Porous carbon loaded nano metal oxide catalyst, preparation method of catalyst, and hydrogen storage material

A technology of nano-metals and hydrogen storage materials, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve the problems that the performance of the hydrogen storage system cannot meet the practical requirements, and achieve Mild conditions, uniform distribution, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

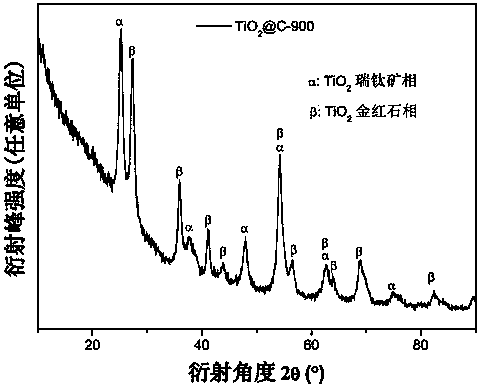

[0047] Nano-TiO 2 Preparation of porous carbon composite catalyst:

[0048] (1) Magnetically stir anhydrous ethanol (60ml) and anhydrous furfuryl alcohol (30ml) in the flask for 20min in the dark, weigh the heated and activated MIL-125(Ti) (0.5g) into the flask, seal it and avoid Light and magnetic stirring for 24h.

[0049] (2) Filtrate to obtain solid powder, put it into a quartz crucible and heat it up to 80°C at a heating rate of 10°C / min under the protection of an inert atmosphere for 24 hours to promote dehydration and condensation between furfuryl alcohol molecules; then raise the temperature at a heating rate of 5°C / min to 150°C, in a dynamic vacuum (1×10 -3 Under Torr) condition, keep warm for 6h.

[0050] (3) Take out the heated solid powder obtained in step (2), repeat steps (1) to (2) once, and then put the product into a quartz tube furnace under the protection of Ar gas flow (100ml / min), at 5°C The heating rate was raised to 900 °C for 3 h at a heating rate o...

Embodiment 2

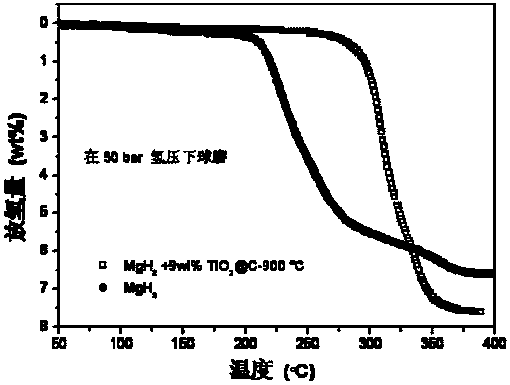

[0053] Nano-TiO 2 C-900 Catalytic NaAlH 4 Preparation of hydrogen storage material: with the nano-TiO of embodiment 1 2 C-900 as catalyst, NaAlH 4 The matrix material is mixed uniformly in argon atmosphere glove box according to a certain proportion, among which TiO 2 The mass fractions of C-900 in the mixture are: 3wt%, 5wt%, 7wt%, 9wt%, 10wt%. Put each mixture in a stainless steel ball mill tank, and perform ball milling on a high-energy ball mill. The ball milling atmosphere is an argon atmosphere, the rotation speed is 500 rpm, the ball-to-material ratio is 120:1, and the ball milling time is 24 hours, corresponding to five parts of hydrogen storage. Materials, respectively numbered as:

[0054] NaAlH 4 +3wt%TiO 2 C-900,

[0055] NaAlH 4 +5wt%TiO 2 C-900,

[0056] NaAlH 4 +7wt%TiO 2 C-900,

[0057] NaAlH 4 +9wt%TiO 2 C-900,

[0058] NaAlH 4 +10wt%TiO 2 C-900.

[0059] The hydrogen desorption kinetics of five parts of hydrogen storage materials was tested...

Embodiment 3

[0066] Nano-TiO 2 The preparation process of the porous carbon composite catalyst is the same as in Example 1.

[0067] Nano-TiO 2 C-900 Catalytic NaAlH 4 Preparation of hydrogen storage material: with the nano-TiO of embodiment 1 2 C-900 as catalyst, NaAlH 4 The matrix material is mixed uniformly in argon atmosphere glove box according to a certain proportion, among which TiO 2 The mass fraction of C-900 in the mixture is: 9wt%. Put the mixture in a stainless steel ball mill tank, and perform ball milling on a high-energy ball mill. The ball milling atmosphere is an argon atmosphere, the rotation speed is 500 rpm, the ball-to-material ratio is 120:1, and the ball milling time is 24 hours. The corresponding hydrogen storage material is named: NaAlH 4 +9wt%TiO 2 C-900.

[0068] The hydrogen absorption and desorption cycle performance of the above hydrogen storage materials was tested by volume method. The dehydrogenation process is: under vacuum conditions (initial vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com