Patents

Literature

48results about How to "Improve the kinetic performance of hydrogen absorption and desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium base composite hydrogen storage material and preparation method

The invention discloses a magnesium-based composite hydrogen storage material comprising the following compositions by weight percent: 1.0-10.0% of Al, 1.0-5.0% of Ni, and the balance of Mg. A preparation method thereof comprising the following steps: at first, smelting block-shaped metal Mg and Al by a medium frequency induction to prepare Mg17Al12 alloy which is crushed to 300 meshes; hydrogenising Mg powder at 340 DEG C under a hydrogen atmosphere of 4.0MPa to prepare MgH2; then blending Mg17Al12, MgH2, Ni powder in accordance with contents by weight percent for ball-grinding for 60 to 100 hours under an atmosphere of argon. The magnesium-based composite hydrogen storage material can reversely absorb and release hydrogen at low temperature, and has high hydrogen storage capacity, excellent activation performance and superior hydrogen absorbing and releasing kinetics property. The magnesium-based composite hydrogen storage material can be used for manufacturing hydrogen source to facilitate purification and storage and transportation of hydrogen, and can also used for hydrogen storage material for fuel cells.

Owner:ZHEJIANG UNIV

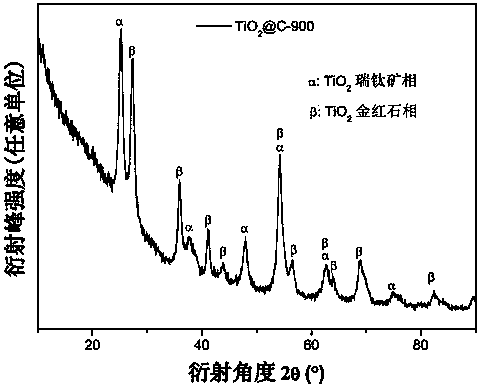

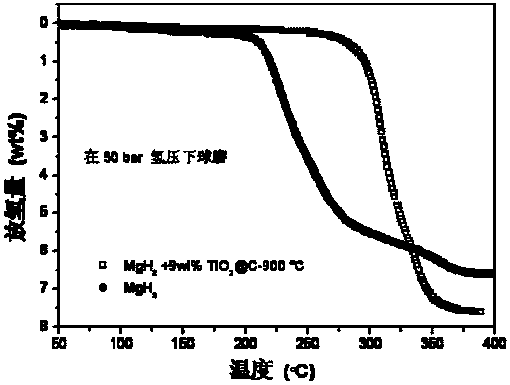

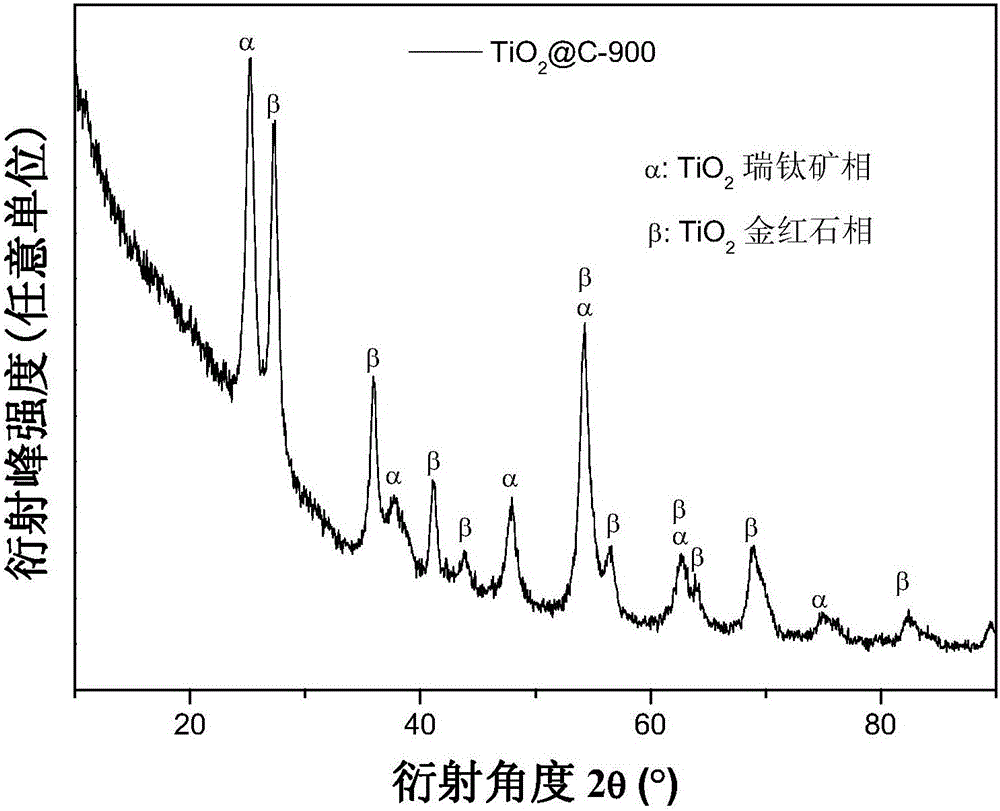

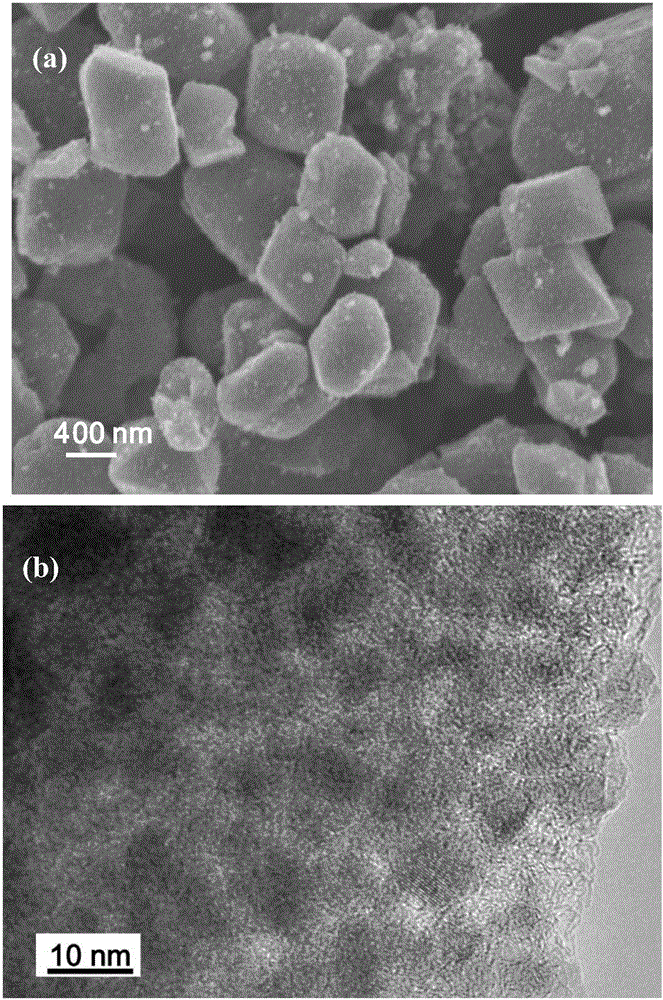

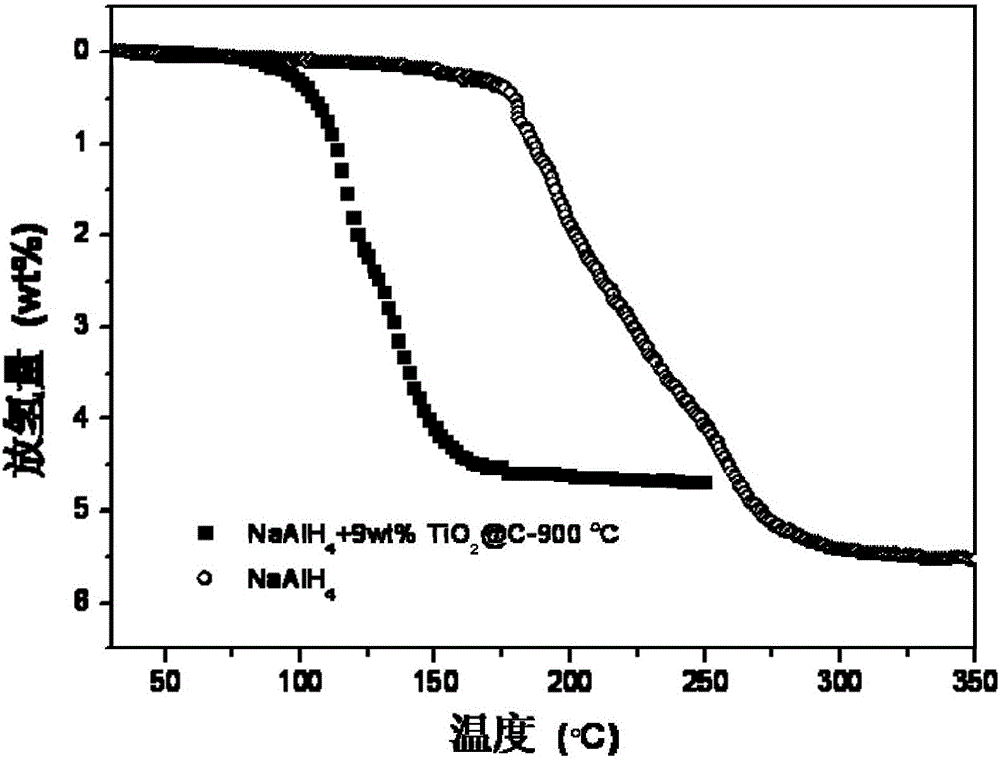

Porous carbon loaded nano metal oxide catalyst, preparation method of catalyst, and hydrogen storage material

ActiveCN104069842ARealize controllable modulationEasy to prepareCatalyst carriersHydrogen productionAlcoholMetal framework

The invention discloses a porous carbon loaded nano metal oxide catalyst, a preparation method of catalyst, and a hydrogen storage material applying the catalyst. The preparation method comprises the following steps: (1) immersing an organic metal framework into a mixed solution of furfuryl alcohol and alcohol, and stirring for 12-60 hours under a sealed condition; (2) filtering a product obtained from the step (1) to obtain solid powder, and rising the temperature to 140-165 DEG C under inert atmosphere protection; (3) rising the temperature of the product obtained from the step (1) to 700-1000 DEG C under inert gas flow protection; and keeping the temperature and cooling so as to obtain the porous carbon loaded nano metal oxide catalyst. The preparation method of the catalyst provided by the invention is simple and convenient; the hydrogen storage material in which the catalyst is added has the advantages of low hydrogen discharge temperature, high hydrogen discharge velocity, good hydrogen absorption and discharge reversibility and long circulation service life.

