Patents

Literature

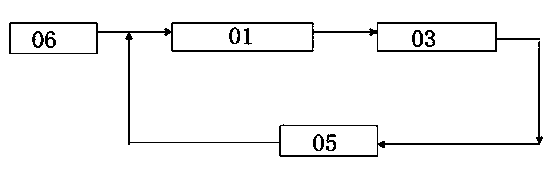

77 results about "Hydrogen cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The hydrogen cycle consists of hydrogen exchanges between biotic (living) and abiotic (non-living) sources and sinks of hydrogen-containing compounds. Hydrogen (H) is the most abundant element in the universe. On Earth, common H-containing inorganic molecules include water (H₂O), hydrogen gas (H₂), methane (CH₄), hydrogen sulfide (H₂S), and ammonia (NH₃). Many organic compounds also contain H atoms, such as hydrocarbons and organic matter. Given the ubiquity of hydrogen atoms in inorganic and organic chemical compounds, the hydrogen cycle is focused on molecular hydrogen, H₂.

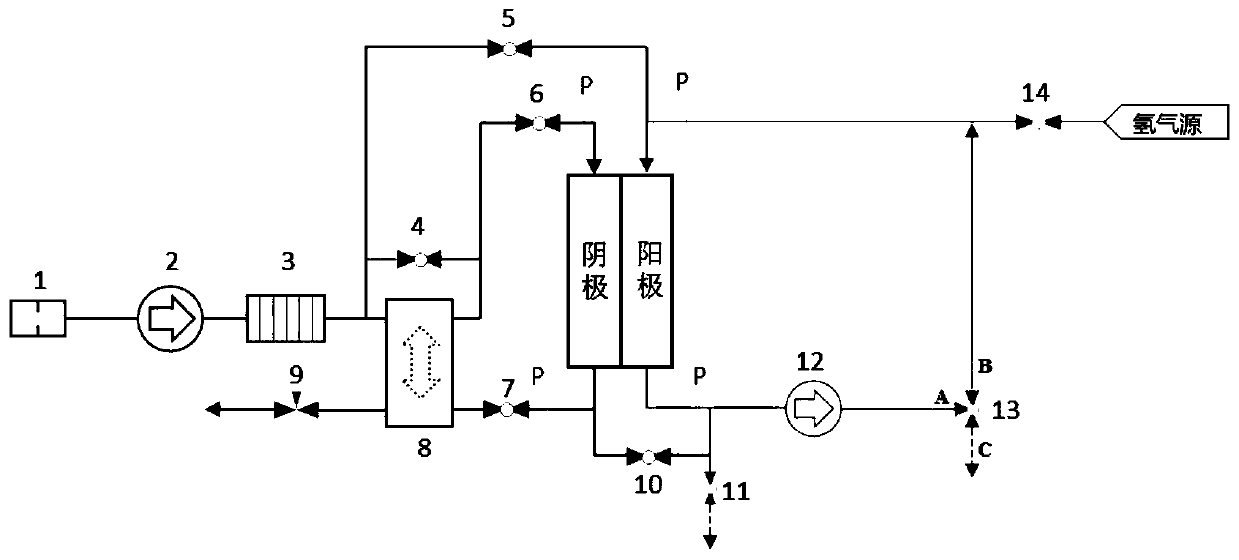

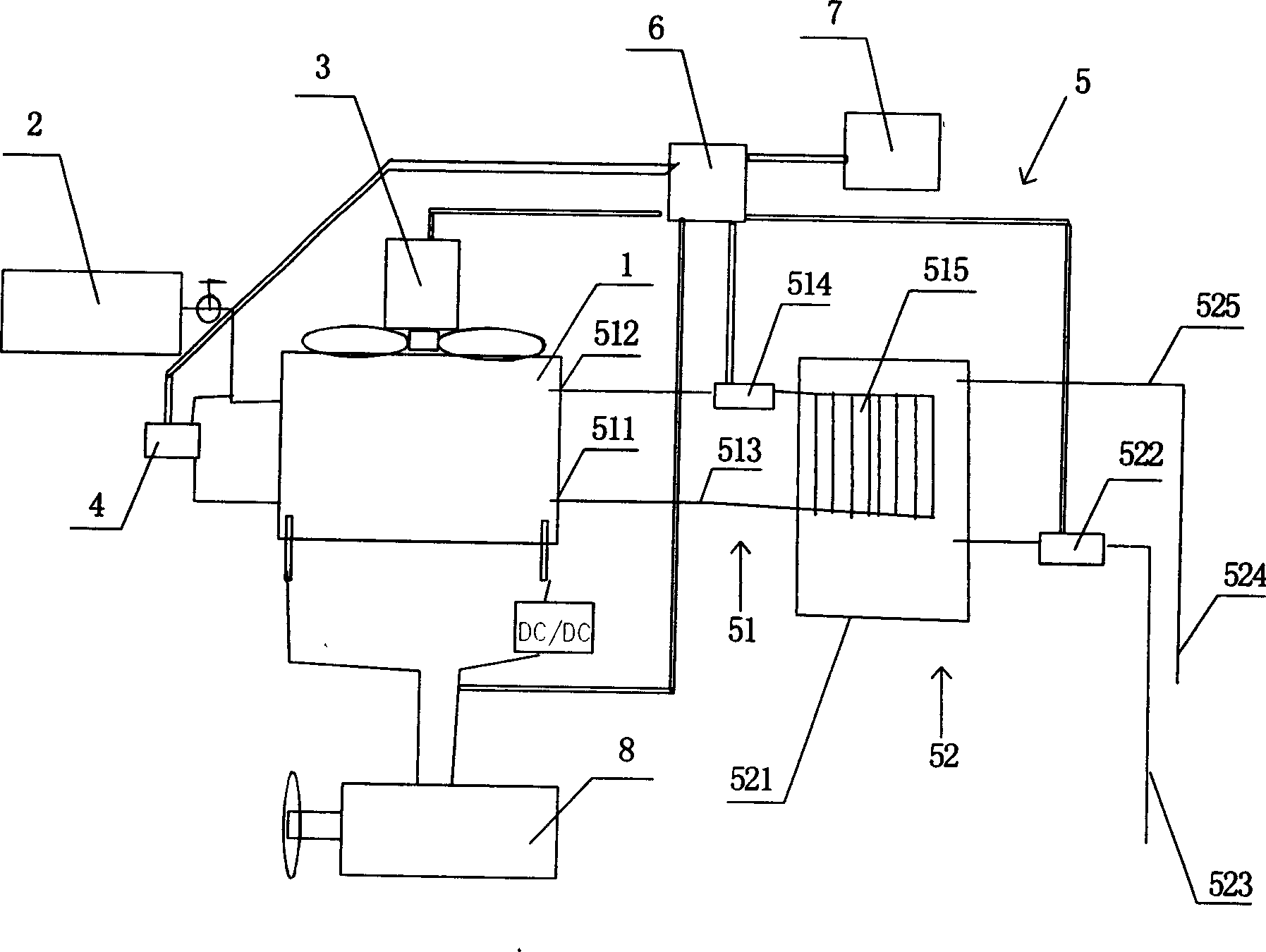

Fuel cell engine purging system and control method thereof

The invention discloses a fuel cell engine purging system and a control method thereof. The fuel cell engine purging system is mainly composed of an air filter, an air compressor, an intercooler, a humidifier bypass valve, an anode purging shut-off valve, an electric pile air inlet shut-off valve, an electric pile air outlet shut-off valve, an air humidifier, a back pressure valve, a vacuum shut-off valve, a hydrogen tail exhaust valve, a hydrogen cycle pump, a three-way steering valve and a hydrogen inlet shut-off valve. The residual water can be fully removed in a short time with low energyconsumption.

Owner:佛山市清极能源科技有限公司

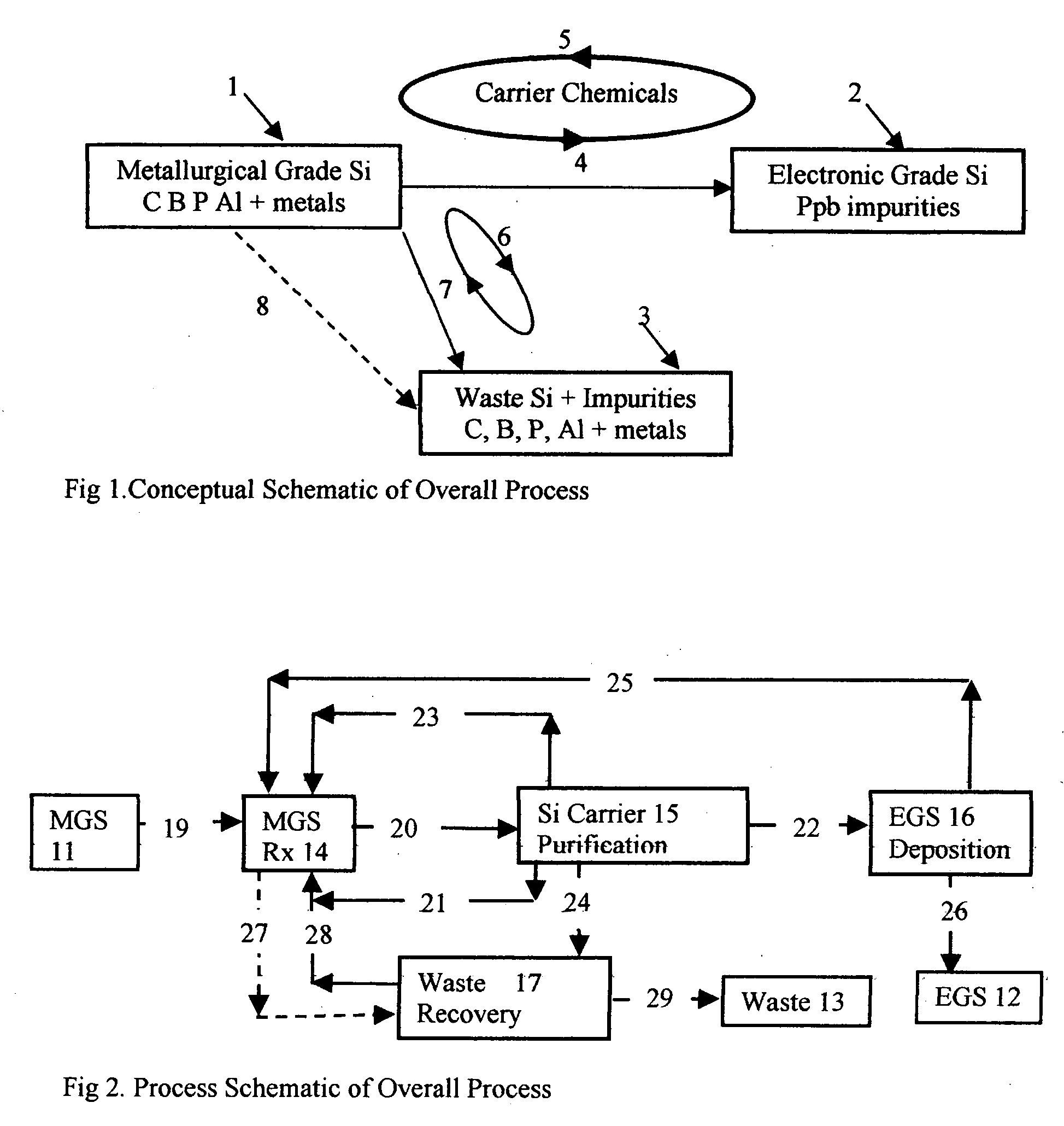

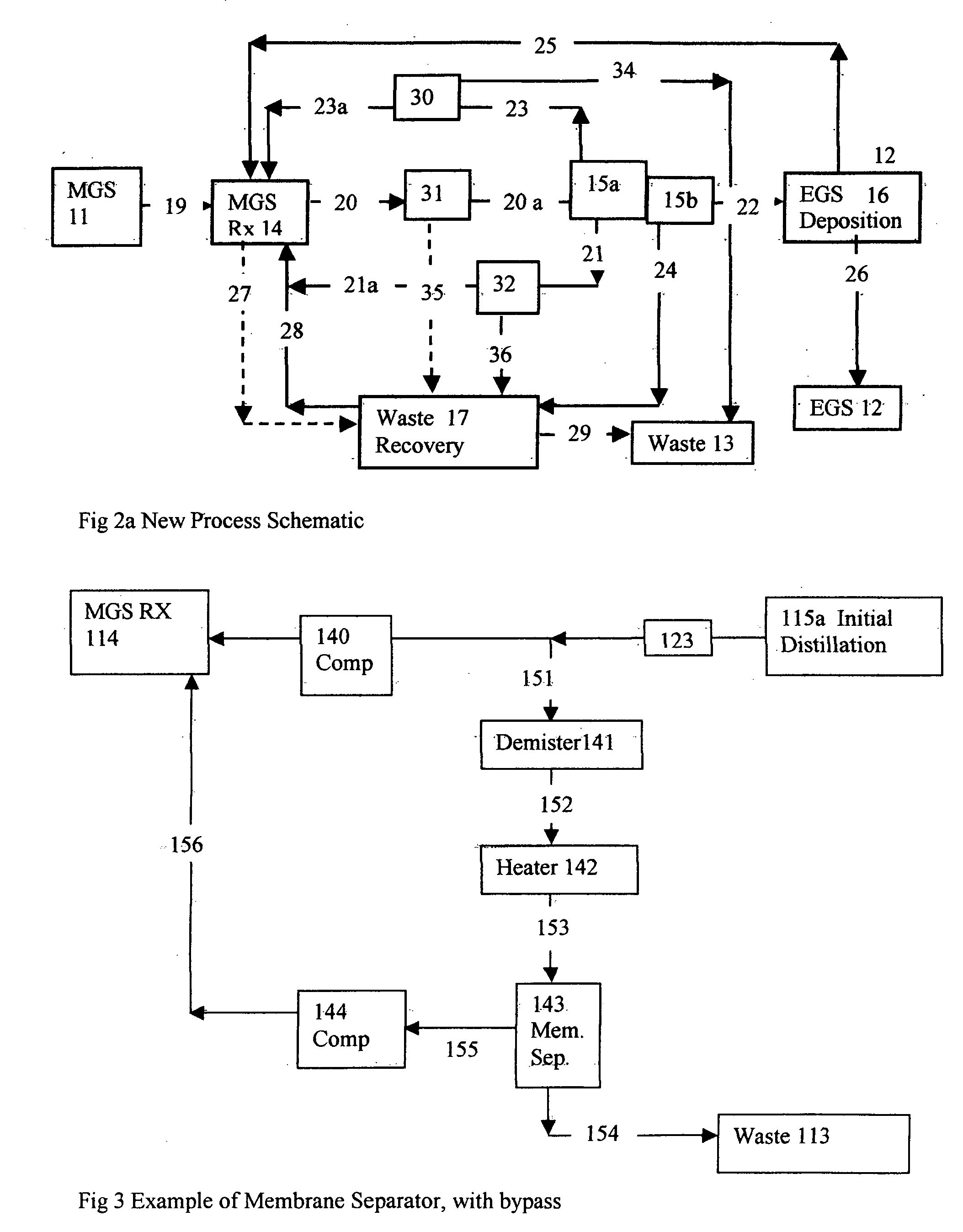

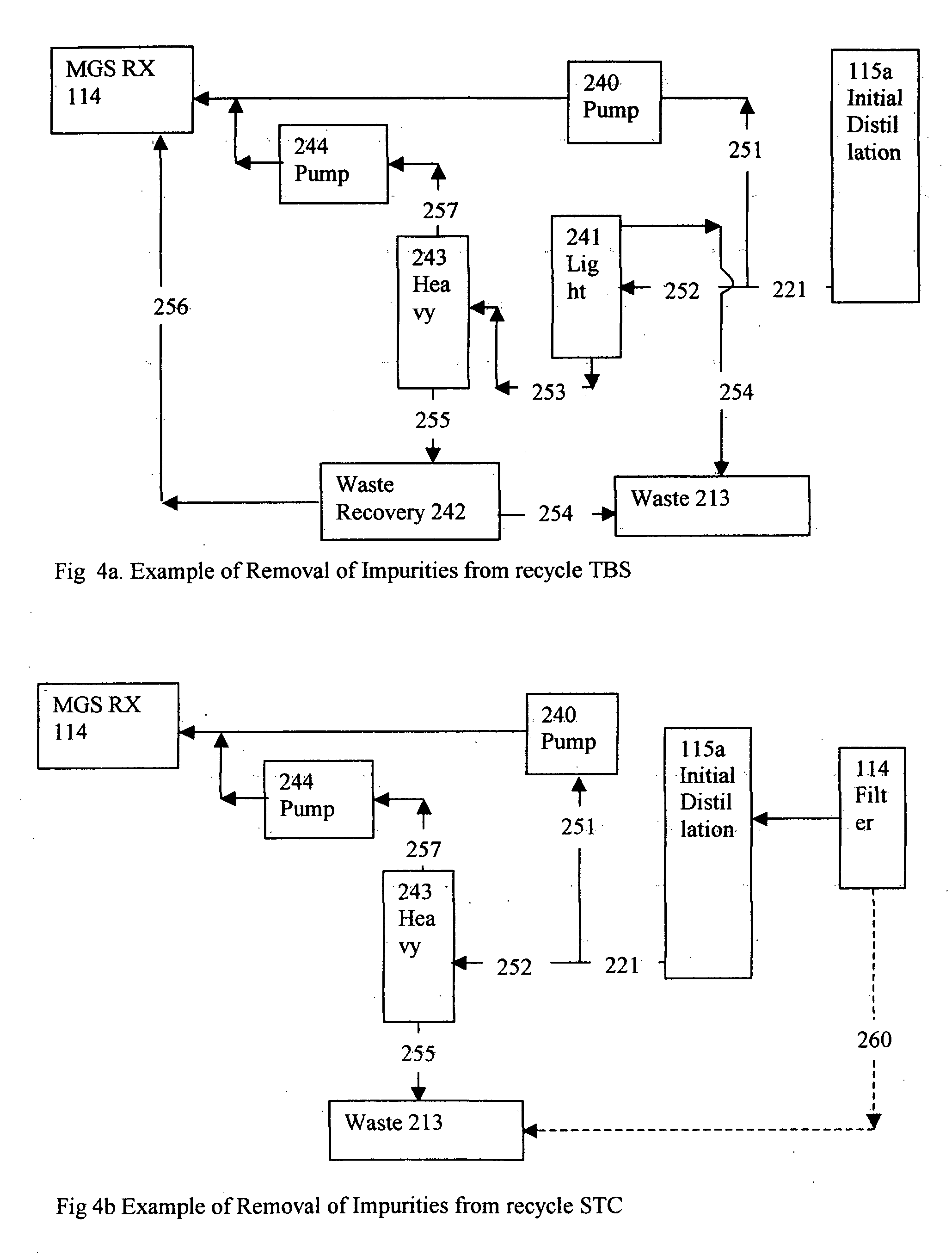

Set of processes for removing impurities from a silcon production facility

A set of three low cost processes for removing boron, phosphorus, carbon and other metal and nonmetal impurities during the process of converting metallurgical grade silicon to electronic grade silicon. One process removes boron by using one or more high temperature solids removal devices to remove solid titanium diboride from a halosilane reactor effluent stream where the high temperature is preferably greater than 200 C., more preferably greater than 300 C. and most preferably greater than 400 C. A second process removes carbon as methane and phosphorus as phosphine by means of a membrane separator which processes all or part of a hydrogen recycle stream to recover hydrogen while rejecting methane and phosphine. A third process separates a high boiling halosilane stream into a large low impurity stream and one or more small high impurity streams some of which can be sent for halogen recovery.

