Patents

Literature

230results about "Hydrogen separation by selective and reversible uptake" patented technology

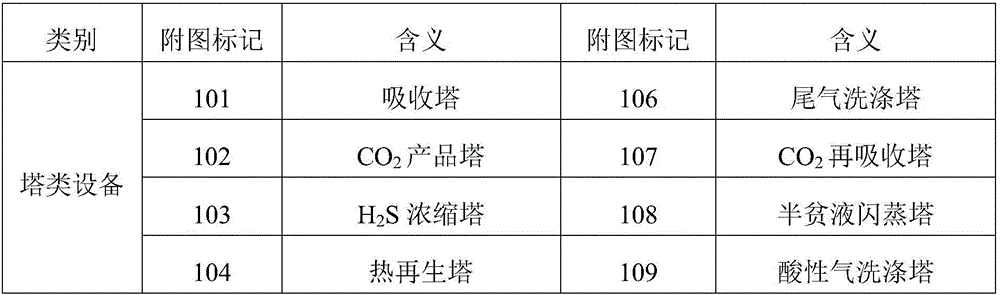

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

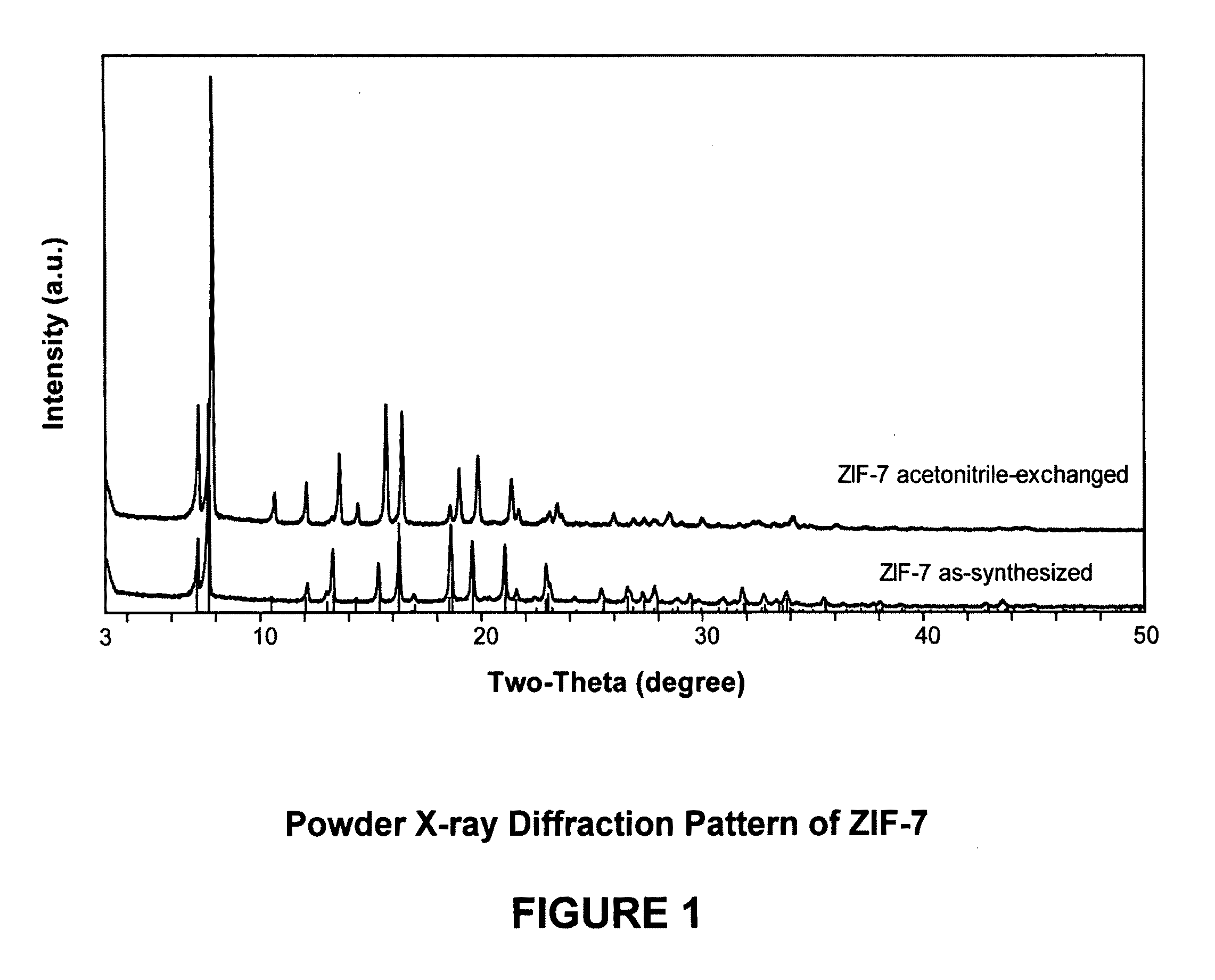

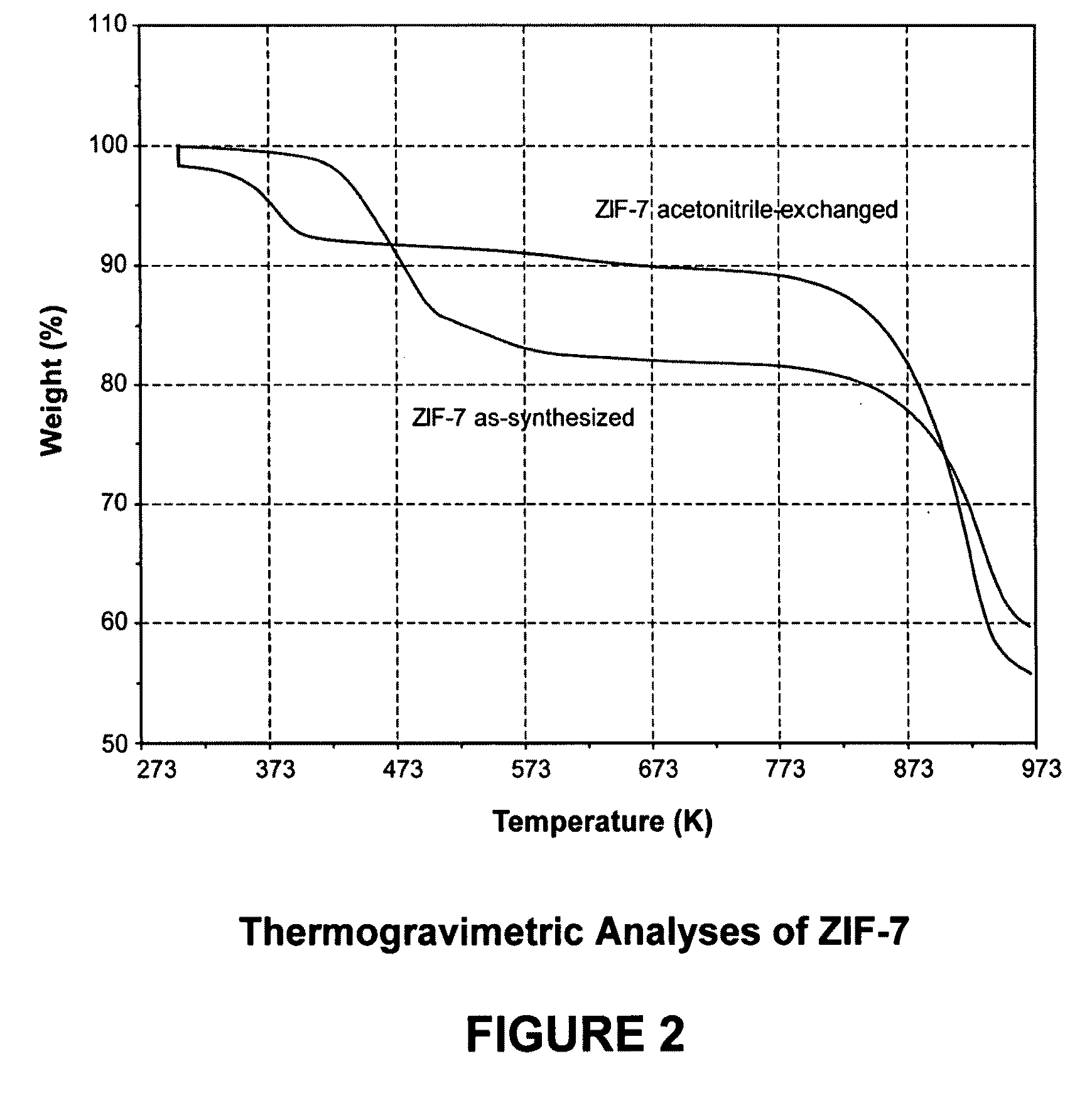

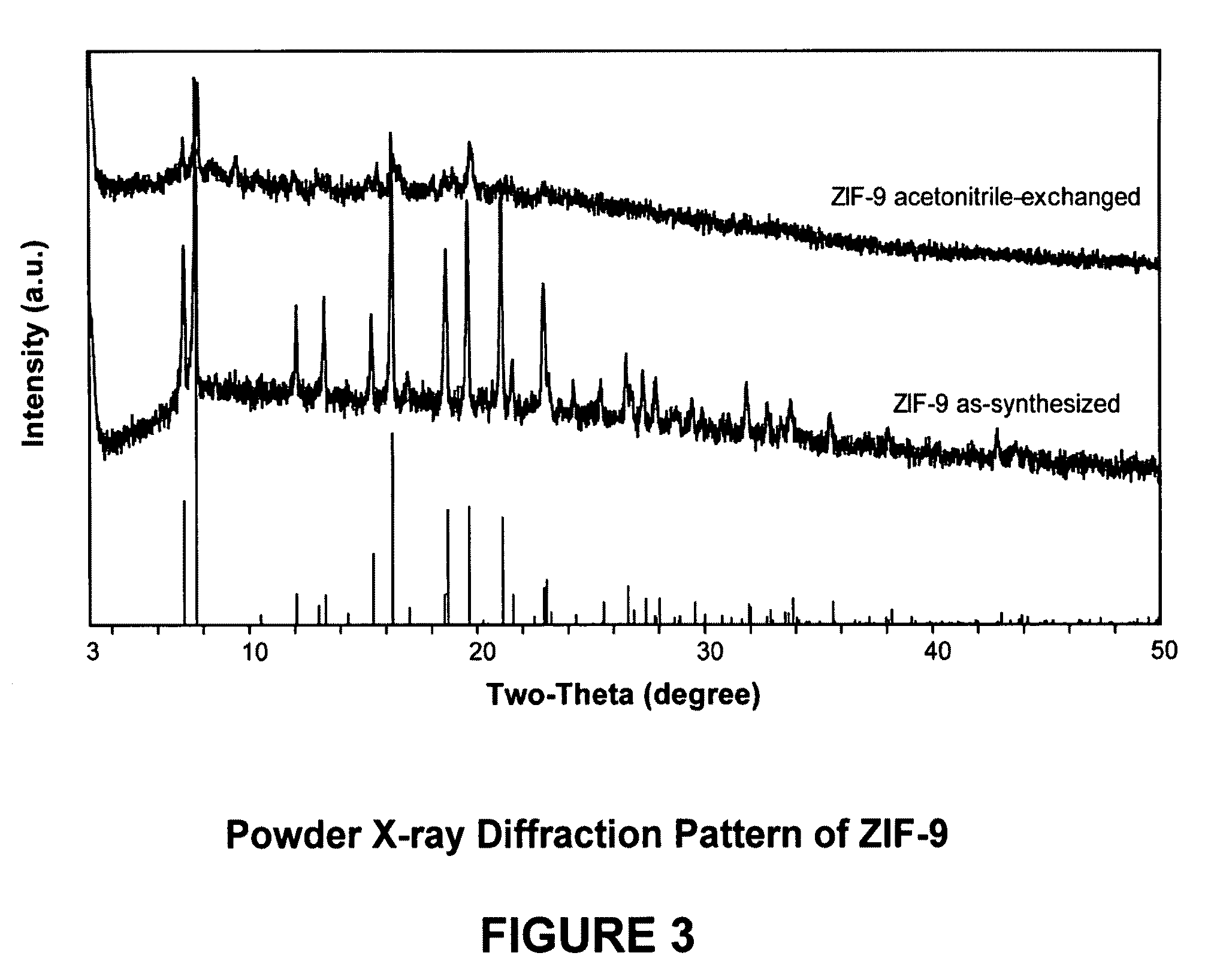

Separation of carbon dioxide from methane utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of carbon dioxide (“CO2”) from methane (“CH4”) in streams containing both carbon dioxide and methane utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate carbon dioxide from natural gas streams preferably for sequestration of at least a portion of the carbon dioxide present in the natural gas.