Owner:ZHEJIANG UNIV

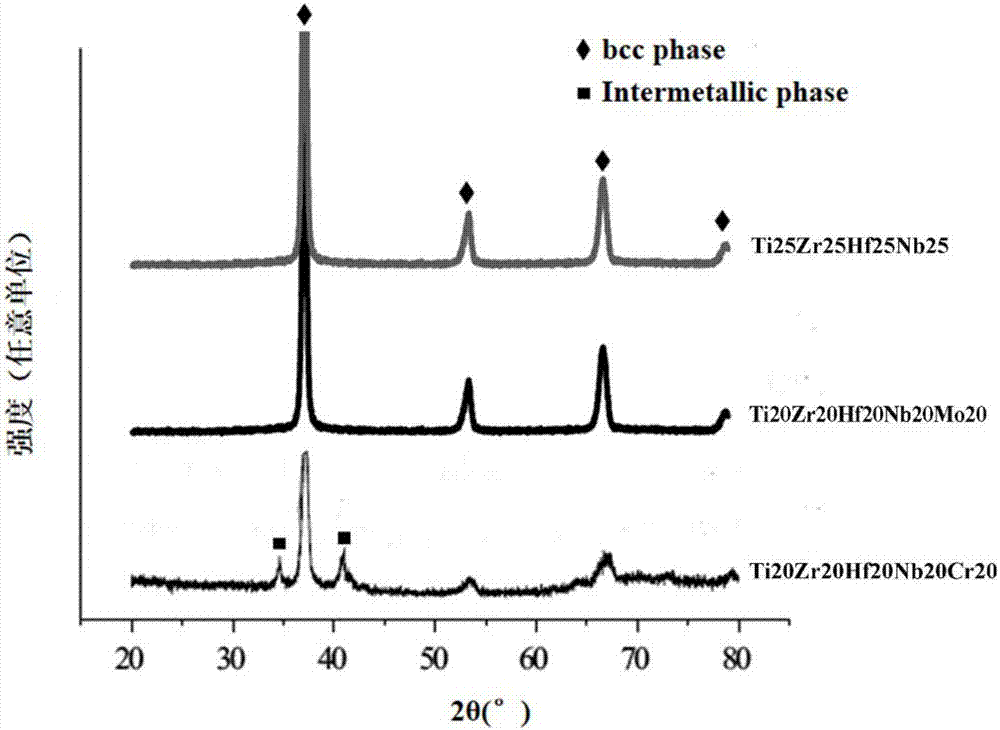

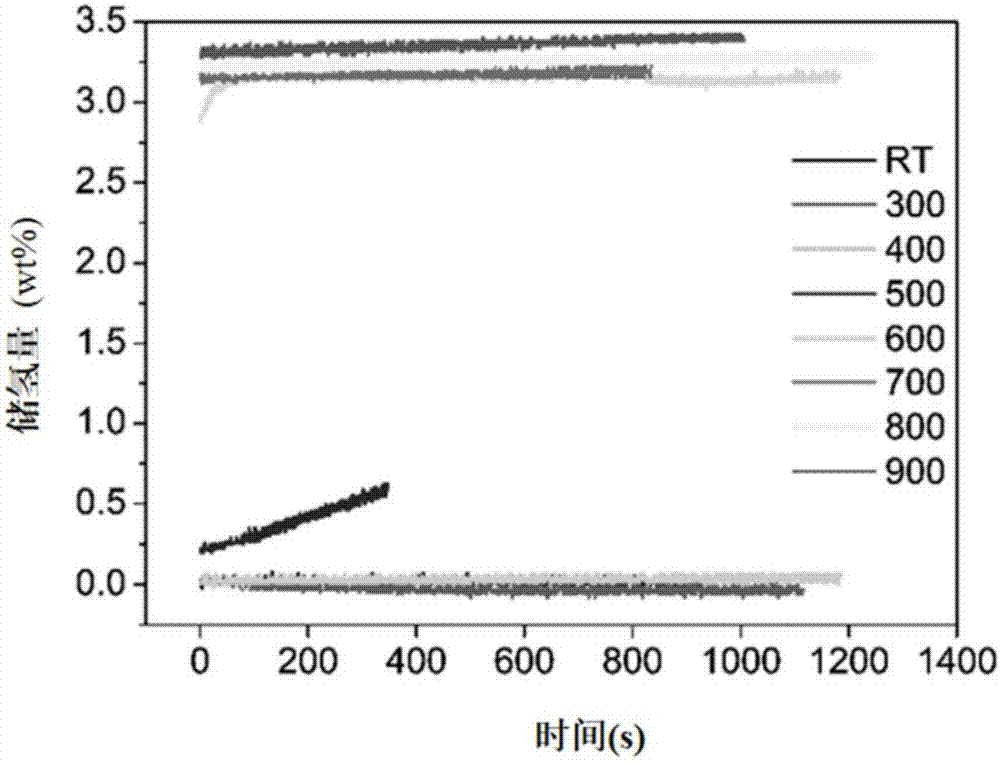

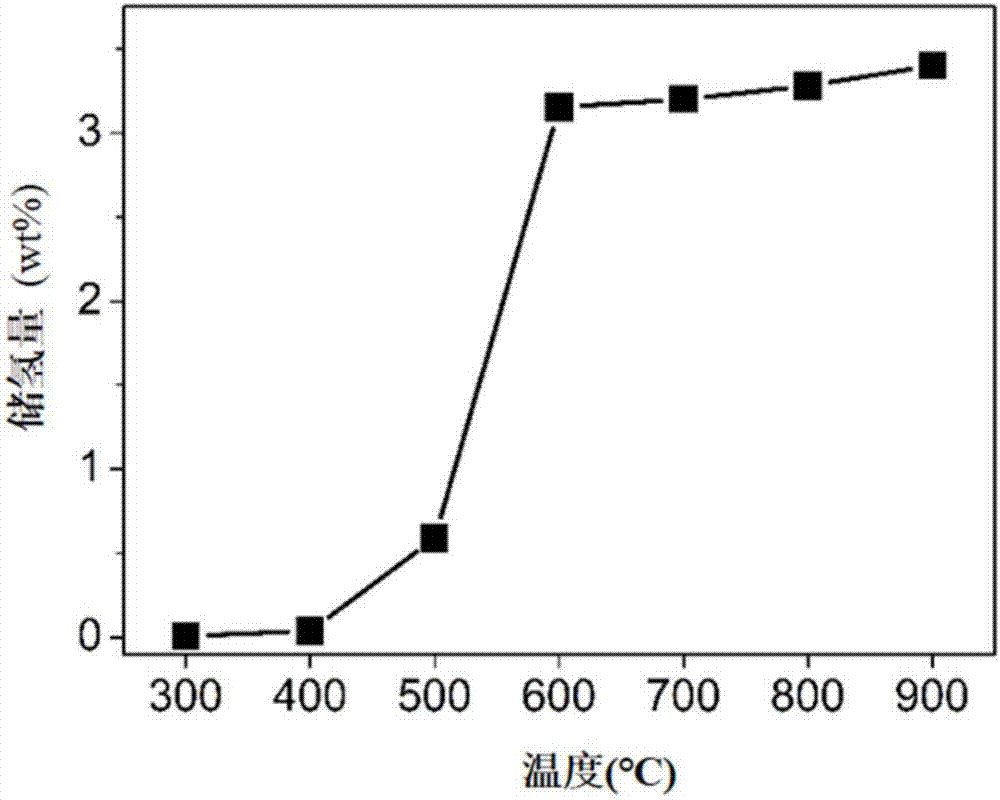

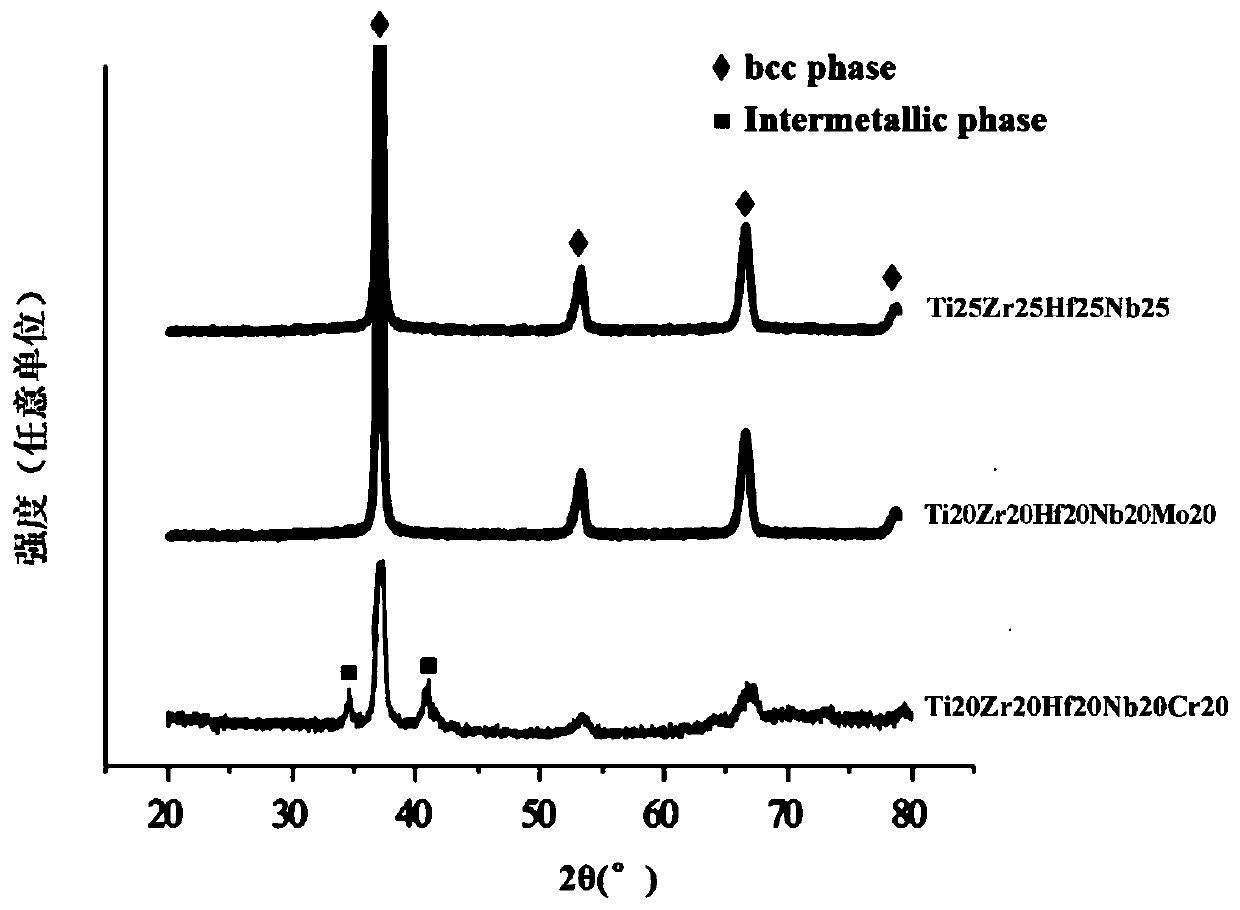

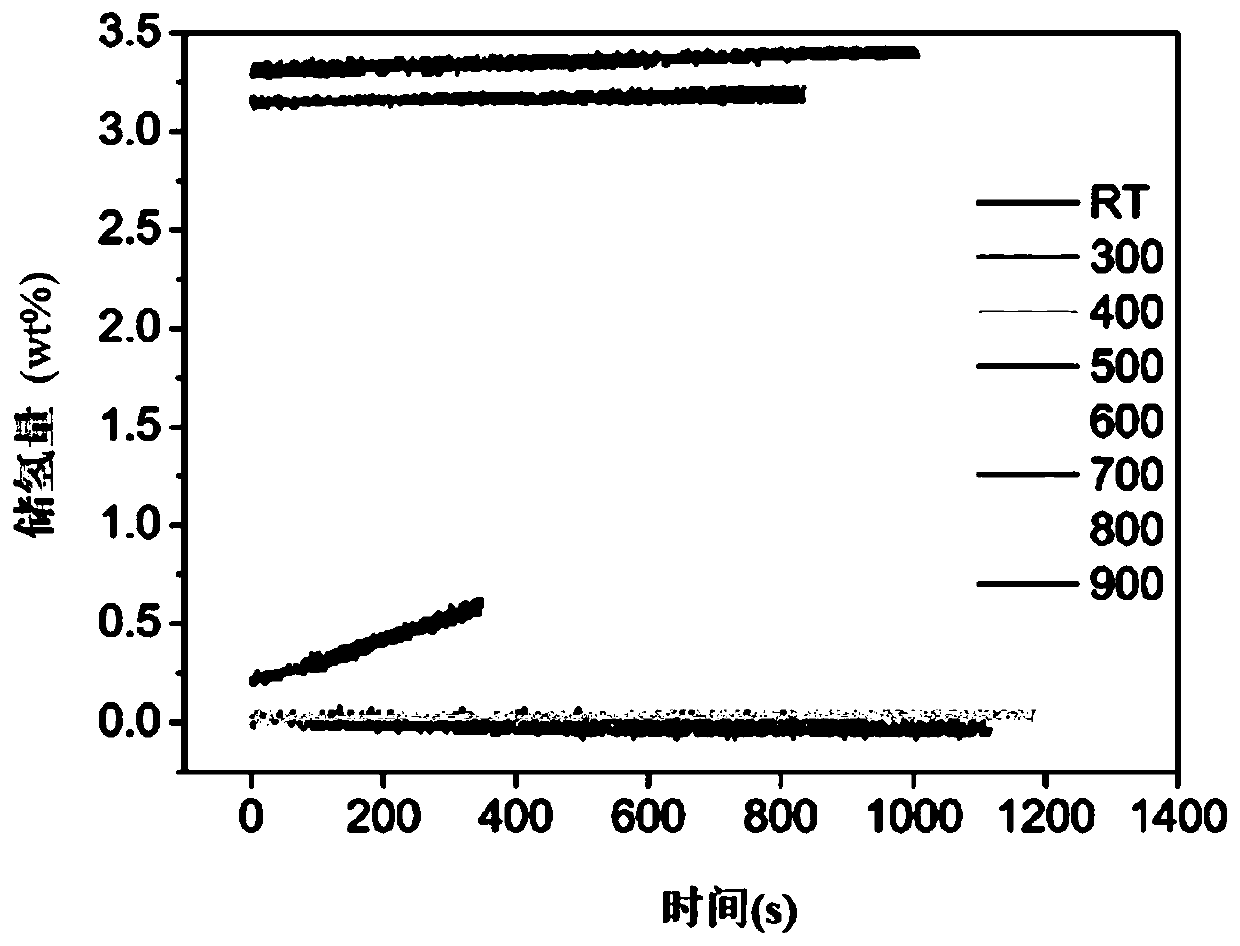

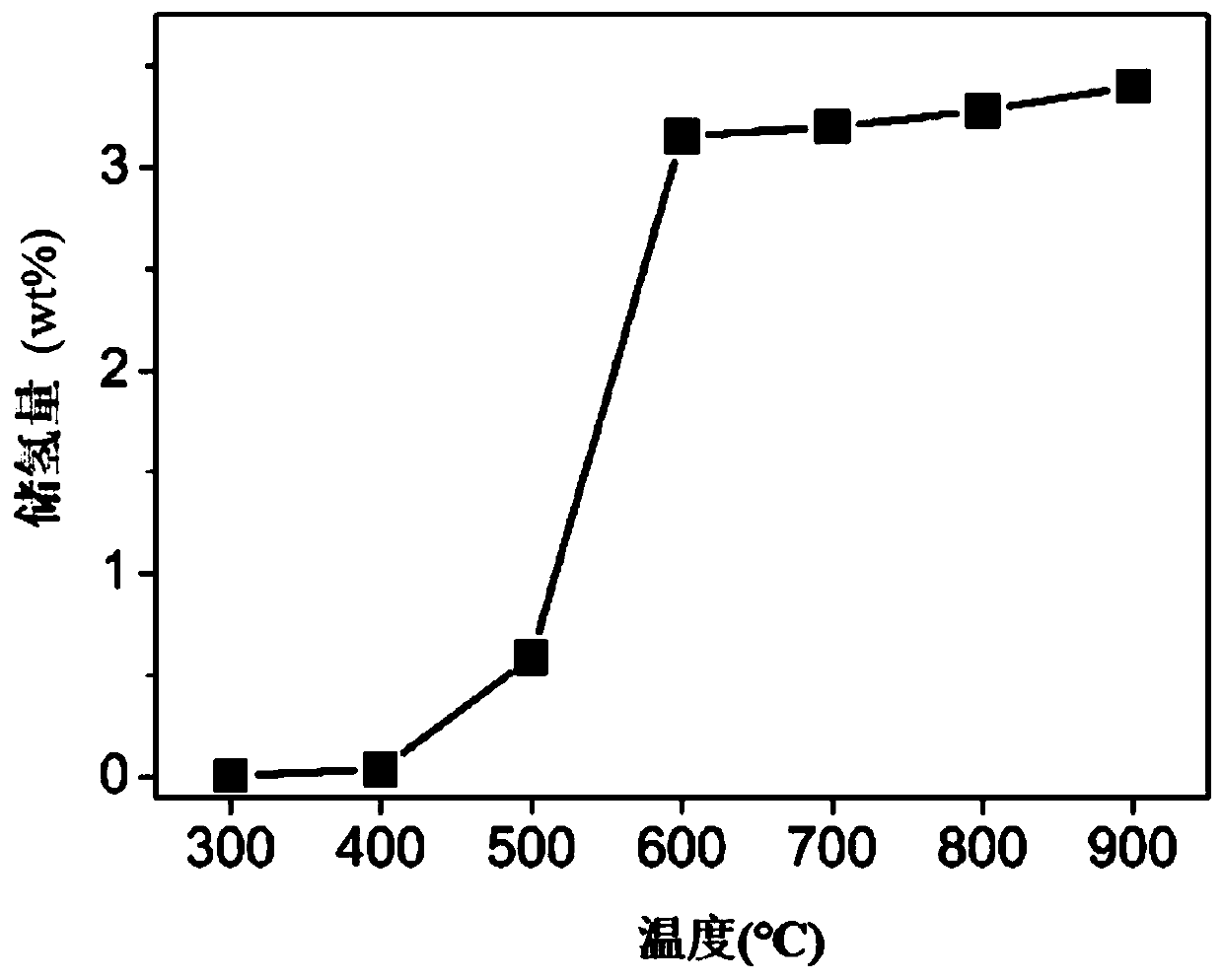

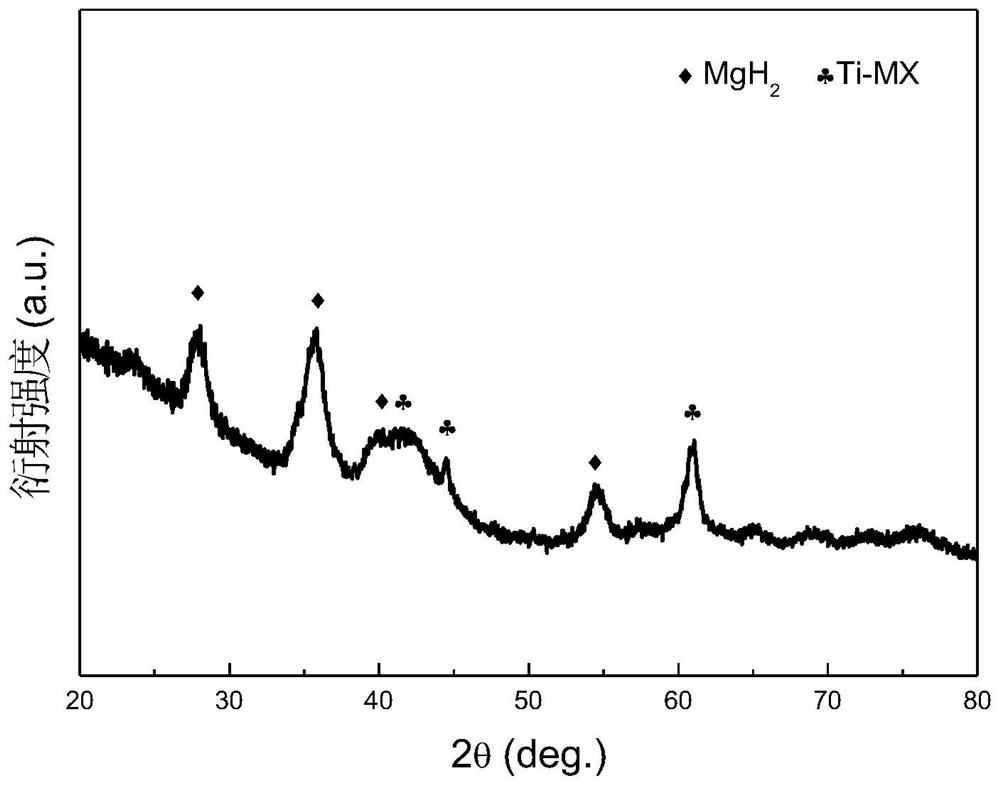

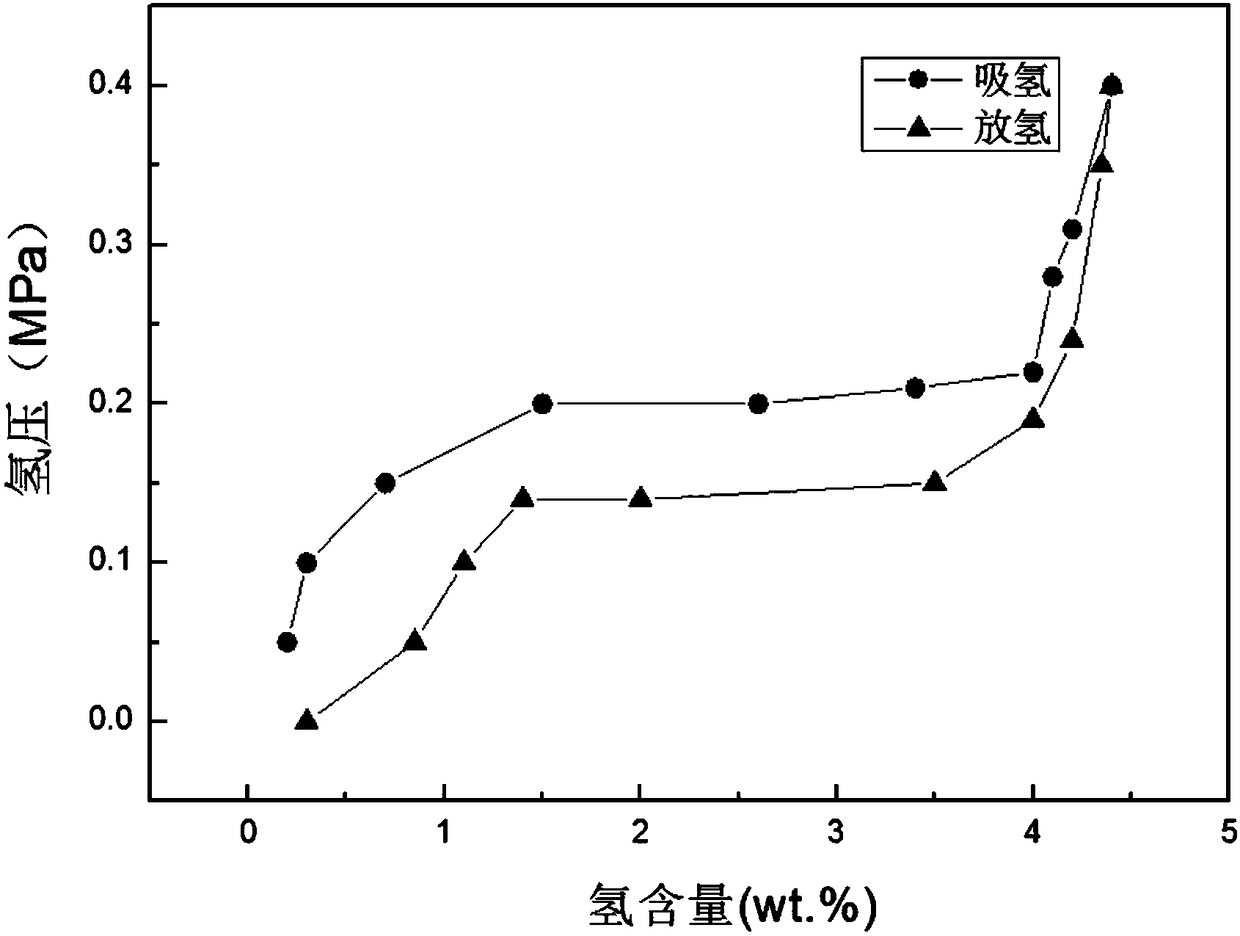

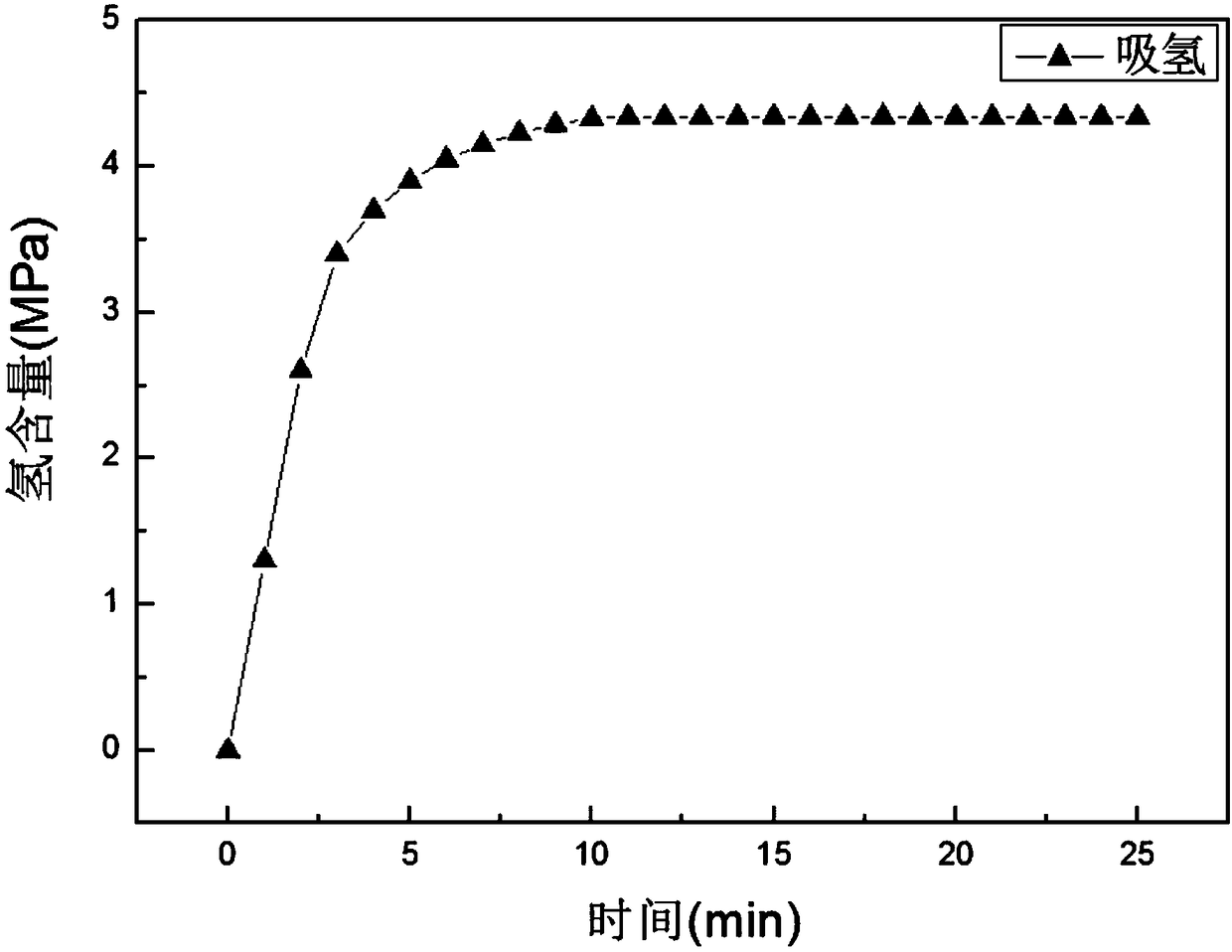

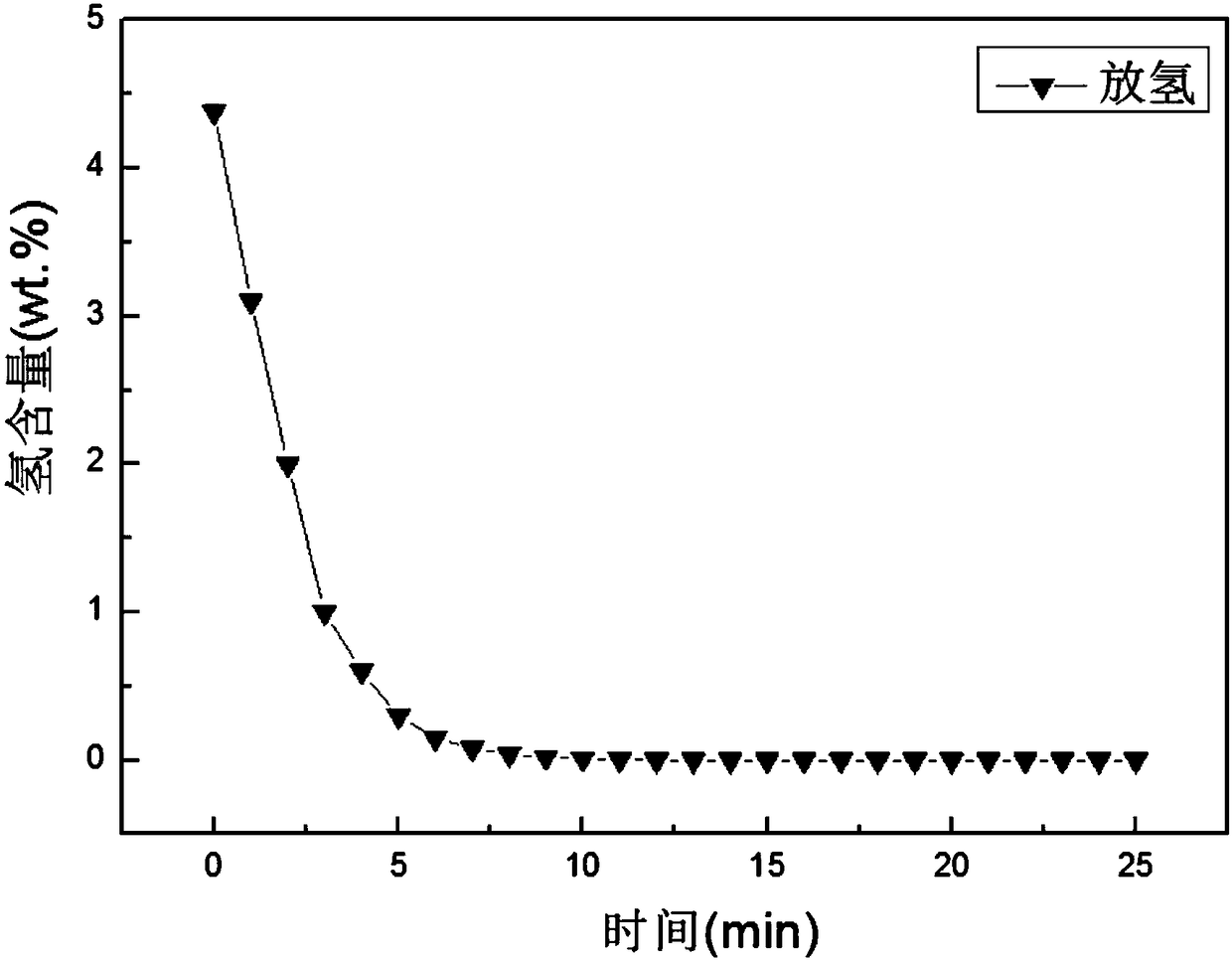

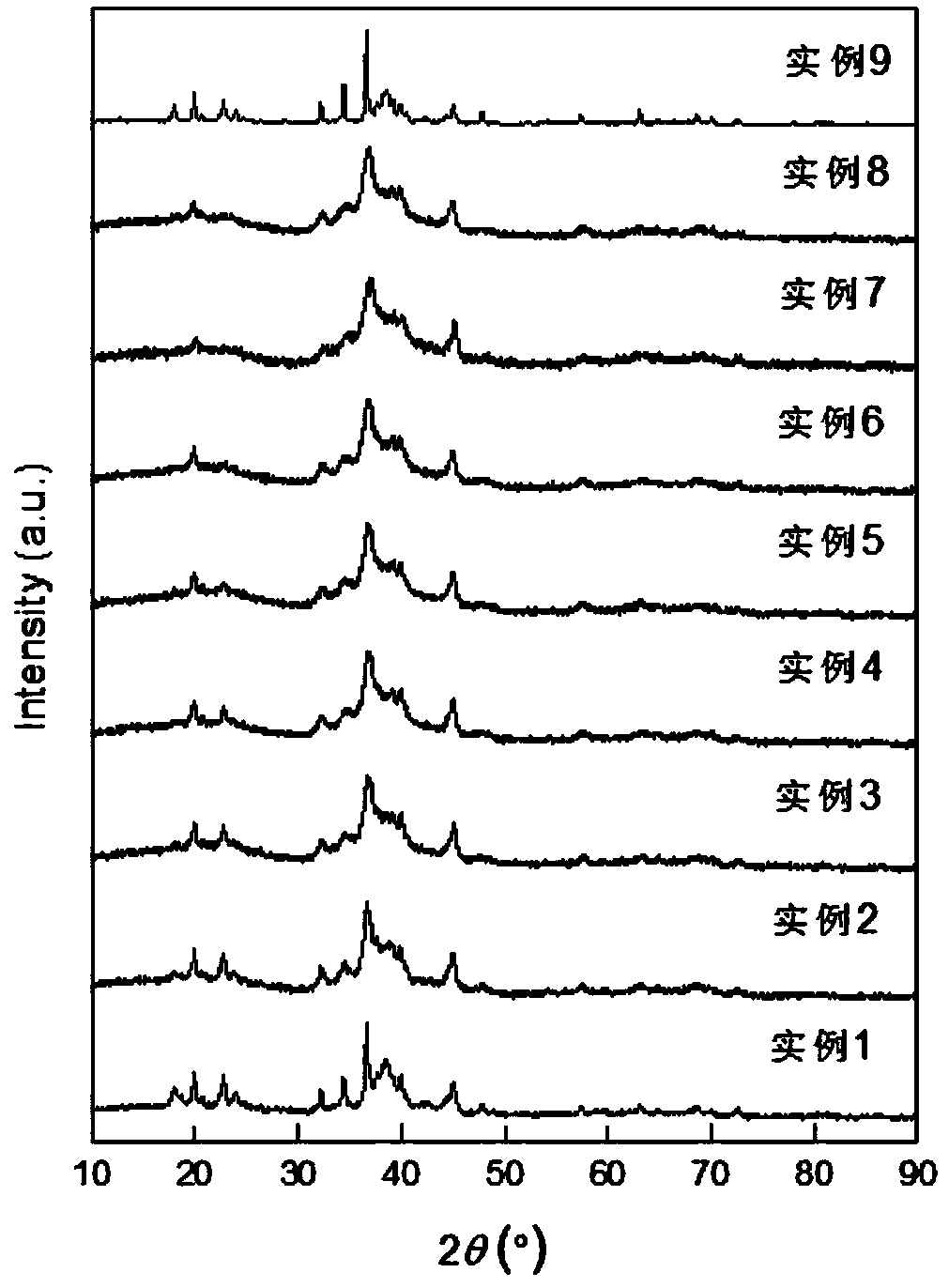

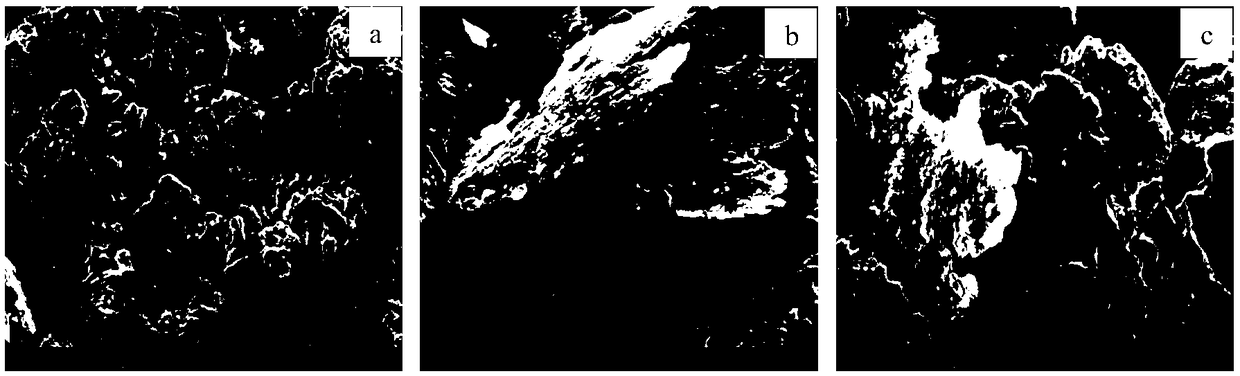

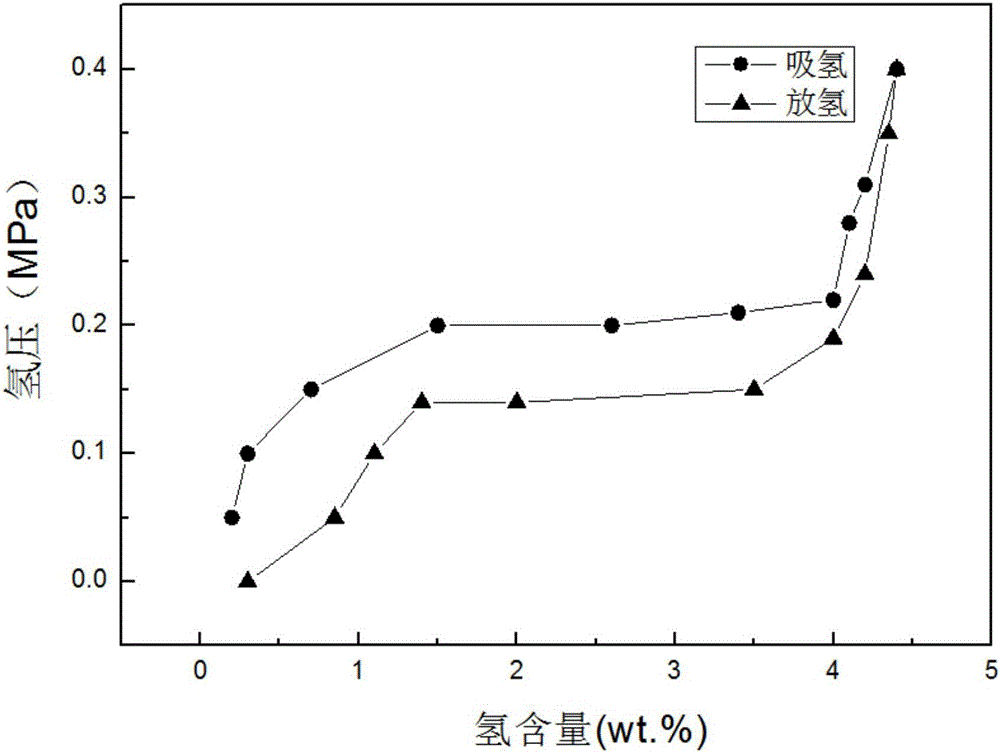

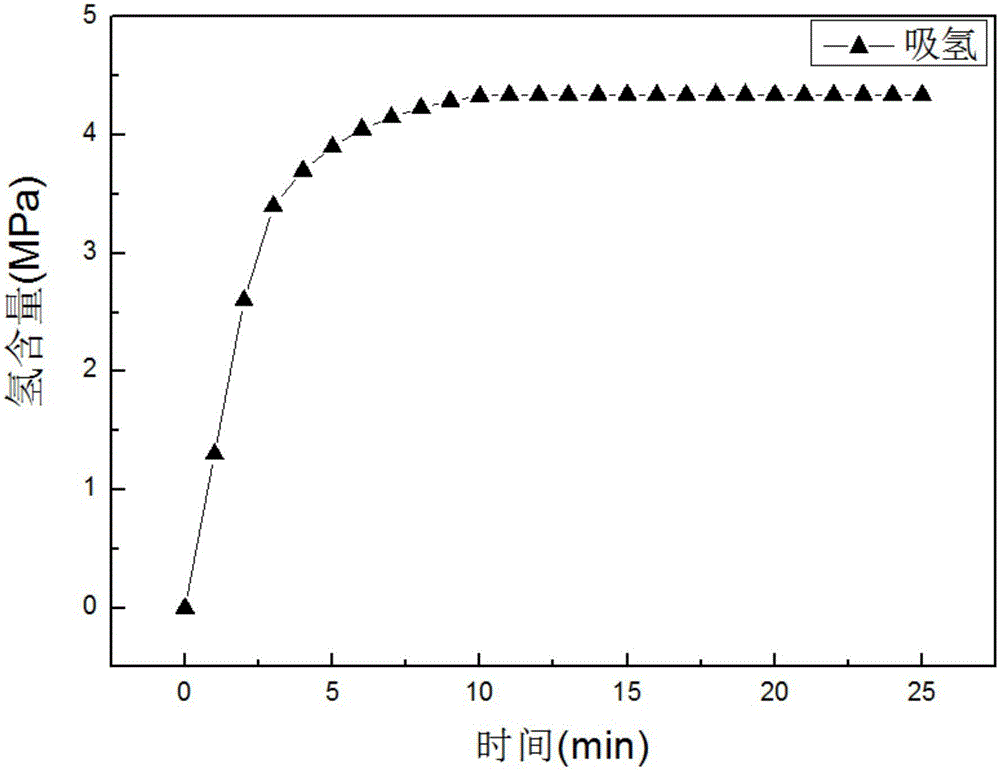

Hydrogen storage high-entropy alloy taking body-centered cubic structure as principal thing and preparation method for hydrogen storage high-entropy alloy

ActiveCN107338385AHigh hydrogen storage capacityFast hydrogen absorption and desorptionElectric arc furnaceHigh entropy alloys

The invention belongs to the field of hydrogen storage materials, and relates to a hydrogen storage high-entropy alloy taking a body-centered cubic structure as the principal thing and a preparation method for the hydrogen storage high-entropy alloy. A component expression formula of high-entropy alloy is as follows: (TiaZrbNbc)xMy, wherein a is greater than or equal to 5at% and smaller than or equal to 35at%, b is greater than or equal to at5% and smaller than or equal to 35at%, c is greater than or equal to 5at% and smaller than or equal to 35at%, a+b+c is equal to x, x is greater than or equal to 15at% and smaller than or equal to 100at%, M is any one or more of Hf, Fe, Co, Cr, Mn, Ni, Mo and W; and atomic percent of each M is 0-35%, and x+y is equal to 100. The preparation method for the hydrogen storage high-entropy alloy comprises the following steps of: adopting a non-consumable vacuum electric-arc furnace to smelt to prepare alloy; and adopting suction casting to sucking alloy into a water-cooling cooper mould, thereby obtaining a high-entropy alloy rod. The high-entropy alloy has high hydrogen storage capacity (3 mass% or more) and excellent hydrogen absorption and desorption dynamic performances; when hydrogen absorption and desorption amount is great, the high-entropy alloy, in comparison with a pure element, does not need to completely purify, so that cost can be saved to a great extent. The hydrogen storage high-entropy alloy taking the body-centered cubic structure as the principal thing has the characteristics of the high-entropy alloy, and has a wide application prospect in the fields of new energy resources and transportation.

