LaCl3 catalyzed high-capacity hydrogen storing alloy powder and preparation method thereof

A hydrogen storage alloy and high-capacity technology, applied in the field of hydrogen storage alloy materials, can solve the problems of extremely poor hydrogen absorption and desorption kinetics of the alloy, and achieve good hydrogen absorption and desorption cycle stability, excellent hydrogen absorption and desorption kinetics, and good hydrogen absorption and desorption. The effect of hydrogen desorption capacity

Active Publication Date: 2017-11-24

INNER MONGOLIA UNIV OF SCI & TECH

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, crystalline rare earth magnesium-based alloys have almost no ability to desorb hydrogen at room temperature, and the hydrogen absorption and desorption kinetics of alloys prepared by conventional melting and casting processes are extremely poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

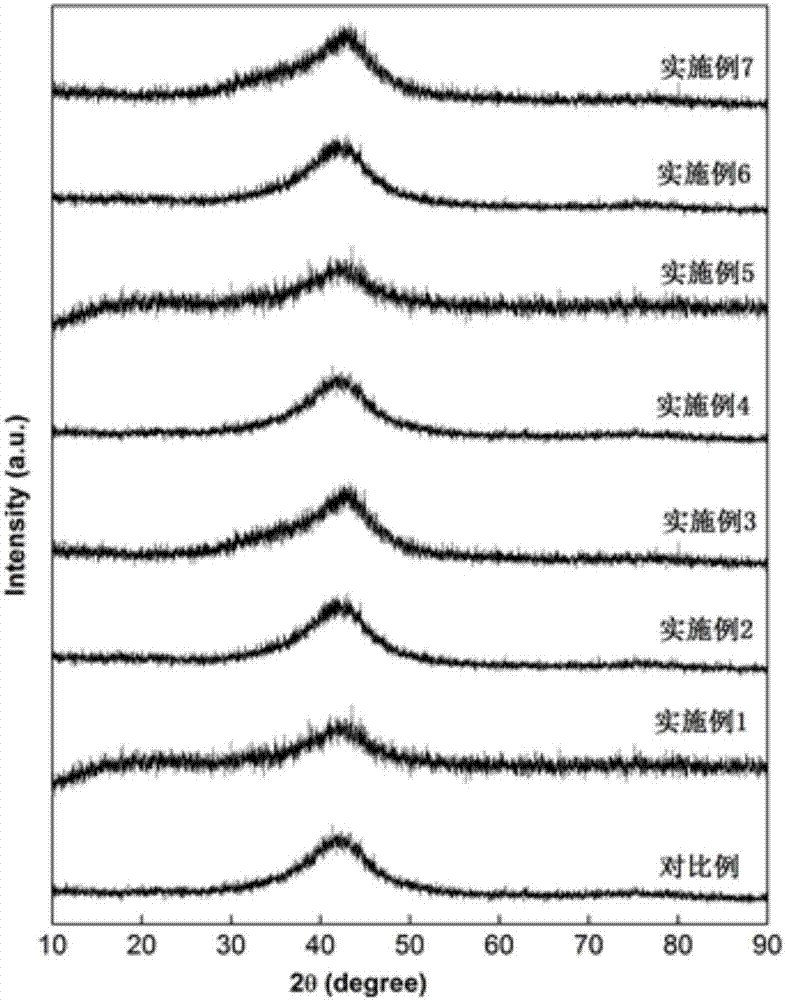

Embodiment 1

[0022] Example 1: Mg 43 Ti 5 Al 2 La 5 YNi 3 Cu 0.5 Co 0.5 +4wt.%LaCl 3 ;

Embodiment 2

[0023] Example 2: Mg 43 Ti 5 Al 2 La 5 SmNi 2 CuCo+4wt.%LaCl 3 ;

Embodiment 3

[0024] Example 3: Mg 44 Ti 2 Al 4 La 4 Nd 2 Ni 2 CuCo+4wt.%LaCl 3 ;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