Owner:XSI INT A BRITISH VIRGIN ISLANDS +1

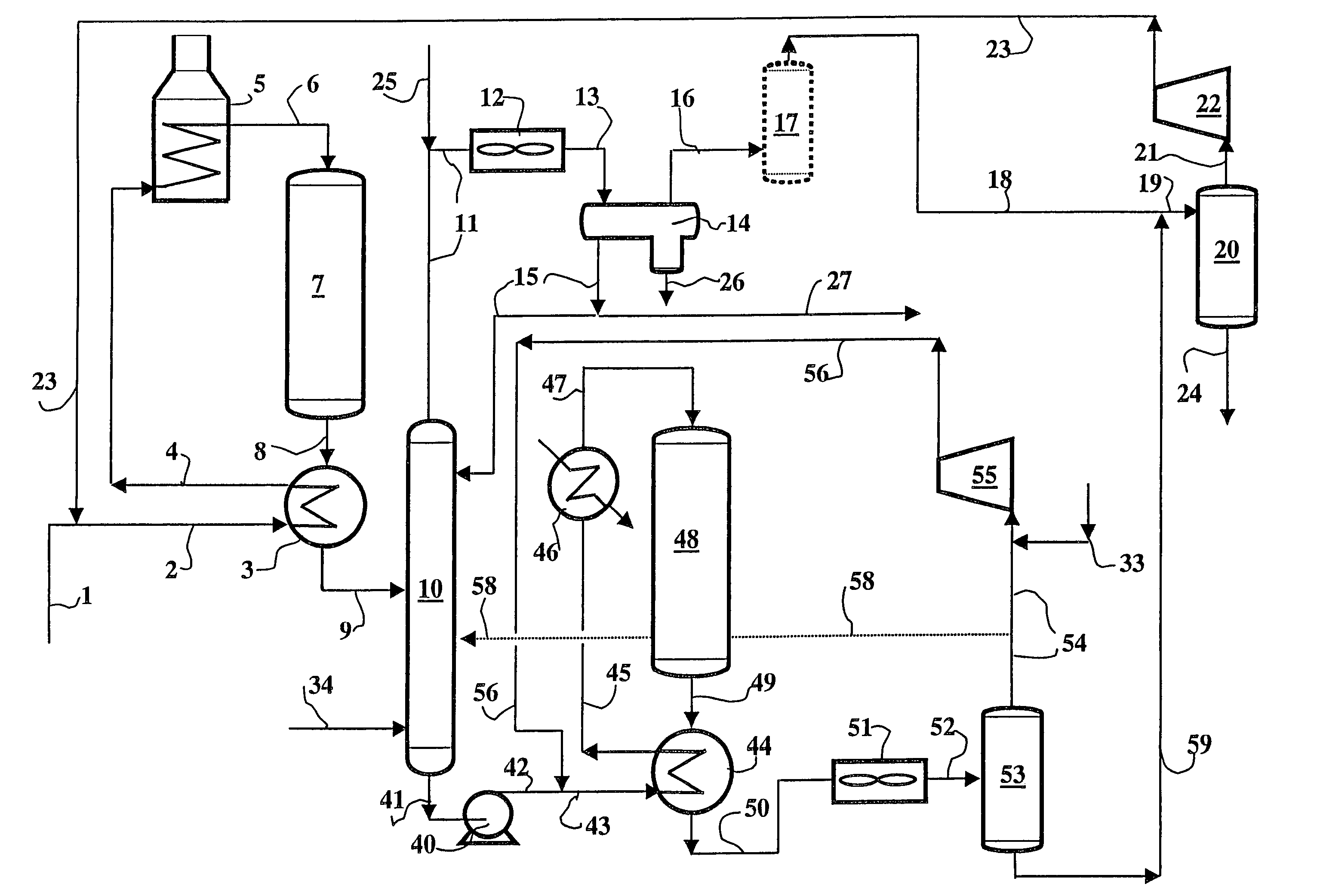

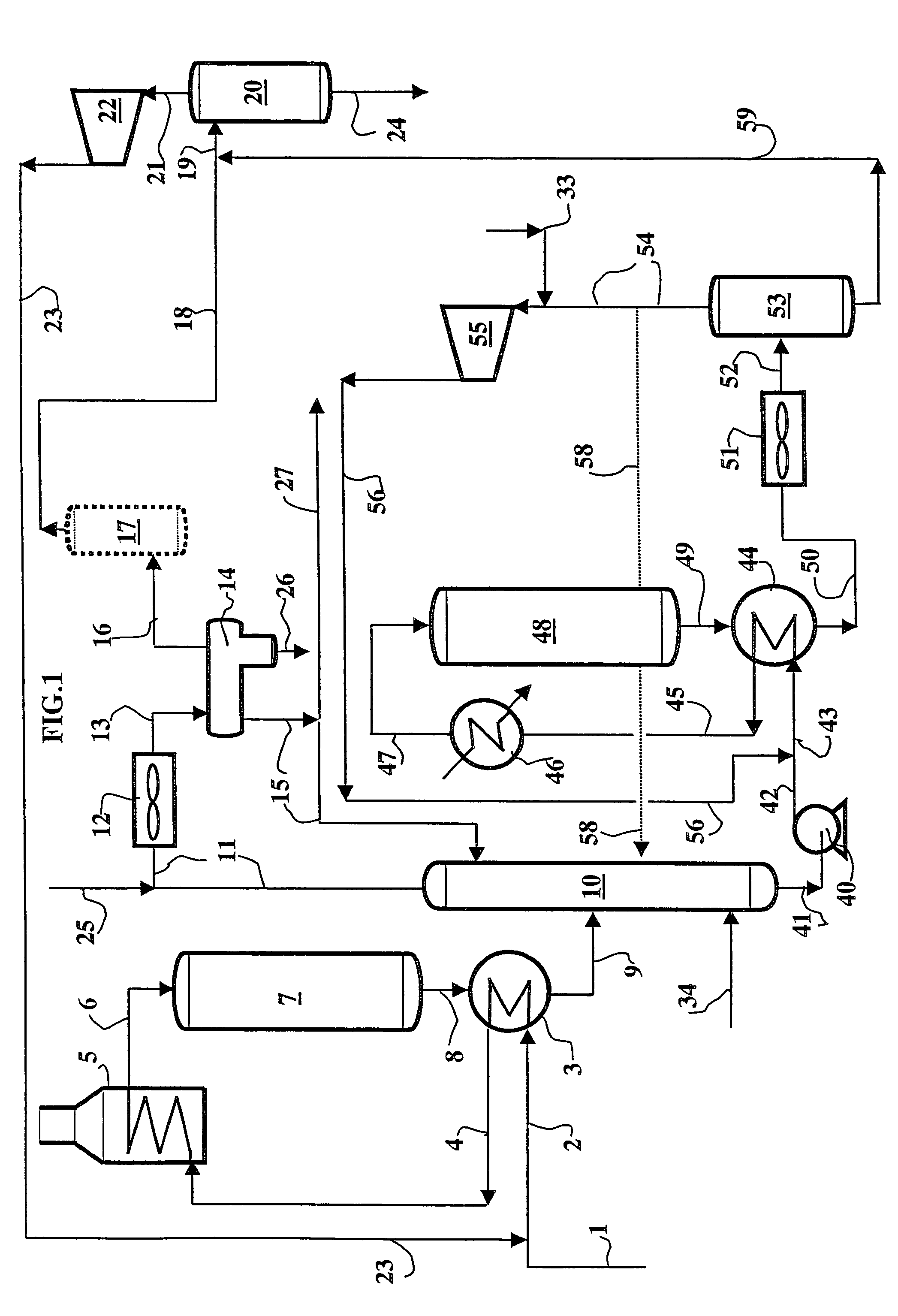

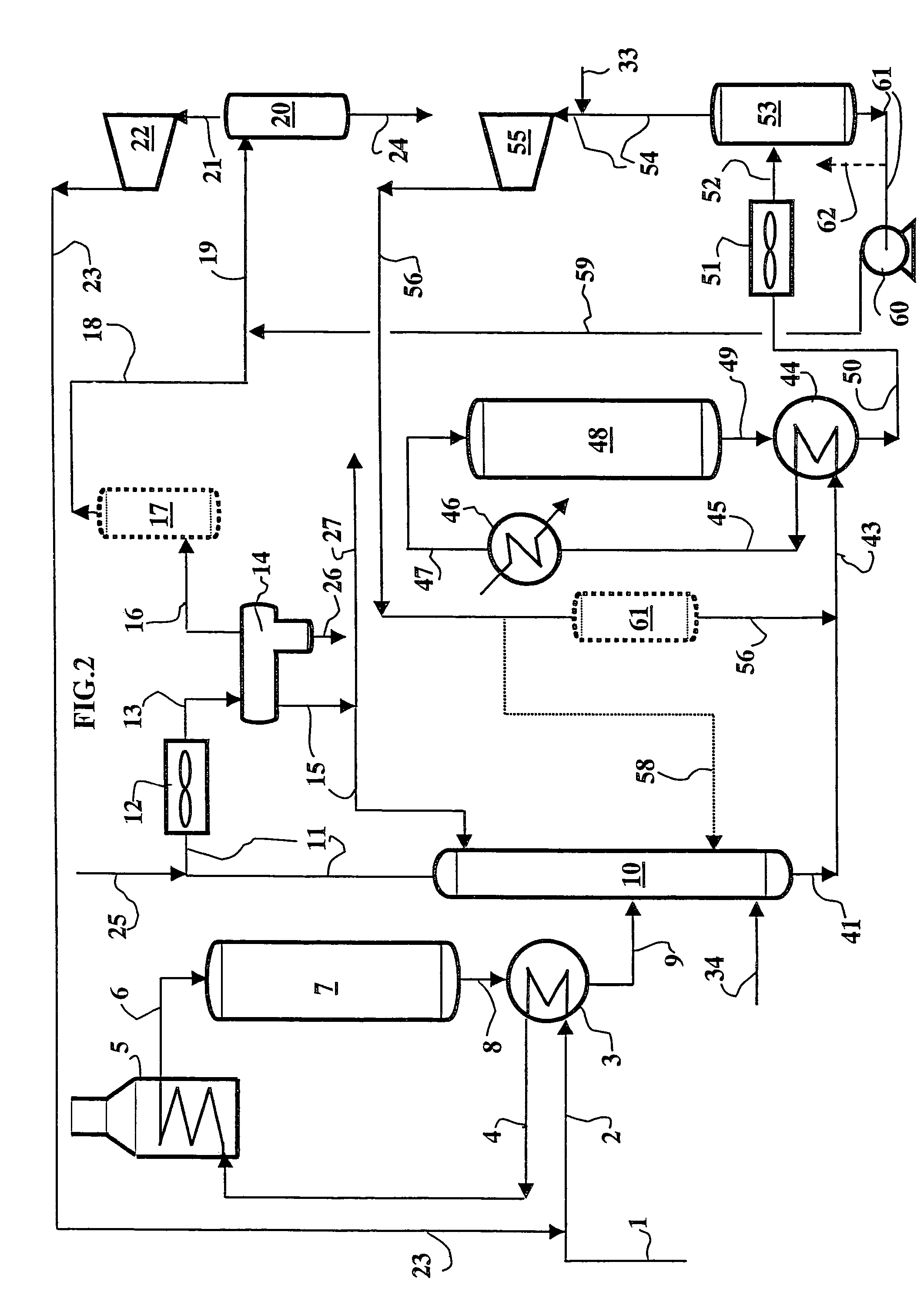

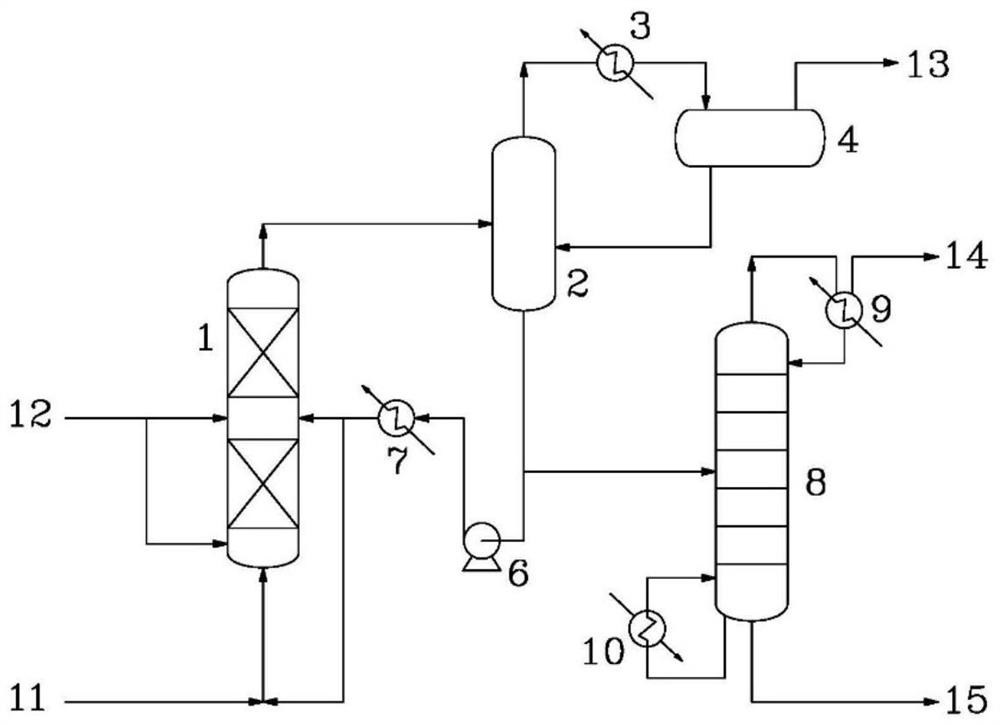

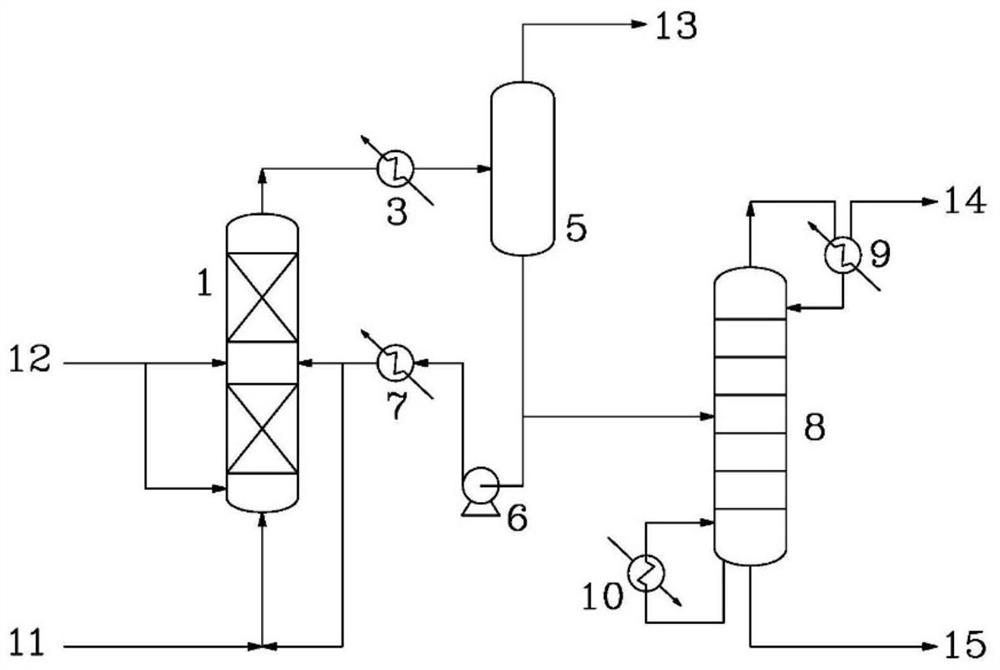

Two-step method for middle distillate hydrotreatment comprising two hydrogen recycling loops

InactiveUS7384540B2Lower levelImprove energy efficiencyTreatment with hydrotreatment processesRefining by aromatic hydrocarbon hydrogenationPtru catalystProcess engineering

A process for hydrotreating a hydrocarbon feed comprises at least two steps with intermediate stripping of the effluent from the first step with pressurized hydrogen substantially free of impurities which are undesirable for the catalyst for the second step, in particular to eliminate part of the H2S formed, each step being carried out with a hydrogen recycle loop that is exclusive to that step.

