Nano magnesium hydride loaded composite material and preparation method thereof

A composite material, a technology of magnesium hydride, which is applied in the field of nano-magnesium hydride-loaded composite materials and its preparation, can solve the problems of hydrogen storage capacity and hydrogen absorption and desorption kinetic performance deterioration, free surface loss, interlayer stacking and other problems, and achieves good performance. Hydrogen absorption and desorption kinetic performance, accelerated hydrogen absorption and desorption rate, high chemical and physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of a composite material loaded with nano-magnesium hydride, comprising the following steps:

[0042] Step (1), adding a cationic surfactant to the aqueous dispersion of the two-dimensional transition metal carbide to wrinkle and agglomerate the two-dimensional transition metal carbide nanosheets, followed by washing and drying;

[0043] Step (2), put the product obtained in step (1) into a sealed container, evacuate the sealed container to a vacuum, then raise the temperature to 600-1000°C, keep it warm for 2-5 hours, and then fill the sealed container with 1-10MPa High-pressure hydrogen and heat preservation for 2 to 5 hours;

[0044] Step (3), adding the product obtained in step (2) and dibutylmagnesium into an organic solvent to obtain a mixture, and ultrasonically dispersing the mixture, and then in a hydrogen pressure of 3 to 6MPa and a temperature of 180 to 220°C Under the condition, stir and heat for 12-48 hours, centrifuge and dry to obtain...

