Patents

Literature

38results about How to "Fast hydrogen absorption and desorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving hydrogen storage property of lithium borohydride

InactiveCN102502488AImprove hydrogen storage performanceImproved hydrogen releaseHydrogen productionAlkaline earth metalHydrogen fuel cell

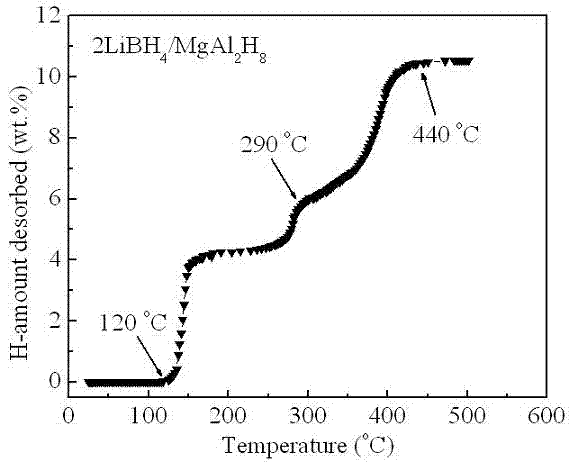

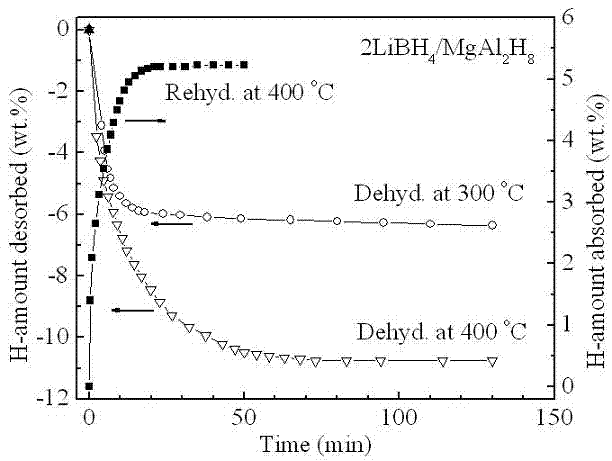

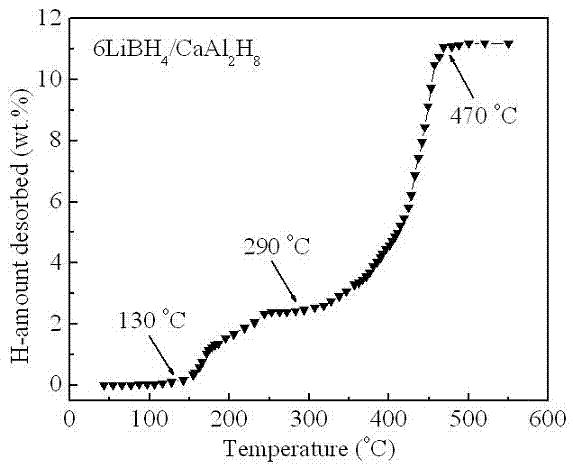

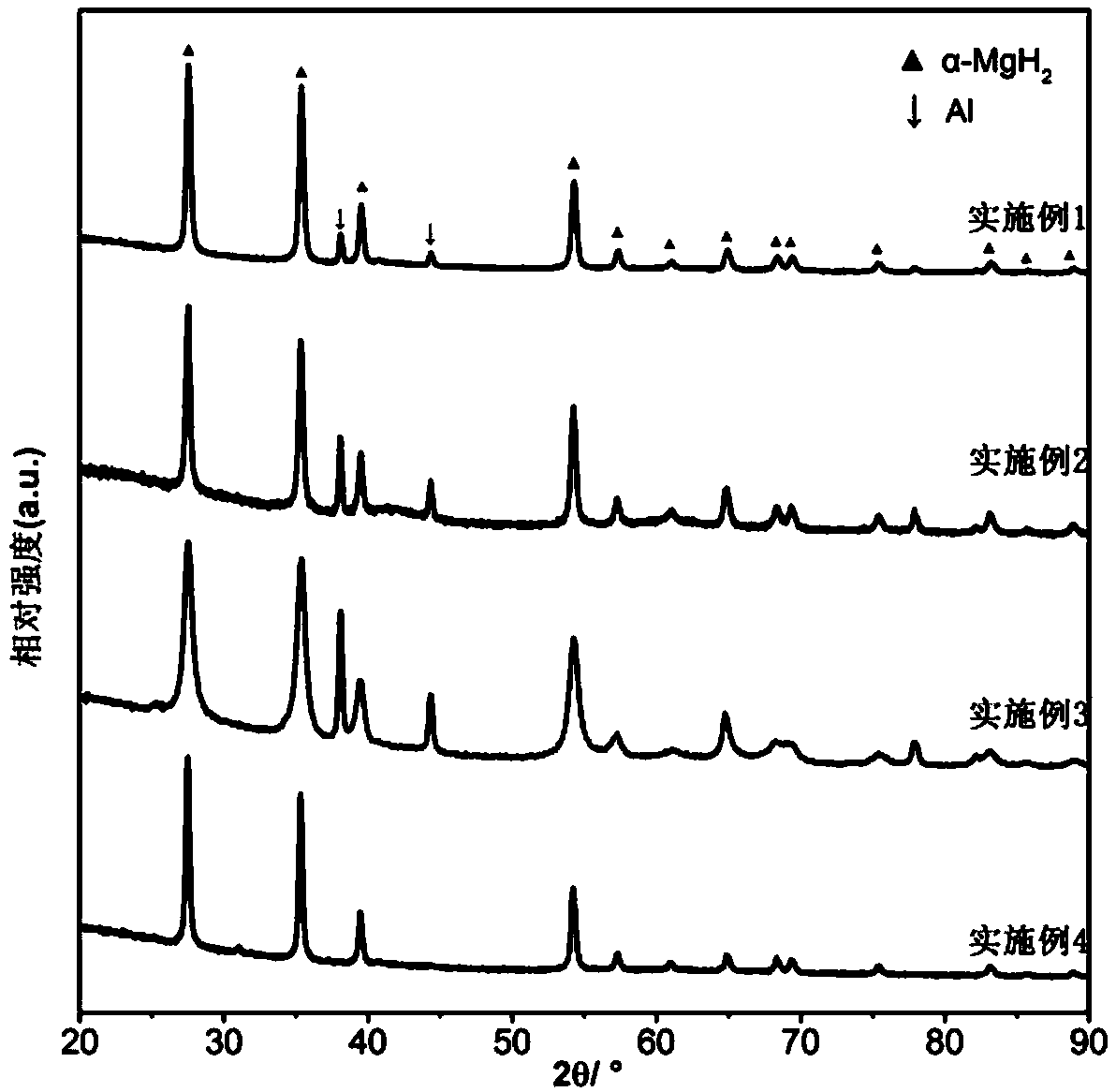

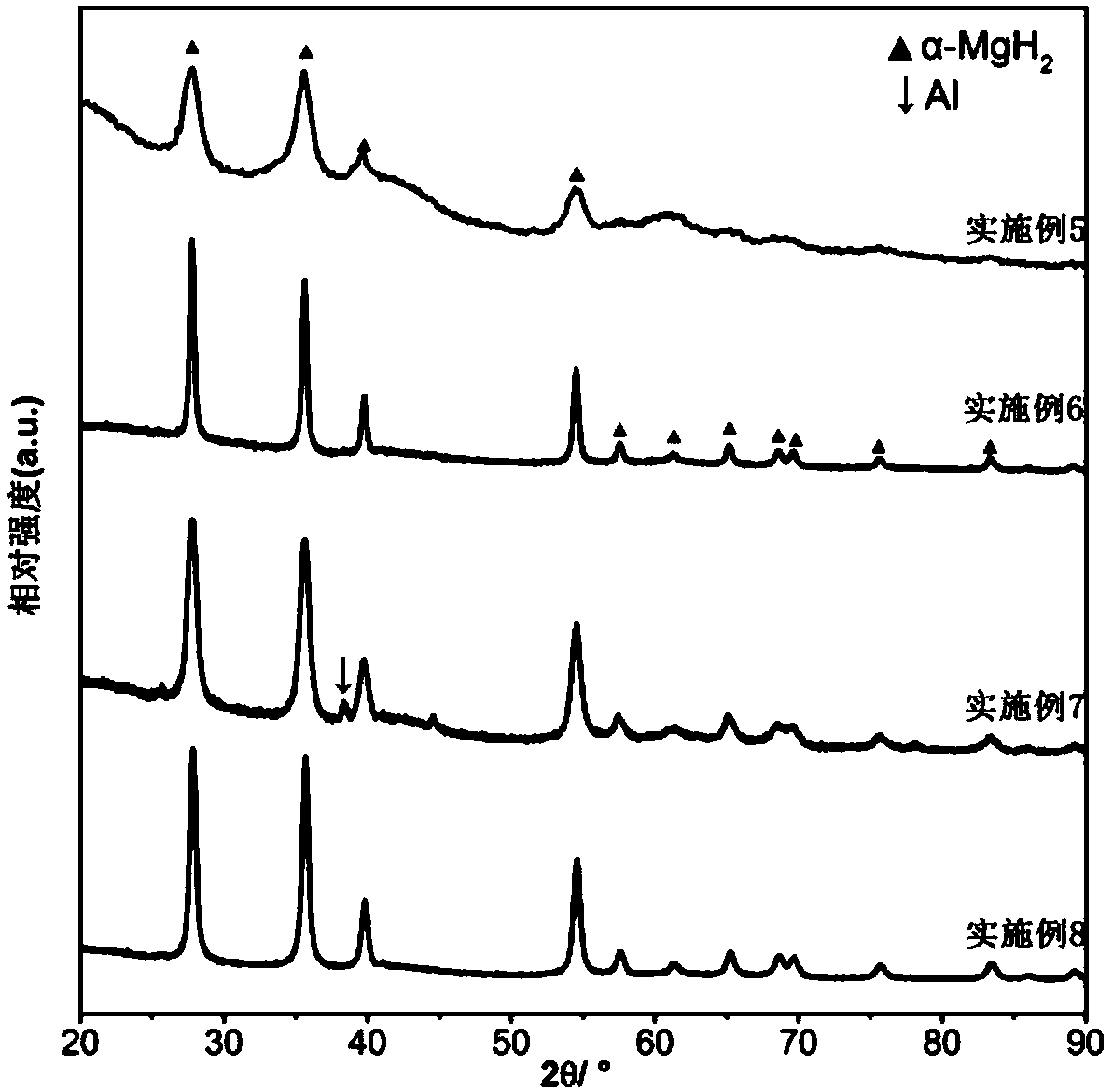

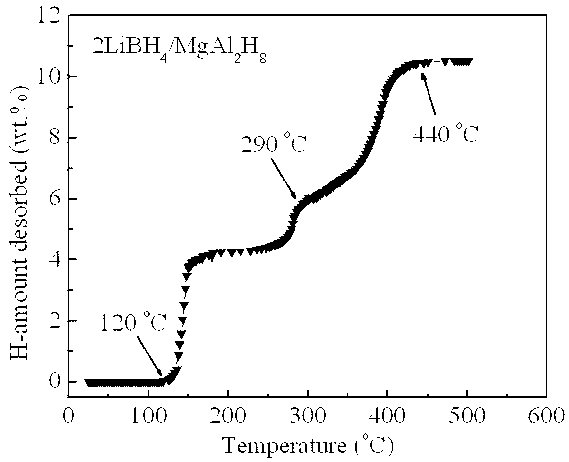

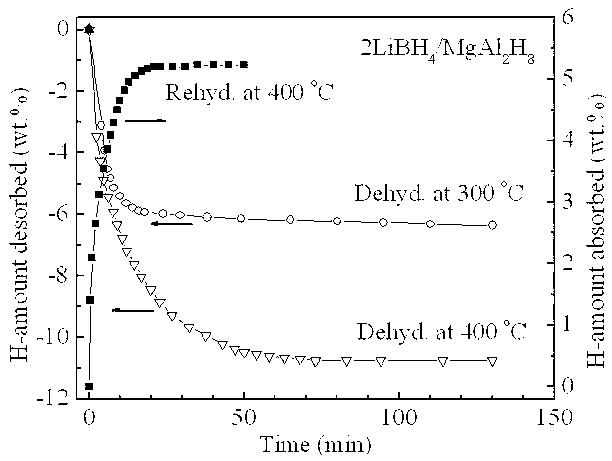

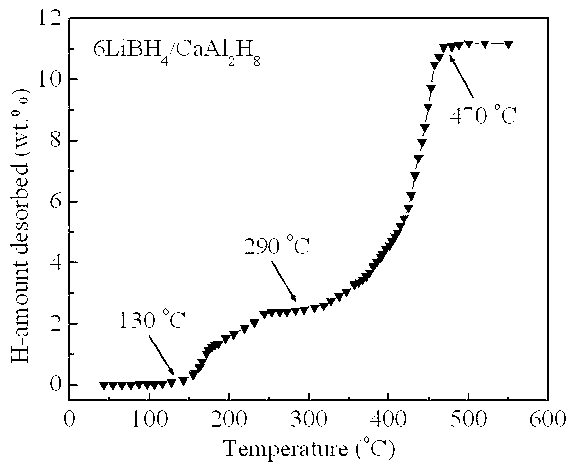

The invention provides a method for improving a hydrogen storage property of lithium borohydride, and belongs to the technical field of hydrogen storage materials. The method comprises the following steps of: mixing the lithium borohydride and alkaline-earth metal alanate according to the molar ratio of 2:1-10:1 under the protection of vacuum or inert gases, and heating mixed powder of the lithium borohydride and the alkaline-earth metal alanate to a certain temperature to ensure that the alkaline-earth metal alanate is decomposed into alkaline-earth metal hydride, aluminum or aluminum alloy in advance. By the method, double effects of in situ and concerted catalysis in the process of discharging and absorbing hydrogen of the lithium borohydride by using the alkaline-earth metal alanate are achieved, so that a hydrogen discharging temperature of the lithium borohydride is greatly reduced, and the hydrogen absorbing and discharging dynamic properties of the lithium borohydride are improved. The method is suitable for storing the hydrogen safely and efficiently and is particularly applied in fields of hydrogen fuel cells and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing magnesium-silver hydrogen storage material

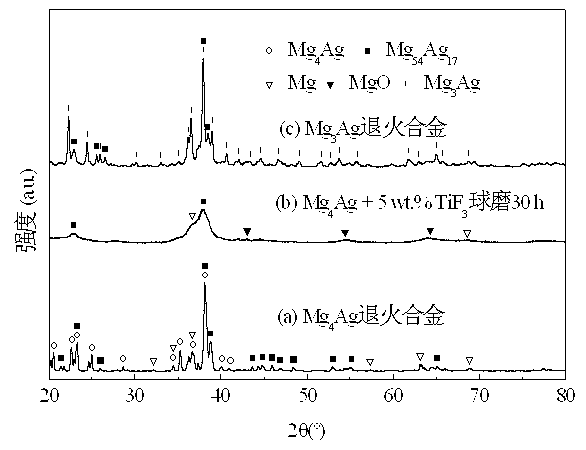

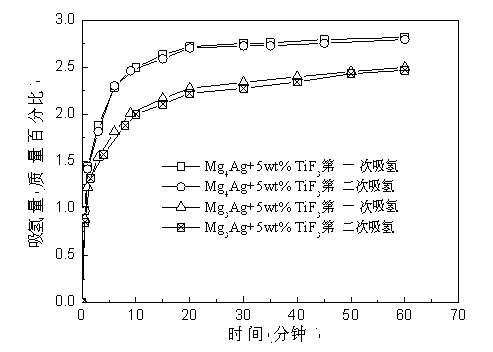

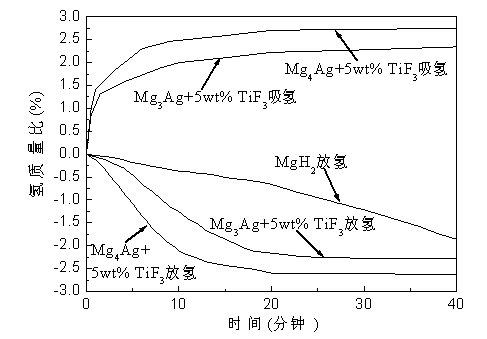

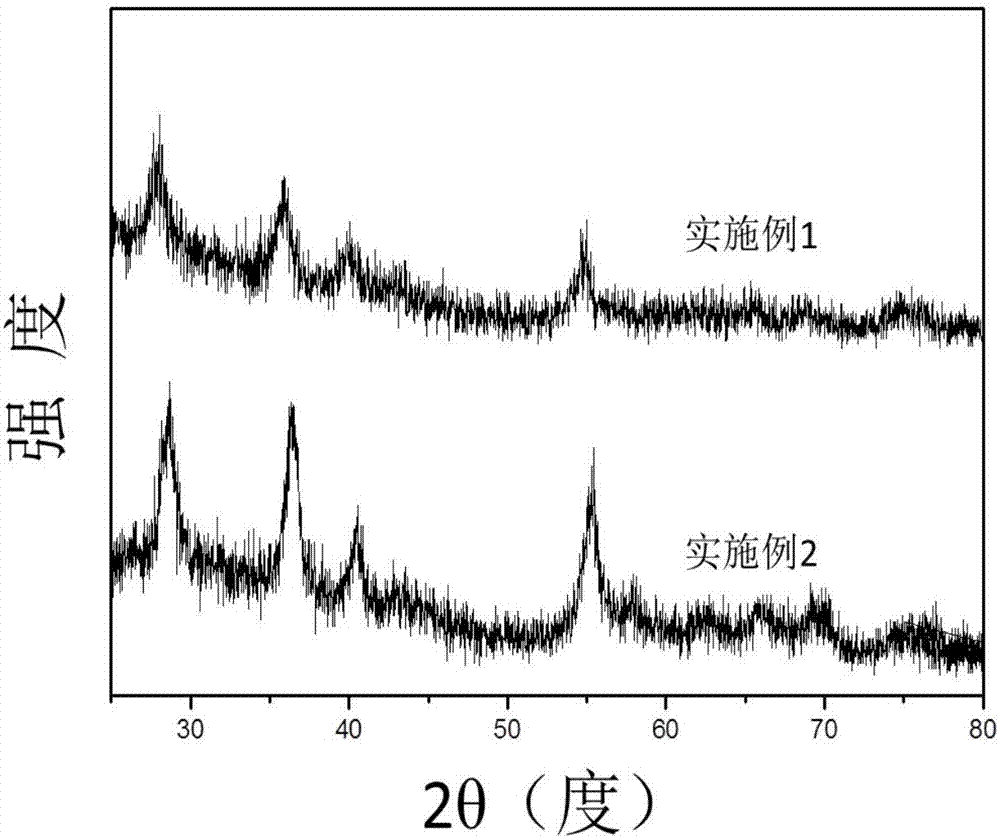

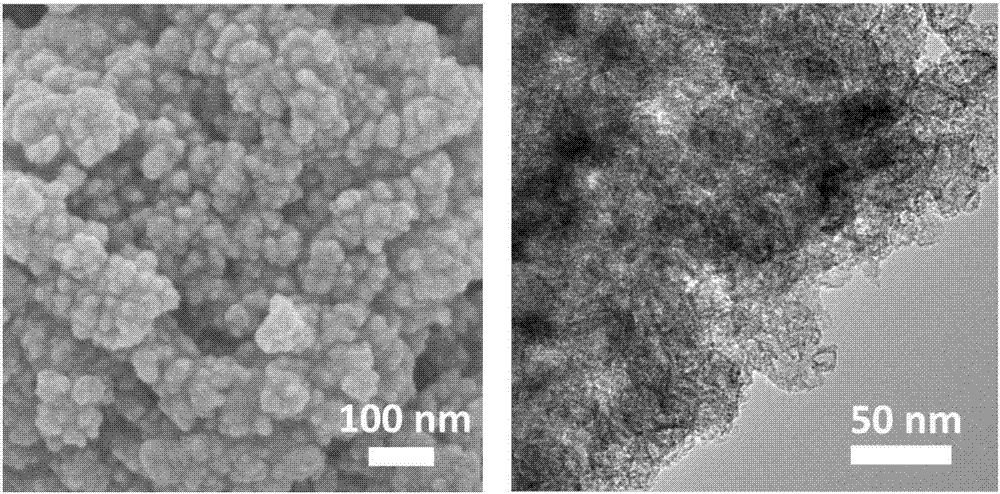

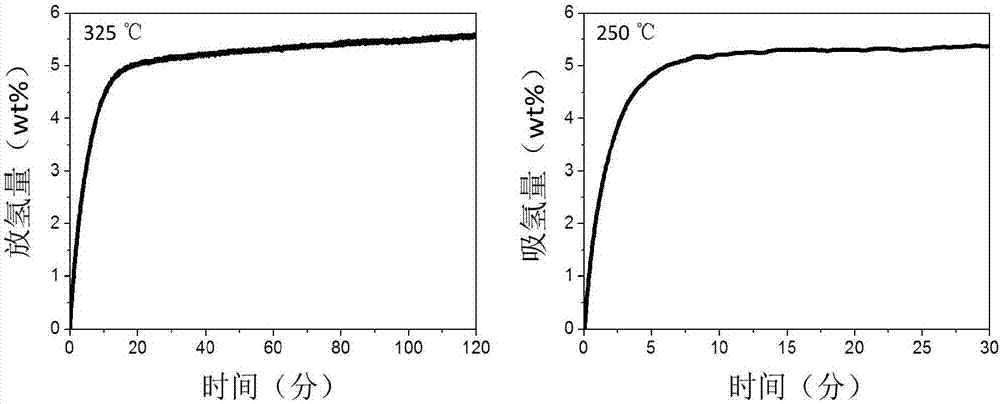

The invention provides a method for preparing a magnesium-silver hydrogen storage material and belongs to the technical field of hydrogen storage materials. The method comprises the following steps of: performing induction smelting of a magnesium-silver alloy which contains 75 to 80 molar percent of Mg and the balance of Ag, wherein 8 to 10wt% of burning loss of Mg is increased during smelting; and annealing the smelted alloy for 6 hours at the temperature of 300 DEG C, grinding into 100 meshes powder in a glove box, adding 5wt% of TiF3 into the powder, performing ball milling for 30 hours in a ball milling tank, thus obtaining the magnesium-silver hydrogen storage material. The method has the advantages that the raw materials and energy consumption are reduced, the preparation process is simple and consumes short time, the method is easy to control and the like; and the magnesium-silver hydrogen storage material prepared by the method has the characteristics of high hydrogen storage quantity, high hydrogen absorption and release rate, high cycle stability and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