Owner:INST FR DU PETROLE

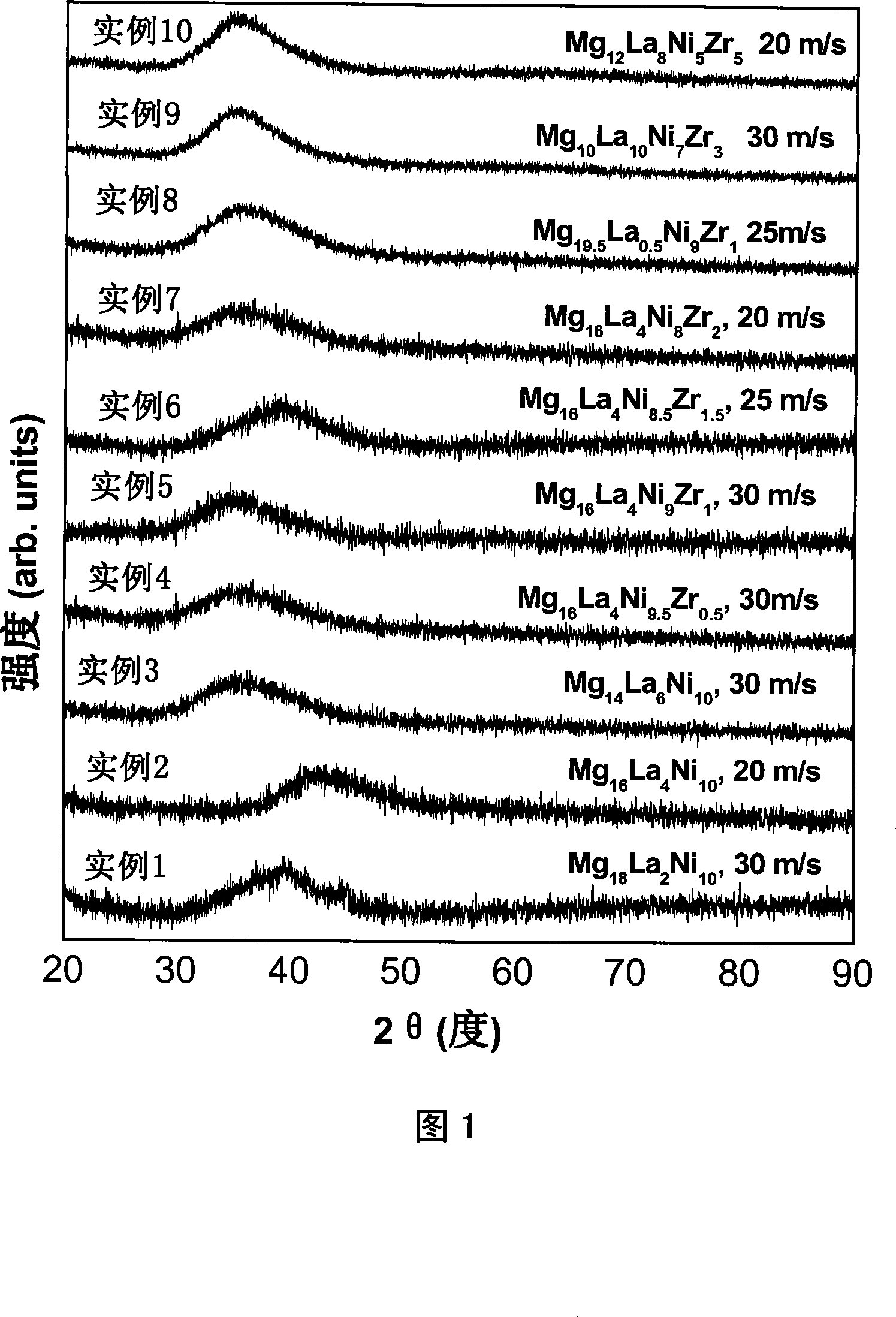

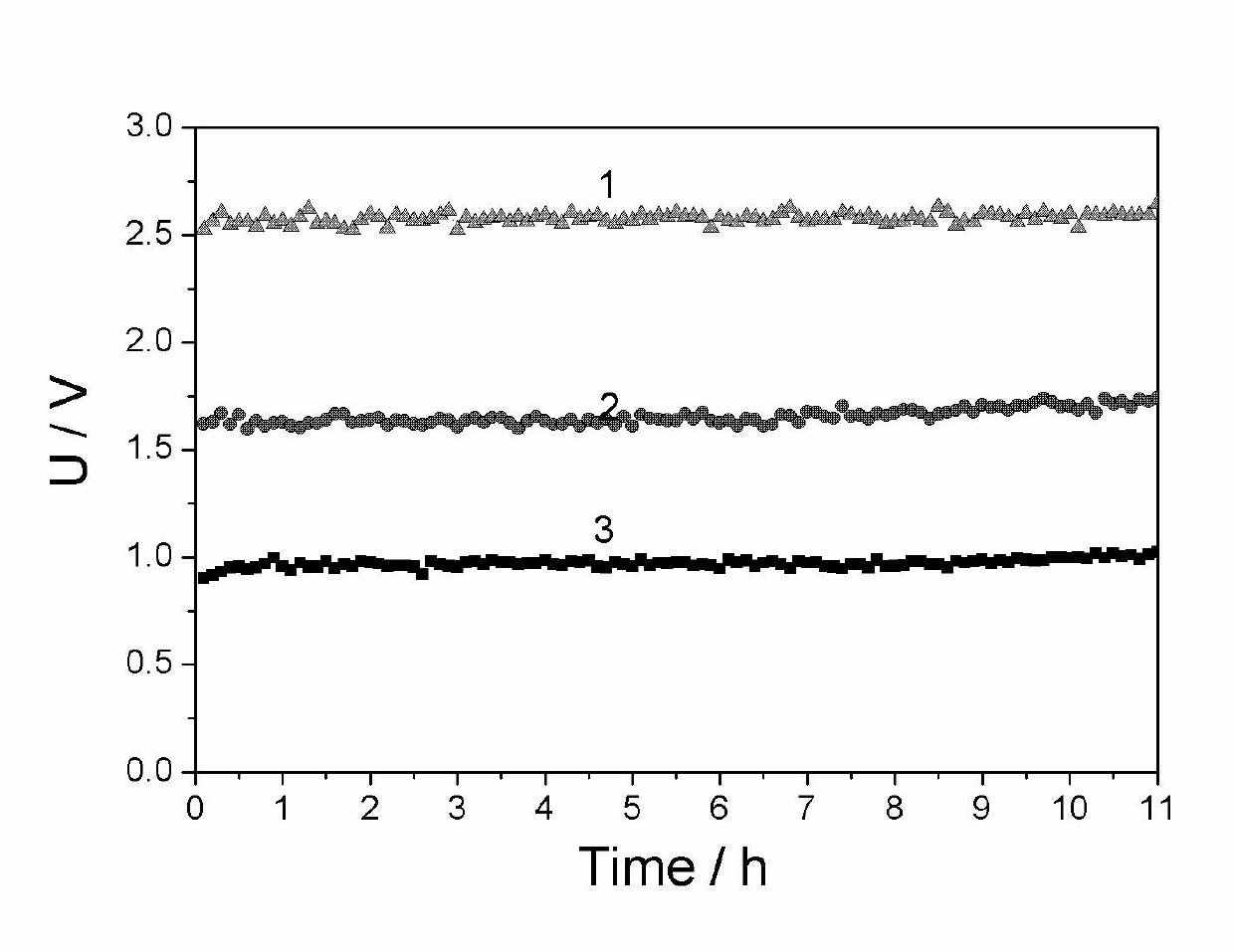

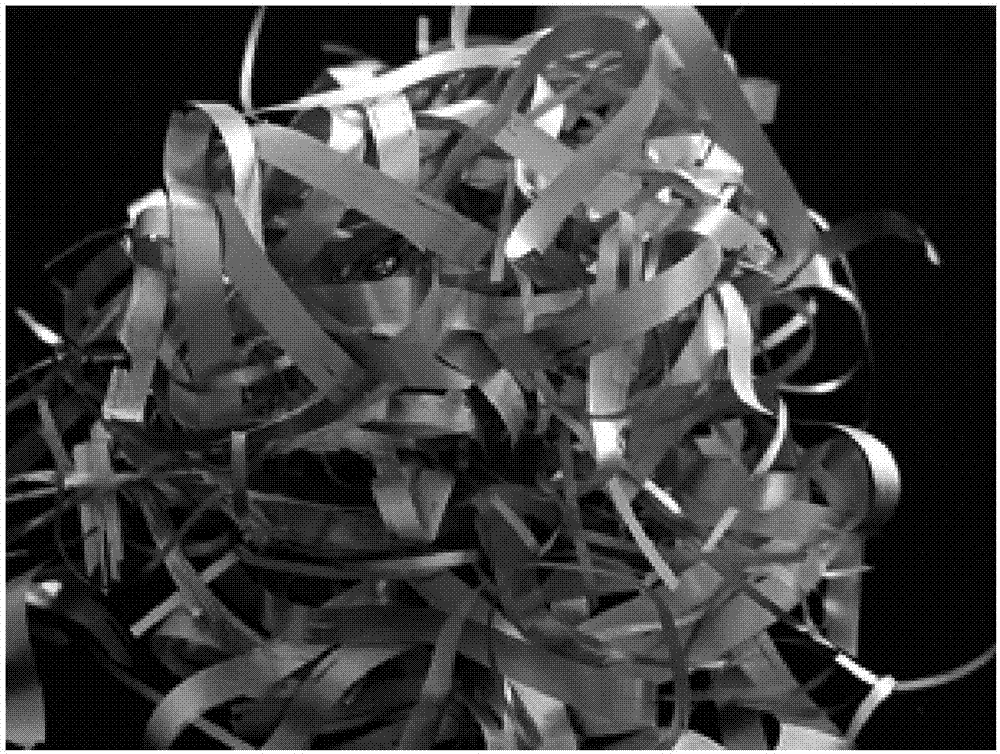

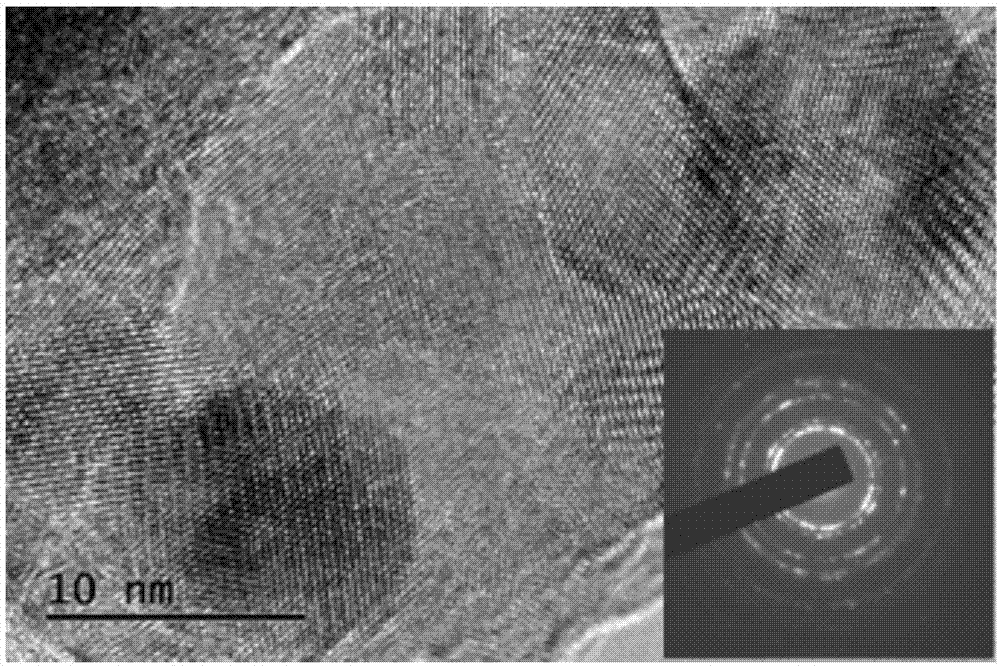

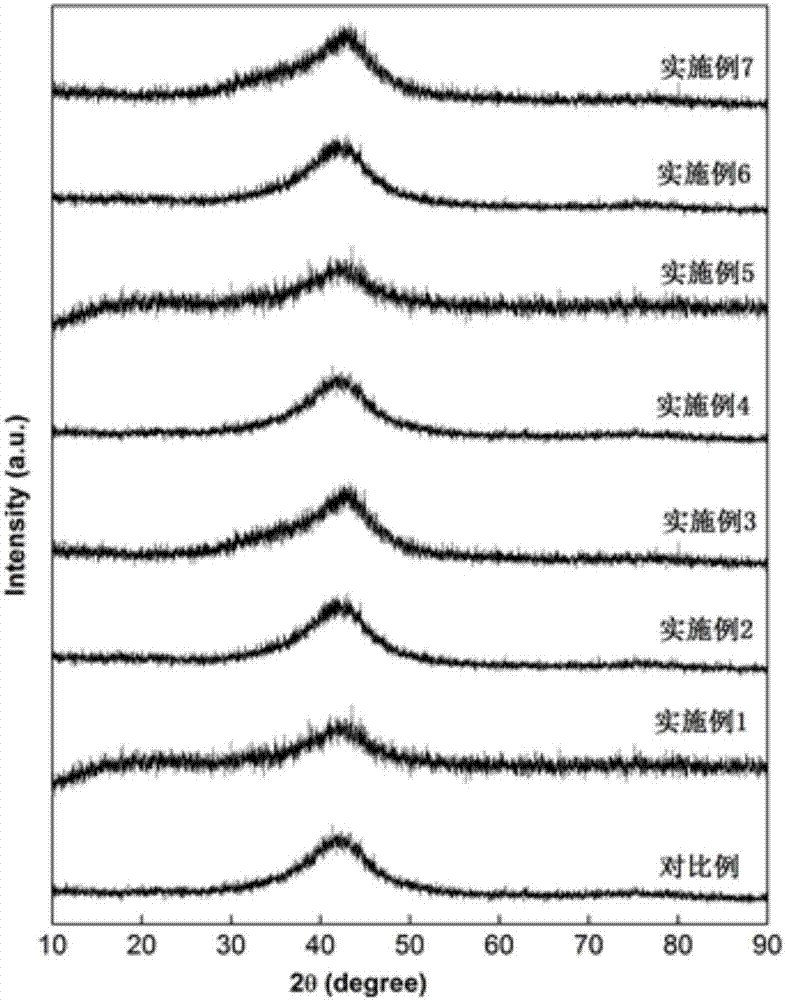

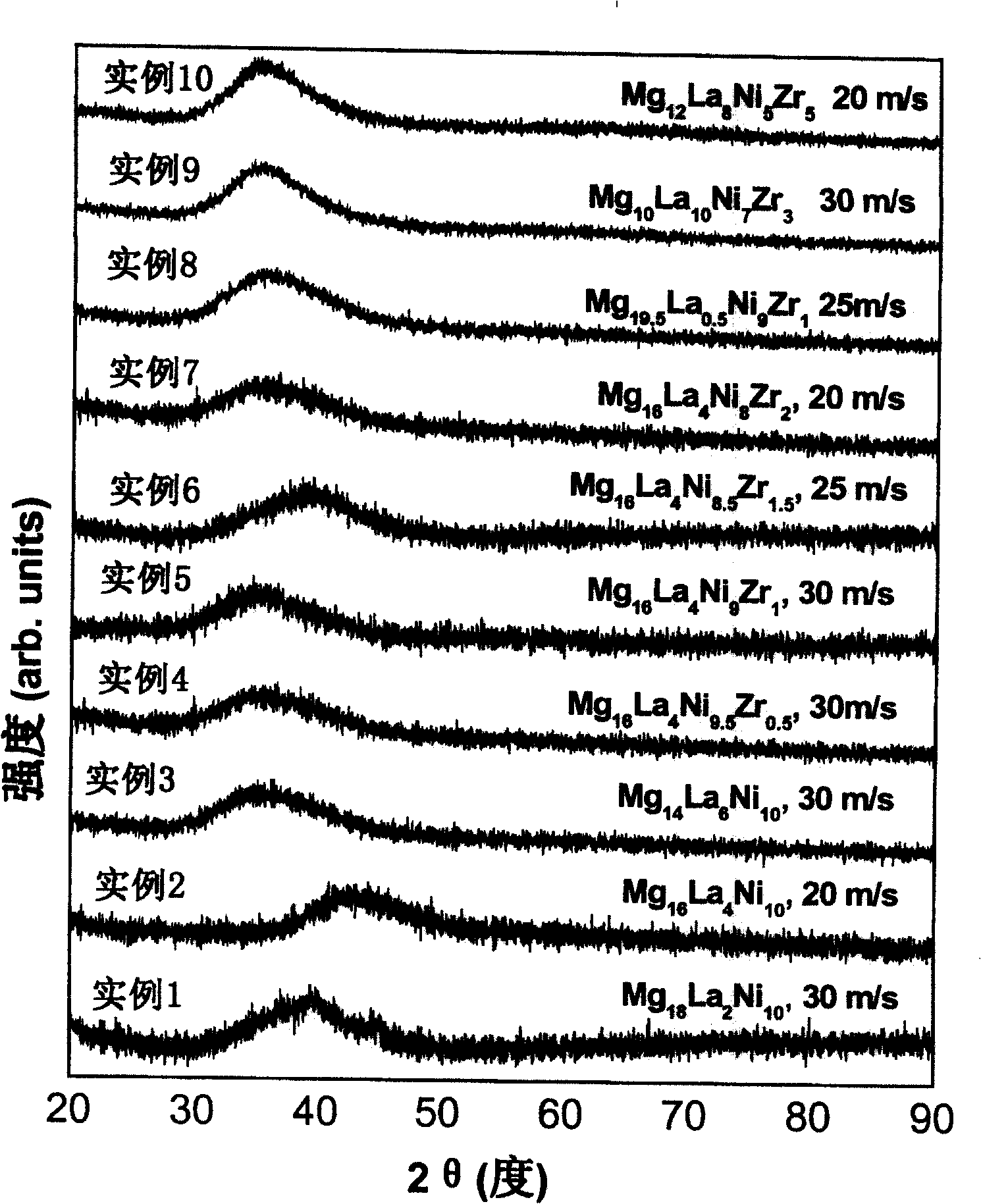

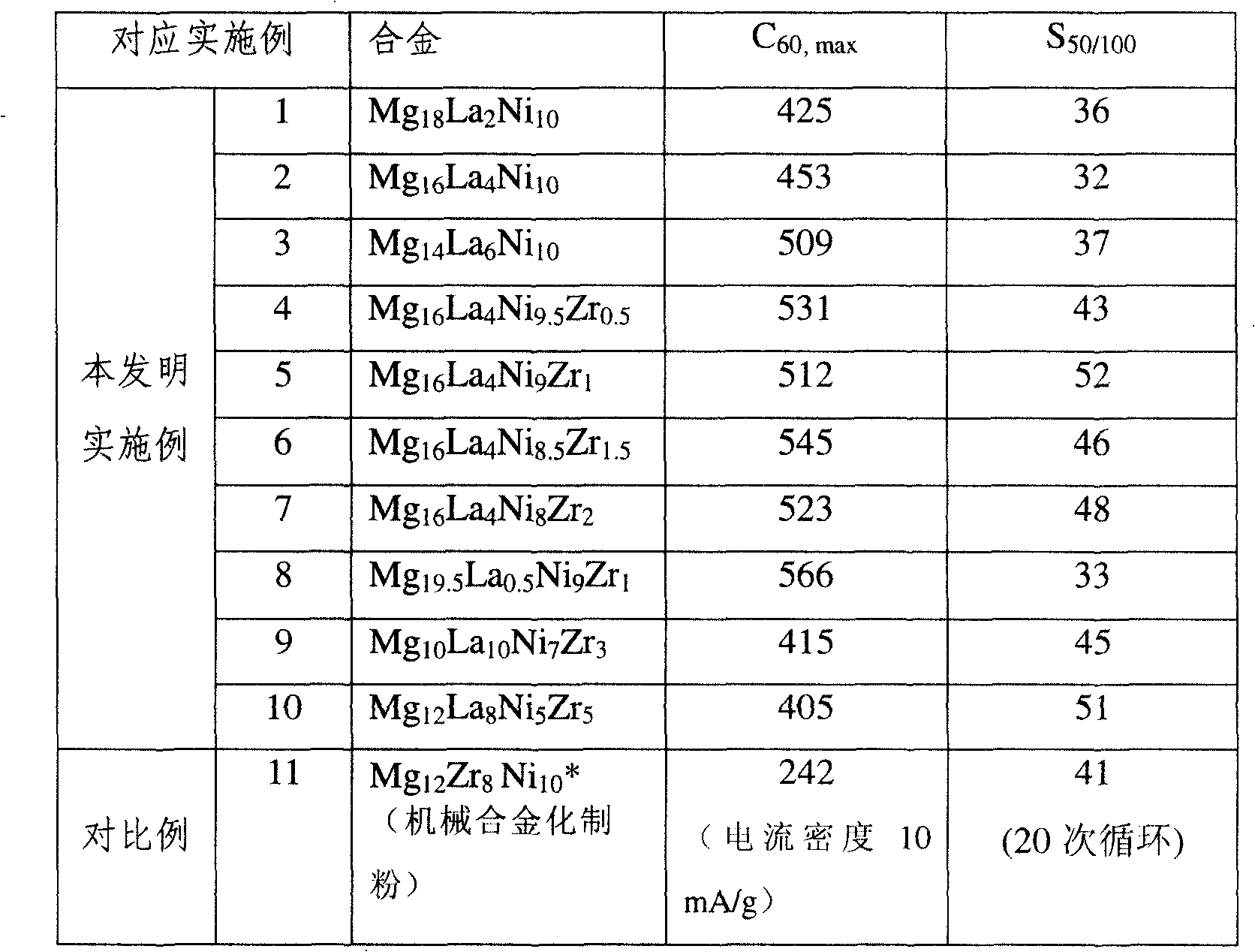

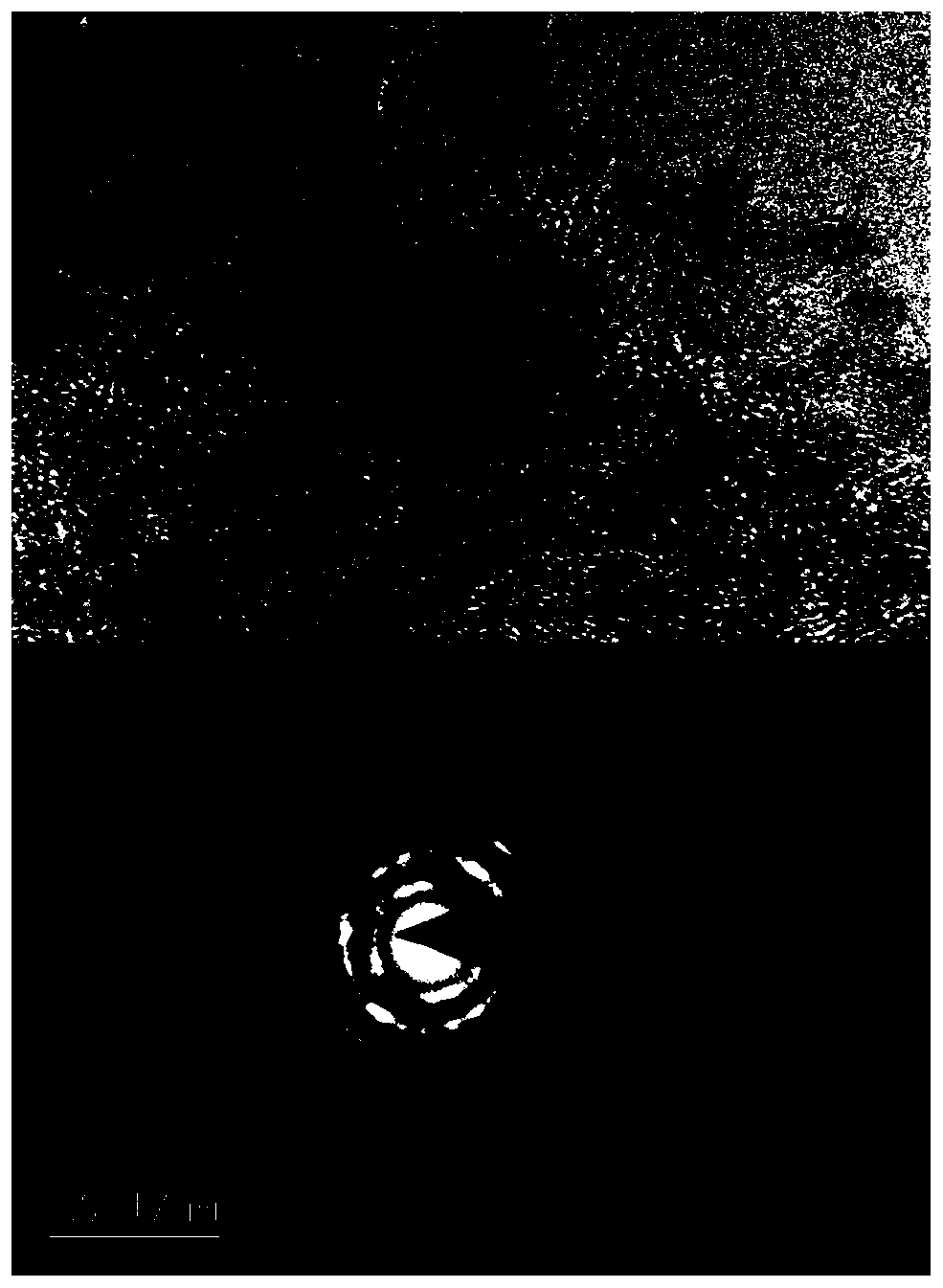

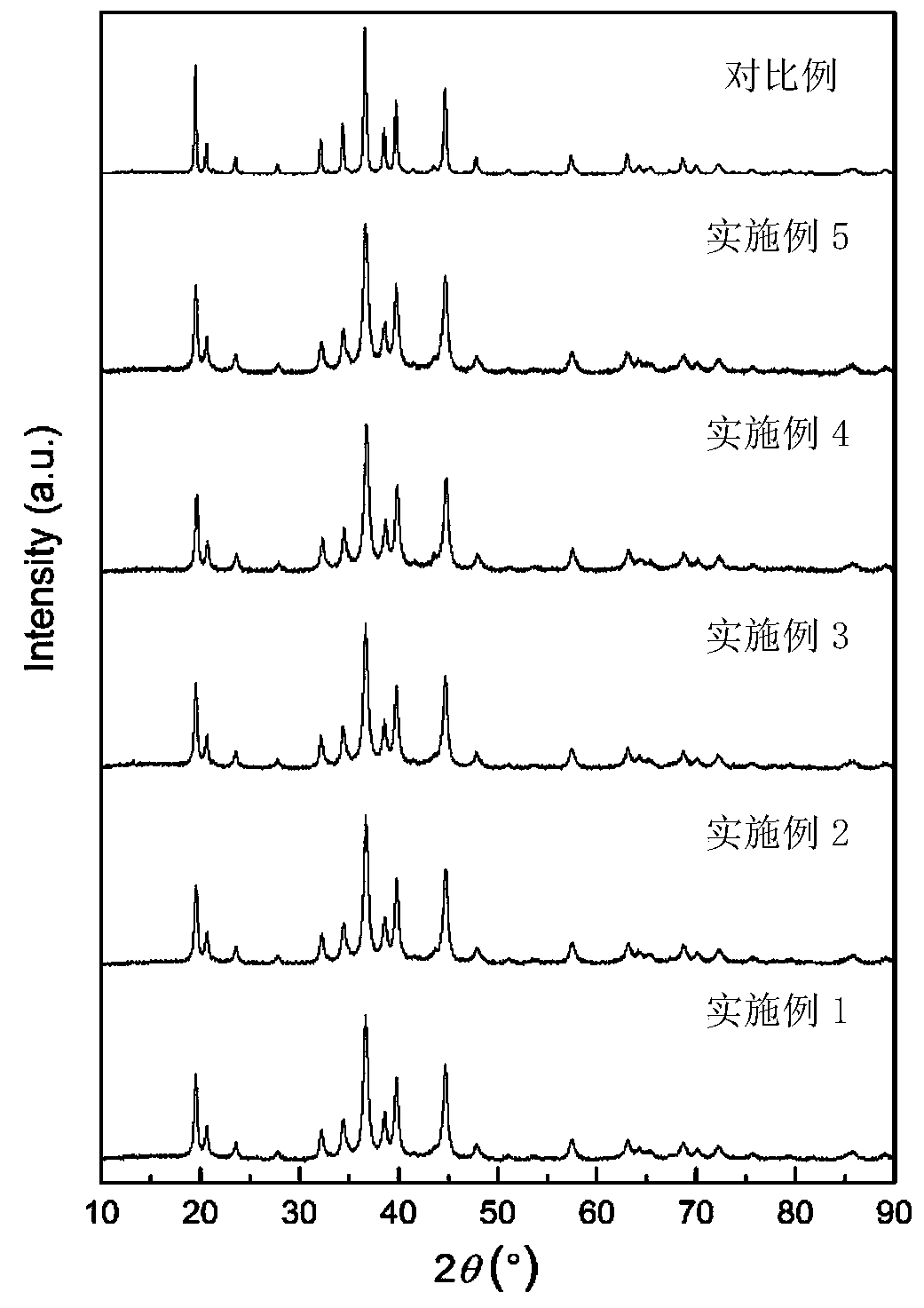

High capacity Mg2Ni-type hydrogen storing alloy amorphous band and preparation method thereof

ActiveCN101078094AHigh electrochemical capacityGood cycle hydrogen storage and discharge stabilityElectricityElectrochemistry

This patent belongs to hydrogen storage alloy technology field, and it provides a kind of Mg2Ni type hydrogen storage alloy amorphous zonal material and the method to prepare it. The chemical formula of this amorphous zonal material is Mg20-xLaxNi10-yZry. In the formula: 0.5<=x<=10, 0<=y<=5. The preparation method of the above amorphous zonal material is as following (1)To weigh material according to the chemical formula Mg20-xLaxNi10-yZry. (2) To melt the raw material, which has been weighed, and Mg20-xLaxNi10-yZry alloy can be obtained. (3) To make it into Mg2Ni type hydrogen storage alloy fast quenched thin strip, the thickness of which is between 20 and 35 mu m, and the breadth of which is between 1and 20mm, according to fast quenching blast strip technology. The Mg2Ni type hydrogen storage alloy amorphous zonal material in this patent owns high electrochemistry capability and favorable stability to season hydrogen cycle. The preparation technology is stable and easy to operate, the efficiency of it is high, and it is suitable to produce in batches, the thickness of the amorphous zonal material prepared by the method is uniform and the length of it is continuous.