Owner:UNIV OF SCI & TECH BEIJING

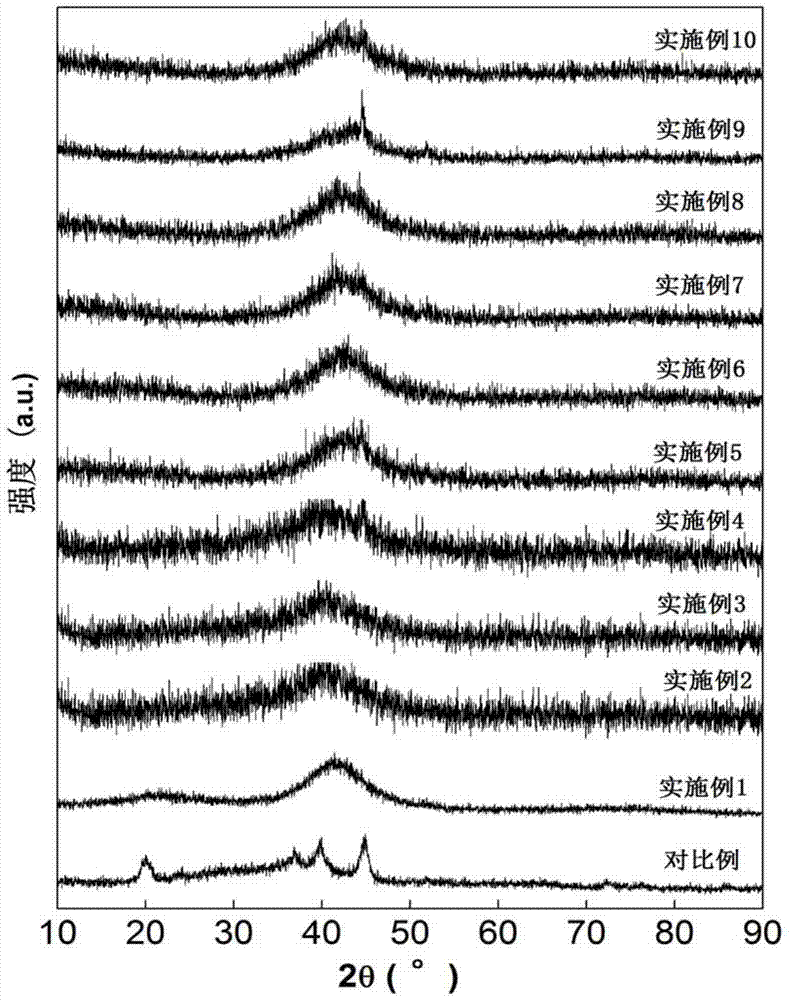

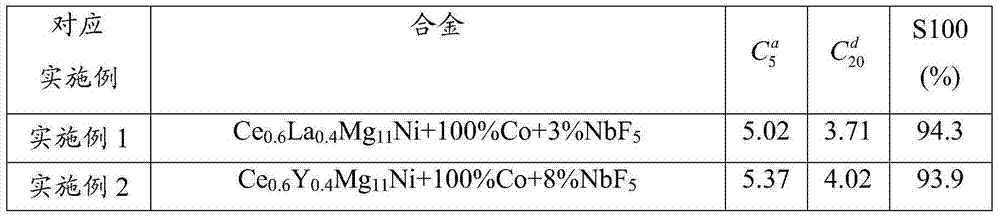

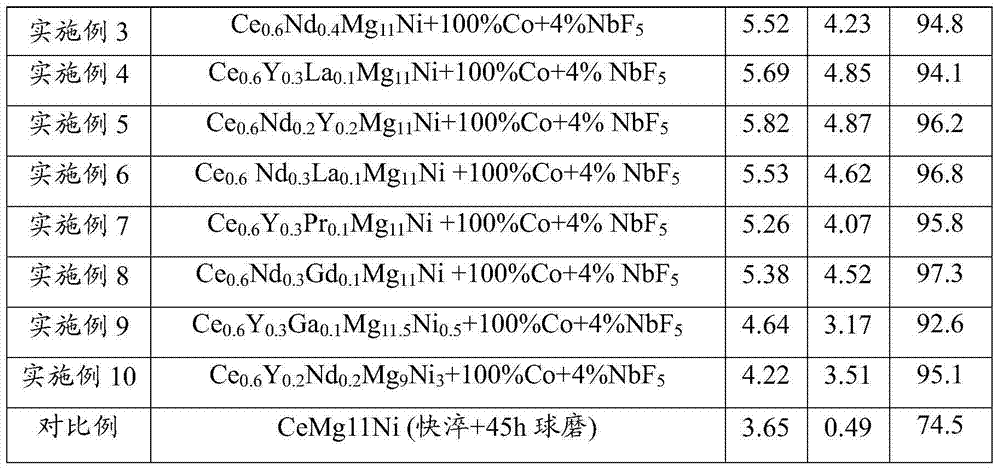

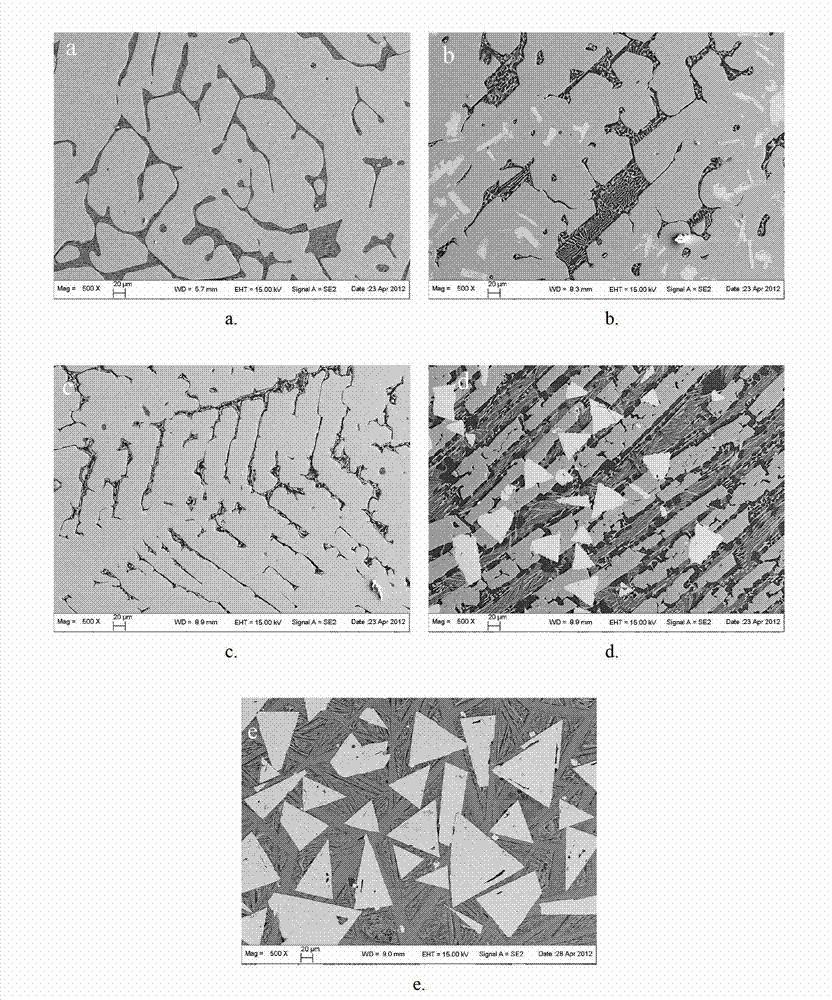

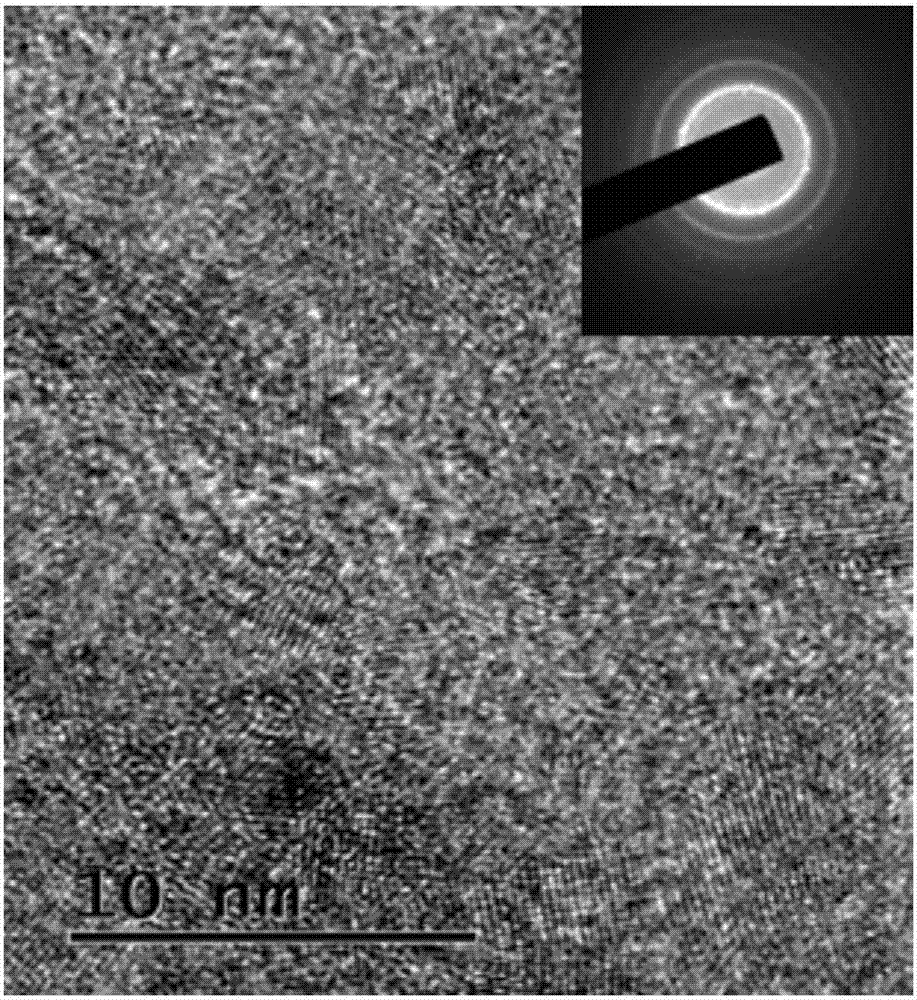

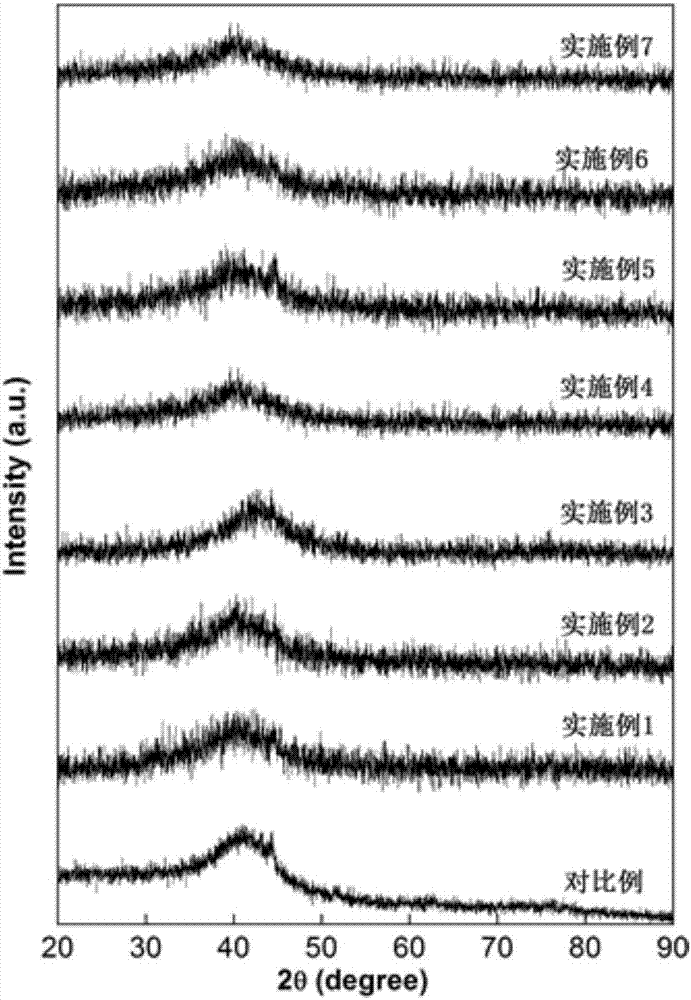

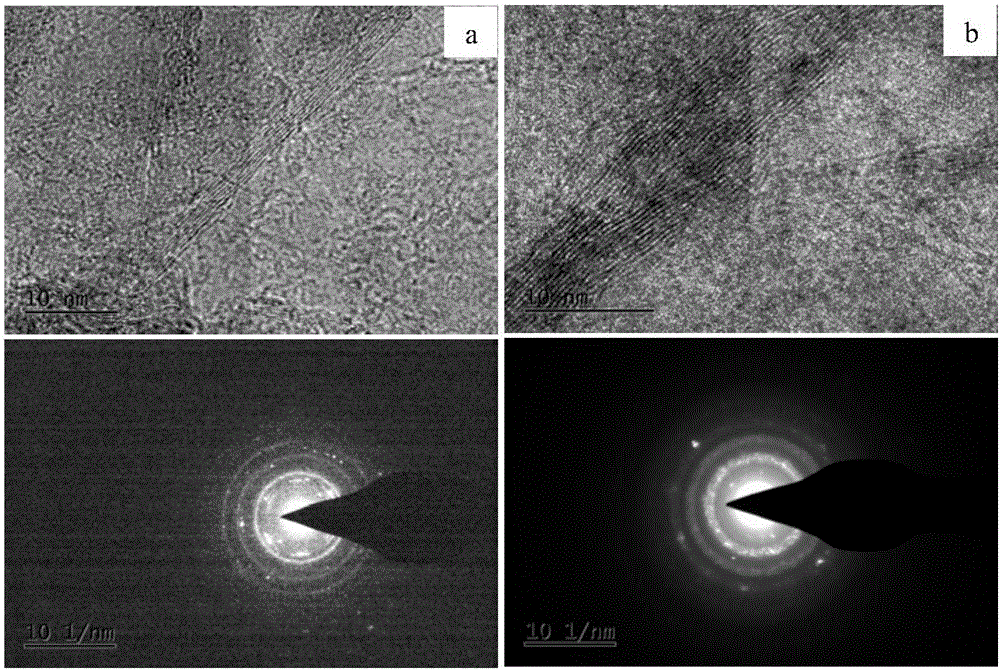

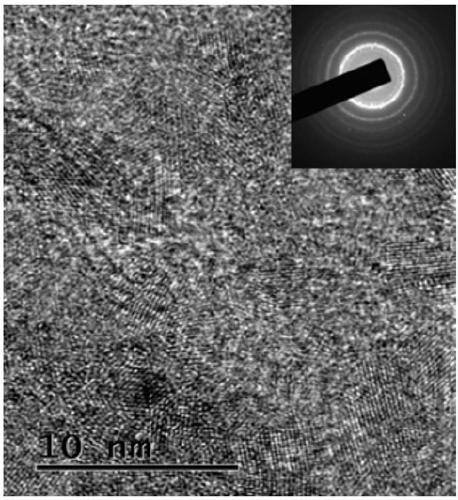

High-capacity RE-Mg-Ni-Co based hydrogen storage alloy and preparation method thereof

InactiveCN103695753AHigh hydrogen absorption and desorption capacityImproved hydrogen absorption and desorption kineticsRare-earth elementYttrium

The invention belongs to the field of hydrogen storage material preparation and particularly provides a high-capacity RE-Mg-Ni-Co based hydrogen storage alloy and a preparation technology thereof. The high-capacity RE-Mg-Ni-Co based hydrogen storage alloy has a chemical formula of Ce(1-x)RExMg(12-y)Niy+100(wt)%Co+z(wt)%NbF5, wherein x and y represent the atomic ratio, x is greater than 0 and smaller than 0.5, y is greater than 0.5 and smaller than 3, z represents the percentage content of NbF5 in a Ce(1-x)RExMg(12-y)Niy alloy and is greater than 2 and smaller than 8, RE is one of rare earth elements, namely lanthanum, neodymium, yttrium, praseodymium and gadolinium, and the mass of Co is equal to that of the Ce(1-x)RExMg(12-y)Niy alloy. The hydrogen storage alloy is prepared through the steps of proportioning ingredients according to the chemical formula Ce(1-x)RExMg(12-y)Niy, smelting, quickly quenching so as to obtain a thin alloy strip, crushing, screening, mixing with Co powder according to the mass ratio of 1: 1, carrying out first-time ball milling, and carrying out second-time ball milling in a manner of taking nano-NdF5 as a catalyst, thereby obtaining alloy powder with a nanocrystalline-amorphous structure.