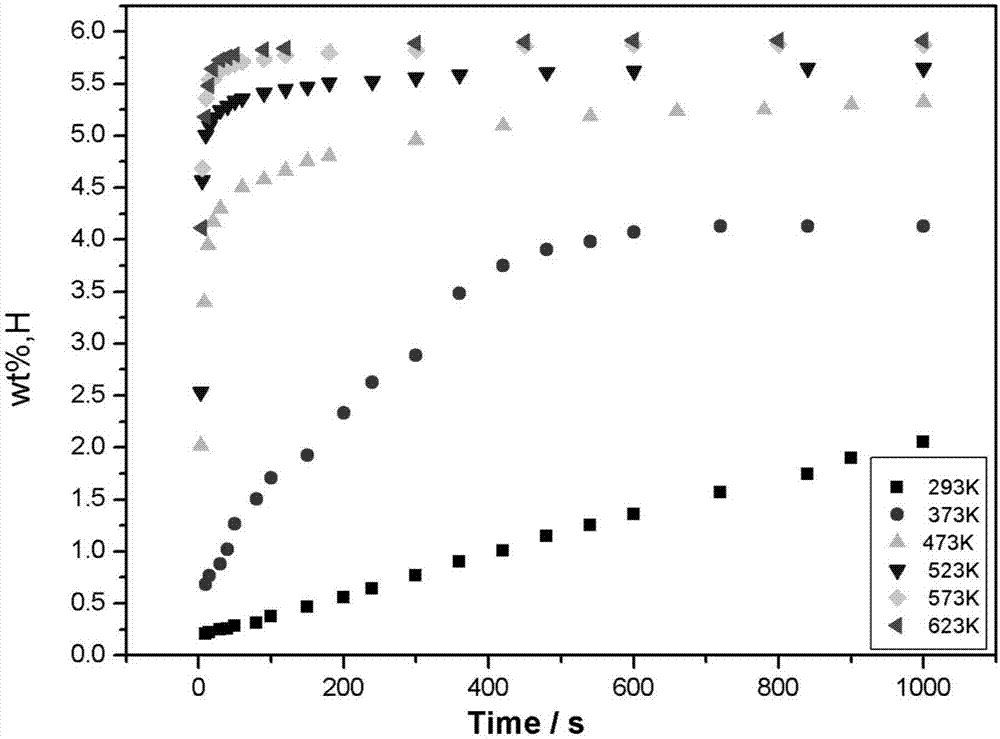

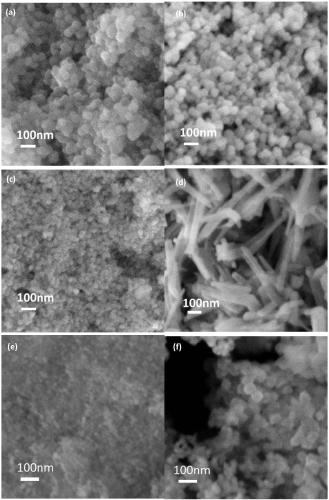

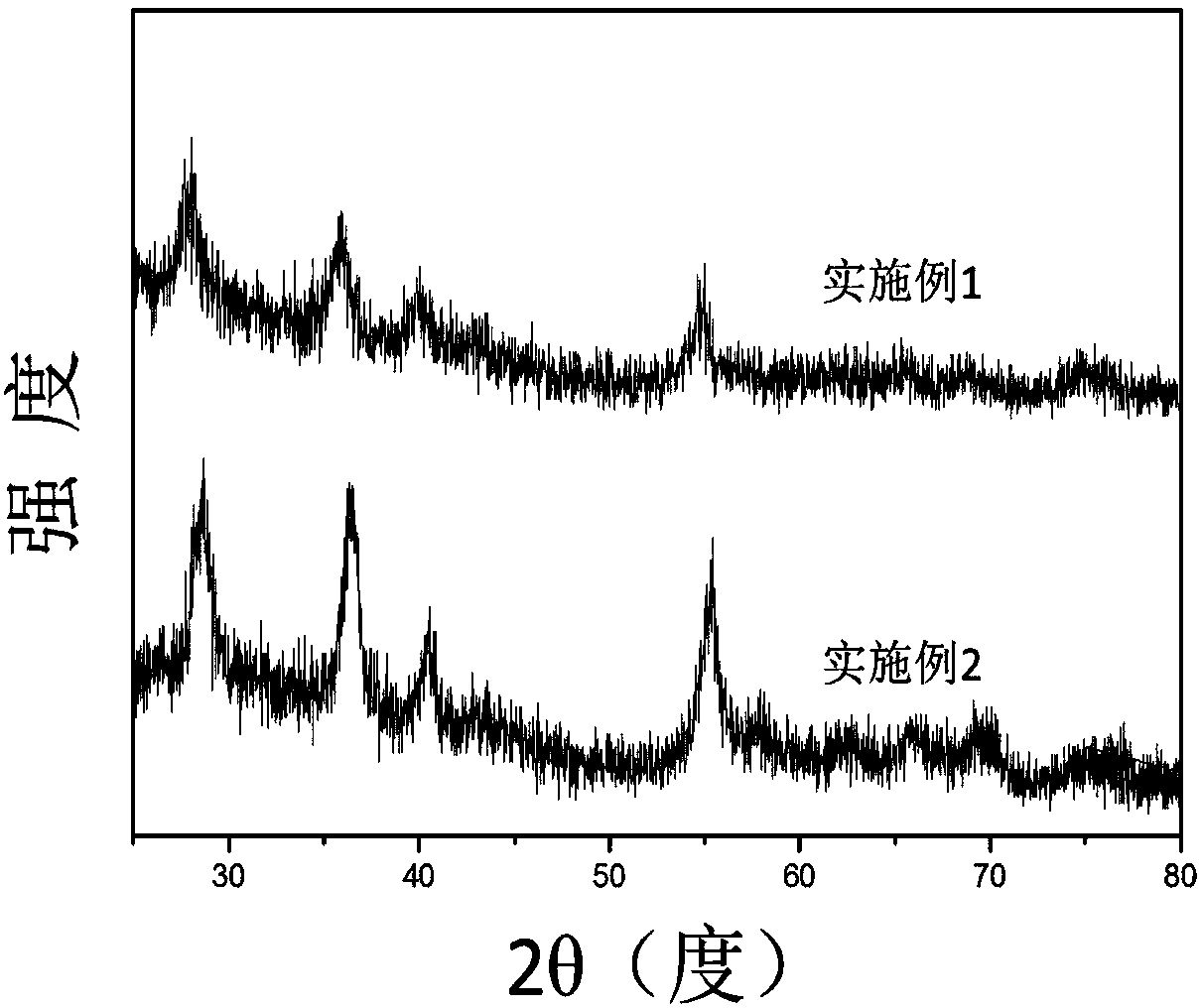

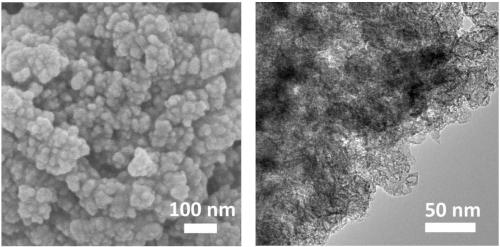

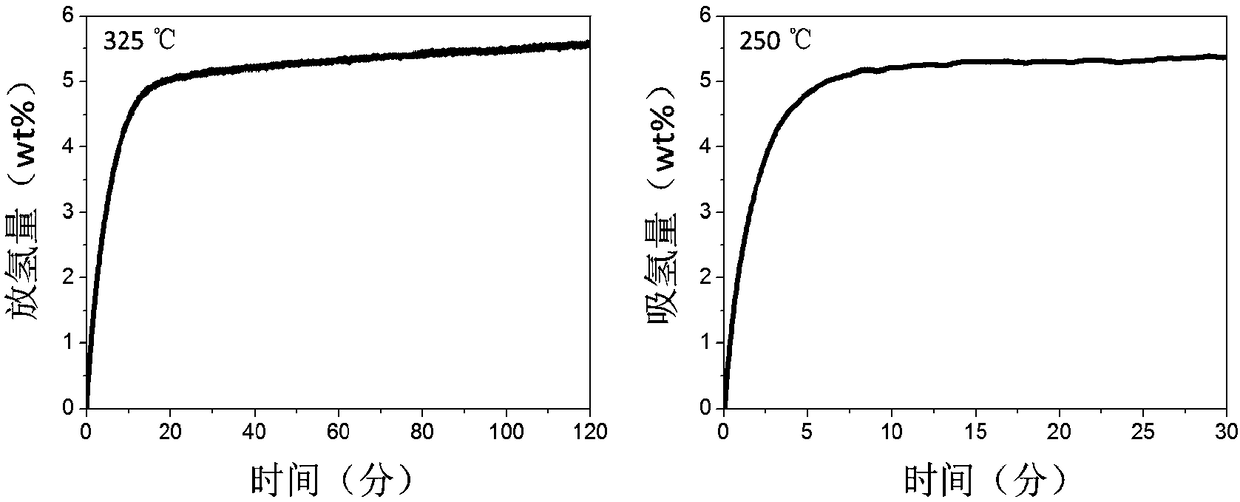

Preparation method of in-situ growth nano magnesium hydride loaded high specific surface material

ActiveCN106865497ALower operating temperatureFast hydrogen absorption and desorption rateHydrogenAlkali/alkaline-earth/beryllium/magnesium hydridesOperating temperatureHydrogen absorption

The invention relates to a preparation method of an in-situ growth nano magnesium hydride loaded high specific surface material. An alkali metal hydride, magnesium halide and a support material are utilized for in situ synthesis of the material under a ball milling condition. The invention has the technical effects that: magnesium hydride is generated in situ on the support material surface through replacement reaction, the nano-composite hydrogen storage material with low operating temperature and fast hydrogen absorption and desorption rate is prepared under a mild condition, the problems of harsh preparation conditions, large product particle size and the like in previous nano magnesium hydride preparation, and the thermodynamic and dynamic performance of the magnesium hydride hydrogen storage material can be improved.

Owner:NANKAI UNIV

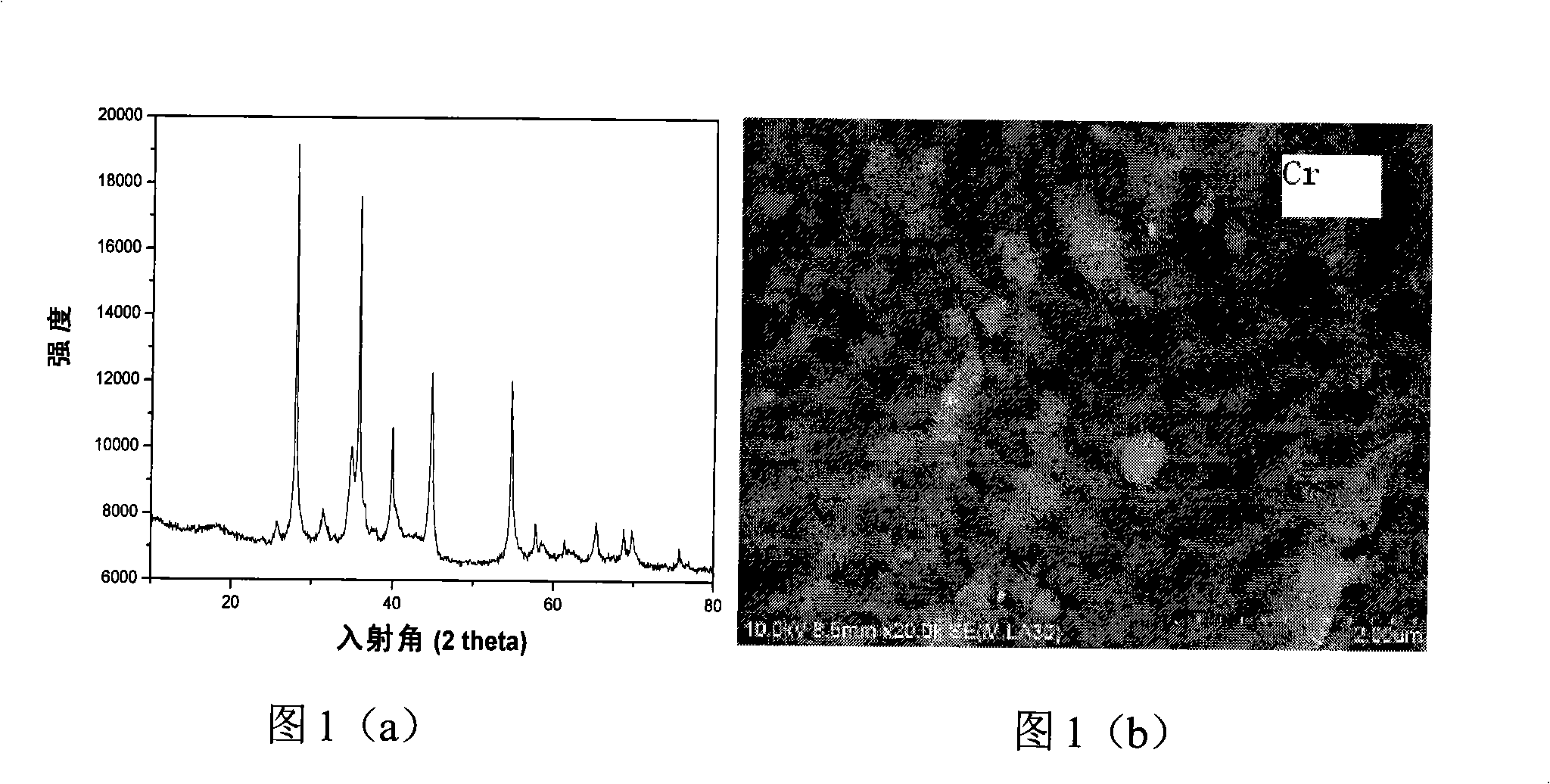

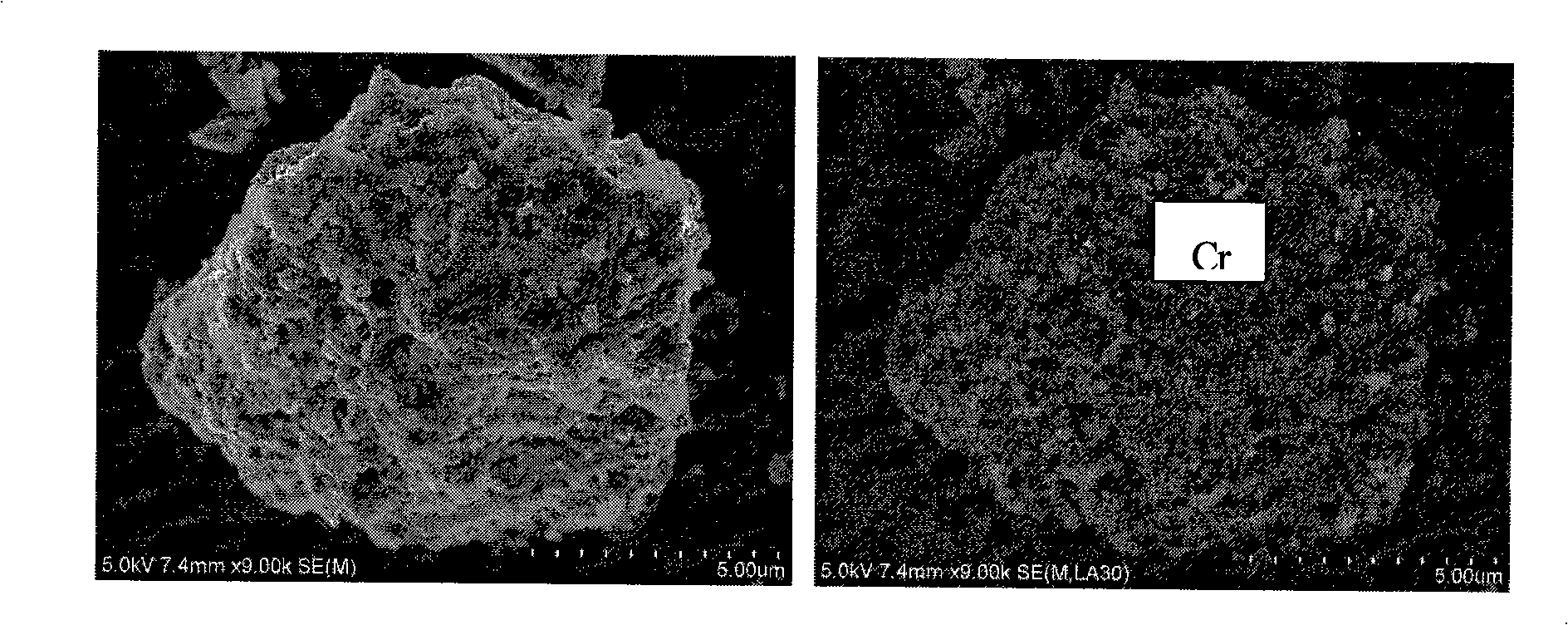

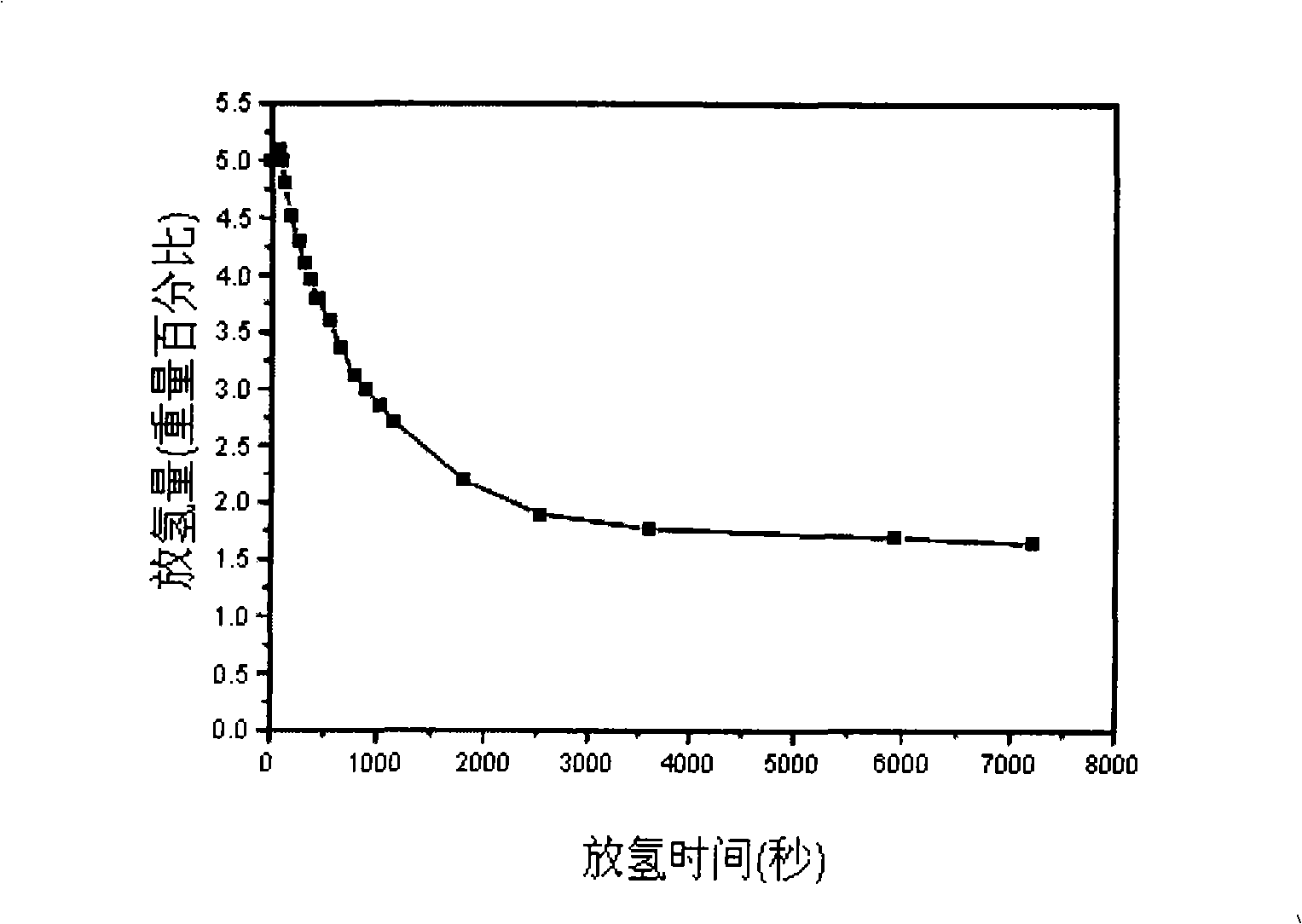

Nano-catalysis complex nitride hydrogen storing material and method for preparing the same

ActiveCN101293630AFast hydrogen absorption and desorption rateImproved hydrogen absorption and desorption rateHydrogen productionHigh pressure hydrogenHigh activity

The invention relates to a nanometer catalysis composite nitride hydrogen storage material and a preparation method thereof; the nanometer catalysis composite nitride hydrogen storage material is characterized in that a precursor is decomposed in a nitride substrate to precipitate nanometer catalysis phase with high activity, so as to realize quick reversible hydrogen absorption and desorption; more particularly, the nitride hydrogen storage material is the nitride composite material system of alloying magnesium powders and LiNH2 nanometer phase which has catalysis effect is uniformly arranged in the LiNH2 substrate; the alloying magnesium powders is a multiple catalysis material system which is formed by Mg powder and transition elements such as Cr, Mn, Ti, Fe, Cu, Ni and Y or other mixtures. The preparation method is characterized in that the nitride hydrogen storage material with high hydrogen absorption and desorption rate is gained by a two-step method: high-pressure hydrogen atmoesphere reaction ball-grinding alloying and inertia gas protection ball-grinding compounding. The composite nitride hydrogen storage material with high hydrogen absorption and desorption rate can be gained by the preparation method of the invention.

Owner:GRIMAT ENG INST CO LTD

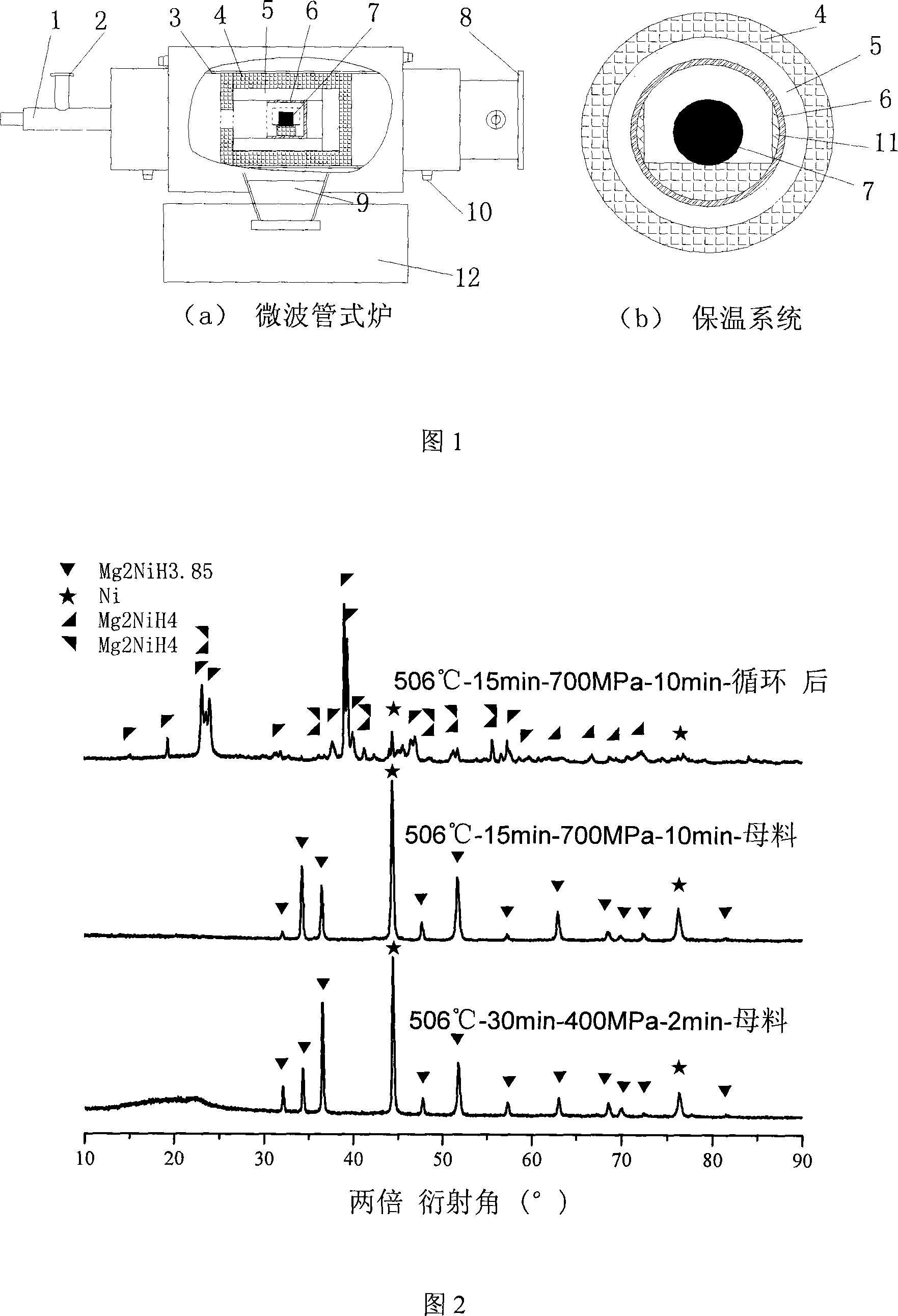

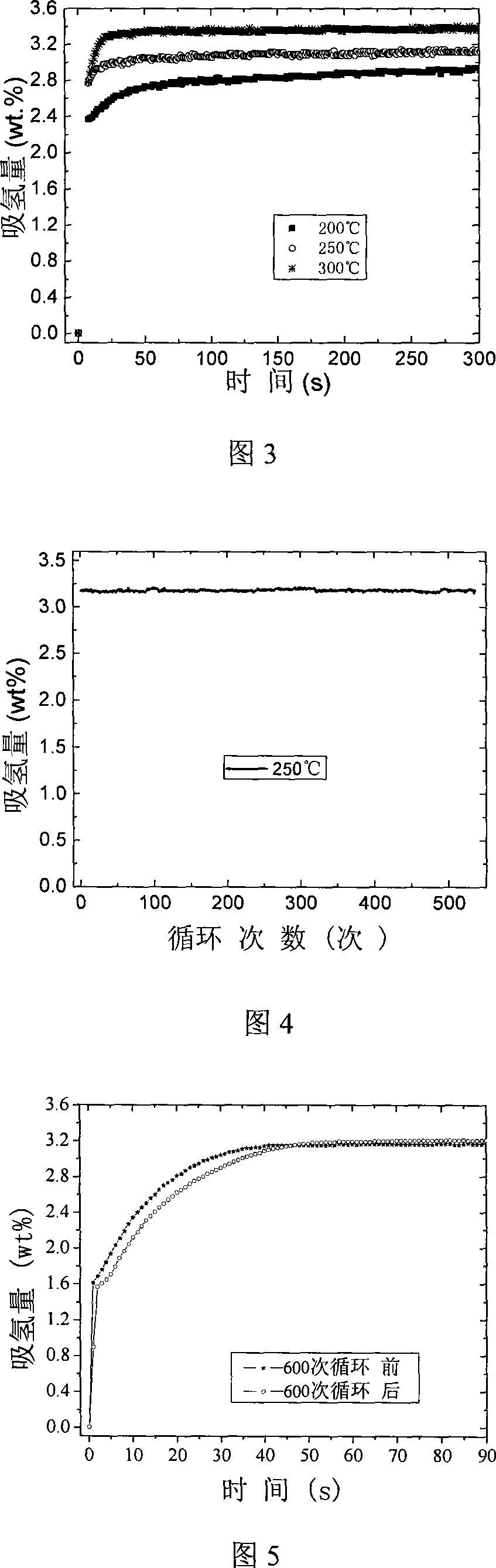

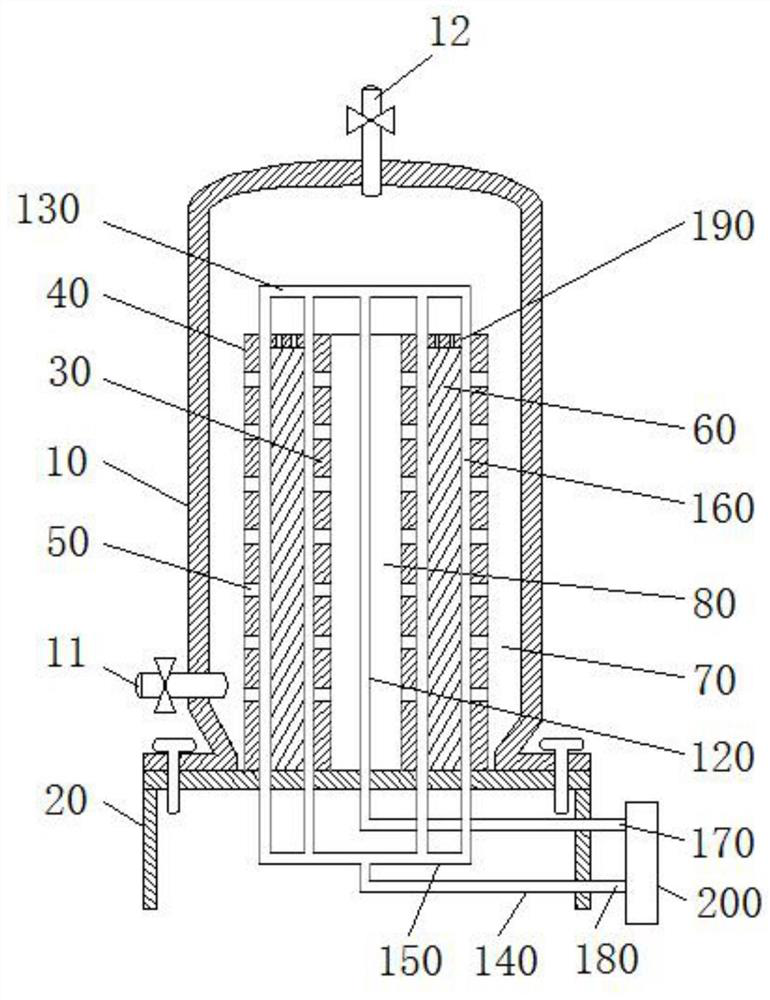

Fast and energy-saving method and device for preparing Mg2NiH4 hydride

InactiveCN101134559ANo pollution in the processMicrowave Leakage SuppressionMultiple metal hydridesChemical industryChemical compositionMicrowave oven

The present invention is fast energy-saving hydride Mg2NiH4 preparing process and apparatus, and belongs to the field of functional metal material preparing technology. The Mg2NiH4 preparing process includes the following steps: mixing Mg powder and Ni powder based on the chemical composition of Mg2Ni, ultrasonic dispersing, drying and pressure molding; setting the mixture in a corundum crucible, setting in a 1.5-3.5 GHz tubular microwave oven, vacuumizing, introducing protecting gas, heating to 456-556 deg.c at the speed of 100-300 deg / min, maintaining for certain time and cooling to room temperature; crushing, and absorbing and releasing hydrogen for five times to activate and obtain the hydride Mg2NiH4. The process has the advantages of high speed, low power consumption, lowered hydrogen absorbing and releasing temperature of Mg2Ni, and obviously raised dynamic performance of Mg2NiH4.

