mgh2-bivo4 hydrogen storage composite material and preparation method thereof

A mgh2-bivo4, composite material technology is applied in the field of hydrogen storage composite materials and their preparation, which can solve the problems of magnesium-based composite materials with less hydrogen desorption, inability to meet wide applications, complex preparation processes, etc., and achieve improved hydrogen absorption/desorption. performance, easy industrialization and promotion, low cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

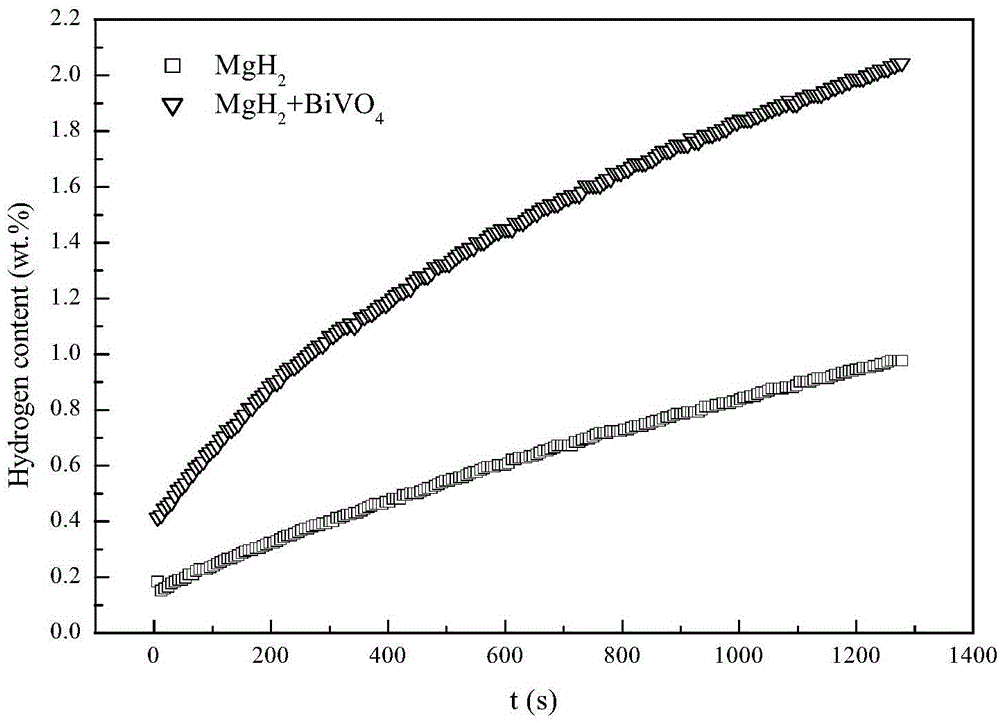

[0017] In an argon-protected glove box, take 2.7gMgH 2 and 0.3gBiVO 4 , placed in the ball mill jar after mixing, adopting Pulverisette6 planetary ball mill to carry out ball milling, put into stainless steel ball 45g, rotating speed is 450r / min, fill the high-purity argon gas of 0.1MPa and carry out ball milling, ball milling time is 1h, every ball milling 20min, Intermittently for 15 minutes, after ball milling, cool down to room temperature naturally, and package under an argon-protected glove box. The prepared MgH 2 Hydrogen storage composite materials were tested for hydrogen absorption rate, and the results were as follows: figure 1 shown. It can be seen from the hydrogen absorption rate curve at 423K in the figure that the MgH 2 BiVO 4 When the hydrogen storage composite material prepared after ball milling is about 400s, the hydrogen absorption capacity is that of pure MgH 2 3 times, and add BiVO 4 After that, the maximum hydrogen absorption capacity and hydroge...