Owner:CENT IRON & STEEL RES INST

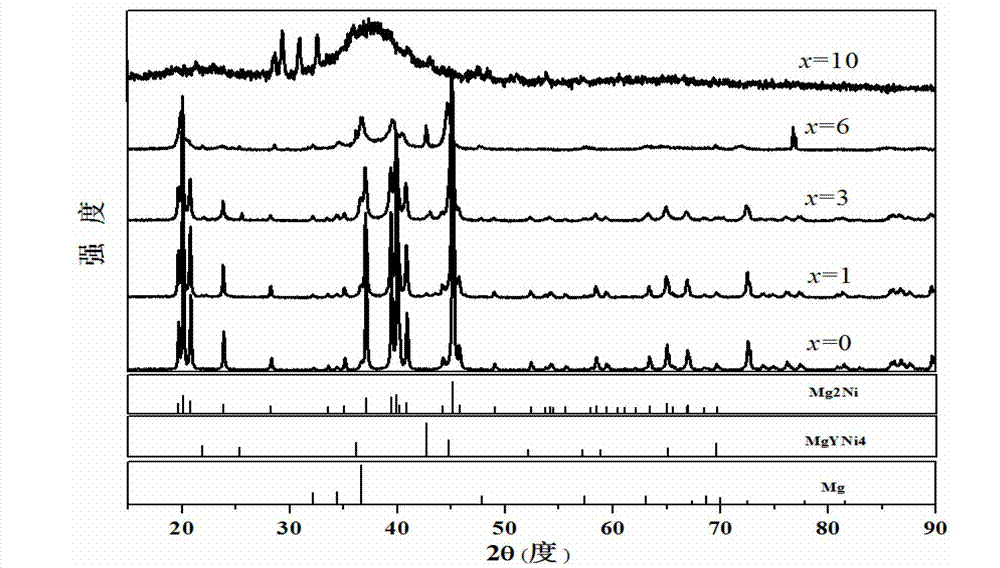

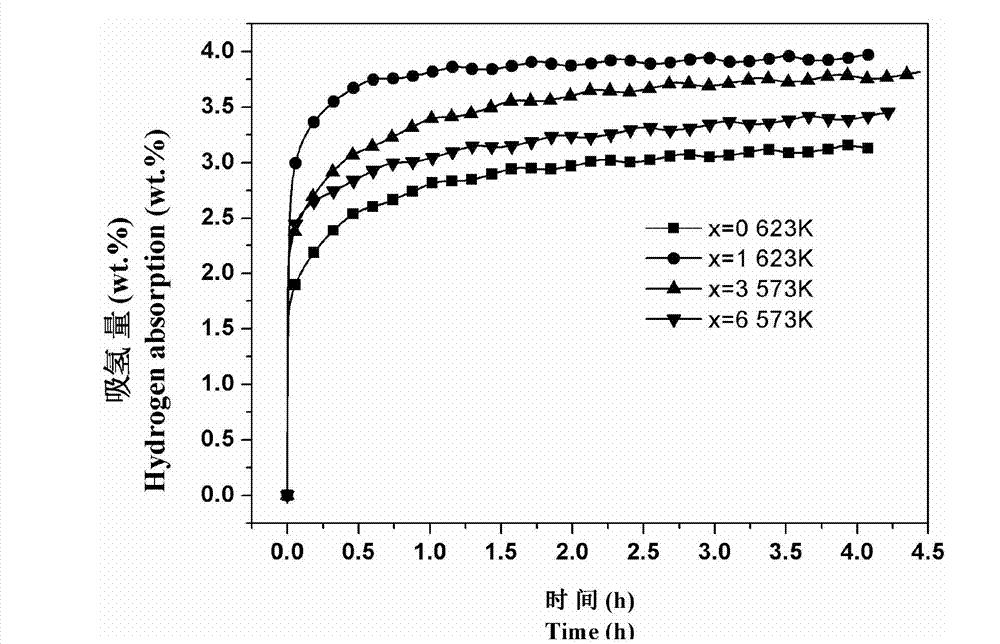

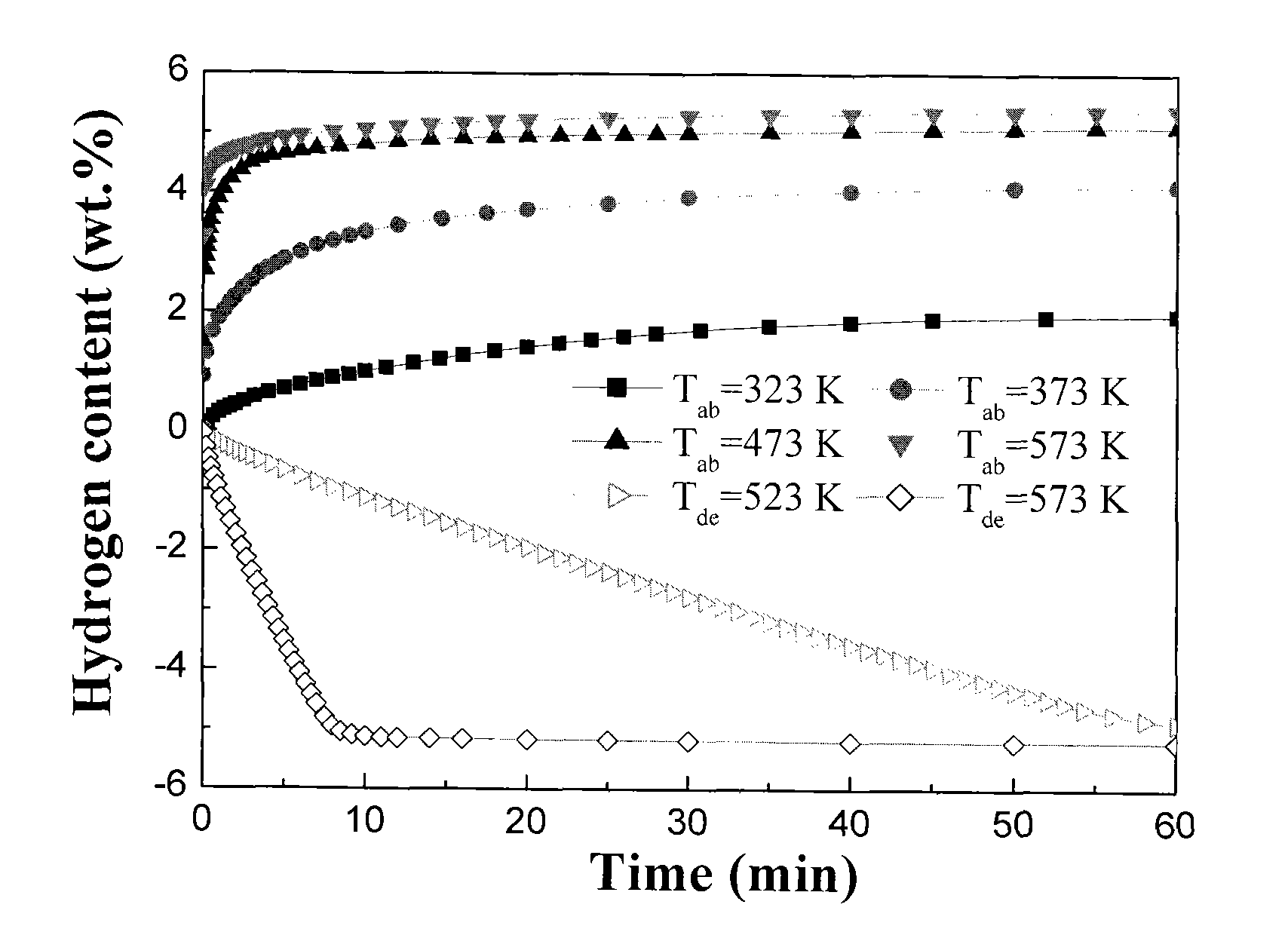

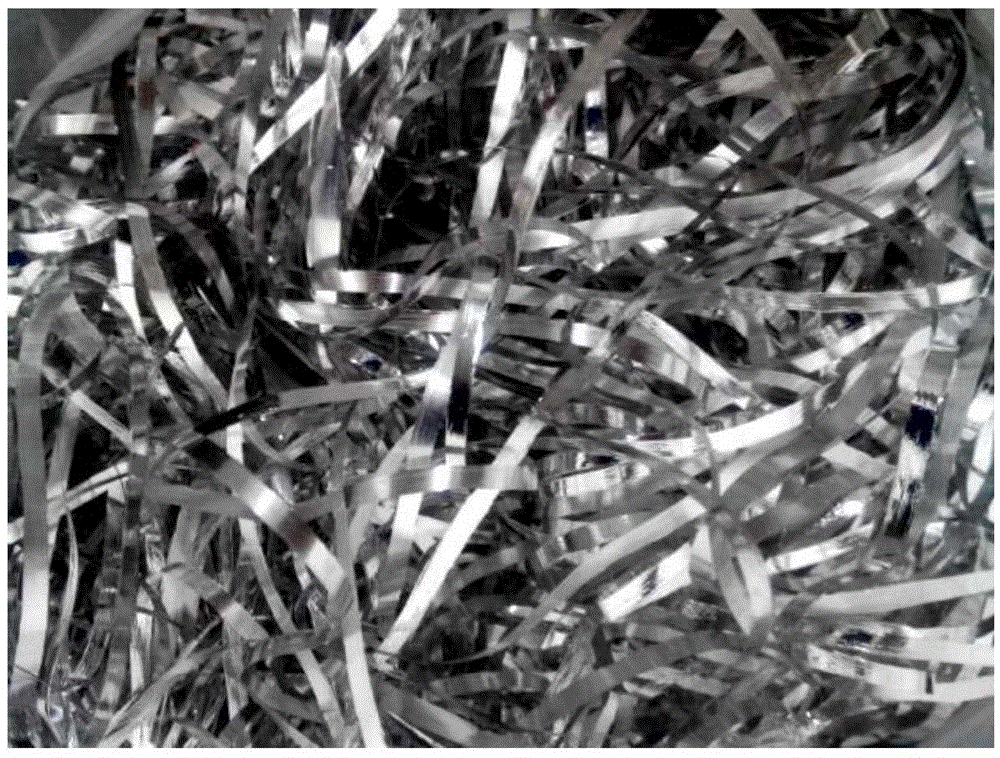

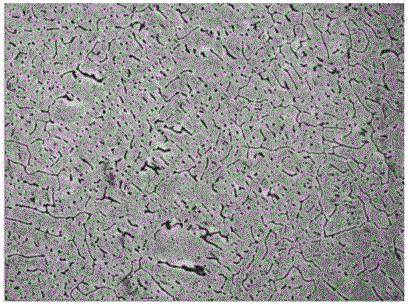

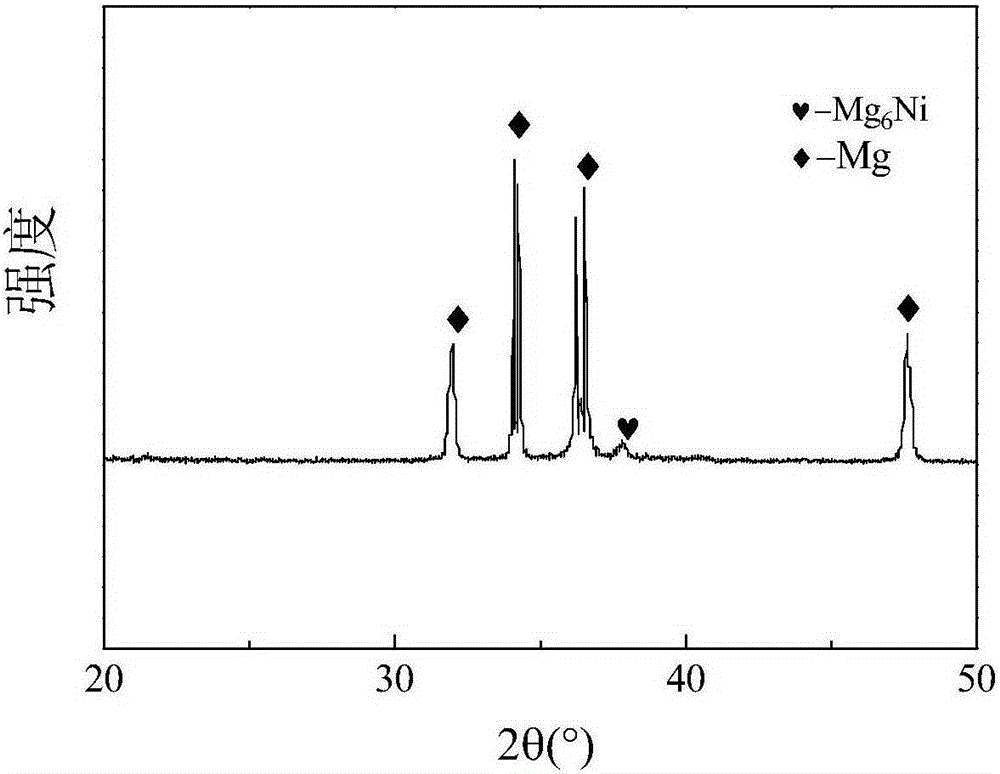

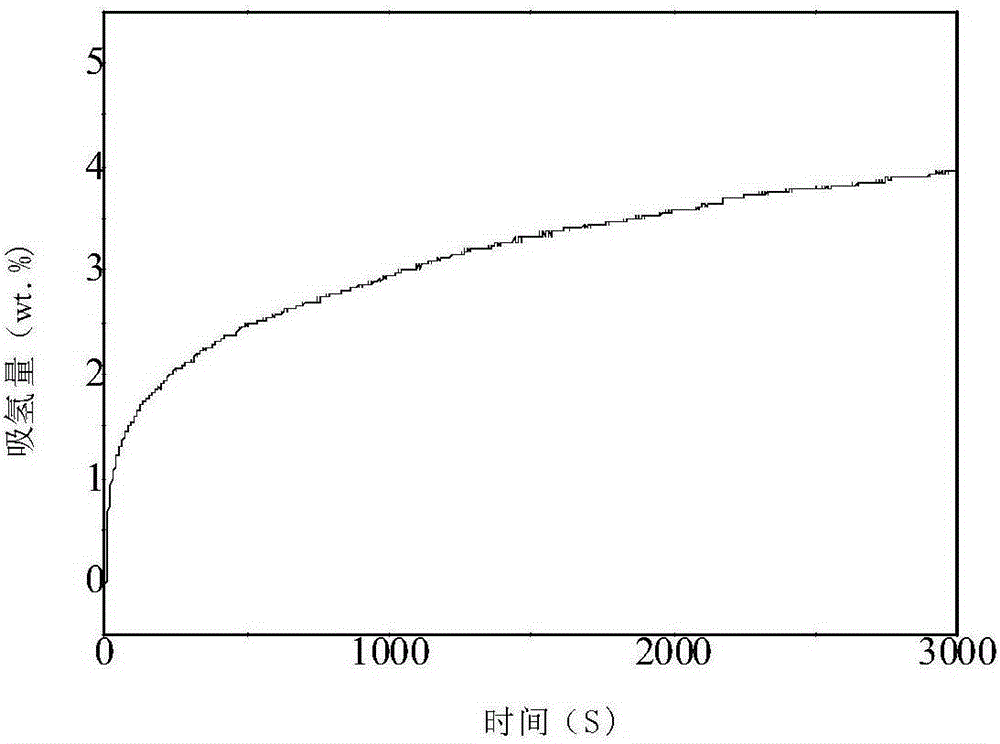

Magnesium-nickel-yttria hydrogen storage alloy thin belt and preparation method thereof

A magnesium-nickel-yttria hydrogen storage alloy thin belt and a preparation method thereof. The hydrogen storage material contains 67at.% of Mg, and 33at.% of nickel and yttrium, wherein yttrium accounts for 0-10at.%, and the rest is nickel. Yttrium is added in a form of a magnesium yttrium intermediate alloy; nickel is added in a form of briquetted nickel powder; a two-step method is adopted to prepare a mother alloy by smelting; and the prepared alloy is remelted and quenched in a single roller melt quenching furnace to obtain a thin belt namely the finished hydrogen storage material. The material provided by the invention improves the hydrogen storage capacity and hydrogen absorption-desorption kinetic properties of a Mg2Ni type hydrogen storage alloy, and overcomes the contradiction that hydrogen storage capacity and dynamic property of Mg base alloy can not be improved at the same time. The invention has the characteristics of simple preparation method, low cost, and low requirement on equipment and environment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

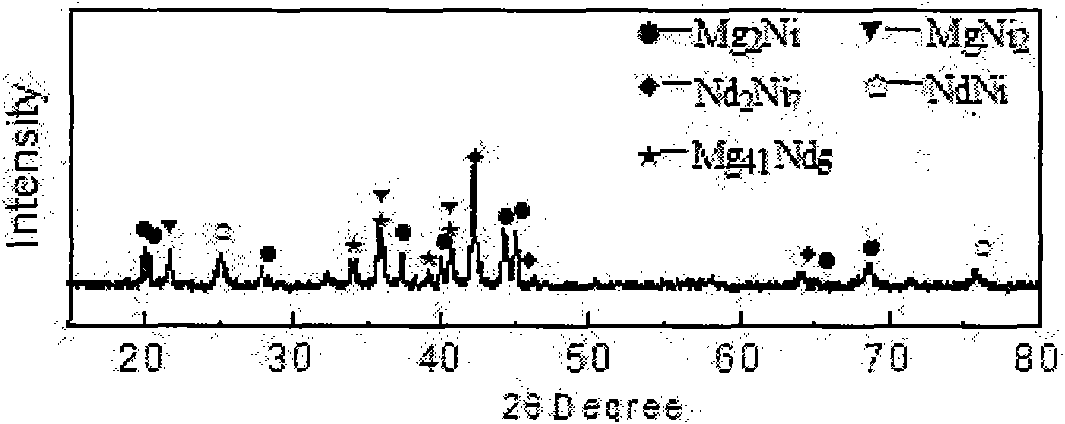

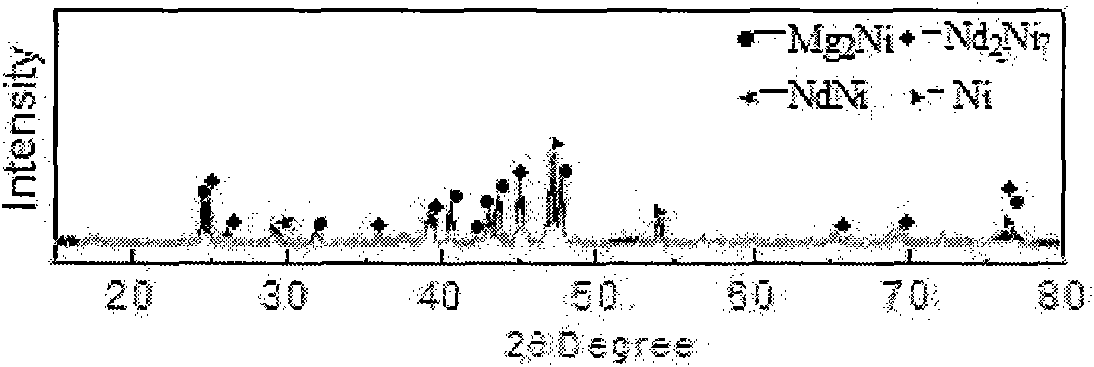

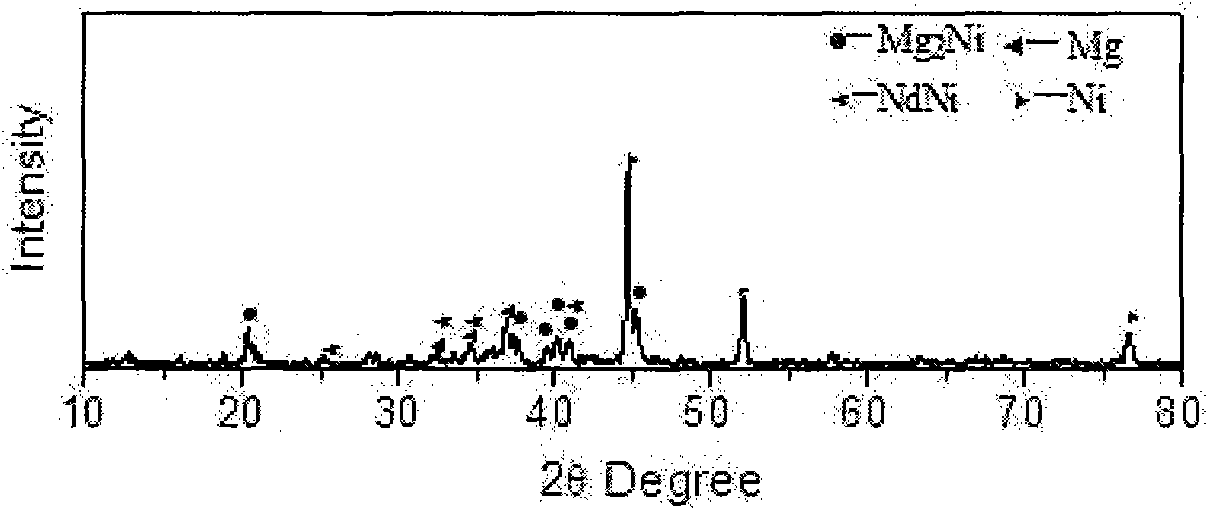

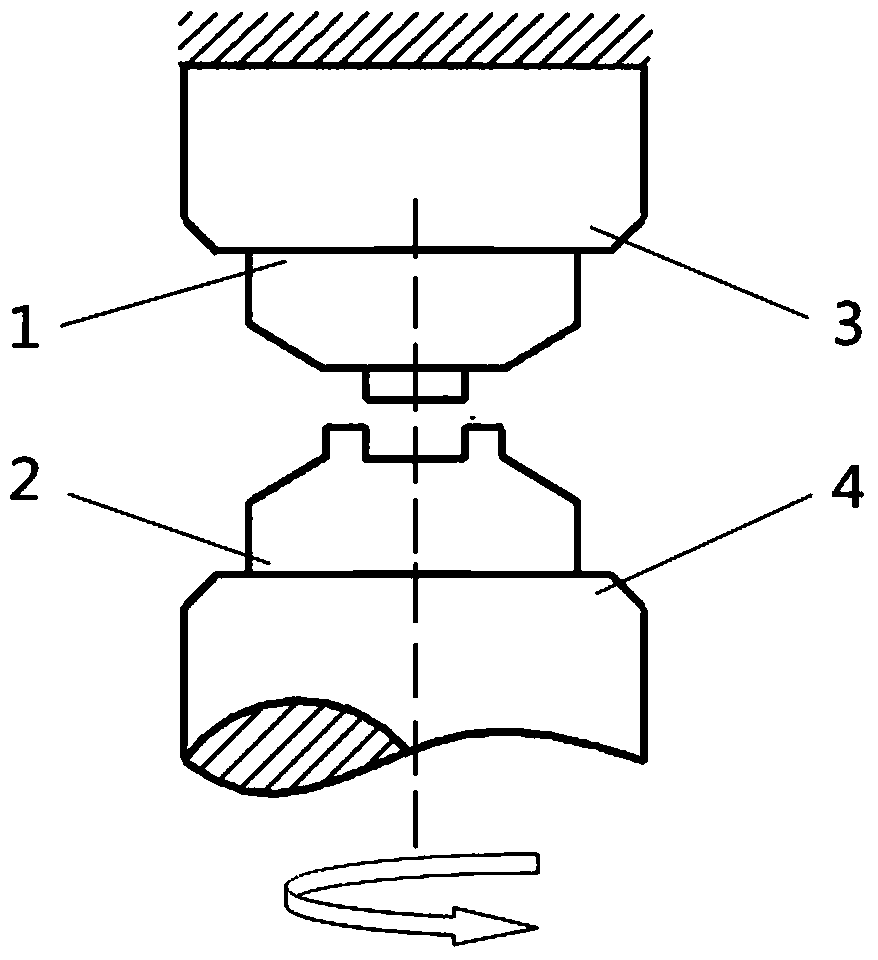

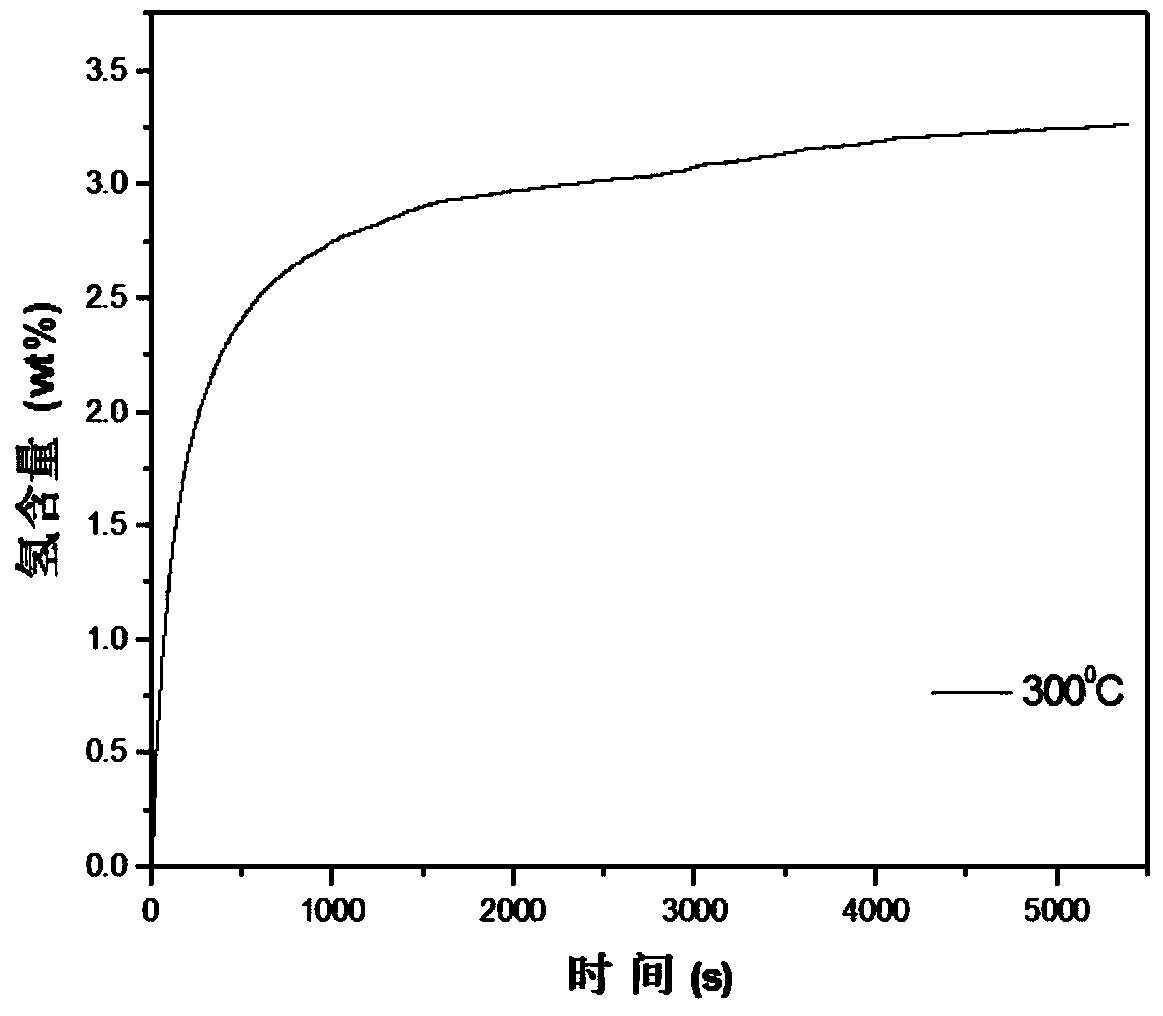

Preparation method of Mg-Ni series hydrogen storage alloy

InactiveCN101575679AImprove the kinetic performance of hydrogen absorption and desorptionPromote activationHydrogen desorptionBiological activation

The invention relates to a preparation method of Mg-Ni series hydrogen storage alloy, which belongs to the preparation of hydrogen storage alloy in metallic functional materials. The method comprises the following steps: by adopting spark plasma sintering technology, Mg powders, Ni powders and NdNi alloyed powders are configured according to the mixture ratio of Mg2-xNdxNi, wherein x is more than or equal to 0.1 and less then or equal to 0.5; the Mg powders, the Ni powders and the NdNi alloyed powders are evenly mixed by a planetary ball mill, and then the powders are put into an SPS special die for compression; spark plasma sintering is carried out to the die filled with original powders under the vacuum atmosphere; while in sintering, the heating speed is 50-150 DEG C, the sintering temperature is 400-500 DEG C, the sintering pressure is 10-30 MPa, and the holding time is 5-10min. The invention solves the problem that the preparation of Mg-Ni series hydrogen storage alloy is difficult and has simple preparation process, time saving, good controllability and low cost; and the prepared hydrogen storage alloy is in multiphase structure and has favorable activation property, good absorption and desorption hydrogen kinetics performance, favorable PCT platform property, high hydrogen desorption and good hydrogen absorption and desorption reversibility.

Owner:UNIV OF SCI & TECH BEIJING

Nano-structure block magnesium material and preparation method thereof

ActiveCN103785844AHigh densityHigh hardnessMaterial nanotechnologyNano structuringVolumetric Mass Density

The invention discloses a block magnesium material which comprises nano-structure magnesium and at least one nano-structure transition metal. The weight of the transition metal accounts for less than 20% of the total weight of the block magnesium material. The invention further discloses a preparation method of the block magnesium material. The preparation method includes the steps: subjecting a metal block to melting, evaporating and cooling to form nanometer metal powder; pressing the nanometer metal block through high-pressure torsion to prepare a block material. The material has dual advantages of an ordinary block material and the nanometer material, good dynamic performance on hydrogen absorption and releasing and high block density and thermal conductivity and thermal efficiency are achieved, and the material is easy to store and transport and can be used as a hydrogen storage material high in capacity; the block magnesium material having the advantages of high density and high hardness can serve as the ideal material with the structure light in weight and high in strength.

