Nano-catalysis complex nitride hydrogen storing material and method for preparing the same

A hydrogen storage material and nano-catalysis technology, which is applied in the field of safe and efficient hydrogen storage materials, can solve the problems of poor hydrogen absorption and desorption kinetic performance, and achieve the effect of improving the hydrogen absorption and desorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put Ti powder, Mg powder and balls, which account for 6% of the weight of Mg powder, into a ball mill tank, the hydrogen pressure in the tank is 0.5MPa, the ball mill time is 10 hours, the ball-to-material ratio is 20:1, and the particle size of Ti powder and Mg powder is 10μm, after vacuuming (vacuum degree 1×10 -2 Pa) Charge hydrogen to carry out reaction ball milling, check the pressure change in the tank at an interval of 2 hours, and supplement hydrogen to maintain the hydrogen pressure in the tank.

[0028] Alloyed Mg powder and LiNH 2 The molar ratio is 10:1, the ball milling time is 10 hours, and the ball-to-material ratio is 10:1. Alloyed Mg powder, LiNH 2 The powder and the balls are put into the ball mill pot together, and after vacuuming (vacuum degree 1×10 -2 Pa) filled with argon protective gas for ball milling composite treatment, the argon gas pressure is 0.15MPa to protect the active metal in the tank, and finally a composite nitride hydrogen storage...

Embodiment 2

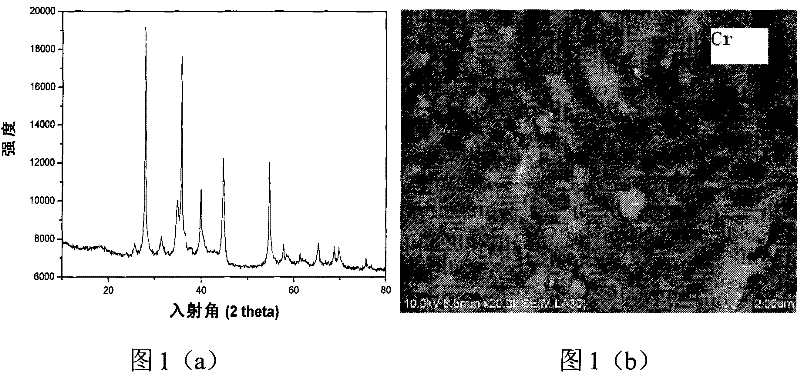

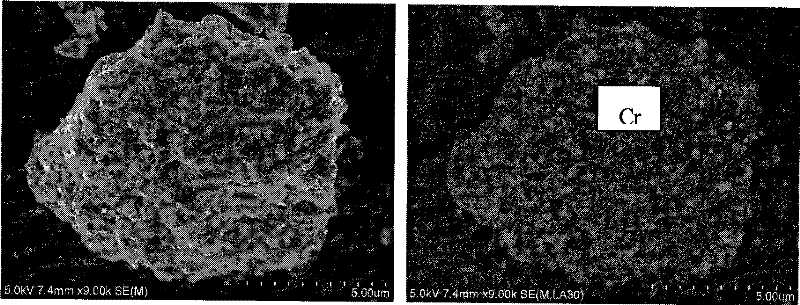

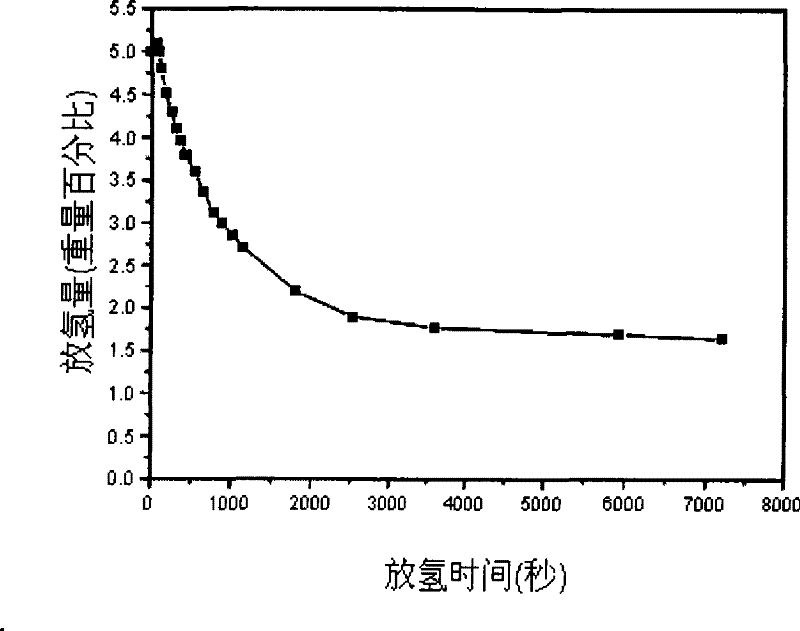

[0031] Put Cr powder, Mg powder and grinding balls accounting for 3% of the weight of Mg powder into the tank, the hydrogen pressure in the tank is 1.0MPa, the ball milling time is 20 hours, the ball-to-material ratio is 30:1, and the particle size of Cr powder and Mg powder is 10 μm , after vacuuming (vacuum degree 1×10 -2Pa) Charge hydrogen to carry out reaction ball milling, check the pressure change in the tank at an interval of 5 hours for ball milling, and supplement hydrogen to maintain the hydrogen pressure in the tank. Fig. 1(a) and Fig. 1(b) show the XRD pattern and microscopic morphology of the alloyed Mg powder.

[0032] Alloyed Mg powder and LiNH 2 The molar ratio is 15:1, the ball milling time is 15 hours, and the ball-to-material ratio is 20:1. Alloyed Mg powder, LiNH 2 The powder and the grinding balls are placed in the tank together, and after vacuuming (vacuum degree 1×10 -2 Pa) filling nitrogen protective gas for ball milling composite treatment, nitroge...

Embodiment 3

[0035] Put Ni powder, Mg powder and balls accounting for 0.5% of the weight of Mg powder into a ball mill tank, the hydrogen pressure in the tank is 2 MPa, the ball mill time is 30 hours, the ball-to-material ratio is 40:1, and the particle size of Ni powder and Mg powder is 10 μm , after vacuuming (vacuum degree 1×10-2Pa), fill with hydrogen for reaction ball milling, check the pressure change in the tank at intervals of 4 hours, and supplement hydrogen to maintain the hydrogen pressure of the tank.

[0036] Alloyed Mg powder and LiNH 2 The molar ratio is 5:1, the ball milling time is 20 hours, and the ball-to-material ratio is 30:1. Alloyed Mg powder, LiNH 2 The powder and the balls are put into the ball mill pot together, and after vacuuming (vacuum degree 1×10 -2 Pa) filled with ammonia protective gas for ball milling composite treatment, the ammonia gas pressure is 0.12MPa to protect the active metal in the tank, and finally a composite nitride hydrogen storage material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com