Catalyst of sodium aluminum hydride complex hydride and preparation method thereof

A technology of coordinating hydride and sodium aluminum hydride, applied in the field of hydrogen storage materials, can solve problems such as restricting practical application, reducing catalytic activity, affecting hydrogen absorption and desorption kinetics, etc. The effect of improving the kinetics of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] with CeAl 4 Alloy powder is used as catalyst, and NaH and Al powder are used as matrix materials to prepare CeAl 4 Doped NaAlH 4 Hydrogen storage material.

[0020] The raw materials used are: NaH (purity 95%, ~200 mesh), Al powder (purity greater than 99.9%, ~200 mesh), metal Ce block (purity greater than 99.9%), metal Al block (purity greater than 99.9%). Raw materials are used directly without treatment.

[0021] 1) CeAl 4 Preparation of Alloy Powder Catalyst

[0022] Take metal Ce block and Al block according to the molar ratio of 1:4, and induction melt them into CeAl under the protection of argon. 4 Alloy ingots; then mechanically pulverized to less than 100 mesh; then the mechanically pulverized alloy particles were placed in a stainless steel ball mill tank, filled with 0.6MPa hydrogen gas, and ball milled on a high-energy ball mill for 10 hours to obtain a particle size of micronano Grade CeAl 4 powder catalyst.

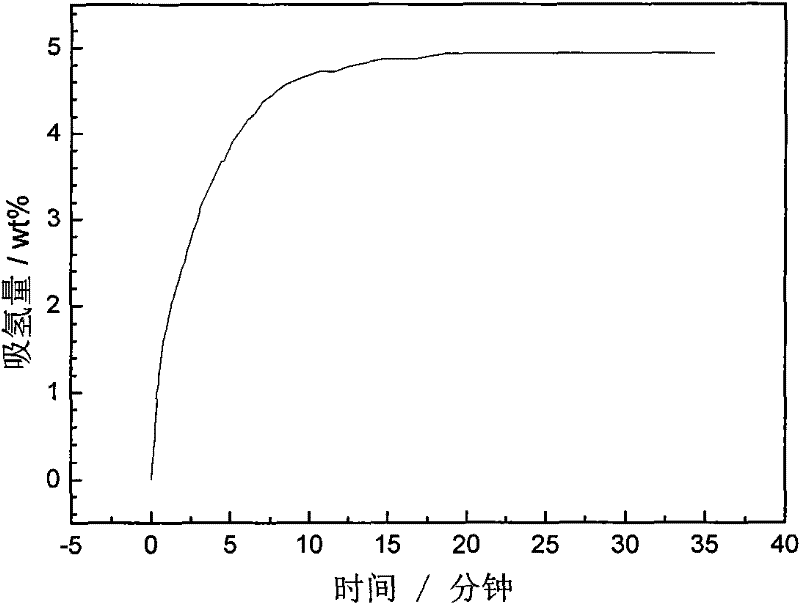

[0023] 2) CeAl 4 Powder catalyst for N...

Embodiment 2

[0028] SmAl 3 Alloy powder as catalyst, NaAlH 4 Powder is used as matrix material to prepare SmAl 3 Doped NaAlH 4 Hydrogen storage material.

[0029] The raw material used is: NaAlH 4 (purity 95%, ~200 mesh), metal Sm block (purity greater than 99.9%), metal Al block (purity greater than 99.9%). Raw materials are used directly without treatment.

[0030] 1) SmAl 3 Preparation of Alloy Powder Catalyst

[0031] Take metal Sm block and Al block according to the molar ratio of 1:3, and induction melt them into SmAl under the protection of argon. 3 Alloy ingots; then mechanically pulverized to below 100 mesh; then the mechanically pulverized particles are placed in a stainless steel ball mill tank, filled with 0.3MPa argon gas in the ball mill tank, and ball milled on a high-energy ball mill for 20 hours to obtain a particle size of micronano Grade SmAl 3 powder catalyst.

