mg-sn-ni ternary hydrogen storage master alloy for fuel cell, hydrogen storage material and preparation method

A mg-sn-ni, intermediate alloy technology, applied in the field of hydrogen storage alloy materials, can solve the problems of easy crushing, high price, and lattice deformation of alloys, and achieve improved formation ability, improved surface activity, and hydrogen absorption and desorption kinetics The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

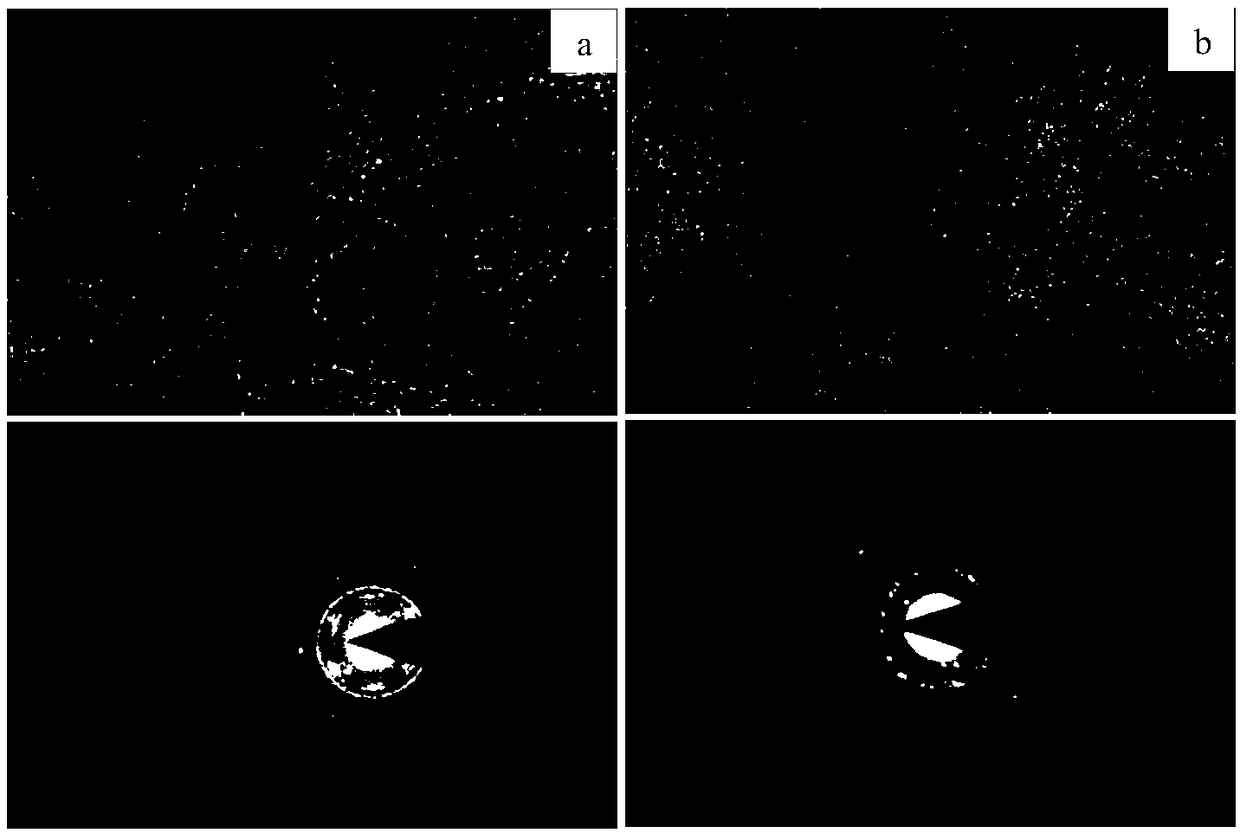

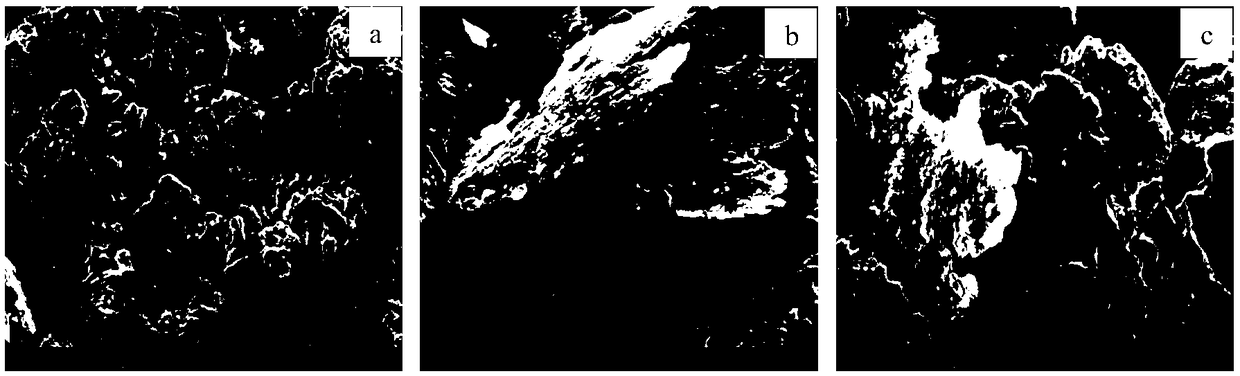

Image

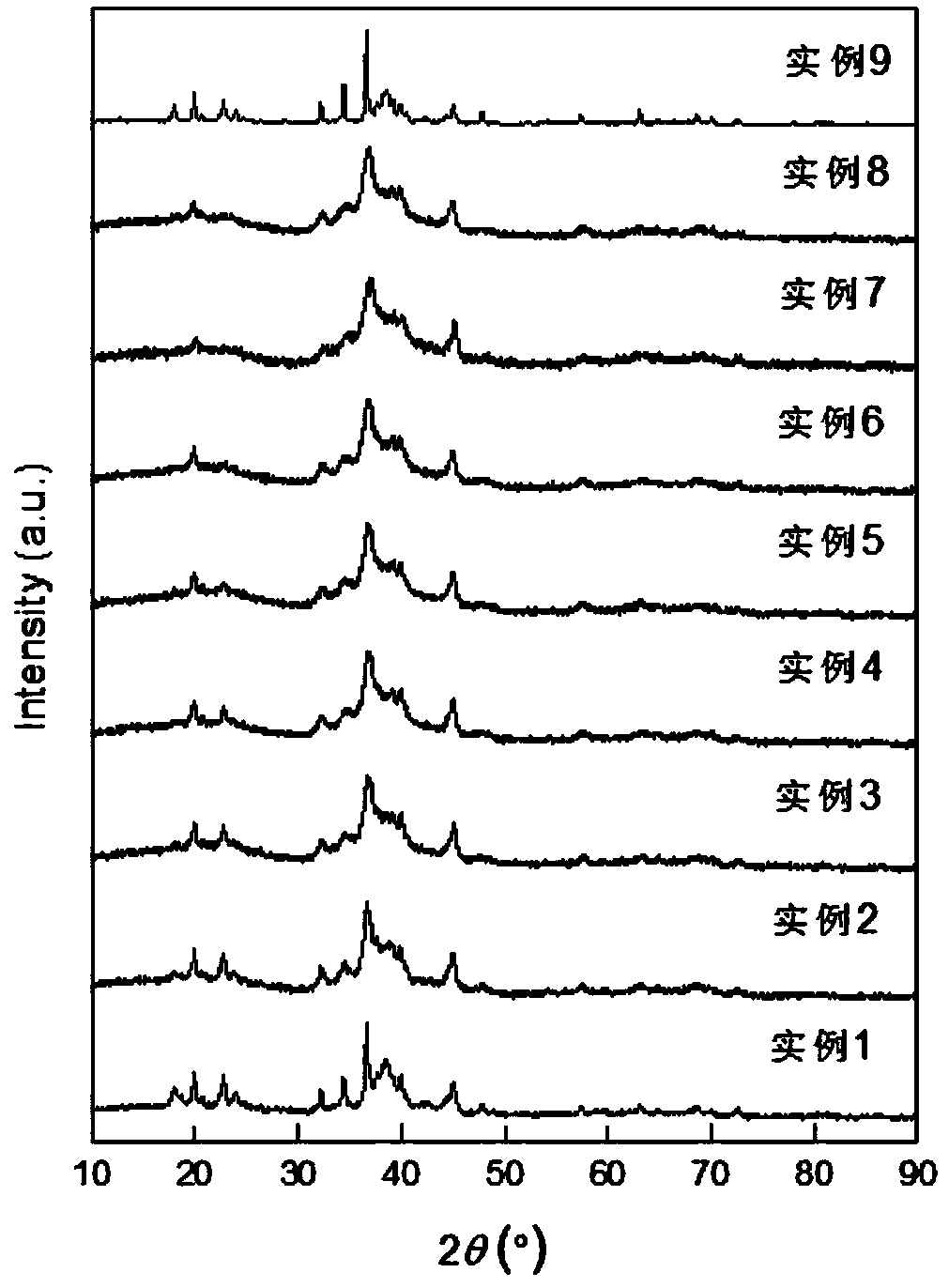

Examples

preparation example Construction

[0033] The preparation method of the high-capacity Mg-Sn-Ni hydrogen storage material for the fuel cell of the present invention comprises the following steps:

[0034] a. Ingredients: Mg according to the chemical formula 85 sn5 Ni 10 Perform batching, wherein the magnesium in the chemical formula composition increases the burning loss by 5% to 10% during the ratio, and the purity of the raw materials is ≥ 99.5%;

[0035] b. Preparation of as-cast master alloy: put prepared raw materials into a magnesia crucible, add all materials except magnesium into the crucible in no particular order, and finally put magnesium on top. Melting by induction heating, vacuuming to 1×10 -2 ~5×10 -5 Pa, then fill in an inert protective gas with a pressure of 0.01-0.1MPa, that is, fill in high-purity helium or argon+helium mixed gas, and the volume ratio of the mixed gas is about 1:1; the melting temperature is 1300-1500°C, to ensure The metal raw material is completely melted. The melted al...

Embodiment 1

[0039] Example 1: Mg 85 sn 5 Ni 10 +3(wt.%)C (ball milling 10h)

Embodiment 2

[0040] Example 2: Mg 85 sn 5 Ni 10 +5(wt.%)C (ball milling 10h)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com