A kind of high-capacity mg-zn-ni ternary hydrogen storage alloy and its preparation method

A mg-zn-ni, hydrogen storage alloy technology, applied in the field of hydrogen storage alloy materials, can solve the problems of magnesium-based hydrogen storage materials limitation, slow hydrogen desorption rate, reducing the thermal stability of alloy hydrides, hydrogen absorption and desorption of alloys, etc. Achieve the effects of improving hydrogen absorption and desorption kinetics, increasing formation capacity, increasing nucleation points and diffusion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

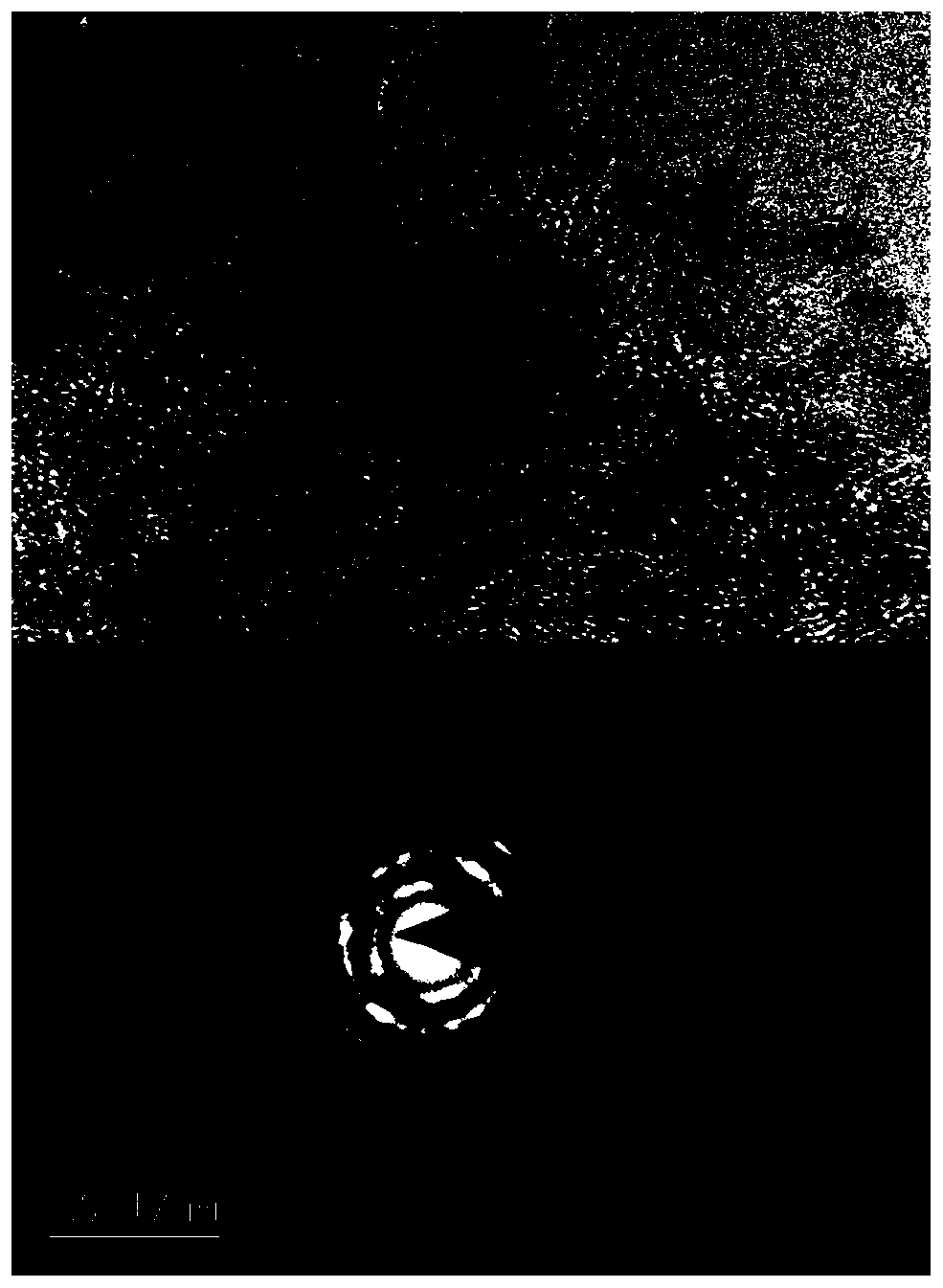

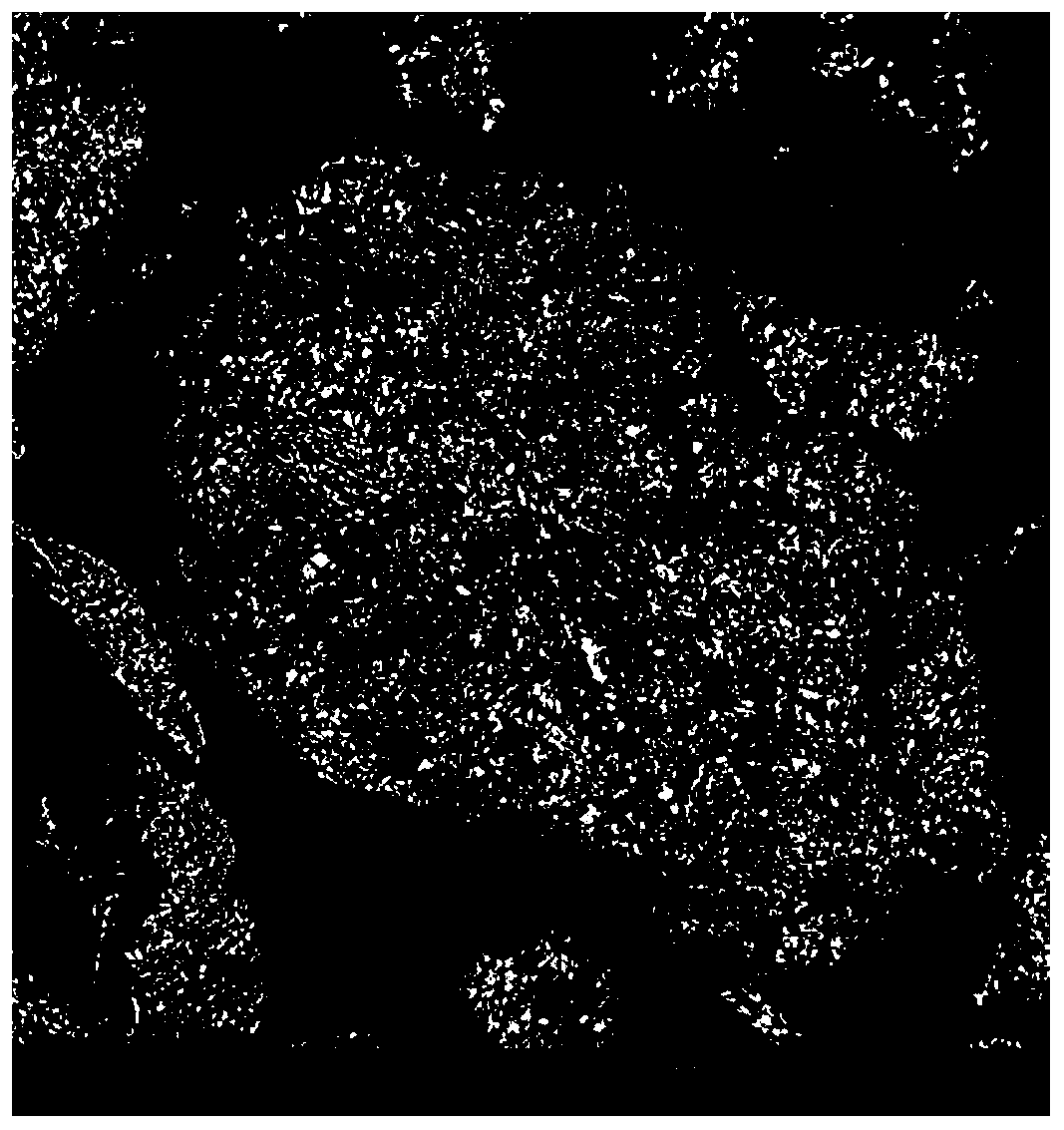

Image

Examples

preparation example Construction

[0037] The preparation method of the high-capacity Mg-Zn-Ni ternary hydrogen storage alloy for the fuel cell of the present invention comprises the following steps:

[0038] a. Ingredients: Mg according to the chemical formula 85 Zn 5 Ni 10Perform batching, wherein the magnesium in the chemical formula composition increases the burning loss by 5% to 10% during the ratio, and the purity of the raw materials is ≥ 99.5%;

[0039] b. Preparation of as-cast master alloy: put prepared raw materials into a magnesia crucible, add all materials except magnesium into the crucible in no particular order, and finally put magnesium on top. Using conventional heating methods, including arc melting, induction heating melting or other heating methods, vacuumize to 1×10 -2 Pa~5×10 -5 Pa, then fill in an inert protective gas with a pressure of 0.01MPa~0.1MPa, the inert protective gas is high-purity helium; the heating power at the beginning of smelting is adjusted to about 5kW, and the temp...

