Nanocrystalline amorphous Mg-M-Y hydrogen storage alloy and preparation method and application thereof

A technology of hydrogen storage alloy and nanocrystal, which is applied in the field of high-efficiency hydrogen storage materials, can solve the problems of poor hydrogen absorption and desorption performance, and achieve the effect of increasing the rate of hydrogen absorption and desorption, and improving the rate of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The elemental powders of Mg, Y, and Ti are prepared in the following proportions, that is, 80% (weight) of Mg, 5% (weight) of Y, and 15% (weight) of Ti. The prepared Mg powder, Ti powder and Y powder Put into the ball mill tank, the ball-to-material ratio is 20:1, the particle size of Ti powder, Mg powder, and Y powder are all 10μm. After vacuuming, fill with hydrogen for reactive ball milling. The speed of the ball mill is 1200 rpm and the hydrogen pressure in the tank is maintained at 0.5 MPa, the ball milling interval is 2 hours to check the pressure change in the tank, add hydrogen to maintain the hydrogen pressure of the tank, the ball milling time is 40 hours, directly obtain nanocrystalline amorphous Mg 80 Ti 15 Y 5 alloy.

[0023] The alloy has a grain size of 10nm and a particle size of less than 500nm. The components are uniformly dispersed and the hydrogen absorption and desorption rate is significantly improved. The hydrogen absorption can reach 5.5 mass.% at 20...