Owner:SHANGHAI UNIV

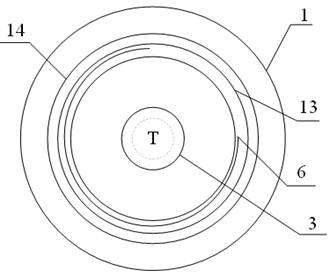

High-pressure composite metal hydride hydrogen storage tank and hydrogen storage method thereof

ActiveCN113375039AAbundant storageHigh mass density of hydrogen storageVessel geometry/arrangement/sizeContainer filling methodsMetallurgyGaseous hydrogen

The invention discloses a high-pressure composite metal hydride hydrogen storage tank and a hydrogen storage method thereof. The hydrogen storage tank comprises a base support and a hydrogen storage tank shell with an opening in the bottom, and the hydrogen storage tank shell is installed on the base support in a sealed and buckled mode. A hydrogen inlet and a hydrogen outlet are formed in the hydrogen storage tank shell. A hydrogen storage alloy storage space, a gaseous hydrogen storage gap and a circulating heat exchange system are arranged in the hydrogen storage tank shell. The hydrogen storage alloy storage space is filled with hydrogen storage alloy, and the circulating heat exchange system is used for absorbing heat when the hydrogen storage alloy absorbs hydrogen and heating the hydrogen storage alloy when the hydrogen storage alloy releases hydrogen. According to the high-pressure composite metal hydride hydrogen storage tank and the hydrogen storage method thereof, a gas hydrogen storage gap is formed in the hydrogen storage tank, the size of a reserved gap can be adjusted according to the requirement of hydrogen storage mass density, hydrogen storage of different mass densities is achieved, the advantages of high mass density of high-pressure gas hydrogen storage and high volume density of solid hydrogen storage are fully combined, and the volume of the solid hydrogen storage part is adjusted, the purpose of storing more hydrogen under equal pressure is achieved.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

Preparation method of hydrogen storage material nano catalysis system

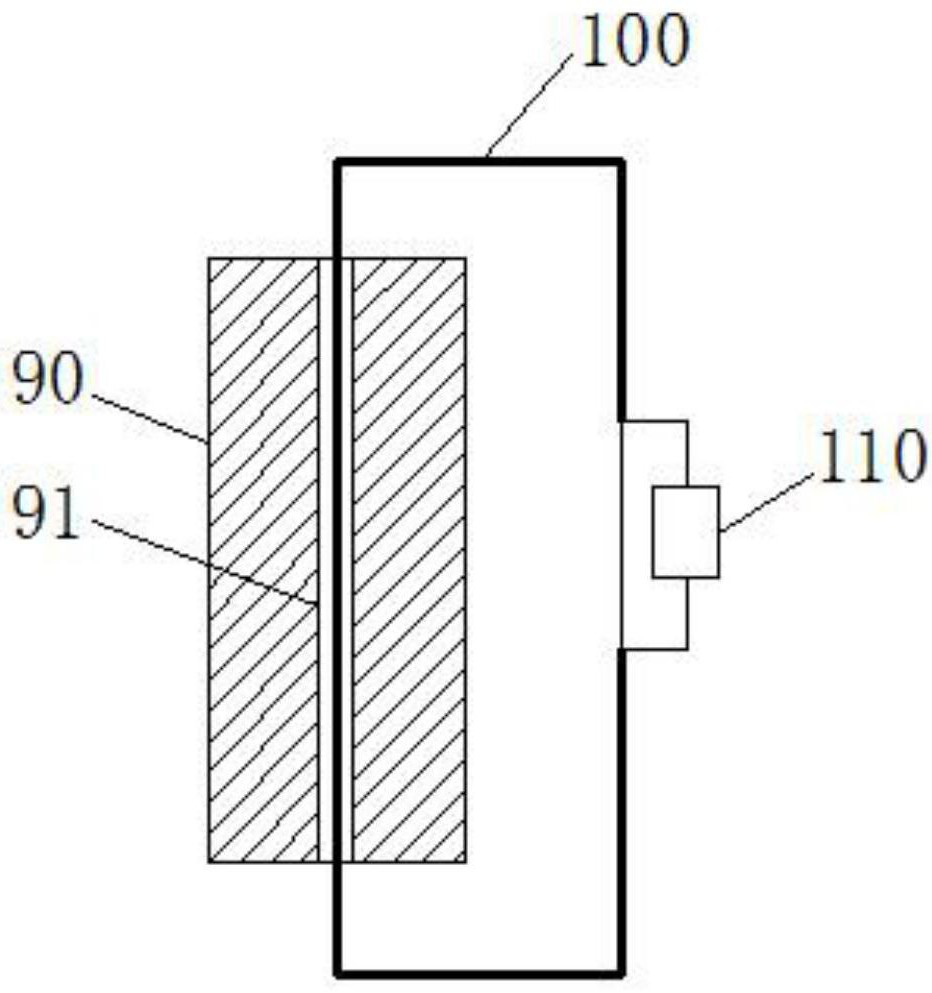

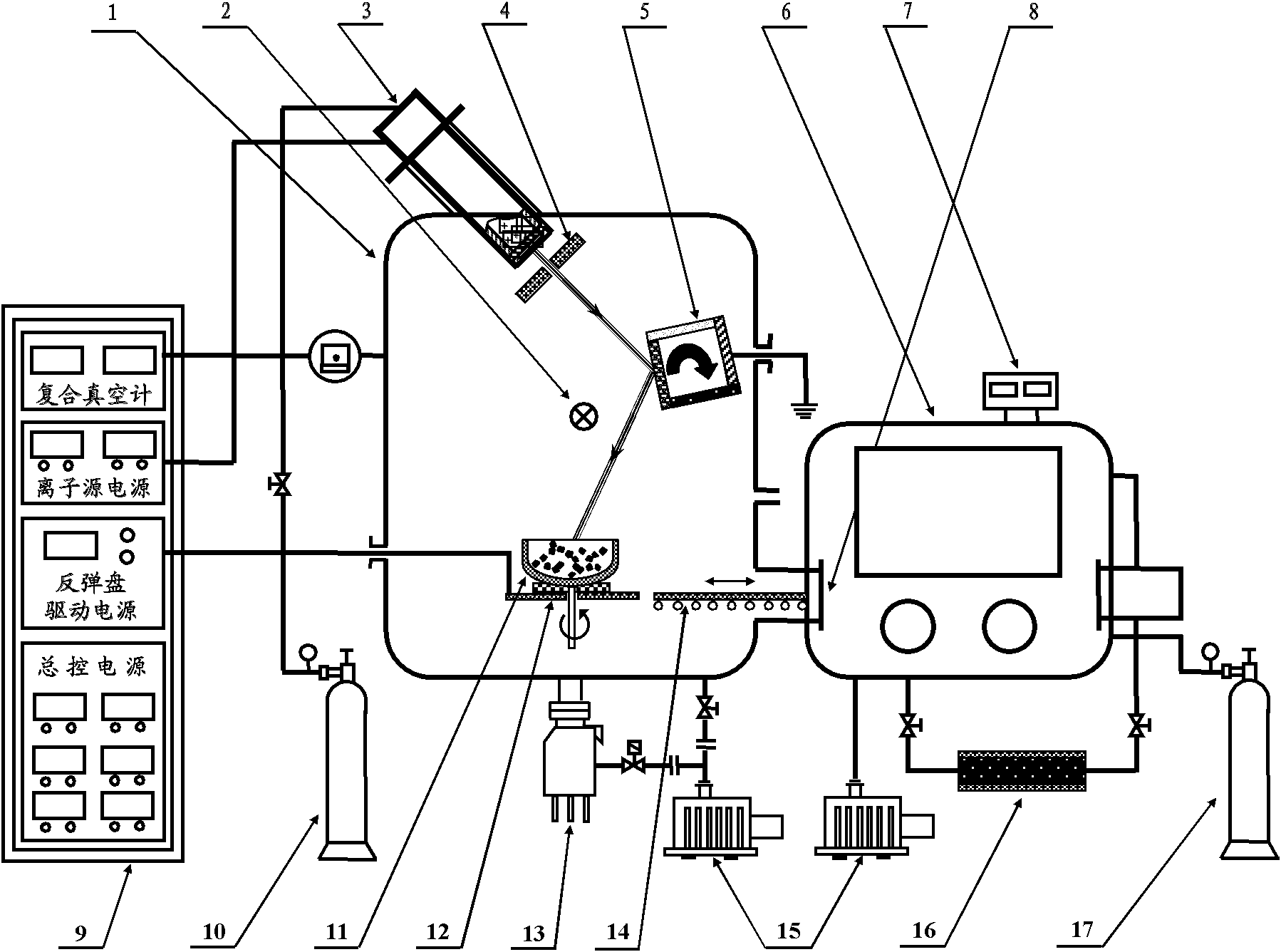

InactiveCN102464297AFast preparationSimple structureHydrogen productionSurface phaseCatalyst nanoparticles

The invention relates to the field of hydrogen storage materials, in particular to a preparation method of a hydrogen storage material nano catalysis system. A catalyst nano particle is prepared by combining and applying an ion beam sputtering or magnetic control sputtering technology and a rebounding disk technology, a transition metal nano particle is prepared by adopting an ion beam sputtering or magnetic control sputtering transition metal target material, hydrogen storage material powder is driven by adopting the rebounding disk technology to make a multiple-dimensional and / or multiple-mode movement, and in-situ uniform surface phase compounding of the catalyst nano particle and the hydrogen storage material powder is realized. A device for preparing the hydrogen storage material nano catalysis system comprises a sputtering system, a nano particle / powder material composite system and a feeding / sampling system. The invention is suitable for preparing various hydrogen storage material nano catalysis systems. The hydrogen storage material nano catalysis system prepared by adopting the invention has hydrogen storage performance remarkably superior to the material prepared by adopting the traditional metal phase ball grinding method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

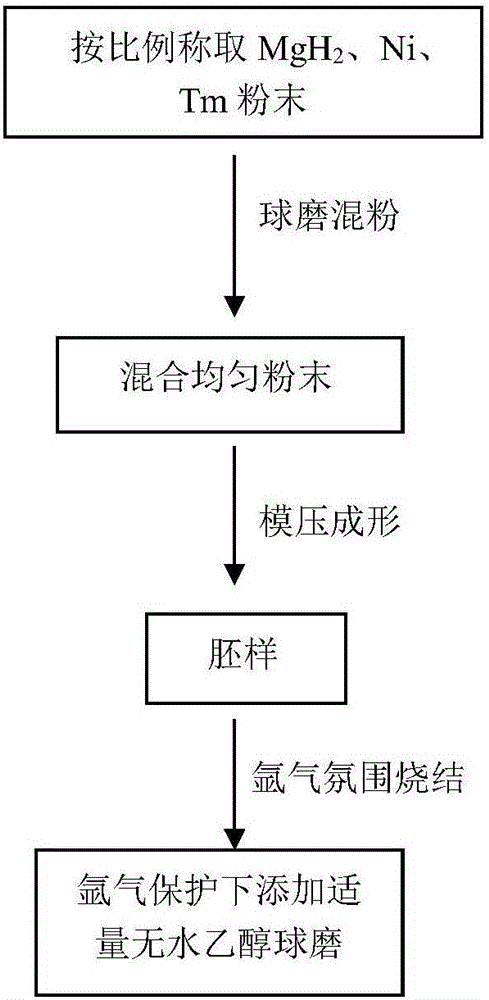

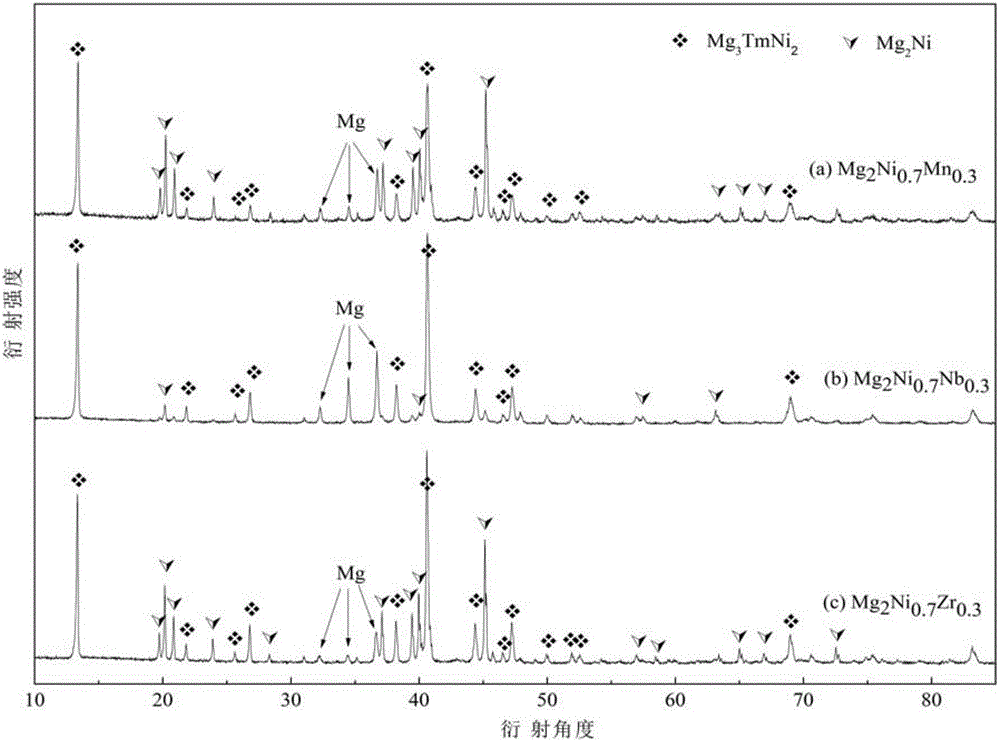

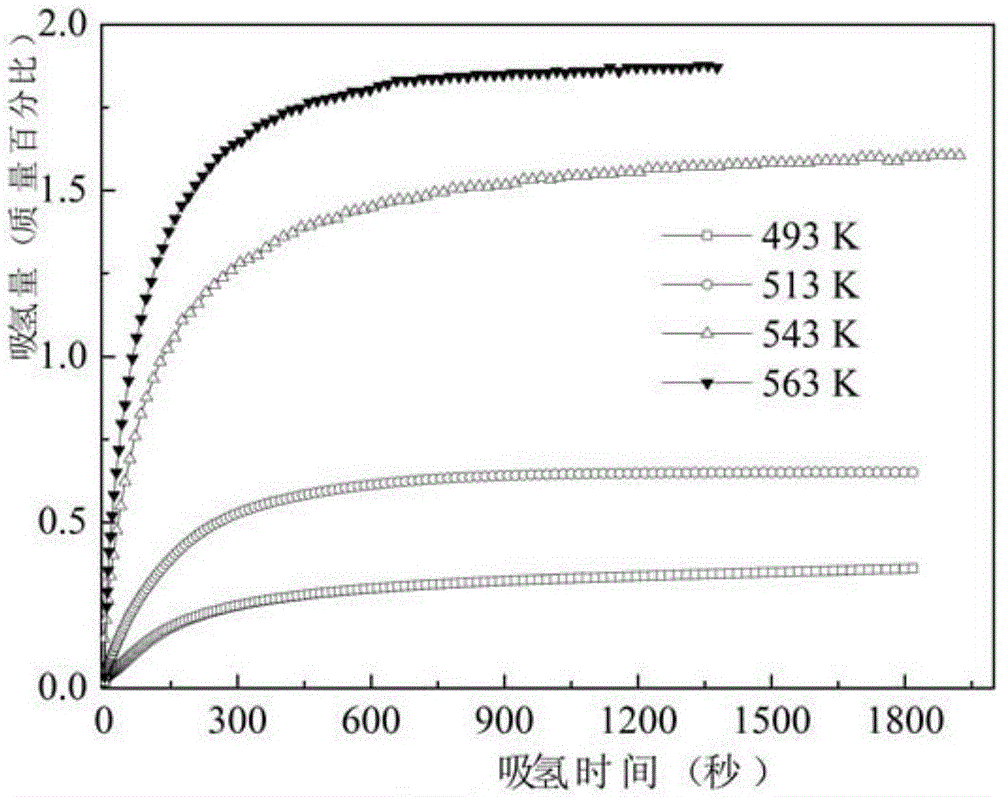

Magnesium-based composite hydrogen storage material and preparation method thereof

InactiveCN106086491AThe alloy composition is accurate and uniformReduce oxidationCell electrodesMagnesiumCorrosion

The invention relates to a magnesium-based composite hydrogen storage material. The magnesium-based composite hydrogen storage material is composed of Mg, Ni and Tm, wherein Tm is any one or two of Mn, Zr, Nb, Al and Ti; and the chemical components of the magnesium-based composite hydrogen storage material can be represented as Mg2Ni(1-x)Tmx, and x is larger than 0 and smaller than or equal to 0.3. According to the magnesium-based composite hydrogen storage material, Mg2Ni serves as the main phase, an intermetallic compound Mg3TmNi2 of a cubic structure is grown in the Mg2Ni matrix phase in situ, Mg accounting for 4-6% of the total weight is dispersed in alloy, Mg is firstly corroded and oxidized in a strong-basicity electrolyte to form dense Mg(OH)2 which covers the surface of the alloy, and corrosion of Mg2Ni is effectively lowered. The magnesium-based composite hydrogen storage material has good hydrogen absorption / desorption performance and strong base corrosion resistance, and has good application prospects in the aspects of a hydrogen storage device and a high-capacity nickel-hydrogen secondary battery. A preparation method of the magnesium-based composite hydrogen storage material is simple in process and low in requirement for equipment, and the economic cost is effectively reduced.

Owner:XIAMEN UNIV OF TECH

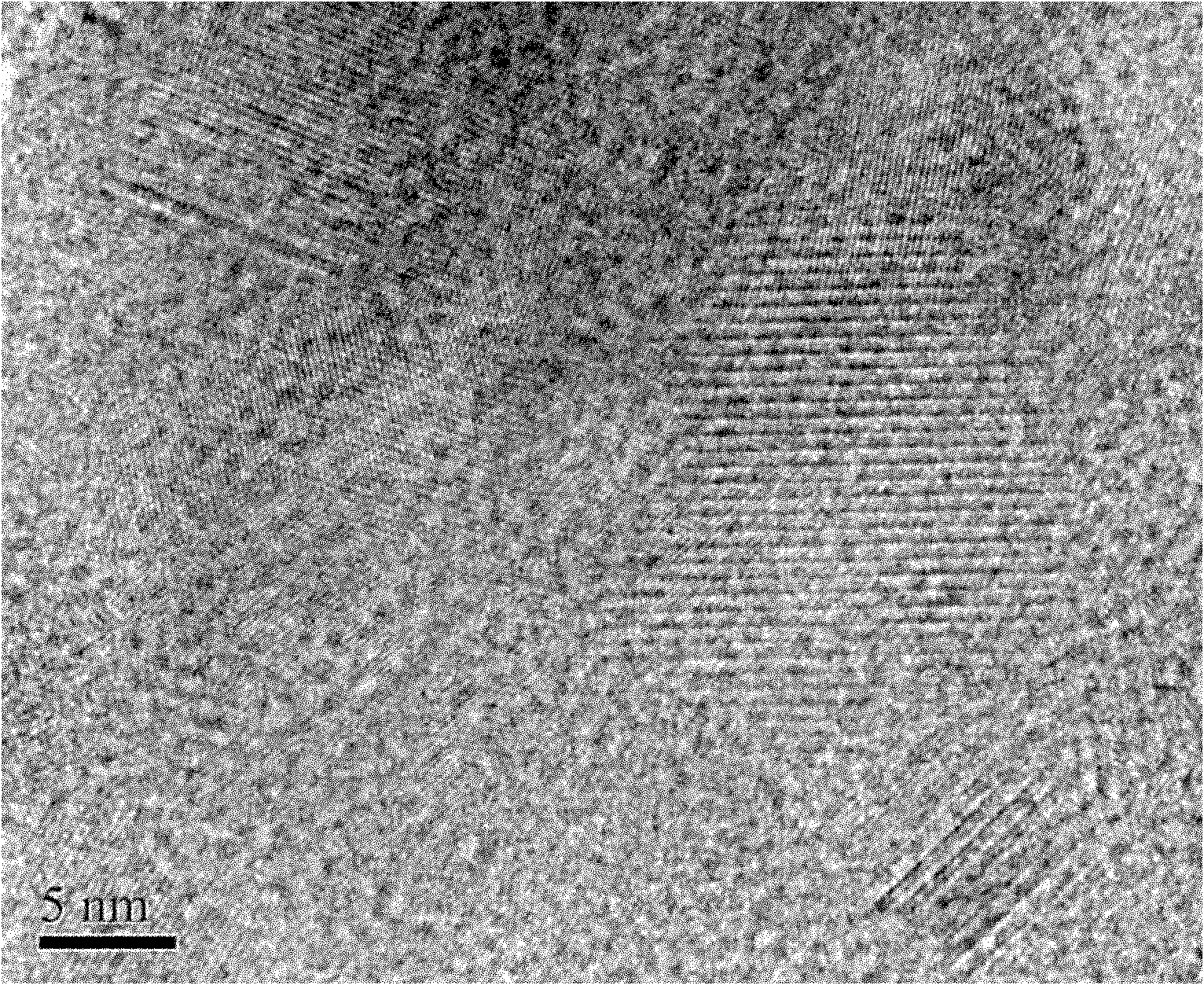

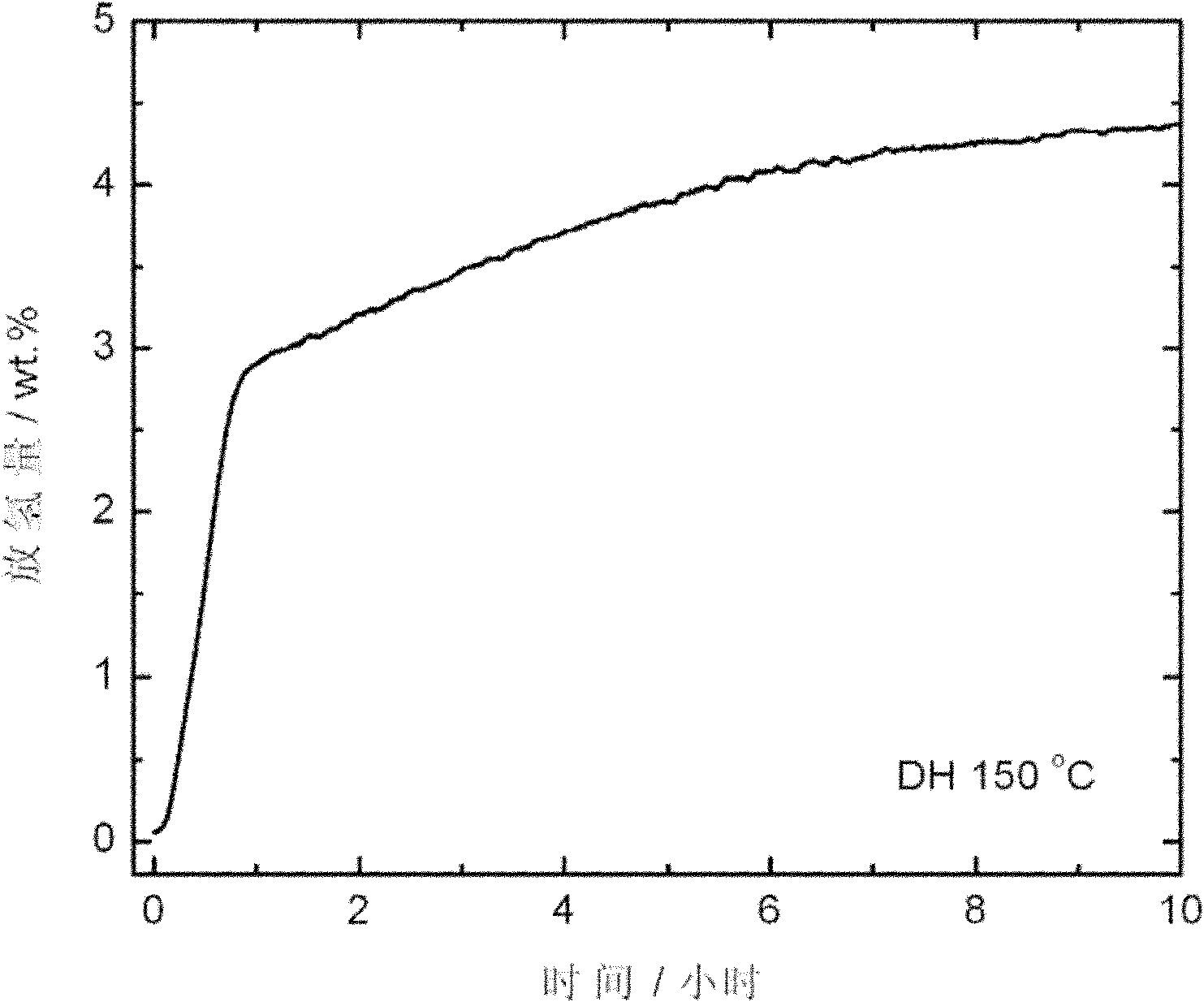

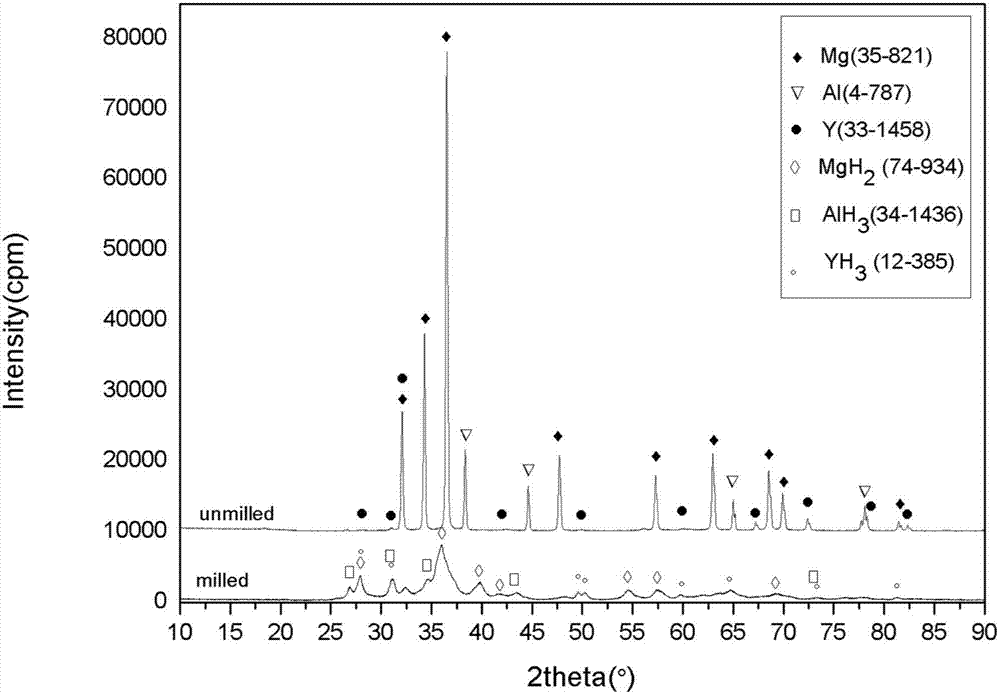

Nanocrystalline amorphous Mg-M-Y hydrogen storage alloy and preparation method and application thereof

InactiveCN107190193AImproved hydrogen absorption and desorption rateFast hydrogen absorption and desorption rateMagnesiumHydrogen atmosphere

The invention relates to a nanocrystalline amorphous Mg-M-Y hydrogen storage alloy and a preparation method thereof. Specifically, the nanocrystalline amorphous magnesium-based hydrogen storage alloy is composed of three components, by weight, of 65-87% of Mg, 2-15% of Y and 4-23% of M; and the M is one of aluminum (Al), nickel (Ni), iron (Fe), cobalt (Co), manganese (Mn), vanadium (V), chromium (Cr), copper (Cu) or titanium (Ti). The preparation method of the nanocrystalline amorphous Mg-M-Y hydrogen storage alloy is that the nanocrystalline amorphous Mg-M-Y hydrogen storage alloy is directly obtained by adopting reaction ball mill under the hydrogen atmosphere. The process route is shortened, the material preparation efficiency is greatly improved, and by adoption of the obtained nanocrystalline amorphous Mg-M-Y alloy, the high hydrogen absorption and desorption speed rate and the hydrogen storage amount are achieved without activation.

