Preparation method of magnesium-based hydrogen storage composite material

A composite material and hydrogen storage technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of high hydrogen desorption temperature, slow hydrogen absorption and desorption rate, easy formation of dense oxide films, etc., and achieve a simple preparation method. , the effect of reducing energy barrier and improving hydrogen absorption/desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A kind of MgH 2 -Ce 0.8 co 0.1 Zr 0.1 o 2 Preparation method of composite material

[0044] This embodiment is a kind of MgH 2 -Ce 0.8 co 0.1 Zr 0.1 o 2 The preparation method of the composite material is prepared according to the following sequence of steps:

[0045] (1) MgH 2 material preparation

[0046] Take a certain amount of Mg powder and place it in a hydrogenation tube, react at 400°C and 4Mpa hydrogen pressure to prepare MgH 2 Material;

[0047] (2) Preparation of additives

[0048] (21) Dissolve cerium nitrate hexahydrate in methanol and water mixed solvent (volume ratio of methanol and water is 7:3), after ultrasonic mixing, the solution is recorded as A;

[0049] (22) Dissolving zirconium oxychloride in ethylene glycol and water mixed solvent (the volume ratio of ethylene glycol and water is 4:1), after ultrasonic mixing, the solution is recorded as B;

[0050] (23) Cobalt nitrate hexahydrate was dissolved in deionized water, and...

Embodiment 2-4

[0057] Embodiment 2-4 A kind of preparation method of magnesium-based hydrogen storage composite material

[0058] In this example, magnesium-based hydrogen storage composite materials were prepared respectively, and the preparation method was similar to that of Example 1, the only difference being that the corresponding technical parameters in the preparation process were different, see the following table for details:

[0059]

Embodiment 5

[0060] Performance test of embodiment 5 magnesium-based hydrogen storage composite material

