Multi-element graded metal based nanoparticle catalyst and preparation method therefor

A nanoparticle, metal-based technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that hinder the application of catalysts, and there is no controllable and efficient means for the regulation of electronic structure. Achieve good crystallinity, uniform particle size distribution, and solve the effect of insufficient activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

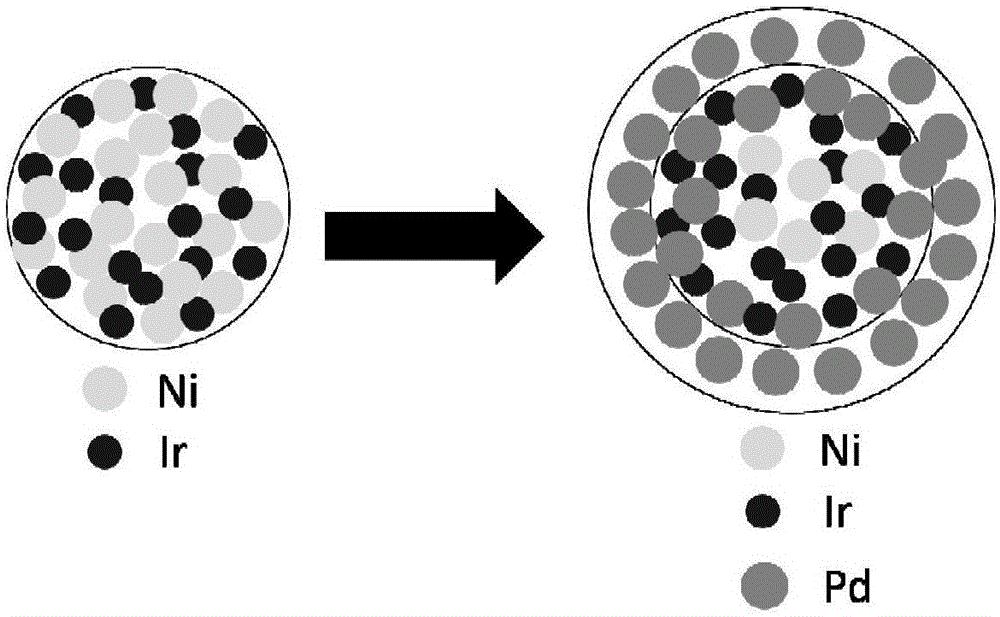

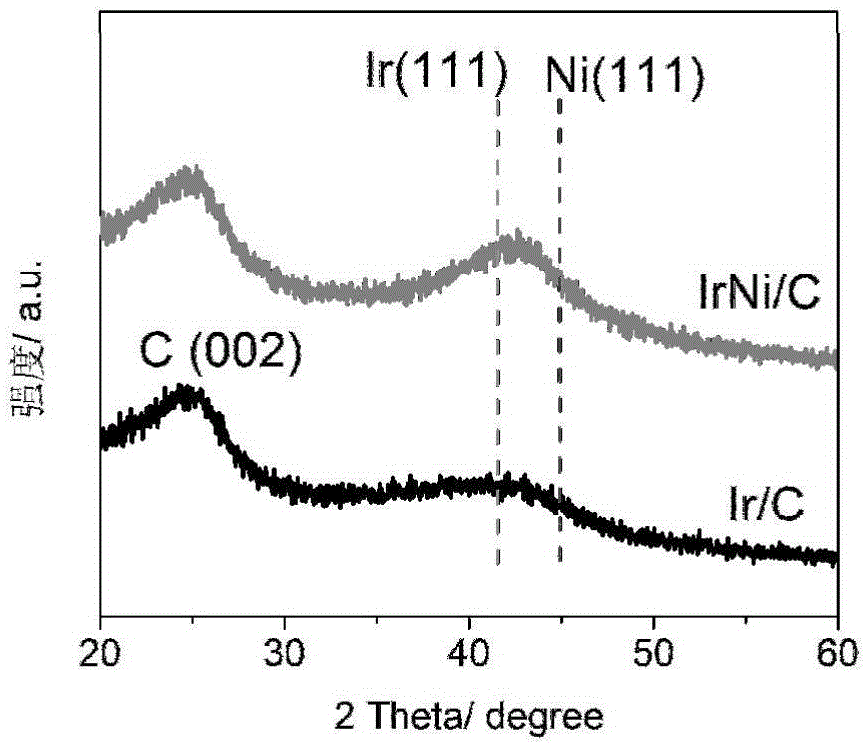

[0044] 1. Preparation of IrNi / C nanoparticles: Disperse nickel chloride, chloroiridic acid and XC-72R in ethylene glycol so that the molar ratio of Ni to Ir precursor is 1:1, and the total mass of all metals in the precursor is The ratio to XC-72R mass is 0.25:1. The pH = 10 was adjusted using NaOH in polyol and the solution was saturated by bubbling argon. Use microwaves to heat the solution to a temperature of 130°C, cool it down to room temperature naturally, wash and dry it, and then IrNi / C can be obtained.

[0045] 2. Then take a certain amount of IrNi / C and chloropalladium acid and disperse them in ethylene glycol. The molar ratio of Ni to Pd is 3:1, and it is protected by argon all the time. Use NaOH polyol solution to adjust the pH to 10, treat in an oil bath for 3 hours, and treat at a temperature of 110°C. The gradient PdIrNi / C composite catalyst can be obtained after washing and drying.

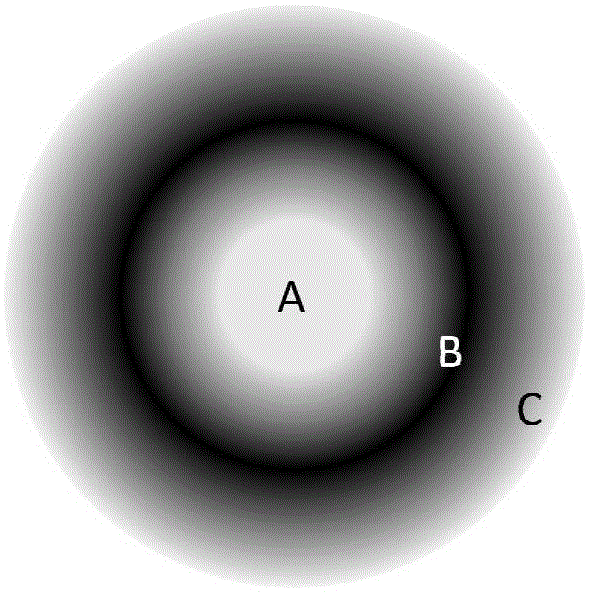

[0046] The IrNi metal alloy nanoparticles synthesized by the first step of ...

Embodiment 2