Owner:EXXON RES & ENG CO

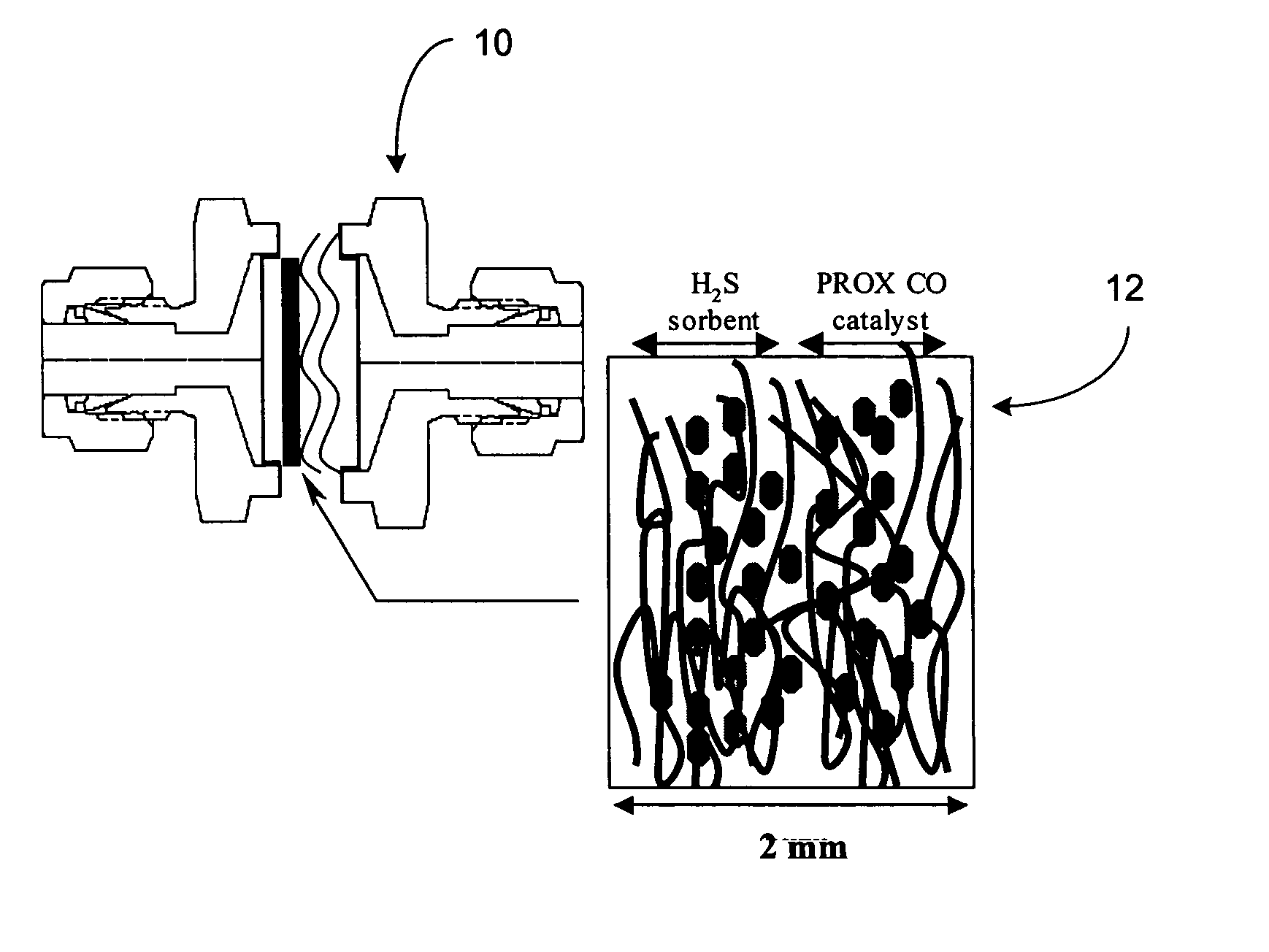

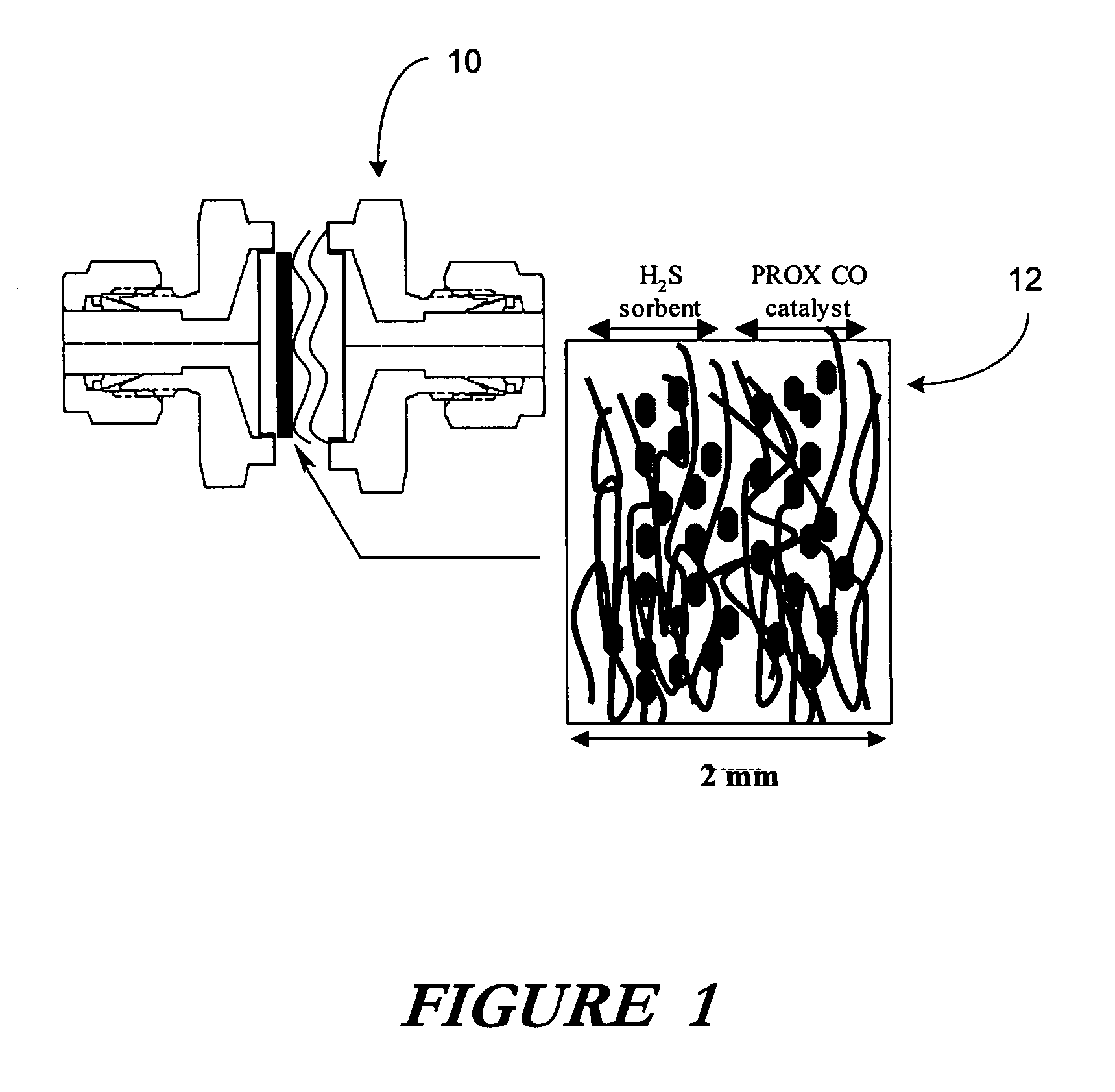

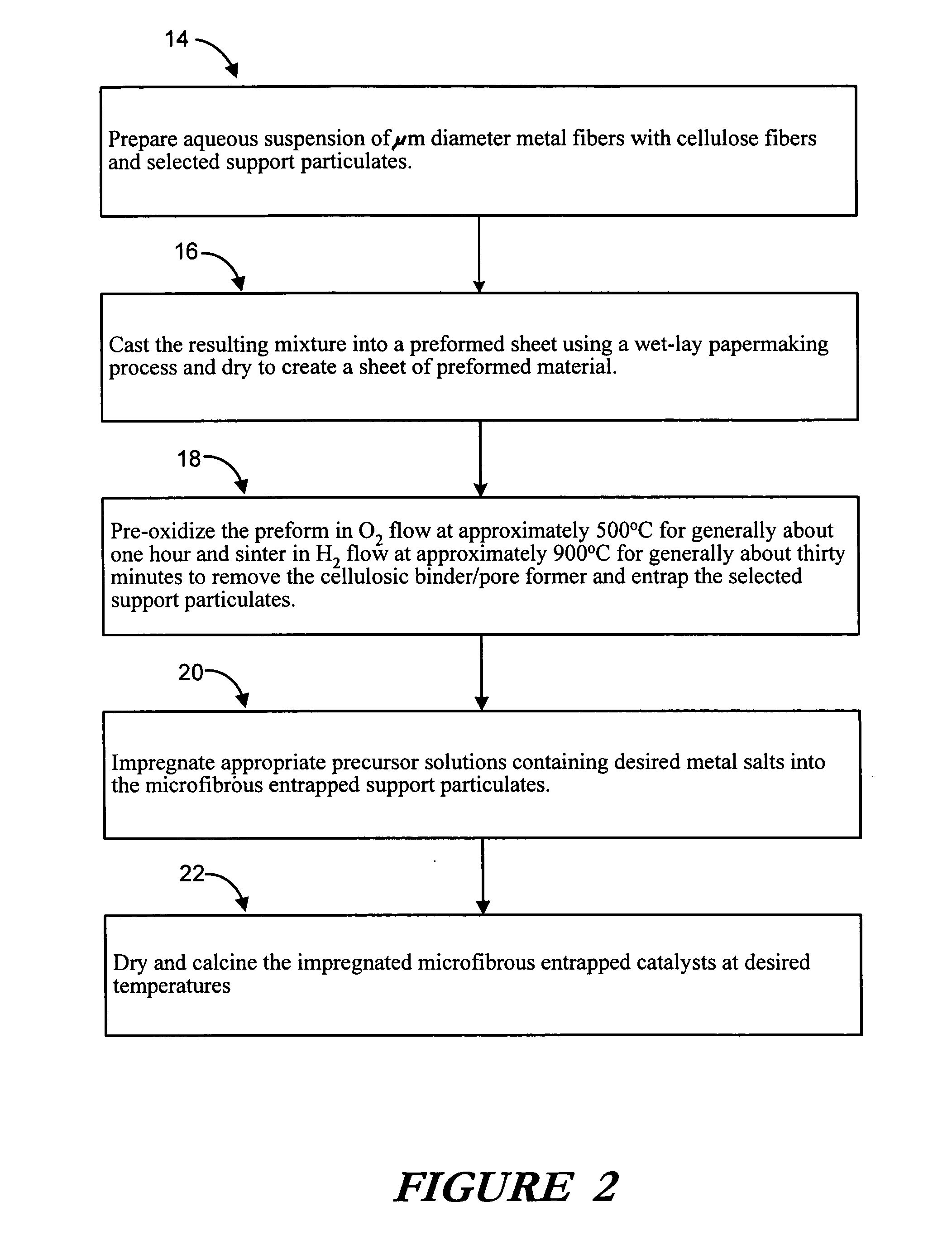