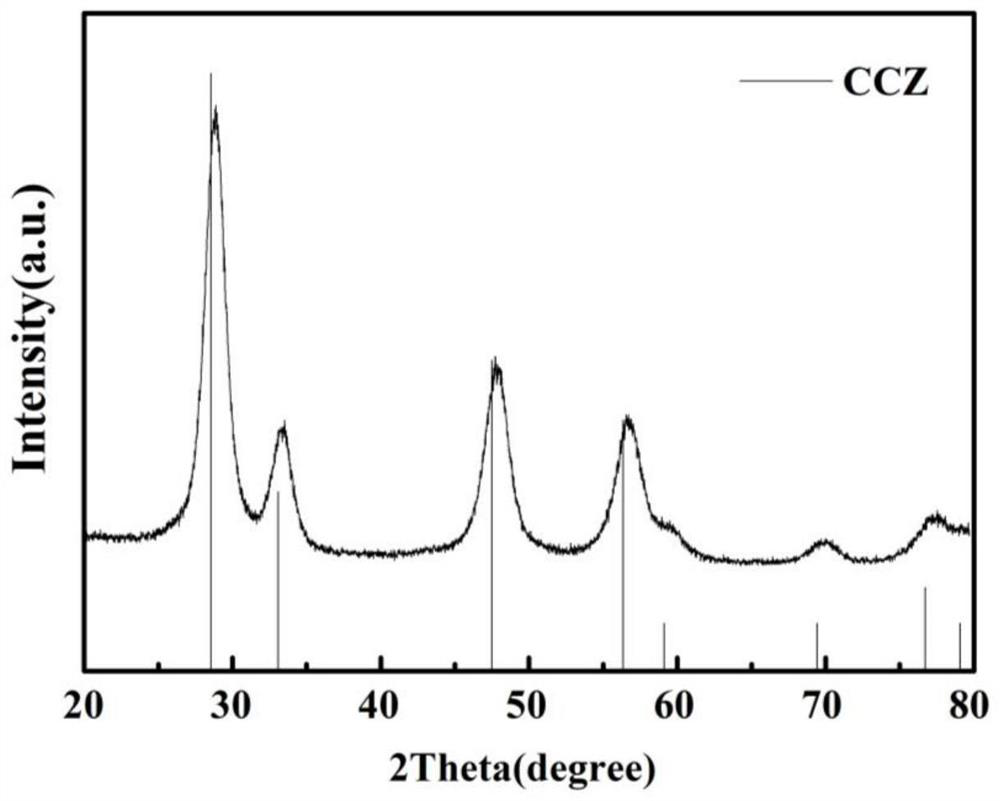

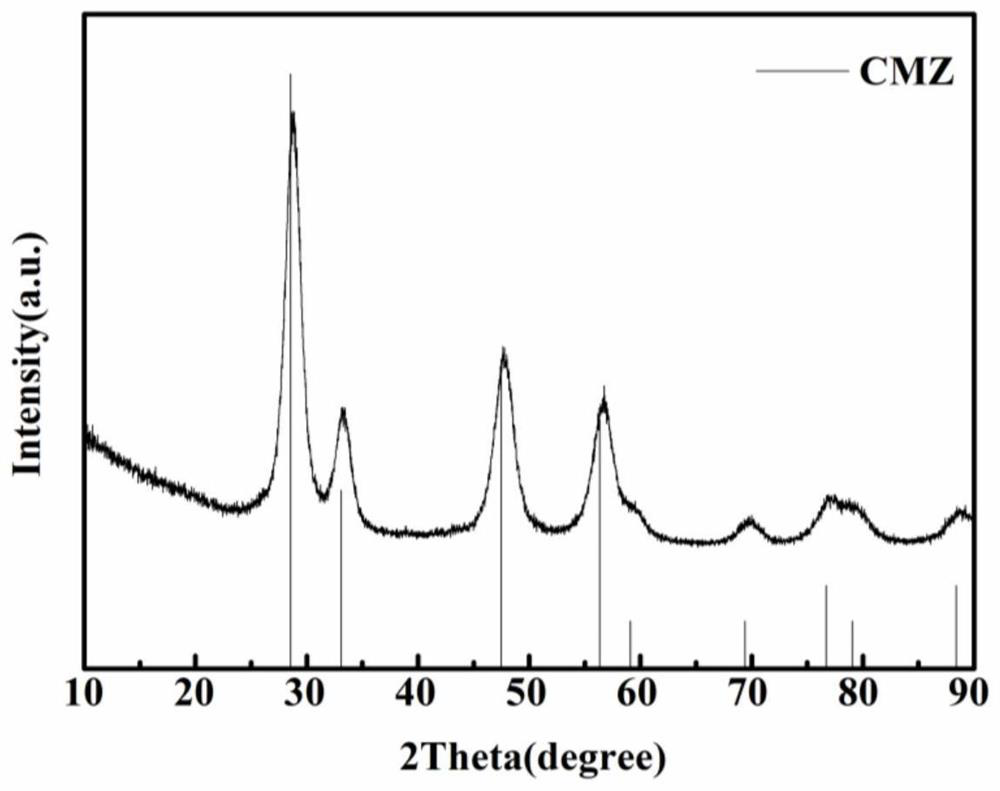

[0061] This embodiment carries out performance test to the composite material prepared in embodiment 1-4, wherein figure 1 and figure 2 Be the sample Ce prepared by the present invention respectively 0.8 co 0.1 Zr 0.1 o 2 XRD patterns and Ce 0.8 mn 0.1 Zr 0.1 o 2 The XRD pattern of the sample, it can be seen from the figure that the synthesized sample Ce 0.8 co 0.1 Zr 0.1 o 2 and Ce 0.8 mn 0.1 Zr 0.1 o 2 The XRD curve of the sample is significantly shifted compared with the standard card (PDF#34-0394), indicating that Mn / Co and Zr have entered CeO 2 Inside, a solid solution is formed.

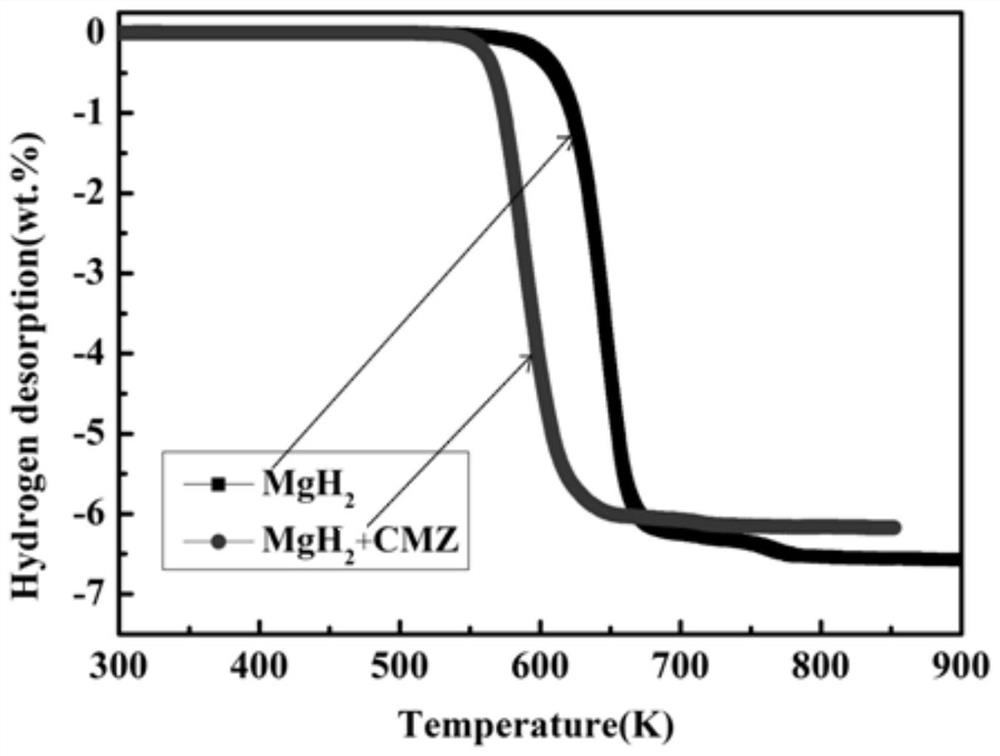

[0062] From Figure 3 to Figure 6 It can be seen that, using the solid solution material obtained by the method of the present invention as a catalyst can significantly improve the MgH 2 The hydrogen absorption and desorption rate and thermodynamic performance. MgH 2 -Ce 0.8 mn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com