Welded adiabatic gas cylinder

A technology of hot gas bottle and thermal insulation layer, which is applied in the direction of fixed-capacity gas storage tank, gas/liquid distribution and storage, pressure vessel, etc. It can solve the problems of poor safety and stability in use, large heat leakage, and difficulty in vacuuming, etc., and achieve a high loading rate High, low heat leakage, good effect of low temperature insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

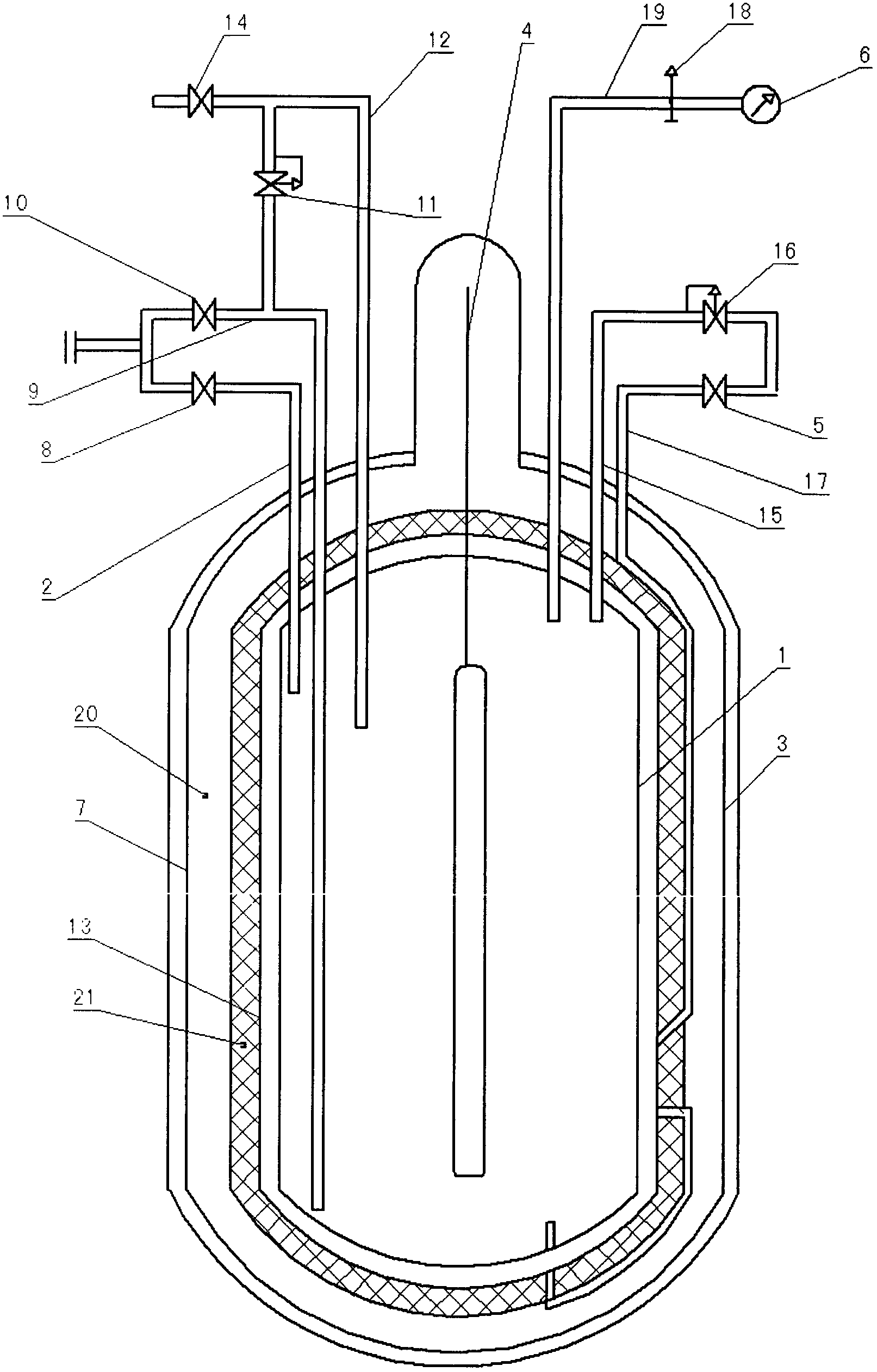

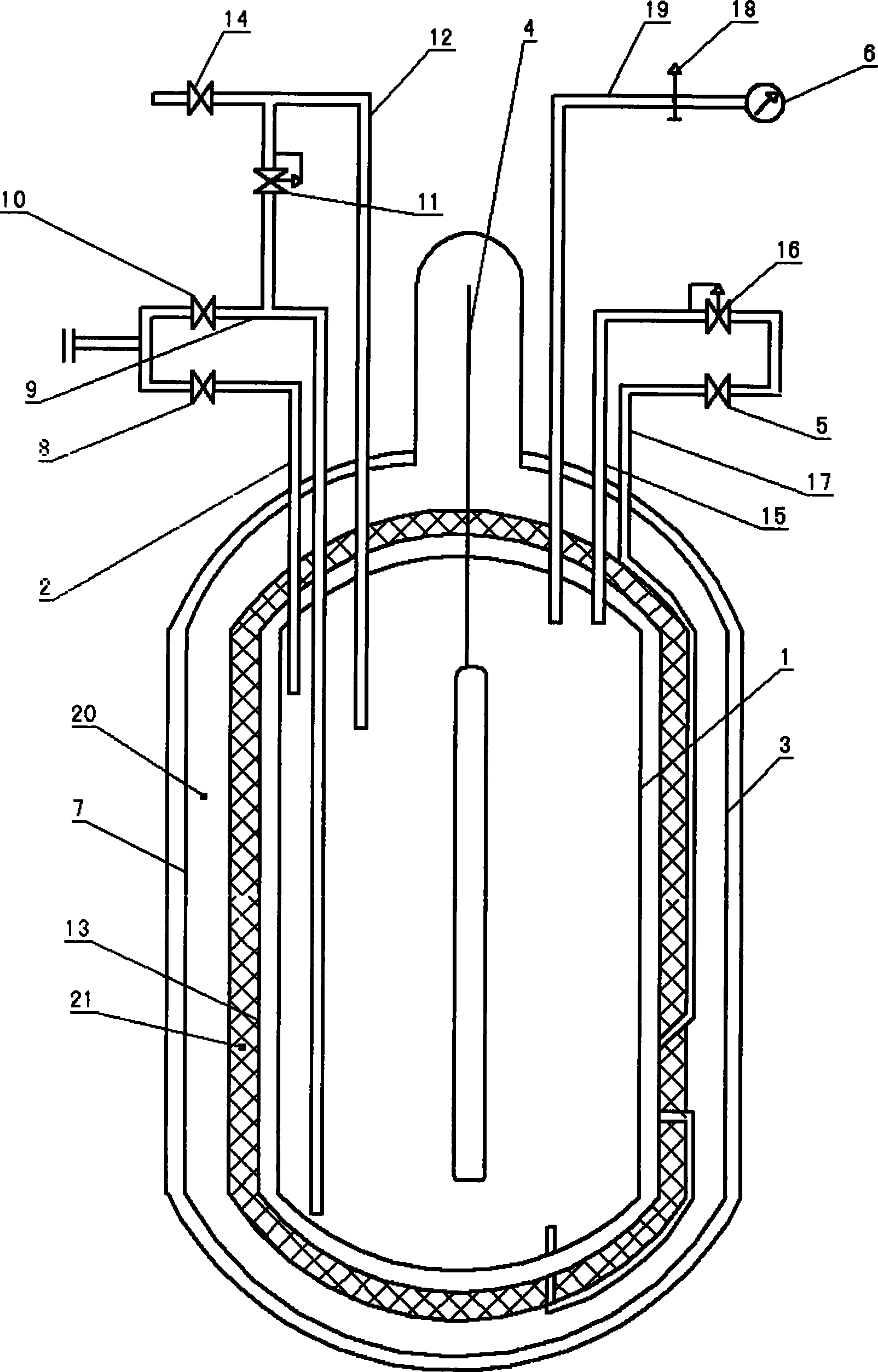

[0021] Such as figure 1 As shown, a welded insulated gas cylinder includes a cylinder body, a valve seat, a safety valve 18, a rupture disc, a pressure gauge 6, a liquid level gauge 4 and a connecting pipe 19, and the cylinder body is composed of an inner tank 1 and an outer shell 3 , a vacuum interlayer 20 is formed between the inner tank 1 and the outer shell 3, and a heat insulating layer 21 is provided in the vacuum interlayer 20; an upper liquid inlet pipe 2 and an exhaust pipe 12 are inserted into the upper part of the bottle body, and the exhaust pipe The connecting pipe 19 between the pipe 12 and the exhaust port is provided with an exhaust valve 14; the upper part of the bottle body is also inserted with a pressurizing pipe 17 and a boost regulating pipe 15, and the two are respectively provided with a boosting valve. 5 and boost regulator valve 16 and communicated; the welded heat insulating gas cylinder is also provided with a support system and an internal evaporat...

Embodiment 2

[0023] A welded heat-insulating gas cylinder, the same as in Example 1, the difference is that the heat-insulating layer 21 is set as a two-layer heat-insulating wrapping layer structure, and holes are punched on each layer; the radiation-proof layer adopts a 6 μm aluminum foil structure , and the getter layer attached to the outer wall 13 of the inner tank in the inner evaporator adopts a low-temperature getter layer structure with an activation temperature of 15° C., that is, a propylene glycol layer structure.

Embodiment 3

[0025] A welded heat-insulating gas cylinder is the same as that in Example 1, except that the heat-insulating layer 2 is perforated with holes every two layers, and the radiation-proof layer adopts a 10 μm aluminum foil structure.

[0026]In this way, when in use, a welded insulating gas cylinder of the present invention adopts a high-vacuum multilayer insulation method, and its aluminum foil has been degreased and dewaxed before use; during the wrapping process of the multilayer insulation body, its Bandage according to the designed layer density, by controlling the density of the layer, prevent the increase of air resistance between the layers; at the same time, avoid the disconnection of the reflective layer, so that the radiation window is left to cause a short circuit, that is, the reflective layer is connected; each wrapping After a certain number of layers, holes should be properly drilled, or holes should be drilled in advance on each layer of insulation material to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com