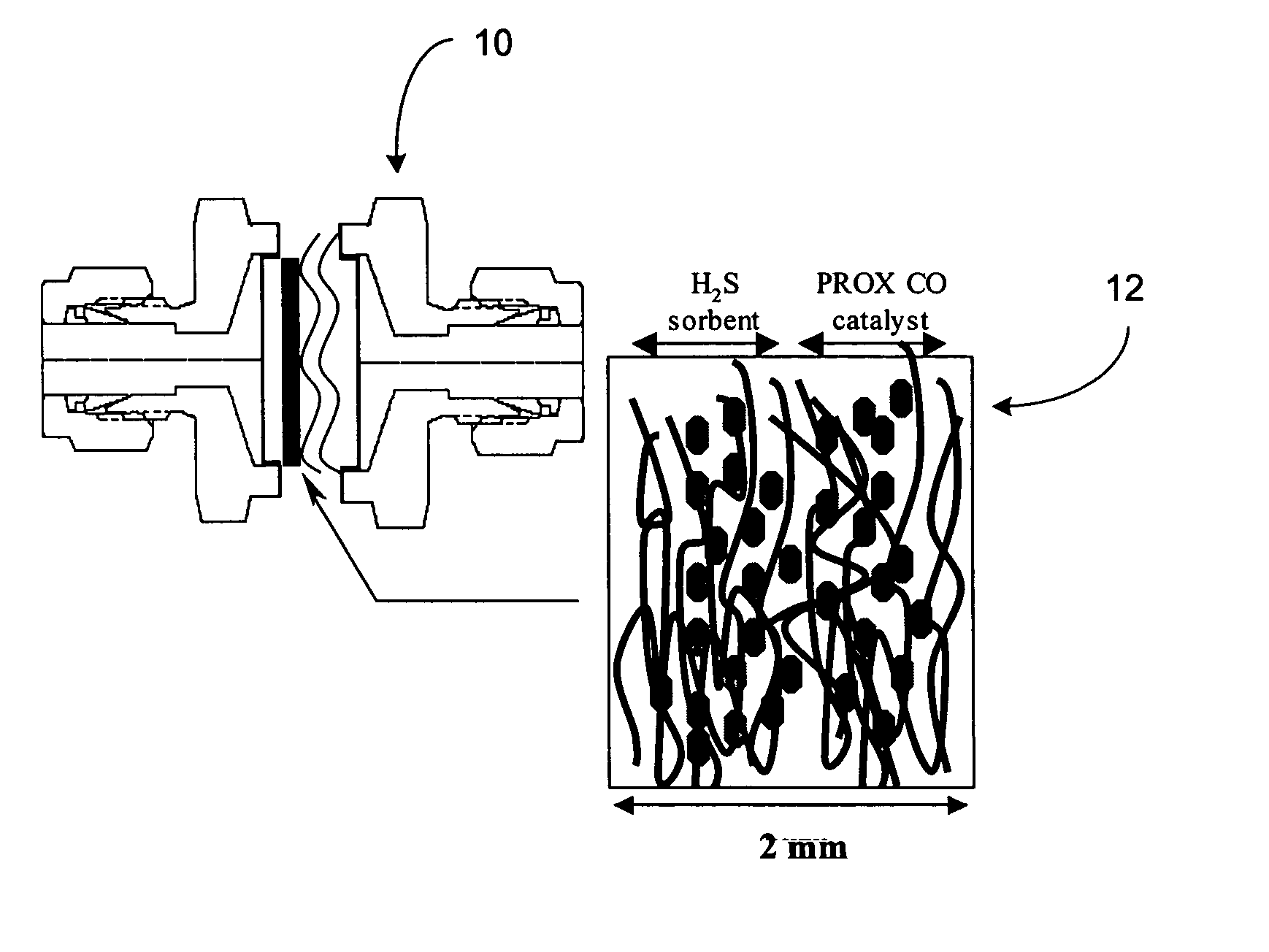

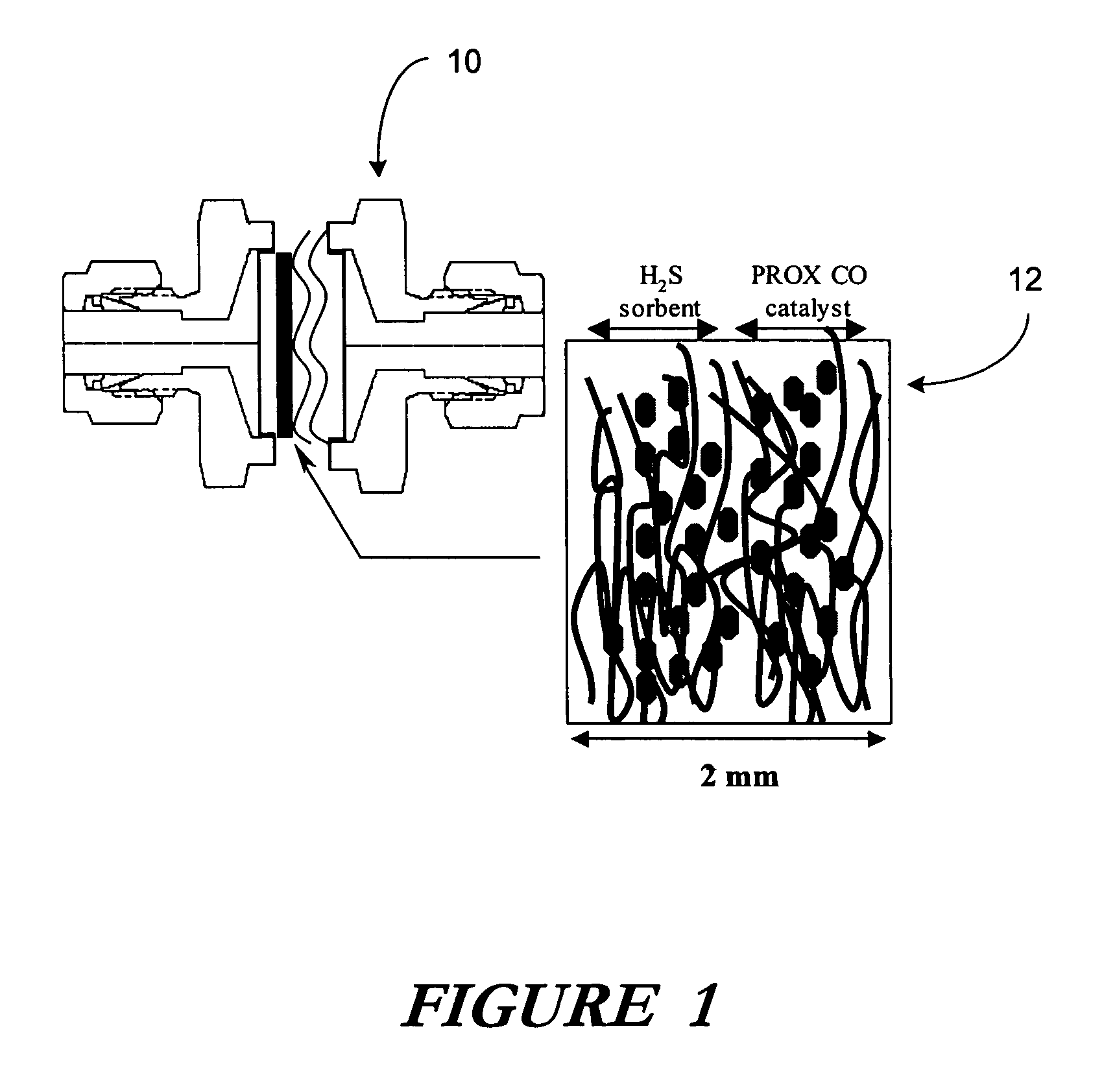

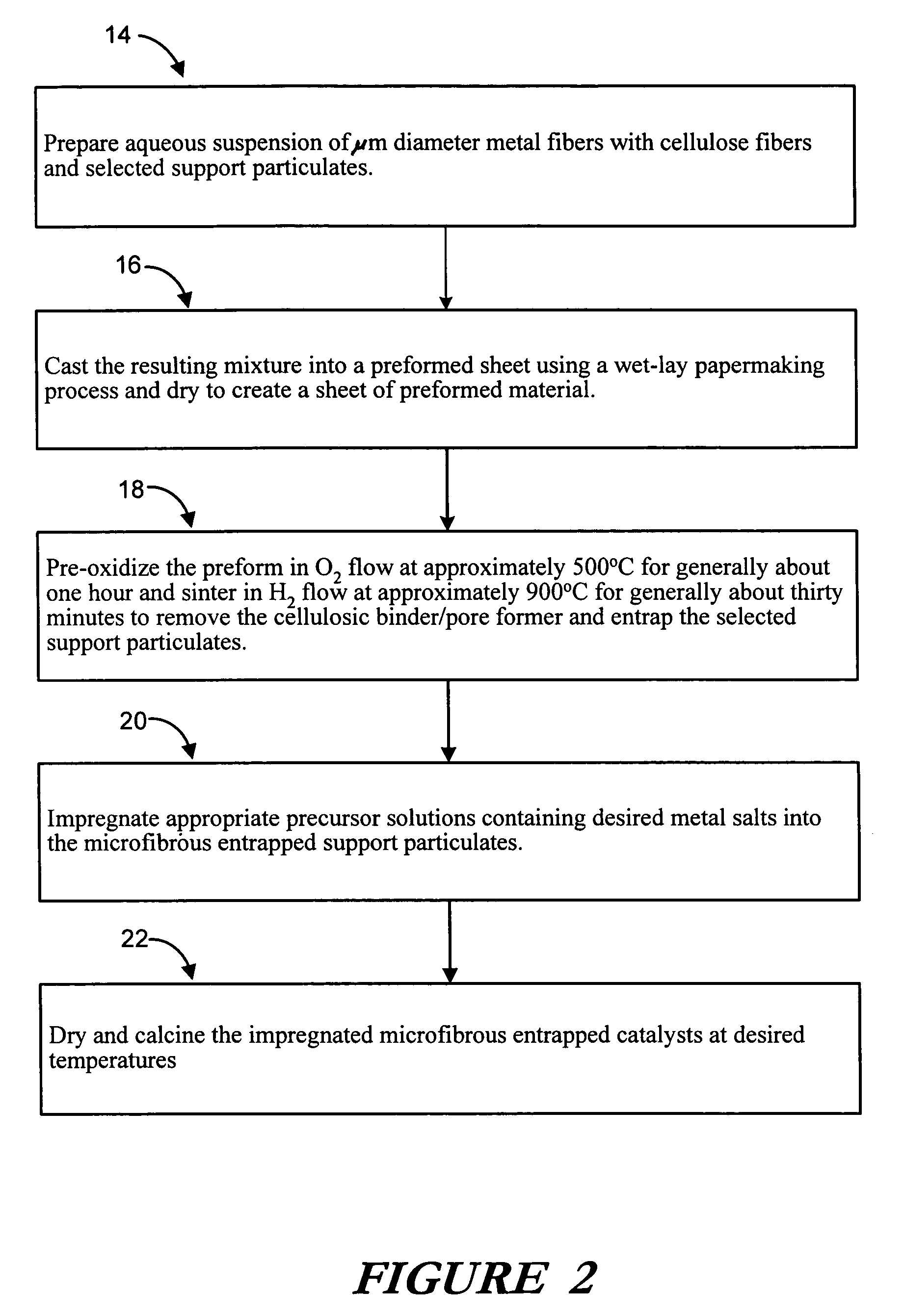

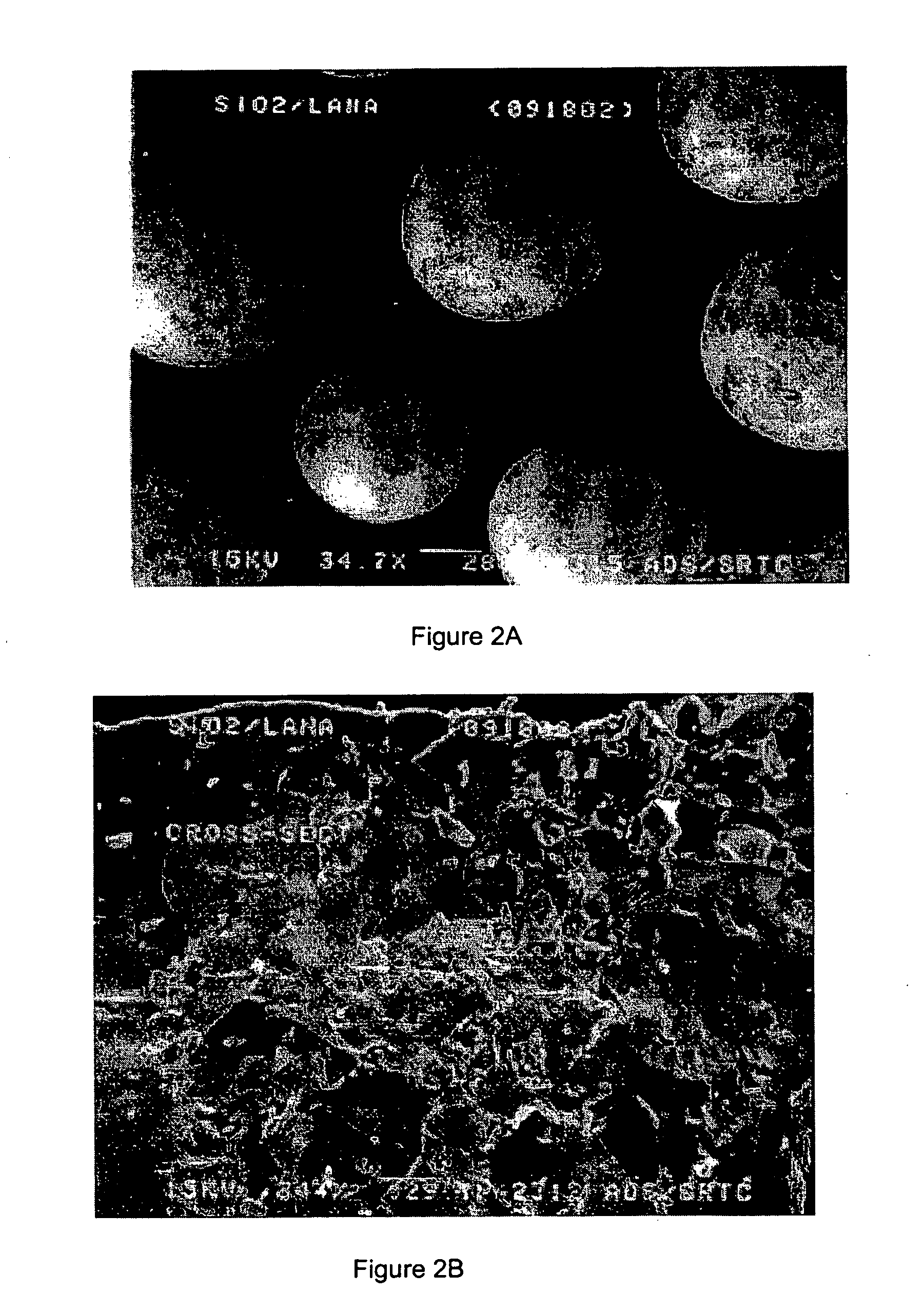

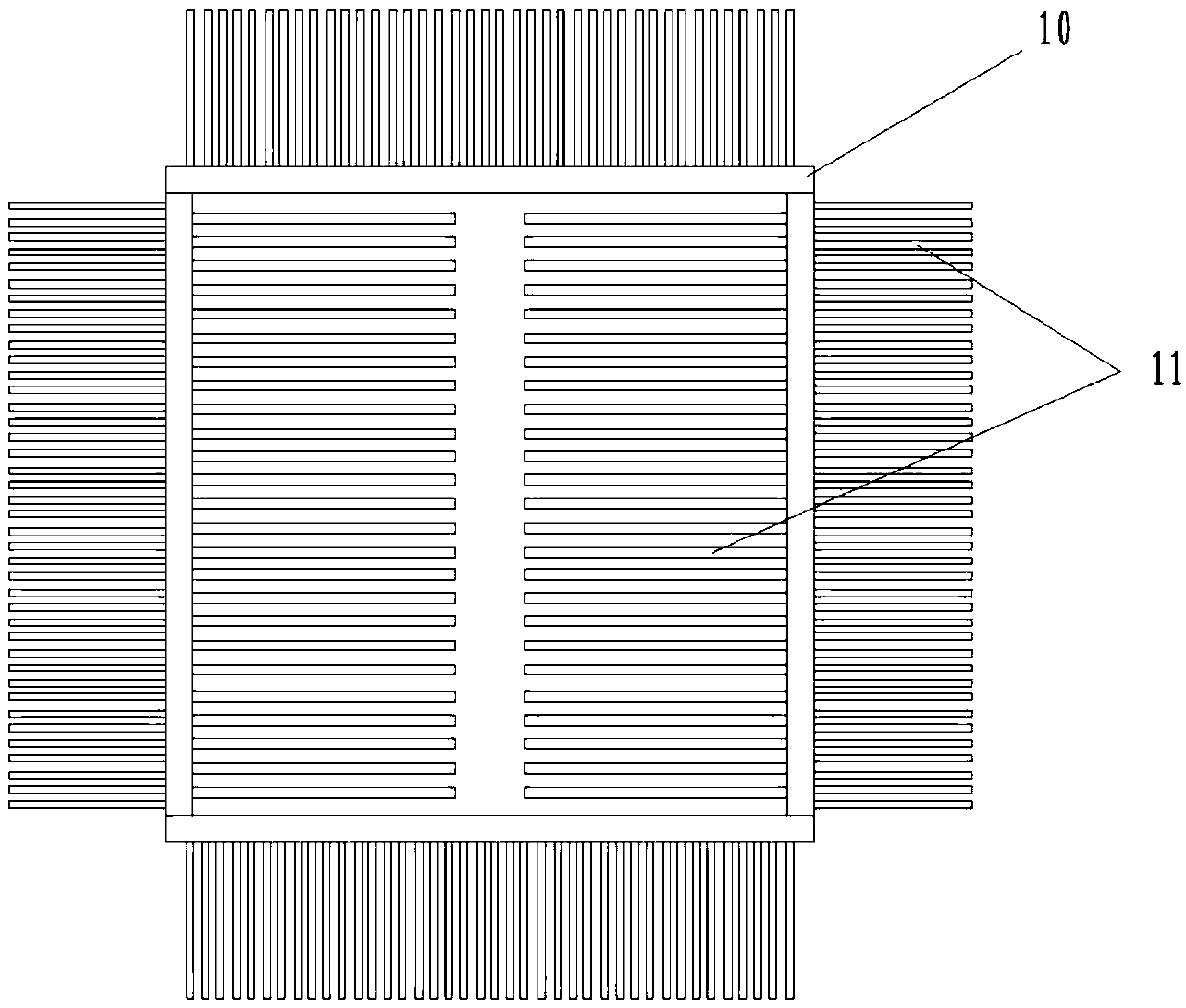

Microfibrous entrapment of small reactive particulates and fibers for high contacting efficiency removal of contaminants from gaseous or liquid streams