Owner:CENT IRON & STEEL RES INST

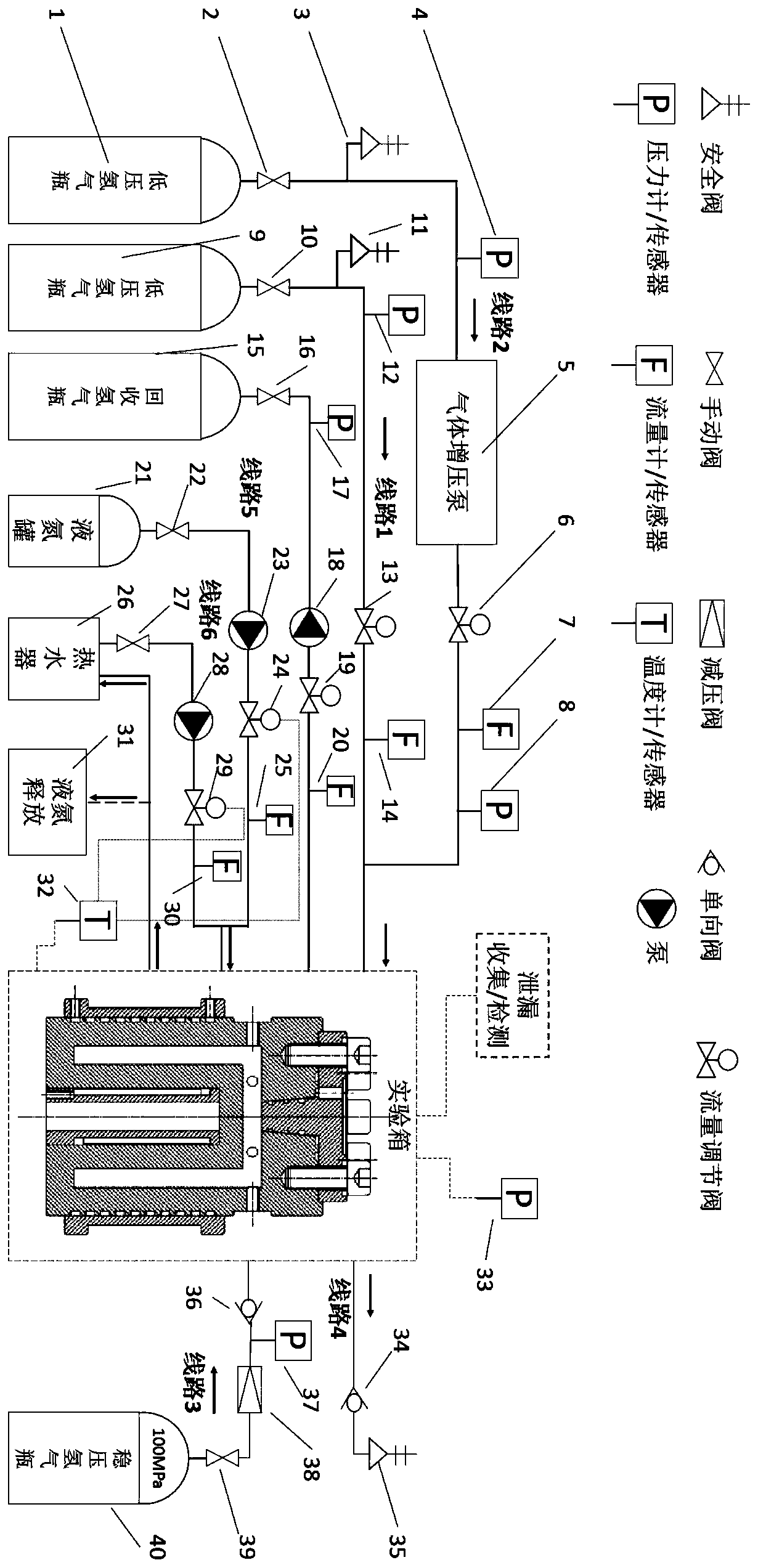

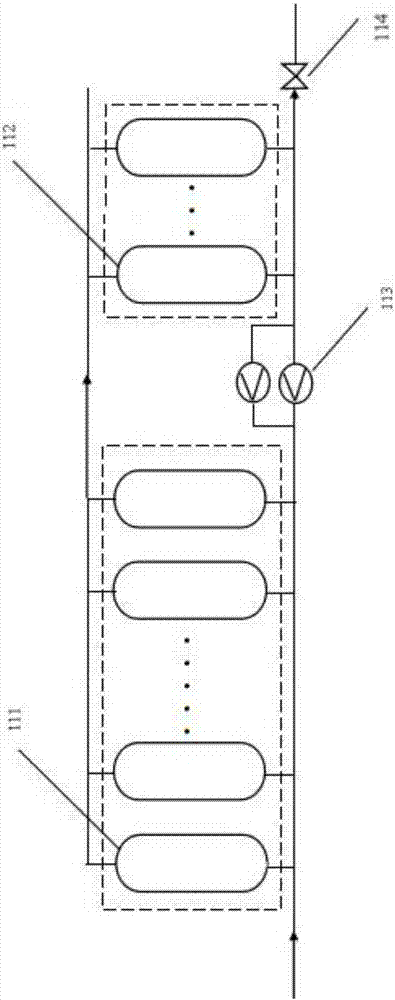

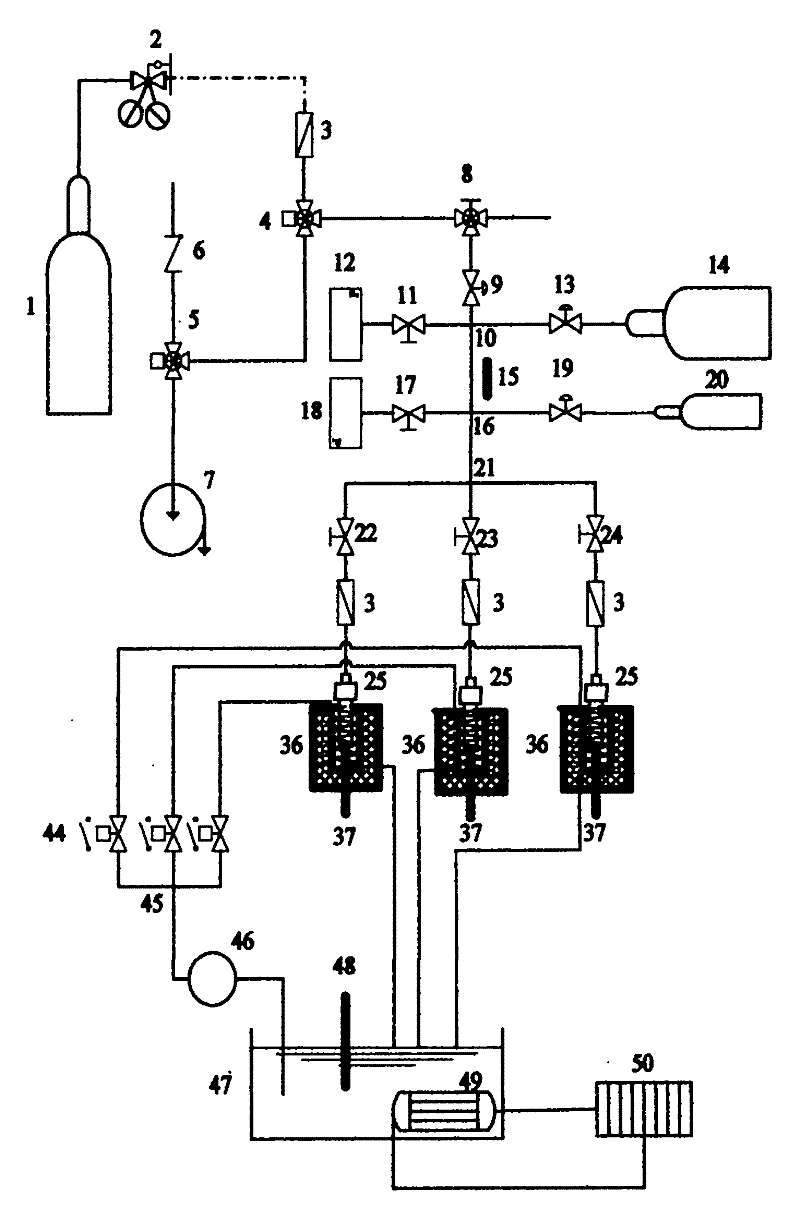

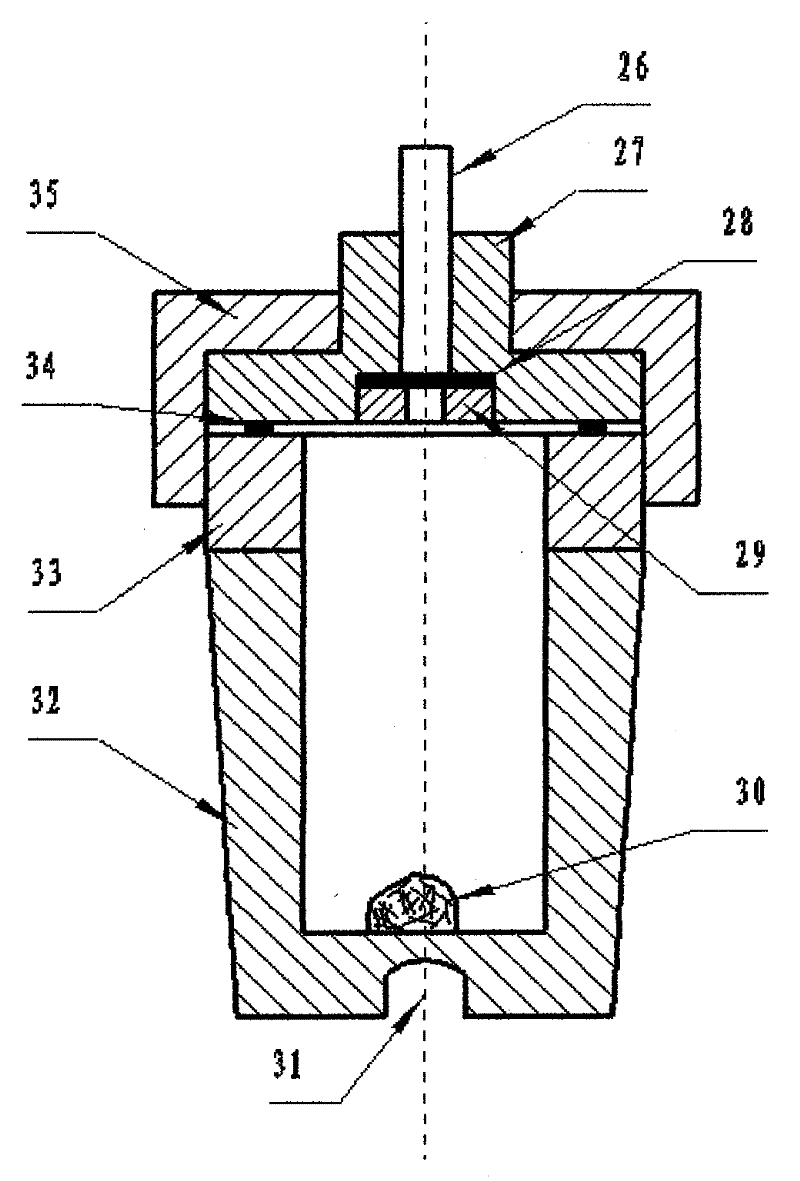

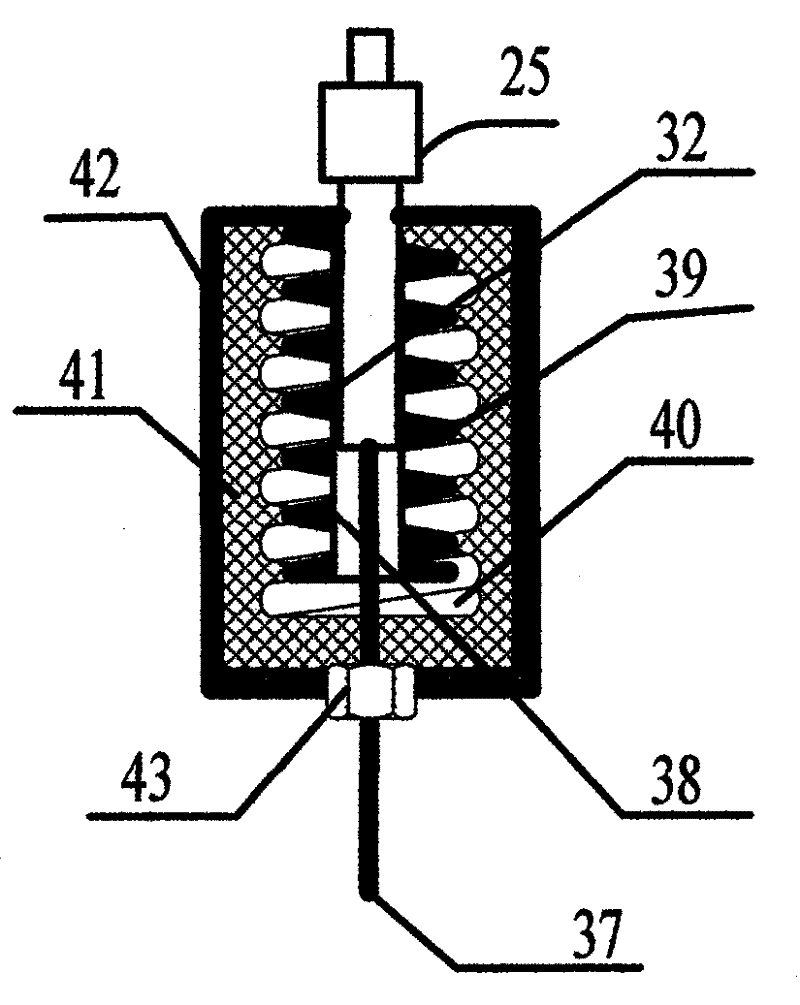

Metal hydride thermal adsorption and desorption hydrogen cycling comprehensive test device

InactiveCN101858841AAutomatic control is reliableThe control process is stable and reliableMaterial analysisDesorptionData acquisition

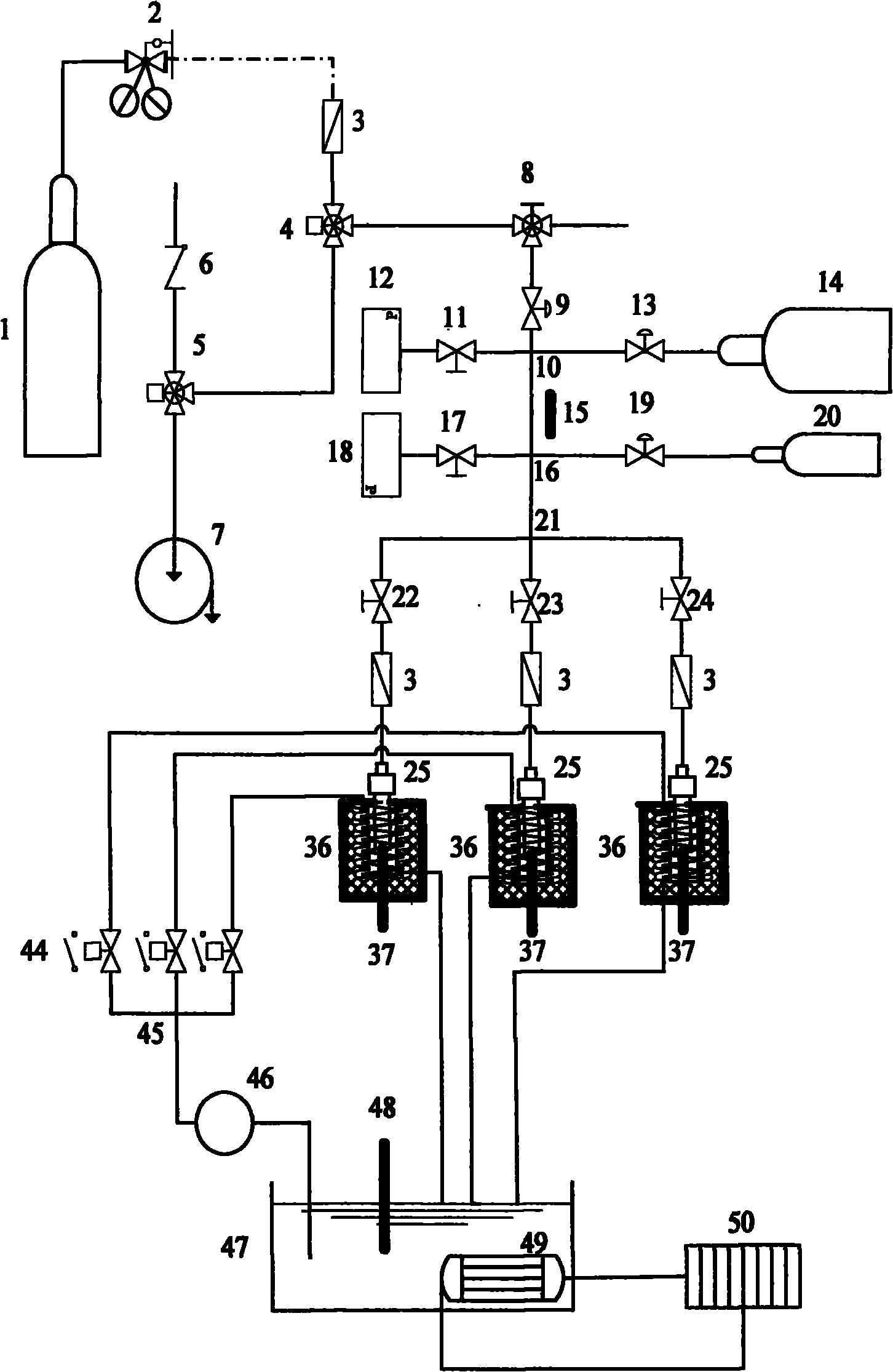

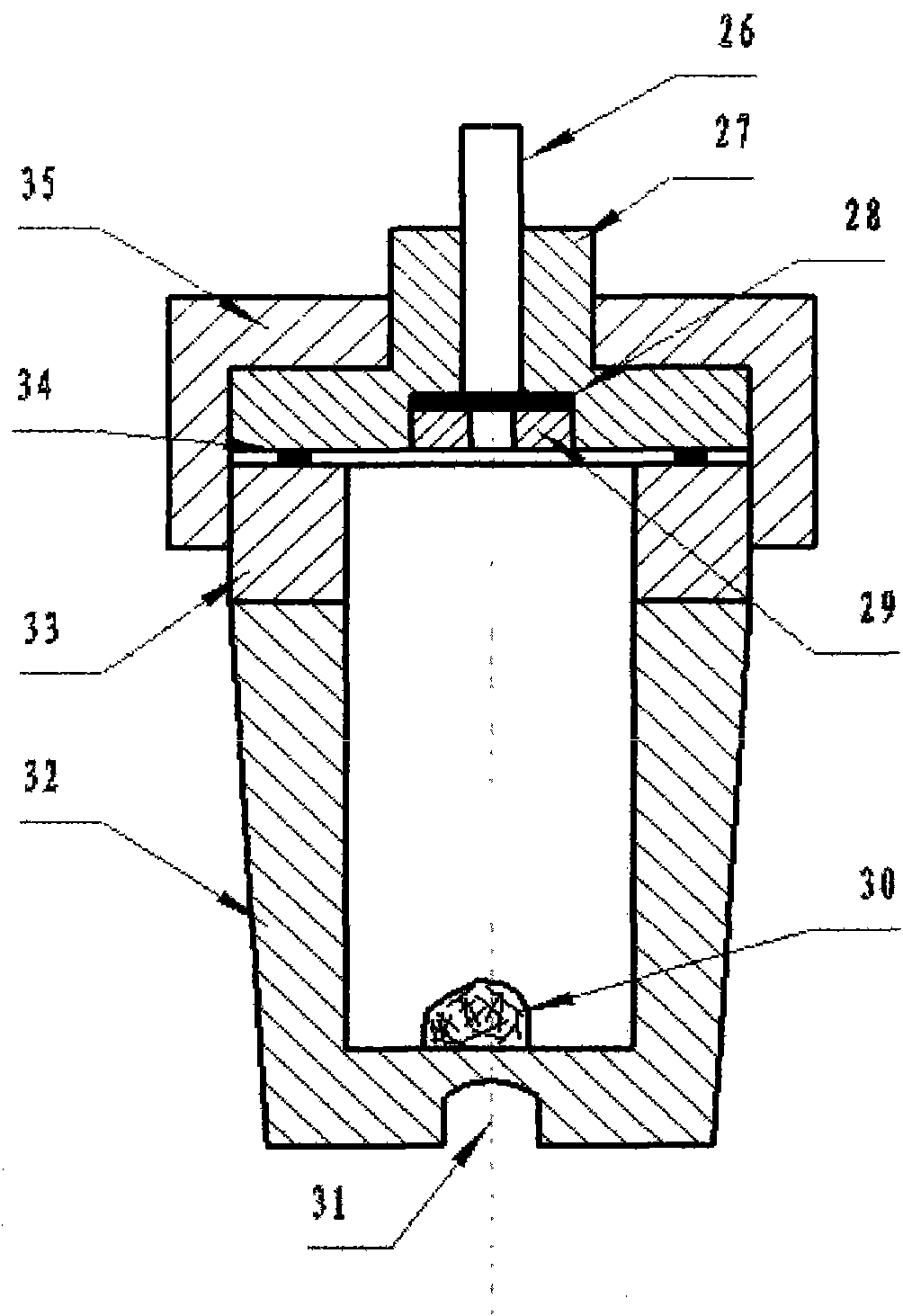

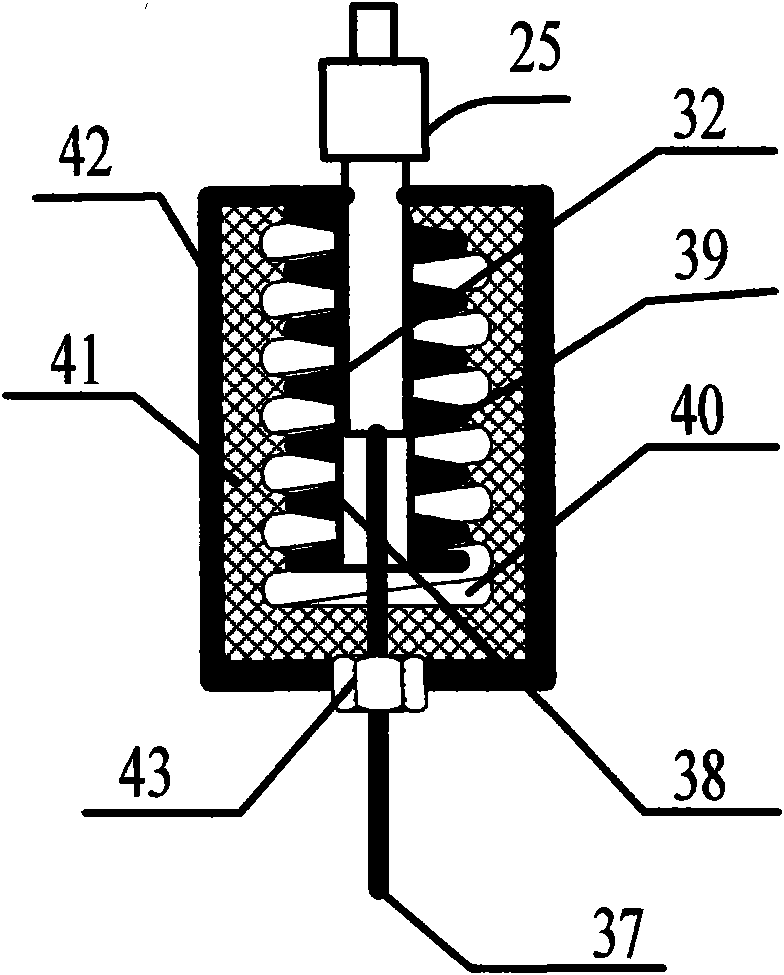

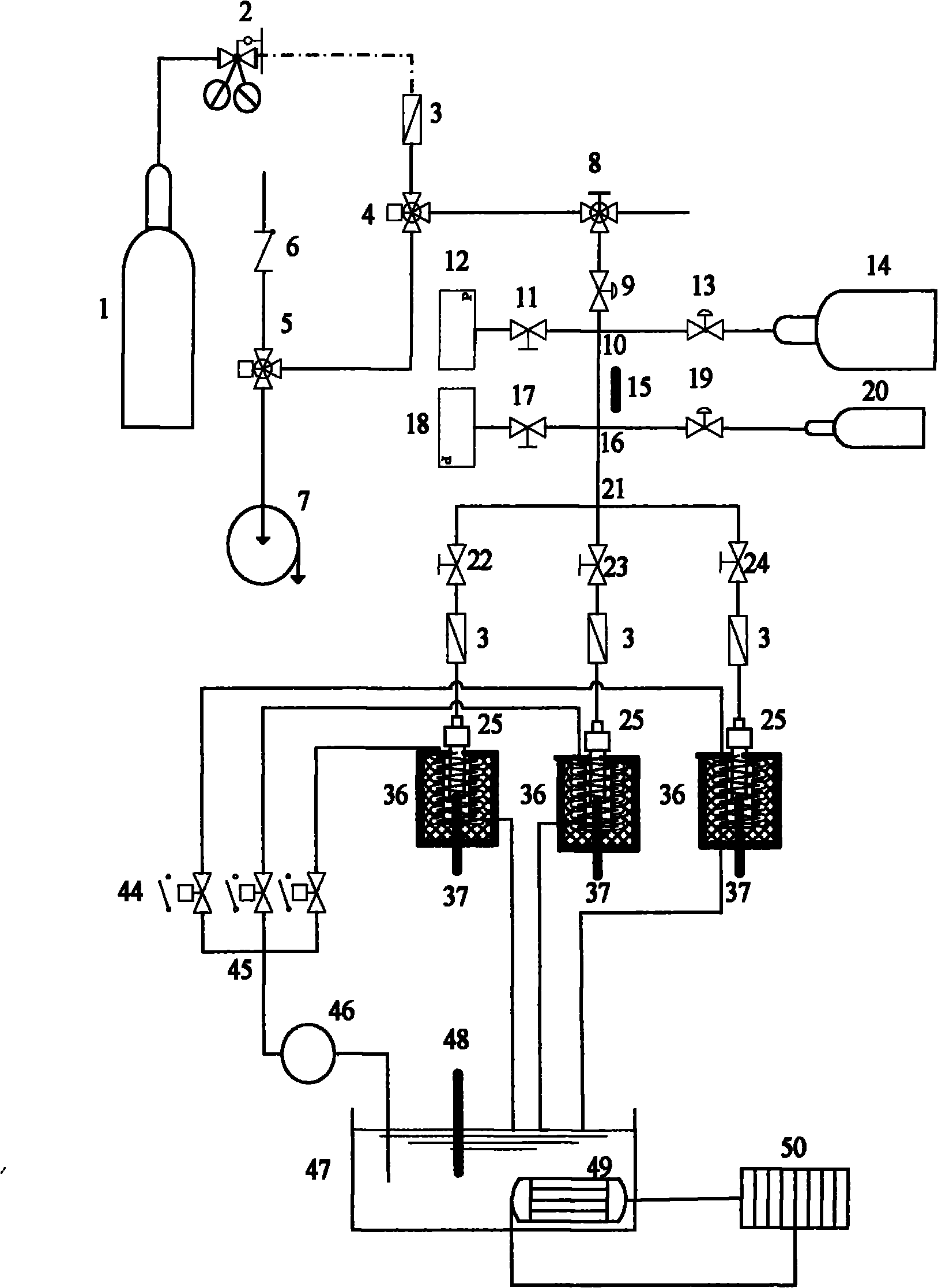

The invention discloses a metal hydride thermal adsorption and desorption hydrogen cycling comprehensive test device, which consists of a gas cycling system, a sample chamber heating and cooling system and a computer data collection and control system. The gas cycling system provides a vacuum environment and high-purity hydrogen source to the test system; the sample chamber heating and cooling system rapidly and circularly heats and cools the test sample; and the computer data collection and control system controls a heating and cooling program to run and controls the opening and closing of relevant electromagnetic valve and electric valve and instantly collect the pressure and temperature signal of the system. While completing the test of the cycle of the metal hydride thermal adsorption and desorption of hydrogen, the system also can test the alloy adsorption and desorption hydrogen performance such as PCT curve and dynamics curve and the constant-temperature adsorption and desorption hydrogen service life in situ.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

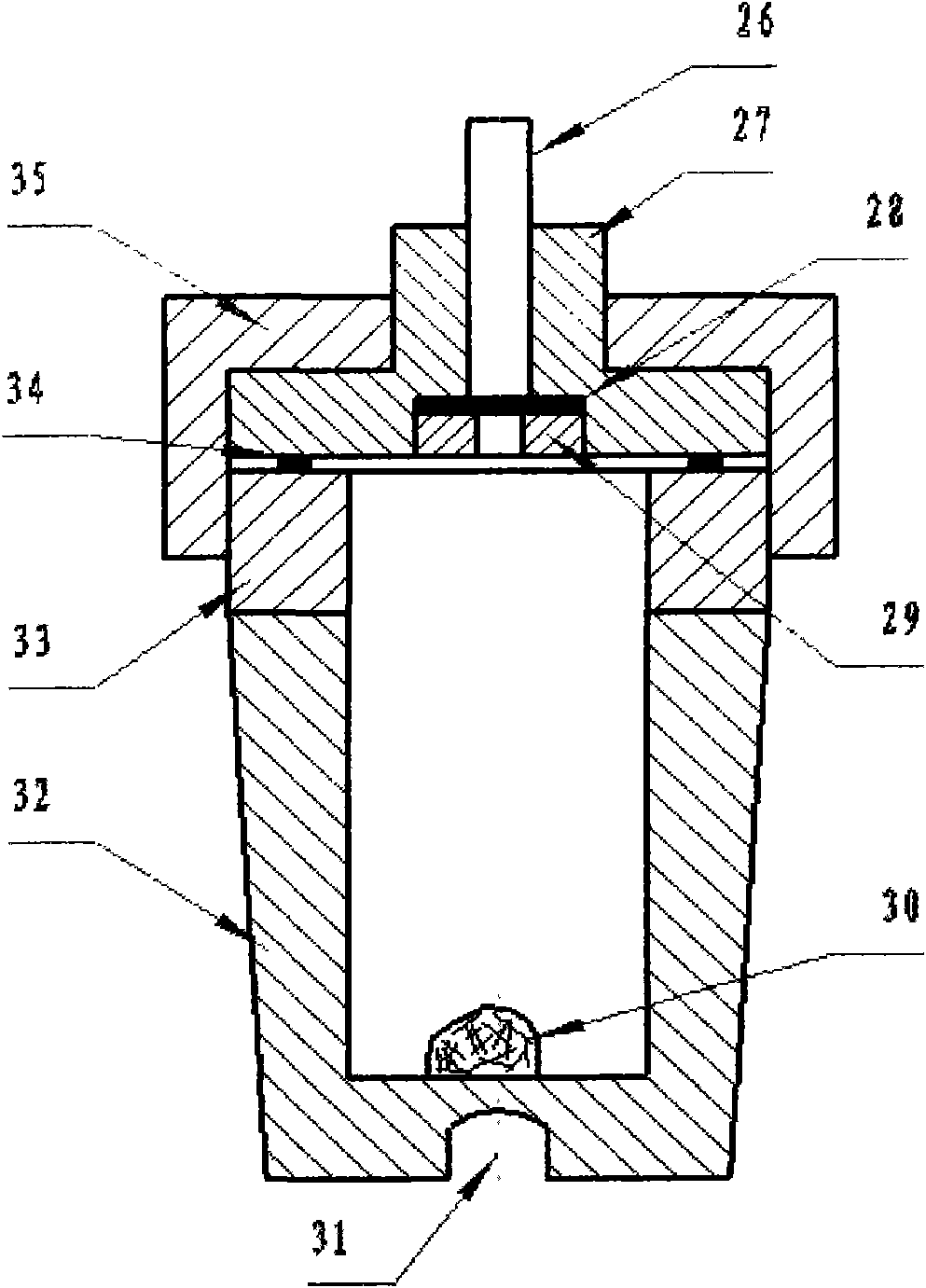

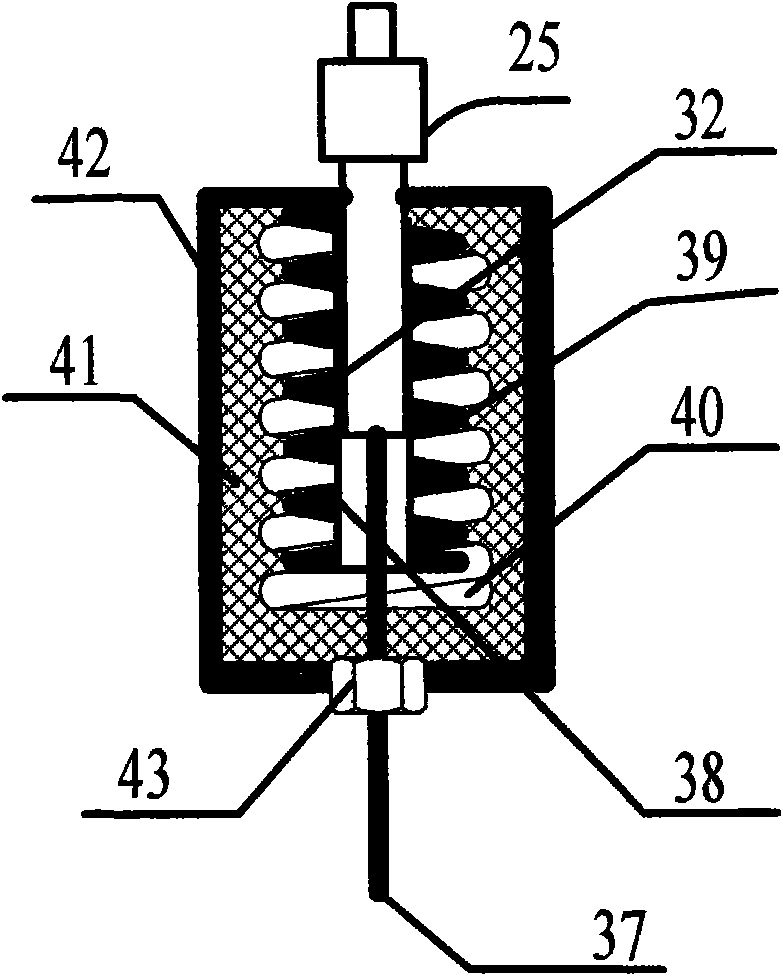

Test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and special device thereof