Owner:YANTAI UNIV

Rare earth hydrogen storage alloy and preparation method and application thereof

ActiveCN112961996AImprove performancePromote activationHydrogenTransportation and packagingMischmetalHydrogen desorption

The invention provides rare earth hydrogen storage alloy and a preparation method and application thereof. The preparation method comprises the following steps that type-A metal, type-B metal and rare earth metal are mixed and then sequentially subjected to smelting and vacuum suction casting to obtain an alloy bar; and the obtained alloy bar is subjected to surface modification to obtain the rare earth hydrogen storage alloy. According to the preparation method, through optimal design, vacuum suction casting and surface modification of all the components, the activation performance, the hydrogen absorption and desorption rate, the effective hydrogen desorption amount and the cycle stability of the alloy are remarkably improved; and the preparation method is simple in technological process, low in cost and beneficial to large-scale production, and has a good industrial application prospect.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI +1

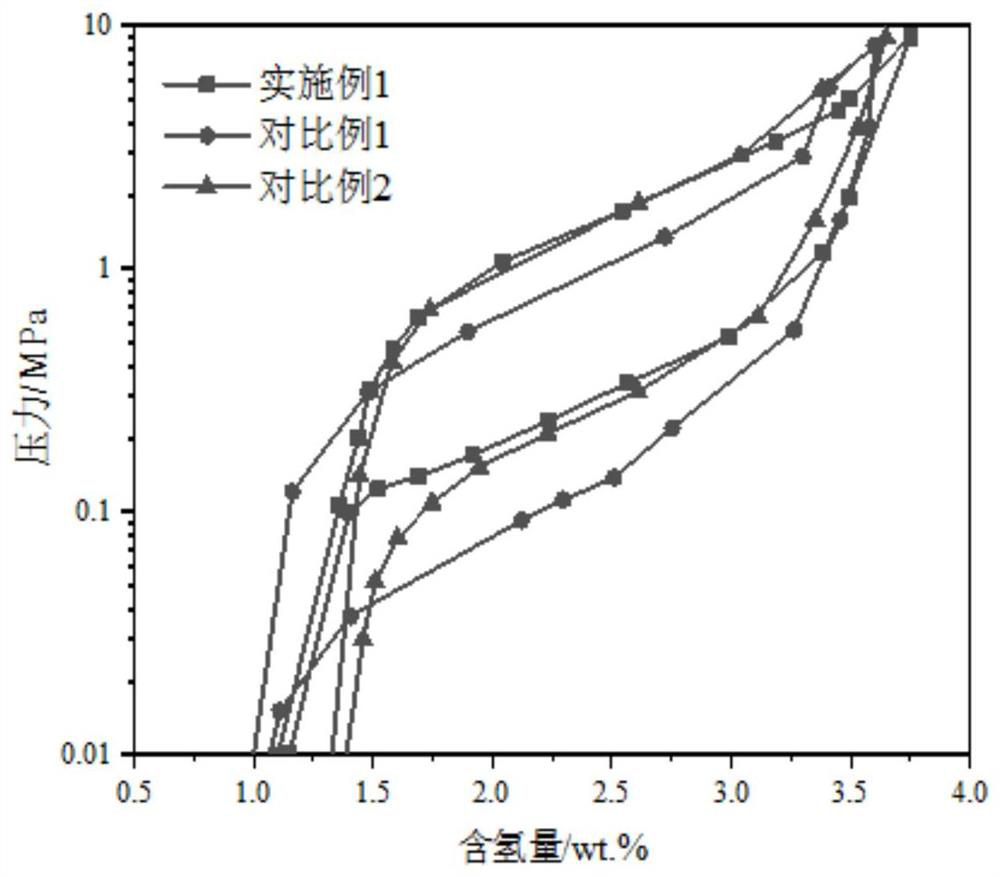

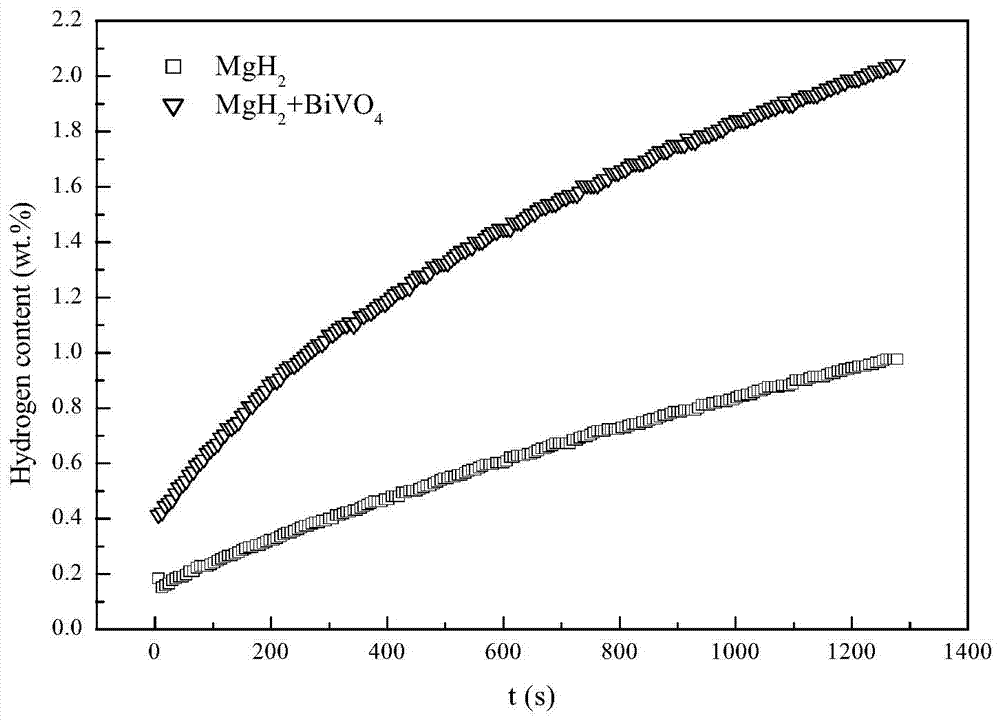

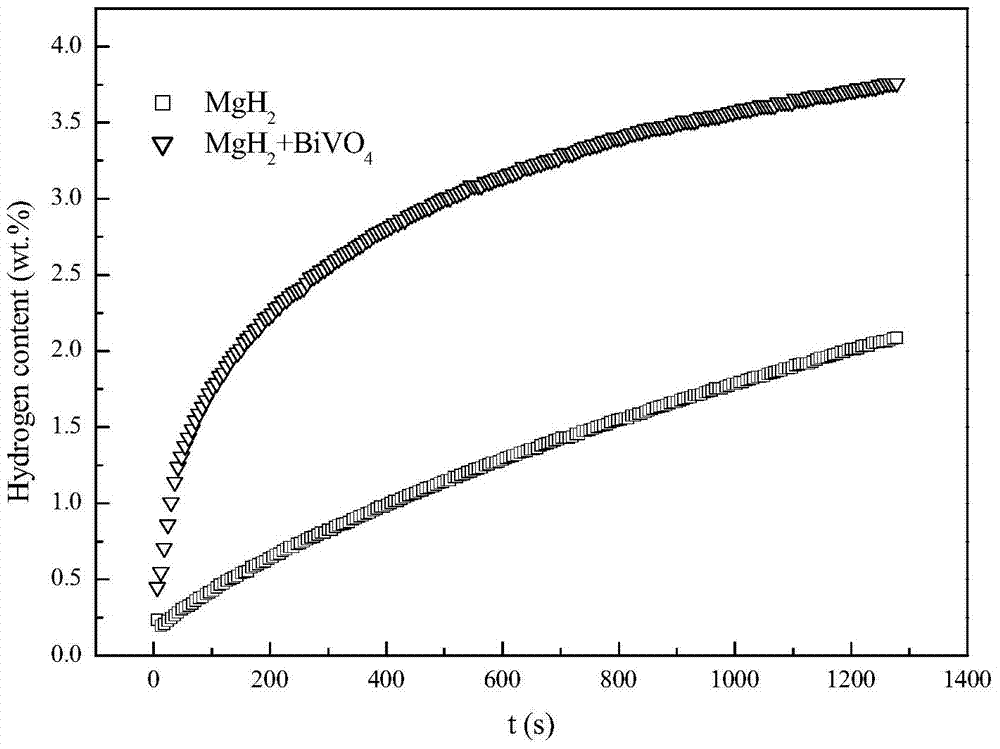

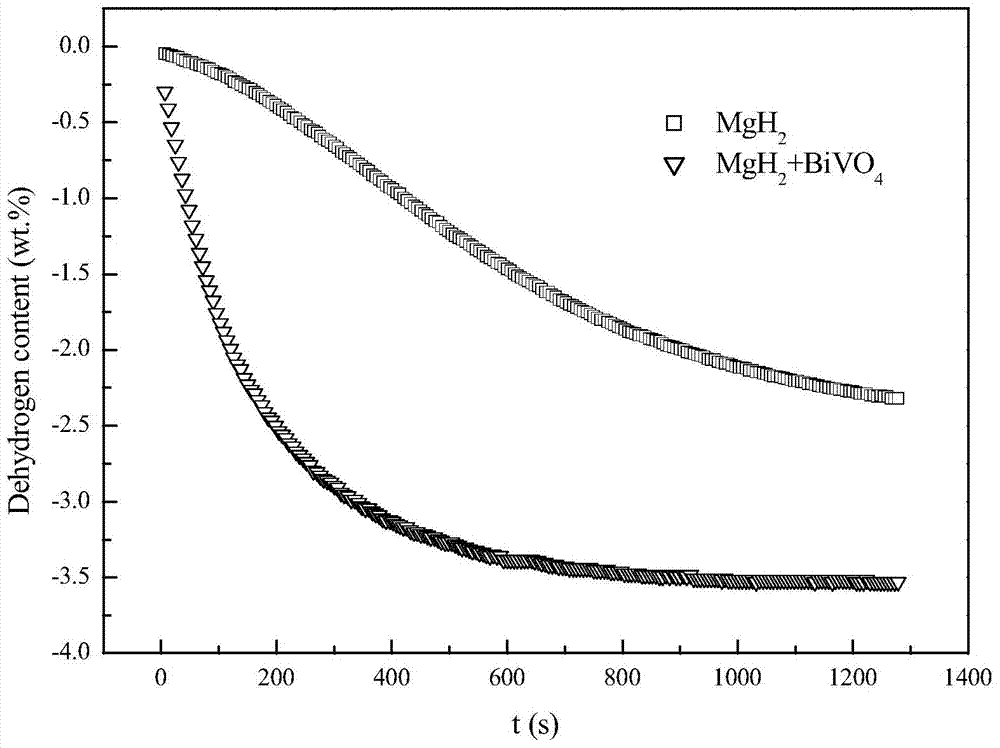

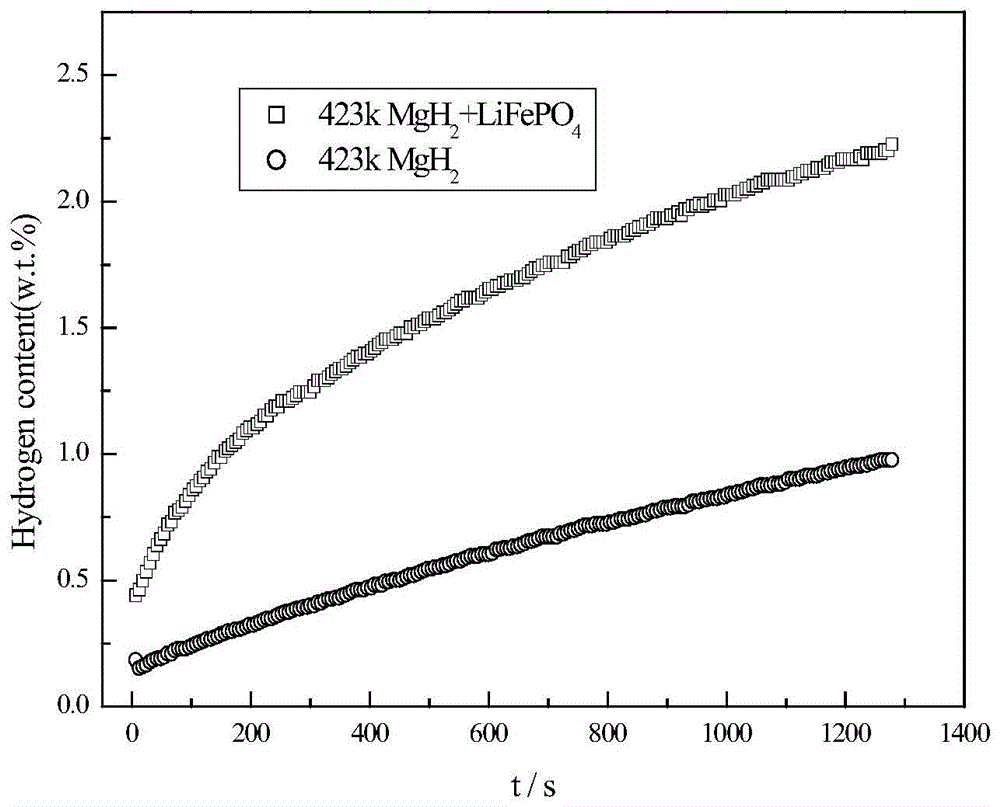

MgH2-BiVO4 hydrogen storage composite material and preparation method thereof

InactiveCN103864012AImprove hydrogen absorption/desorption performanceRaw materials are easy to getHydrogen productionBall millGlovebox

Owner:YANSHAN UNIV

Nanometer magnesium hydride hydrogen-storage material preparation method

PendingCN109665494AFast hydrogen absorption and desorption rateImprove thermodynamic performanceHydrogen separation by selective and reversible uptakeAlkali/alkaline-earth/beryllium/magnesium hydridesAlkaneMaterials preparation

The invention belongs to the technical field of nanomaterial preparation and discloses a nanometer magnesium hydride hydrogen-storage material preparation method. By adoption of a thermal field assisted mechanical ball milling process, alkane solution of dibutyl magnesium is subjected to wet ball milling for 1-4h under a condition of heating at 100-200 DEG C to obtain magnesium hydride suspension,and the magnesium hydride suspension is dried to obtain magnesium hydride in a nanometer structure. The particle size of the obtained magnesium hydride is generally smaller than 10nm, size uniformityis achieved, and the hydrogenation and dehydrogenation temperature of nanometer magnesium hydride is sharply lowered. The nanometer magnesium hydride preparation process is convenient and simple in operation, low in time consumption and low in operating temperature; problems of high time consumption or high operating temperature and large grain size of hydrides in previous preparation of nanometer magnesium hydride are solved; in addition, the hydrogen storage performance of magnesium hydride is improved, and a promising application prospect is achieved.