Owner:氢储(上海)能源科技有限公司 +1

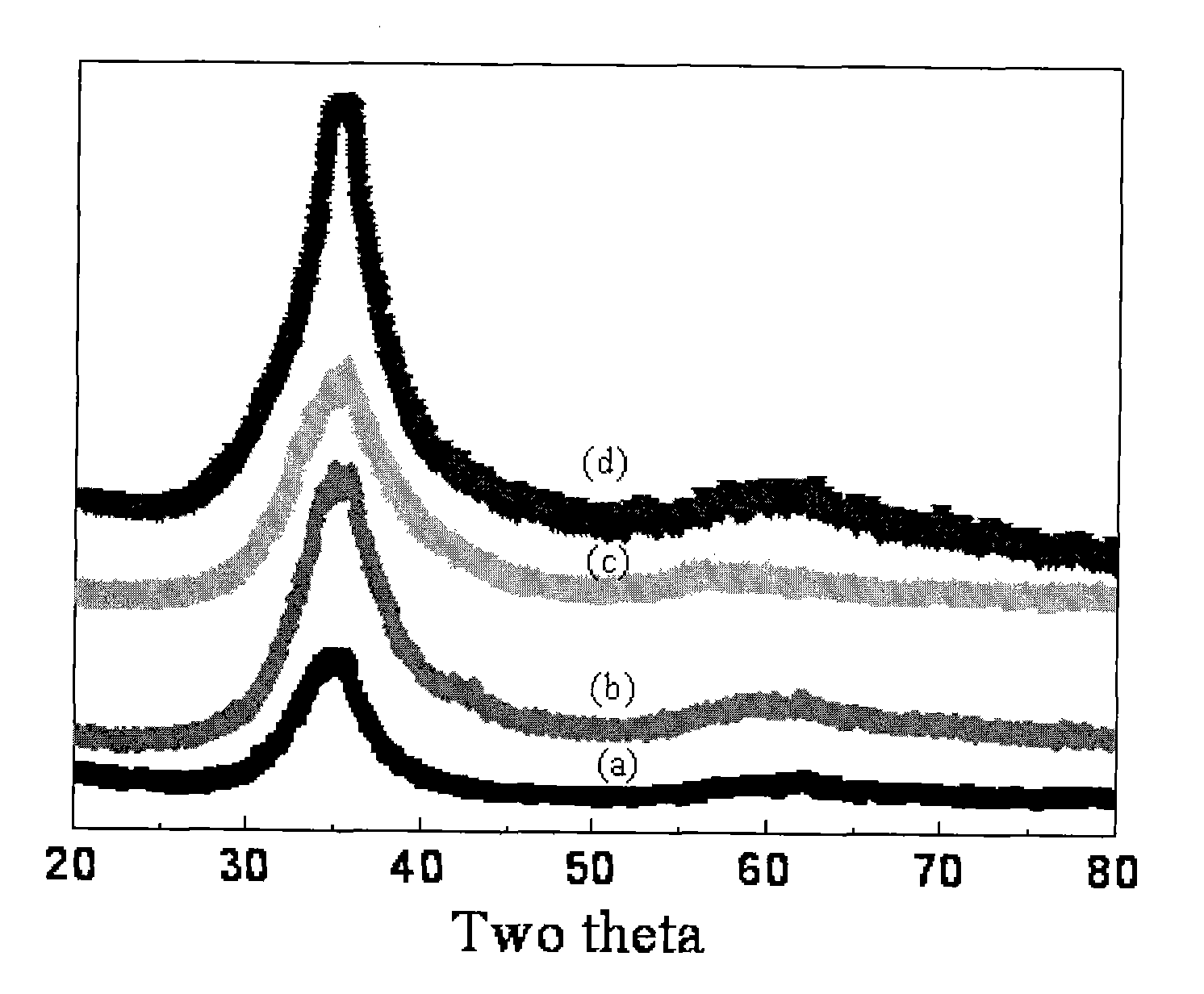

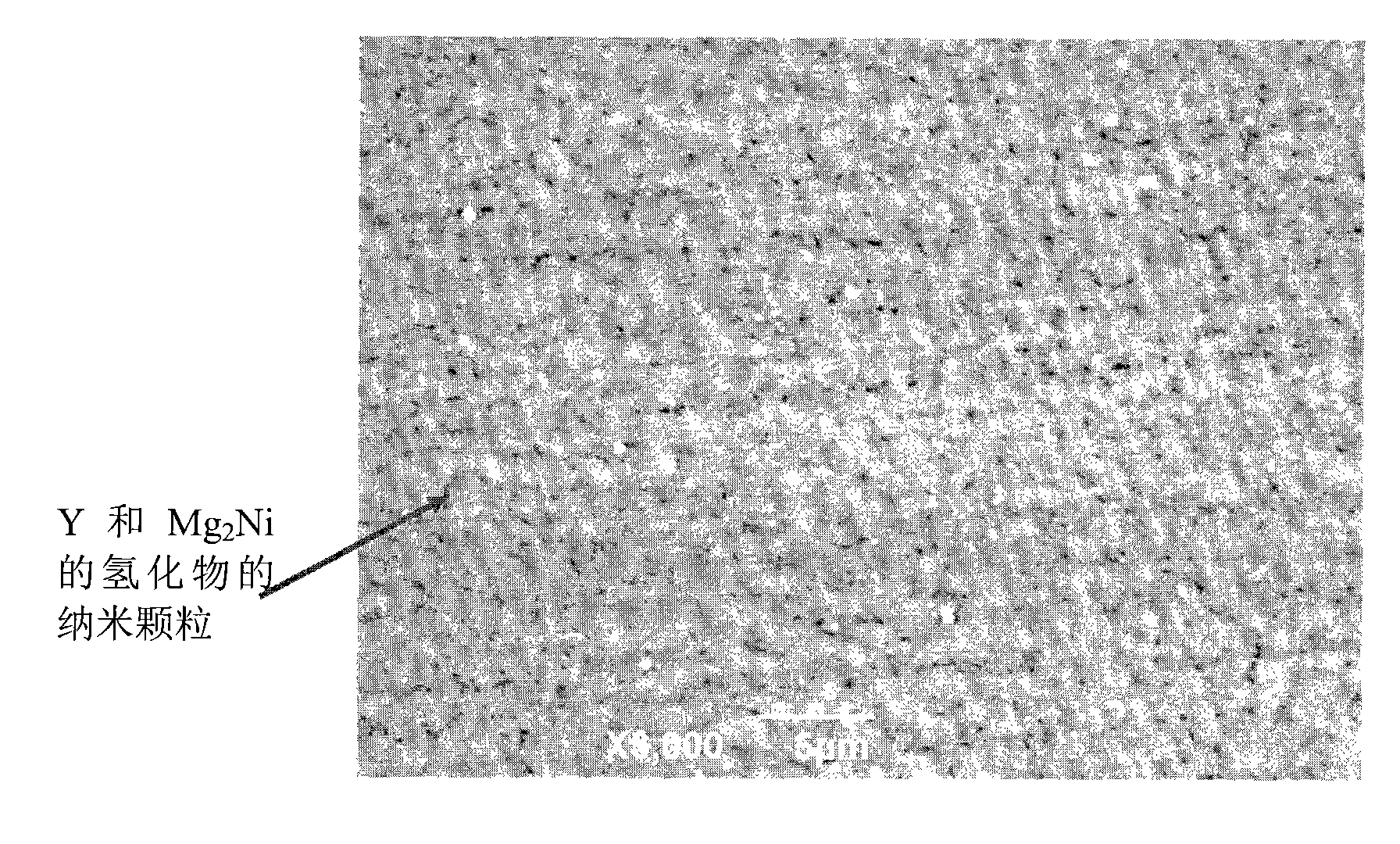

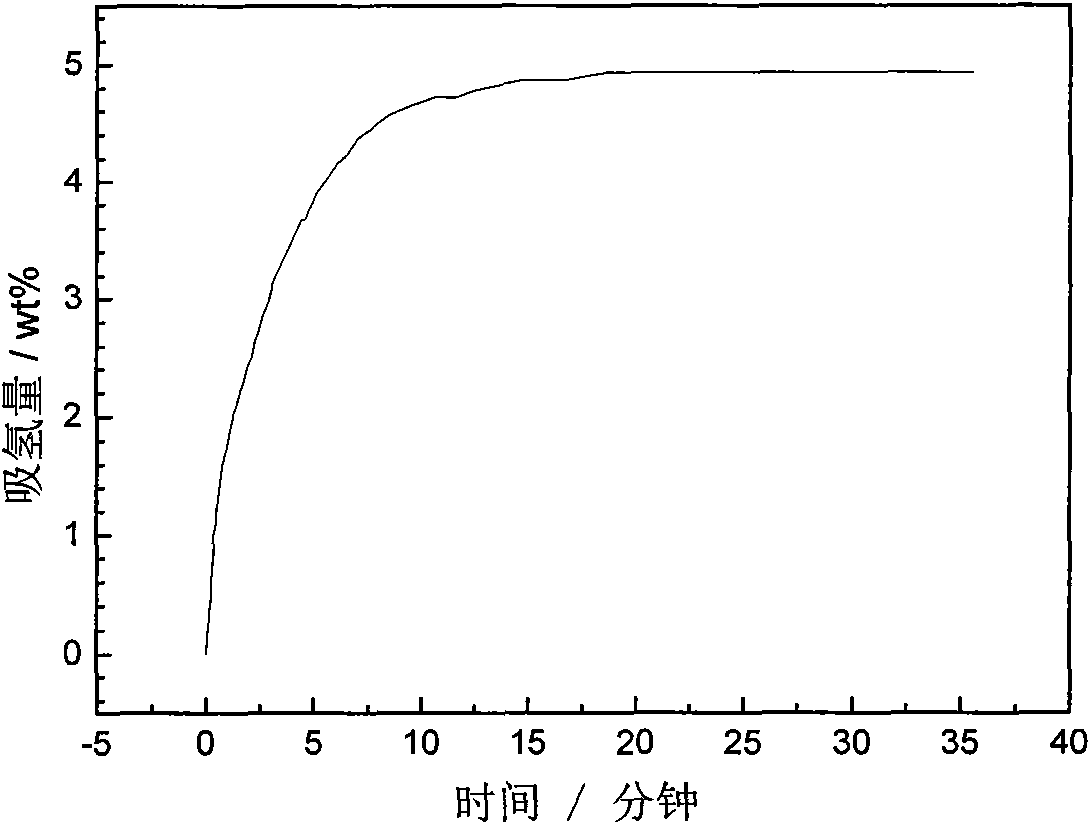

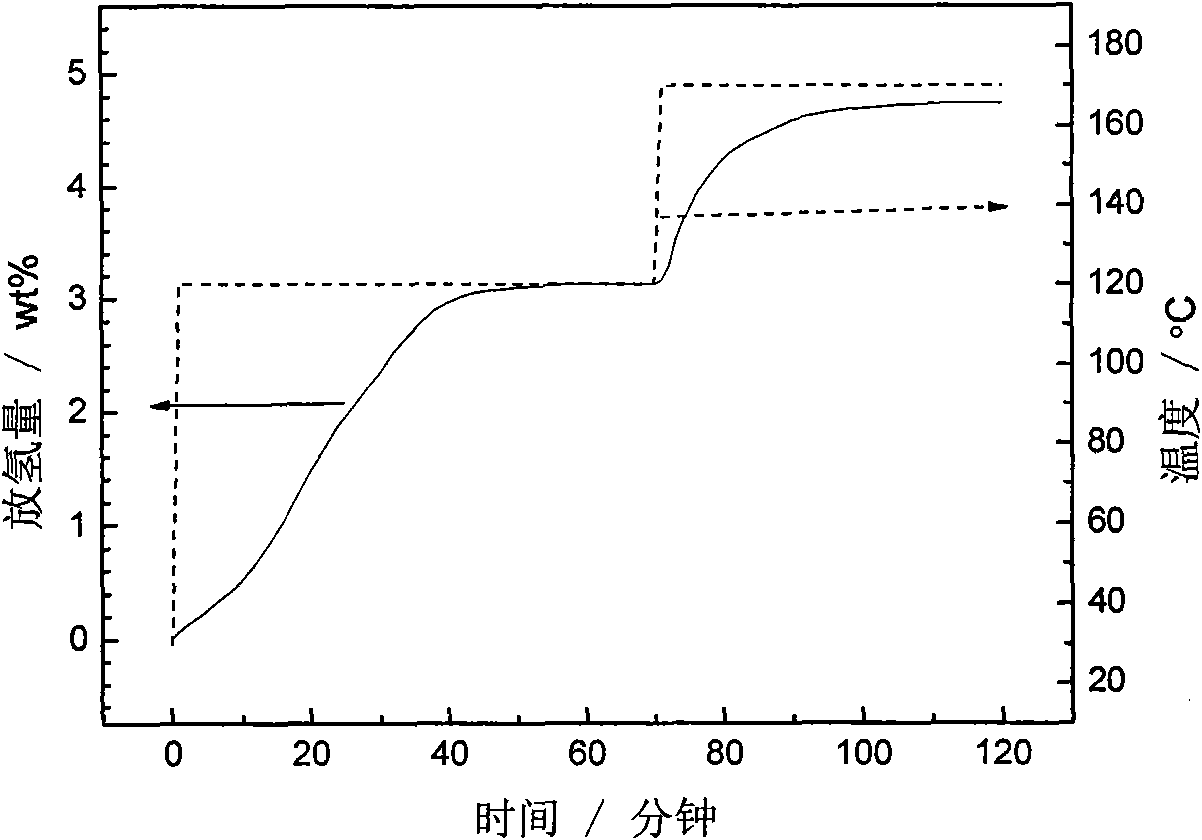

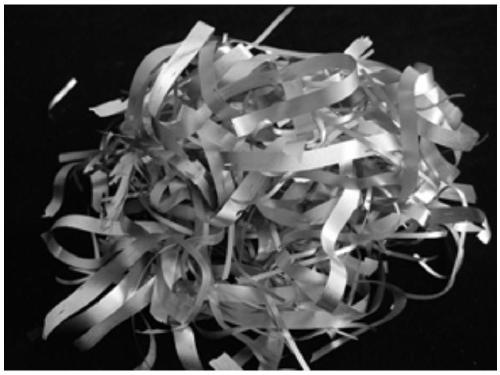

Amorphous magnesium-yttrium-transition metal hydrogen storage material and preparation method thereof

The invention provides an amorphous magnesium-yttrium-transition metal hydrogen storage material and a preparation method thereof, belonging to the technical field of hydrogen storage materials. The content of Mg in the hydrogen storage material is 70-90at.%, the transition metal is Co, Ni and Cu, and the yttrium and the transition metal are added in a combined addition manner based on the mol ratio of 1 to 1. The preparation method comprises the steps of: firstly, melting and preparing intermediate alloy of the yttrium and the transition metal by using an induction melting furnace; secondly, remelting and rapidly quenching the metal Mg and the intermediate alloy of the yttrium and the transition metal in a vacuum single-roller liquor rapid quenching furnace, wherein the prepared material is an amorphous ribbon with the width of 3mm and the thickness of 30-50 microns; and grinding the prepared amorphous ribbon into powder with different granularities in a glove box, wherein the amorphous ribbon or powder is the finished products of hydrogen storage materials. In the invention, the provided hydrogen storage material overcomes the disadvantage of low hydrogen storage amount; the combined addition of the Y and the transition metal facilitates the formation of the amorphous body and improves the hydrogen storage performance of the material. In addition, the invention has the characteristics of simple preparation method and low cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Catalyst of sodium aluminum hydride coordination oxide and preparation method thereof

InactiveCN101642703ANo lossImprove the kinetic performance of hydrogen absorption and desorptionHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsCeriumBall mill

The invention relates to a catalyst of sodium aluminum hydride coordination oxide and a preparation method thereof. A chemical general formula of the catalyst is RExAly, wherein x is smaller than 10 but larger than or equal to 1, and y is smaller than 20 but larger than or equal to 1. In the formula, the RE is Sc, Y, La, Ce, Pr, Sm, Nd, Ml (lanthanum-rich mixed tombarthite) or Mm (cerium-rich mixed tombarthite). The preparation method is as follows: according to a chemical amount proportion of the RExAly, RE and the Al block-shaped metal raw materials are weighed and proportionally mixed; theraw materials are then melted into an RExAly alloy cast ingot under an argon protection atmosphere and then crushed and put into a high-power ball mill for ball milling; and then the RExAly catalyst with a particle size of micro-nanometer level is obtained. The preparation process of the catalyst is simple, the operation is easy, and the cost is low. The catalyst is used for reversible catalysis hydrogen storage of sodium aluminum hydride, greatly improves the dynamic performance of the sodium aluminum hydride in terms of hydrogen absorption and release and does not undergo elementary reactionwith a matrix hydrogen storage material group to generate inert byproducts so that the system reversible hydrogen storage amount is not damaged.

Owner:ZHEJIANG UNIV

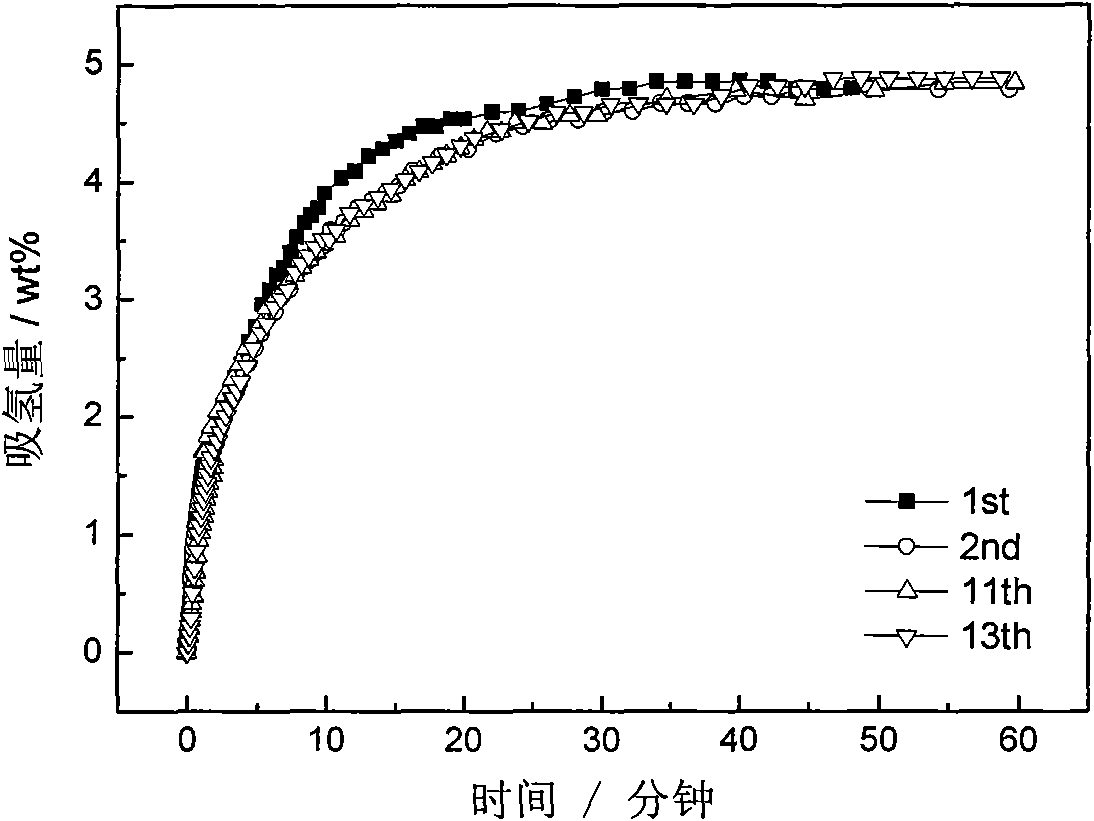

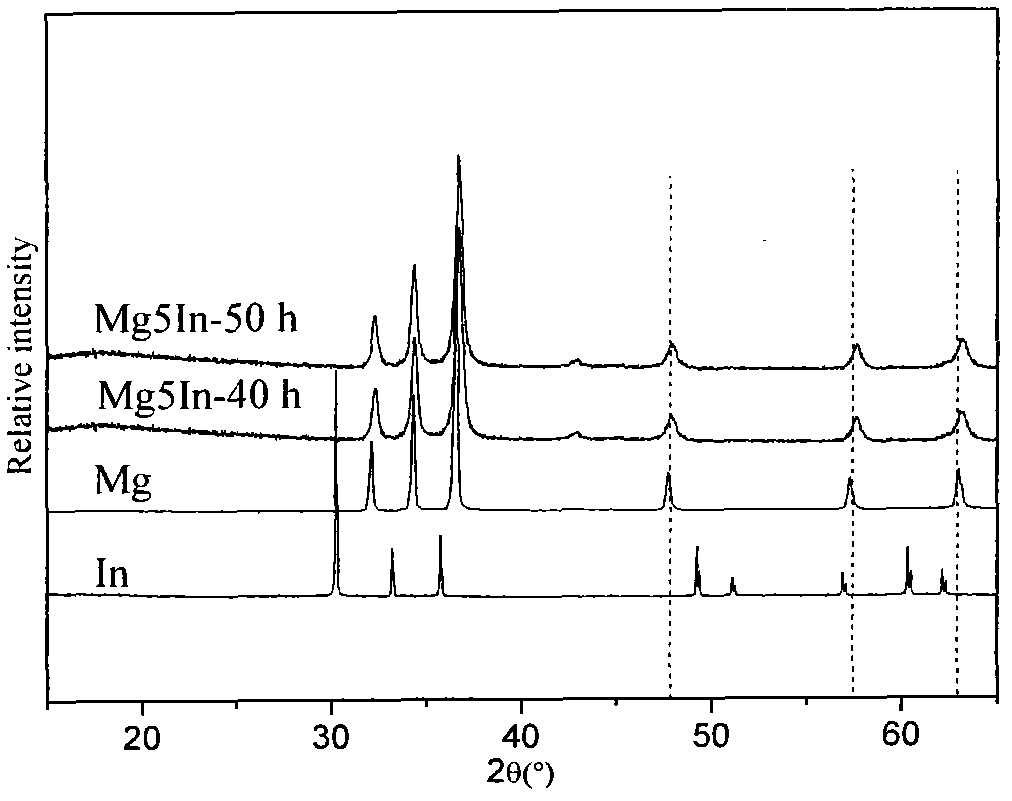

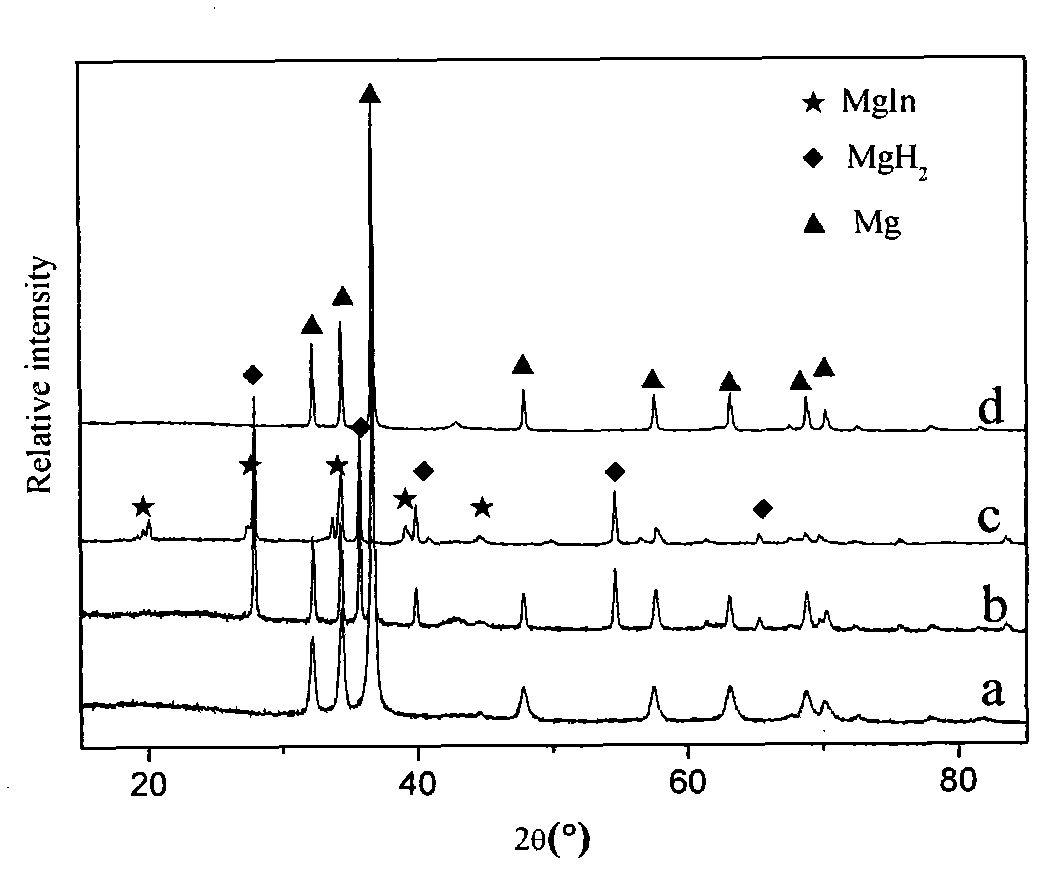

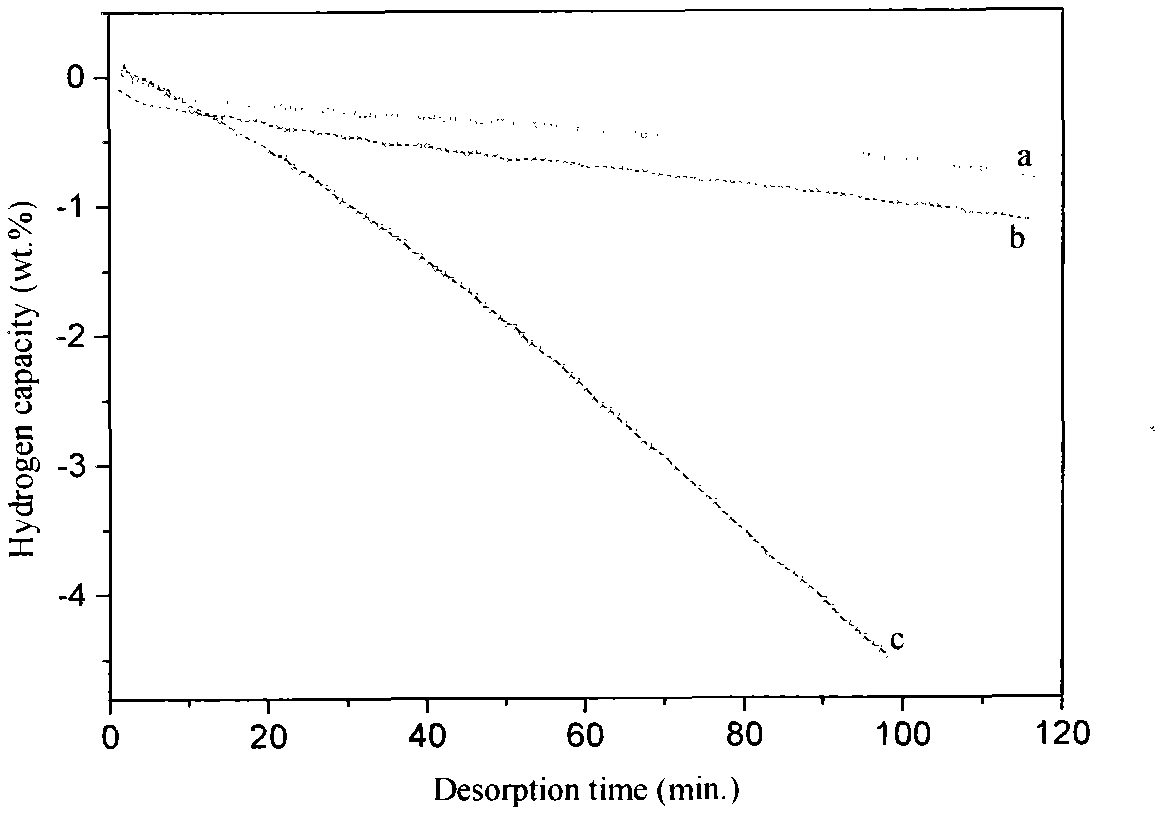

Magnesium indium solid solution and preparation method thereof

ActiveCN101967590AImprove the kinetic performance of hydrogen absorption and desorptionAchieve destabilizationIndiumSolid solution

The invention discloses magnesium indium solid solution and a preparation method thereof. The preparation method comprises the following steps of: preparing a sample A in a molar ratio of magnesium powder to indium powder of (100-x):x, wherein x is more than 0 and less than 12; mixing the sample A on a ball mill to obtain mixed powder B, and then pressing and forming to obtain a green body C; introducing argon in a vacuum furnace for protecting and sintering the green body C, crushing the sintered green body C, and then performing ball-milling on the crushed green body C in an argon atmosphere to obtain the magnesium indium solid solution; and adding an appropriate amount of indium to prepare the magnesium indium solid solution. Therefore, a hydrogen adsorption and desorption reaction path of the magnesium is changed so as to achieve the effects of reducing hydrogen adsorption and desorption enthalpy change and reducing the stability of thermodynamics of magnesium hydride (MgH2). A magnesium indium alloy also has high reversibility, and the problem of irreversibility or low reversibility is solved.