InactiveCN101858842AAutomatic control is reliableThe control process is stable and reliableMaterial analysisDesorptionData acquisition

The invention discloses a test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and a special device thereof. The test device consists of a gas cycling system, a sample chamber heating and cooling system and a computer data collection and control system. The gas cycling system provides a vacuum environment and high-purity hydrogen source to the test system; the sample chamber heating and cooling system rapidly and circularly heats and cools the test sample; and the computer data collection and control system controls a heating and cooling program to run and controls the opening and closing of relevant electromagnetic valve and electric valve and instantly collect the pressure and temperature signal of the system. While completing the test of the cycle of the metal hydride thermal adsorption and desorption of hydrogen, the system also can test the alloy adsorption and desorption hydrogen performance such as PCT curve and dynamics curve and the constant-temperature adsorption and desorption hydrogen service life in situ.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

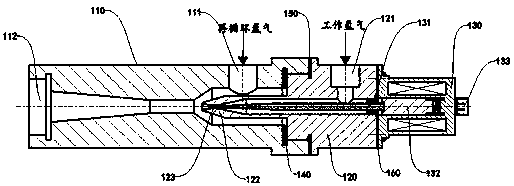

Variable-throat ejector used for fuel cell system

PendingCN108400354AAutomatic control performanceReduce the cross-sectional areaMotive system fuel cellsThroatAutomatic control

The invention discloses a variable-throat ejector used for a fuel cell system. The ejector comprises an ejector main body, a nozzle and an electromagnetic valve, wherein a recycling hydrogen inlet anda hydrogen outlet are formed in the inner side of the ejector main body; the nozzle has a high-pressure hydrogen inlet and a gradually shrunk and gradually expanded nozzle for allowing high-pressurehydrogen to flow into the ejector main body; and the electromagnetic valve has a probe for adjusting the cross sectional area size of the nozzle throat and a valve body for controlling the probe to move. By virtue of the variable-throat ejector used for the fuel cell system provided by the invention, the cross sectional area of the throat can be changed according to electric pile power and hydrogen amount needed by the electric pile; the ejector can control the position of the probe through the electromagnetic valve in the working process so as to control the flow of recycling gas in the hydrogen cycle loop; and more specifically, the working performance of the ejector can be controlled automatically, so that the cycle amount of the recycling gas is increased by reducing the cross sectional area of the throat in a small-power working condition of the electric pile.

Owner:安徽明天氢能科技股份有限公司

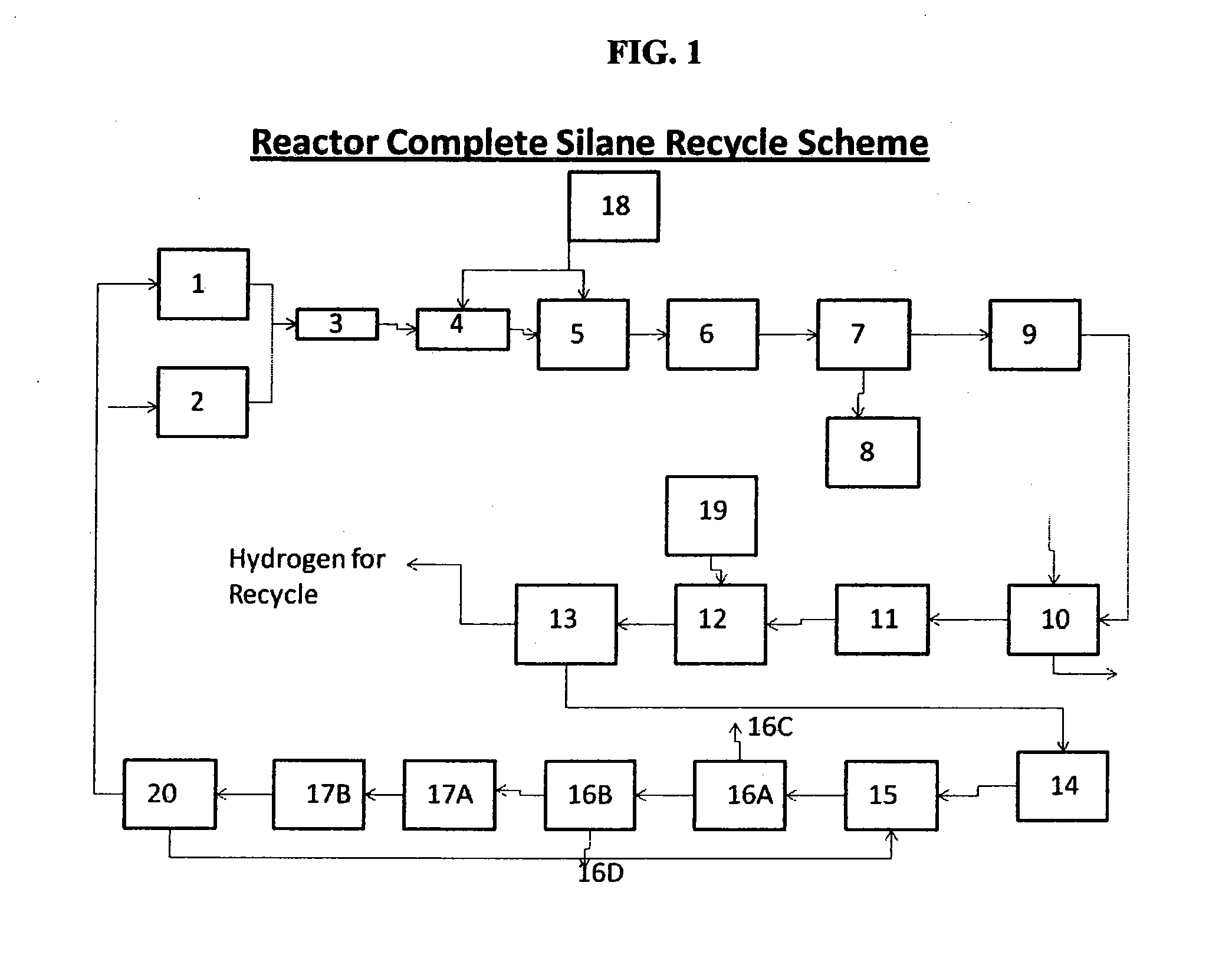

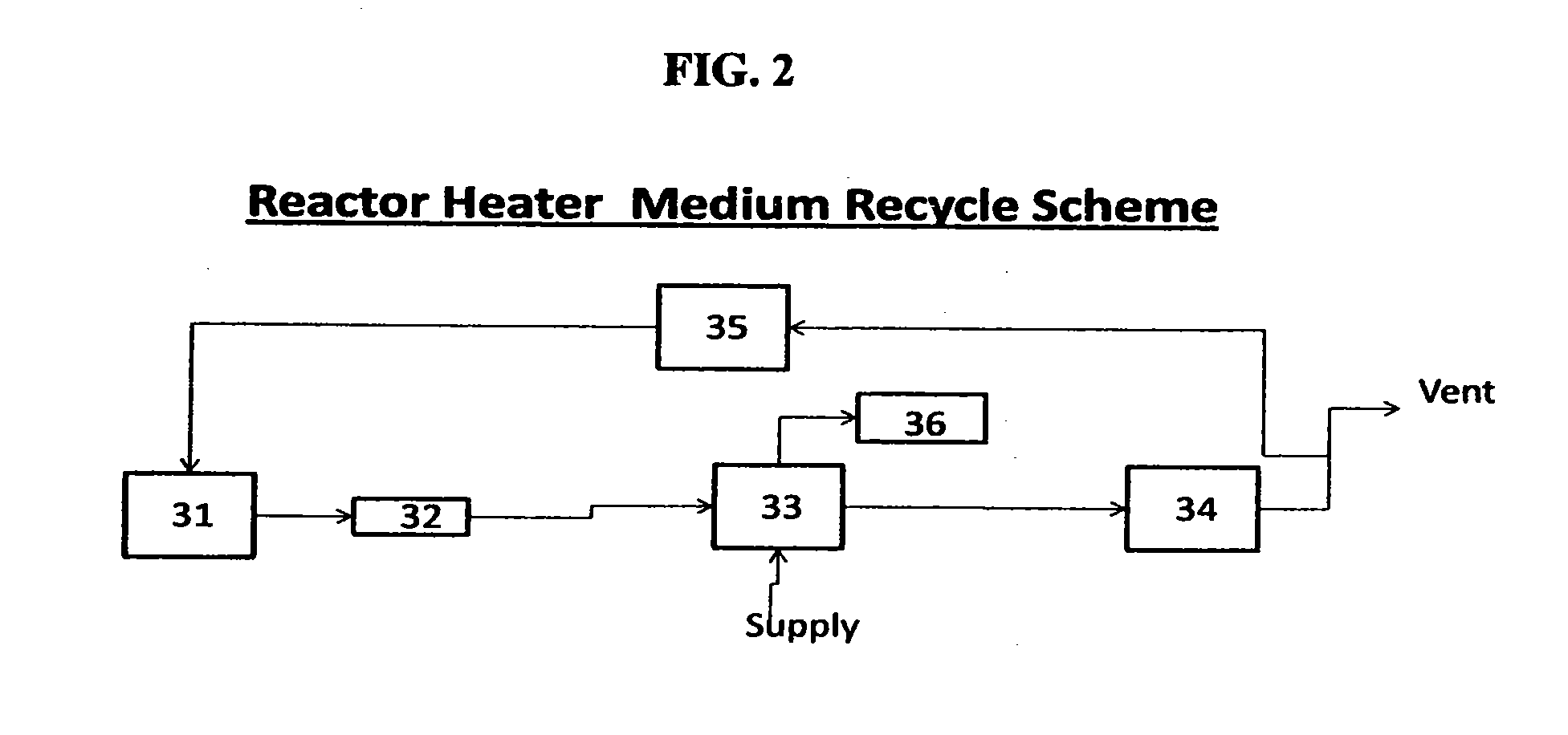

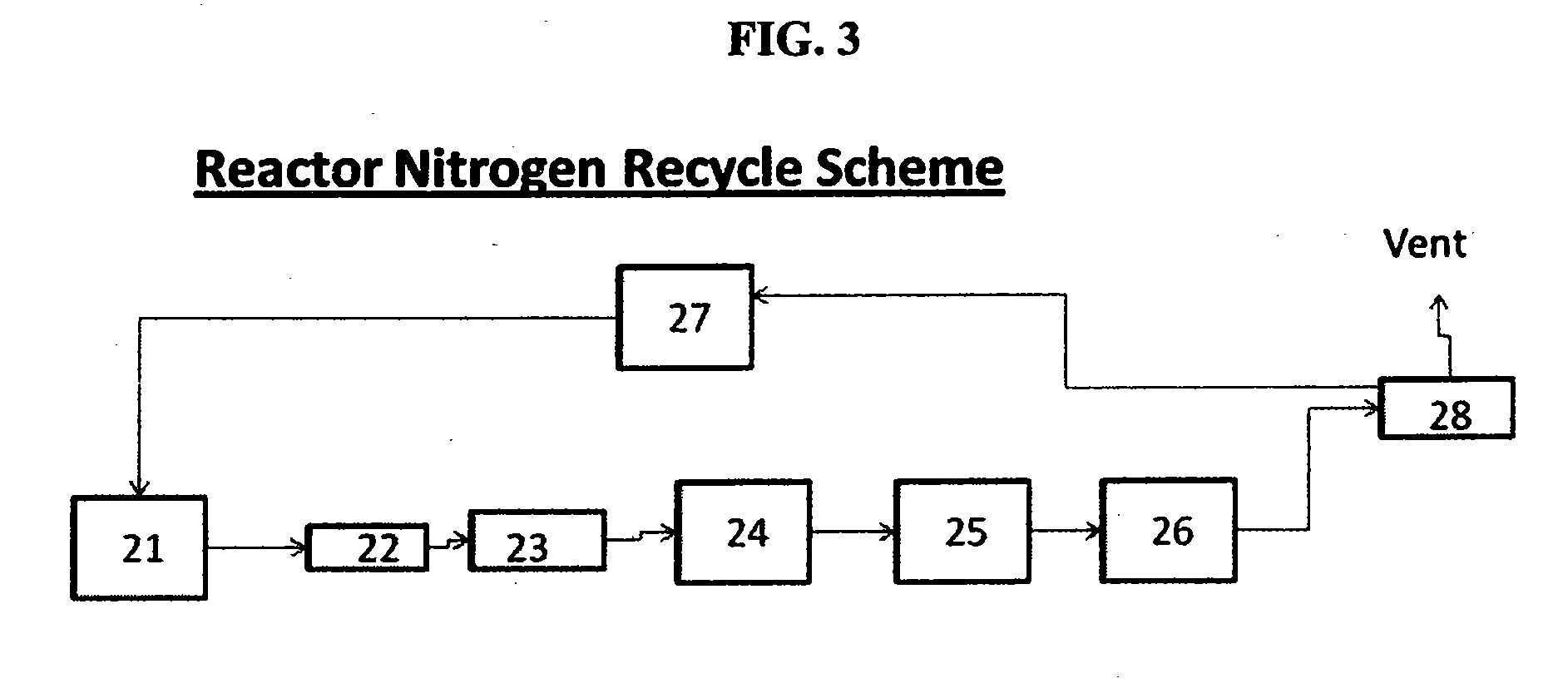

CVD-Siemens Monosilane Reactor Process with Complete Utilization of Feed Gases and Total Recycle

InactiveUS20120058022A1Increased cost-effectivenessSave energyPolycrystalline material growthSolidificationHydrogenSilanes

The present invention relates to a monosilane (SiH4) and hydrogen recycle process / system for chemical vapor deposition (CVD) of monosilane-based CVD polysilicon. In particular, the present invention relates to the substantially complete silane utilization and unconverted (from the reactor) contamination-free complete silane and hydrogen recycle process of producing polysilicon chunk materials via the decomposition of gaseous silane precursors.

Owner:SAVI RES

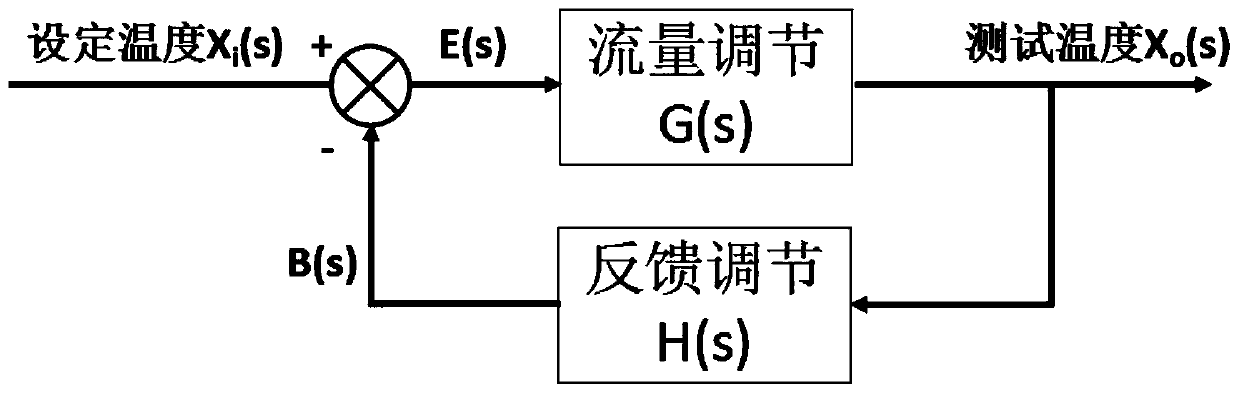

Auxiliary system for controllable temperature-control pressure gas sealing test platform

ActiveCN110221640AAvoid direct contactEffective temperature controlDetection of fluid at leakage pointVolume/mass flow by differential pressureTemperature controlHigh pressure hydrogen

The invention discloses an auxiliary system for a controllable temperature-control pressure gas sealing test platform. The system comprises a gas supercharging / pressure reducing cycle system, an experimental box pressure-stabilizing system, a leakage detection system, a temperature control system and a safety protection system; the auxiliary system is connected with the experimental box through apipeline and used for simulating an on-service environment of the high-pressure hydrogen-storage sealing part; the gas supercharging / pressure reducing system can provide the hydrogen environment withdifferent pressure and different hydrogen cycle frequency for the experimental box, and the hydrogen charging efficiency can be improved due to the existence of the low-pressure hydrogen-charging line; the temperature control system performs feedback regulation through the difference between the set test temperature and the actual temperature; the feedback regulation is used for a flow regulatingvalve and used for regulating the flow velocity of the heat transferring medium, thereby realizing intelligent temperature control.

Owner:TSINGHUA UNIV

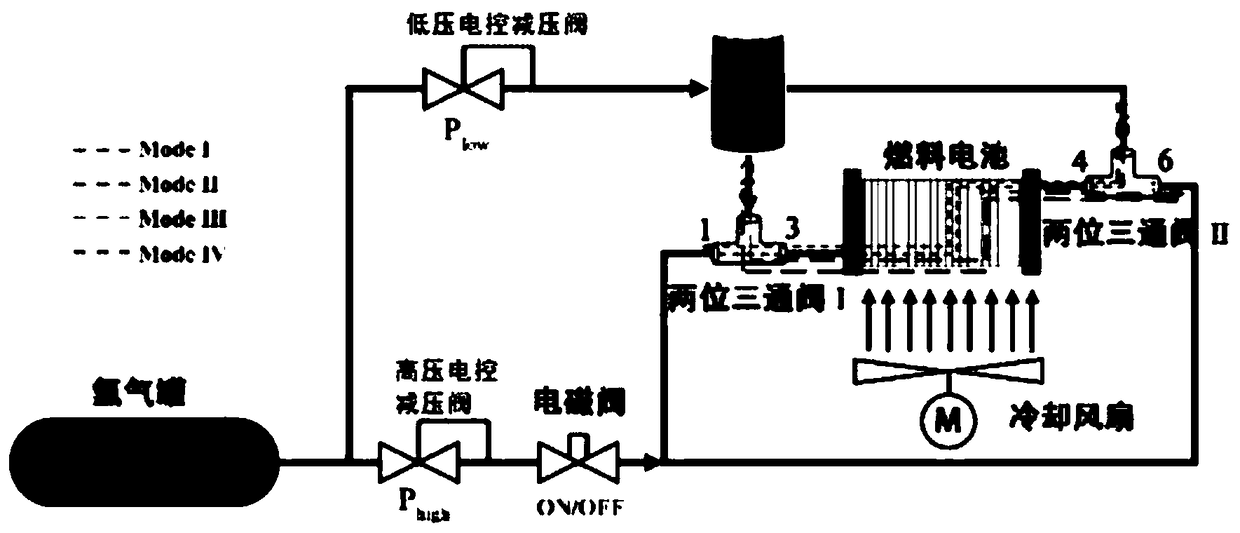

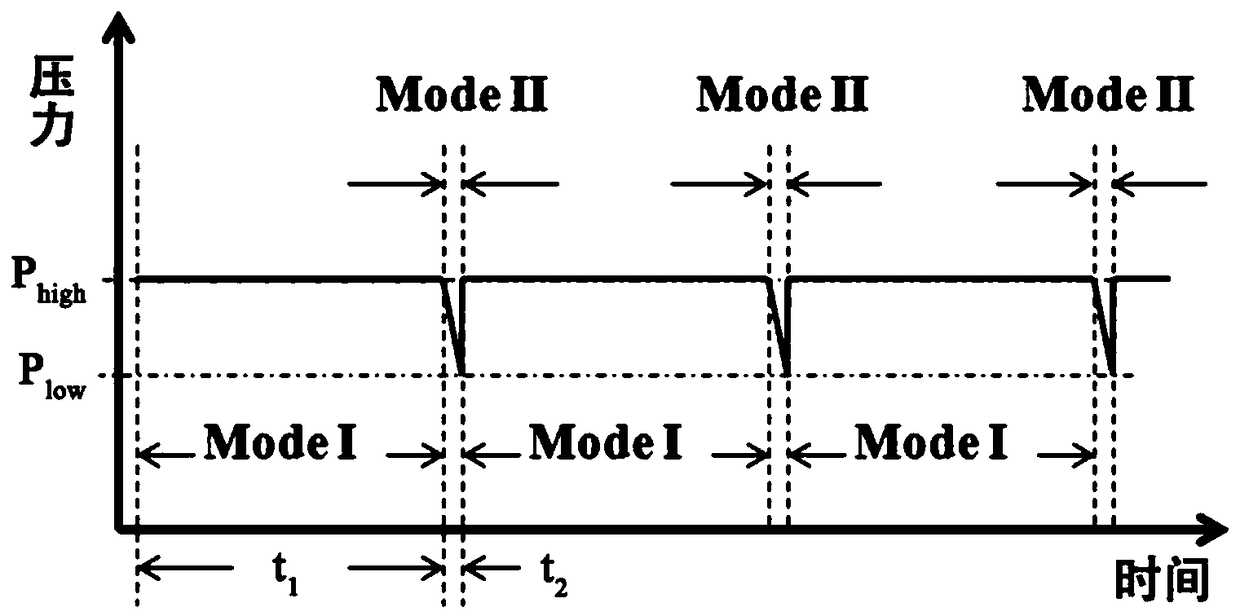

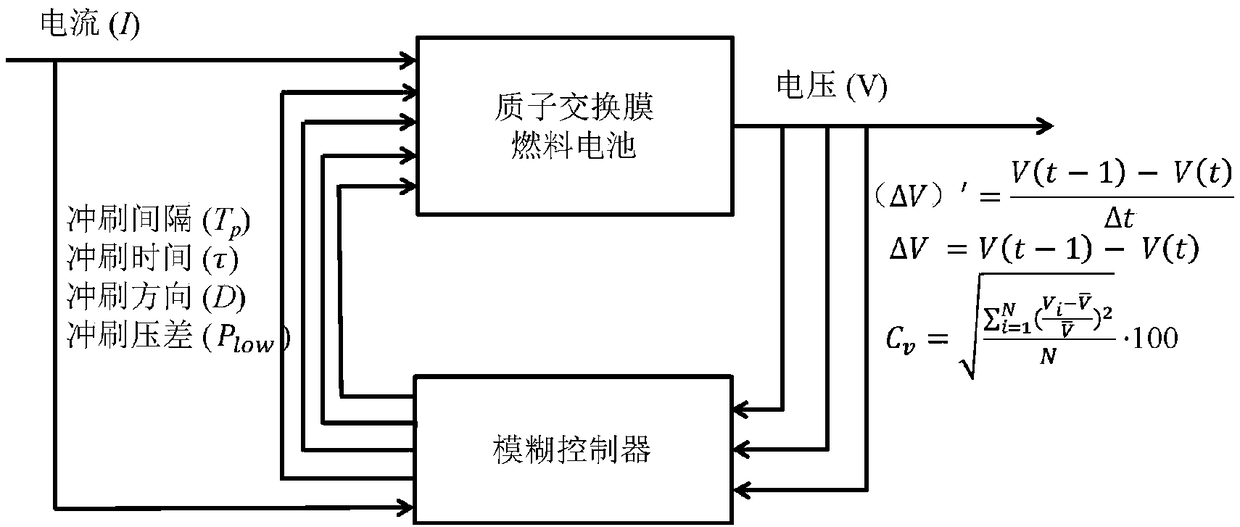

Fuel cell multi-mode switching anode pressure pulsating water erosion control system

ActiveCN109216736AImprove washing effectGood voltage uniformityFuel cell controlFuel cellsControl system

The invention relates to a fuel cell multi-mode switching anode pressure pulsating water scouring control system, belonging to the fuel cell technical field. The technical points of the method are asfollows: (1) the pressure difference of anode scouring for fuel cell stack is dynamically adjusted to achieve the optimal scouring effect of anode water; (2) adjusting the direction of anode scouringdynamically to achieve the optimal distribution of anode runner water; (3) The anode is sealed to realize the anode hydrogen cycle with zero hydrogen emission. The invention can realize the optimal anode water scouring effect of the fuel cell, reduce the pressure fluctuation of the anode of the fuel cell, avoid the voltage fluctuation caused by the pressure sudden drop in the traditional anode drainage control, and optimize the distribution of the anode water in the stack to improve the uniformity of the working voltage of the fuel cell unit.