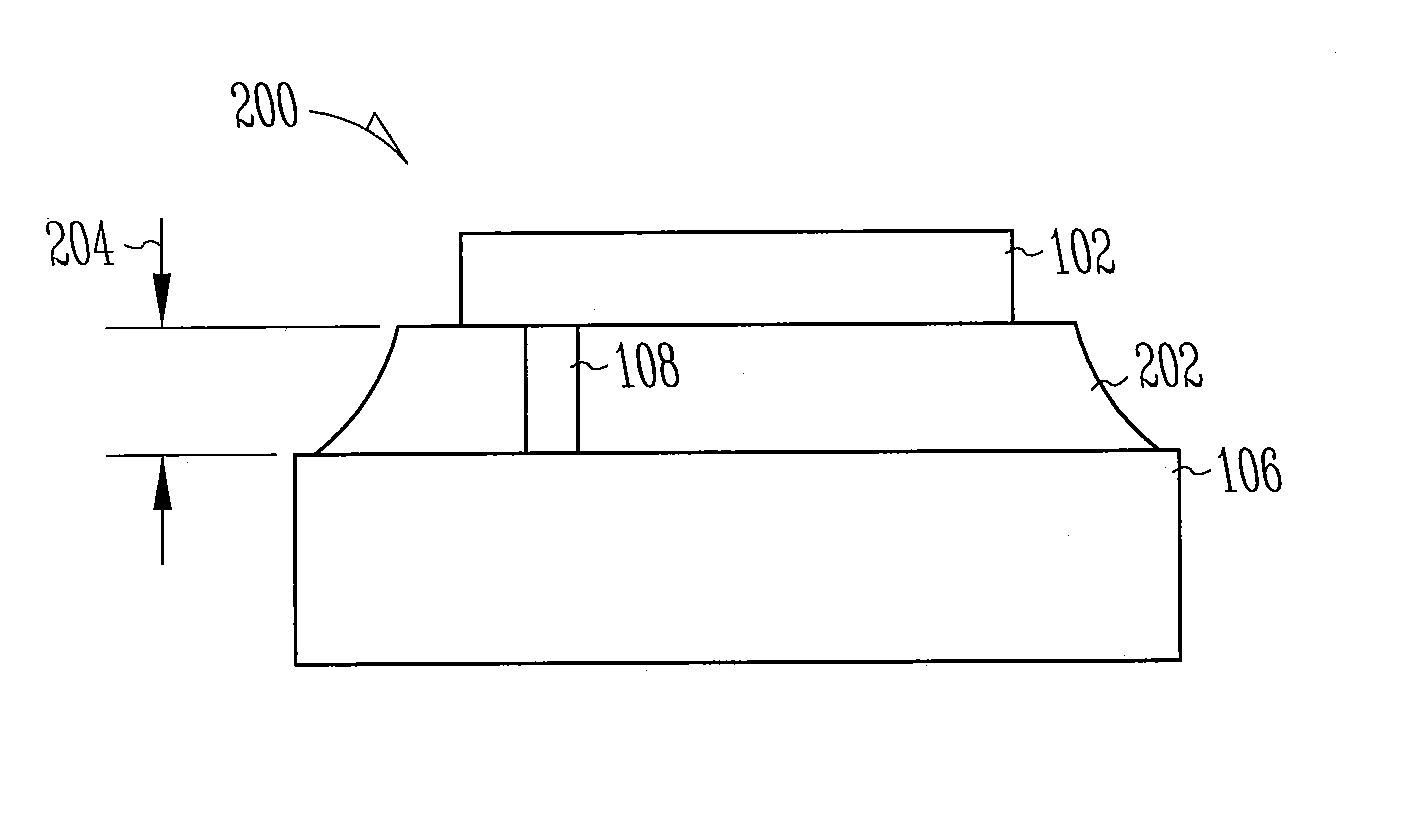

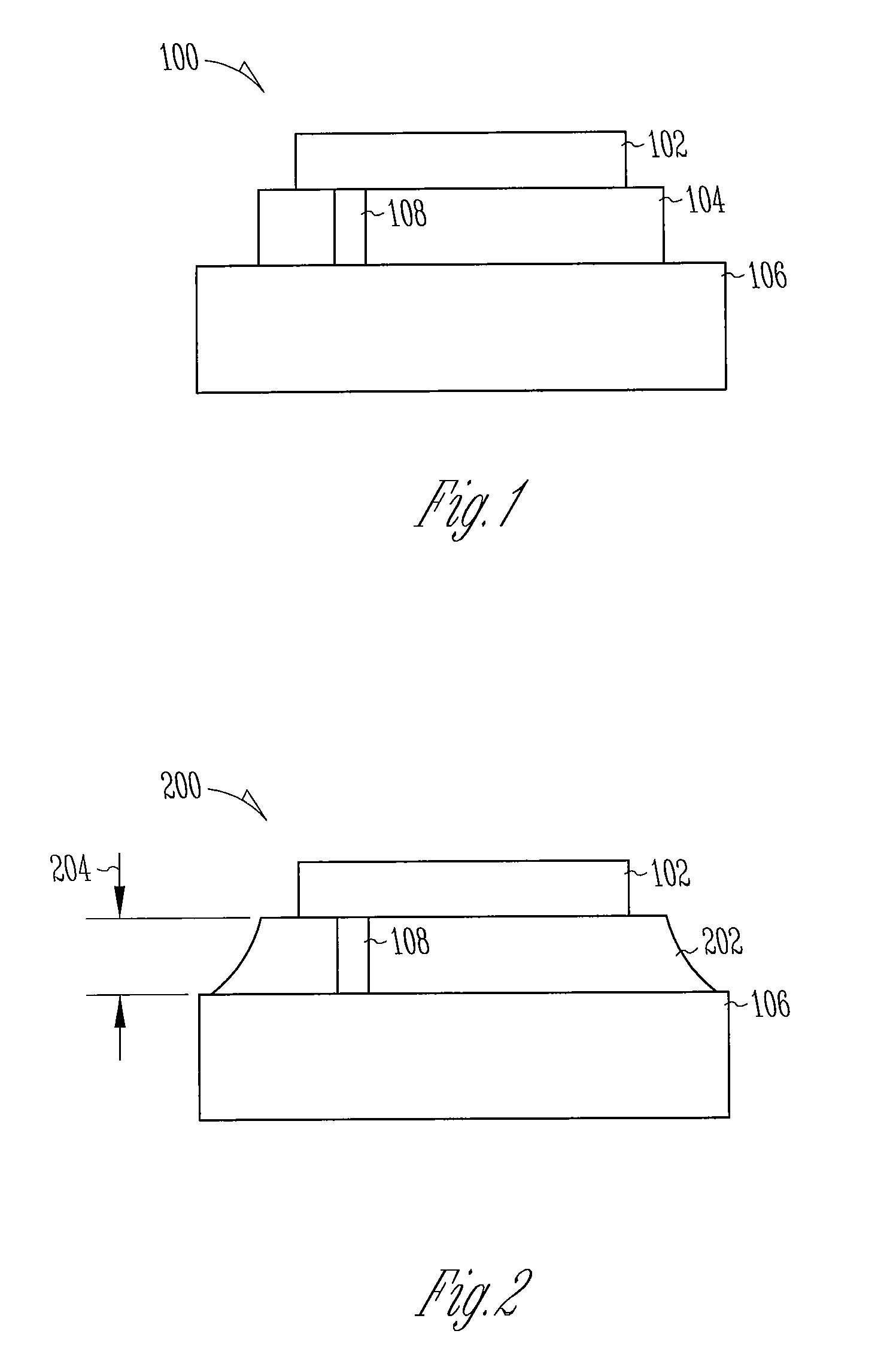

ActiveUS20050169820A1High contacting efficiency removalHigh contact efficiencyHydrogen separation by selective and reversible uptakeCombination devicesParticulatesFiber

A microfibrous matrix with embedded supporting particulates / fibers and chemically reactive materials is provided as a filtration system for the removal of contaminants and other harmful agents from liquid and gaseous streams. Such filter may be used for example to protect the intolerant anodes and cathodes of fuel cells from damaging H2S while simultaneously aiding the selective conversion of CO to CO2 in fuel streams predominated by hydrogen. In general, the reactive materials utilized as well as the supporting matrix of fibers may be broadly selected to remove specific contaminants at specific reaction conditions inherent to the application. Such materials may include chemically reactive materials as high surface area carbons, zeolites, silicas, aluminas, inorganic metal oxides, polymer resins, ZnO, ZnO / Carbon, Pt / γ-Al2O3, PtCo / γ-Al2O3, ZnO / SiO2 and various other catalysts, sorbents or reactants. In an alternative embodiment, entrapped sorbents and other reactants may be used to provide a highly efficient gas and / or liquid separation and purification methodology for gas masks, building filtration systems, and / or as polishing media located downstream of traditional packed bed filtration systems so as to achieve the high volume loading / capacity of the packed bed along with the overall contacting efficiency of the outlet polishing layer.

