Magnesium-based hydrogen storage alloy and preparation method thereof

A magnesium-based hydrogen storage alloy and alloy powder technology, which is applied in the field of hydrogen storage materials, can solve the problems that restrict the large-scale application and promotion of magnesium-based hydrogen storage alloys, slow hydrogen absorption and desorption rate, and poor hydrogen absorption and desorption performance, and achieve improved absorption and desorption. Hydrogen desorption performance, improving low-temperature hydrogen absorption and desorption capacity and hydrogen absorption and desorption rate, improving low-temperature hydrogen absorption and desorption performance and the effect of hydrogen absorption and desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

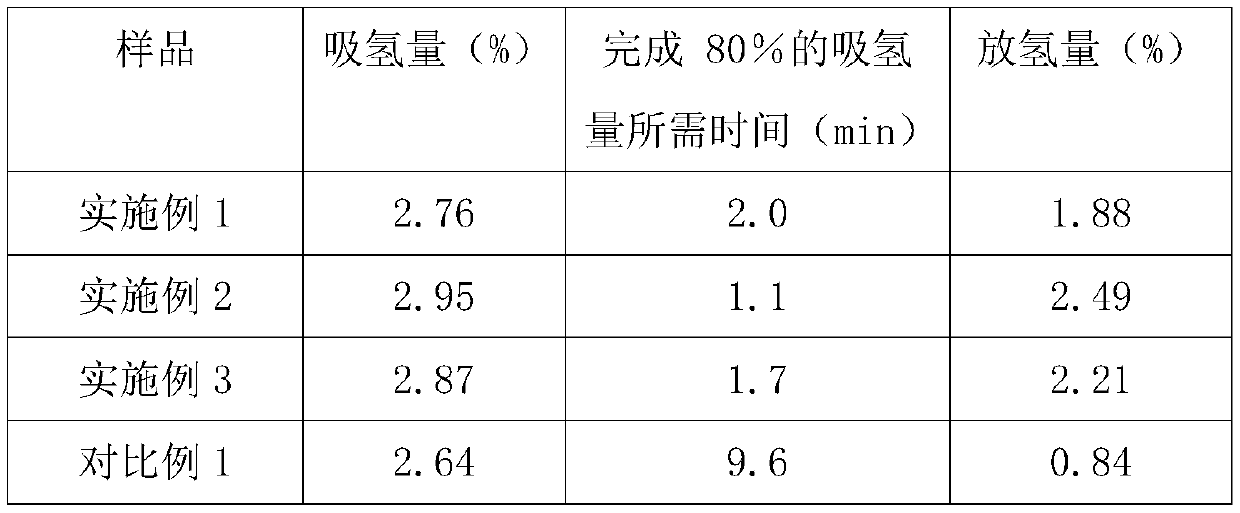

Examples

Embodiment 1

[0025] A magnesium-based hydrogen storage alloy, which is made of Mg 2 Ni alloy powder made with nickel-coated carbon nanotubes, Mg 2 The weight ratio of Ni alloy powder to nickel-coated carbon nanotubes is 100:0.5.

[0026] Mg 2 The preparation method of Ni alloy powder is as follows: mix Mg and Ni powders with a purity of >99% according to the atomic ratio of 2:1 to obtain mixed metal powder, add the mixed metal powder into a ball mill tank, and then add stainless steel grinding balls, stainless steel grinding balls and all The weight ratio of the mixed metal powder is 1:0.05, put the ball mill jar into the planetary ball mill, and carry out ball milling at room temperature under the protection of argon, the ball milling time is 5h, and the speed is 300r / min, to obtain 2 Ni alloy powder.

[0027] The preparation method of nickel-coated carbon nanotubes is as follows: First, oxidize the multi-walled carbon nanotubes with a diameter of 10-20nm and a length of 5-10μm in a 4m...

Embodiment 2

[0034] A magnesium-based hydrogen storage alloy, characterized in that it is made of Mg 2 Ni alloy powder made with nickel-coated carbon nanotubes, Mg 2 The weight ratio of Ni alloy powder to nickel-coated carbon nanotubes is 100:0.8.

[0035] Mg 2 The preparation method of Ni alloy powder is as follows: mix Mg and Ni powders with a purity of >99% according to the atomic ratio of 2:1 to obtain mixed metal powder, add the mixed metal powder into the ball mill tank, and then add stainless steel grinding balls, stainless steel grinding balls and mix The weight ratio of the metal powder is 1:0.08, put the ball mill jar into a planetary ball mill, and carry out ball milling at room temperature under the protection of argon. 2 Ni alloy powder.

[0036] The preparation method of nickel-coated carbon nanotubes is as follows: First, oxidize the multi-walled carbon nanotubes with a diameter of 10-20nm and a length of 5-10μm in a 4.2mol / L sulfuric acid solution at 55°C for 25min, and ...

Embodiment 3

[0043] A magnesium-based hydrogen storage alloy, which is made of Mg 2 Ni alloy powder made with nickel-coated carbon nanotubes, Mg 2 The weight ratio of Ni alloy powder to nickel-coated carbon nanotubes is 100:1.

[0044] Mg 2 The preparation method of Ni alloy powder is as follows: mix Mg and Ni powders with a purity of >99% according to the atomic ratio of 2:1 to obtain mixed metal powder, add the mixed metal powder into the ball mill tank, and then add stainless steel grinding balls, stainless steel grinding balls and mix The weight ratio of the metal powder is 1:0.1, put the ball mill jar into the planetary ball mill, and carry out ball milling at room temperature under the protection of argon, the ball milling time is 1-h, and the speed is 500r / min to obtain Mg 2 Ni alloy powder.

[0045] The preparation method of nickel-coated carbon nanotubes is as follows: First, oxidize the multi-walled carbon nanotubes with a diameter of 10-20nm and a length of 5-10μm in a 4.5mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com