Graphene-based carbon fiber high in strength and hydrogen storage capacity, and preparation method thereof

An alkenyl carbon fiber, high-strength technology, used in fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of harsh hydrogen storage conditions, low hydrogen storage capacity at room temperature, and poor experimental controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

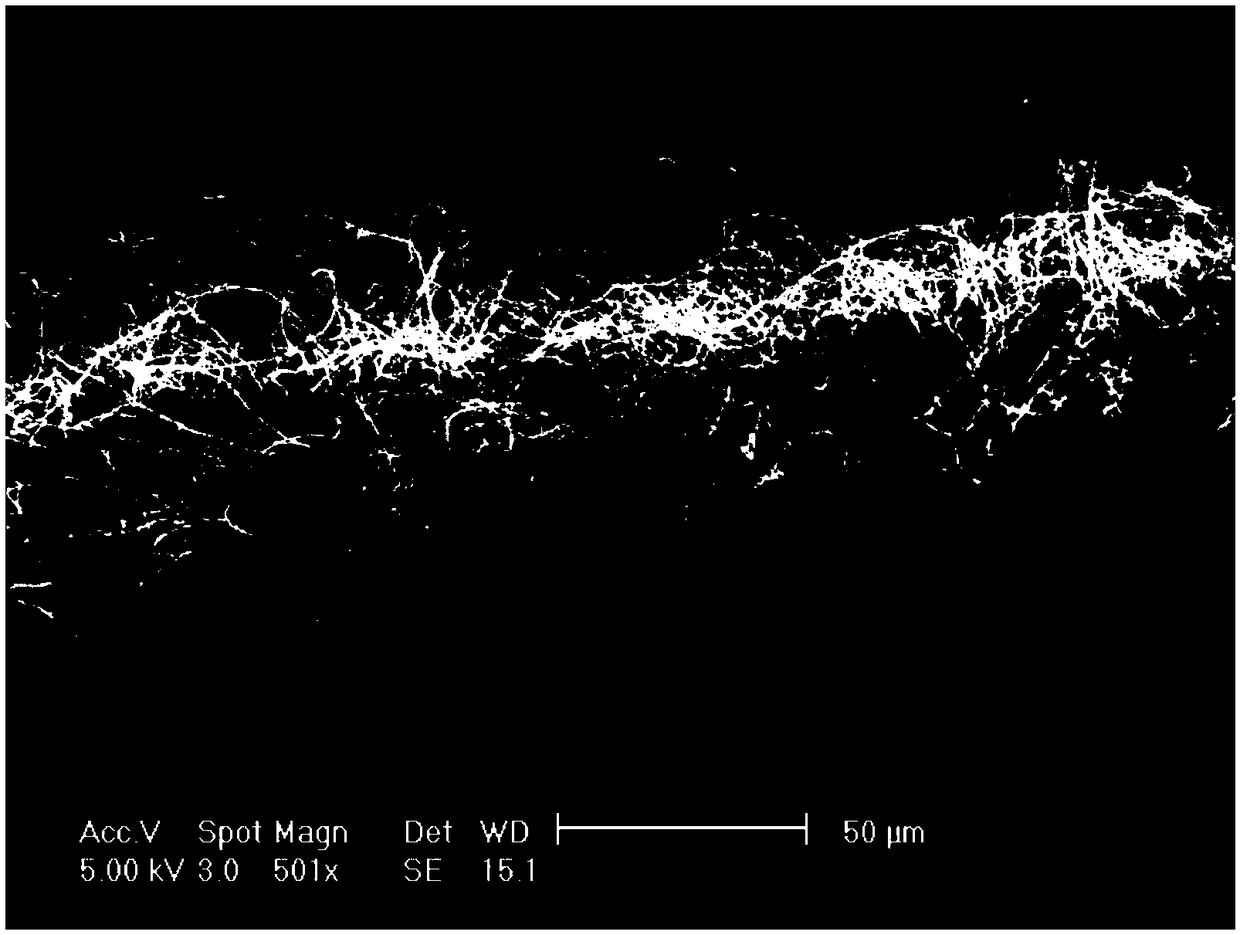

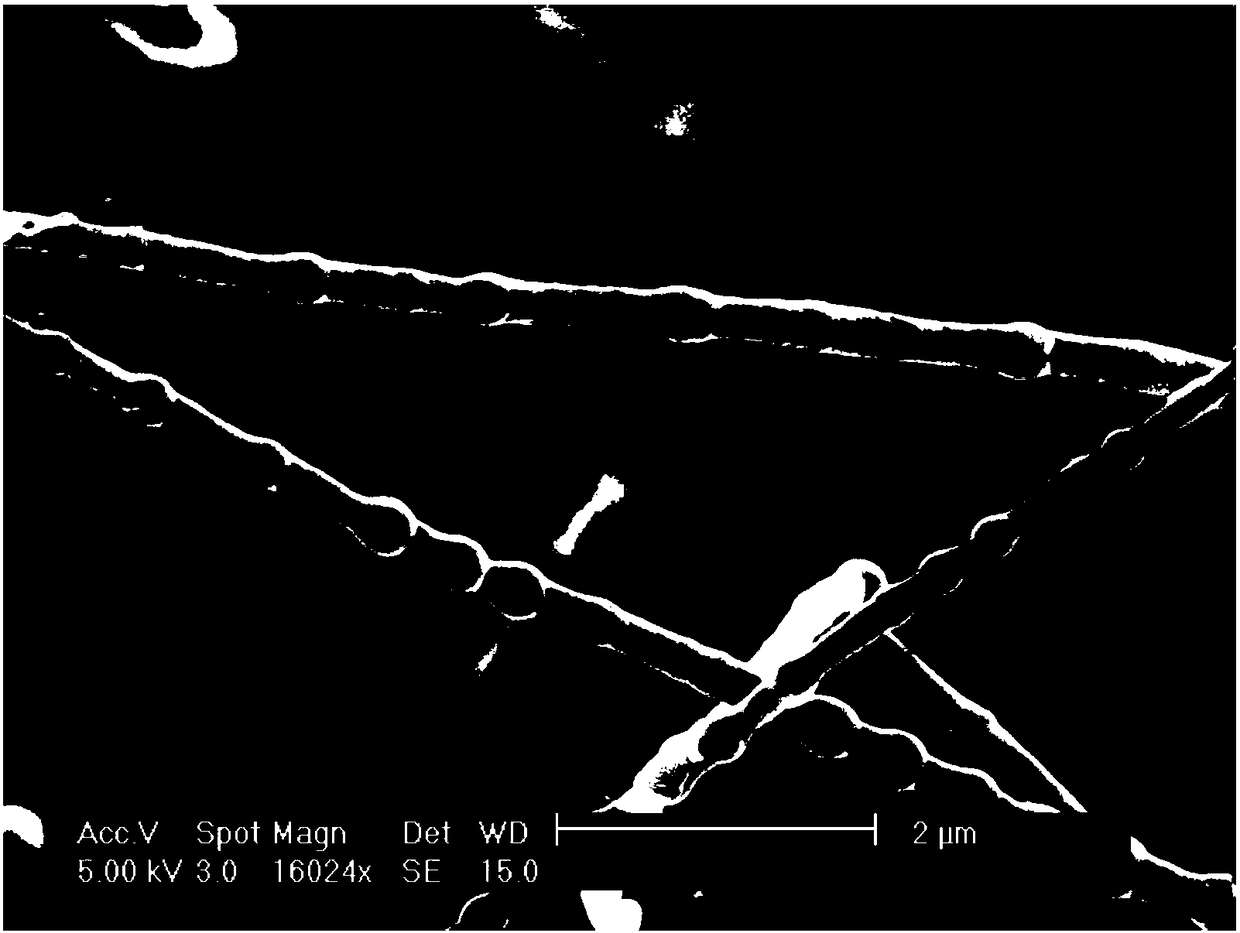

Image

Examples

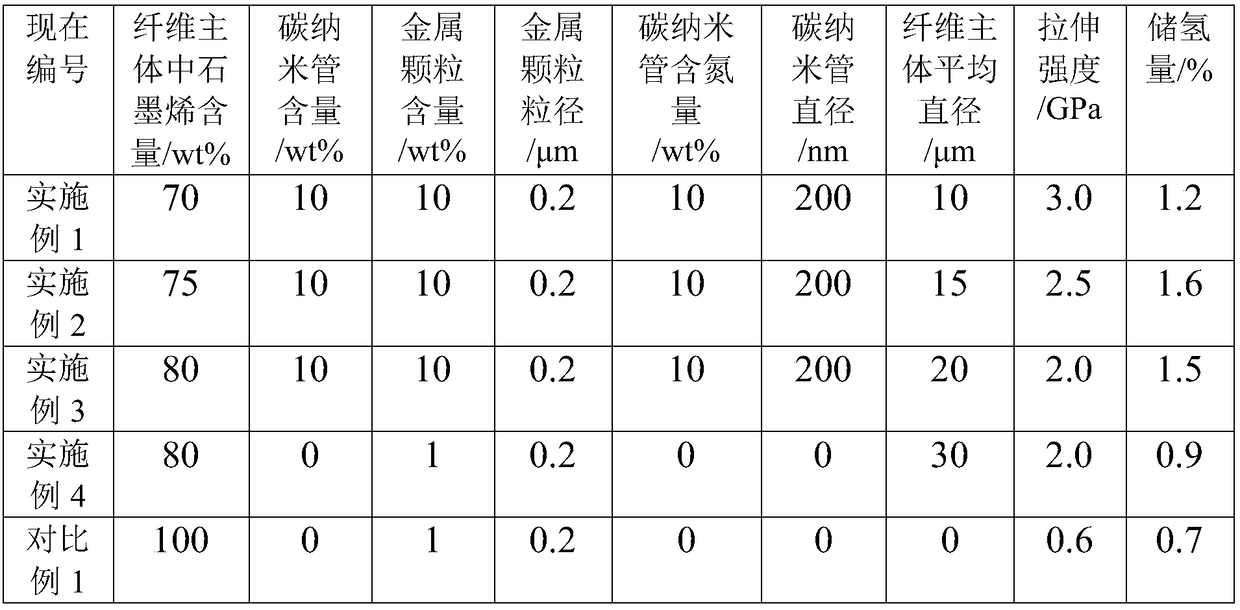

Embodiment 1

[0055] Mix 0.5wt% graphene oxide aqueous solution with 5wt% phenolic resin ethanol solution to obtain a spinning solution, and control the ratio of the solid content of the graphene oxide aqueous solution to the solid content of the phenolic resin ethanol solution to be 70:30. Adopt syringe pump to inject spinning solution into coagulation bath, coagulation bath is selected as methanol / ethyl acetate (v / v)=1:1, solute is selected as nickel chloride, coagulation bath concentration is 2wt%, and spinning parameter is controlled as : The spinneret diameter is 80 μm, and the injection speed is 0.05 mL / min. After solidification for 1 min, the graphene oxide-based initial fibers were obtained by drying. The polymer content in the obtained graphene-based initial fiber is 30wt%.