Owner:AUBURN UNIV

Microfibrous entrapment of small reactive particulates and fibers for high contacting efficiency removal of contaminants from gaseous or liquid streams

ActiveUS7501012B2High contacting efficiency removalHigh contact efficiencyHydrogen separation by selective and reversible uptakeCombination devicesParticulatesFiber

Owner:AUBURN UNIV

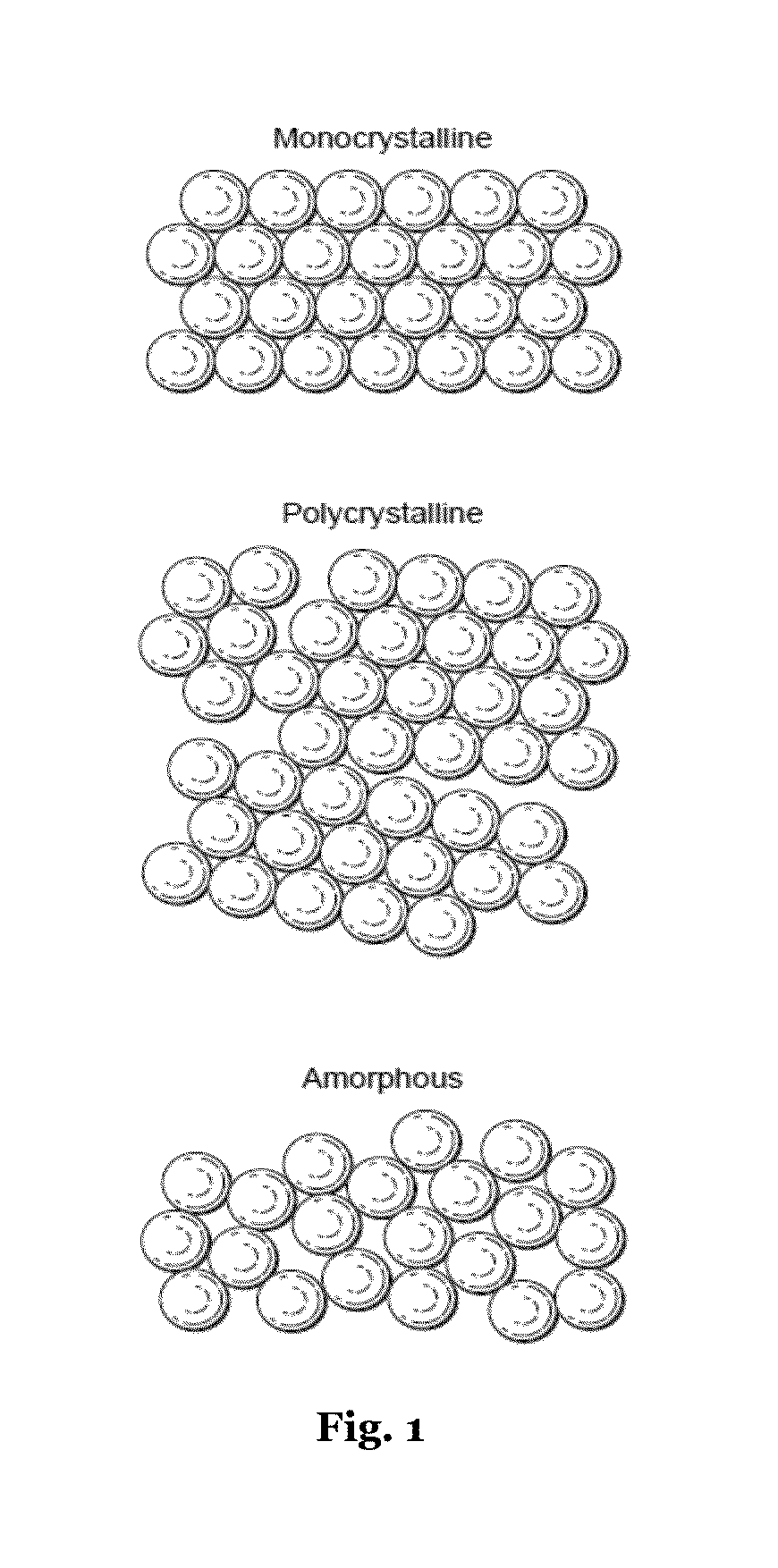

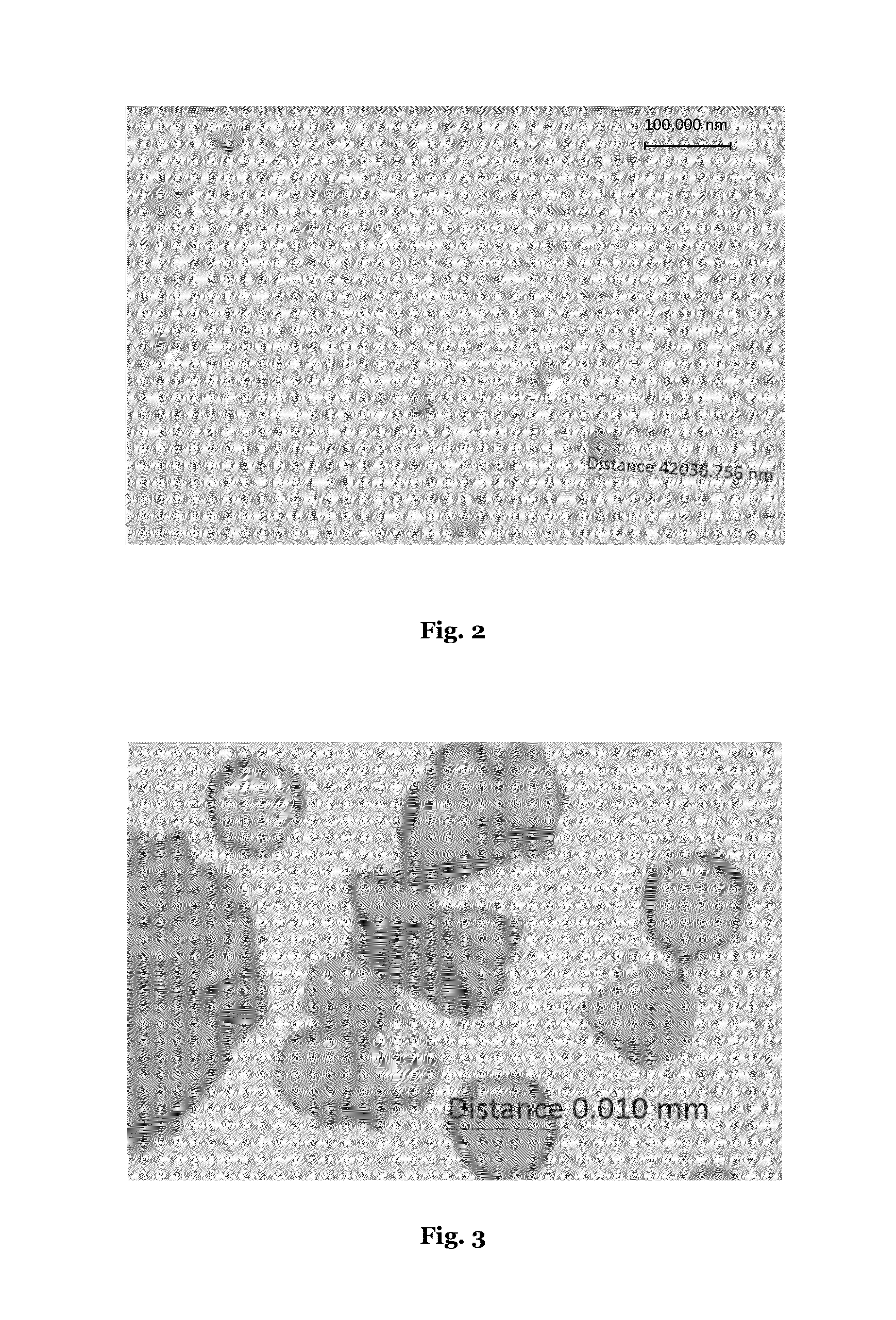

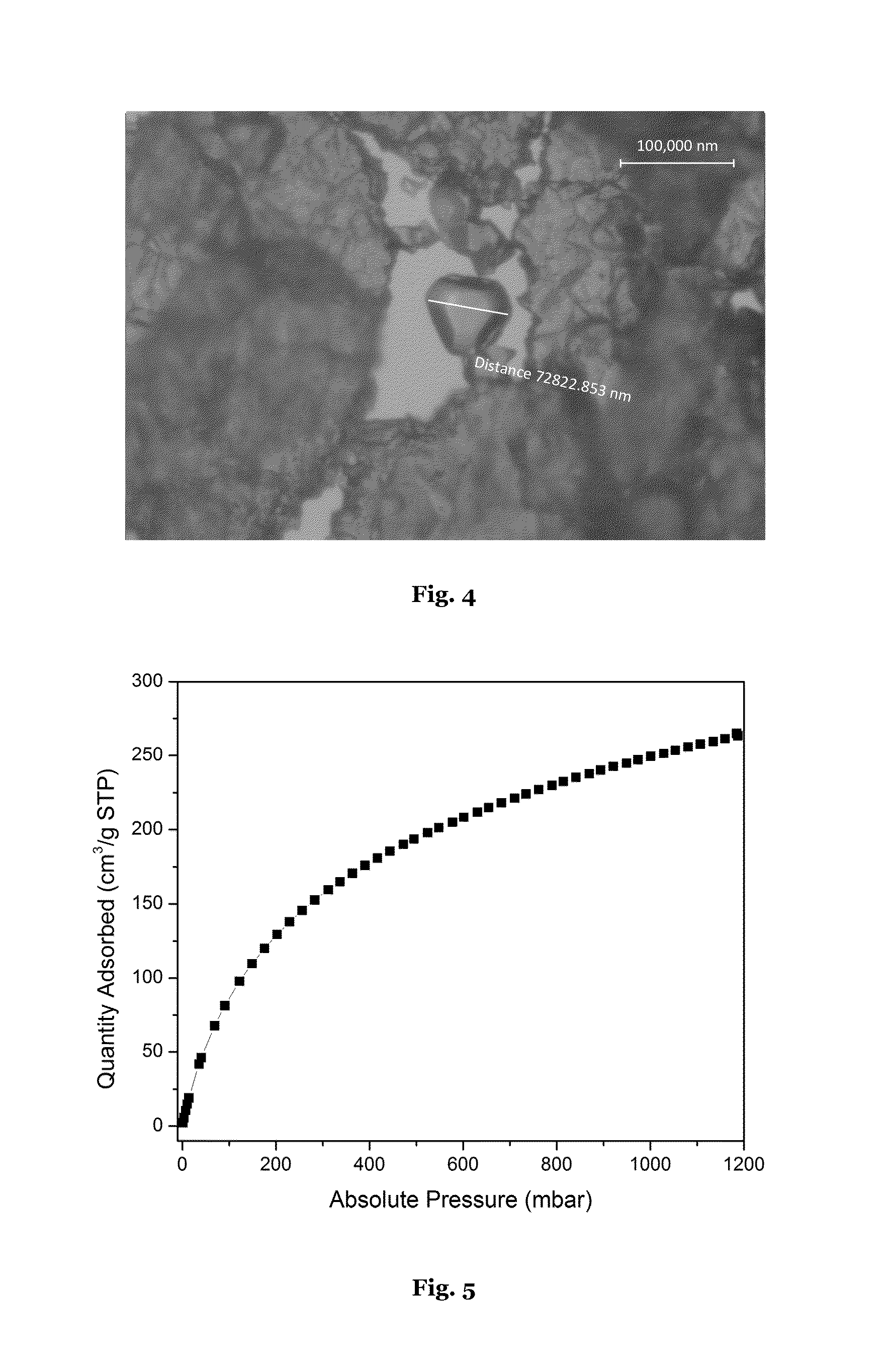

Aluminum metal organic framework materials

ActiveUS9102691B2Small sizeSlow reaction rateCarbon compoundsNickel organic compoundsPhysical chemistryMetal-organic framework