Embodiment 2

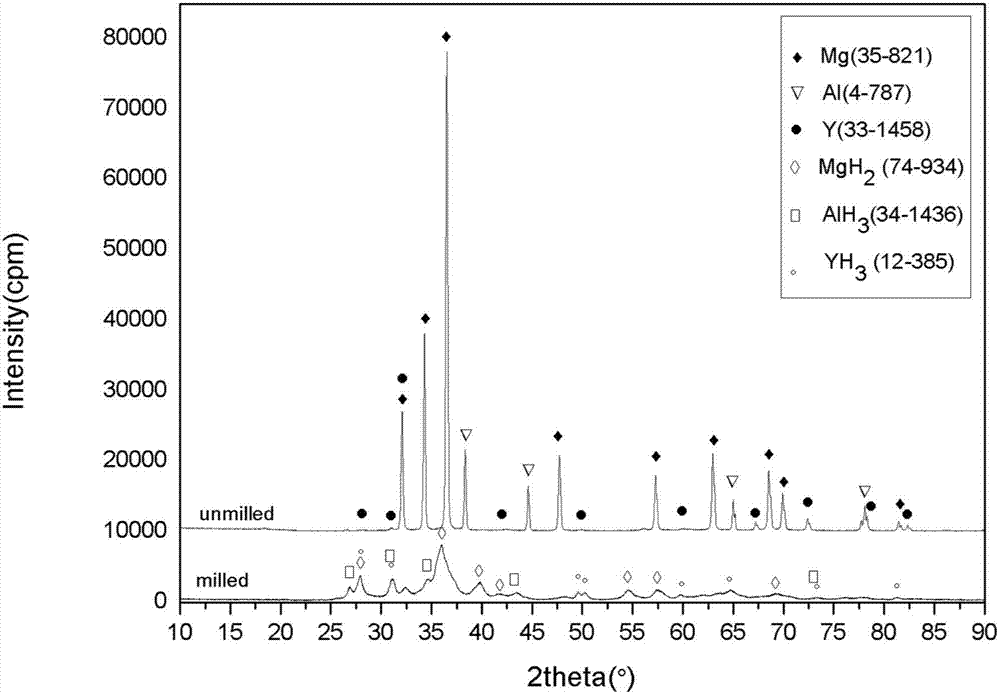

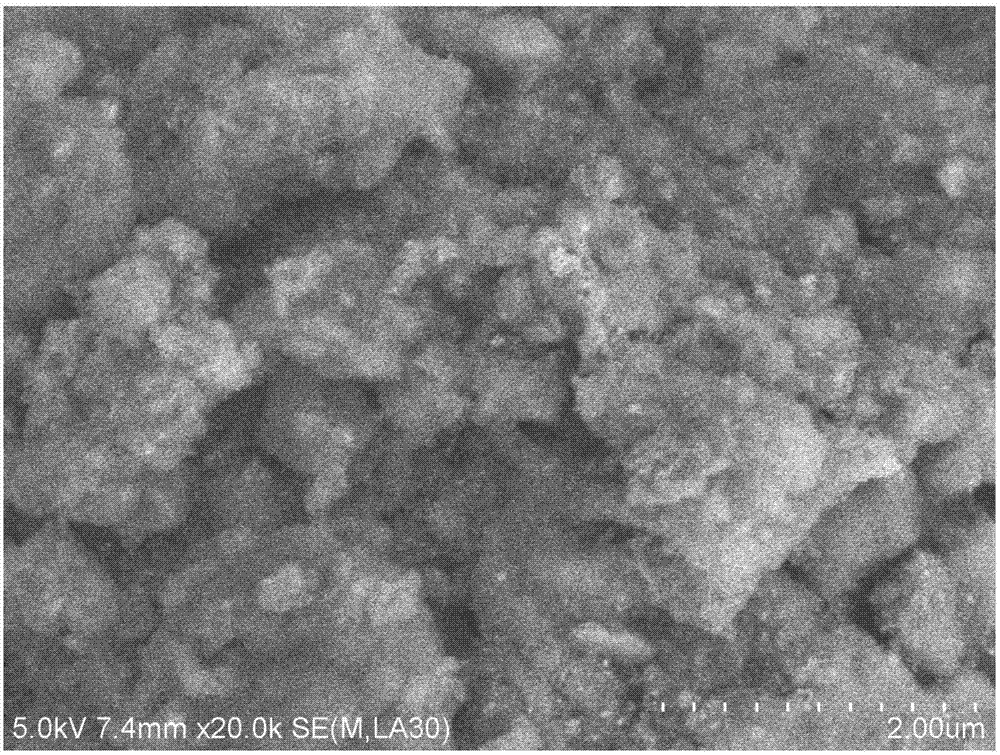

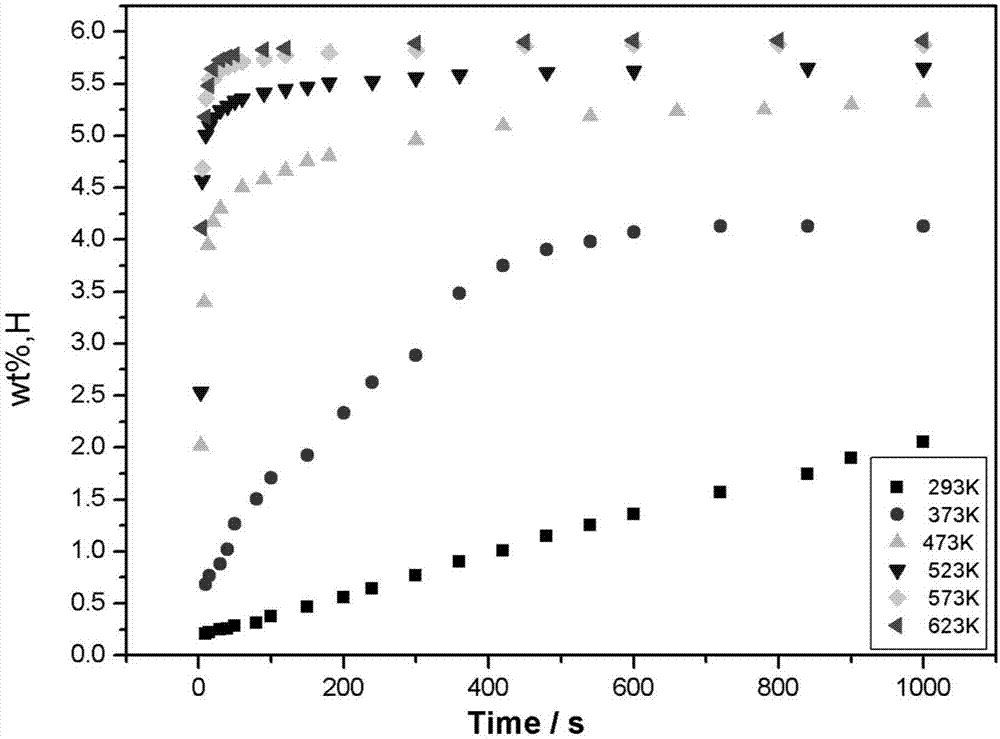

[0025] The elemental powders of Mg, Y, and Al are prepared in the following proportions, that is, Mg is 85% by weight, Y is 9% by weight, and Al is 6% by weight. Place the prepared Mg powder, Al powder and Y powder Into the ball mill tank, the ball-to-material ratio is 30:1, the particle size of Al powder, Mg powder, and Y powder are all 20μm. After vacuuming, hydrogen is charged for reactive ball milling. The speed of the ball mill is 1300 rpm and the hydrogen pressure in the tank is maintained at 1.0 MPa. , The ball milling interval is 2 hours to check the pressure change in the tank, and add hydrogen to maintain the hydrogen pressure of the tank. The ball milling time is 60 hours to directly obtain nanocrystalline amorphous Mg. 85 Al 6 Y 9 alloy.

[0026] The alloy has a grain size of 8nm and a particle size of less than 500nm. The components are uniformly dispersed and the hydrogen absorption and desorption rate is significantly increased. The hydrogen absorption can reach 5.6...

Embodiment 3

[0030] The elemental powders of Mg, Y, and Ni are prepared in the following proportions, that is, Mg is 73% by weight, Y is 12% by weight, and Ni is 15% by weight. Place the prepared Mg powder, Ni powder and Y powder Into the ball mill tank, the ball-to-battery ratio is 40:1, the particle size of Ni powder, Mg powder, and Y powder are both 20μm. After vacuuming, hydrogen is charged for reactive ball milling. The speed of the ball mill is 1400 rpm, and the hydrogen pressure in the tank is 1.5MPa. The ball milling interval is 2 hours to check the pressure change in the tank, and add hydrogen to maintain the hydrogen pressure of the tank. The ball milling time is 40 hours to directly obtain nanocrystalline amorphous Mg. 73 Ni 15 Y 12 alloy.

[0031] The alloy has a grain size of 15nm and a particle size of less than 500nm. The components are uniformly dispersed and the hydrogen absorption and desorption rate is significantly improved. The hydrogen absorption can reach 5.3 mass.% at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com