Owner:SOUTH CHINA UNIV OF TECH

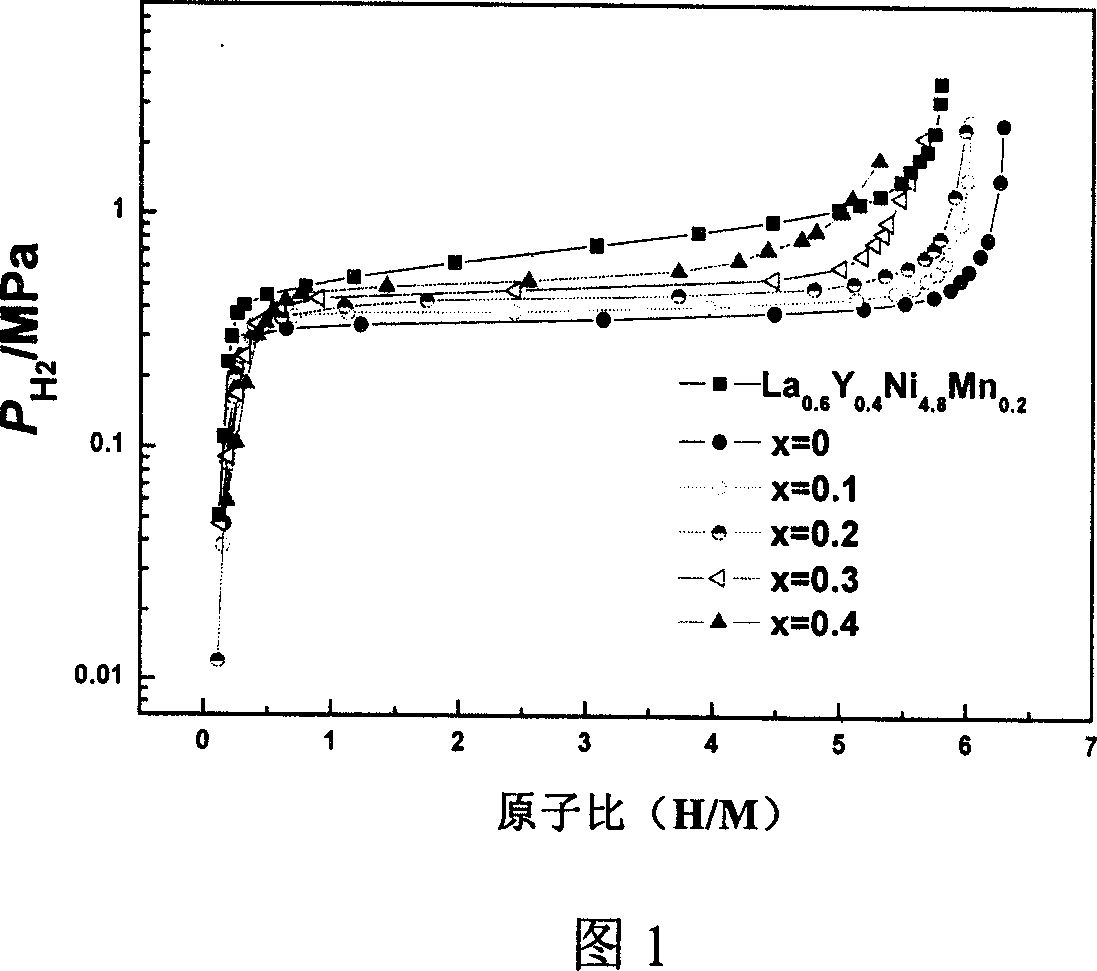

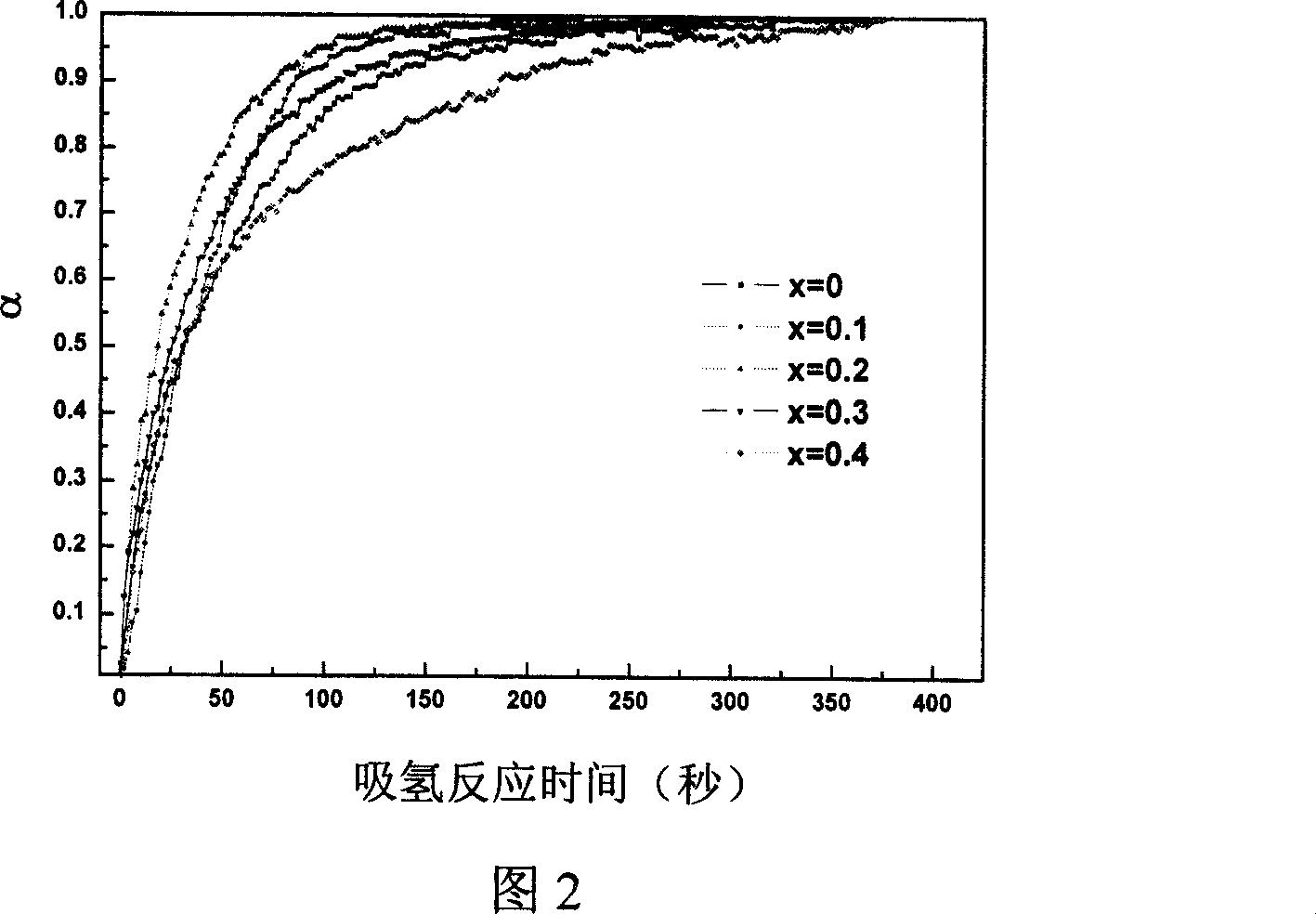

Hydrogen-storage alloy of metal oxide for air-conditioner

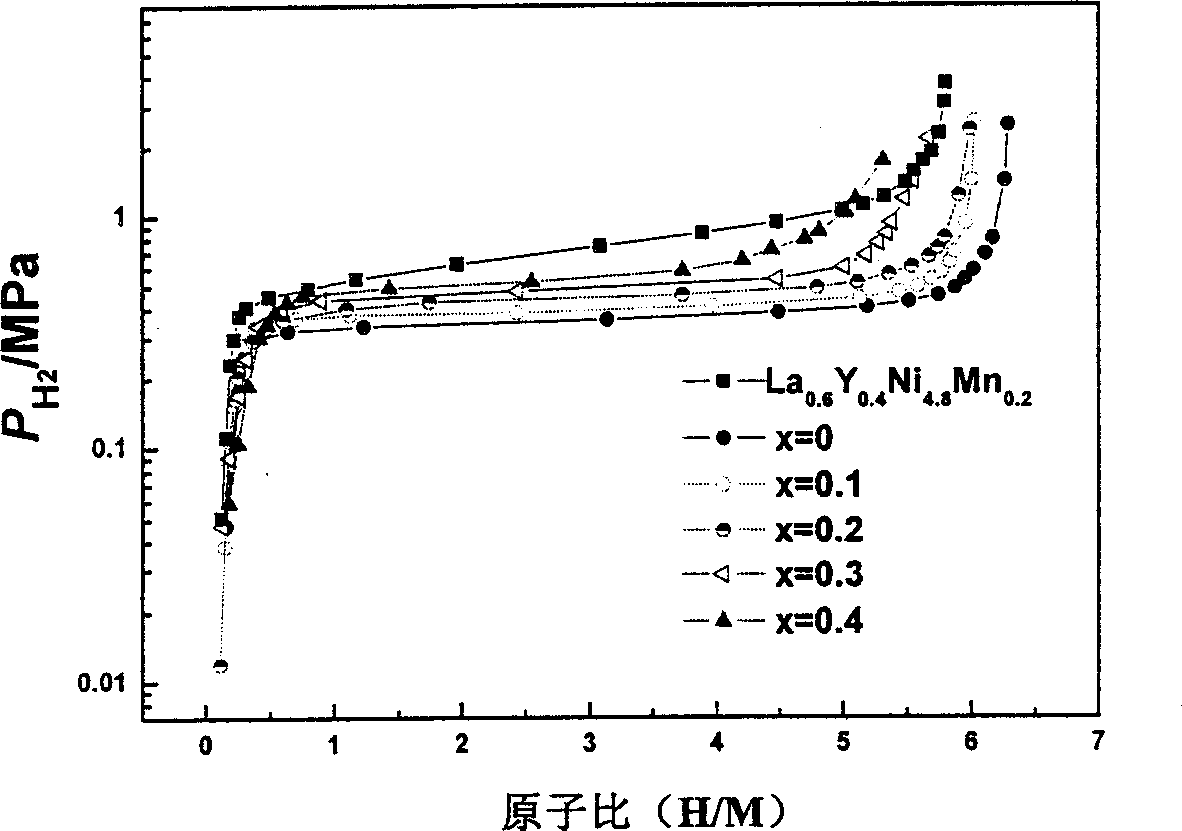

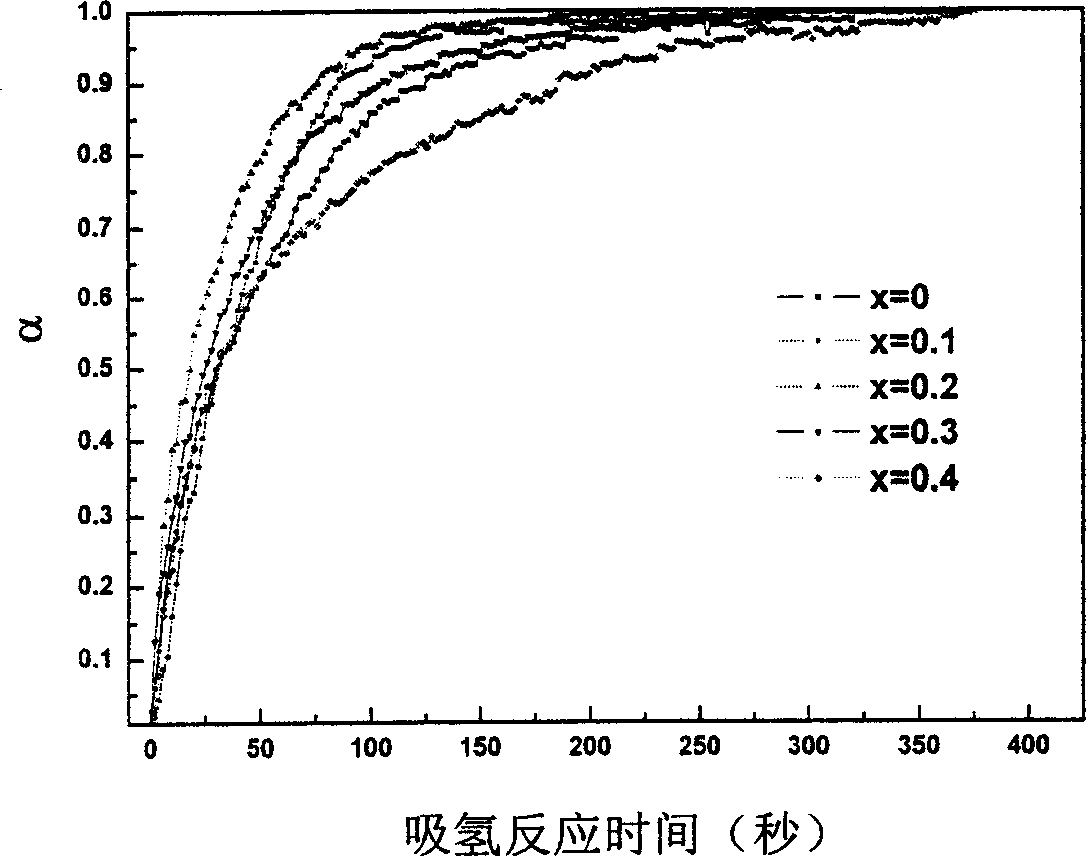

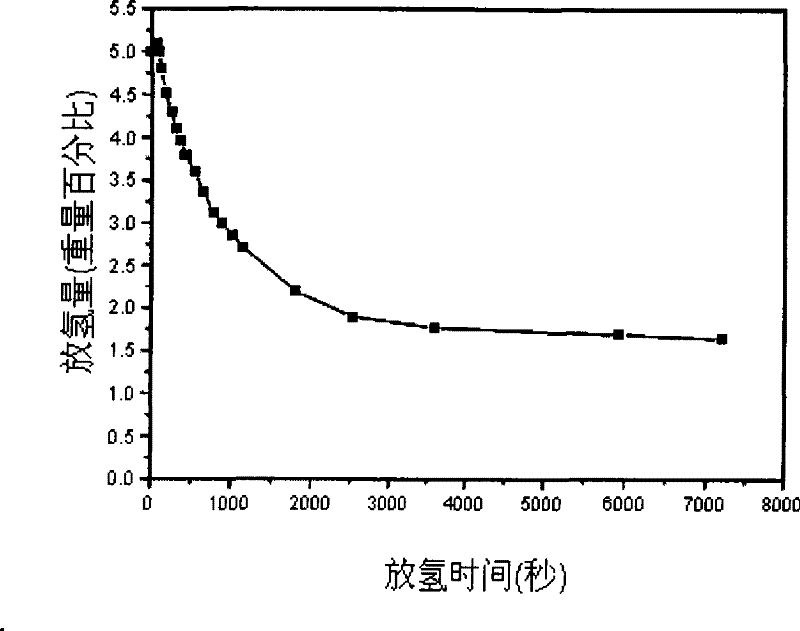

A holding hydrogen alloy used for making metallic hydride air conditioning. The chemical formula is La0.6Nd0.4Ni4.8Mn0.2Cux(x=0.1-0.4). Release hydrogen dosage of it is 1.43wt% at common temperature. Decomposition pressure at 18íµ is between 1amp and 1.5amp. Hysteresis coefficient is 0.09-0.24. Rate of grade of parallel line is 0.05-0.1. Absorbing hydrogen dosage can reach 90% in 50-80s. Meanwhile, Releasing and absorbing hydrogen dosage dynamic property is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

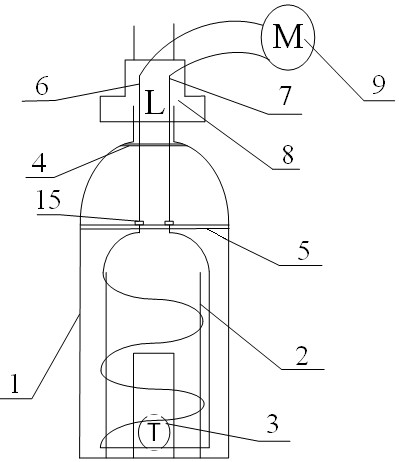

Solid hydrogen storage and desorption device and method based on temperature feedback regulation

ActiveCN114440124AFast hydrogen absorption and desorption rateIncrease contact areaContainer filling methodsFluid handledPhysical chemistryHydrogen desorption

The invention discloses a solid hydrogen storage and desorption device and method based on temperature feedback regulation. During hydrogen storage, cooling liquid is injected into a liquid guide pipe, the cooling liquid circularly flows in the liquid guide pipe through a pump, a hydrogen storage material in a hydrogen storage bed body is cooled, and meanwhile, hydrogen is filled into a hydrogen storage tank body; hydrogen enters the hydrogen storage tank body after being filtered, and hydrogen storage is achieved at low temperature; during hydrogen desorption, the temperature in the hydrogen storage material is collected through the wireless temperature sensor, the hydrogen desorption speed and the hydrogen desorption temperature are determined according to needs, the temperature and the flowing speed of liquid in the liquid guide pipe are determined, and heating hydrogen desorption is achieved.

Owner:高志杰

Magnesium-based hydrogen storage alloy and preparation method thereof

ActiveCN109898002AGood dispersionImprove hydrogen absorption and desorption performanceElectronHydrogen absorption

The invention discloses a magnesium-based hydrogen storage alloy and a preparation method thereof. The magnesium-based hydrogen storage alloy is prepared from raw materials of Mg2Ni alloy powder and nickel-plated carbon nano-tubes, wherein the weight ratio of the Mg2Ni alloy powder to the nickel-plated carbon nano-tubes is 100:(0.5-1). The preparation method includes the steps that the Mg2Ni alloypowder and the nickel-plated carbon nano-tubes are subjected to high-current electron beam pulse surface radiation pretreatment, then mechanical alloying is carried out through planet ball-milling, finally, high-current electron beam pulse surface radiation treatment is carried out, and the magnesium-based hydrogen storage alloy is obtained. The poor hydrogen heat absorption and release and dynamics performance of the magnesium-based hydrogen storage alloy is effectively improved, the low-temperature hydrogen absorption and release performance of the magnesium-based hydrogen storage alloy isgreatly improved, the hydrogen absorption and release rate of the magnesium-based hydrogen storage alloy is effectively increased, and thus the magnesium-based hydrogen storage alloy has higher practical application value.

Owner:三桥惠(佛山)新材料有限公司

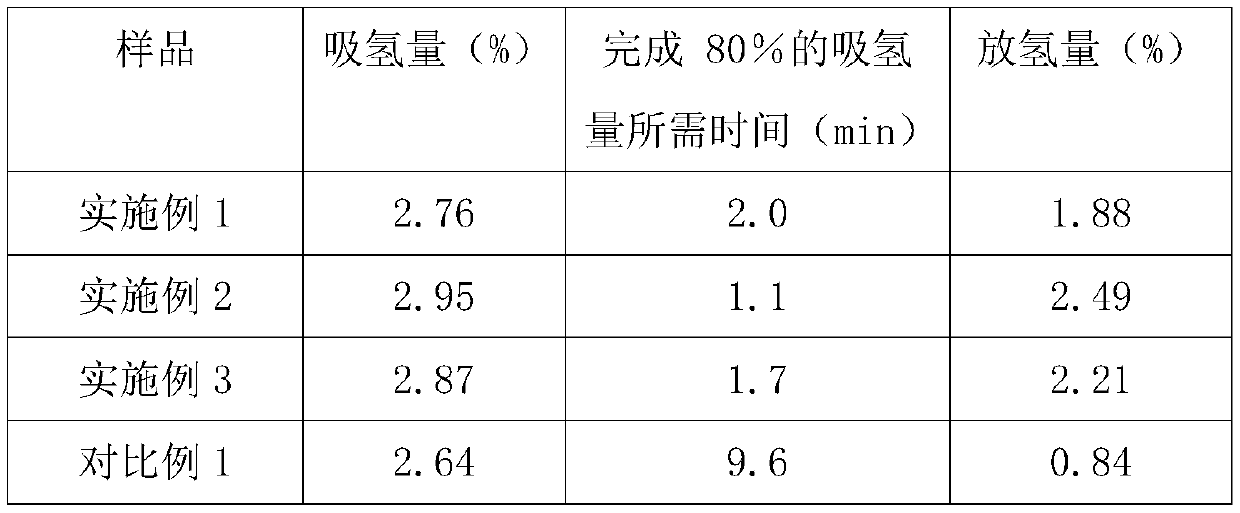

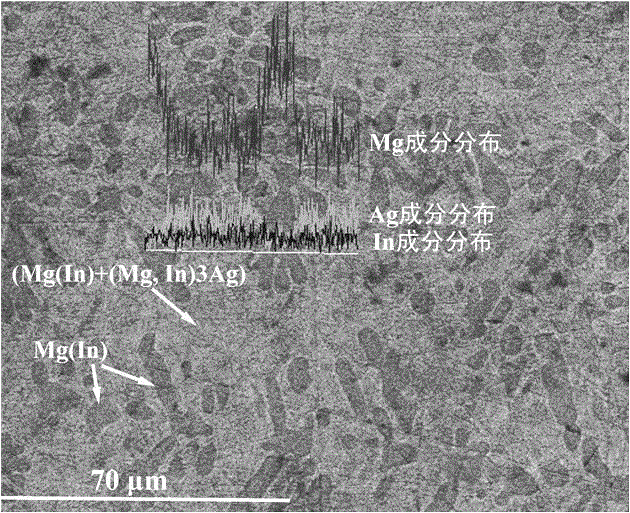

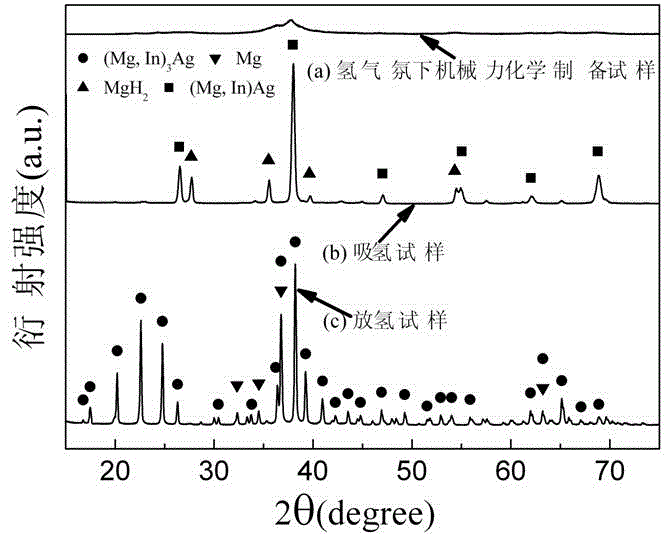

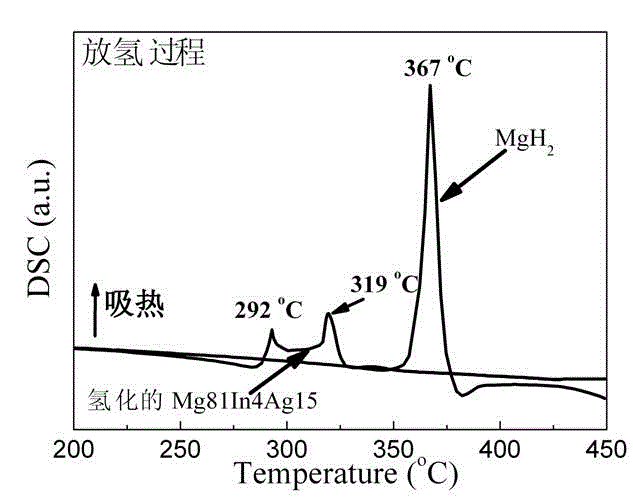

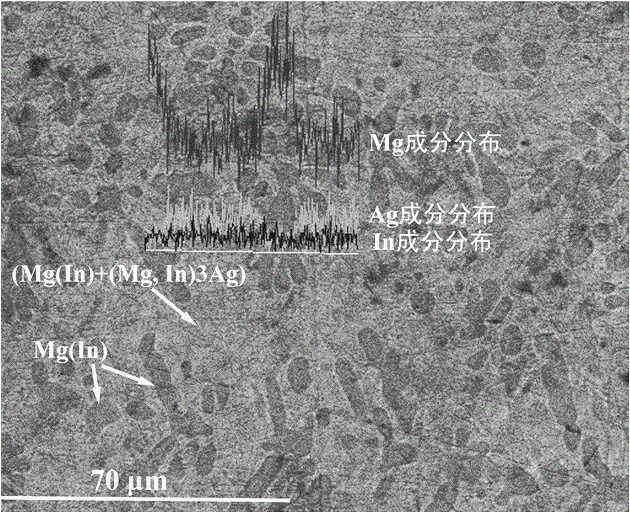

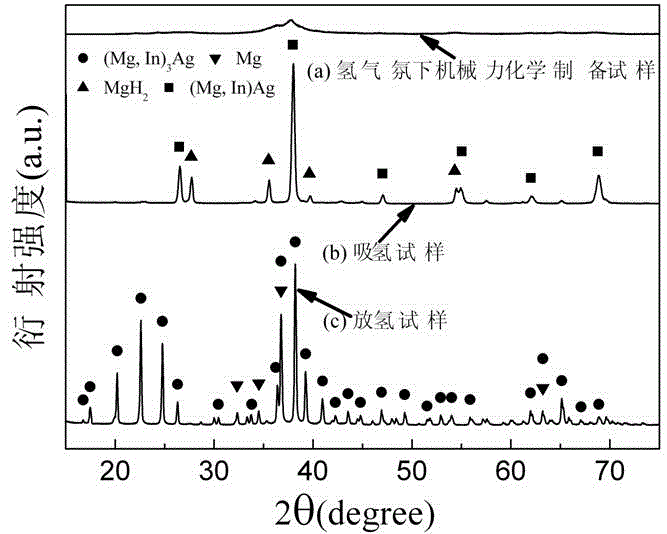

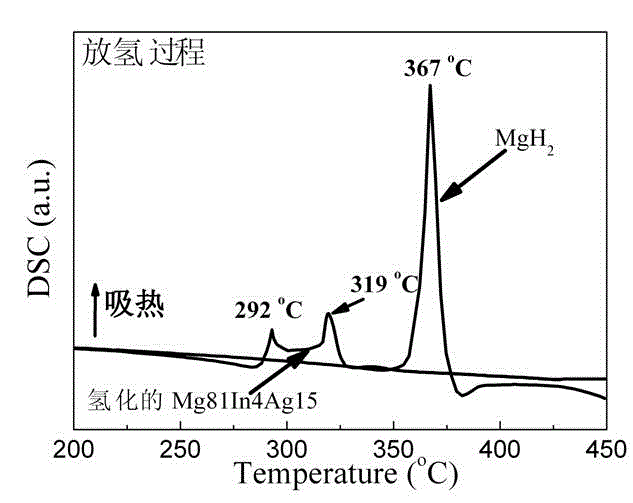

A kind of mg-in-ag ternary hydrogen storage material and preparation method thereof

ActiveCN103556022BHigh hydrogen storage capacityExcellent casting propertiesBinary alloySurface oxidation

The invention discloses a novel Mg-In-Ag ternary hydrogen storage alloy system and a preparation method thereof, belonging to the technical field of hydrogen storage materials. The composition of the hydrogen storage material is as follows: the atomic percentage of (Mg+In) is 80-85%, wherein the proportion of In in (Mg+In) is 3-6%, and the rest is Ag. Weigh the Mg block and Ag sheet according to the alloy composition, use the induction melting furnace to melt the Mg-Ag binary low-melting point alloy first, then weigh the In block according to the proportion and melt it together with the above binary alloy to obtain the Mg-In-Ag ternary alloy The alloy is ground into alloy powder after removing the surface oxide skin, and then put into a ball mill jar filled with hydrogen to prepare a highly active powder hydrogen storage material by mechanochemistry, which can be directly used as the final hydrogen storage material product. The hydrogen storage material of the invention has the characteristics of no need for hydrogen absorption and desorption activation, high hydrogen storage capacity, low hydrogen absorption and desorption temperature, and fast hydrogen absorption and desorption rate.

Owner:北京鼎浩安捷科技有限公司

Mg-In-Ag ternary hydrogen storage material and preparation method thereof

ActiveCN103556022AHigh hydrogen storage capacityExcellent casting propertiesBinary alloySurface oxidation

The invention discloses an Mg-In-Ag ternary hydrogen storage alloy system and a preparation method thereof, which belong to the technical field of the hydrogen storage material. The hydrogen storage material consists of the following components: the atomic percentage of (Mg + In) is 80 to 85 percent, wherein the content of In accounts for 3 to 6 percent in (Mg + In), and the balance is Ag. The preparation method comprises the following steps of measuring Mg blocks and Ag pieces according to the alloy components, firstly smelting Mg-Ag binary low-melting-point alloy by adopting a sensing smelting furnace, then measuring In blocks according to the proportion, smelting the In blocks with the binary alloy to obtain the Mg-In-Ag ternary alloy; grinding the alloy with the surface oxide skin being removed into alloy powder, placing the alloy powder into a ball-milling tank with hydrogen, and mechanically and chemically preparing the high-activity powder hydrogen storage material which can be directly used as a final hydrogen storage material product. The hydrogen storage material has the characteristics that the activation for absorbing and releasing the hydrogen is not needed, the hydrogen storage capacity is large, the temperature for absorbing and releasing the hydrogen is low and the speed for absorbing and releasing the hydrogen is high.

Owner:北京鼎浩安捷科技有限公司

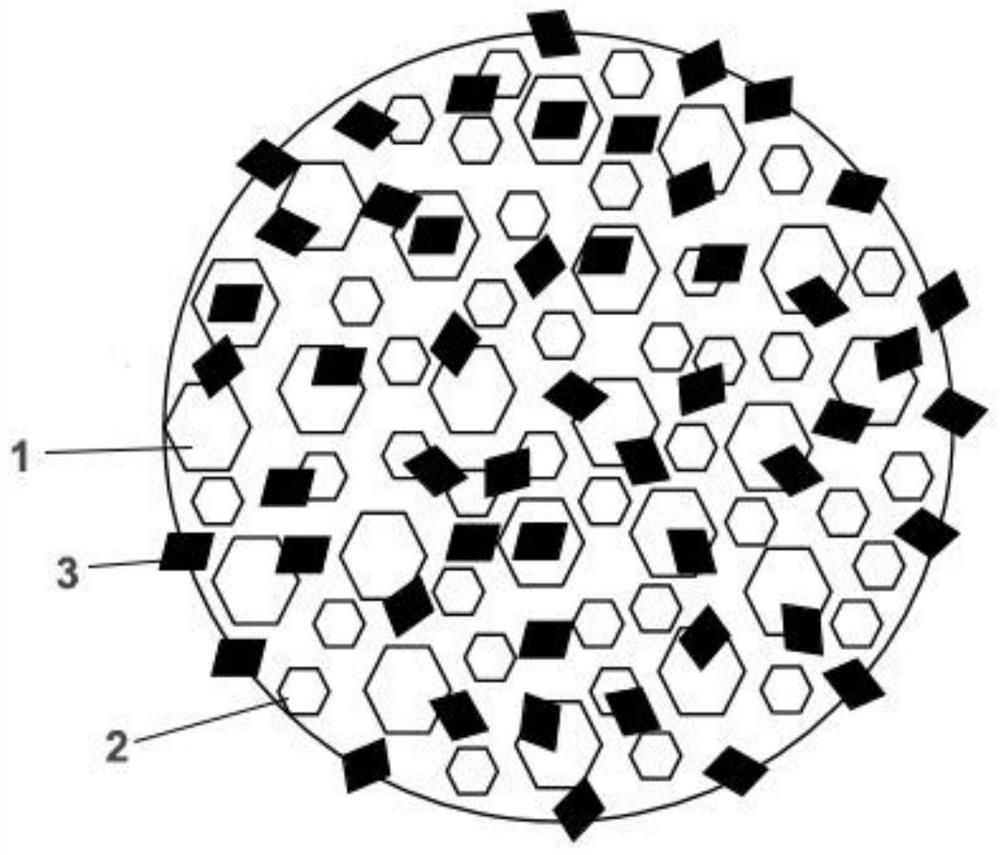

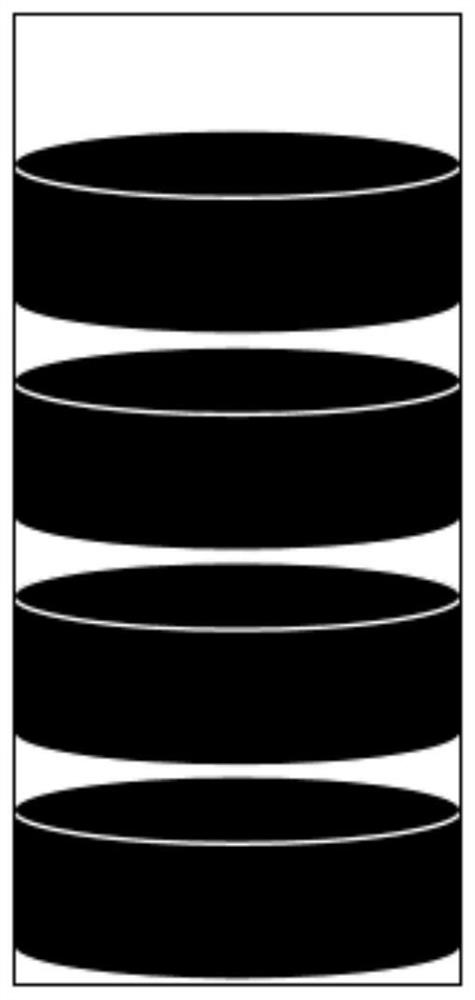

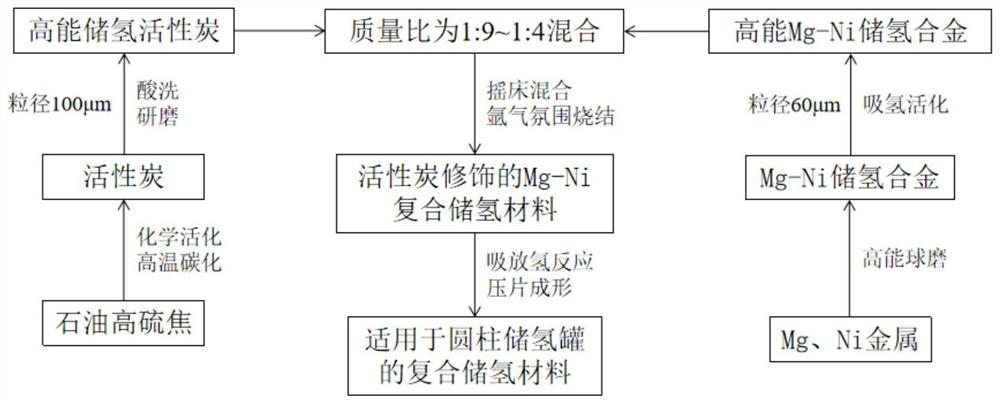

Magnesium nickel-petroleum coke activated carbon composite hydrogen storage material and preparation method thereof

PendingCN112777564ATake advantage ofLarge hydrogen storage capacityHydrogenActivated carbonArgon atmosphere

The invention relates to a magnesium nickel-petroleum coke activated carbon composite hydrogen storage material and a preparation method thereof, and belongs to the technical field of hydrogen storage alloy materials. The method comprises the following steps: 1, preparing petroleum coke activated carbon; 2, preparing Mg-Ni hydrogen storage alloy; and 3, loading the composite hydrogen storage material: 31) uniformly mixing the petroleum coke activated carbon prepared in the step 1 with the Mg-Ni hydrogen storage alloy prepared in the step 2, and then placing the mixture on a muffle furnace protected by an argon atmosphere for high-temperature sintering; 32) placing the sintered composite hydrogen storage material in a hydrogenation reactor for activating treatment; and (33) putting the activated composite hydrogen storage material into a tablet press, and extruding the composite hydrogen storage material into a cylindrical shape. The spherical cage effect can be generated by means of dense apertures and gaps of the petroleum coke activated carbon, discrete aggregation of the pulverized hydrogen storage alloy is efficiently limited, and the magnesium nickel-petroleum coke activated carbon composite hydrogen storage material has the advantages of being high in hydrogen storage capacity, high in hydrogen absorption and desorption rate, low in strain accumulation and the like.