Embodiment 1

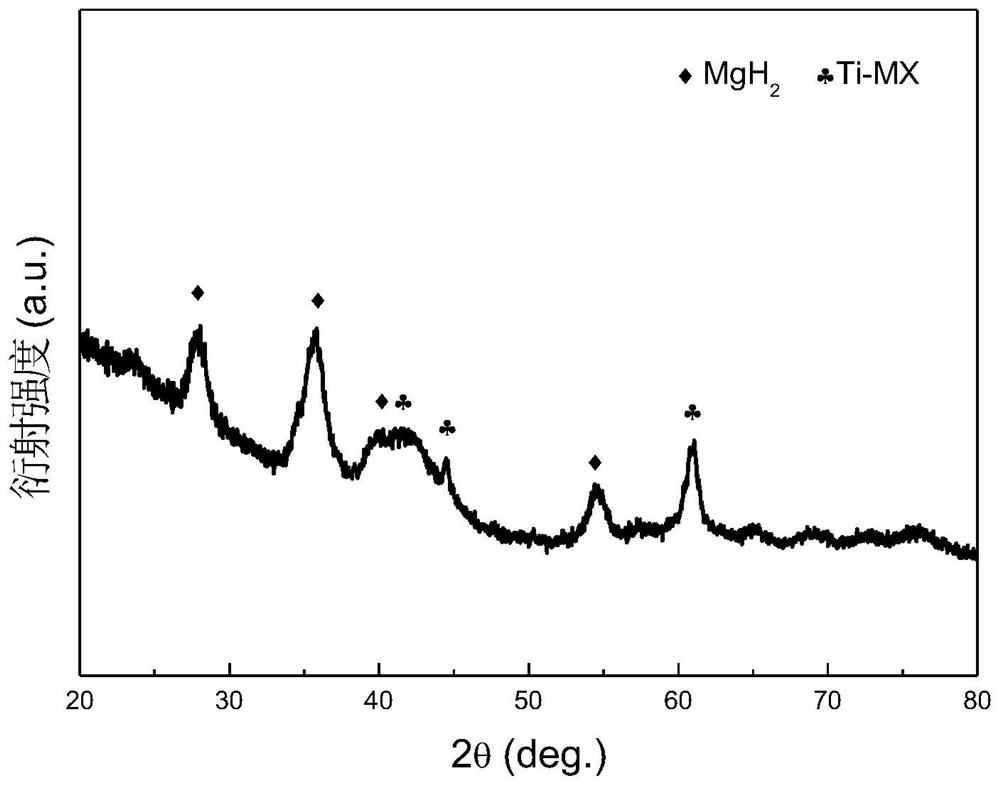

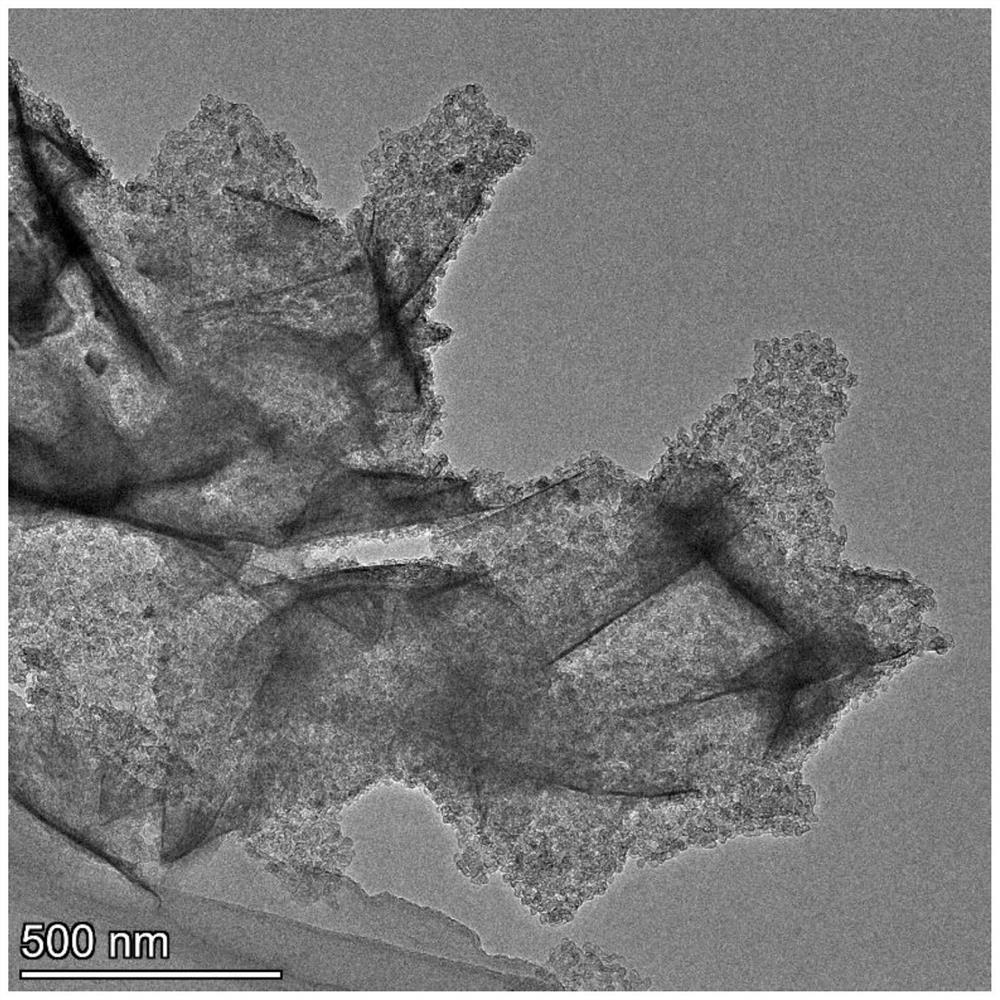

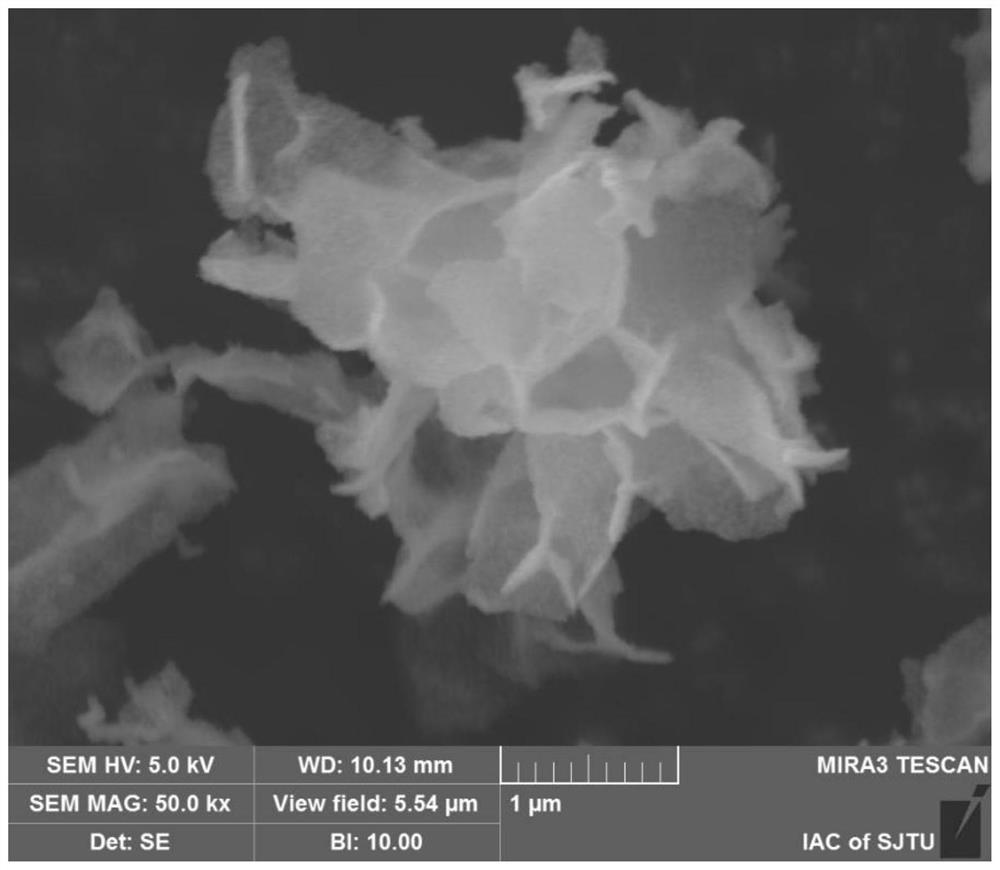

[0054] Two-dimensional transition metal carbide supported nano-magnesium hydride composite material 60MgH 2 Preparation of @Ti-MX1:

[0055] (1) Get 5g cetyltrimethylammonium bromide (CTAB) and dissolve in 100ml deionized water;

[0056] (2) The CTAB solution prepared in step (1) was added dropwise to 500ml of Ti with a concentration of 2mg / ml under agitation. 3 C 2 T x In the aqueous dispersion, the reaction product was centrifuged and washed 3 times, and the centrifuged product was freeze-dried for 72 hours;

[0057] (3) Put the product obtained in step (2) into a sealed stainless steel container. After the sealed stainless steel container is continuously evacuated, it is heated to 800° C. at a heating rate of 5° C. / min, and then filled with 3 MPa of hydrogen after holding for 2 hours. Insulate for 2 hours, and finally cool down to room temperature with the furnace, and the product is denoted as Ti-MX1;

[0058] (4) Take 30mg of Ti-MX1, 3.5ml of dibutylmagnesium heptane...

Embodiment 2

[0066] Two-dimensional transition metal carbide supported nano-magnesium hydride composite material 35MgH 2 Preparation of @Ti-MX2:

[0067] (1) Get 5g cetyltrimethylammonium bromide (CTAB) and dissolve in 100ml deionized water;

[0068] (2) The CTAB solution prepared in step (1) was added dropwise to 500ml of Ti with a concentration of 2mg / ml under agitation. 3 C 2 T x In the aqueous dispersion, the reaction product was centrifuged and washed 3 times, and the centrifuged product was freeze-dried for 72 hours;

[0069] (3) Put the product obtained in step (2) into a sealed stainless steel container, and after continuously vacuuming the sealed stainless steel container, heat it to 600°C at a heating rate of 5°C / min, keep it warm for 5h, then fill it with 3MPa hydrogen, keep it warm 5h, finally cooled to room temperature with the furnace, and the product was denoted as Ti-MX2;

[0070] (4) Take 30mg of Ti-MX2, 1.3ml of dibutylmagnesium heptane solution with a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com