Embodiment 2

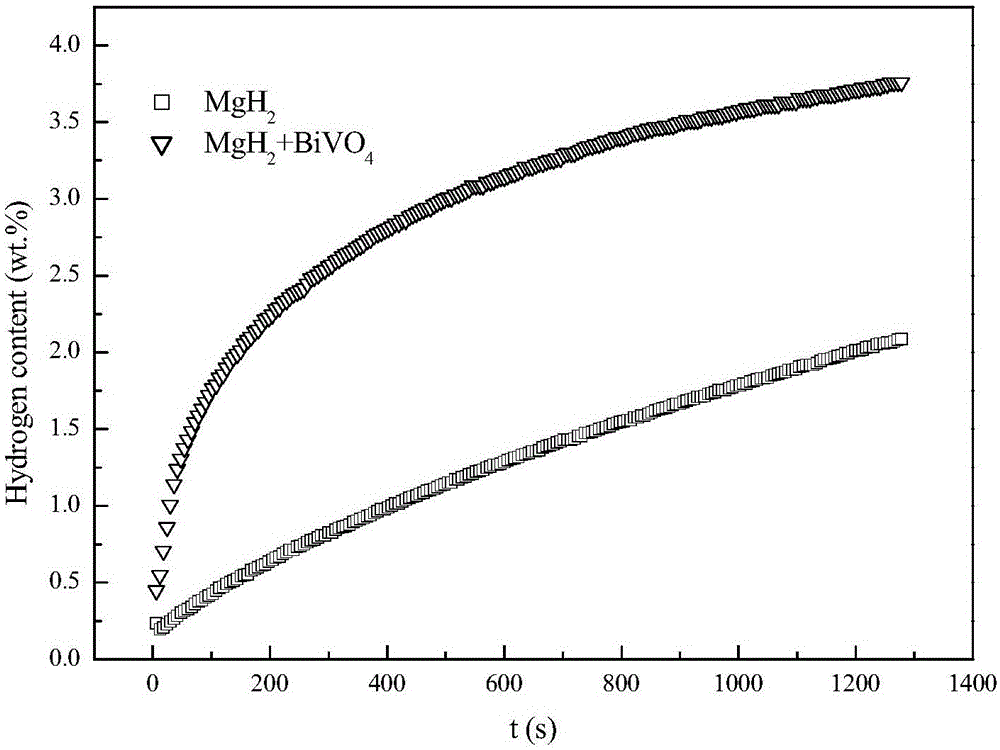

[0019] In an argon-protected glove box, take 2.4gMgH 2 and 0.6gBiVO 4 , after mixing, put it in a ball mill tank, adopt Pulverisette6 planetary ball mill to carry out ball milling, put 60g of stainless steel balls, the rotating speed is 500r / min, fill in high-purity argon gas of 0.2MPa and carry out ball milling, the ball milling time is 2h, every ball milling 30min, Intermittently for 20 minutes, after ball milling, cool down to room temperature naturally, and package under an argon-protected glove box. The prepared MgH 2 Hydrogen storage composite materials were tested for hydrogen absorption rate, and the results were as follows: figure 2 shown. It can be seen from the hydrogen absorption rate curve at 473K in the figure that the MgH 2 BiVO 4 The hydrogen absorption rate of the hydrogen storage composite prepared after ball milling is significantly better than that without BiVO 4 MgH 2 . In addition, when the hydrogen absorption reaches 2wt%, adding BiVO 4 The hyd...

Embodiment 3

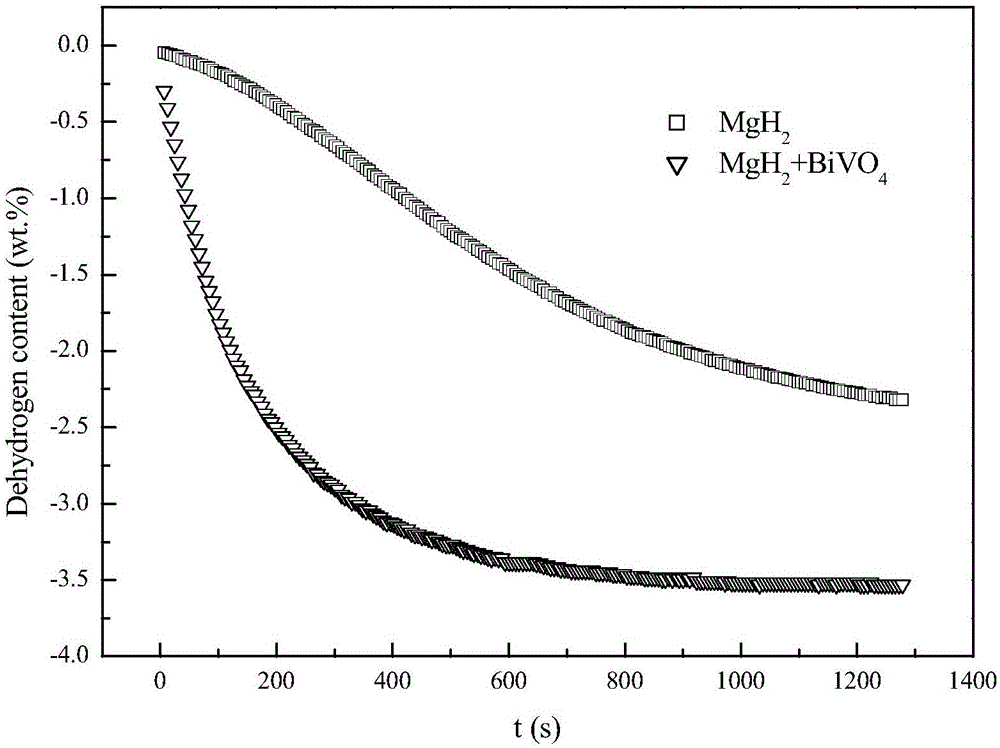

[0021] In an argon-protected glove box, take 2.1 g of MgH 2 and 0.9gBiVO 4 , placed in the ball mill jar after mixing, adopt Pulverisette6 planetary ball mill to carry out ball milling, put into stainless steel ball 75g, rotating speed is 500r / min, fill the high-purity argon gas of 0.3MPa and carry out ball milling, ball milling time is 2h, every ball milling 30min, Intermittently for 20 minutes, after ball milling, cool down to room temperature naturally, and package under an argon-protected glove box. The prepared MgH 2 Hydrogen storage composite materials were tested for hydrogen desorption rate, and the results were as follows: image 3 shown. It can be seen from the hydrogen desorption rate curve at 573K in the figure that the MgH 2 BiVO 4 The hydrogen release rate and hydrogen release capacity of the hydrogen storage composite materials prepared after ball milling have been greatly improved. At 700s, the MgH 2 -BiVO 4 The hydrogen release capacity of the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com