Owner:SHANDONG UNIV

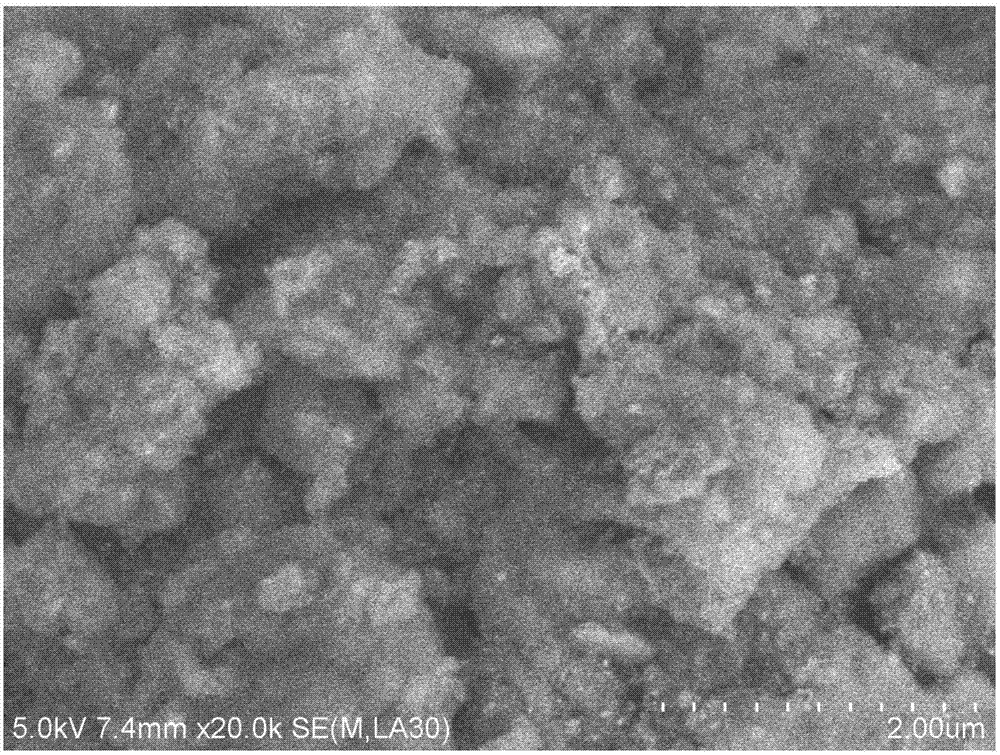

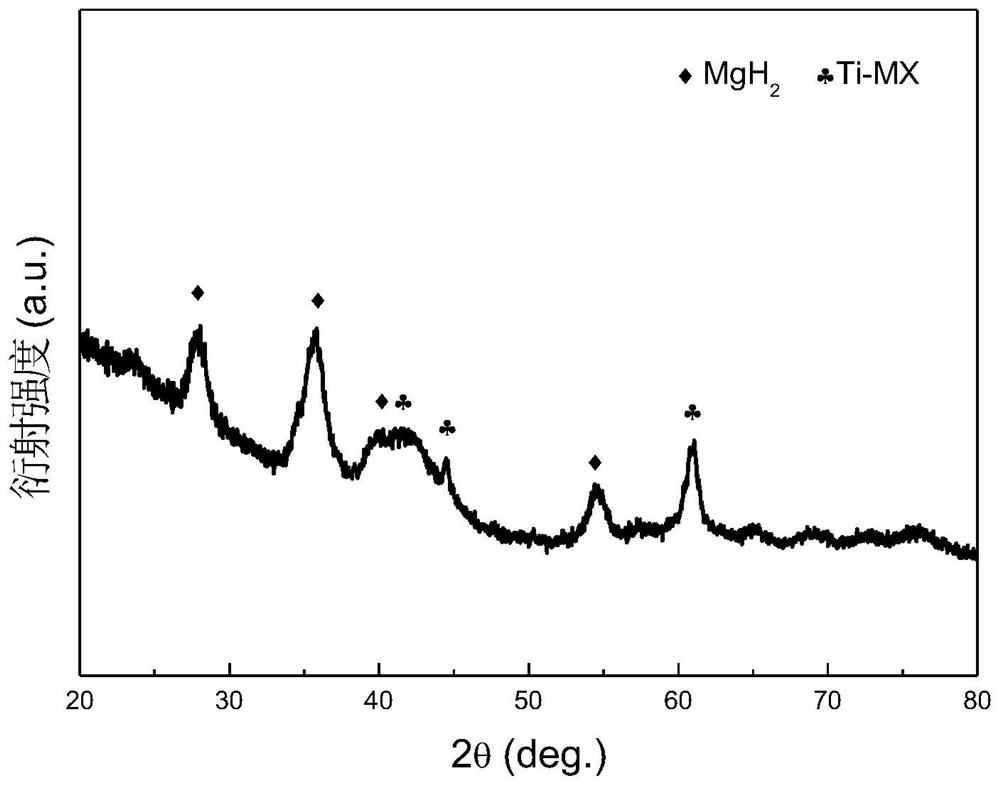

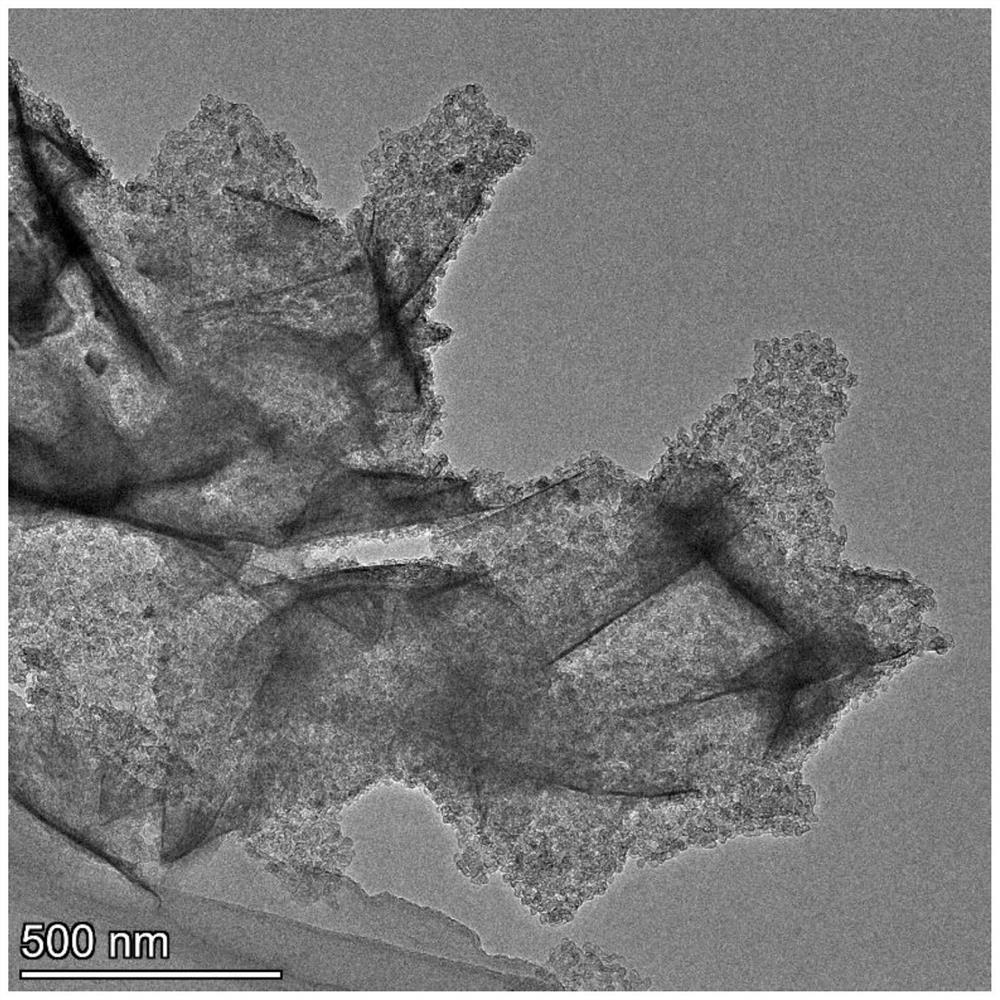

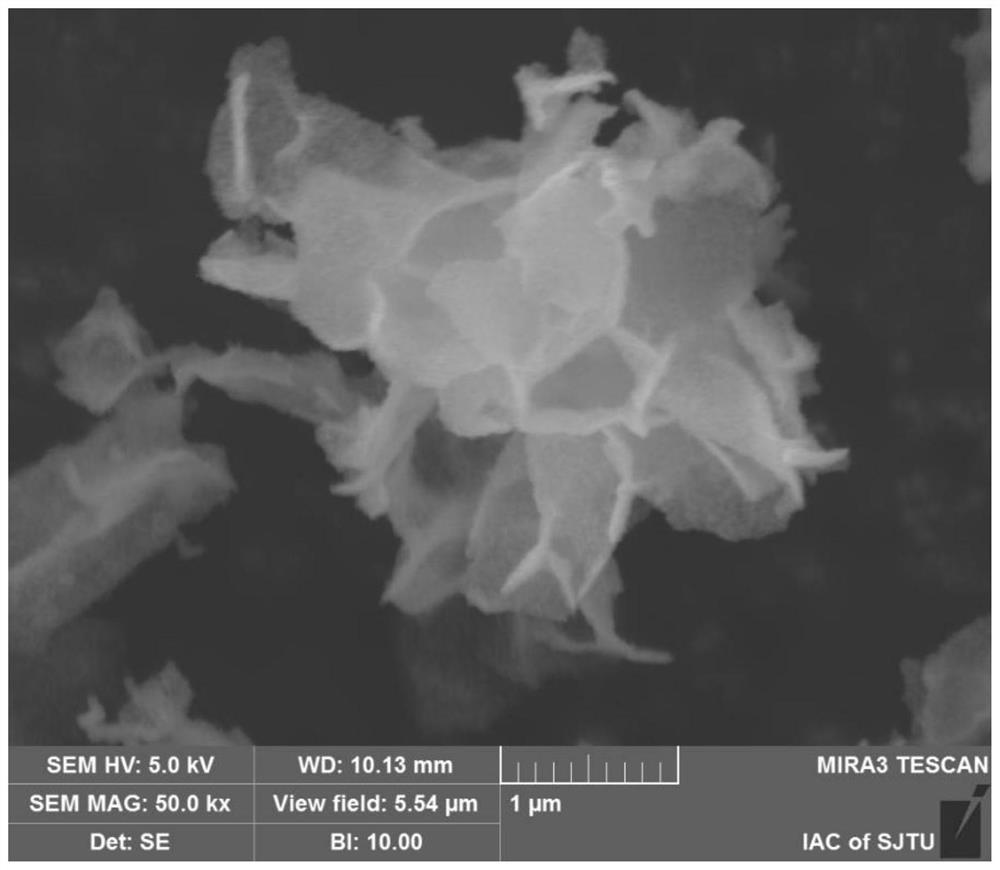

Nano magnesium hydride loaded composite material and preparation method thereof

The invention discloses a preparation method of a nano magnesium hydride loaded composite material, the preparation method comprises the following steps: adding a cationic surfactant into an aqueous dispersion of two-dimensional transition metal carbide to enable two-dimensional transition metal carbide nanosheets to wrinkle and avoid re-stacking, and then washing and drying; putting the dried product into a sealed container, vacuumizing the sealed container, raising the temperature to a high temperature, keeping the temperature for a period of time, filling high-pressure hydrogen into the sealed container, and keeping the temperature for a period of time; and finally, adding a product subjected to heat treatment and dibutyl magnesium into an organic solvent to obtain a mixture, carrying out ultrasonic dispersion, stirring and heating for 12-48 hours under the conditions that the hydrogen pressure is 3-6 MPa and the temperature is 180-220 DEG C, and carrying out centrifugal drying to obtain the nano magnesium hydride loaded composite material. The prepared two-dimensional transition metal carbide nano magnesium hydride loaded composite material has the advantages of high hydrogen storage density, rapid hydrogen absorption and desorption dynamic performance, excellent cycle stability and the like.

Owner:SHANGHAI JIAO TONG UNIV

Hydrogen-storage alloy of metal oxide for air-conditioner

InactiveCN1313632CHigh hydrogen storage capacityPromote activationOther chemical processesSorption machinesHysteresisDecomposition

A holding hydrogen alloy used for making metallic hydride air conditioning. The chemical formula is La0.6Nd0.4Ni4.8Mn0.2Cux(x=0.1-0.4). Release hydrogen dosage of it is 1.43wt% at common temperature. Decomposition pressure at 18 DEG C is between 1amp and 1.5amp. Hysteresis coefficient is 0.09-0.24. Rate of grade of parallel line is 0.05-0.1. Absorbing hydrogen dosage can reach 90% in 50-80s. Meanwhile, Releasing and absorbing hydrogen dosage dynamic property is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

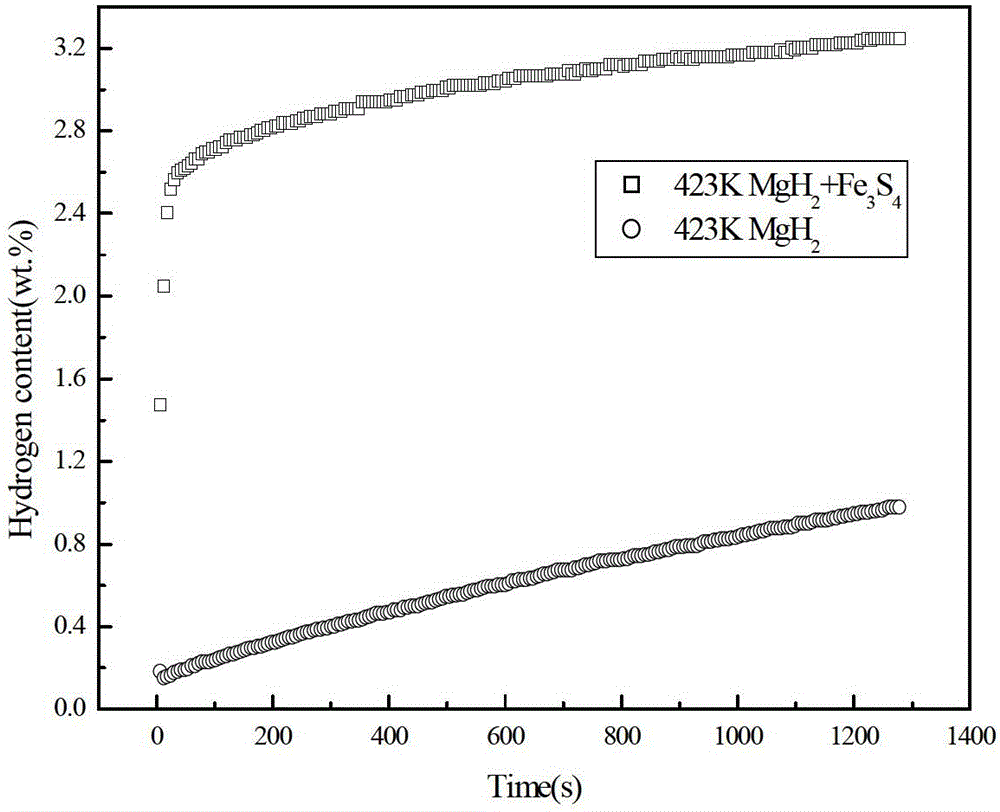

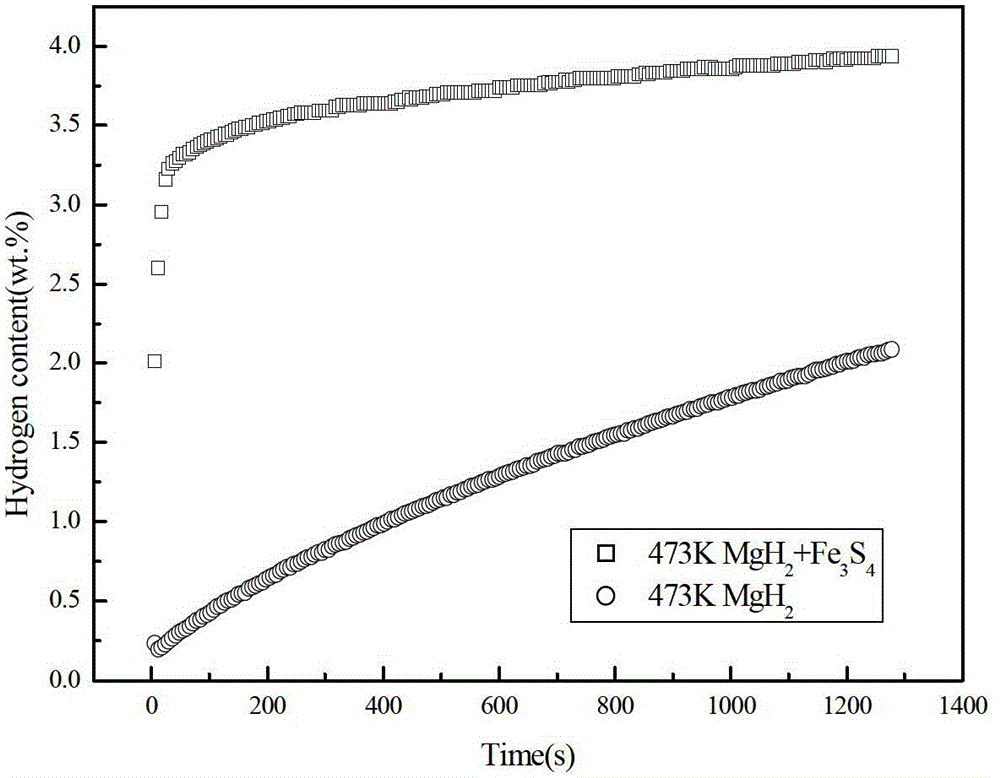

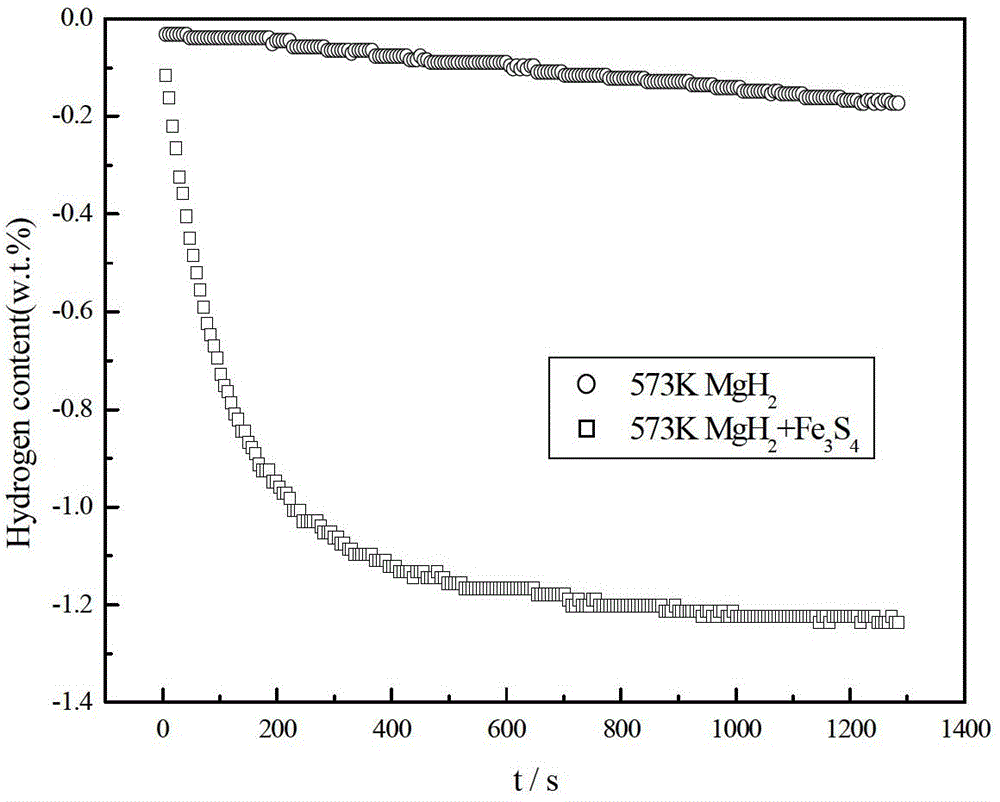

Magnesium hydride (MgH2) and ferrum-containing sulfide composite hydrogen storage material and preparation method thereof

InactiveCN103359687BImprove hydrogen absorption and desorption performanceFast hydrogen absorption and desorption rateHydrogen productionFuel cellsHydrogen absorption

The invention discloses a magnesium hydride (MgH2) and ferrum-containing sulfide composite hydrogen storage material and a preparation method thereof. The composite hydrogen storage material comprises MgH2 and 10-30 wt% of ferrum-containing sulfide, wherein the ferrum-containing sulfide is Fe3S4 or FeS or FeS2. The method comprises the following steps of: adding the ferrum-containing sulfide which serves as an additive into MgH2, and carrying out ball milling at the pressure of 0.1-0.5MPa in the atmosphere of high-purity argon to prepare the composite hydrogen storage material. The hydrogen absorption and desorption rate of the MgH2 and ferrum-containing sulfide composite hydrogen storage material is over 2 times higher that that of the MgH2 hydrogen storage material which contains no ferrum-containing sulfide. The MgH2 and ferrum-containing sulfide composite hydrogen storage material is simple in preparation process, has stable performances and can be used for storing hydrogen in the field of fuel cells.

Owner:YANSHAN UNIV

Method for improving hydrogen storage property of lithium borohydride

InactiveCN102502488BLow hydrogen release temperatureFast hydrogen absorption and desorption rateHydrogen productionAlkaline earth metalHydrogen fuel cell

The invention provides a method for improving a hydrogen storage property of lithium borohydride, and belongs to the technical field of hydrogen storage materials. The method comprises the following steps of: mixing the lithium borohydride and alkaline-earth metal alanate according to the molar ratio of 2:1-10:1 under the protection of vacuum or inert gases, and heating mixed powder of the lithium borohydride and the alkaline-earth metal alanate to a certain temperature to ensure that the alkaline-earth metal alanate is decomposed into alkaline-earth metal hydride, aluminum or aluminum alloy in advance. By the method, double effects of in situ and concerted catalysis in the process of discharging and absorbing hydrogen of the lithium borohydride by using the alkaline-earth metal alanate are achieved, so that a hydrogen discharging temperature of the lithium borohydride is greatly reduced, and the hydrogen absorbing and discharging dynamic properties of the lithium borohydride are improved. The method is suitable for storing the hydrogen safely and efficiently and is particularly applied in fields of hydrogen fuel cells and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

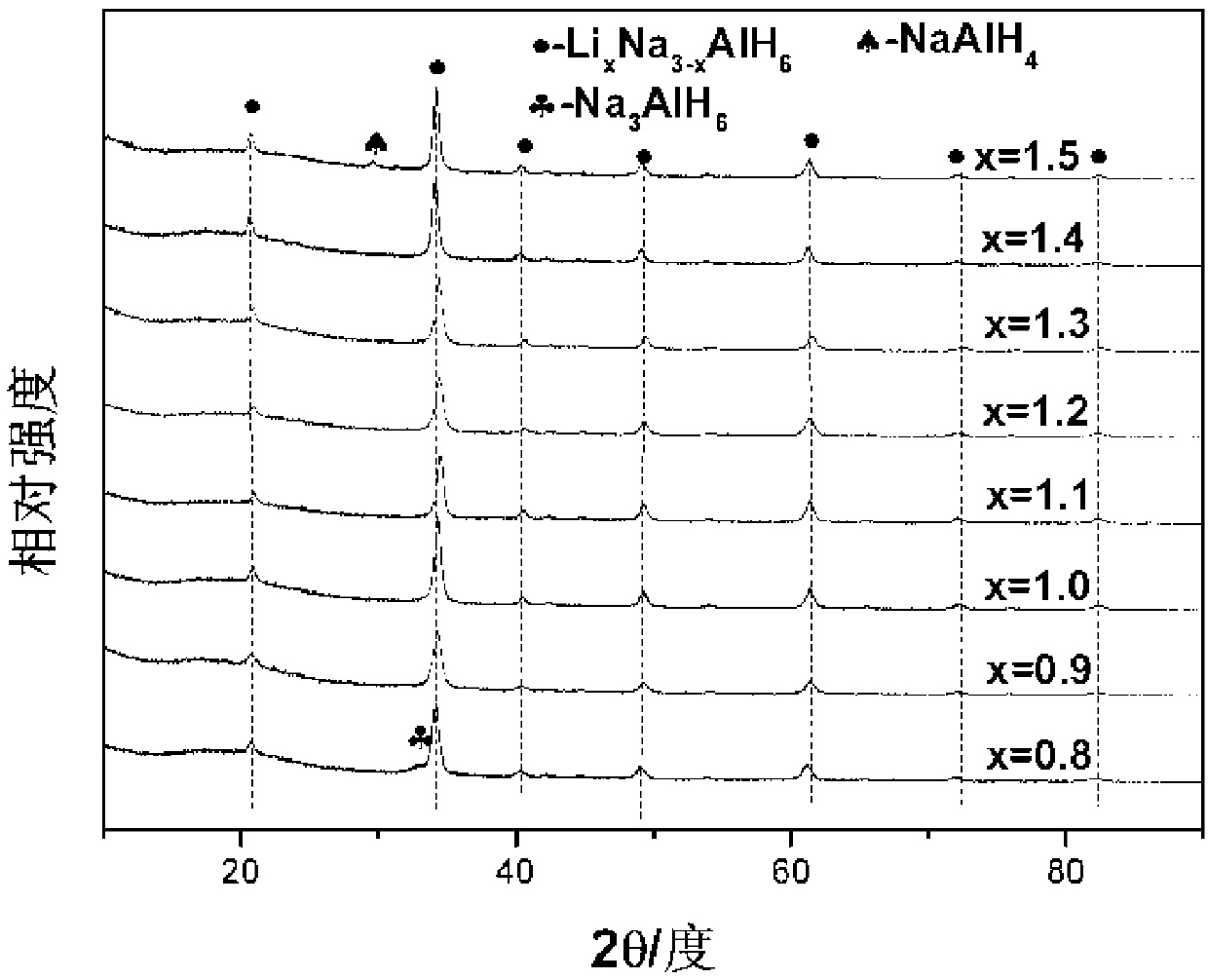

A kind of lithium sodium double alkali metal aluminum hydride compound and its synthetic method