[0056] Put the graphene oxide-based initial fiber into the constant temperature section of the tubular carbonization furnace, and place a mixture of epoxy resin and melamine resin with a weight ratio of 1:2 o...

Embodiment 2

[0058] Mix 1.5wt% graphene oxide aqueous solution with 15wt% phenolic resin ethanol solution to obtain spinning solution, and control the ratio of the solid content of the graphene oxide aqueous solution to the solid content of the phenolic resin ethanol solution to be 75:25. A syringe pump is used to inject the spinning solution into the coagulation bath, the coagulation bath is selected as methanol / ethyl acetate (v / v)=1:1, the solute is nickel chloride, and the concentration of the coagulation bath is 2wt%. The spinning parameters are controlled as follows: the diameter of the spinneret is 80 μm, and the injection speed is 0.05 mL / min. After solidification for 1 min, the graphene oxide-based initial fibers were obtained by drying. The polymer content in the obtained graphene-based initial fiber is 25wt%.

[0059]The graphene oxide-based initial fiber was placed in the constant temperature section of the tubular carbonization furnace, and a mixture of epoxy resin and melamin...

Embodiment 3

[0061] Mix 2wt% graphene oxide aqueous solution with 20wt% phenolic resin ethanol solution to obtain spinning solution, and control the ratio of the solid content of graphene oxide aqueous solution to the solid content of phenolic resin ethanol solution to be 80:20. A syringe pump is used to inject the spinning solution into the coagulation bath, the coagulation bath is selected as methanol / ethyl acetate (v / v)=1:1, the solute is selected as nickel chloride, and the concentration of the coagulation bath is 2wt%. The spinning parameters are controlled as follows: the diameter of the spinneret is 80 μm, and the injection speed is 0.05 mL / min. After solidification for 1 min, the graphene oxide-based initial fibers were obtained by drying. The polymer content in the obtained graphene-based initial fiber is 20wt%.

[0062] The graphene oxide-based initial fiber was placed in the constant temperature section of the tubular carbonization furnace, and a mixture of epoxy resin and mela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com