Owner:CHONGQING UNIV

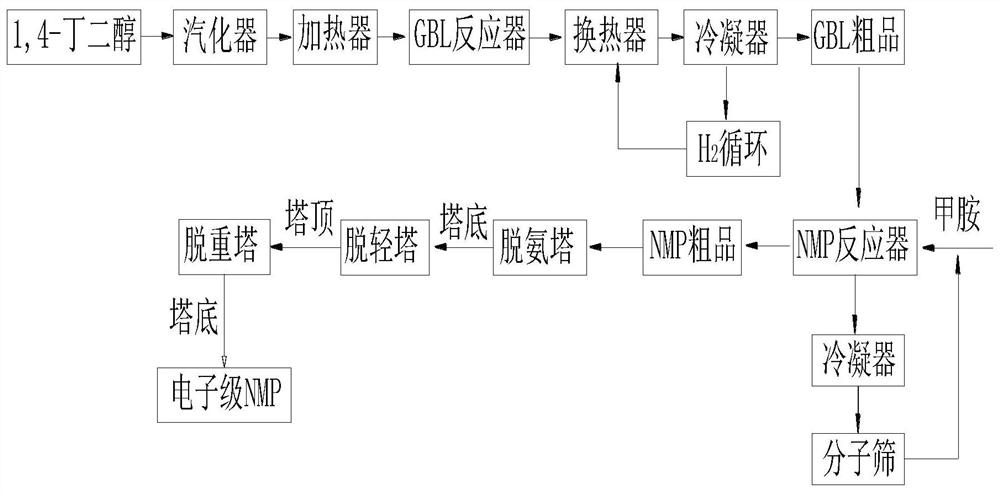

Process for synthesizing NMP by adopting solid strong acid catalyst

ActiveCN112142641AHigh purityReduce energy consumptionOrganic chemistryChemical industryPtru catalystAcid catalyzed

The invention discloses a process for synthesizing NMP by adopting a solid strong acid catalyst. The process comprises the following steps that 1, 4-butanediol is preheated by a preheater and then enters a vaporizer to be vaporized; the vaporized gas-phase material enters a heater to be heated and then enters a GBL reactor to react, and the temperature of 180-250 DEG C and the normal pressure condition are controlled under the action of a copper-based catalyst; generated mixed gas of butyrolactone and hydrogen firstly passes through a heat exchanger and then enters a first-stage condenser anda second-stage condenser, one part of hydrogen is emptied, and the other part of hydrogen is sent to a hydrogen cycle by a fan; a gamma-butyrolactone crude product is obtained after condensation,the gamma-butyrolactone crude product is directly fedinto an NMP reactor, and a methylamine solution and a solid strong acid catalyst are added to react to obtain an NMP crude product. The process overcomes the defects in the prior art, can synthesize high-purity NMP, fully utilizes heat energy to achieve the effects of saving energy and reducing consumption, improves the utilization rate of resources,and has higher social use value and application prospect.

Owner:安徽英特力工业工程技术有限公司

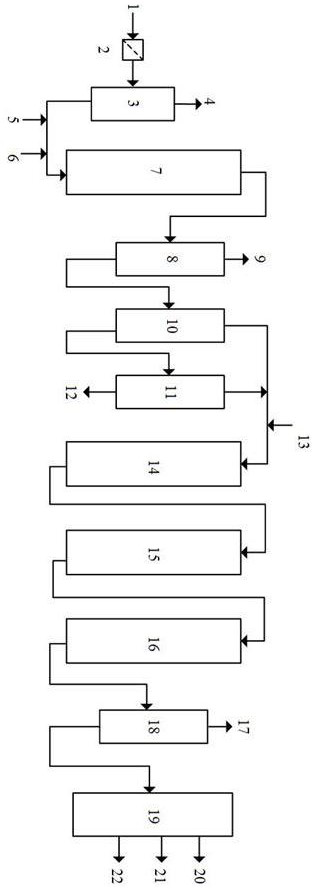

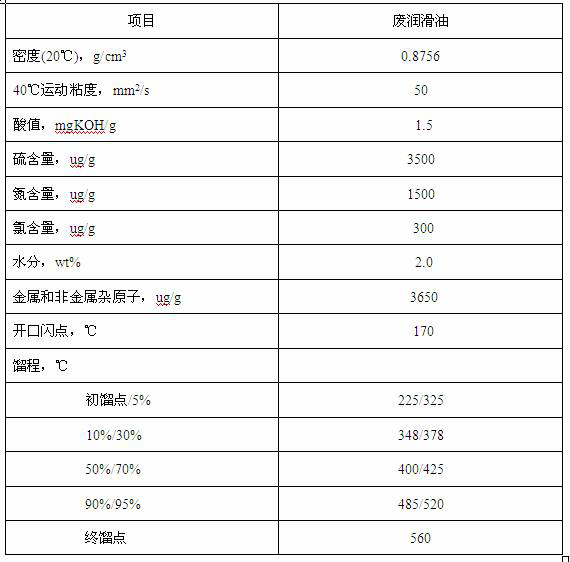

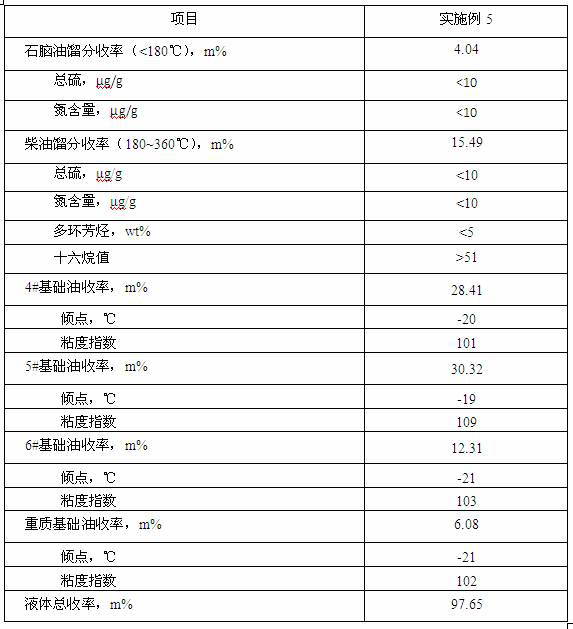

Waste lubricating oil hydrogenation recycling method

ActiveCN112500917AImprove conversion rateImprove liquid yieldOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with hydrotreatment processesSlurry reactorPtru catalyst

The invention relates to a waste lubricating oil hydrogenation recycling method, which comprises two steps of slurry reactor hydrogenation pretreatment and deep hydrogenation treatment, and specifically comprises: removing mechanical impurities from waste lubricating oil, and carrying out flash evaporation to separate out free water and a part of light hydrocarbons; mixing the material at the bottom of the flash tower with hydrogen and a self-vulcanization oil-soluble transition metal catalyst, and then feeding the mixture into a slurry bed reactor for hydrogen pretreatment; separating a reaction effluent to obtain a liquid product, and carrying out hydrocyclone separation and solvent washing to remove solid residues to obtain a pretreated lubricating oil component; mixing the components with hydrogen and then enabling a mixture to enter a hydrofining reactor, an isomerization-visbreaking reactor and a supplemental refining reactor which are connected in series for hydrotreatment; andseparating reaction products to obtain high-quality naphtha, diesel oil and lubricating oil base oil. The method provided by the invention has the advantages of simple process flow, high oil product liquid yield, good lubricating oil base oil quality and the like, and can realize full-fraction resource utilization of the waste lubricating oil. In addition, the oil-soluble catalyst is simple in dispersion, free of vulcanization, small in catalyst addition amount and high in low-temperature hydrogenation activity, coking possibly occurring in the preheating process of the waste lubricating oil can be effectively avoided, and long-period stable operation of the device is guaranteed.

Owner:青岛翌星环保技术有限公司

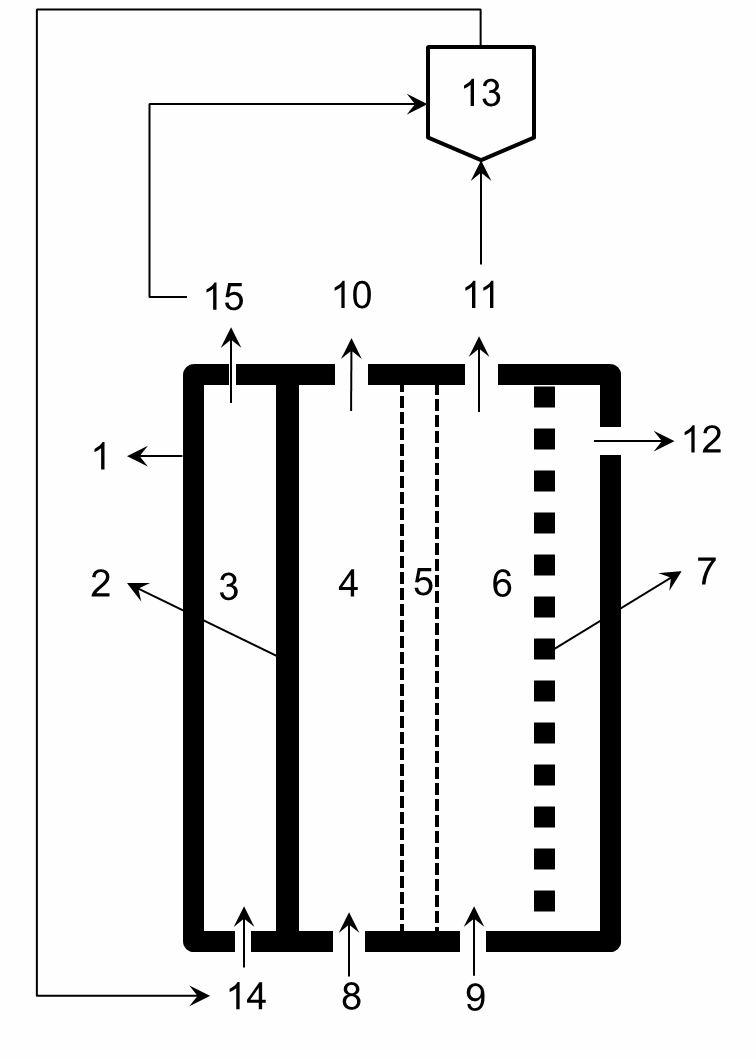

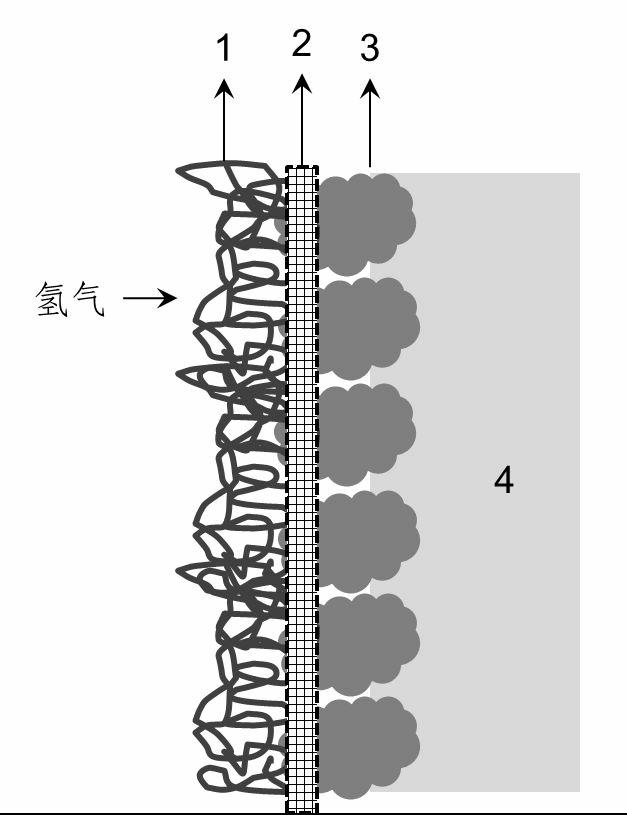

Method and device for hydrogen-circulating electrolysis and application of the method and device in production of aluminum oxide

ActiveCN102605383AReduce oxidation corrosionImprove corrosion resistanceCellsSodium bicarbonateCarbonization

The invention discloses a device for electrolyzing a water solution by hydrogen circulation. The device comprises a hydrogen anode, a hydrogen evolution cathode, an electrolytic cell and a hydrogen collecting and processing device, wherein the electrolytic cell is divided into an anode chamber and a cathode chamber via a diaphragm. The electrolysis method comprises the following steps: collecting the hydrogen generated by the cathode, introducing the hydrogen into an anode gas chamber, and oxidizing the hydrogen at the anode into hydrogen ions in the solution, wherein the reaction at the cathode is a hydrogen evolution reaction; and hydrogen generated by the cathode is effectively utilized at the anode, so that the hydrogen circulation is achieved, and the cell voltage is reduced to 0.9-1.3V, and the power consumption is greatly reduced. The electrolysis method and device can be applied to the production process of aluminum oxide by an alkali-dissolution and carbonization-precipitation method, i.e., sodium carbonate solution is electrolyzed based on a hydrogen-circulating electrolysis technology to obtain a sodium hydroxide solution at the cathode zone and a sodium bicarbonate solution at the anode zone, and the sodium hydroxide solution and the sodium bicarbonate solution are used for dissolving ore and breaking down a sodium aluminate solution, respectively. By using the hydrogen-circulating electrolysis for breaking down the sodium carbonate solution, the power consumption of the aluminum oxide production by the alkali-dissolution and carbonization-precipitation method can be significantly reduced.

Owner:BEIJING UNIV OF CHEM TECH

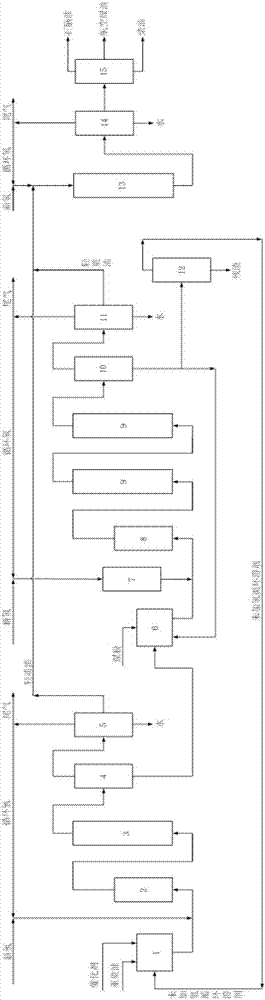

Method for co-processing coal high in inertinite content and heavy oil

ActiveCN106906001ALow viscosityGuaranteed concentrationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productNaphtha

The invention relates to a method for co-processing coal high in inertinite content and heavy oil. The method includes the steps that heavy oil, a first hydrogenation-free recycling solvent and a catalyst are mixed to prepare oil slurry, hydrocracking is conducted to obtain a first product, and separation is conducted to obtain first light distillate oil and first heavy distillate oil; the first heavy distillate oil, a second hydrogenation-free recycling solvent and pulverized coal are mixed to prepare coal-oil slurry, hydrocracking is conducted to obtain a second product, and separation is conducted to obtain second light distillate oil and second heavy distillate oil; one part of the second heavy distillate oil is separated to obtain residue and third heavy distillate oil, wherein the third heavy distillate oil serves as the first hydrogenation-free recycling solvent for preparing the oil slurry; the other part of the second heavy distillate oil serves as the second hydrogenation-free recycling solvent for preparing the coal-oil slurry; hydrogenation upgrading is conducted on the first light distillate oil and the second light distillate oil to obtain a third product, and separation is conducted to obtain naphtha, aviation kerosene and diesel oil. The method improves the conversion rate of the coal high in inertinite content, and the yield of the liquid product is increased.

Owner:CCTEG CHINA COAL RES INST

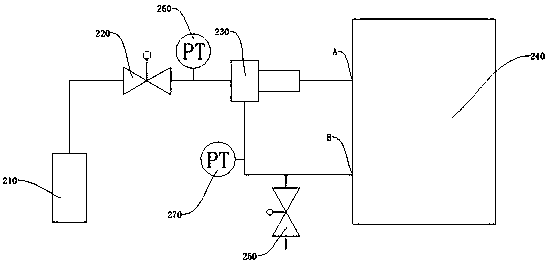

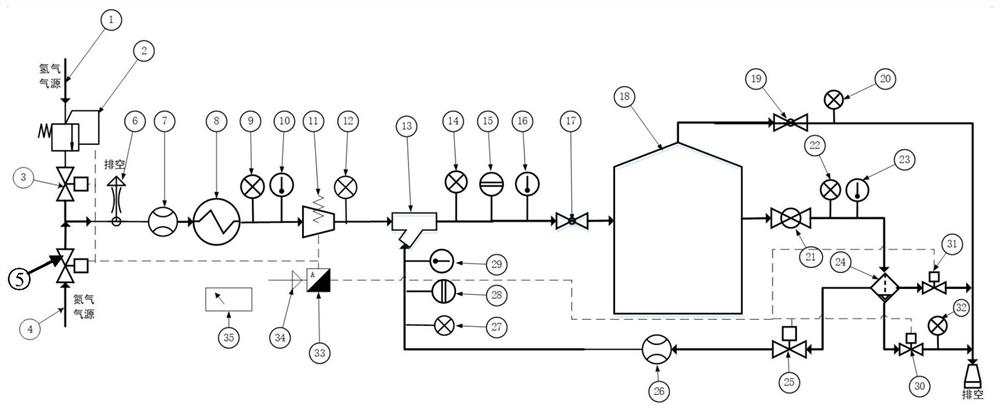

Fuel cell hydrogen cycle test system

The invention discloses a fuel cell hydrogen cycle test system. A hydrogen gas source is connected with the inlet pipeline of a heat exchanger, the outlet of the heat exchanger is connected with the hydrogen inlet pipeline of a hydrogen cycle device, and the hydrogen outlet of the hydrogen cycle device is connected with the inlet pipeline of a heating and humidifying device; the first outlet of the heating and humidifying device is connected with an emptying pipeline, and the second outlet of the heating and humidifying device is connected with the reflux inlet of the hydrogen circulating device through a reflux pipeline; the heat exchanger adjusts the temperature of hydrogen supplied by the hydrogen source; the heating and humidifying device heats, humidifies and discharges the hydrogen; and the hydrogen circulating device sucks and reflows the hydrogen and supplies the hydrogen to the heating and humidifying device again. The heating and humidifying device is adopted to replace a galvanic pile, the actual consumption flow, pressure, temperature and humidity of the galvanic pile are completely simulated, heat exchange and humidifying are carried out on hydrogen, it is guaranteed that discharged hydrogen reaches a saturated state, and through suction backflow of the hydrogen circulating device, the characteristics of a fuel cell hydrogen circulating system are completely simulated and analyzed.

Owner:SHANGHAI ELECTRICGROUP CORP

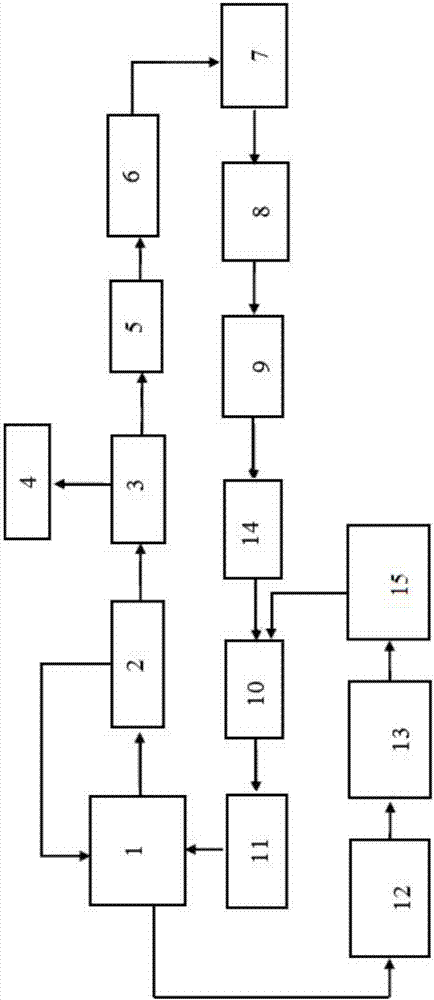

Biogas hydrogen production circulating system and technology for PTA sewage treatment

PendingCN107986578ALow running costAchieve recyclingHydrogenWater contaminantsOxygenEnergy conservation

The invention provides a biogas hydrogen production circulating system and technology for PTA sewage treatment. The system comprises: a PTA device, a settling tank, an anaerobic baffled reactor, a sedimentation tank, a biogas collection tank, a desulfurization adsorption device, a nitrogen-oxygen removal device, a cracking reactor, an alkaline washing tower I, a gas-liquid separator, a pressure swing adsorption device, a vapor heat exchanger, an alkaline washing tower II, a desalted water washing tower I and a desalted water washing tower II. According to the system and technology provided bythe invention, a sewage treatment unit in traditional technology is changed; sewage produced in a production process of the PTA device is subjected to biochemical treatment to generate biogas; methanein the biogas is extracted and converted into hydrogen; the hydrogen, together with the hydrogen converted from the released gas, is subjected to pressure swing adsorption to obtain high-purity hydrogen which is applied to a refining reaction of the PTA device; purchase of raw materials and energy is not needed, the operation cost of the PTA device is lowered, recycling of internal resources of the PTA device is realized, and an aim of energy conservation and emission reduction is achieved.