Owner:SOUTH CHINA UNIV OF TECH

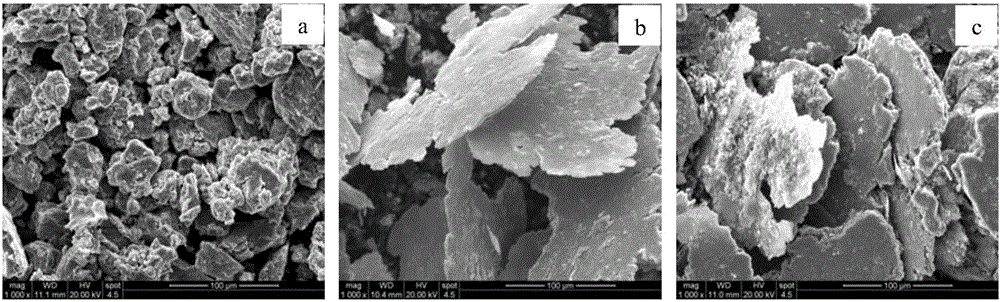

Nano titanium trifluoride catalyzed Mg-RE-Ni-Al-Ti-Co based hydrogen storing alloy and preparation method thereof

The invention relates to a nano titanium trifluoride catalyzed Mg-RE-Ni-Al-Ti-Co based hydrogen storing alloy and a preparation method thereof. The hydrogen storing alloy has the following chemical composition: Mg18-x-yLaxREyNi2-z-mAlzTim+50(wt)%Co+n(wt)%TiF3, wherein x, y, z and m are atomic ratios; x is more than 1 and less than 3; y is more than 0.2 and less than 1; z is more than 0 and less than 1; m is more than 0 and less than 1; n is a mass percent of TiF3 accounting for Mg18-x-yLaxREyNi2-z-mAlzTim; n is more than 3 and less than 8; and RE comprises at least one of rare earth elements such as Ce, Nd, Y, Sm and Gd. The hydrogen storing alloy provided by the invention has high hydrogen storing capacity and excellent dynamics performance, and has high hydrogen absorption and desorption capacity at a low temperature. Moreover, the hydrogen absorption and desorption dynamics performance is greatly improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Low-temperature high-capacity Mg-RE-Ni-based A2B-type hydrogen storage alloy and preparation method thereof

ActiveCN105671405AEnhanced nanocrystalEnhanced Amorphous Formation AbilityFuel cellsRare-earth elementCerium

The invention belongs to the technical field of hydrogen storage alloy materials, and particularly relates to a high-capacity Mg-RE-Ni-based A2B-type hydrogen storage alloy used for fuel cells and the preparation technology of the alloy. According to the hydrogen storage alloy, the amount of added A-side elements is increased for 25at.%; Mg is partly replaced by rare earth elements; Ni is partly replaced by Ti and Al; the chemical formula of the alloy is Mg25-xRExNi10-y-zTiyAlz, wherein the x, y, z in the formula are atomic ratios; x is greater than 1 and smaller than 5; y is greater than 1 and smaller than 3; z is larger than 0.2 and smaller than 1; and RE is one or more of the rare earth elements of lanthanum, cerium, praseodymium, neodymium, samarium and yttrium. The hydrogen storage alloy has high hydrogen storage capacity and fast hydrogen absorption and desorption dynamics; the hydrogen desorption temperature for a hydride is obviously lowered, and reversible hydrogen absorption and desorption can be performed at 200 DEG C; and the circulation stability for hydrogen absorption and desorption is remarkably improved.

Owner:CENT IRON & STEEL RES INST

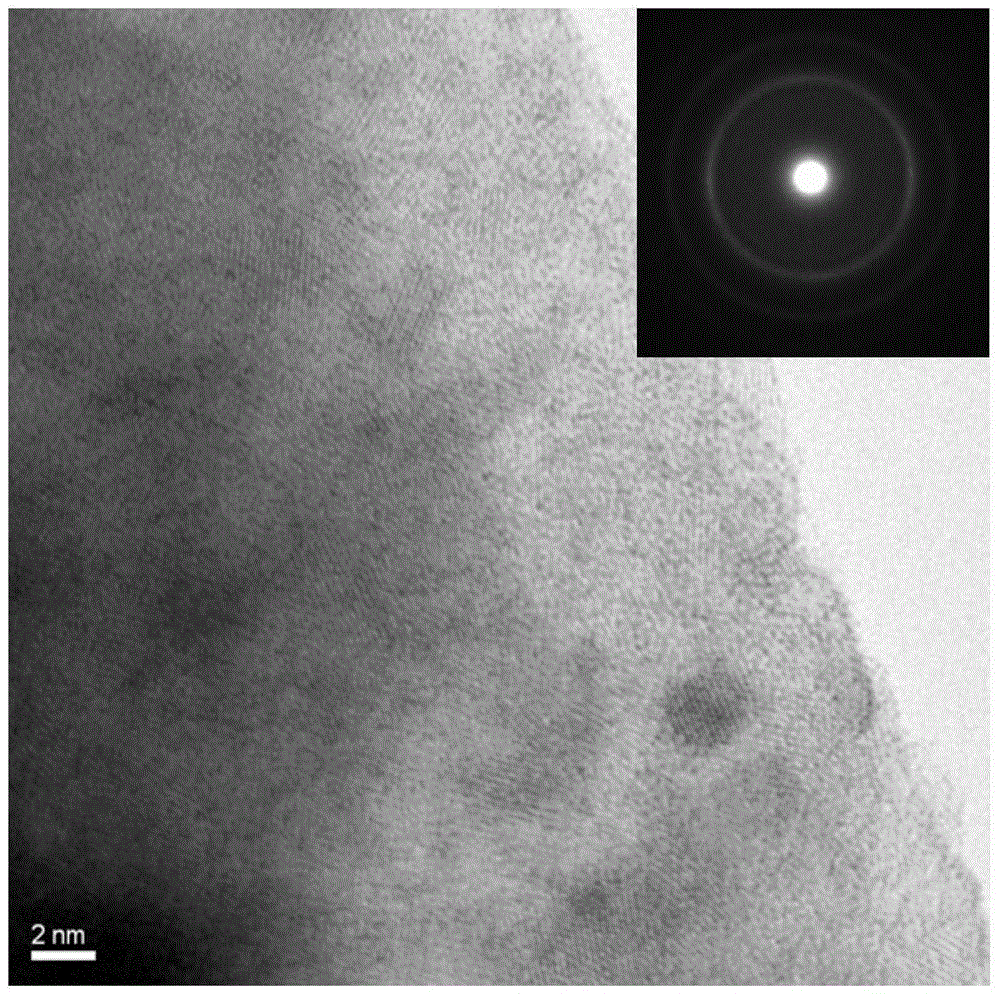

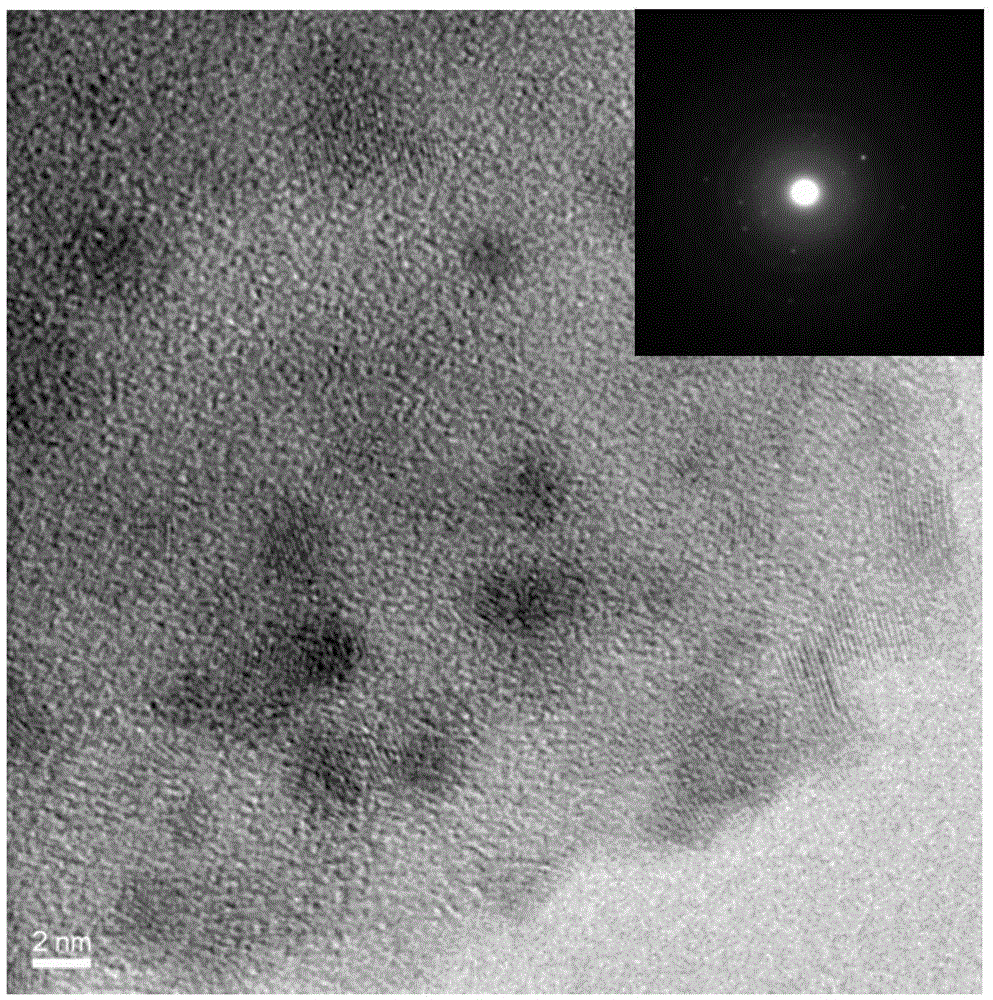

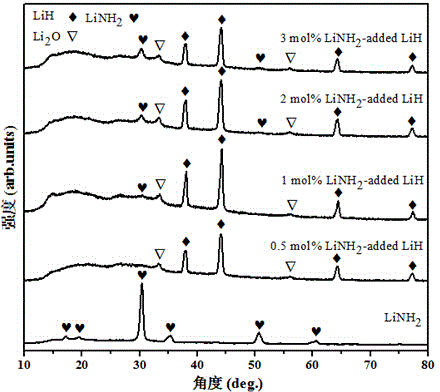

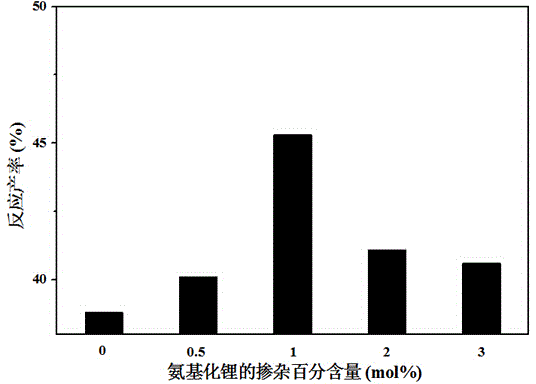

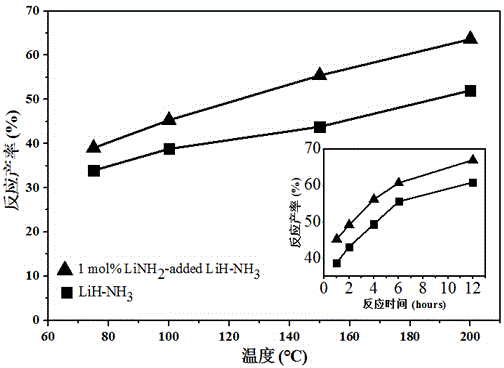

Preparing method for improving LiH-NH<3> hydrogen storing system dehydrogenizing kinetics

InactiveCN104925751AGood dispersionImproved dehydrogenation kineticsHydrogenSolid-state chemistryHydrogen

The invention provides a preparing method for improving LiH-NH3 hydrogen storing system dehydrogenizing kinetics, and belongs to the technical field of solid state chemistry hydrogen storing. The method comprises the following steps that under the condition of hydrogen, after pre-ball-milling is carried out on alkali metal amides, the alkali metal amides are mixed with LiH, ball-milling treatment is carried out, and LiH materials adulterating with the alkali metal amides are obtained; under the condition without oxygen, hydrogen evolution reaction is carried out on the LiH materials adulterating with the alkali metal amides and the hydrogen, cooling is carried out after the reaction is finished, LiH-NH3 which improves the hydrogen storing system dehydrogenizing kinetics is obtained. Due to the fact that adulterating LiNH2 has the crystal nucleus function in the process that the LiH and NH3 are reacted to generated LiNH2 and H2, the hydrogen evolution reaction is accelerated to carry out, and the LiH-NH3 system dehydrogenizing kinetics can be effectively improved.

Owner:YANGZHOU UNIV

Mg-Sn-Ni ternary hydrogen storage intermediate alloy used for fuel cell, hydrogen storage material and preparation method

ActiveCN106756355AImproved hydrogen absorption and desorption kineticsLower the hydrogen decomposition temperatureCell electrodesBond energyHigh energy

The invention relates to a high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy used for a fuel cell, and a hydrogen storage material and preparation method of the high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy. According to the atomic percent, the alloy comprises the chemical component of Mg<100-a-b>SnNi, wherein a is within the range of 4-6, and b is within the range of 9-11. The preparation method comprises the steps that induction heating and smelting are adopted under inert gas protection, and molten alloy is poured into a copper casting mold to obtain a cylindrical alloy ingot; and the ingot is mechanically crushed into powder and screened, the screened alloy powder and 1-5wt% of catalyst graphite are together loaded into a stainless steel ball milling tank, after vacuum pumping, high-purity argon gas is injected, and ball milling is conducted for certain time in an all-dimensional planetary high-energy ball mill to obtain alloy powder of a nanocrystalline-non-crystalline structure. According to the high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy used for the fuel cell, and the hydrogen storage material and preparation method of the high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy, bond energy between Mg and H can be wakened through Sn and Ni, and the hydrogen storage performance of the magnesium-based hydrogen storage material is effectively improved; and through component design, microstructure adjustment and control and adding of the graphite, the heat stability of hydride of the alloy is reduced, and hydrogen absorption and desorption thermodynamics and kinetics performance of the alloy is improved.

Owner:CENT IRON & STEEL RES INST

Magnesium, aluminum, boron and nickel-based hydrogen storage material and preparing method thereof

The invention discloses a magnesium, aluminum, boron and nickel-based hydrogen storage material. The chemical component of the magnesium, aluminum, boron and nickel-based hydrogen storage material is xAl-yB-zNi-(1-x-y-z)Mg, wherein the mass fraction, by weight, of x is larger than or equal to 1% and smaller than or equal to 5%, the mass fraction, by weight, of y is larger than or equal to 0.5% and smaller than or equal to 1%, and the mass fraction, by weight, of z is larger than or equal to 5% and smaller than or equal to 20%. A preparing method for the hydrogen storage material comprises the steps that magnesium powder, nickel powder, boron powder and aluminum powder are evenly mixed according to the composition and pressed into a cylinder with the diameter of 10 mm and the height of 8 mm; and then a cubic press is used for heat preservation and pressure maintaining for 30-60 min at 4-6 GPa and 1200-1800 DEG C; and liquid nitrogen is immediately used for cooling an alloy, and the magnesium, aluminum, boron and nickel-based hydrogen storage material is obtained. The preparing method is simple and short in production period, and the prepared hydrogen storage alloy has the good performance of being short in activation period, high in hydrogen absorbing and desorbing rate and the like.

Owner:YANSHAN UNIV

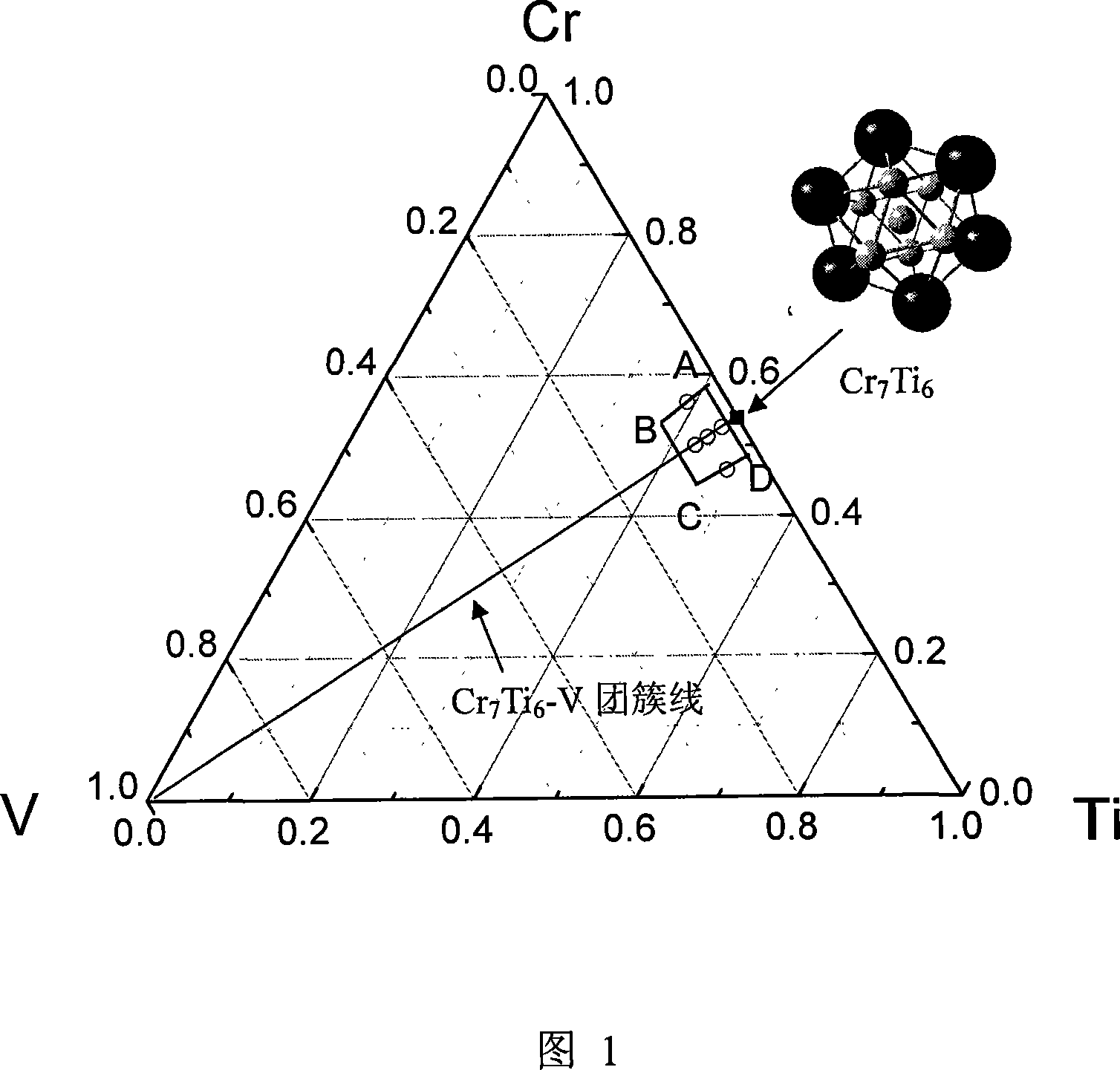

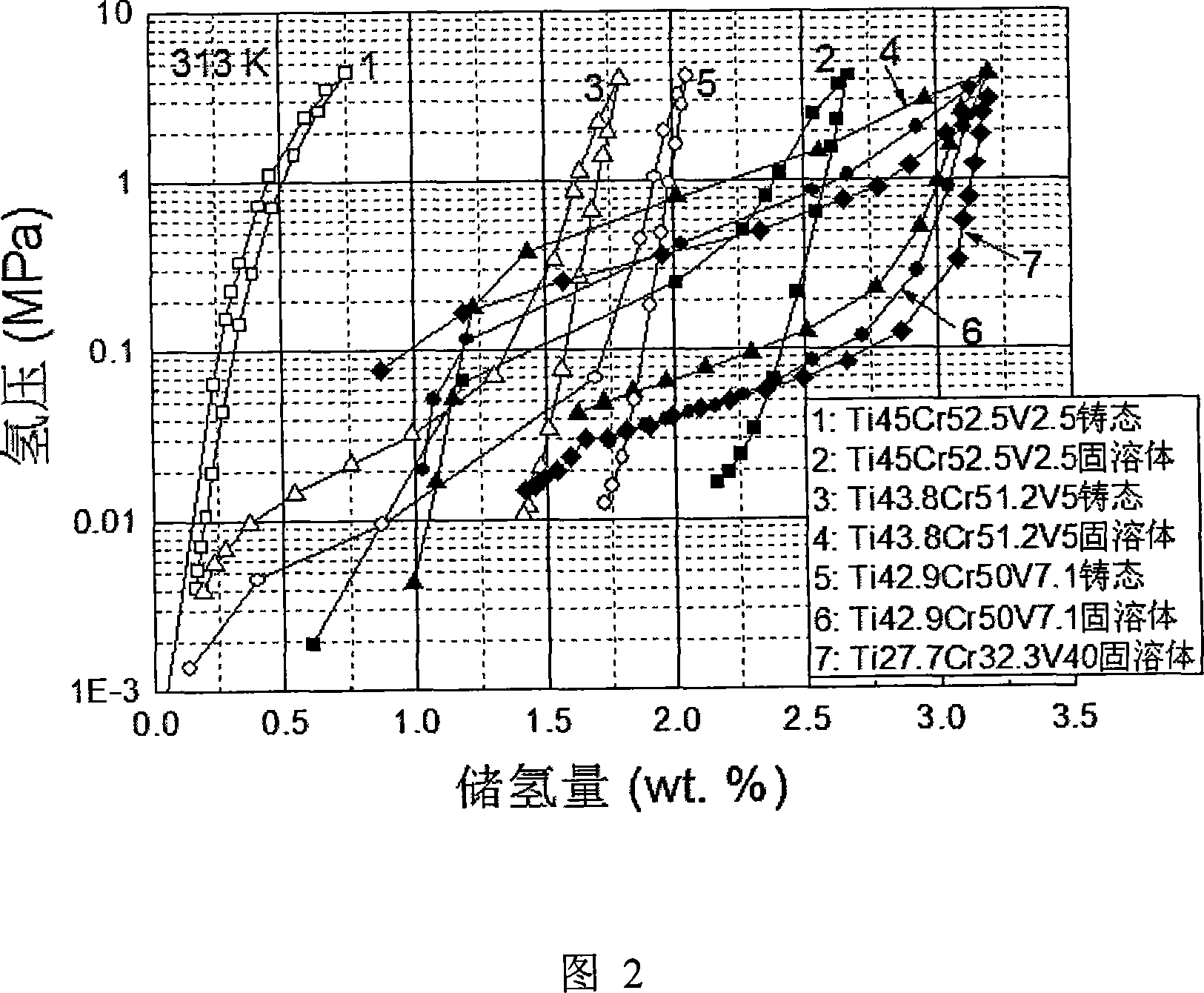

Ti-Cr-V solid solution alloy with high weight of hydrogen and low V content

The invention relates to a Ti-Cr-V solid solution alloy with high hydrogen storage capacity as well as low V content, which belongs to the new material field. The invention comprises a Ti element, a Cr element and a V element and is characterized in that the alloy is formed by the alloying of the a binary cluster Cr7Ti6 and the nearby composite by adding few V; the composite scope is (TiCry)(100 minus x) / (1 plus y)Vx, that is, V atom per centage scope x is equal to 2 minus 10at. per cent, and Cr / Ti atom per centage scope y is equal to 0.96 minus 1.44; the maximum hydrogen absorption capacity of the solid solution alloy Ti43.8Cr51.2V5 and Ti42.9Cr50V7.1 with maximum hydrogen uptake is 3.2wt. per cent (313K), which processes good hydriding and dehydriding kinetics performance; the solid solution alloy with low V content is processed by adopting the vacuum arc melting and the water-cooled copper mold method. The invention has the advantages that the invention defines the composite range of the low V content in accordance with the cluster, which overcomes the arbitrary composite selection. By adoption of the water-cooled copper mold method, the invention ensures the alloy is the V solid solution alloy structure with low V content, and simplies the process preparation; the invention is capable of replacing the solid solution alloy with V content, lowers the material cost and is capable of being used as fuel cell hydrogen source alloy.

Owner:DALIAN UNIV OF TECH

Porous carbon-supported nano-metal oxide catalyst and its preparation method and hydrogen storage material

ActiveCN104069842BRealize controllable modulationEasy to prepareCatalyst carriersHydrogen productionPorous carbonMetal framework

Owner:ZHEJIANG UNIV

A hydrogen storage high-entropy alloy based on a body-centered cubic structure and its preparation method

ActiveCN107338385BHigh hydrogen storage capacityFast hydrogen absorption and desorptionElectric arc furnaceHigh entropy alloys

The invention belongs to the field of hydrogen storage materials, and relates to a hydrogen storage high-entropy alloy taking a body-centered cubic structure as the principal thing and a preparation method for the hydrogen storage high-entropy alloy. A component expression formula of high-entropy alloy is as follows: (TiaZrbNbc)xMy, wherein a is greater than or equal to 5at% and smaller than or equal to 35at%, b is greater than or equal to at5% and smaller than or equal to 35at%, c is greater than or equal to 5at% and smaller than or equal to 35at%, a+b+c is equal to x, x is greater than or equal to 15at% and smaller than or equal to 100at%, M is any one or more of Hf, Fe, Co, Cr, Mn, Ni, Mo and W; and atomic percent of each M is 0-35%, and x+y is equal to 100. The preparation method for the hydrogen storage high-entropy alloy comprises the following steps of: adopting a non-consumable vacuum electric-arc furnace to smelt to prepare alloy; and adopting suction casting to sucking alloy into a water-cooling cooper mould, thereby obtaining a high-entropy alloy rod. The high-entropy alloy has high hydrogen storage capacity (3 mass% or more) and excellent hydrogen absorption and desorption dynamic performances; when hydrogen absorption and desorption amount is great, the high-entropy alloy, in comparison with a pure element, does not need to completely purify, so that cost can be saved to a great extent. The hydrogen storage high-entropy alloy taking the body-centered cubic structure as the principal thing has the characteristics of the high-entropy alloy, and has a wide application prospect in the fields of new energy resources and transportation.