ActiveCN106698347BSmall molecular weightHigh hydrogen storage capacityMultiple metal hydridesLithiumOctahedron

Owner:SOUTHEAST UNIV

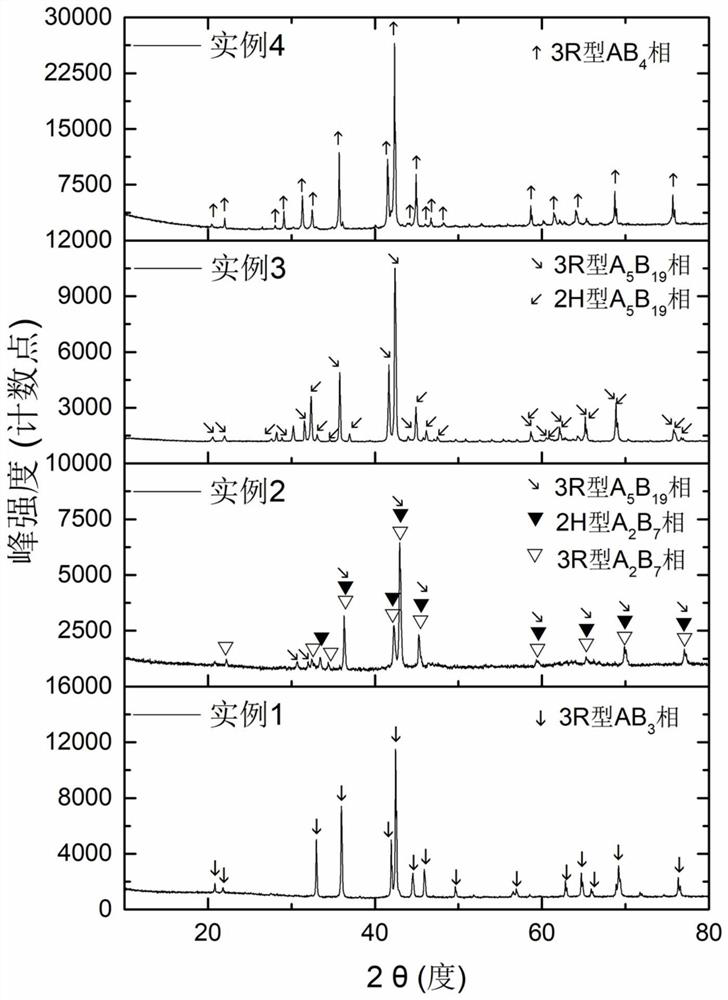

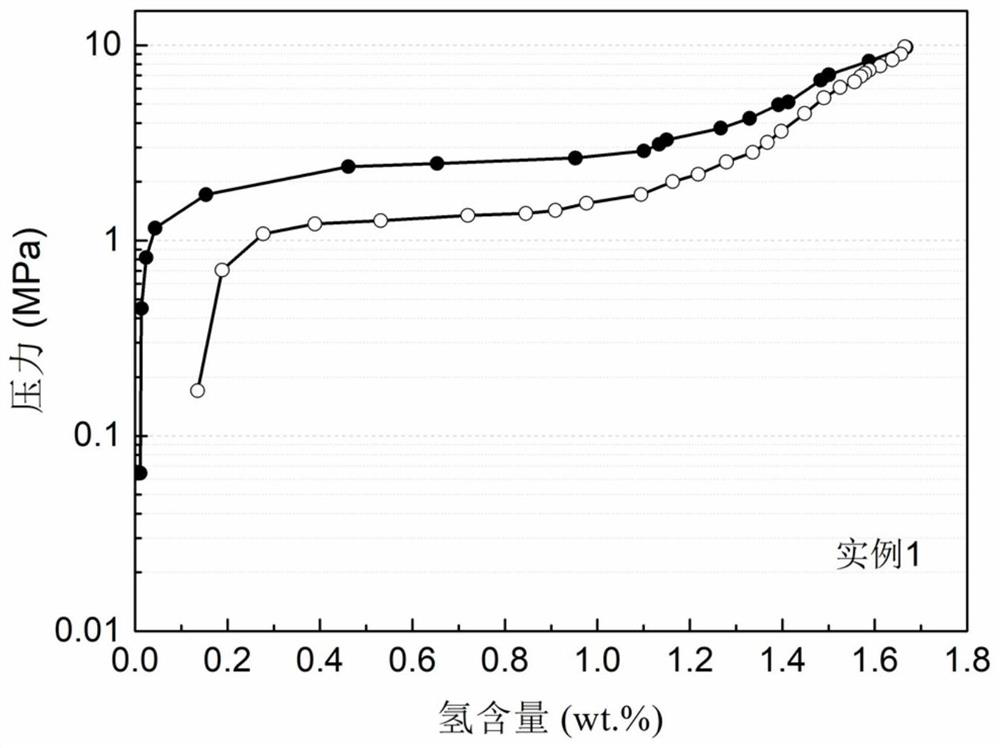

A hydrogen storage alloy suitable for low-pressure solid-state hydrogen storage and its preparation method

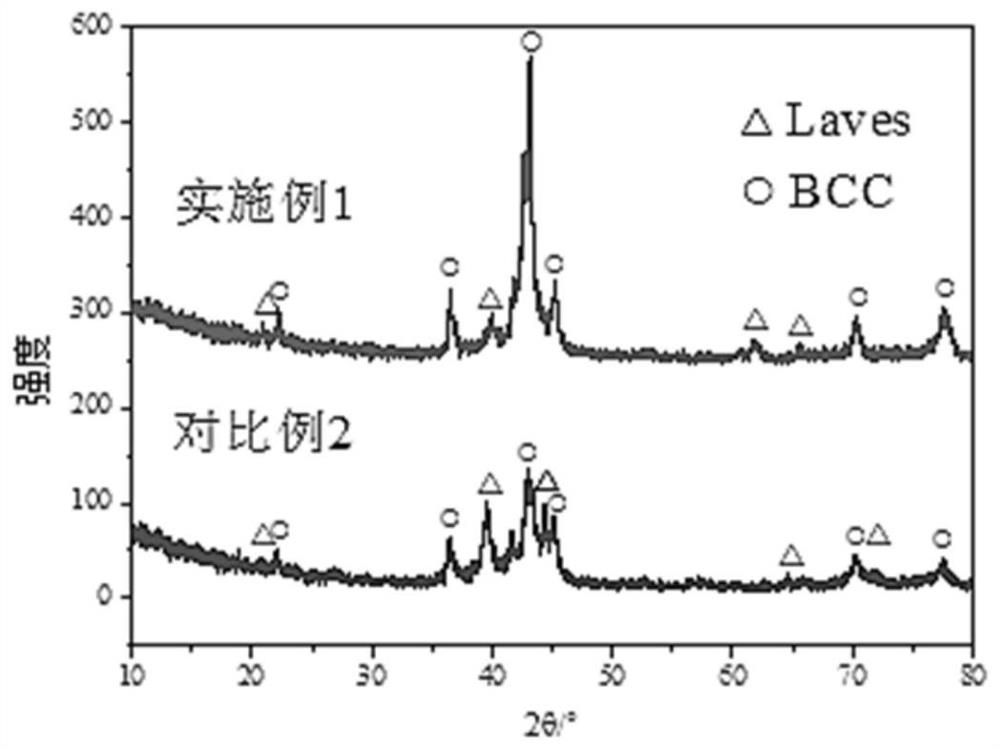

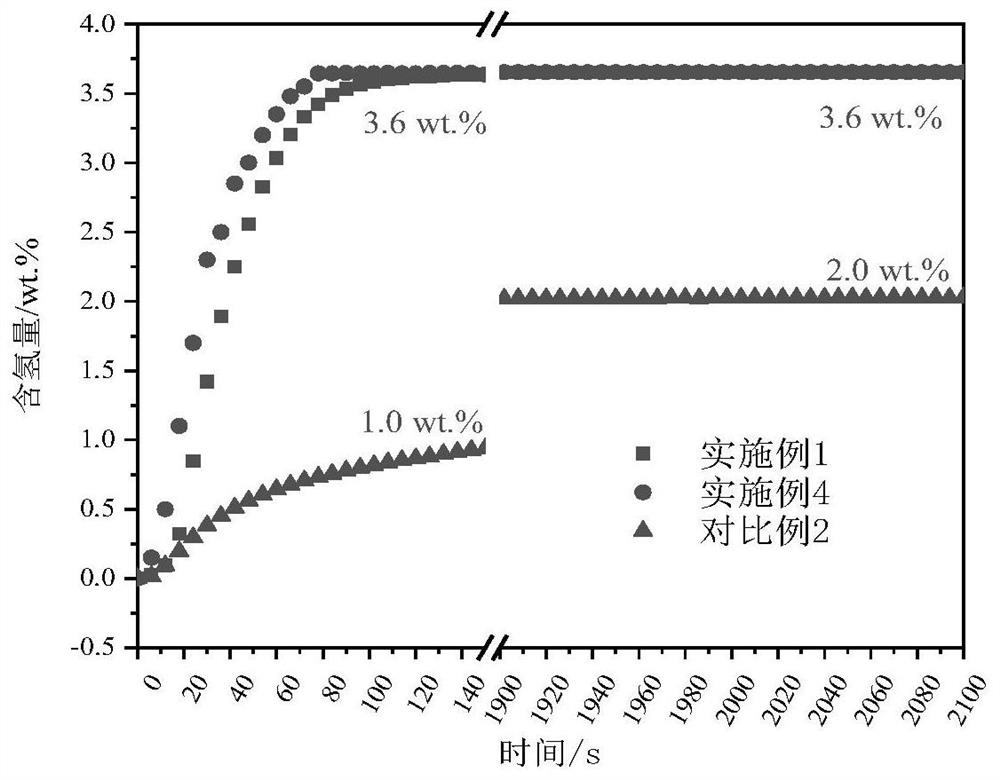

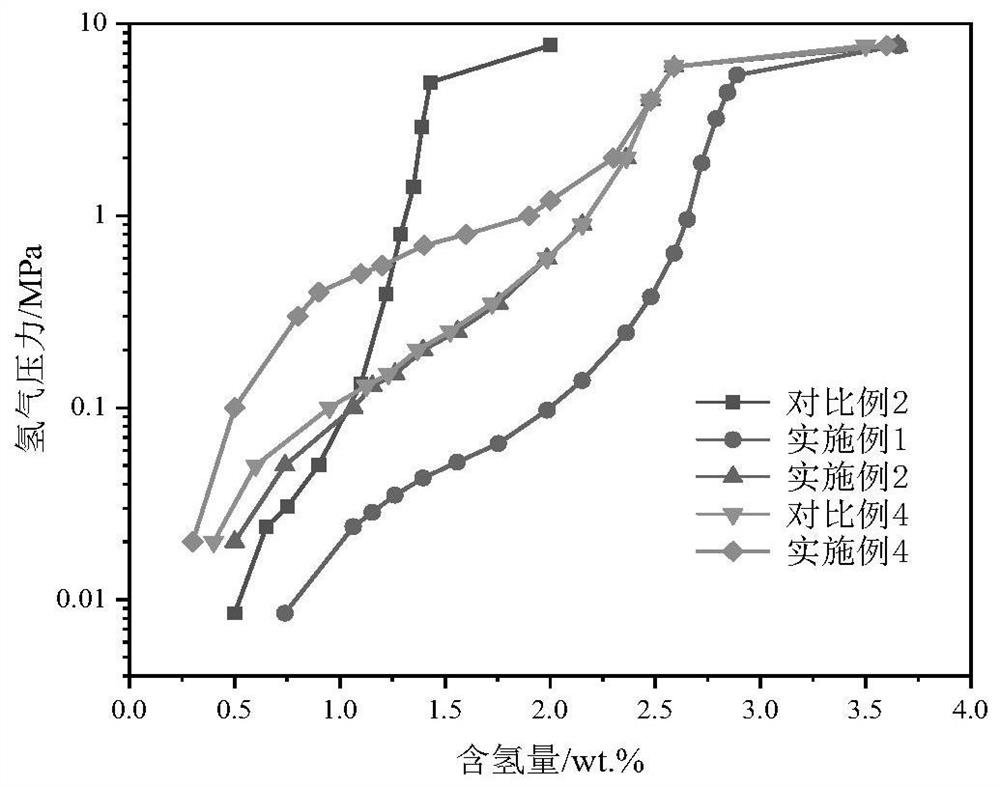

ActiveCN112877567BEasy to operateProcess conditions are easy to controlHydrogenPhysical chemistryHeat treating

The invention discloses a hydrogen storage alloy suitable for low-pressure solid-state hydrogen storage and a preparation method thereof. The hydrogen storage alloy can be composed of R 1‑x‑y m x Mg y (Ni 1‑b T b ) a The general chemical formula shows that, in the formula, x , y , a , b Indicates the molar ratio, 0≤ x ≤0.35, 0.15≤ y ≤0.30, 2.90≤ a ≤4.10, and b The value satisfies 0≤a b ≤0.20; the present invention also provides a preparation method of the above alloy, which prepares a hydrogen storage alloy through batching, smelting and heat treatment. The preparation method is simple and can effectively eliminate AB in the alloy. 5 Phase and AB 2 The phase non-superlattice structure ensures the purity of the superlattice phase structure and the hydrogen storage performance of the obtained alloy. The hydrogen storage alloy prepared has a reversible hydrogen absorption and desorption capacity greater than 1.6wt% at 25~100°C, within 5 minutes That is to absorb and release hydrogen to more than 80% of the maximum capacity, and the hydrogen release platform pressure is greater than 1MPa.

Owner:包头中科轩达新能源科技有限公司

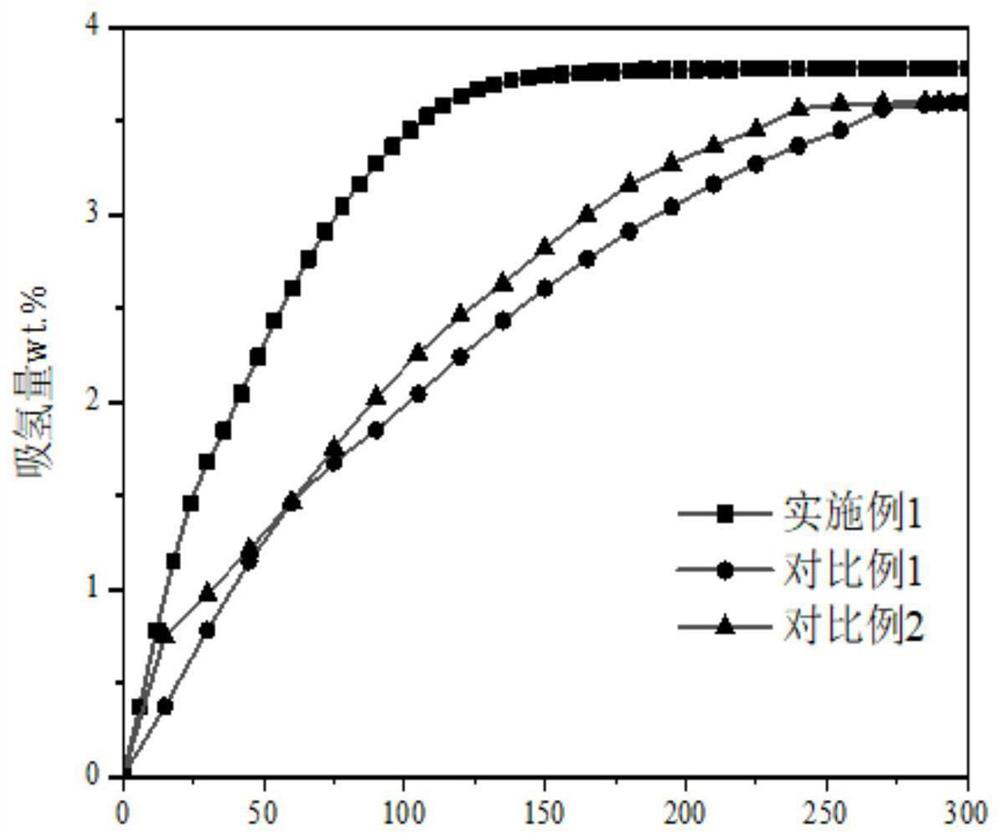

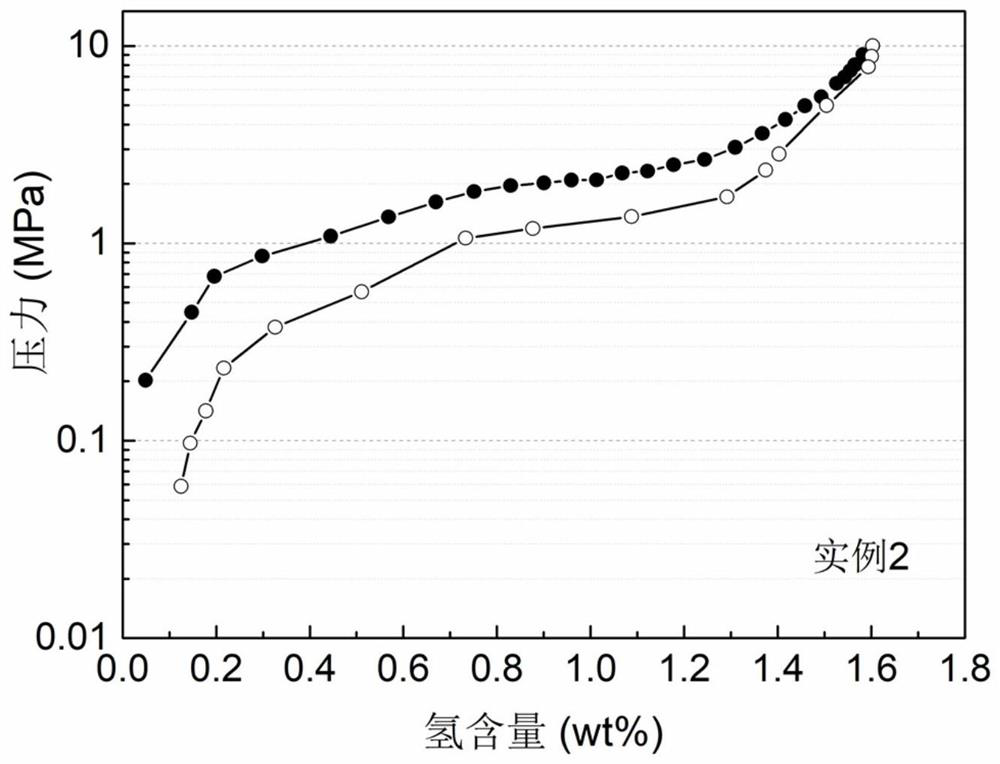

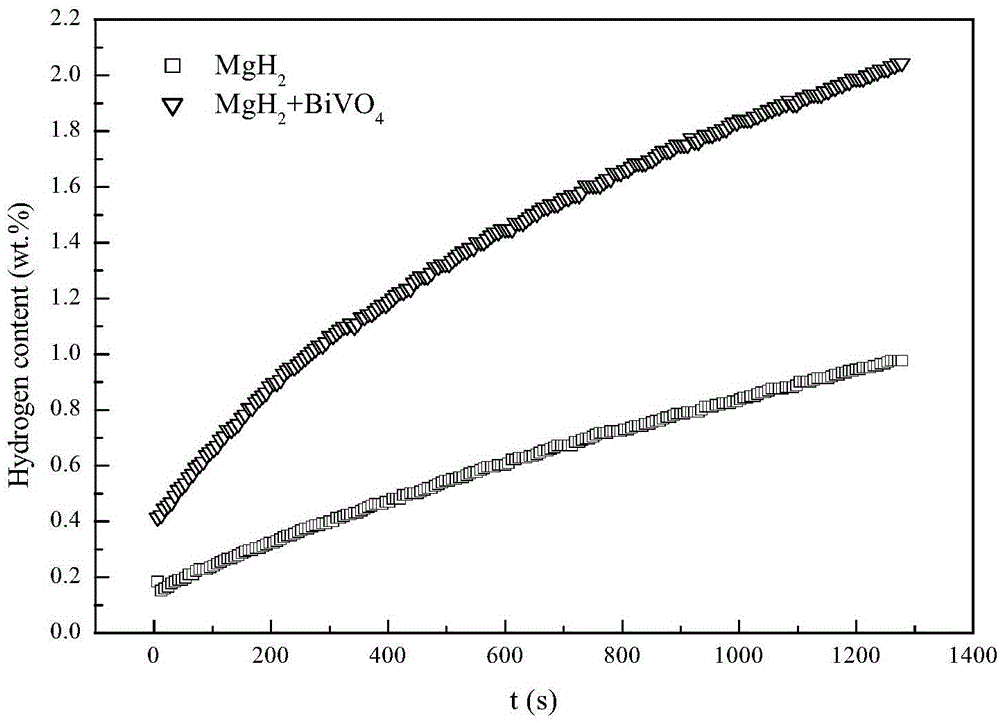

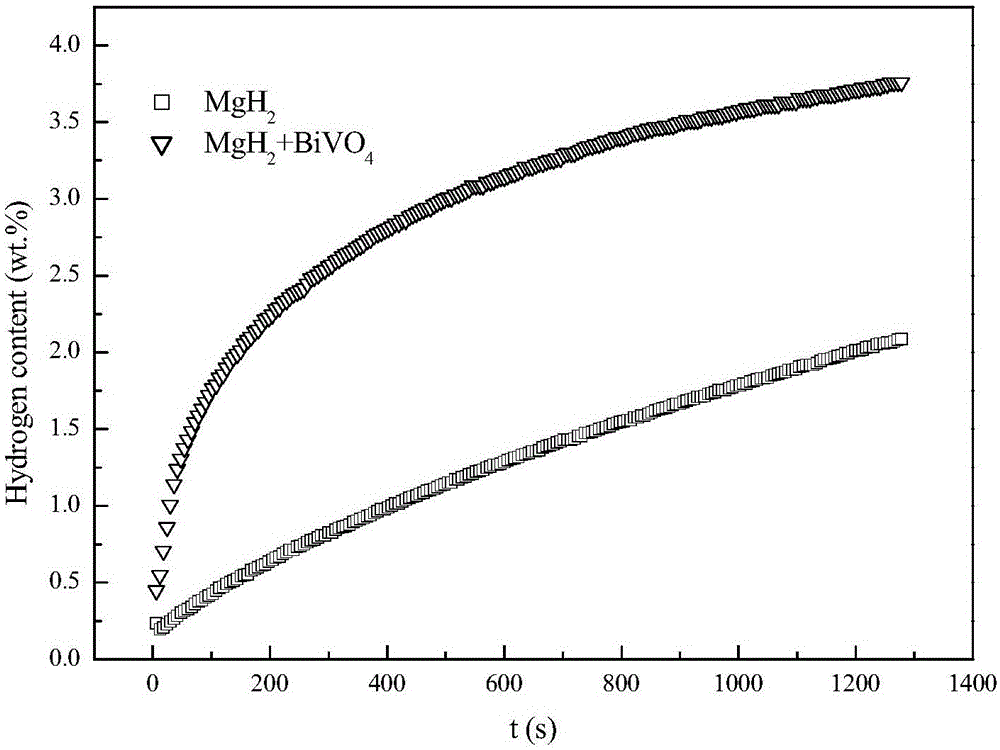

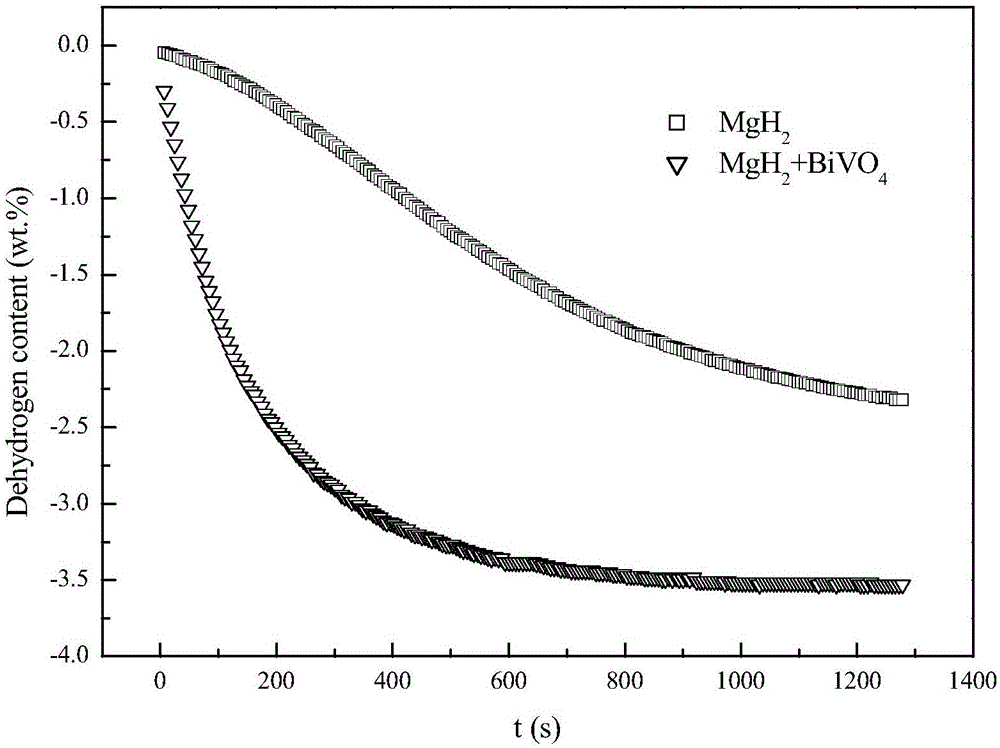

mgh2-bivo4 hydrogen storage composite material and preparation method thereof

InactiveCN103864012BImprove hydrogen absorption/desorption performanceFast hydrogen absorption and desorption rateHydrogen productionMass ratioRoom temperature

The invention discloses an MgH2-BiVO4 hydrogen storage composite material which consists of MgH2 and BiVO4, wherein the content of the BiVO4 accounts for 10-40% of the total mass of the composite material. A preparation method of the hydrogen storage composite material comprises the following steps: in a glove box protected by argon, putting the MgH2 powder and the BiVO4 in a ball milling tank, and performing ball milling in the presence of 0.1-0.5MPa argon at a ball-material mass ratio of (15-35):1 and the revolving speed of 450-550r / min for 1-3 hours, wherein 15-25 minutes of intermittence is spaced between every two times of 20-45 minutes of ball milling; after the ball milling, naturally cooling to the room temperature so as to obtain the MgH2-BiVO4 hydrogen storage composite material. Under relatively low temperature, compared with the MgH2 without the addition of BiVO4, the hydrogen absorption rate and maximum hydrogen absorption amount of the hydrogen storage composite material are improved by more than one time; at the same time, the preparation method is simple, the preparation cost is low and the hydrogen storage composite material is suitable for industrialization-scale preparation.