[0052] 1. Preparation of IrNi / graphene nanoparticles: Disperse nickel chloride, chloroiridic acid and graphite oxide in ethylene glycol so that the molar ratio of Ni to Ir precursor is 0.1:1, and the total mass of all metals in the precursor is The ratio to the mass of graphite oxide is 0.25:1. The pH = 12 was adjusted using NaOH in polyol and the solution was saturated by bubbling argon. Use microwaves to heat the solution to a temperature of 140° C., cool it down to room temperature naturally, wash and dry it, and then IrNi / graphene can be obtained.

[0053] 2. Then take a certain amount of IrNi / graphene, and disperse it in ethylene glycol with chloropalladium acid. The molar ratio of Ni to Pd is 0.1:1, and it is protected by argon all the time. Use NaOH polyol solution to adjust pH=12, treat in oil bath for 5h, and treat at 90°C. The gradient PdIrNi / graphene composite catalyst can be obtained after washing and drying.

Embodiment 3

[0055] 1. Preparation of IrNi / graphene nanoparticles: Disperse nickel chloride, chloroiridic acid and graphite oxide in ethylene glycol so that the molar ratio of Ni to Ir precursor is 0.5:1, and the total mass of all metals in the precursor is The ratio to the mass of graphite oxide is 0.4:1. The pH = 9 was adjusted using NaOH in polyol and the solution was saturated by bubbling argon. Use microwaves to heat the solution to a temperature of 150° C., naturally cool to room temperature, wash and dry, and then obtain IrNi / graphene.

[0056] 2. Then take a certain amount of IrNi / graphene and chloropalladium acid and disperse it in ethylene glycol, the molar ratio of Ni to Pd is 0.1:1, and it is protected by argon all the time. Use NaOH polyol solution to adjust the pH=9, treat in an oil bath for 8 hours, and treat at a temperature of 120°C. The gradient PdIrNi / graphene composite catalyst can be obtained after washing and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com