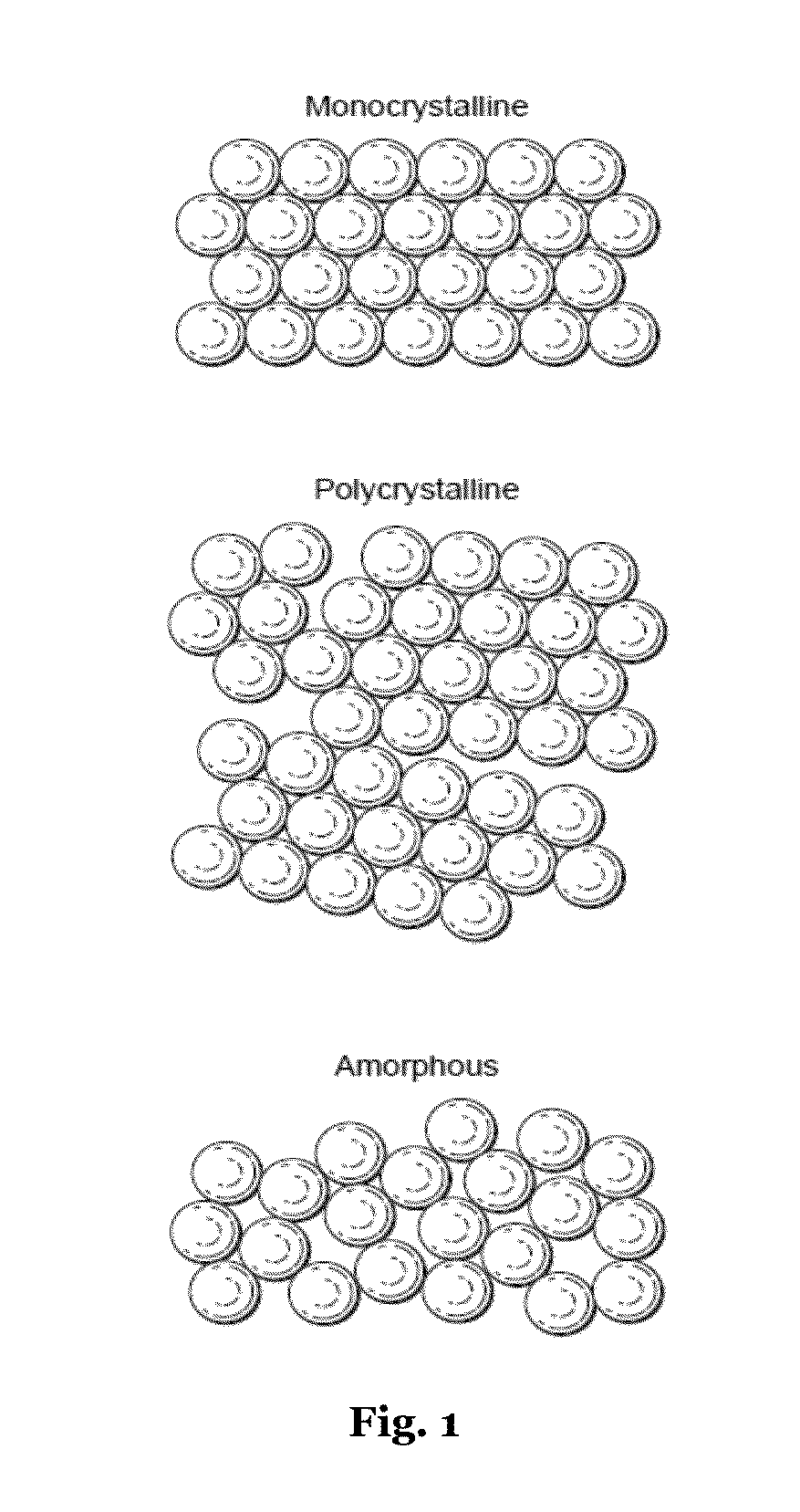

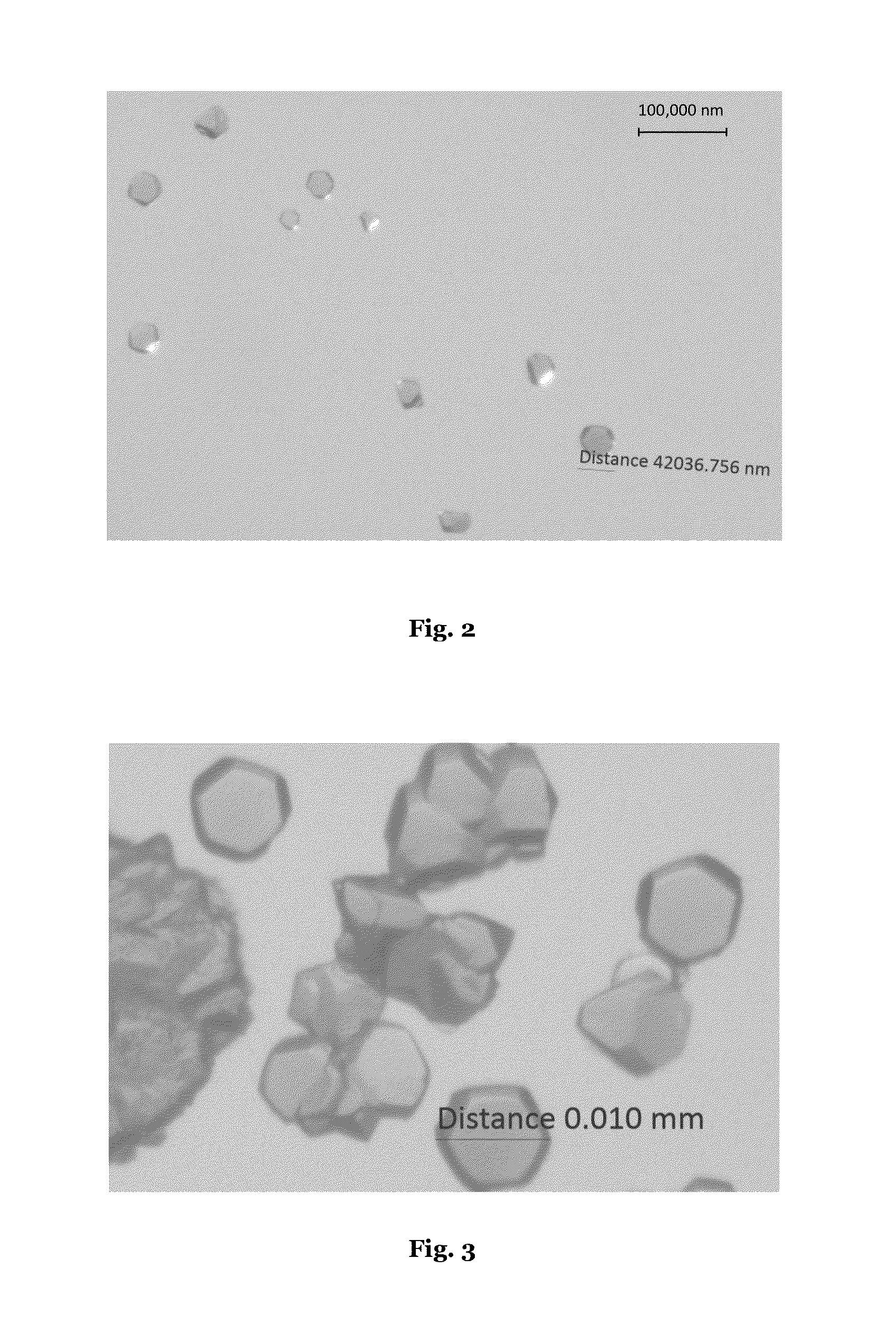

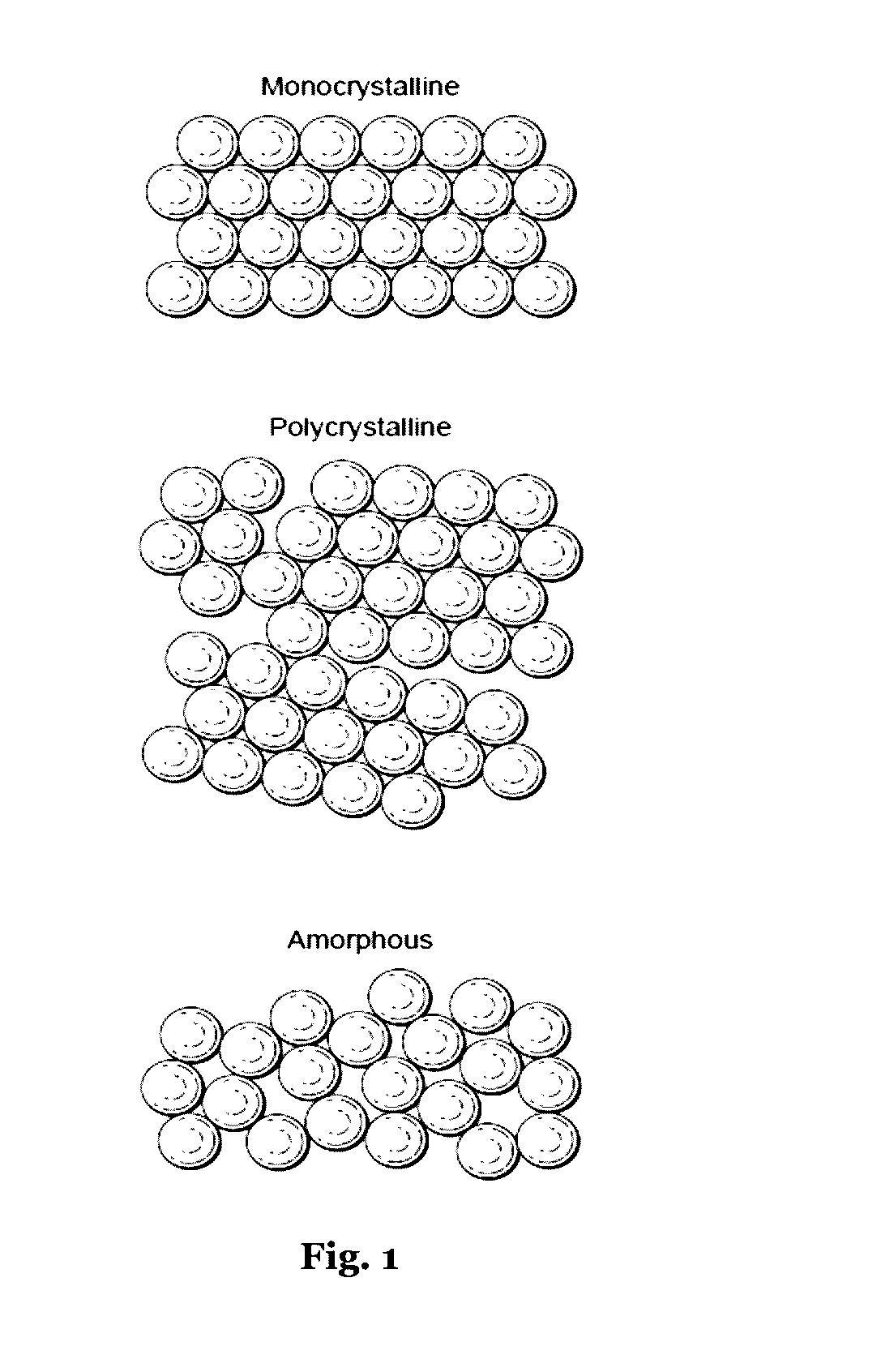

The invention relates to monocrystalline single crystals of metal-organic framework materials comprising at least one aluminum metal ion, processes