Preparation method of mg-re-ni-al-ti-co based hydrogen storage alloy catalyzed by nano titanium trifluoride

A hydrogen storage alloy and alloy technology, applied in the field of hydrogen storage materials, can solve problems such as poor hydrogen absorption and desorption kinetics of alloys, and achieve the effects of improving surface properties, increasing surface activity, and improving hydrogen absorption and desorption capacity and kinetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

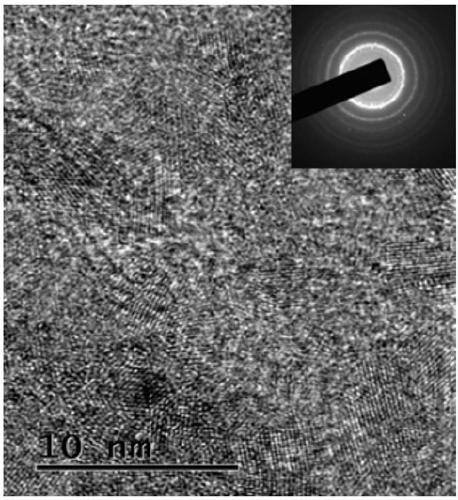

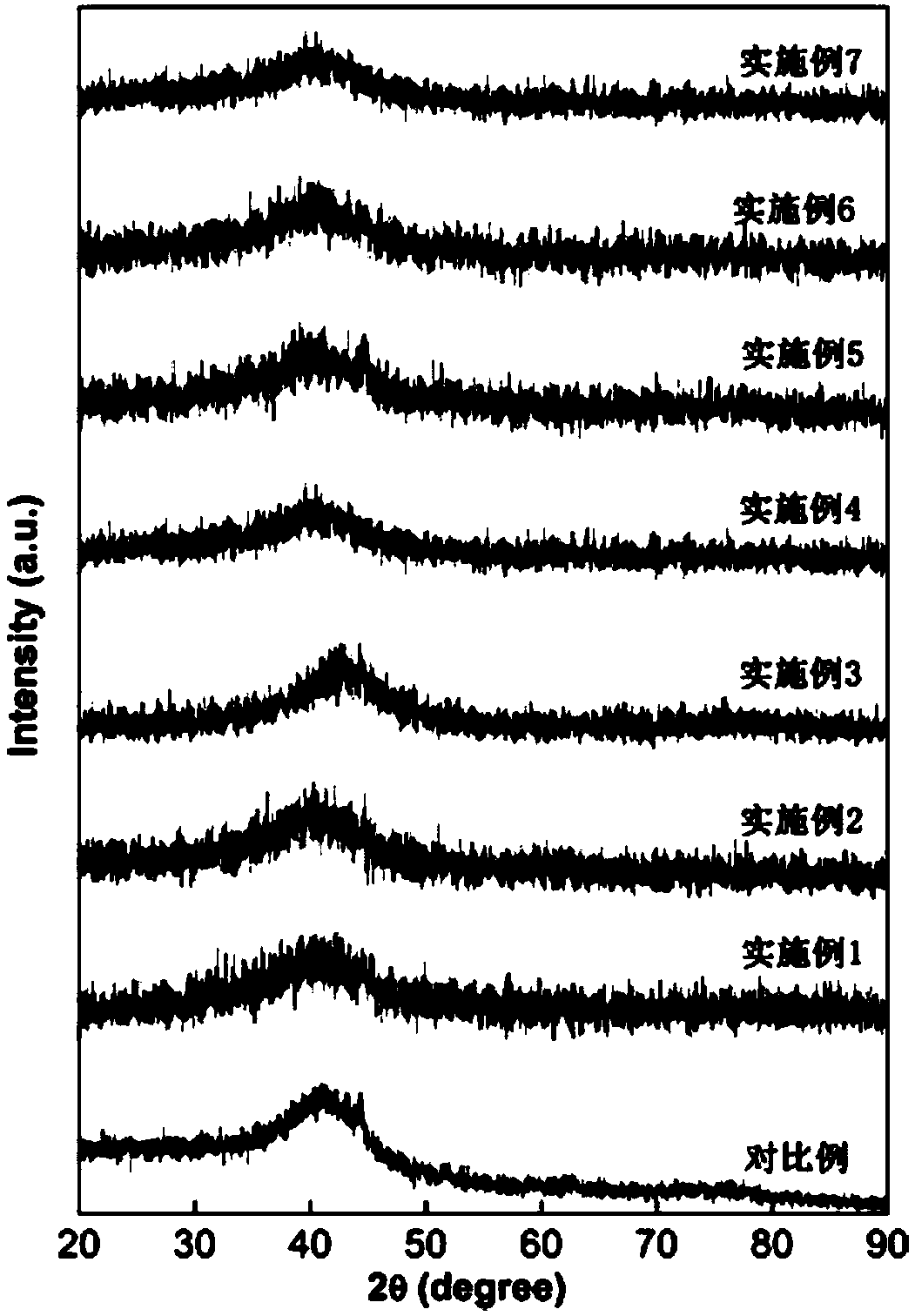

[0039] The invention provides a hydrogen storage alloy whose chemical formula is Mg 16 La 1.5 Y 0.5 NiAl 0.5 Ti 0.5 +50(wt)%Co+4(wt)%TiF 3 ; Wherein, select particle size to be 200 purpose cobalt powders, and the quality of Co accounts for Mg 16 La 1.5 Y 0.5 NiAl 0.5 Ti 0.5 50% of alloy mass; TiF 3 The mass accounts for Mg 16 La 1.5 Y 0.5 NiAl 0.5 Ti 0.5 4% of the alloy mass.

[0040] Using the preparation method provided by the present invention to prepare the hydrogen storage alloy of this embodiment includes the following steps:

[0041] S101: Select bulk metal magnesium, rare earth metal lanthanum and yttrium, metal nickel, metal aluminum and titanium; the purity of each metal is ≥99.5%, and the metal-based master alloy is polished to remove the surface oxide layer, and weighed according to the chemical dosage ratio. Take by weighing metal magnesium 1054.1g, metal lanthanum 564.8g, metal yttrium 120.5g, metal nickel 159.1g, metal aluminum 36.5g and metal ti...

