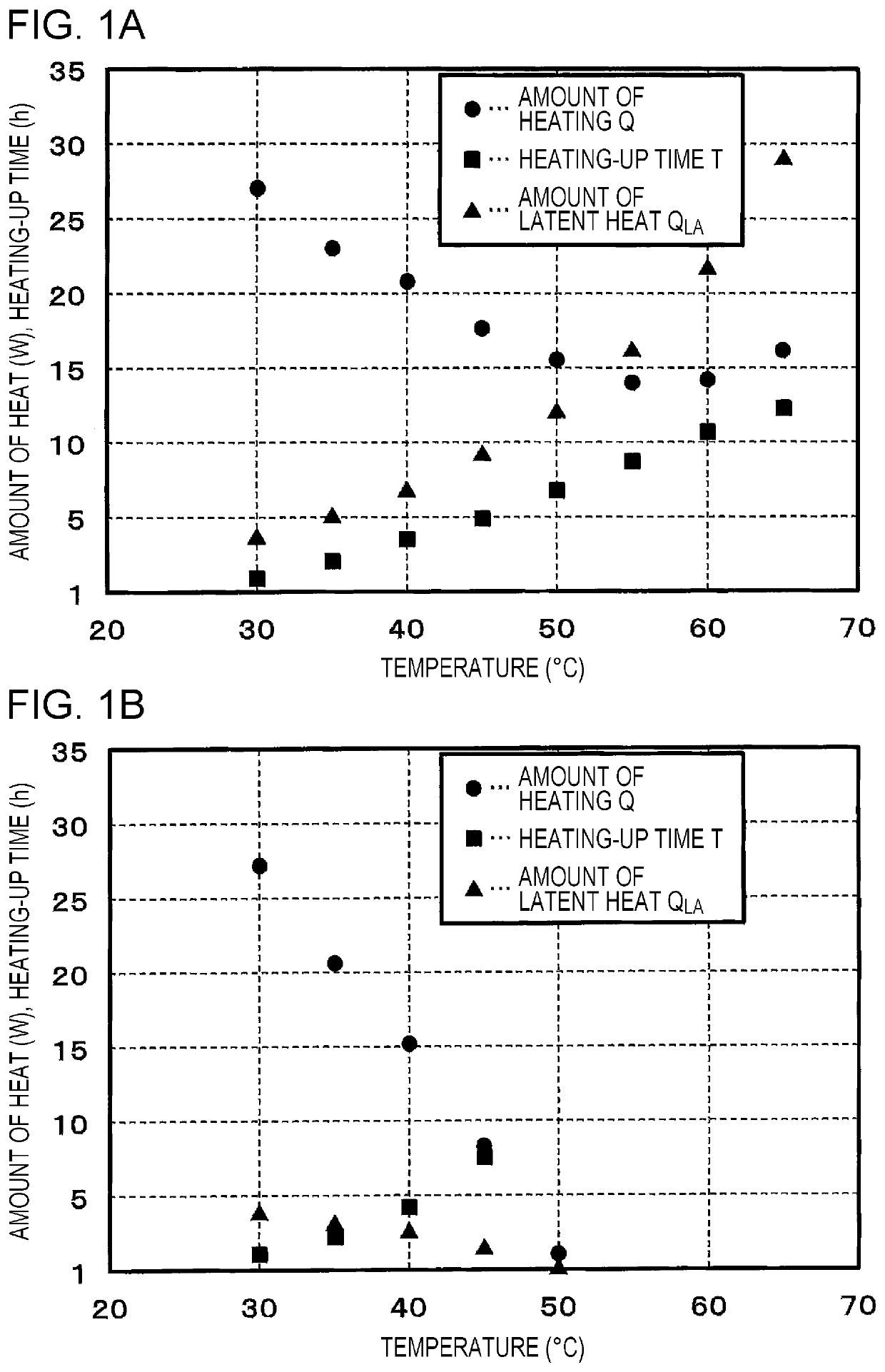

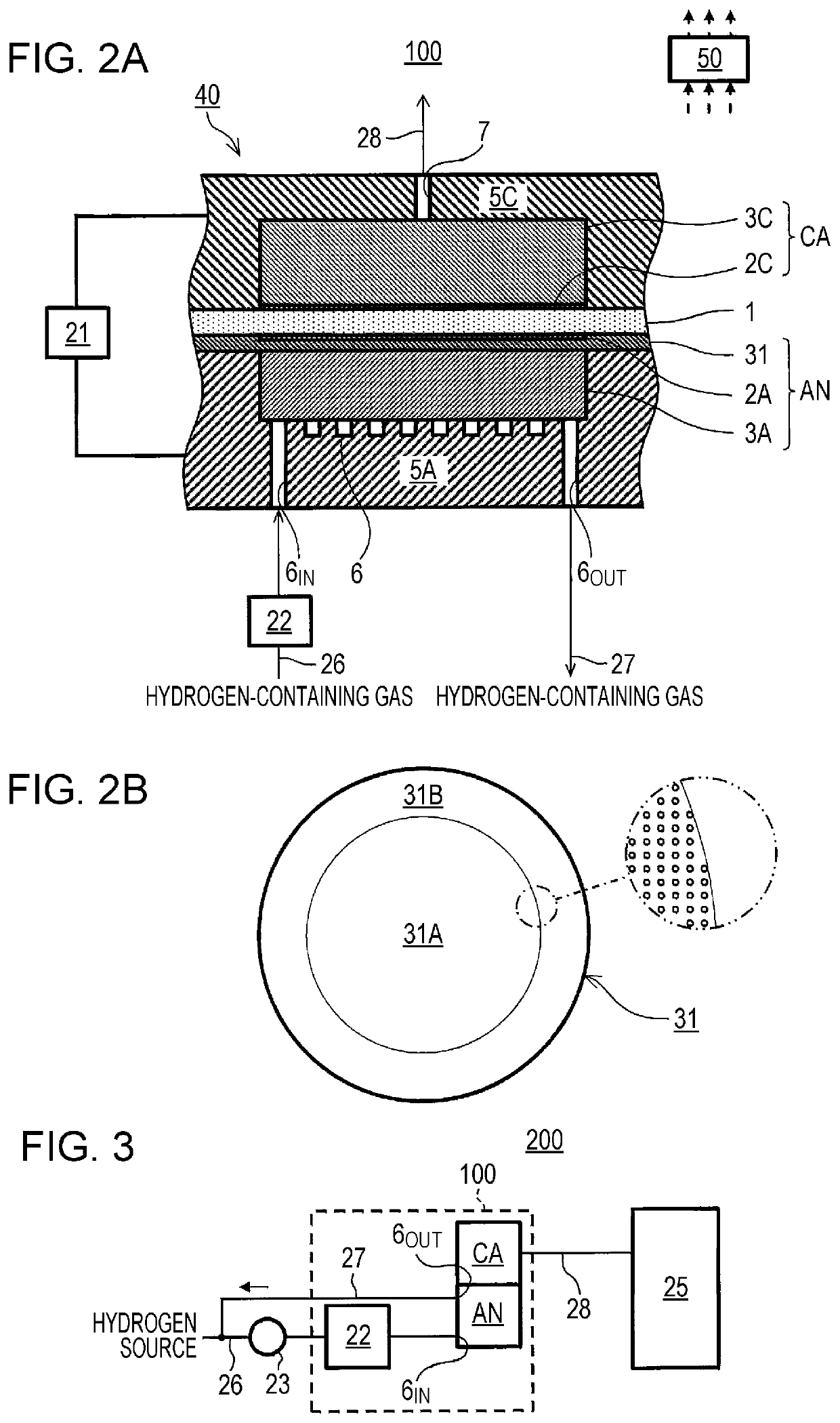

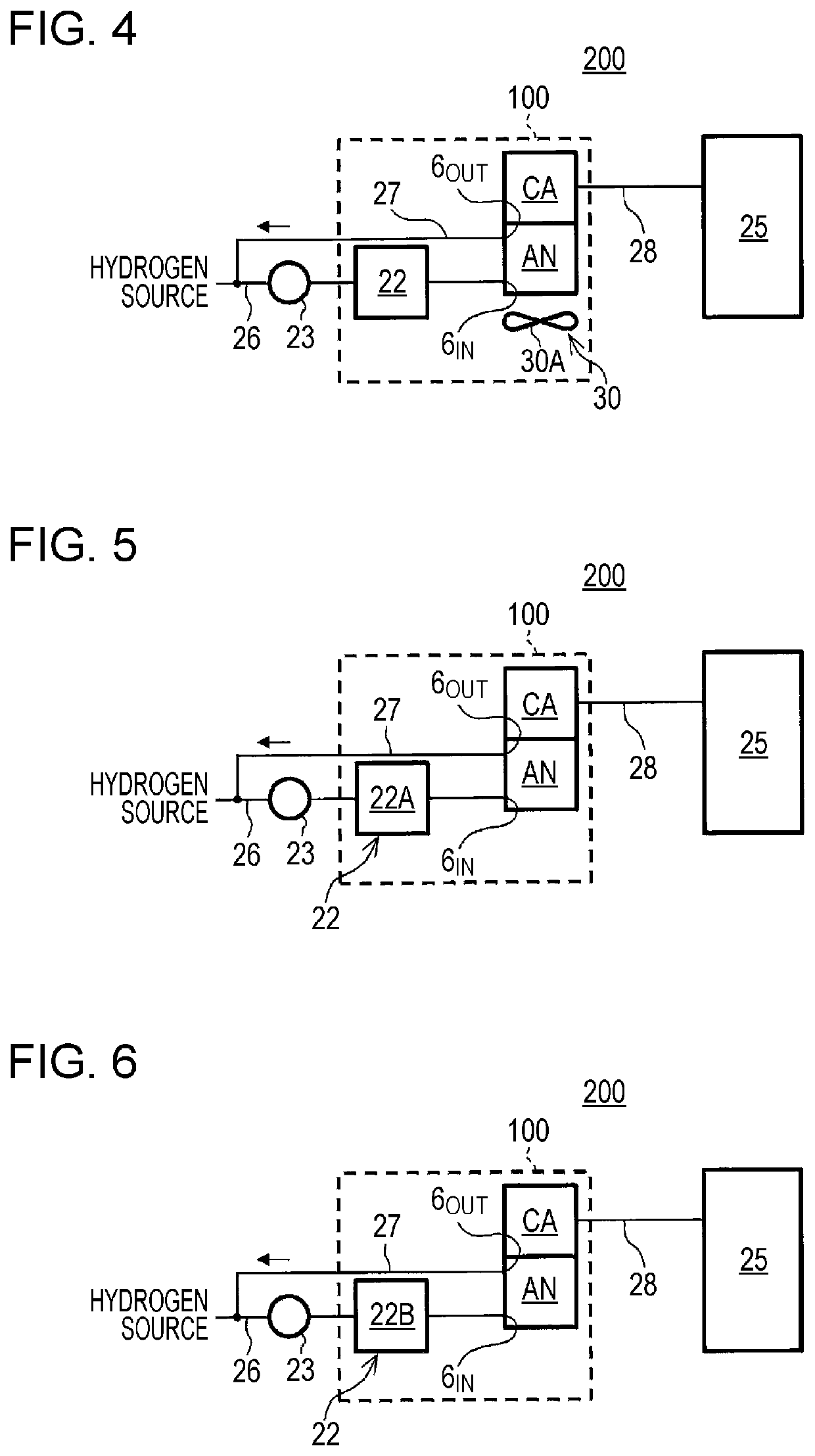

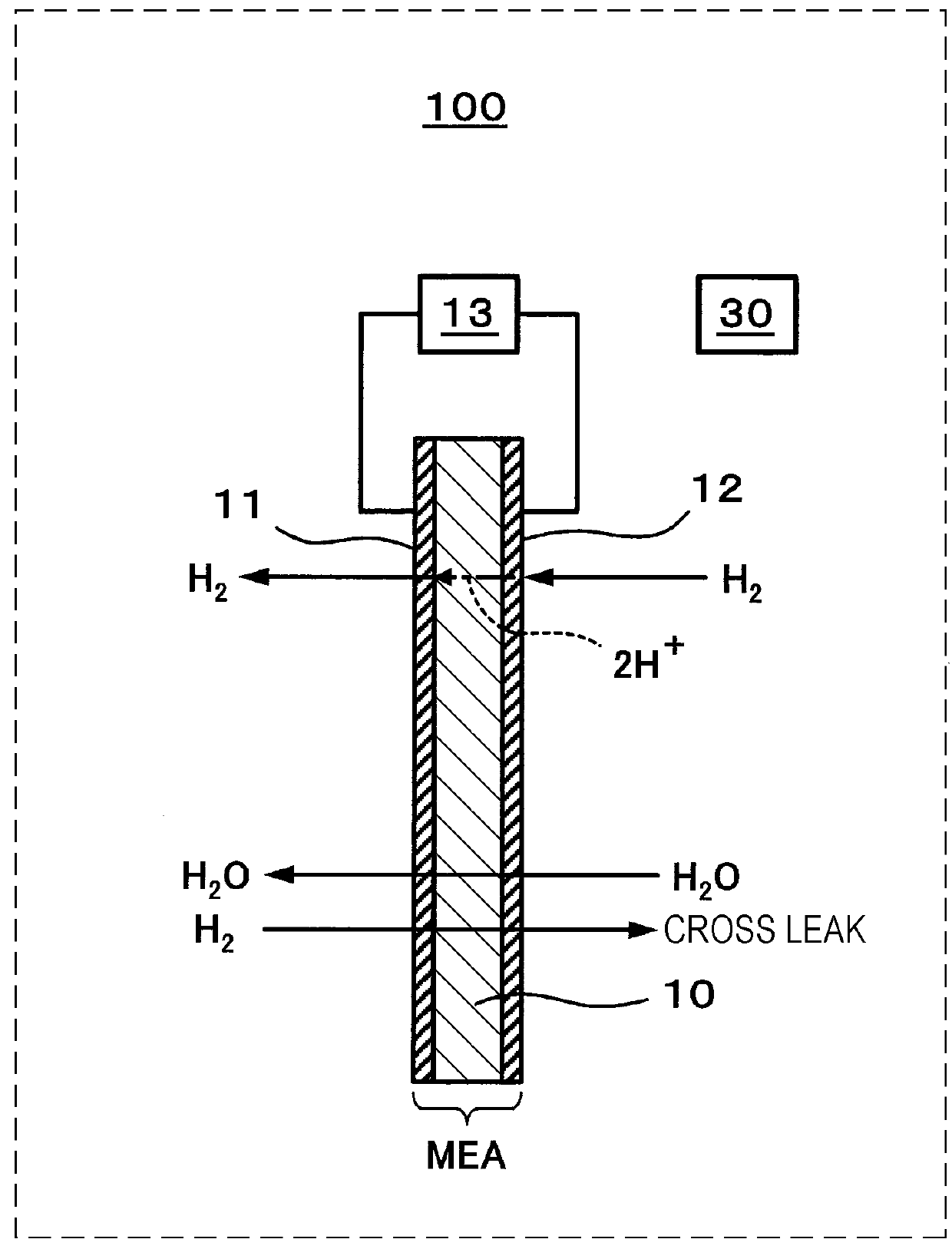

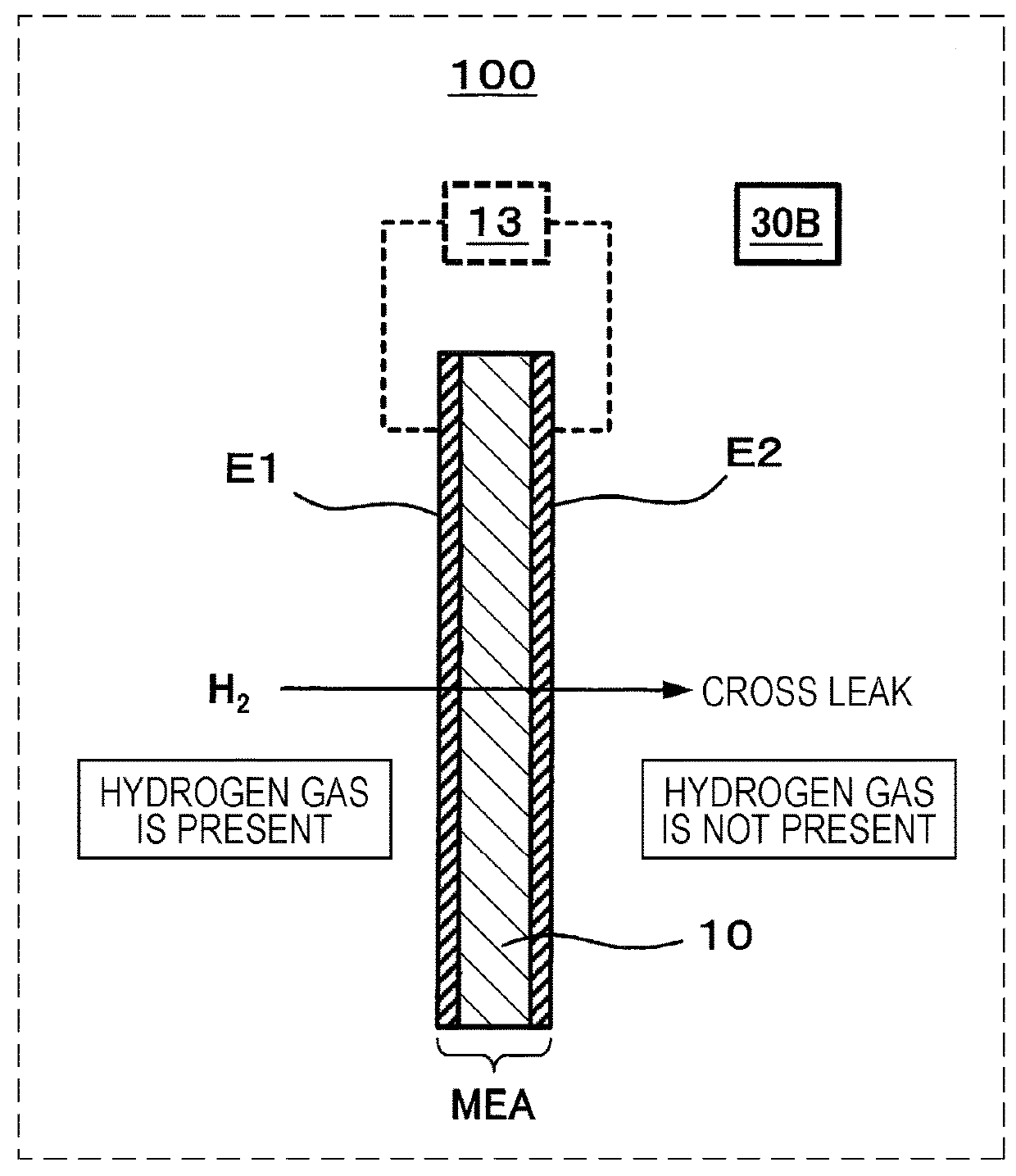

Electrochemical hydrogen compressor and method for operating electrochemical hydrogen compressor

An electrochemical hydrogen compressor includes: a cell including a proton conductive electrolyte membrane having a pair of principal surfaces, a cathode disposed on a first one of the principal surfaces of the electrolyte membrane, and an anode disposed on a second one of the principal surfaces of the electrolyte membrane; a voltage applicator that applies a voltage between the anode and the cathode; a dew point adjuster that adjusts a dew point of a hydrogen-containing gas to be supplied to the anode; and a controller that, when the temperature of the cell increases, controls the dew point adjuster to increase the dew point of the hydrogen-containing gas.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