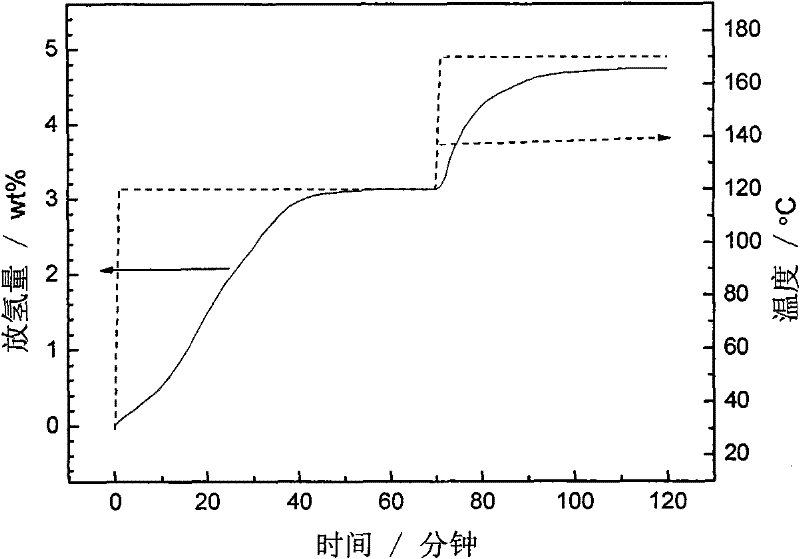

[0032]2) SmAl 3 Alloy powder catalyst for NaAlH 4 Preparation of hydrogen storage materials

[0...

Embodiment 3

[0037] to La 3 al 11 Alloy powder is used as catalyst, and NaH and Al powder are used as matrix materials to prepare La 3 al 11 Doped NaAlH 4 Hydrogen storage material.

[0038] The raw materials used are: NaH (purity 95%, ~200 mesh), Al powder (purity greater than 99.9%, ~200 mesh), metal La block (purity greater than 99.9%), metal Al block (purity greater than 99.9%). Raw materials are used directly without treatment.

[0039] 1) La 3 al 11 Preparation of Alloy Powder Catalyst

[0040] According to the molar ratio of 3:11, the metal La block and Al block are taken, and induction melting is carried out under the protection of argon to form La 3 al 11 alloy ingot. After that, mechanically pulverize to below 100 mesh, put the mechanically pulverized particles in a stainless steel ball mill tank, and fill the ball mill tank with 1.5MPaH 2 , milled on a planetary ball mill for 30 hours to obtain La 3 al 11 catalyst.

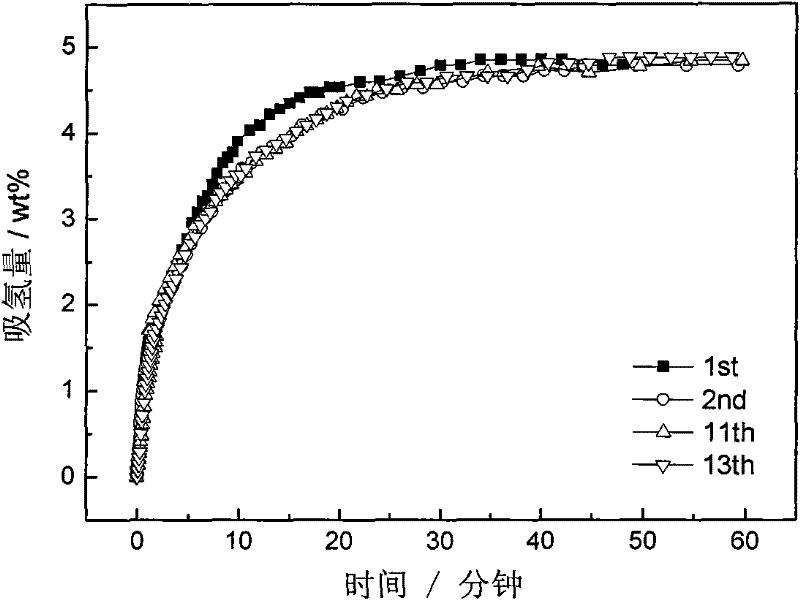

[0041] 2) La 3 al 11 Alloy powder catalyst for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com