Embodiment 2

[0047] The invention provides a hydrogen storage alloy whose chemical formula is Mg 16 LaSmNiAl 0.5 Ti 0.5 +50(wt)%Co+6(wt)%TiF 3 ; Wherein, select particle size to be 200 purpose cobalt powders, and the quality of Co accounts for Mg 16 LaSmNiAl 0.5 Ti 0.5 50% of alloy mass; TiF 3 The mass accounts for Mg 16 LaSmNiAl 0.5 Ti 0.5 6% of the alloy mass. In addition, according to Mg 16 LaSmNiAl 0.5 Ti 0.5 +50(wt)%Co+6(wt)%TiF 3 The raw materials were weighed, and then the alloy powder of this example was prepared by the method in Example 1.

Embodiment 3

[0049] The invention provides a hydrogen storage alloy whose chemical formula is Mg 16 La 1.5 Gd 0.5 NiAl 0.2 Ti 0.8 +50(wt)%Co+3(wt)%TiF 3 ; Wherein, select particle size to be 200 purpose cobalt powders, and the quality of Co accounts for Mg 16 La 1.5 Gd 0.5 NiAl 0.2 Ti 0.8 50% of alloy mass; TiF 3 The mass accounts for Mg 16 La 1.5 Gd 0.5 NiAl 0.2 Ti 0.8 3% of the alloy mass. In addition, according to Mg 16 La 1.5 Gd 0.5 NiAl 0.2 Ti 0.8 +50(wt)%Co+3(wt)%TiF 3 The raw materials were weighed, and then the alloy powder of this example was prepared by the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com