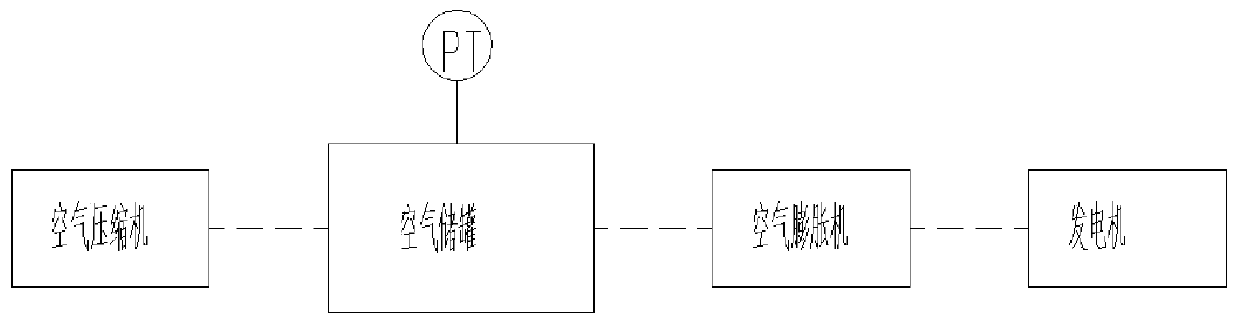

Metal hydrogen storage material hydrogen energy negative pressure work applying system

InactiveCN109555570ARealize green transportationConducive to energy saving and emission reductionSteam engine plantsHydrogen compressionAtmospheric air

The invention relates to a metal hydrogen storage material hydrogen energy negative pressure work applying system. The system comprises a hydrogen reaction bed unit, a hydrogen compression unit, a hydrogen expander, a power generator, a storage battery and an external power grid. The hydrogen reaction bed unit is provided with a hydrogen reaction bed and a heat exchange center. The hydrogen reaction bed is provided with a negative pressure hydrogen input and a negative pressure hydrogen outlet. The negative pressure hydrogen outlet of the hydrogen reaction bed is connected with the hydrogen compression unit, and the hydrogen compression unit is connected with the negative pressure hydrogen inlet of the hydrogen reaction bed through the hydrogen expander. According to the hydrogen absorption / release characteristic of a metal hydrogen storage material in the reaction bed, a negative pressure end is formed by hydrogen absorption of the metal hydrogen storage material, the metal hydrogen storage material obtained after hydrogen absorption is subjected to hydrogen release cycle use at lower pressure, a normal pressure end is formed by released negative pressure hydrogen under the auxiliary effect of barometric pressure and magnetic force or / and mechanical force or / and hydraulic force, the working medium hydrogen cyclically flows between the normal pressure end and the negative pressure end to drive the expander to apply work to drive the power generator to generate power or drive equipment, and energy of the nature is fully utilized.