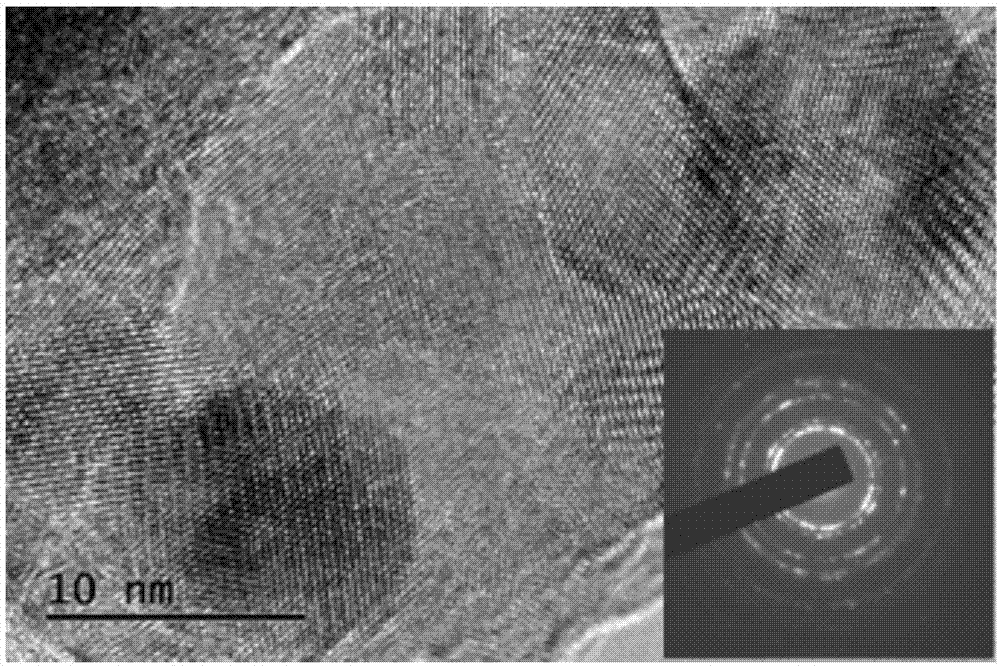

The invention relates to LaCl3 catalyzed high-capacity hydrogen storing alloy powder. The chemical formula composition of the powder is Mg50-x-yTixAlyLa6-zREzNi4-m-nCumCon+Q wt.%LaCl3. According to the LaCl3 catalyzed high-capacity hydrogen storing alloy powder, titanium and aluminum are used for partially replacing magnesium in rare earth magnesium alloy, multicomponent rare earth, nickel, copper and cobalt are added, and a rapid quenching alloy ribbon with a nanocrystalline+non-crystalline structure is obtained through a rapid quenching process. A trace of LaCl3 catalyst is added, the thermal stability of alloy hydride can be obviously reduced through ball milling, the hydrogen desorption capacity of alloy at low temperature is improved, and the hydrogen absorption and desorption dynamics is further improved. The prepared hydrogen storing alloy powder has high hydrogen absorption and desorption capacity and excellent hydrogen absorption and desorption dynamics and has good hydrogen absorption and desorption cycling stability.

Description

Technical field [0001] The invention belongs to the technical field of hydrogen storage alloy materials, and particularly relates to a LaCl 3 Catalytic high-capacity Mg-Ti-Al-La-RE-Ni-Cu-Co-based hydrogen storage alloy powder and preparation method thereof. Background technique [0002] Hydrogen is considered to be an irreplaceable clean energy source, and it is very likely to be used in fuel cells. The technical bottleneck faced by the use of hydrogen as a fuel is the lack of an efficient and reliable hydrogen storage system. Among all hydrogen storage methods, metal hydrides are considered to be ideal hydrogen fuel carriers for fuel cells due to their efficient and safe hydrogen storage performance. However, the hydrogen storage capacity of currently commercialized hydrogen storage materials cannot meet the requirements of fuel cells. . Magnesium-based alloys are recognized as the most potential hydrogen storage materials due to their high hydrogen storage density and extreme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C23/06B22D11/06B22F9/04H01M8/04082

CPCB22D11/06B22F9/04B22F2009/043C22C23/06H01M8/04216Y02E60/50

Inventor 任慧平侯忠辉蔡颖冯佃臣翟亭亭张羊换

Owner INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com