Owner:YISHENG DAHUA PETROCHEM

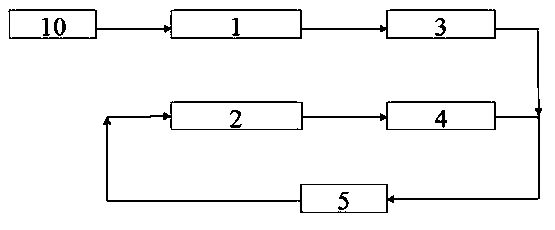

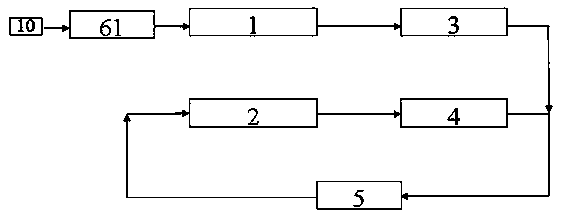

Hydrogen combined optimized utilization technology of hydrogenation apparatus

ActiveCN102399584AReduce dosageReduce lossTreatment with hydrotreatment processesThermodynamicsHydrogenation reaction

The invention discloses a hydrogen combined optimized utilization technology of a hydrogenation apparatus. Excessive hydrogen from a hydrogen pipe net passes through a first reaction unit and conducts a catalysis hydrogenation reaction with raw oil; residual hydrogen enters a first cold-high pressure separating unit for gas-liquid separation, then mixes with cycling hydrogen from a second cold-high pressure separating unit, is treated by a hydrogen cycle unit and enters to a second reaction unit to conduct a catalysis hydrogenation reaction with raw oil; residual hydrogen enters into the second cold-high pressure separating unit for gas-liquid separation, merges with residual hydrogen from the first cold-high pressure separating unit, is treated by the hydrogen cycle unit and returns to the second reaction unit. According to the technology of the invention, two sets of hydrogenation apparatuses can share a new hydrogen machine or a hydrogen cycle compressor and part of pipes, so as to reduce equipment quantity and energy consumption of the new hydrogen compressor and the cycle hydrogen compressor, and realize small investment and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

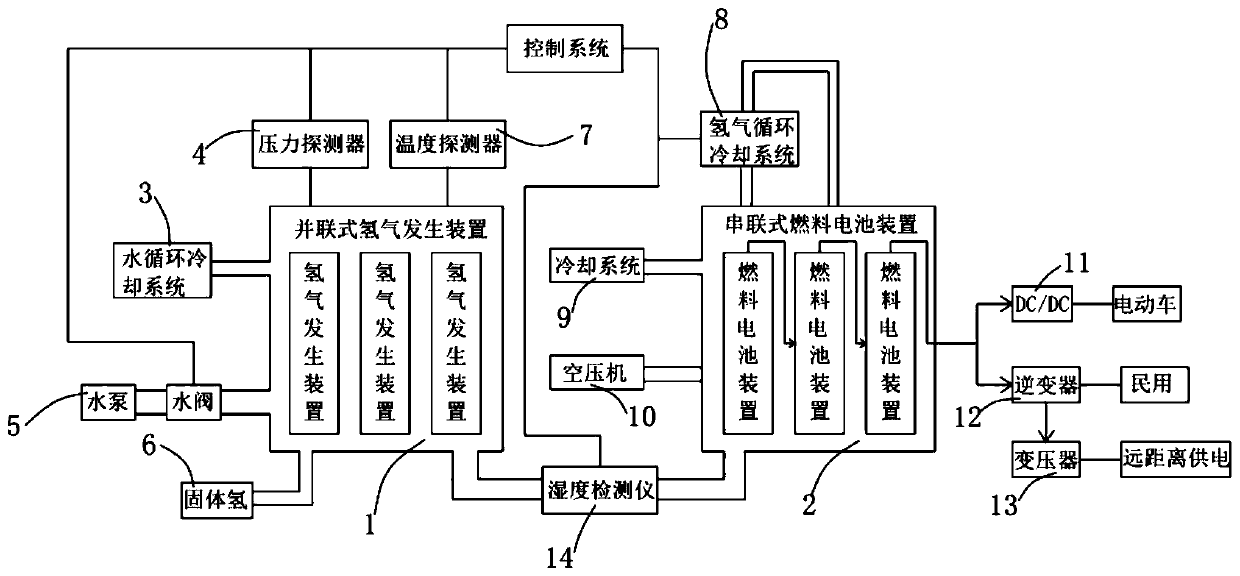

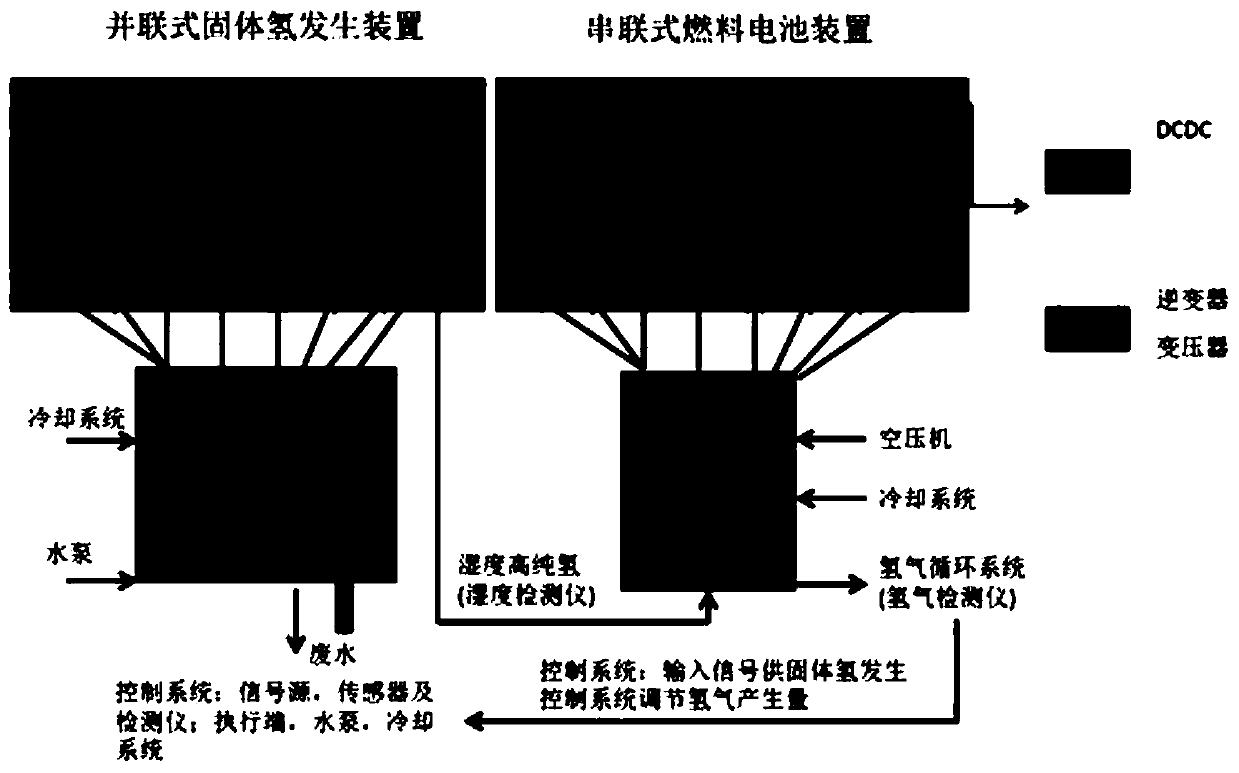

Power station system based on solid hydrogen technology

PendingCN109950588ASustainability for good environmental developmentImprove resource utilizationFuel cellsResource utilizationWater circulation

The invention discloses a power station system based on the solid hydrogen technology. The system comprises a solid hydrogen generating device which is used for preparing hydrogen gas and comprises aparallel hydrogen generating device, a water pump, solid hydrogen, a pressure detector, a temperature detector and a water circulation cooling system, a fuel cell device which is used for generating electricity and comprises a series fuel cell stack, an air compressor, a cooling system and a hydrogen circulation system. According to the present invention, a solid hydrogen power station is an environment-friendly power generation device, the final products are water, heat and electric energy, the solid hydrogen power station has good environmental development sustainability, resource utilization and safety controllability, operational safety and economic benefits, the generation amount of an electric energy source is controlled through a power generation center control system, the solid hydrogen power station is different from a traditional hydrogen energy power station and does not need high-pressure hydrogen cylinders, the conversion efficiency is much higher than that of a traditional thermal power station, the power generation device is simple, and the fuel cell device does not need traditional hydrogen cycle system and humidification system.

Owner:镁格氢动能源技术(苏州)有限公司

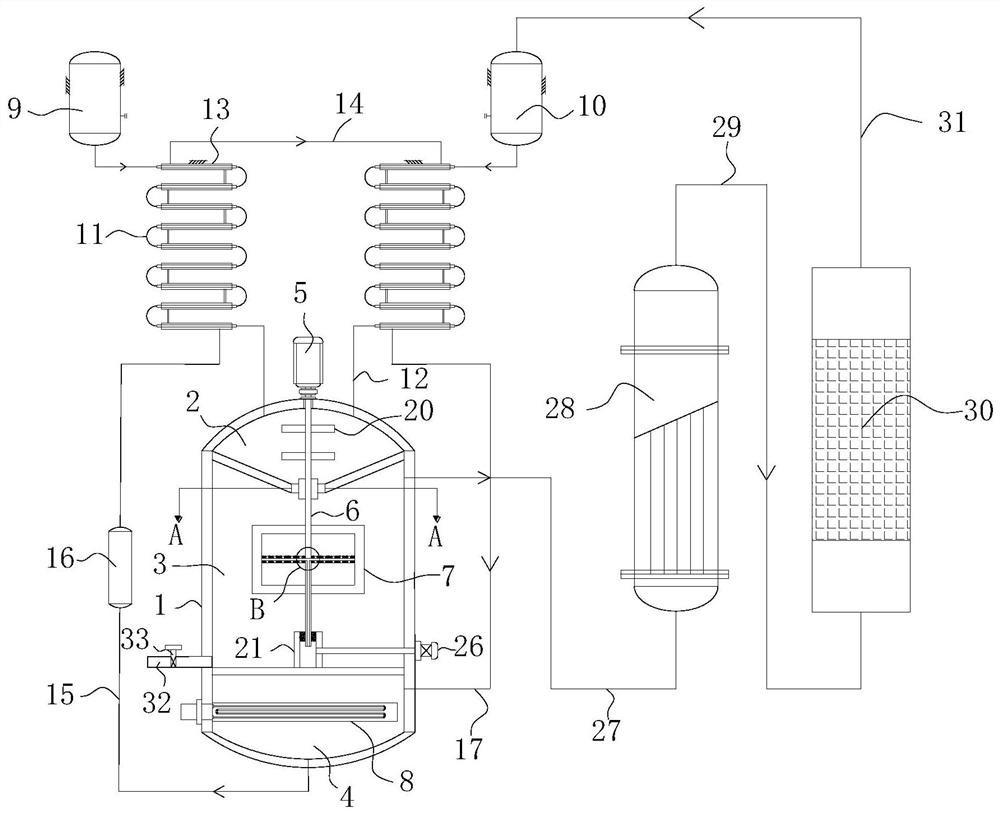

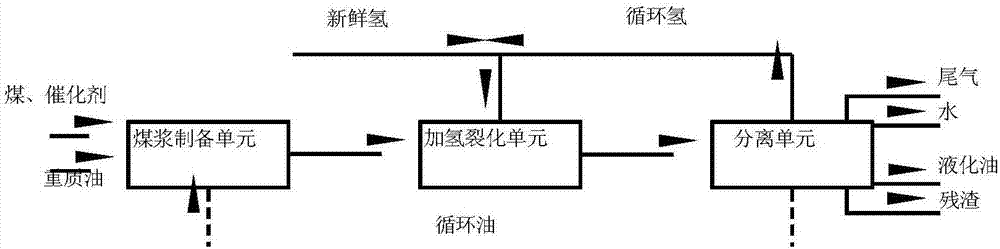

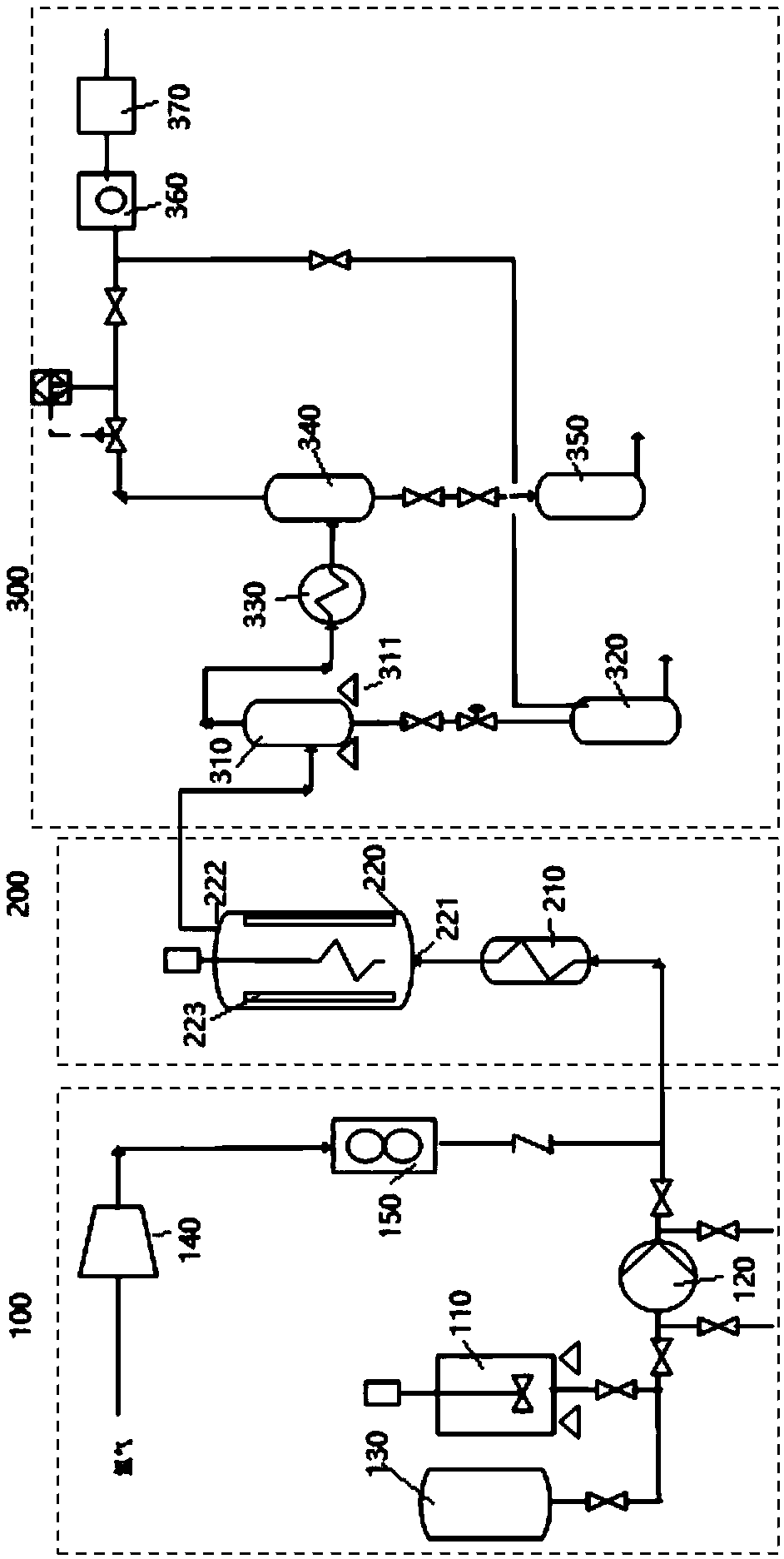

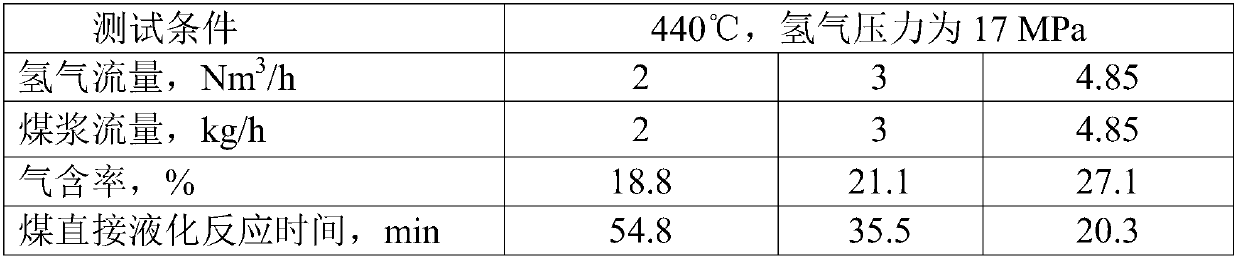

Method and apparatus for evaluating characteristics of coal direct liquefaction reaction

ActiveCN107805521ALean structureReduce equipment investmentTreatment with hydrotreatment processesHydrogenProcess engineering

The invention relates to the field of evaluation of characteristics of coal direct liquefaction reactions, and discloses a method and an apparatus for evaluating the characteristics of a coal direct liquefaction reaction. The method comprises: (1) inputting a hydrogenation circulation solvent and hydrogen into a stirring kettle reactor, and determining and calculating the coal direct liquefactionreaction gas content under a coal direct liquefaction reaction condition, wherein the material enters from the bottom portion and the material is discharged from the top portion in the inputting process; and (2) mixing coal powder, the hydrogenation circulation solvent and a catalyst to prepare a coal slurry, introducing the raw materials comprising the coal slurry and hydrogen into the stirring kettle reactor, carrying out a coal direct coal liquefaction reaction, and determining the coal direct coal liquefaction reaction time according to the coal slurry feeding amount, the coal direct liquefaction reaction gas content and the effective volume of the stirring kettle reactor. With the method and the apparatus of the present invention, the gas content, the reaction time and the reaction characteristic of the coal direct liquefaction reaction can be determined so as to provide the more basic data for the coal direct liquefaction reaction kinetics research and the industrial design.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

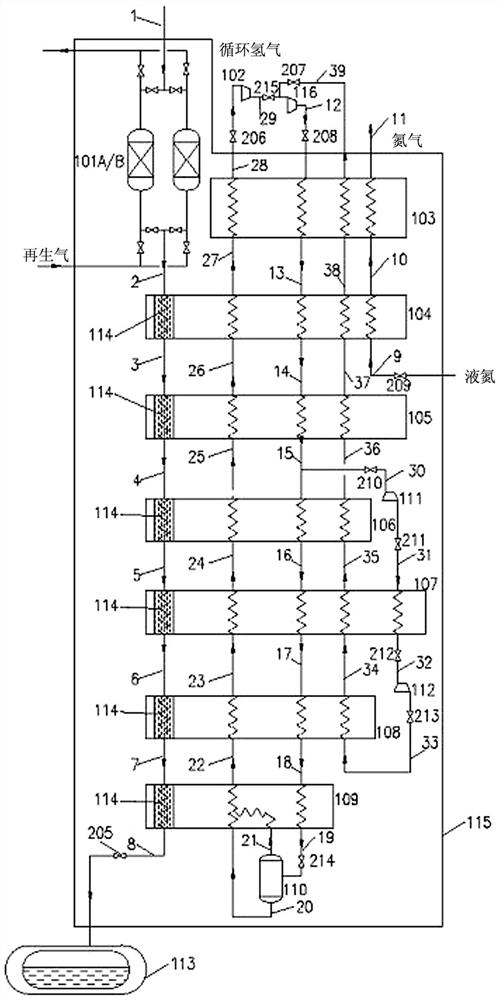

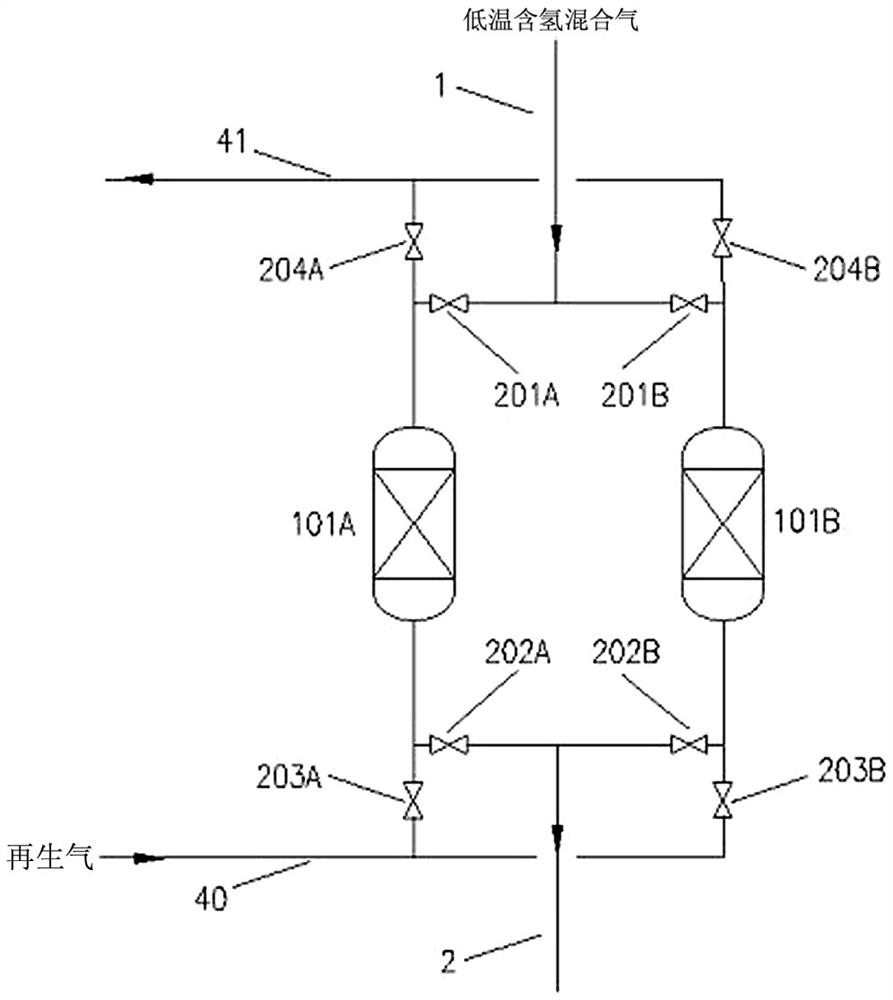

Low-temperature hydrogen liquefaction device and use method

According to the low-temperature hydrogen liquefaction device and the using method, low-temperature hydrogen-containing mixed gas from an alkane dehydrogenation device, a hydrogen / carbon monoxide cryogenic separation device, a low-temperature liquid nitrogen washing device and the like is directly purified and liquefied to obtain a high-purity liquid hydrogen product. The low-temperature hydrogen-containing mixed gas is subjected to low-temperature adsorption to remove impurities in hydrogen, and then enters the multi-stage heat exchanger to exchange heat with low-temperature circulating hydrogen and liquid nitrogen, so that the hydrogen is cooled stage by stage, and finally, a liquid hydrogen product is obtained. The invention provides the device and the method for directly preparing the liquid hydrogen from the low-temperature hydrogen-containing mixed gas, a low-temperature adsorption purification process is adopted, the device has the characteristics of high adsorption capacity, low loss and low energy consumption compared with normal-temperature adsorption, and hydrogen cycle refrigeration is adopted, so that the liquefaction energy consumption is lower. The invention solves the problems of complex hydrogen-containing mixed gas liquefaction process and high energy consumption, has the advantages of energy conservation, high yield, low investment, easiness in adjustment and the like, and is suitable for large-scale hydrogen liquefaction devices.

Owner:HANGZHOU HANGYANG

Fuel cell system operating at low temperature

InactiveCN1805198ALower operating temperatureImprove stabilityFuel cell heat exchangeFuel cellsProduct gas

The invention relates to a low-temperature fuel battery, which comprises a fuel battery pile, a hydrogen-feeding device, an oxygen-feeding device, a hydrogen cycle device, a water-cooling cycle device, and a control device. Wherein, said water cooling cycle device comprises a cycle water-cooling system and a non-cycle water cooling system. Compared to present technique, the invention has lower operation temperature without humidifying gas; simple system and stable operation, especial the prolonged service life of battery pile. The invention can apply the power source of ship and combine the operation condition to integrate the outer condition with said fuel battery system.