Owner:UNIV OF SCI & TECH BEIJING

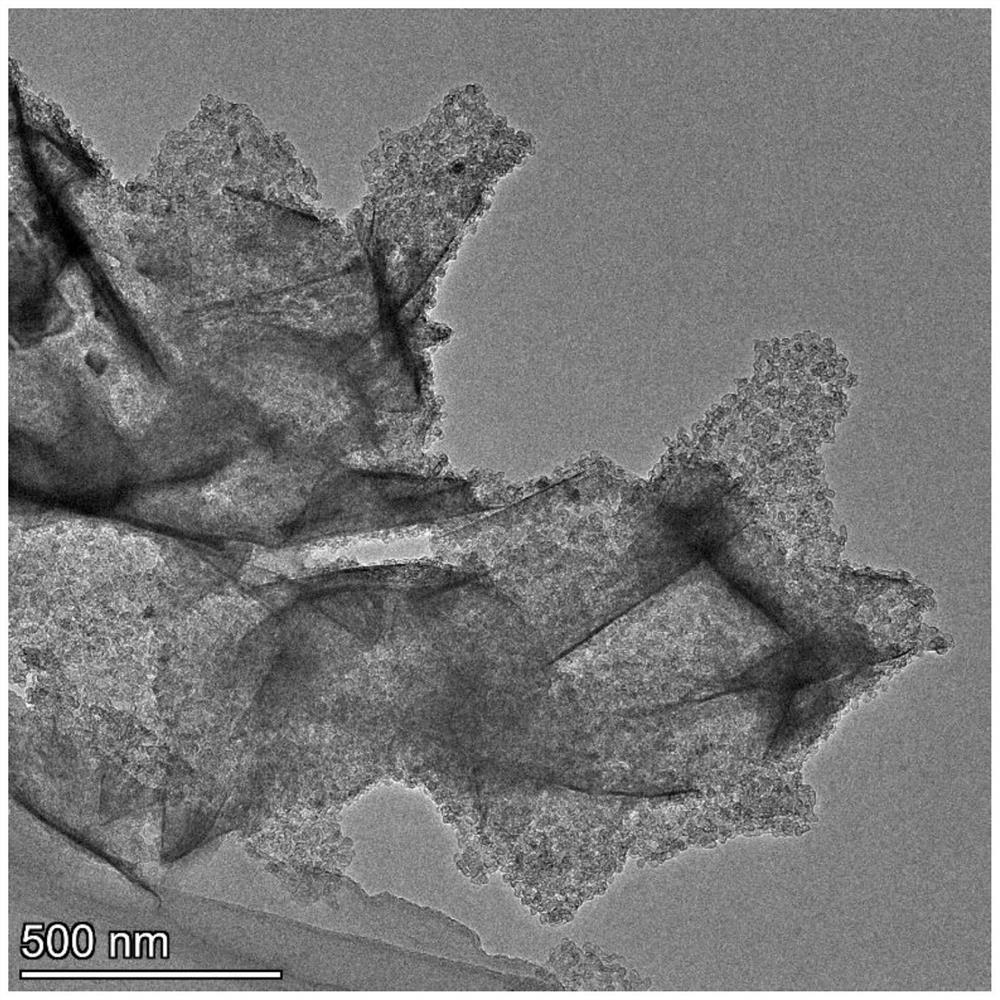

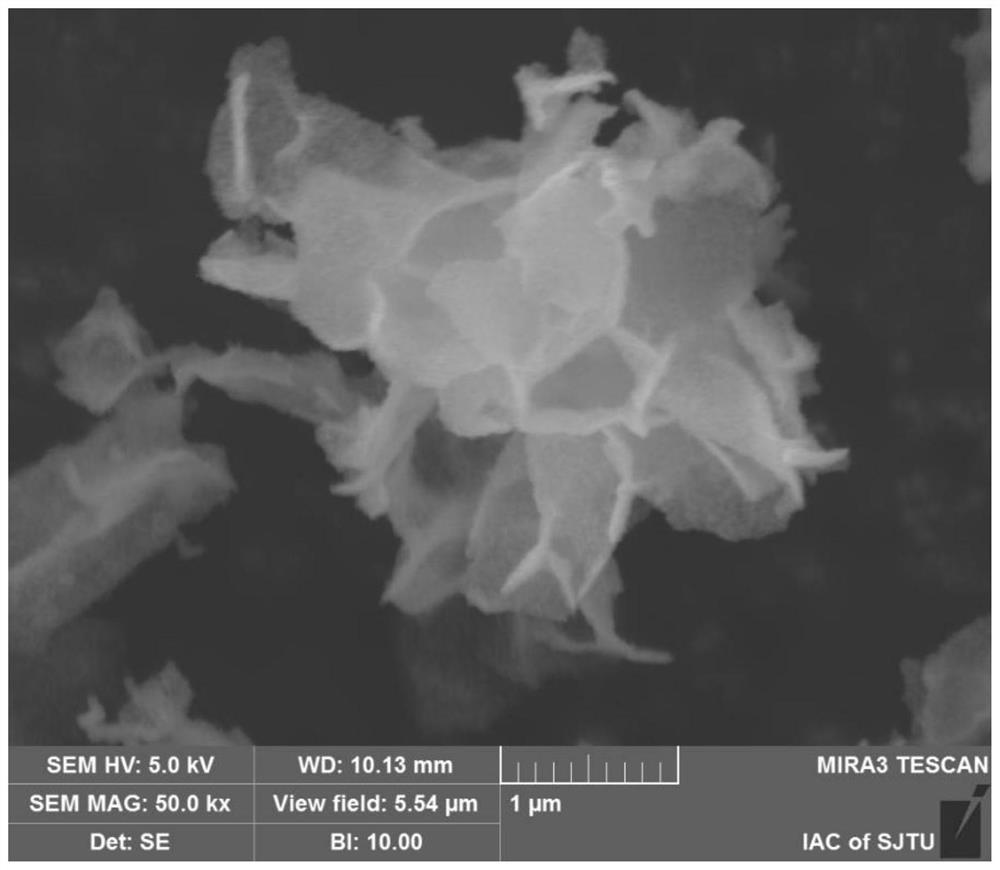

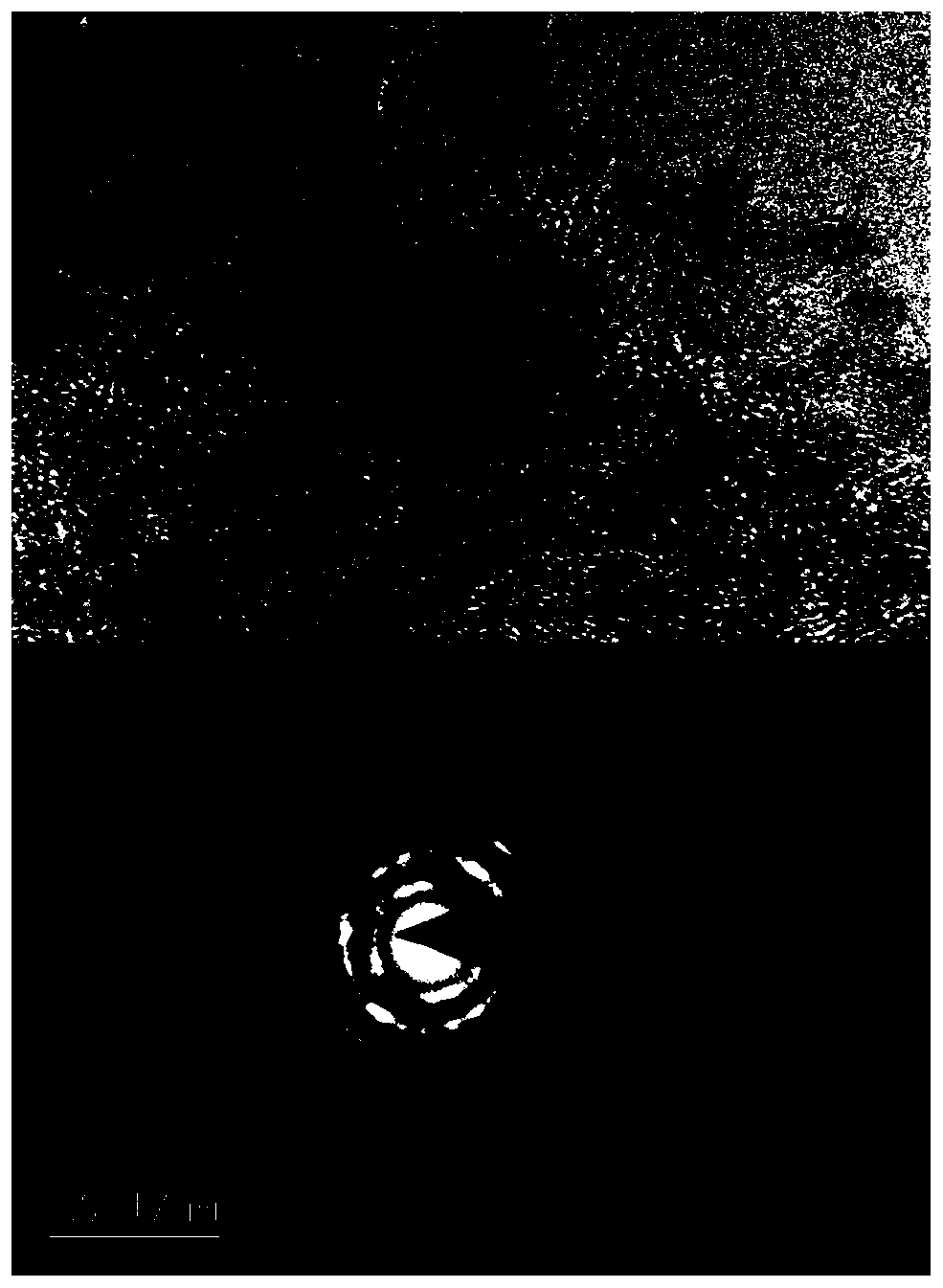

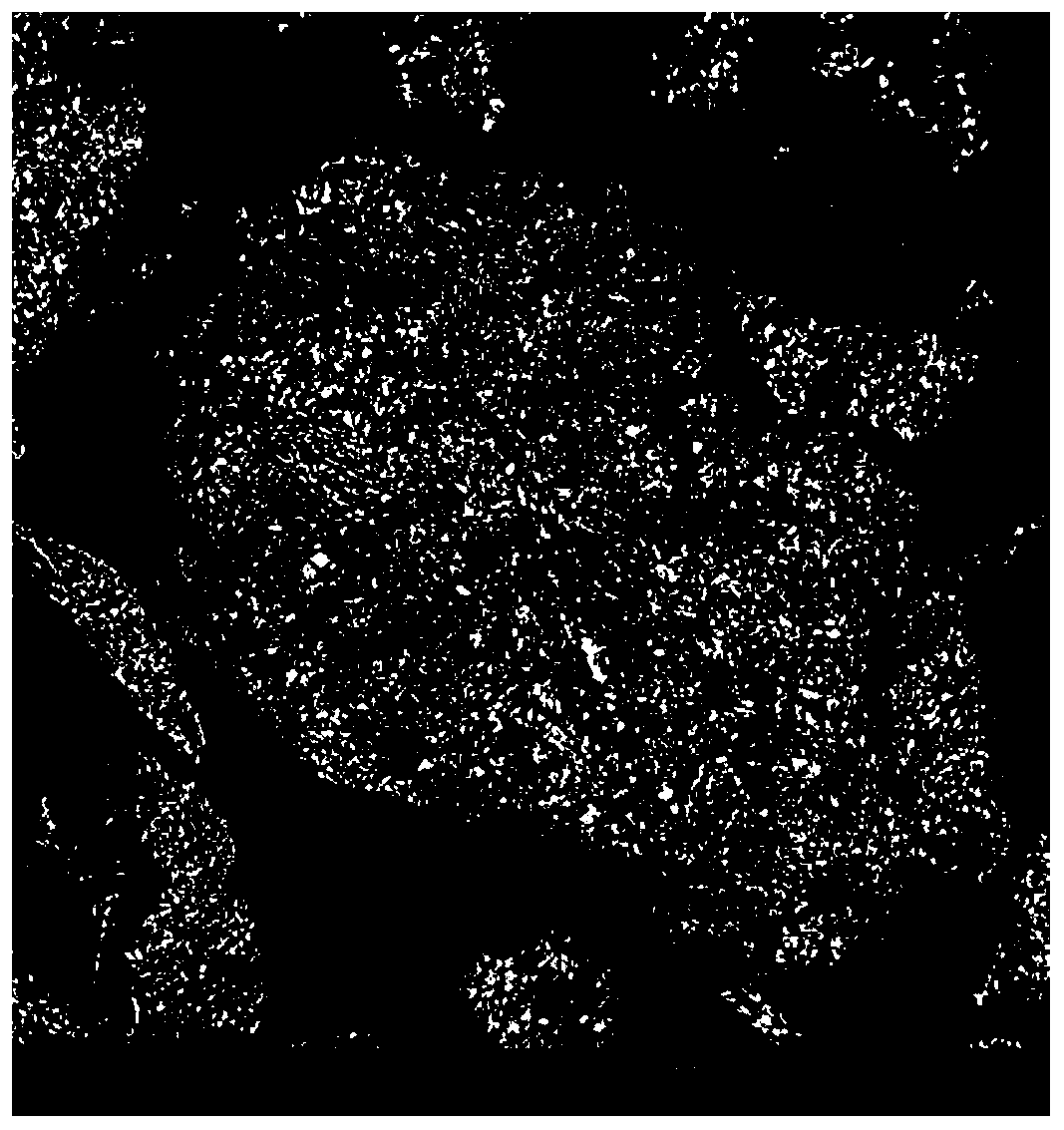

Nano magnesium hydride loaded composite material and preparation method thereof

The invention discloses a preparation method of a nano magnesium hydride loaded composite material, the preparation method comprises the following steps: adding a cationic surfactant into an aqueous dispersion of two-dimensional transition metal carbide to enable two-dimensional transition metal carbide nanosheets to wrinkle and avoid re-stacking, and then washing and drying; putting the dried product into a sealed container, vacuumizing the sealed container, raising the temperature to a high temperature, keeping the temperature for a period of time, filling high-pressure hydrogen into the sealed container, and keeping the temperature for a period of time; and finally, adding a product subjected to heat treatment and dibutyl magnesium into an organic solvent to obtain a mixture, carrying out ultrasonic dispersion, stirring and heating for 12-48 hours under the conditions that the hydrogen pressure is 3-6 MPa and the temperature is 180-220 DEG C, and carrying out centrifugal drying to obtain the nano magnesium hydride loaded composite material. The prepared two-dimensional transition metal carbide nano magnesium hydride loaded composite material has the advantages of high hydrogen storage density, rapid hydrogen absorption and desorption dynamic performance, excellent cycle stability and the like.

Owner:SHANGHAI JIAO TONG UNIV

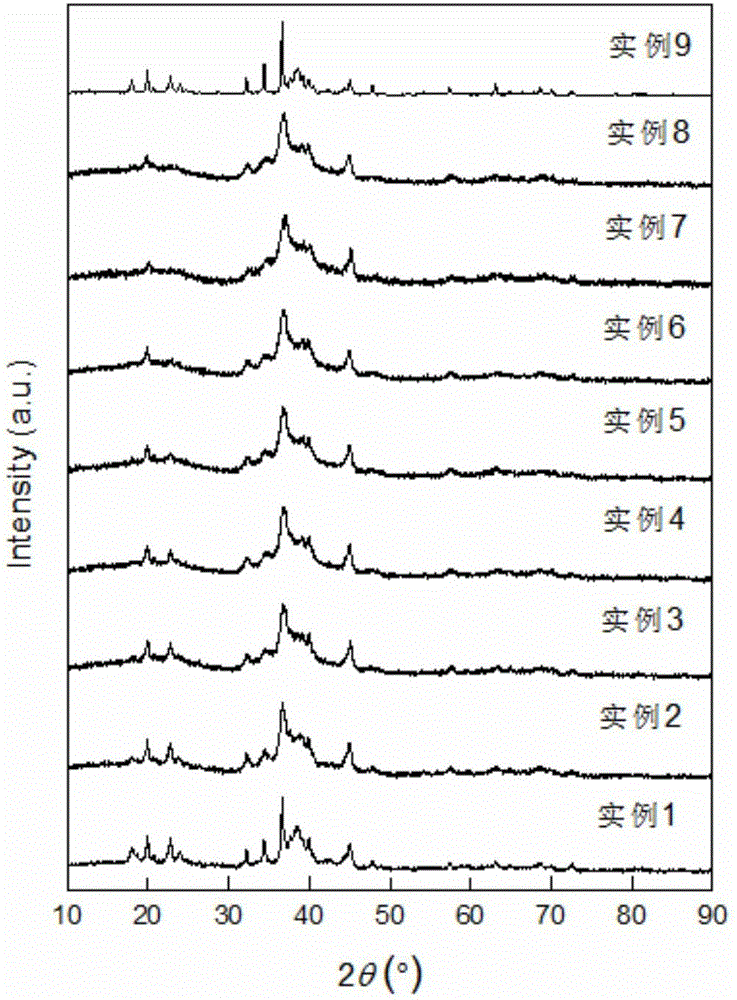

A kind of high-capacity mg-zn-ni ternary hydrogen storage alloy and its preparation method

ActiveCN108097947BImproved hydrogen absorption and desorption kineticsLower the hydrogen decomposition temperaturePtru catalystFuel cells

The invention relates to a high-volume Mg-Zn-Ni ternary hydrogen storage alloy and a preparation method thereof. The hydrogen storage alloy is ultrafine grain powder comprising an Mg85Zn5Ni10 alloy and a catalyst TiF3, wherein the catalyst TiF3 accounts for x% of the Mg85Zn5Ni10 alloy by mass, and x is 0-8. The hydrogen storage alloy has an Mg2Ni phase and an MgZn2 phase, and is further of a nanocrystalline / non-crystalline structure. The Zn and Ni in the alloy can weaken the key energy between Mg and H, and the hydrogen storage performance of a magnesium-based hydrogen storage material is effectively improved. Through component design, control over a microstructure and addition of TiF3, the thermal stability of an alloy hydride is reduced, and the hydrogenation and dehydrogenation thermodynamic and kinetic properties of the alloy are improved. The prepared alloy powder maintains high hydrogen storage volume and fast hydrogenation and dehydrogenation kinetic properties; the dehydrogenation temperature of the hydride is remarkably reduced, and quick reversible hydrogenation and dehydrogenation can be conducted at the temperature of 280 DEG C; and the hydrogenation and dehydrogenation circulation stability is remarkably improved.

Owner:CENT IRON & STEEL RES INST

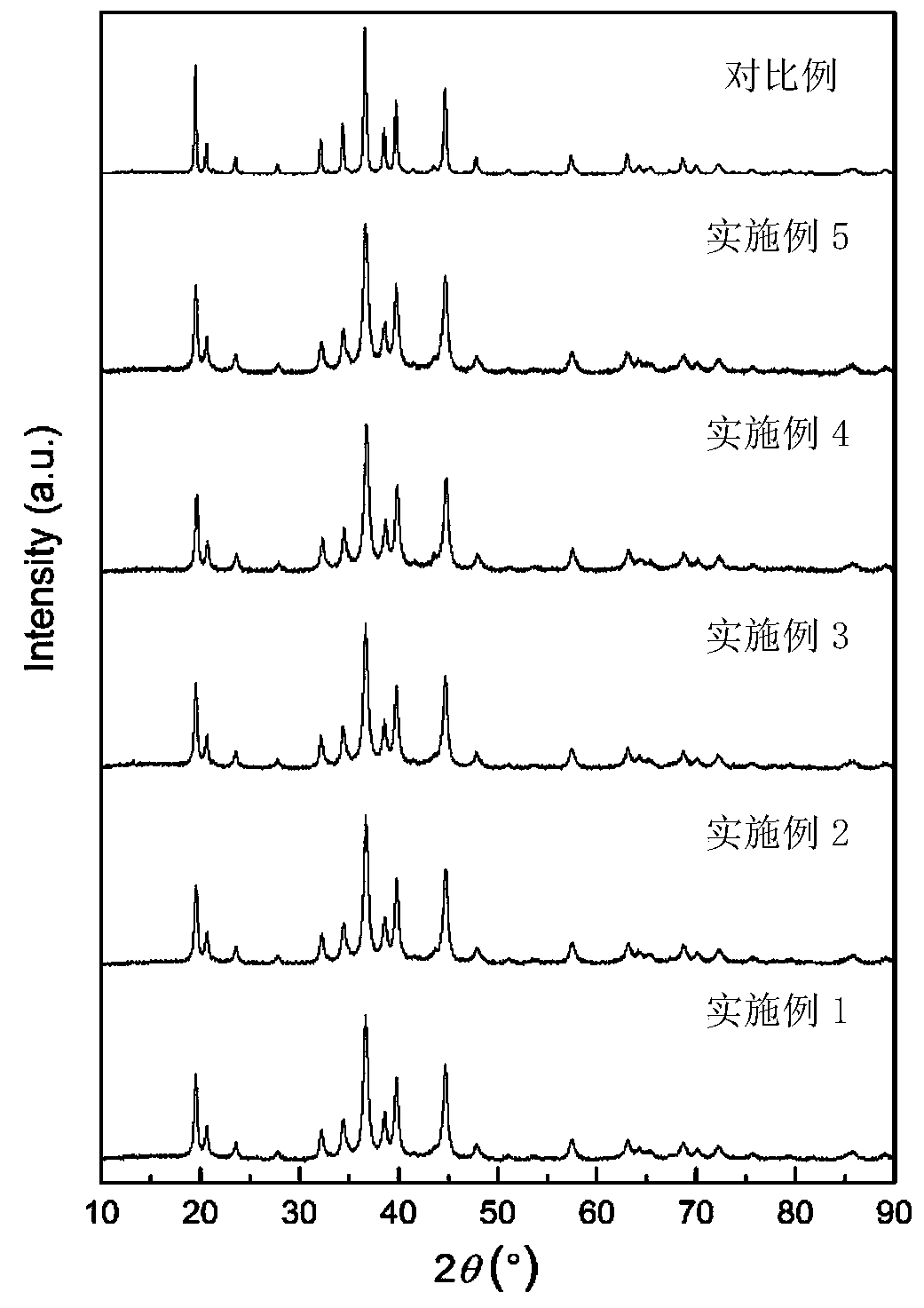

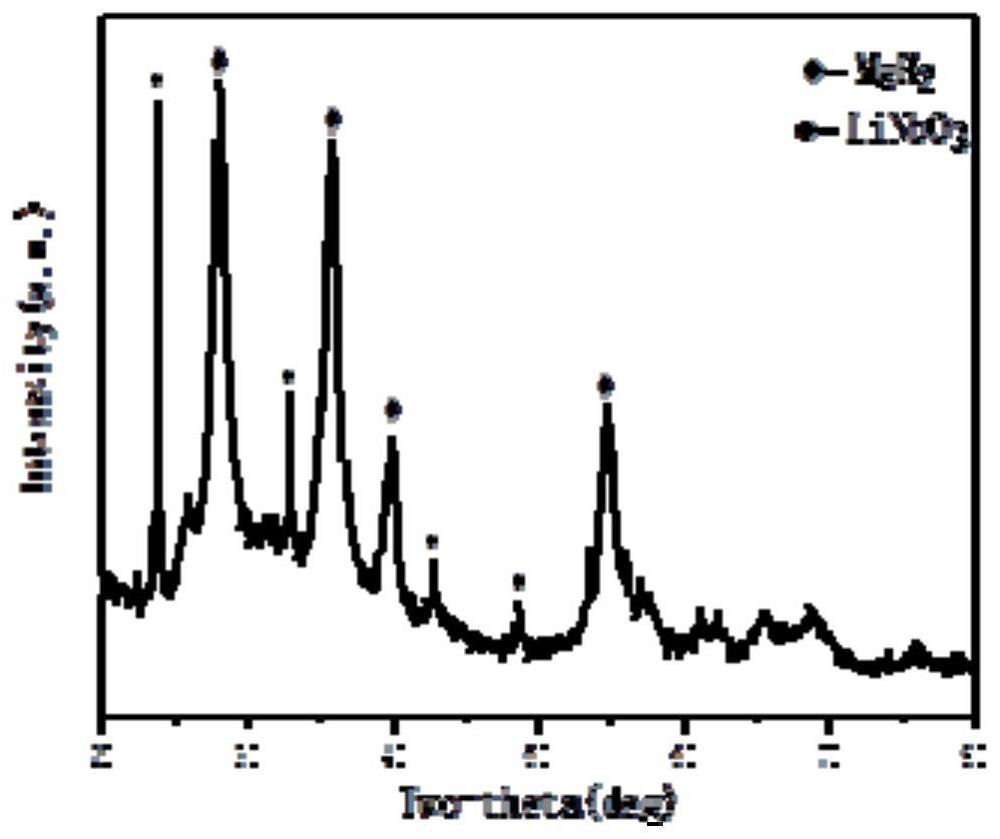

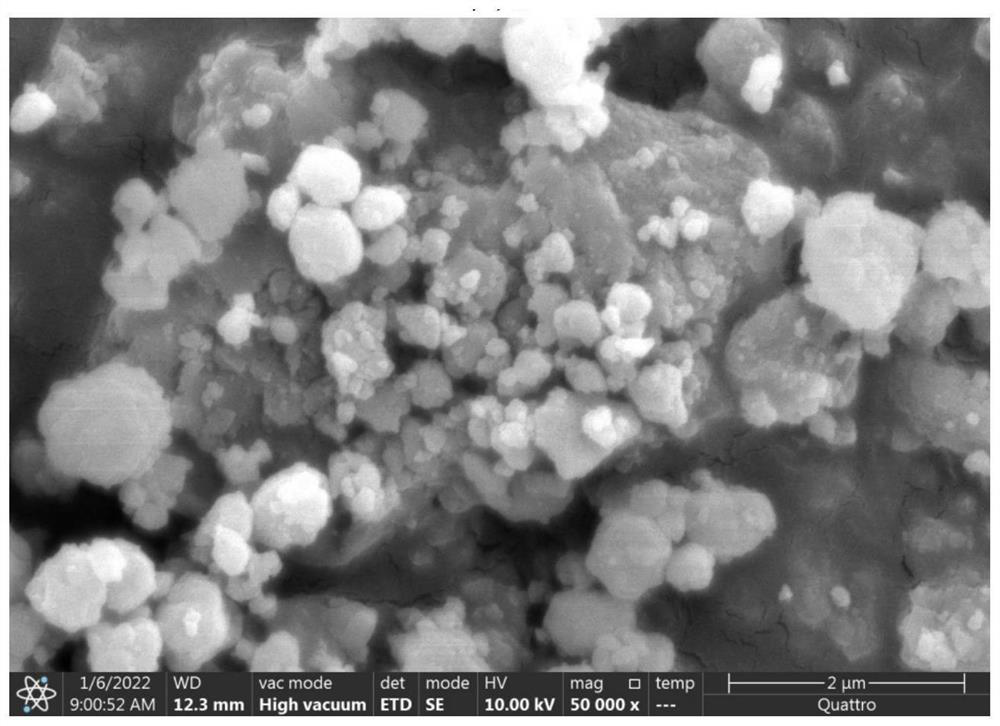

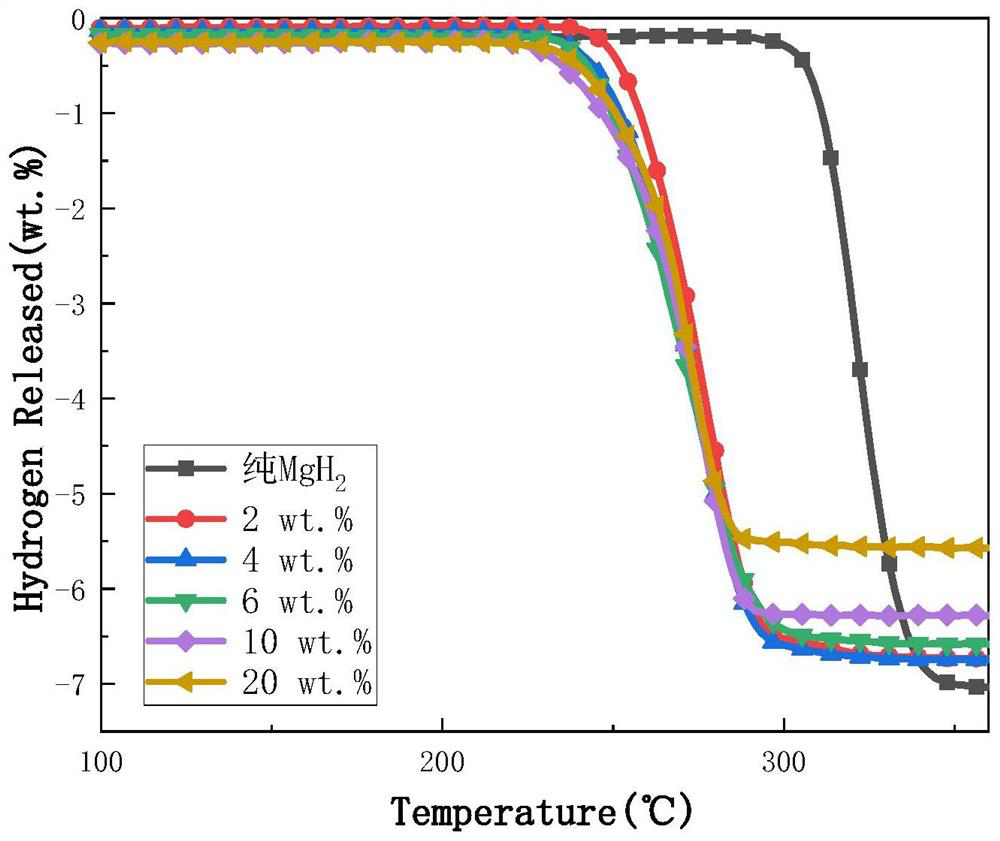

Lithium niobate-doped modified Mg-based hydrogen storage material and preparation method thereof

ActiveCN114804019AImprove hydrogen storage performanceReduce hydrogen absorption and desorption temperatureHydrogenPtru catalystHydrogen atmosphere

The invention provides a lithium niobate-doped modified Mg-based hydrogen storage material and a preparation method thereof, and relates to the technical field of magnesium-based solid hydrogen storage materials. The preparation method comprises the following steps: carrying out ball milling on MgH2 and lithium niobate in an inert gas or hydrogen atmosphere to obtain an efficient magnesium-based hydrogen storage material; in the hydrogen storage material, the mass fraction of the catalyst is 2-20 wt.%. Compared with a material not doped with a lithium niobate catalyst, the magnesium-based hydrogen storage material obtained after ball milling of lithium niobate and MgH2 has the advantages that the catalyst has excellent catalytic activity, the hydrogen absorption and desorption performance of the magnesium-based hydrogen storage material can be further improved, the hydrogen absorption and desorption temperature is remarkably reduced, and the hydrogen absorption and desorption speed is increased. The magnesium-based hydrogen storage material provided by the invention is simple in preparation process and excellent in hydrogen storage performance, and has an important reference value for industrial development of hydrogen energy storage and transportation.