Owner:SHANGHAI KELAIPU ENERGY TECH CO LTD

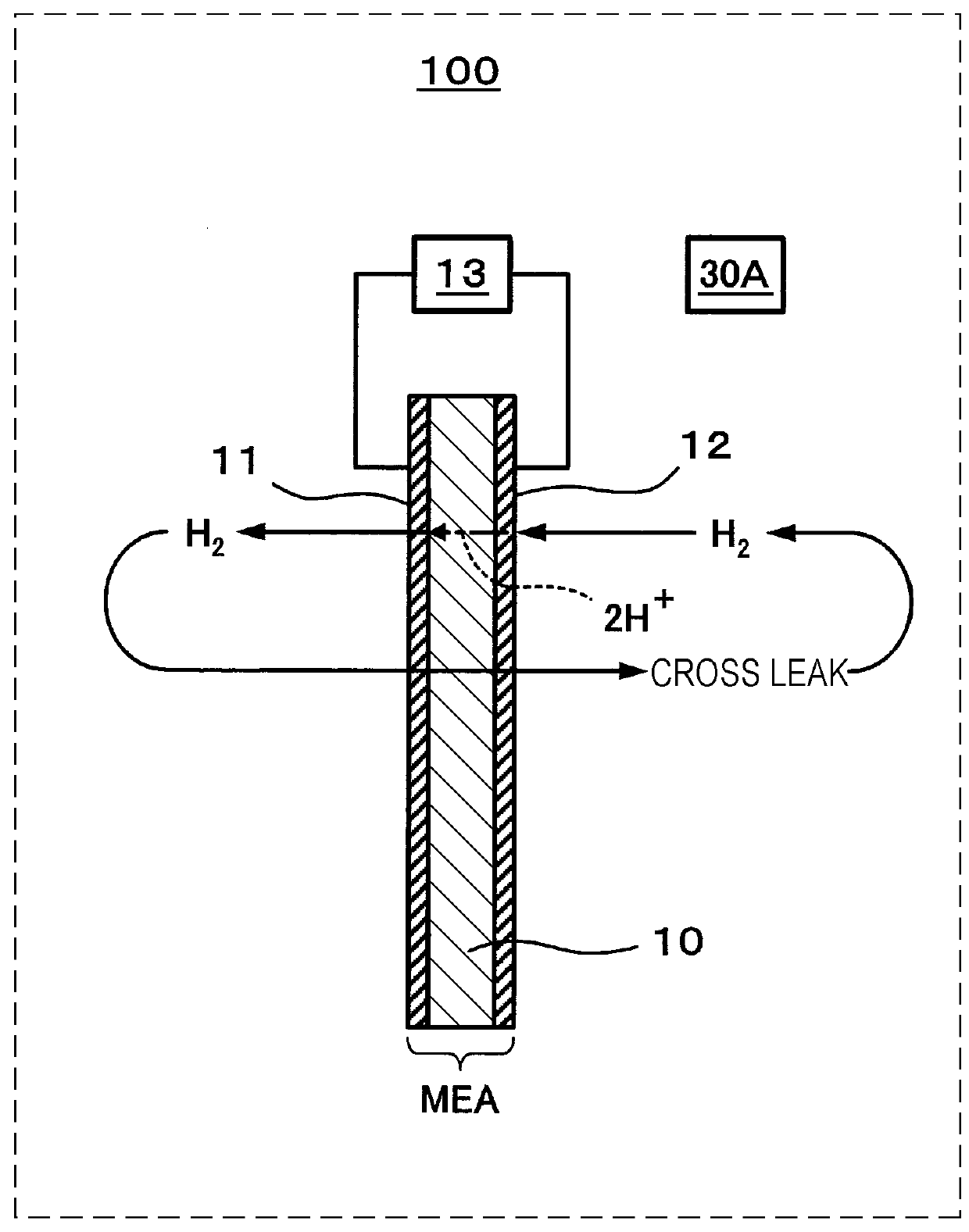

Electrochemical hydrogen compression apparatus

ActiveUS20180166713A1Appropriate detectionCellsDispersed particle separationHydrogen compressionProton

An apparatus includes a proton-conducting electrolyte membrane, an anode, a cathode, a first flow path which is disposed on the anode and through which an anode fluid containing hydrogen as a constituent element flows, a second flow path which is disposed on the cathode and through which hydrogen flows, a voltage applicator, a detector which detects a hydrogen cross leak amount passing through the membrane, where the detector detects the hydrogen cross leak amount from, a natural potential of one electrode of the cathode and the anode after forming a state where hydrogen is present at the one electrode and hydrogen is not present at the other electrode of the cathode and the anode, or a current flowing between the anode and the cathode when the voltage is applied from the voltage applicator in a state where the first flow path and the second flow path are both sealed off.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Gas-electricity system, control method of gas-electricity system and vehicle

The invention discloses a gas-electricity system, a control method of the gas-electricity system and a vehicle, and belongs to the technical field of vehicles. According to the gas-electricity system, an air path is communicated with a cathode inlet of a fuel cell stack assembly, an air compressor is arranged on the air path, and an outlet of the air compressor is communicated with the input end of a hydrogen compression pump device; the output end of the hydrogen compression pump device can be communicated with a hydrogen path; the hydrogen path is communicated with an anode inlet of the fuel cell stack assembly; and the first end of the hydrogen recovery path is communicated with the anode outlet of the fuel cell stack assembly, and the second end of the hydrogen recovery path can be communicated with the hydrogen compression pump device. The gas-electricity system, the control method of the gas-electricity system and the vehicle are low in cost and simple in structure, and the danger of hydrogen leakage explosion caused by electric sparks does not exist.

