Hydrogen combined optimized utilization technology of hydrogenation apparatus

A technology of joint optimization and hydrogenation unit, applied in the fields of hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of high equipment maintenance cost and equipment operation cost, large one-time investment, and many unit equipment, etc. The effect of reducing the amount and loss of lubricating oil of the unit, reducing the total investment, and reducing the amount and loss of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

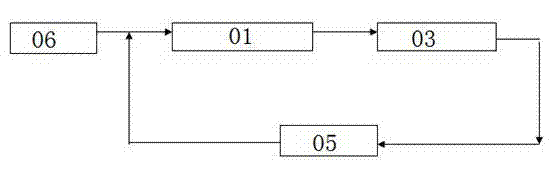

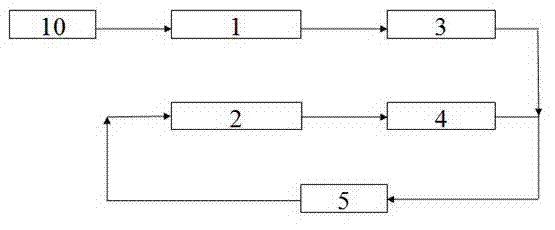

[0036] Such as figure 2 As shown, a hydrogenation unit hydrogen joint optimal utilization process, for the hydrogen pressure from the hydrogen pipeline network is higher than the system pressure of the first reaction unit and the second reaction unit, between the hydrogen pipeline network and the first reaction unit 1 can be The supplementary hydrogen compressor is canceled, and the hydrogen from the hydrogen pipeline network 10 directly enters the first reaction unit 1 to carry out catalytic hydrogenation reaction with the raw material oil, and the remaining hydrogen enters the first cold high-resolution unit 3 for gas-liquid separation and is used as the second reaction unit 2 The supplementary hydrogen and the circulating hydrogen of the second cold high-resolution unit 4 are combined and processed by the hydrogen circulation unit 5, and then enter the second reaction unit 2 to carry out catalytic hydrogenation reaction with the raw material oil, and the remaining hydrogen ...

Embodiment 2

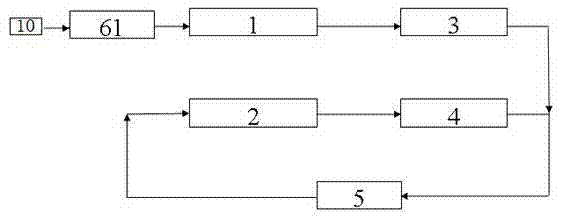

[0039] Such as image 3 As shown in Fig. 1, a joint optimized utilization process of hydrogen in a hydrogenation unit, when the pressure of hydrogen from the hydrogen pipeline network is lower than the system pressure of the first reaction unit and the second reaction unit, a hydrogen pipeline is set between the hydrogen pipeline network and the first reaction unit 1 There is a supplementary hydrogen compressor 61. The hydrogen from the supplementary hydrogen compressor 61 first passes through the first reaction unit 1 to carry out catalytic hydrogenation reaction with the raw material oil, and the remaining hydrogen enters the first cold high-resolution unit 3 for gas-liquid separation as the second reaction The supplementary hydrogen of unit 2 and the circulating hydrogen of the second cold high-resolution unit 4 are combined and processed by the hydrogen circulation unit 5, and then enter the second reaction unit 2 to carry out catalytic hydrogenation reaction with the raw m...

Embodiment 3

[0043] Such as Figure 4 As shown in the figure, a hydrogenation unit hydrogen combined optimal utilization process, when the hydrogen supply capacity of the first supplementary hydrogen unit 61 is greater than the hydrogen consumption of the first reaction unit 2, the first supplementary hydrogen unit 61 is divided into the first reaction unit 1 In addition to supplying hydrogen, hydrogen is also supplied to the second reaction unit 2 . The excess hydrogen from the first supplementary hydrogen unit 61 first passes through the first reaction unit 1 to carry out catalytic hydrogenation reaction with the raw material oil. After the reaction, the remaining hydrogen enters the first cold high-separation unit 3 for gas-liquid separation and then is separated with the second cold high-separation unit 3. The circulating hydrogen in unit 2 is processed by the hydrogen circulation unit and enters the second reaction unit 2 together with the hydrogen from the first supplementary hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com