Owner:YANSHAN UNIV

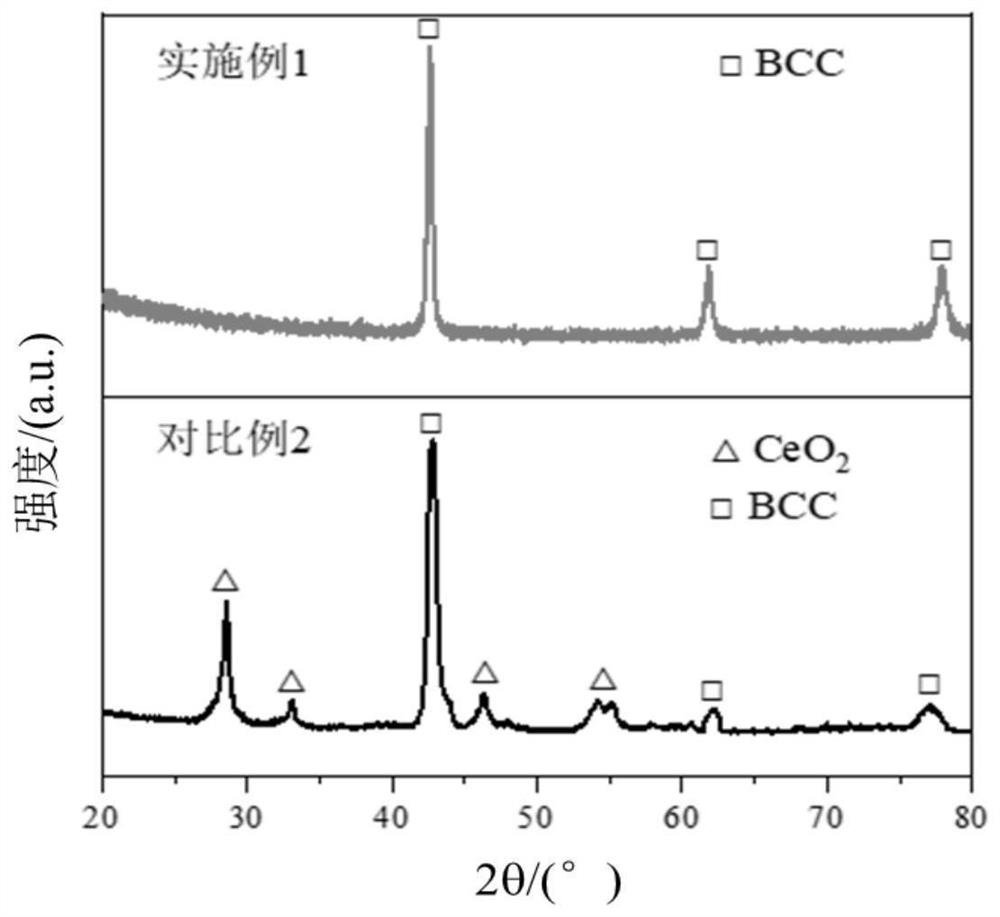

A low vanadium hydrogen storage alloy and its preparation method and use

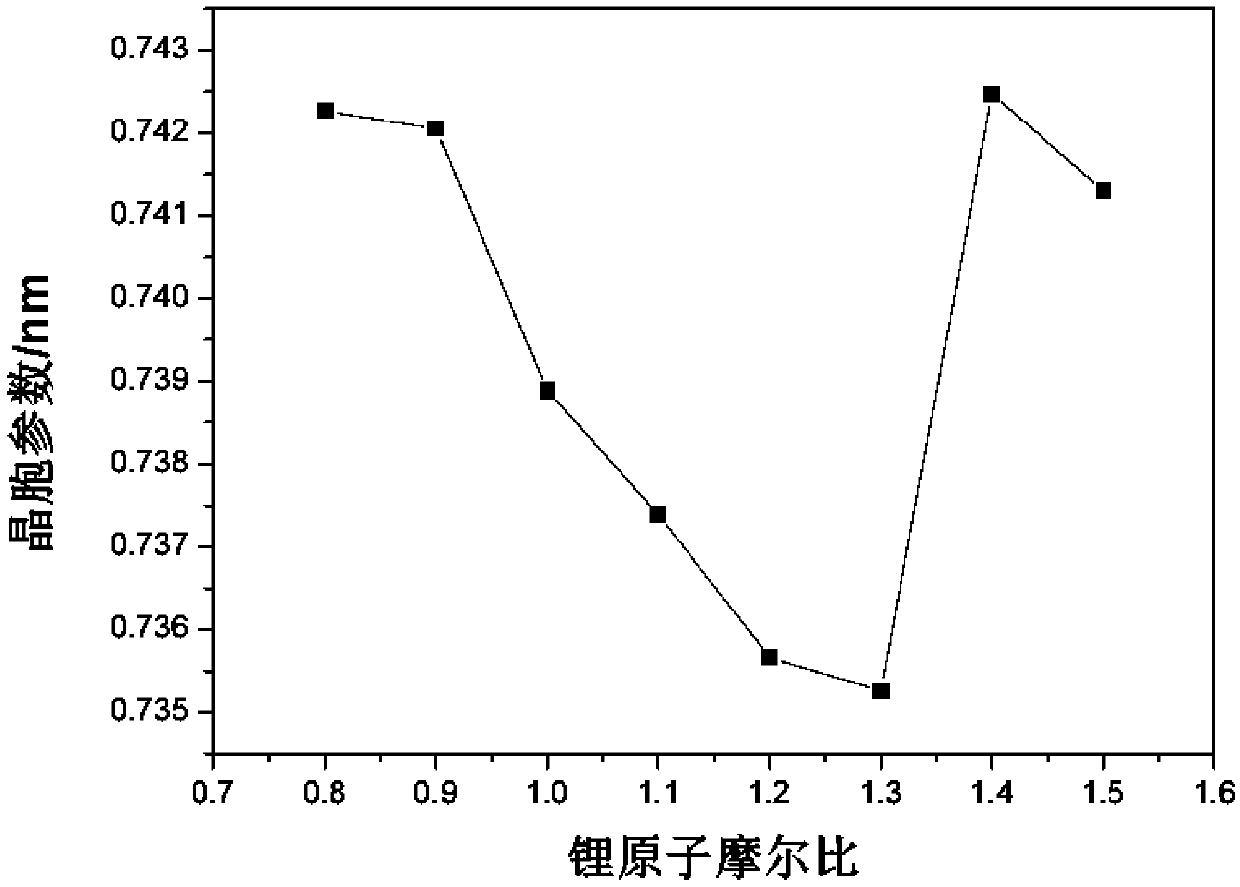

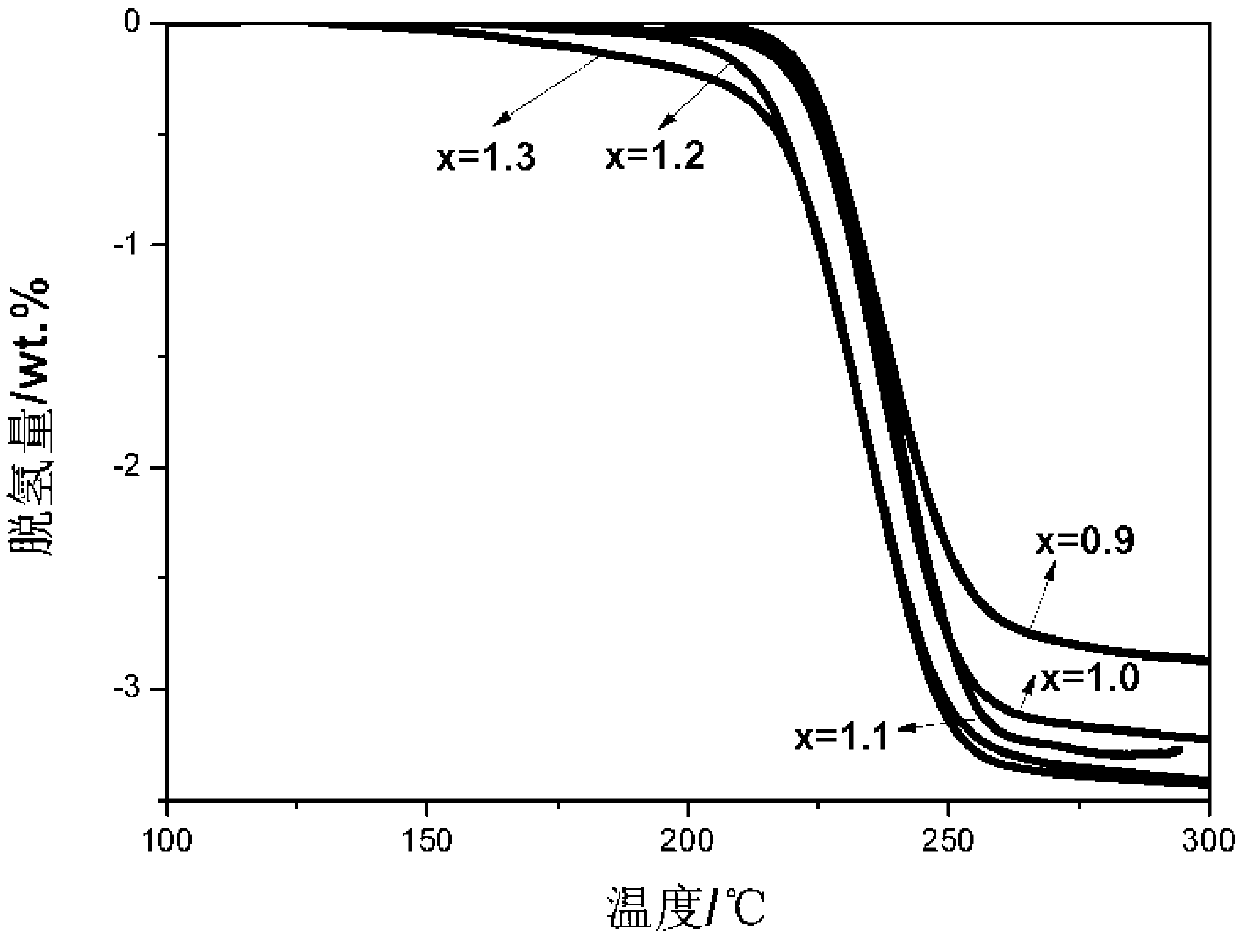

ActiveCN112593135BImprove performanceFast hydrogen absorption and desorption rateHydrogenVanadium atomCrystallinity

The invention relates to a low vanadium hydrogen storage alloy and its preparation method and use. The element composition of the low vanadium hydrogen storage alloy is: (TiV a ) x (CrMo b ) y M 1‑x‑y ; Among them, M is one or a combination of at least two of Zr, Fe, Mn or Ce, x=0.4-0.5, y=0.5-0.6, a=0.05-0.15, b=0.05-0.15. The preparation method includes the following steps: (1) batching according to the formula, and then smelting to obtain an intermediate material; (2) sequentially subjecting the intermediate material obtained in step (1) to vacuum casting and heat treatment to obtain the hydrogen storage alloy . The low vanadium hydrogen storage alloy provided by the present invention, through the optimized design of each component, phase control and process optimization, significantly increases the effective hydrogen release amount, has good cycle performance, high activity and high crystallinity, and has a simple preparation process. The preparation cost is low.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI +2

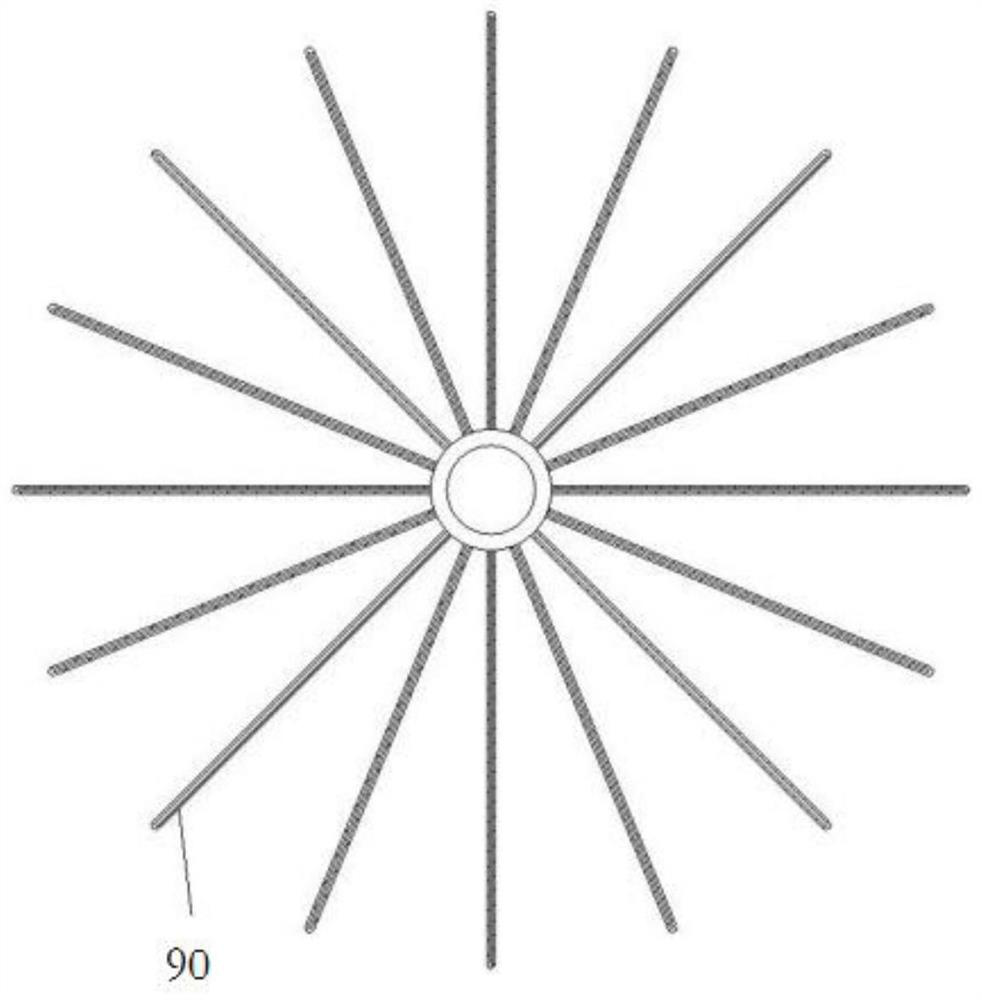

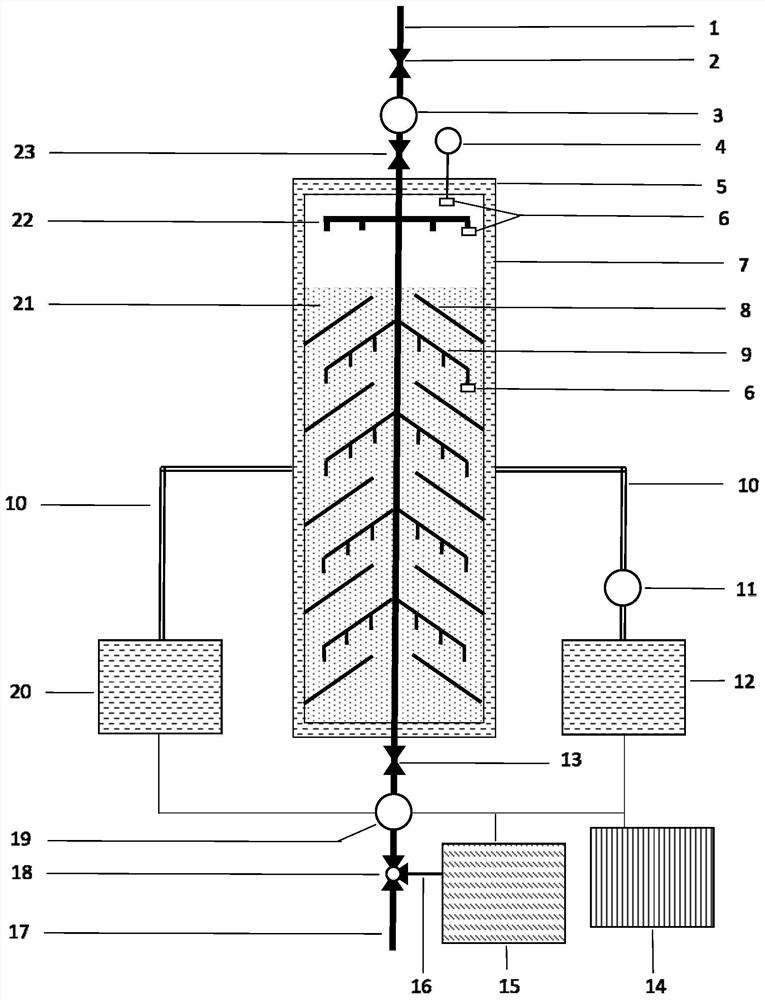

A hydrogen purification device with a fishbone structure

ActiveCN110526212BEasy dischargeArrive quicklyHydrogen separation by selective and reversible uptakeMetallurgyPhysical chemistry

The invention discloses a hydrogen purifying device with a herringbone structure, which comprises a reaction vessel connected with the inlet and exhaust pipes, and the inner chamber of the reaction vessel is provided with a herringbone structure connected with the inlet and exhaust pipes. Hydrogen pipelines are arranged in a shape, and the inner cavity of the reaction vessel is also provided with heat sinks arranged in a herringbone shape, and the hydrogen pipelines and heat sinks are arranged alternately. The invention adopts the hydrogen diffusion pipeline of the fishbone structure and the corresponding heat exchange inner wall, which greatly improves the heat exchange effect during hydrogen absorption and desorption, and significantly improves the hydrogen absorption and desorption rate of the hydrogen storage alloy. The hydrogen of the fishbone structure The pipeline and the inner wall can disperse the stress generated when the hydrogen storage alloy absorbs and releases hydrogen, enhance the pressure bearing strength of the device, and also prevent the hydrogen storage alloy powder from accumulating at the bottom of the device after a long period of use. Therefore, the device can greatly improve the purification efficiency of hydrogen in actual use, and it is also more guaranteed in terms of service life and safety.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD +1

A preparation method of in-situ growth nano-magnesium hydride loaded high specific surface material

ActiveCN106865497BLower operating temperatureFast hydrogen absorption and desorption rateHydrogenAlkali/alkaline-earth/beryllium/magnesium hydridesOperating temperatureHydrogen absorption

Owner:NANKAI UNIV

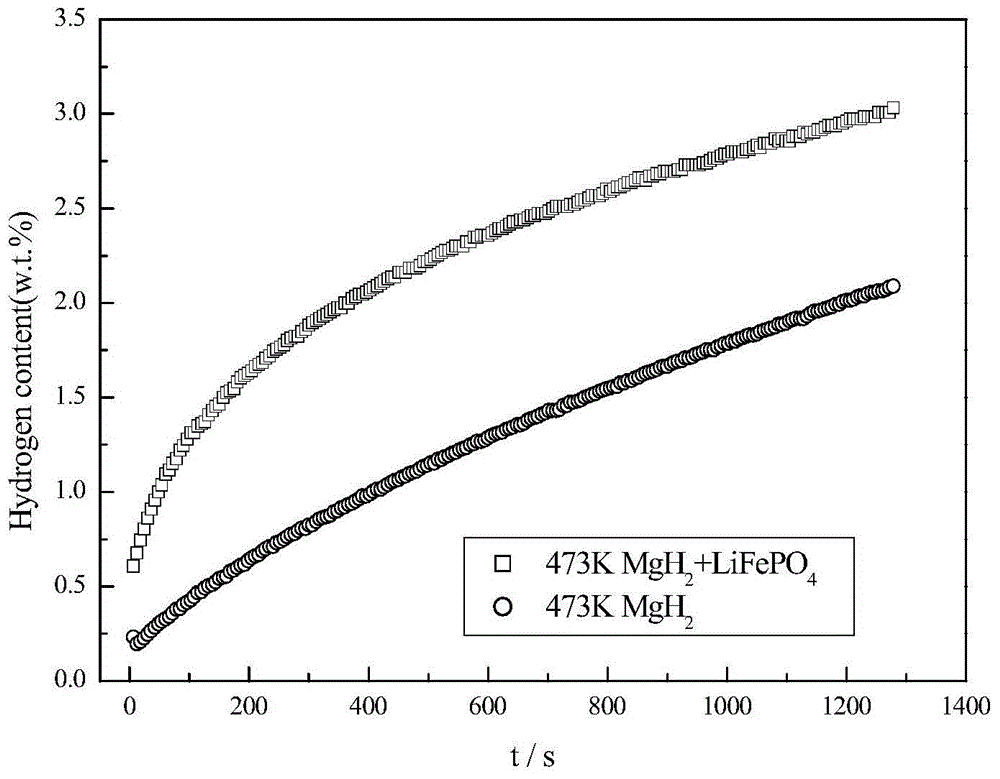

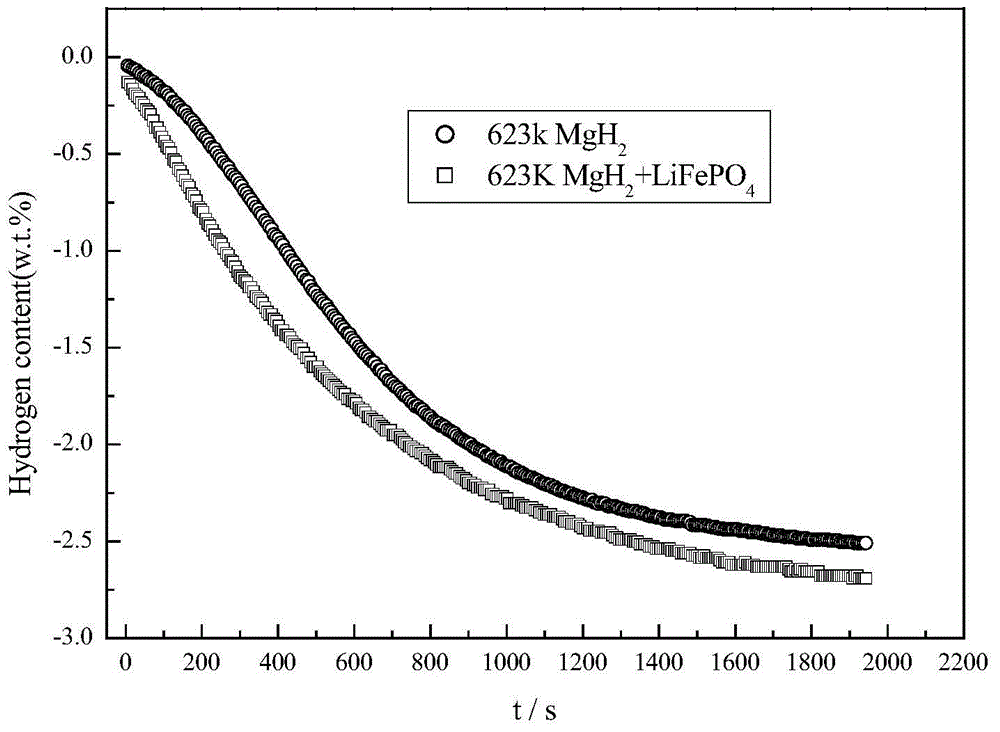

Magnesium metal hydride phosphate complex hydrogen storage composite material and preparation method

InactiveCN103787271BImprove hydrogen absorption and desorption performanceFast hydrogen absorption and desorption rateHydrogen productionPhosphateArgon atmosphere

Owner:YANSHAN UNIV

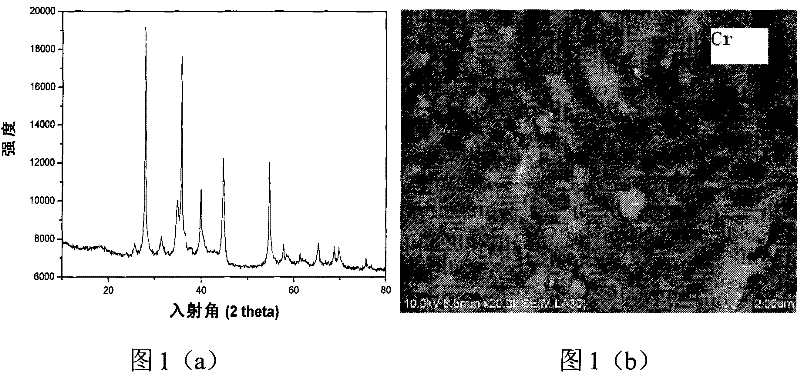

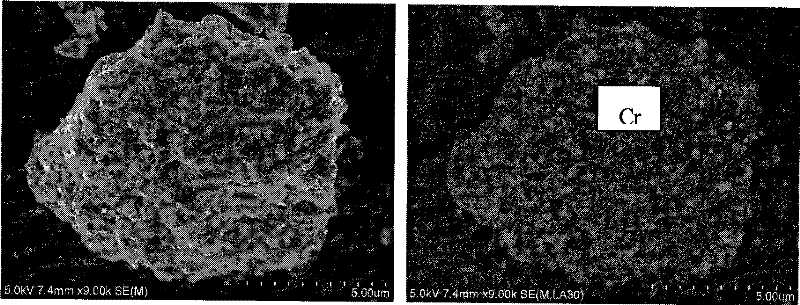

Nano-catalysis complex nitride hydrogen storing material and method for preparing the same

ActiveCN101293630BImproved hydrogen absorption and desorption rateFast hydrogen absorption and desorption rateHydrogen productionHigh pressure hydrogenHigh activity

The invention relates to a nanometer catalysis composite nitride hydrogen storage material and a preparation method thereof; the nanometer catalysis composite nitride hydrogen storage material is characterized in that a precursor is decomposed in a nitride substrate to precipitate nanometer catalysis phase with high activity, so as to realize quick reversible hydrogen absorption and desorption; more particularly, the nitride hydrogen storage material is the nitride composite material system of alloying magnesium powders and LiNH2 nanometer phase which has catalysis effect is uniformly arranged in the LiNH2 substrate; the alloying magnesium powders is a multiple catalysis material system which is formed by Mg powder and transition elements such as Cr, Mn, Ti, Fe, Cu, Ni and Y or other mixtures. The preparation method is characterized in that the nitride hydrogen storage material with high hydrogen absorption and desorption rate is gained by a two-step method: high-pressure hydrogen atmoesphere reaction ball-grinding alloying and inertia gas protection ball-grinding compounding. The composite nitride hydrogen storage material with high hydrogen absorption and desorption rate can be gained by the preparation method of the invention.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com