Owner:田丙伦

Test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and special device thereof

InactiveCN101858842BAutomatic control is reliableThe control process is stable and reliableMaterial analysisDesorptionData acquisition

The invention discloses a test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and a special device thereof. The test device consists of a gas cycling system, a sample chamber heating and cooling system and a computer data collection and control system. The gas cycling system provides a vacuum environment and high-purity hydrogen source to the test system; the sample chamber heating and cooling system rapidly and circularly heats and cools the test sample; and the computer data collection and control system controls a heating and cooling program to run and controls the opening and closing of relevant electromagnetic valve and electric valve and instantly collect the pressure and temperature signal of the system. While completing the test of the cycle of the metal hydride thermal adsorption and desorption of hydrogen, the system also can test the alloy adsorption and desorption hydrogen performance such as PCT curve and dynamics curve and the constant-temperature adsorption and desorption hydrogen service life in situ.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

LaCl3 catalyzed high-capacity hydrogen storing alloy powder and preparation method thereof

ActiveCN107385300AImproved hydrogen absorption and desorption kineticsExcellent hydrogen absorption and desorption kineticsReactant parameters controlRare earthHydrogen desorption

The invention relates to LaCl3 catalyzed high-capacity hydrogen storing alloy powder. The chemical formula composition of the powder is Mg50-x-yTixAlyLa6-zREzNi4-m-nCumCon+Q wt.%LaCl3. According to the LaCl3 catalyzed high-capacity hydrogen storing alloy powder, titanium and aluminum are used for partially replacing magnesium in rare earth magnesium alloy, multicomponent rare earth, nickel, copper and cobalt are added, and a rapid quenching alloy ribbon with a nanocrystalline+non-crystalline structure is obtained through a rapid quenching process. A trace of LaCl3 catalyst is added, the thermal stability of alloy hydride can be obviously reduced through ball milling, the hydrogen desorption capacity of alloy at low temperature is improved, and the hydrogen absorption and desorption dynamics is further improved. The prepared hydrogen storing alloy powder has high hydrogen absorption and desorption capacity and excellent hydrogen absorption and desorption dynamics and has good hydrogen absorption and desorption cycling stability.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

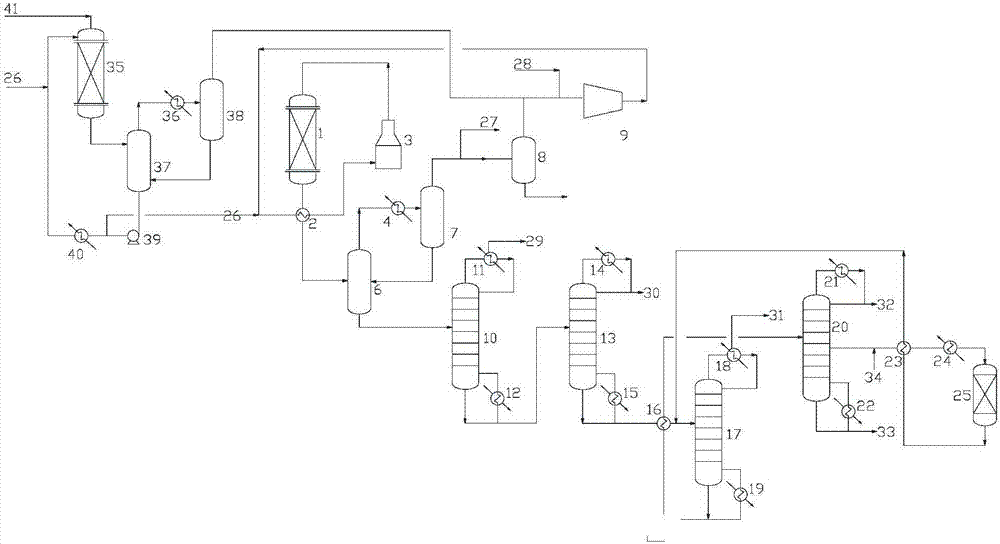

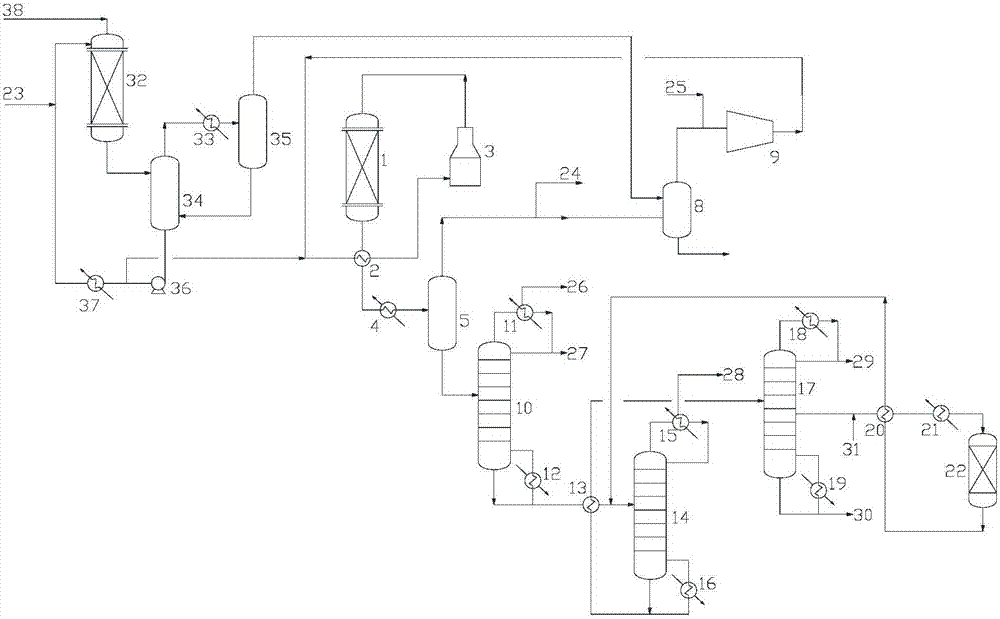

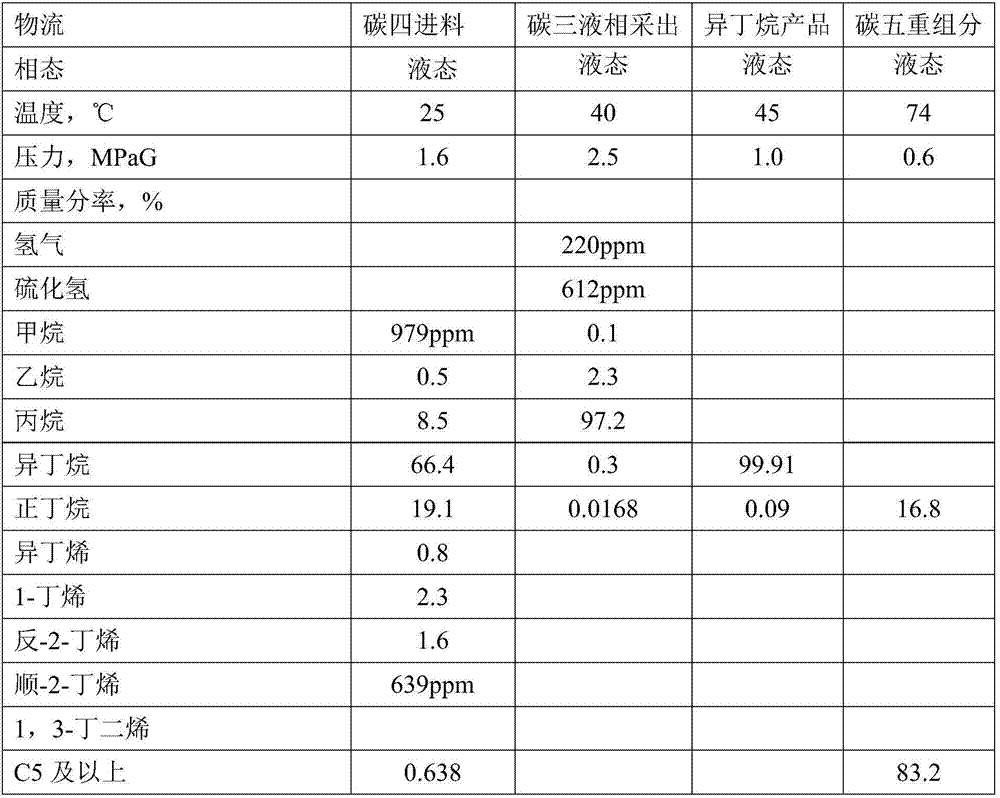

Iso-butane production device and method

InactiveCN107304152AReduce energy consumptionHydrocarbon by isomerisationHydrocarbon by hydrogenationIsomerizationEconomic benefits

The invention discloses an iso-butane production device and method. The device comprises a primary hydrogenation reactor, a primary hydrogenation separation device, a primary hydrogenation circulating pump, a primary circulation cooler, a secondary hydrogenation reactor, a hydrogenation feeding and discharging heat exchanger, a secondary hydrogenation feeding heater, a secondary hydrogenation separation device, a dethanizing column, a depropanizing column, a stabilizer, a finished iso-butane production tower, an isomerization feeding and discharging heat exchanger, an isomerization feeding heater and an isomerization reactor. The method comprises the following steps: enabling C4 raw materials to enter the device through a C4 material feeding pipeline, and hydrogenating and separating so as to produce iso-butane and n-butane; and carrying out an isomerization reaction on the n-butane, separating to produce the iso-butane, and obtaining the C3 by-product. According to the device and method disclosed by the invention, all C4-enriched light dydrocarbons can be treated, the waste heat is recovered, and the economic benefits of the device are improved.

Owner:SINOPEC ENG +1

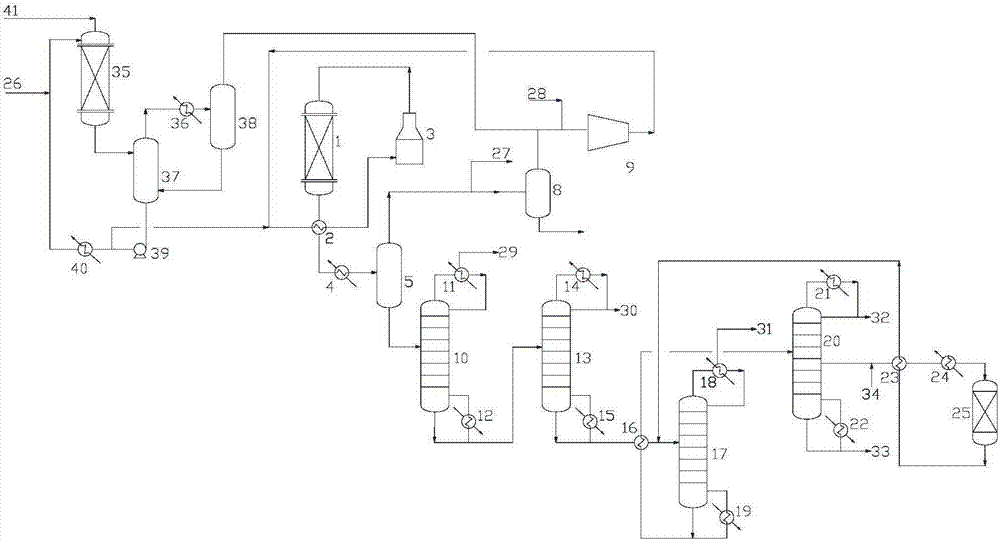

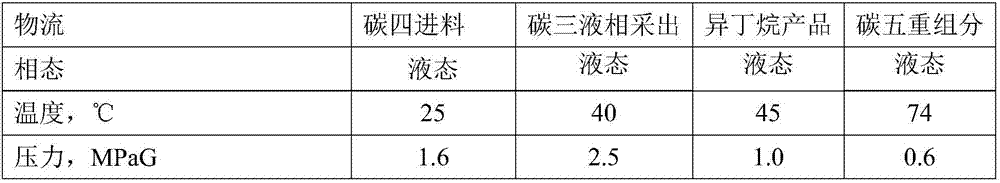

Device and method for producing isobutene through hydrogenation and isomerization

InactiveCN107304154AReduce energy consumptionHydrocarbon by isomerisationHydrocarbon by hydrogenationIsomerizationHydrogenation reaction

The invention relates to a device and method for producing isobutene through hydrogenation and isomerization. The device comprises a primary hydrogenation reactor, a primary hydrogenation separation device, a primary hydrogenation circulating pump, a primary circulating cooler, a hydrogenation feeding / discharging heat exchanger, a secondary hydrogenation reactor, a secondary hydrogenation feeding heater, a secondary hydrogenation separation device, a light fraction removal tower, a stabilization tower, an isobutane finished product tower, an isomerization feeding / discharging heat exchanger, an isomerization feeding heater and an isomerization reactor. The method comprises the steps of enabling a C4 raw material to enter into the device through a C4 feeding pipeline; preparing isobutene and normal butane products after hydrogenation and separation; and preparing the isobutene after isomerization reaction and separation of the normal butane and simultaneously producing byproducts, namely C2 and C3 products. All C4-enriched light dydrocarbon can be treated, and meanwhile, the waste heat is recovered, so that the economic benefit of the device is improved.

Owner:SINOPEC ENG +1

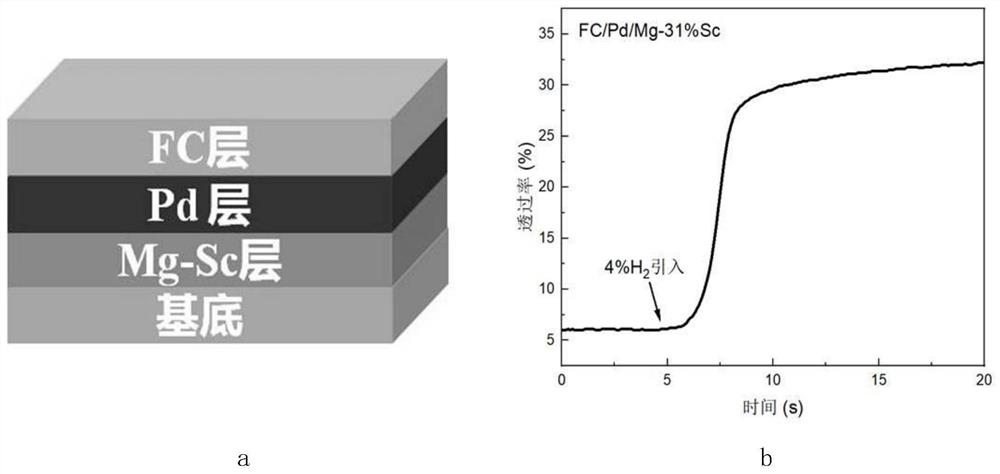

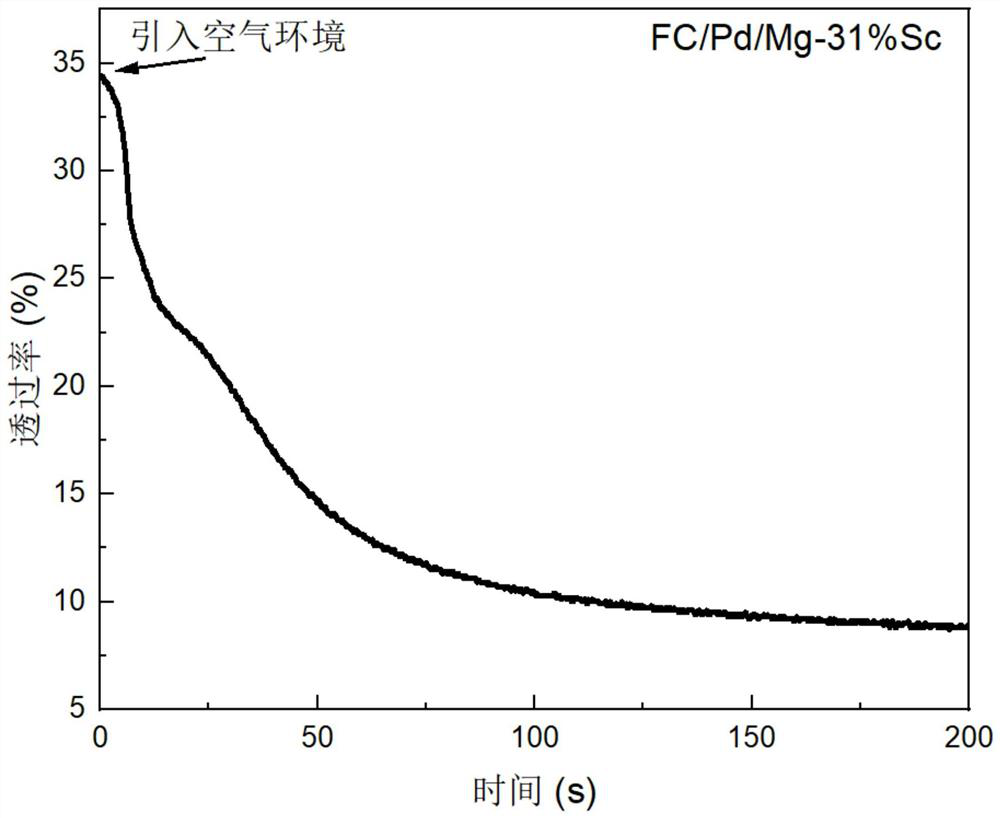

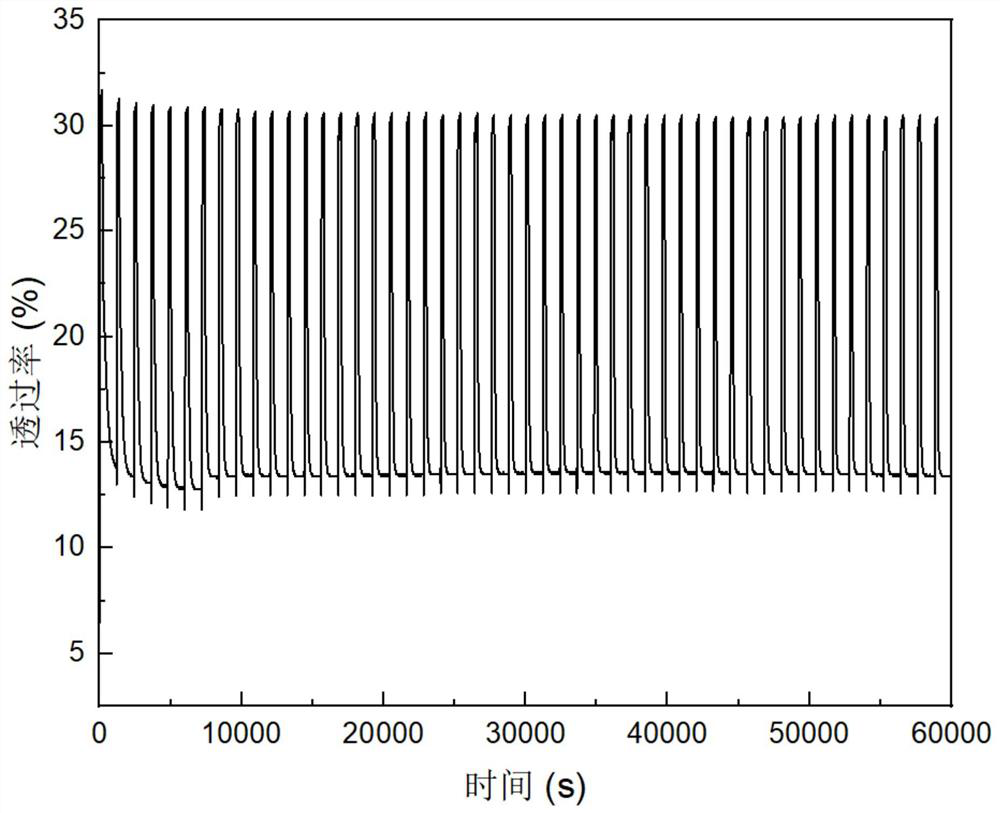

Fluorocarbon/palladium/magnesium-scandium hydrogen-induced color-change film and preparation method thereof

ActiveCN113215544AEasy to operateImprove stabilityVacuum evaporation coatingSputtering coatingPhysical chemistryFluorocarbon

The invention discloses a fluorocarbon / palladium / magnesium-scandium hydrogen-induced color-change film and a preparation method thereof. The film comprises a magnesium-scandium composite film layer, a palladium catalytic layer and a fluorocarbon film layer which are sequentially arranged on a substrate. The preparation method comprises the following steps: firstly, growing the magnesium-scandium composite film layer on the substrate; then, growing the palladium catalytic layer on the magnesium-scandium layer in situ; and finally, depositing the fluorocarbon film layer on Pd. Reversible change-over between hydrogen gas and hydrogen atoms is promoted at a hydrogen suction and separation stage through catalytic effect of palladium; and a composite scandium element is added to accelerate diffusion, in the magnesium matrix, of the hydrogen atoms, so that formation and decomposition of hydrides are quickened, and quick change-over between a reflection state and a transparent state of the film can be realized, and hydrogen suction and discharge circulating durability of the film layer is improved. The whole reaction process can be realized at the room temperature. The light-dimming film has hydrogen suction response, is short in hydrogen removal recovery time, is good in circulating performance, is simple in process, and has an important application prospect in the hydrogen gas sensing field.

Owner:SHANGHAI JIAO TONG UNIV

High capacity Mg2Ni-type hydrogen storing alloy amorphous band and preparation method thereof

ActiveCN100457954CHigh electrochemical capacityGood cycle hydrogen storage and discharge stabilityManufactured materialElectrochemistry

Owner:CENT IRON & STEEL RES INST

A kind of high-capacity mg-zn-ni ternary hydrogen storage alloy and its preparation method

ActiveCN108097947BImproved hydrogen absorption and desorption kineticsLower the hydrogen decomposition temperaturePtru catalystFuel cells

The invention relates to a high-volume Mg-Zn-Ni ternary hydrogen storage alloy and a preparation method thereof. The hydrogen storage alloy is ultrafine grain powder comprising an Mg85Zn5Ni10 alloy and a catalyst TiF3, wherein the catalyst TiF3 accounts for x% of the Mg85Zn5Ni10 alloy by mass, and x is 0-8. The hydrogen storage alloy has an Mg2Ni phase and an MgZn2 phase, and is further of a nanocrystalline / non-crystalline structure. The Zn and Ni in the alloy can weaken the key energy between Mg and H, and the hydrogen storage performance of a magnesium-based hydrogen storage material is effectively improved. Through component design, control over a microstructure and addition of TiF3, the thermal stability of an alloy hydride is reduced, and the hydrogenation and dehydrogenation thermodynamic and kinetic properties of the alloy are improved. The prepared alloy powder maintains high hydrogen storage volume and fast hydrogenation and dehydrogenation kinetic properties; the dehydrogenation temperature of the hydride is remarkably reduced, and quick reversible hydrogenation and dehydrogenation can be conducted at the temperature of 280 DEG C; and the hydrogenation and dehydrogenation circulation stability is remarkably improved.

Owner:CENT IRON & STEEL RES INST

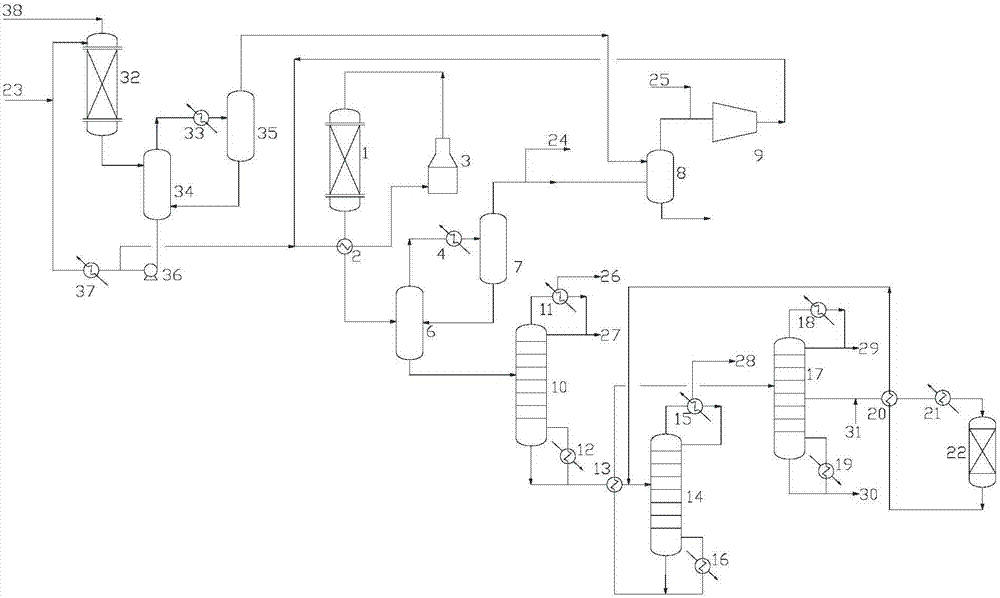

Superimposed oil hydrotreating device and superimposed oil hydrotreating method

InactiveCN111892949AAvoid influenceGuaranteed amount of hydrogenTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a superimposed oil hydrotreating device and a superimposed oil hydrotreating method. The device comprises a hydrogenation reactor, a hydrogenation separation device, a hydrogenation circulating pump and a hydrogenation circulating cooler, wherein an olefin-rich superimposed oil feeding pipeline is connected with an inlet of the hydrogenation reactor; an outlet of the hydrogenation reactor is connected with the hydrogenation separation device; a discharge pipeline at the top of the hydrogenation separation device is used as a hydrogenation tail gas extraction pipeline; abottom discharging pipeline is divided into two paths, one path is connected with the hydrogenation circulating pump and the hydrogenation circulating cooler, then is combined with the olefin-rich superimposed oil feeding pipeline and is finally connected with the inlet of the hydrogenation reactor, and the other path is used as a superposed oil hydrogenation product extraction pipeline or is connected with a stripping tower system; and a fresh hydrogen feeding pipeline is connected with the inlet of the hydrogenation reactor. Through a one-stage liquid-phase hydrogenation treatment mode, allthe olefin-rich superimposed products can be treated; and the device and the method have the characteristics of simple process, reduced investment, high reaction conversion rate, high selectivity andthe like.

Owner:SINOPEC ENG +1

Hydrogen combined optimized utilization technology of hydrogenation apparatus

ActiveCN102399584BReduce dosageReduce lossTreatment with hydrotreatment processesThermodynamicsHydrogenation reaction

The invention discloses a hydrogen combined optimized utilization technology of a hydrogenation apparatus. Excessive hydrogen from a hydrogen pipe net passes through a first reaction unit and conducts a catalysis hydrogenation reaction with raw oil; residual hydrogen enters a first cold-high pressure separating unit for gas-liquid separation, then mixes with cycling hydrogen from a second cold-high pressure separating unit, is treated by a hydrogen cycle unit and enters to a second reaction unit to conduct a catalysis hydrogenation reaction with raw oil; residual hydrogen enters into the second cold-high pressure separating unit for gas-liquid separation, merges with residual hydrogen from the first cold-high pressure separating unit, is treated by the hydrogen cycle unit and returns to the second reaction unit. According to the technology of the invention, two sets of hydrogenation apparatuses can share a new hydrogen machine or a hydrogen cycle compressor and part of pipes, so as to reduce equipment quantity and energy consumption of the new hydrogen compressor and the cycle hydrogen compressor, and realize small investment and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com