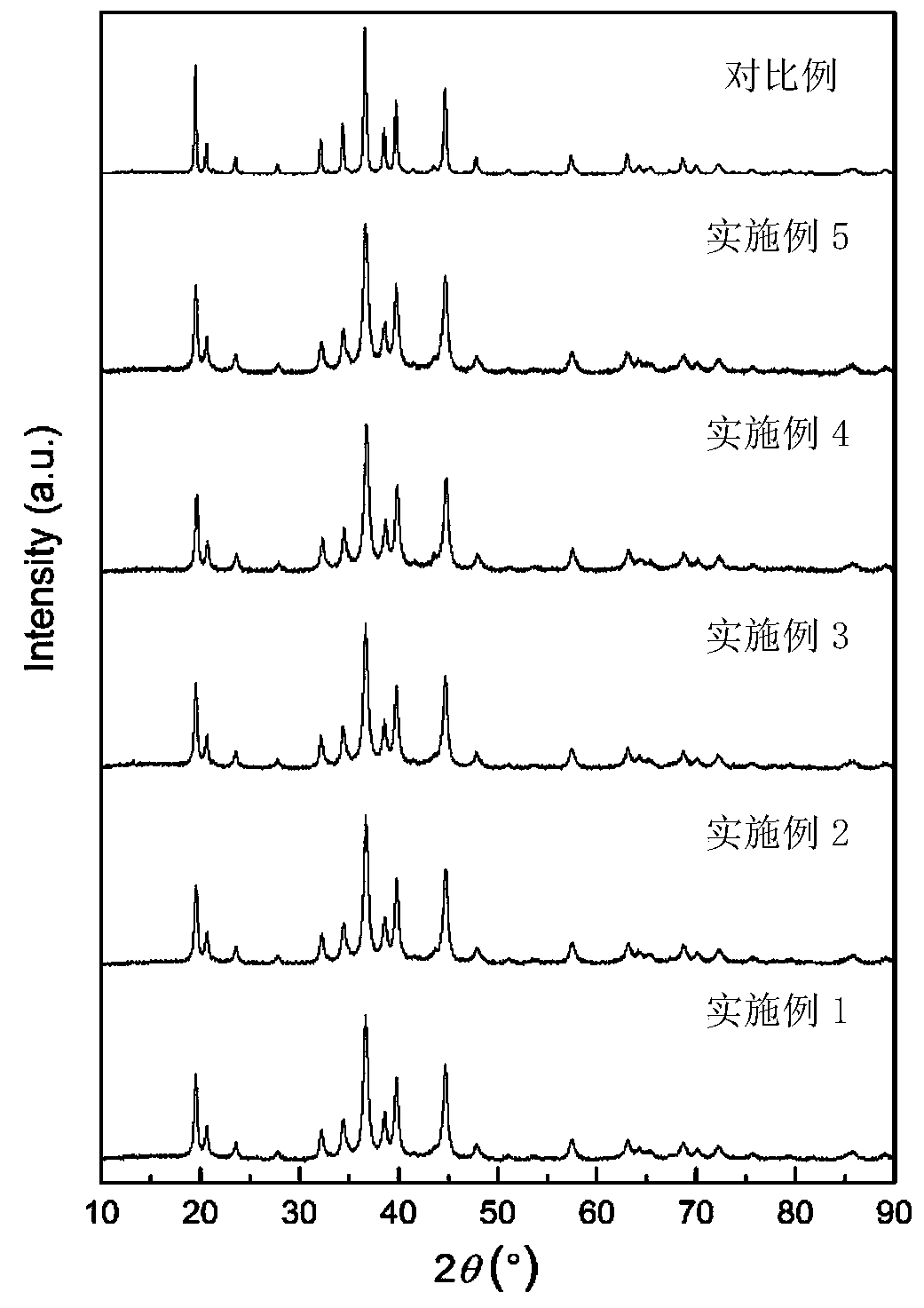

Embodiment 1

[0044] Example 1: Mg 85 Zn 5 Ni 10 (ball milling 5h)

Embodiment 2

[0045] Example 2: Mg 85 Zn 5 Ni 10 +2wt.% (TiF 3 ) (ball milling 5h)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com