Owner:DONGFENG MOTOR GRP

Ultrahigh pressure metal hydride hydrogen compression material

InactiveCN105755381ADifferent target hydrogen release pressurePromote activationHysteresisUltra high pressure

The invention discloses an ultrahigh pressure metal hydride hydrogen compression material. The material is a hydrogen storage alloy, and the chemical composition of the material is ZrxTiyFezMwMmy, wherein M is Ni, V, Mn, Cu, Co or a combination thereof; and x, y, z and w respectively represent the atom ratios of Zr, Ti, Fe and M, v is the molar content of cerium-rich rare earth Mm in the alloy, x is 0.5-1.0, y is 0-0.5, z is 1.5-2.5, w is 0-0.5, and v is 0-0.05. The metal hydride hydrogen compression material has the advantages of easy activation, small hydrogen absorption and release hysteresis, good alloy dynamics performances, realization of hydrogen absorption saturation within 100s, and good alloy efflorescence resistance. The metal hydride hydrogen compression material provides a product hydrogen pressure of 110MPa at 95DEG C or below, provides a product hydrogen pressure of 150MPa at 110DEG C or below, and can effectively utilize solar energy and industrial waste heat to provide heat required by hydrogen release of the material in order to avoid energy consumed by electric heating.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Hydrogen combined optimized utilization technology of hydrogenation apparatus

ActiveCN102399584AReduce dosageReduce lossTreatment with hydrotreatment processesThermodynamicsHydrogenation reaction

The invention discloses a hydrogen combined optimized utilization technology of a hydrogenation apparatus. Excessive hydrogen from a hydrogen pipe net passes through a first reaction unit and conducts a catalysis hydrogenation reaction with raw oil; residual hydrogen enters a first cold-high pressure separating unit for gas-liquid separation, then mixes with cycling hydrogen from a second cold-high pressure separating unit, is treated by a hydrogen cycle unit and enters to a second reaction unit to conduct a catalysis hydrogenation reaction with raw oil; residual hydrogen enters into the second cold-high pressure separating unit for gas-liquid separation, merges with residual hydrogen from the first cold-high pressure separating unit, is treated by the hydrogen cycle unit and returns to the second reaction unit. According to the technology of the invention, two sets of hydrogenation apparatuses can share a new hydrogen machine or a hydrogen cycle compressor and part of pipes, so as to reduce equipment quantity and energy consumption of the new hydrogen compressor and the cycle hydrogen compressor, and realize small investment and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Continuous-output static-hydrogen compression, storage and filling integration system

PendingCN109578812AAchieve continuous outputCompact designPipeline systemsHydrogen technologiesHydrogen compressionHydrogen fuel

The invention provides a continuous-output static-hydrogen compression, storage and filling integration system and belongs to the technical field of hydrogen fuel. The integration system includes a hydrogen source input device, a filling device and at least one hydrogen boosting and storage unit, wherein each hydrogen boosting and storage unit includes a static-hydrogen compression device and a pressurized-hydrogen storage device; the static-hydrogen compression device correspondingly communicates with a hydrogen source input device and the pressurized-hydrogen storage device; and the pressurized-hydrogen storage device further communicates with the inlet end of the filling device or the hydrogen inlet end of the next static-hydrogen compression device. The integration system has no movingparts, completely uses a heat driving method to realize the pressurizing of hydrogen, has compact and quiet design, high reliability and low risk of leakage, can simultaneously improve the purity ofhydrogen in the process of compression, and realizes the continuous output of compressing hydrogen through the hydrogen sucking and discharging method of alternating multiple tanks; and when multiplestages are in parallel operation, the hydrogen compression and conveying capacity of the system is greatly improved and the practicability is improved.

Owner:GUANGDONG INST OF RARE METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com