Owner:CHONGQING UNIV

A nano-magnesium-based reversible hydrogen storage composite material and its preparation method

ActiveCN105734323BImproving the kinetic performance of hydrogen absorption and desorption at medium and low temperaturesIncreased diffusion rateFiberActivated carbon

The invention discloses a nanometer magnesium base reversible hydrogen storage composite material and a preparation method thereof. The nanometer magnesium base reversible hydrogen storage composite material is prepared by 80-95 weight% of magnesium-aluminum alloy Mg17Al12 and 5-20 weight% of carbon-loaded transition metal catalyst; the carbon-loaded transition metal catalyst consists of basal material carbon and transition metal; the basal material carbon is one of graphite powder, graphite fiber, activated carbon, single-wall carbon nanotube and multi-wall carbon nanotube; and the transition metal is one of Fe, Co, Ni and Nb. The preparation method comprises the following steps: the magnesium-aluminum alloy Mg17Al12 and the carbon-loaded transition metal catalyst are uniformly mixed to perform the ball milling in the inert atmosphere to obtain the nanometer magnesium base reversible hydrogen storage composite material. The magnesium base reversible hydrogen storage composite material has such advantages as low effective hydrogen storage temperature and excellent hydrogen absorption / desorption dynamics performance, can be applied to purification, storage and transportation of hydrogen, and in particular, can serve as a hydrogen source alloy of medium / low-temperature fuel cells.

Owner:ZHEJIANG UNIV

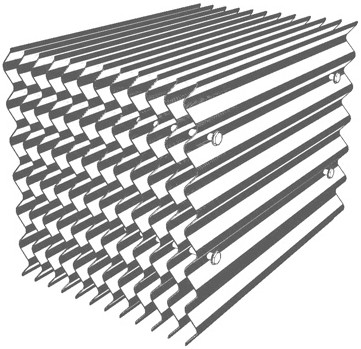

Manufacturing method of corrugated rare earth hydrogen storage material

PendingCN114044487ASpecific hydrogen storage and absorption propertiesImprove the kinetic performance of hydrogen absorption and desorptionHydrogenPolyvinyl chlorideNiobium dioxide

The invention relates to a manufacturing method of a corrugated rare earth hydrogen storage material, which comprises the following steps: grinding titanium oxide powder, boric oxide powder, niobium dioxide powder and rhenium oxide powder into powder with the particle size of 50-80 nanometers, weighing according to a ratio, blending, and fusing to obtain a material A for later use; weighing nano zinc oxide and nano magnesium oxide according to the formula, and mixing to obtain a material B for later use; and weighing polyvinyl chloride, activated carbon and titanium oxide powder according to the formula, blending, putting the mixture into a charging barrel of an extruder after blending is finished, heating and extruding a corrugated material, and then preparing the corrugated-structured rare earth hydrogen storage material after manufacturing and assembling. It is ensured that the rare earth hydrogen storage material can reversibly absorb, store and release a large amount of hydrogen in the normal-temperature state, safe use of hydrogen energy in power generation and combustion links is promoted, the use efficiency of green energy is improved, and meanwhile, the material has the advantages of being high in product yield, low in cost, easy and convenient to operate, long in service life, efficient, capable of saving energy and environmentally friendly, and has wide application value.

Owner:SHANGHAI SUPERHIGH ENVIRONMENTAL PROTECTION TECH CO LTD

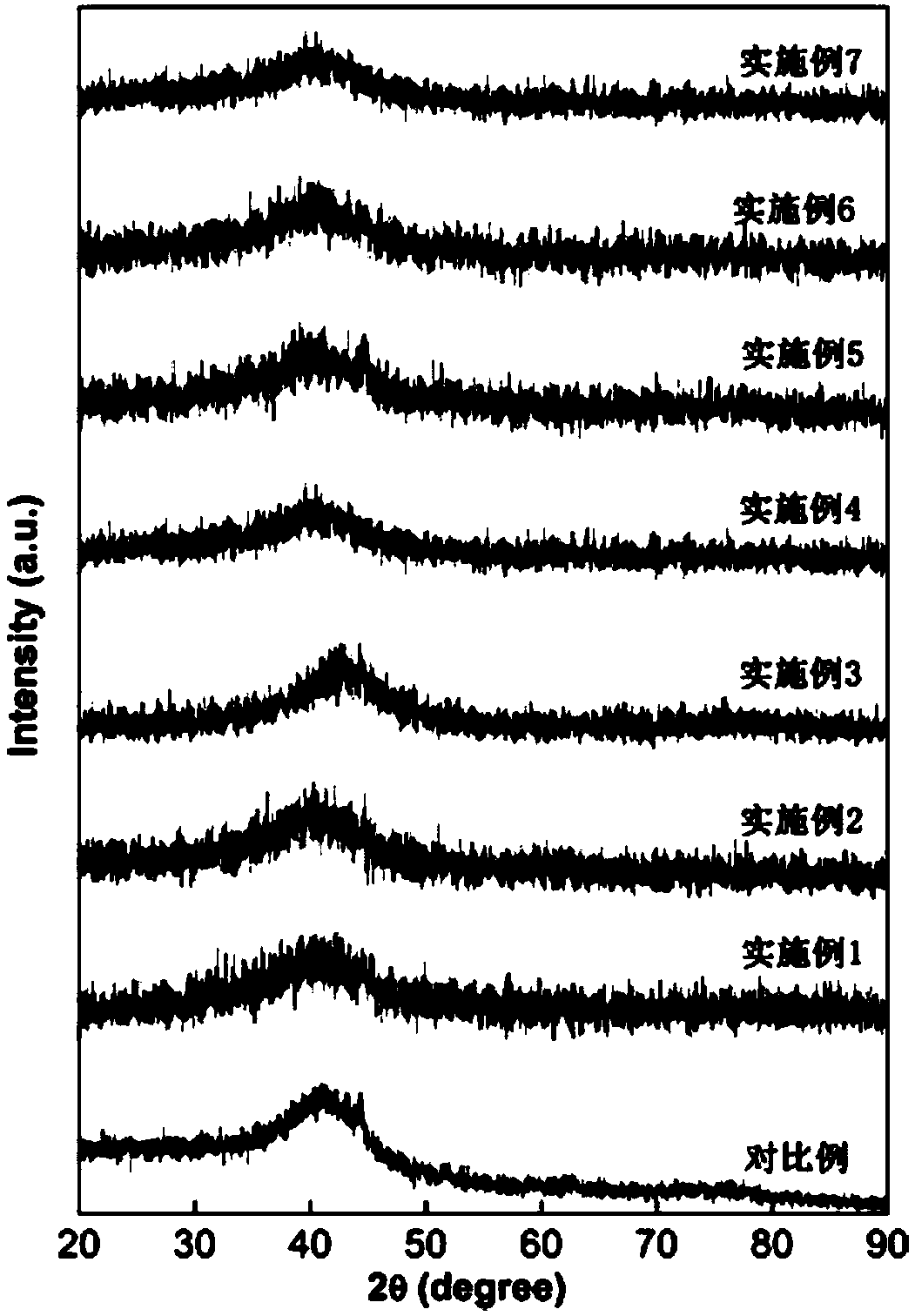

A kind of mg-al-y-based hydrogen storage material and preparation method thereof

The invention relates to a preparation method of a high-performance and high-capacity Mg-Al-Y-based hydrogen storage material. The method comprises the following steps of heating and melting raw materials in a medium-frequency induction melting furnace in an inert atmosphere, casting and molding, and pulverizing and crushing the ingot into 200-300 mesh powder, mixed with the porous carbon-based catalyst Tm@C supporting transition metal and metal fluoride for high-energy ball milling to obtain a hydrogen storage material composed of the following components: Mg x Al y Y z +a%Tm@C+b%metal fluoride, where: Mg x Al y Y z is Mg‑Al‑Y hydrogen storage alloy, x, y, z are atomic ratios, where x+y+z=100, 5≤y≤15, 5≤z≤10, a and b are Mg‑Al‑Y The mass of hydrogen storage alloy powder is the mass percentage of added Tm@C and metal fluoride, a and b are 3-5. By adding porous carbon-based catalyst and metal fluoride in the present invention, the dehydrogenation kinetic performance of the prepared hydrogen storage material is greatly improved, and the dehydrogenation temperature is significantly reduced.

Owner:CENT IRON & STEEL RES INST

A magnesium-based hydrogen storage alloy containing a long-period ordered stacking structure and its preparation method

ActiveCN106756369BSimple process equipmentLower activation energyMaterial nanotechnologyTransportation and packagingAdditive ingredientArgon atmosphere

Owner:YANSHAN UNIV

mg-sn-ni ternary hydrogen storage master alloy for fuel cell, hydrogen storage material and preparation method

ActiveCN106756355BImproved hydrogen absorption and desorption kineticsLower the hydrogen decomposition temperatureCell electrodesPtru catalystHeat stability

The invention relates to a high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy used for a fuel cell, and a hydrogen storage material and preparation method of the high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy. According to the atomic percent, the alloy comprises the chemical component of Mg<100-a-b>SnNi, wherein a is within the range of 4-6, and b is within the range of 9-11. The preparation method comprises the steps that induction heating and smelting are adopted under inert gas protection, and molten alloy is poured into a copper casting mold to obtain a cylindrical alloy ingot; and the ingot is mechanically crushed into powder and screened, the screened alloy powder and 1-5wt% of catalyst graphite are together loaded into a stainless steel ball milling tank, after vacuum pumping, high-purity argon gas is injected, and ball milling is conducted for certain time in an all-dimensional planetary high-energy ball mill to obtain alloy powder of a nanocrystalline-non-crystalline structure. According to the high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy used for the fuel cell, and the hydrogen storage material and preparation method of the high-capacity Mg-Sn-Ni ternary hydrogen storage intermediate alloy, bond energy between Mg and H can be wakened through Sn and Ni, and the hydrogen storage performance of the magnesium-based hydrogen storage material is effectively improved; and through component design, microstructure adjustment and control and adding of the graphite, the heat stability of hydride of the alloy is reduced, and hydrogen absorption and desorption thermodynamics and kinetics performance of the alloy is improved.

Owner:CENT IRON & STEEL RES INST

Magnesium-based hydrogen storage alloy containing long-period ordered accumulation structure and preparation method of magnesium-based hydrogen storage alloy

ActiveCN106756369ASimple process equipmentLower activation energyMaterial nanotechnologyTransportation and packagingDehydrogenationHot Temperature

The invention provides magnesium-based hydrogen storage alloy containing a long-period ordered accumulation structure. The chemical molecular formula of the magnesium-based hydrogen storage alloy is Mg-aX-bY-cLi, X represents one of V or Co, a, b and c represent mass percentage, a is larger than or equal to 3% and smaller than or equal to 8%, b is larger than or equal to 17% and smaller than or equal to 19%, c is larger than or equal to 0.5% and smaller than or equal to 1% and the balance Mg. The preparation method of the magnesium-based hydrogen storage alloy mainly includes the steps that alloy particles containing the above ingredients are put into a ball milling tank, stainless steel grinding balls with the size being 4-6 mm are added into the ball milling tank according to the ball material ratio of (15:1)-(20:1), the rotation speed is 300-400 r / min, rotation is stopped for 10 minutes after operation is performed for 30 minutes, powder with the average particle size being 50-90 nm is obtained after ball milling is performed for 30-50 hours and placed into a vacuum high-temperature furnace, the power is heated to 200 DEG C under an argon gas atmosphere, heat preservation is performed for 24 hours, and the magnesium-based hydrogen storage alloy containing the long-period ordered accumulation structure is prepared. According to the process, equipment is simple and easy to control, the cost is low, the hydrogenation and dehydrogenation temperature of the prepared magnesium-based hydrogen storage alloy is moderate, and hydrogenation and dehydrogenation dynamics performance is good.

Owner:YANSHAN UNIV

Magnesium vanadium composite hydrogen occluding alloy

InactiveCN101307405BImprove mechanical propertiesLarge hydrogen absorption capacityHydrogen fuel cellHydrogen fuel

The invention relates to a magnesium vanadium composite hydrogen storage alloy and a method for manufacturing the same, belonging to the metal material field. The invention is characterized in that vanadium base sosoloid hydrogen storage alloy powder containing transition elements and magnesium powder are mixed according to a certain volume proportion to manufacture the magnesium vanadium composite hydrogen storage alloy through a spark plasma sintering method. A chemical formula of the hydrogen storage alloy is MgX(V1-RMR)1-X, wherein, V is metal vanadium; M is a mixture of transition elements Ni, Zr, Mn and Ti in equal weight; R is more than or equal to 5 percent and less than or equal to 10 percent in percentage by weight; Mg is metal magnesium powder; and X is more than or equal to 75percent and less than or equal to 85 percent in percentage by volume. Compared with the prior art, the hydrogen storage alloy has the prominent advantages that: under the condition of room temperatureand at a temperature of 300 DEG C, the hydrogen storage alloy can rapidly absorb and discharge hydrogen and has simple manufacturing process and short processing time. The alloy can be used for manufacturing a hydrogen fuel tank, a hydrogen accumulator, etc. and is particularly suitable for a hydrogen fuel cell, a hydrogen fueled engine and other systems.

Owner:UNIV OF SCI & TECH BEIJING

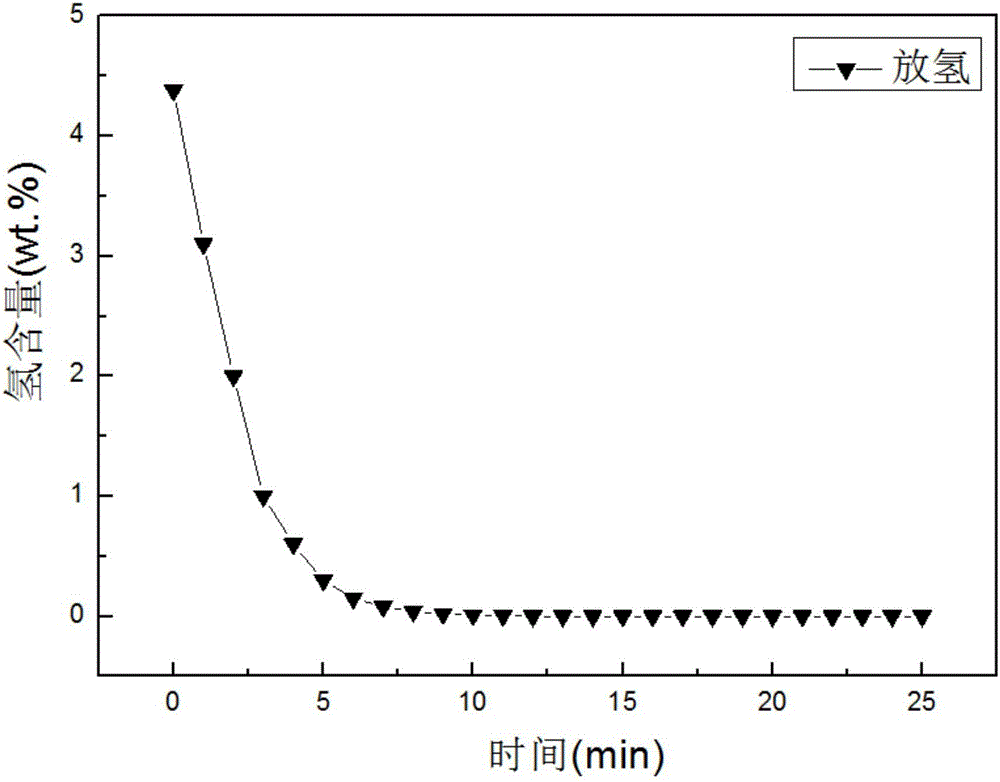

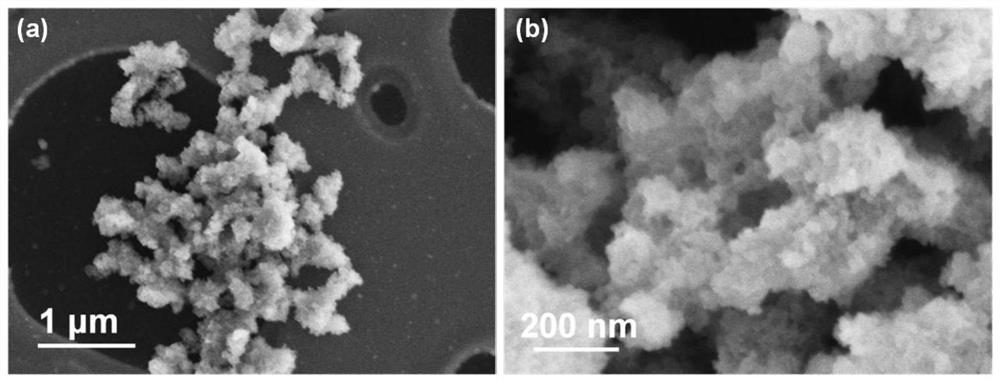

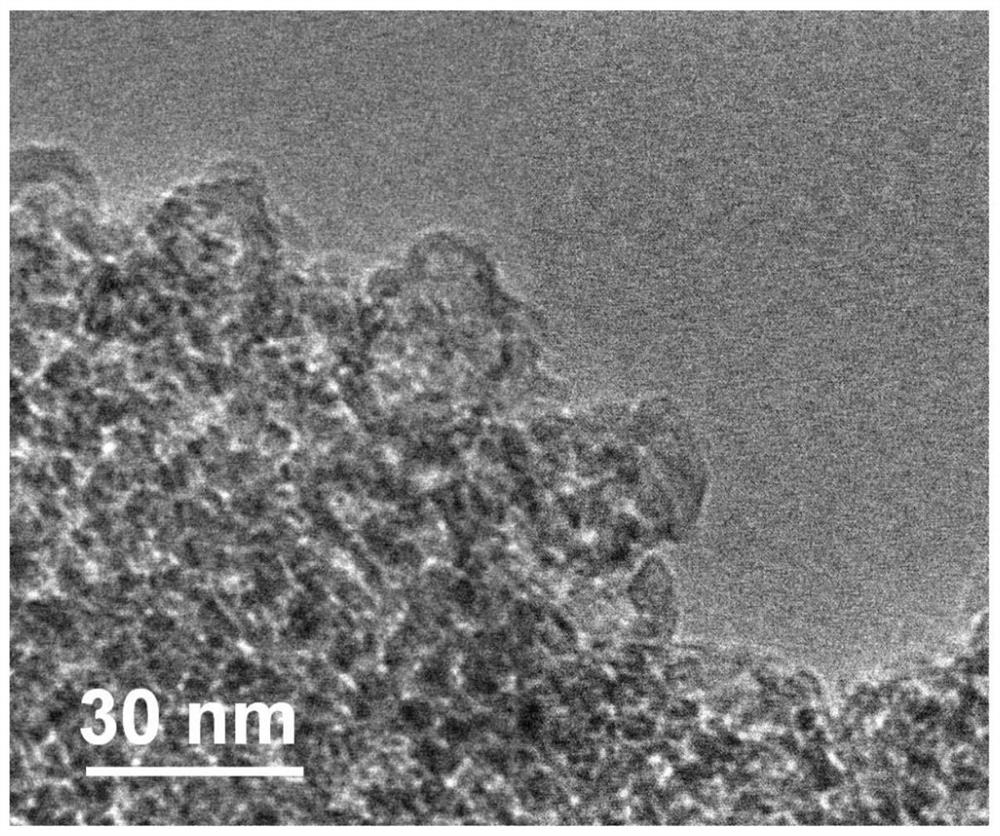

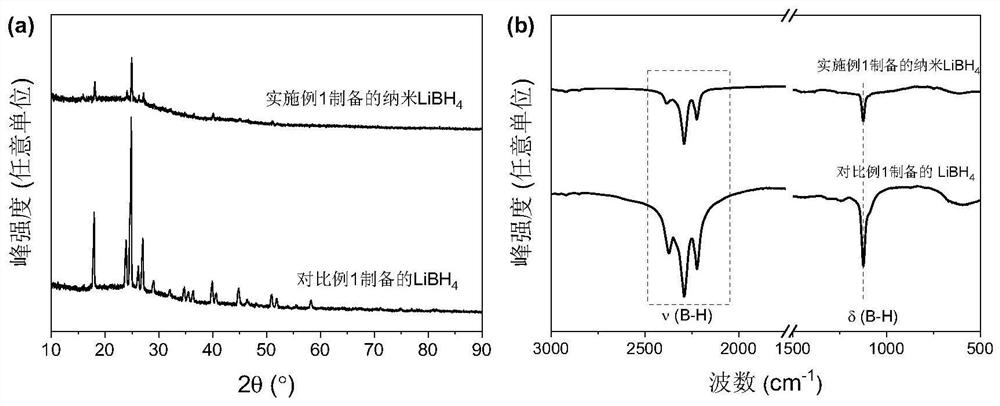

A kind of nano lithium borohydride, its in-situ preparation method and application

ActiveCN112320757BImprove performanceSmall particle sizeReversible hydrogen uptakeMonoborane/diborane hydridesPtru catalystSolvothermal reaction

The invention relates to the technical field of hydrogen storage materials and nanomaterials, and specifically discloses a nano-lithium borohydride, its in-situ preparation method and application. The preparation method is to mix butyl lithium and triethylamine borane in an organic solvent , heating and reacting under high-pressure hydrogen, and obtaining nano-lithium borohydride after post-treatment, and can also add carrier materials and transition metallocenes to obtain nano-lithium borohydride containing carriers and catalysts. Based on the solvothermal reaction, the present invention combines the hydrogen absorption reaction of butyllithium and the absorption of BH by lithium hydride 3 Reaction combined in one time, LiBH can be obtained through one-time hydrothermal synthesis 4 , can better control the particle size of the product, and the obtained nano-lithium borohydride hydrogen storage material has the advantages of high hydrogen storage capacity, low hydrogen absorption and desorption operating temperature, and fast hydrogen absorption and desorption rate.

Owner:ZHEJIANG UNIV

Preparation method of mg-re-ni-al-ti-co based hydrogen storage alloy catalyzed by nano titanium trifluoride

ActiveCN107099724BHigh hydrogen storage capacityImprove hydrogen absorption and desorption performanceRare-earth elementChemical composition

The invention relates to a nano titanium trifluoride catalyzed Mg-RE-Ni-Al-Ti-Co based hydrogen storing alloy and a preparation method thereof. The hydrogen storing alloy has the following chemical composition: Mg18-x-yLaxREyNi2-z-mAlzTim+50(wt)%Co+n(wt)%TiF3, wherein x, y, z and m are atomic ratios; x is more than 1 and less than 3; y is more than 0.2 and less than 1; z is more than 0 and less than 1; m is more than 0 and less than 1; n is a mass percent of TiF3 accounting for Mg18-x-yLaxREyNi2-z-mAlzTim; n is more than 3 and less than 8; and RE comprises at least one of rare earth elements such as Ce, Nd, Y, Sm and Gd. The hydrogen storing alloy provided by the invention has high hydrogen storing capacity and excellent dynamics performance, and has high hydrogen absorption and desorption capacity at a low temperature. Moreover, the hydrogen absorption and desorption dynamics performance is greatly improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com