Manufacturing method of corrugated rare earth hydrogen storage material

A technology for hydrogen storage materials and manufacturing methods, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as complex processes and general effects, and achieve the effects of wide application value, high safety, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

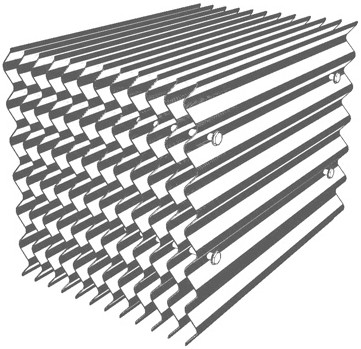

[0017] see figure 1 , the present invention provides a method for manufacturing corrugated rare earth hydrogen storage materials. Titanium oxide, boron oxide, niobium dioxide and rhenium oxide powders are ground to a particle size of 50-80 nanometers, weighed and blended according to the proportioning ratio, The blended materials are added to a solution made of ionized water and white glue for fusion, and after the fusion is completed, it is used as a slurry (material A) for later use.

[0018] Weigh and mix the nano-zinc oxide and nano-magnesium oxide according to the formula, and use it as a surface co-extrusion material (material B) for later use.

[0019] Then weigh polyvinyl chloride, activated carbon and titanium oxide powder according to the formula and blend them. After the blending is completed, put them into the barrel of the extruder, heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com