for preparing the same, methods for employing the same, and the use thereof. The invention also relates to monocrystalline aluminum metal-organic frameworks.

Owner:TEXAS A&M UNIVERSITY

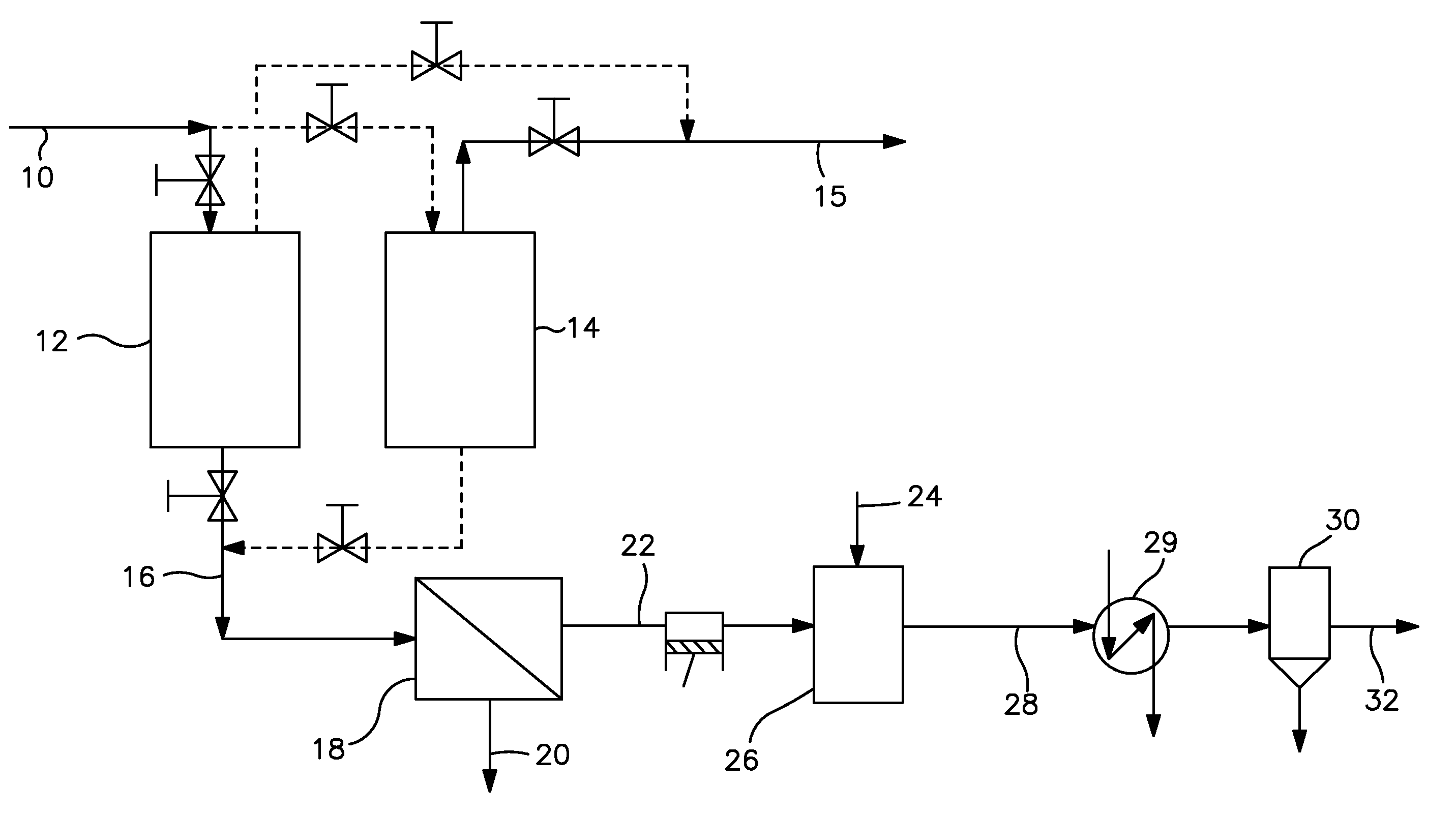

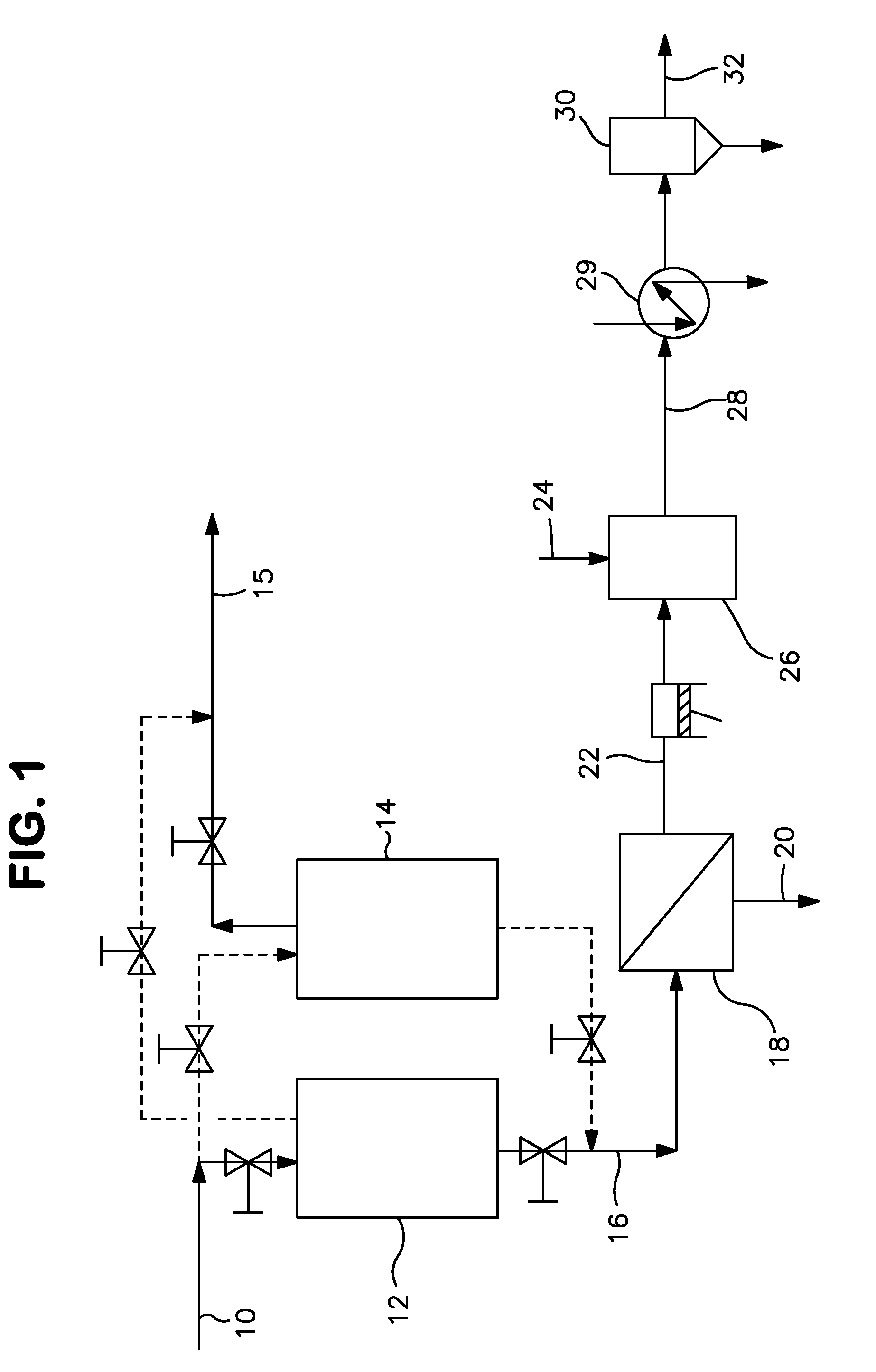

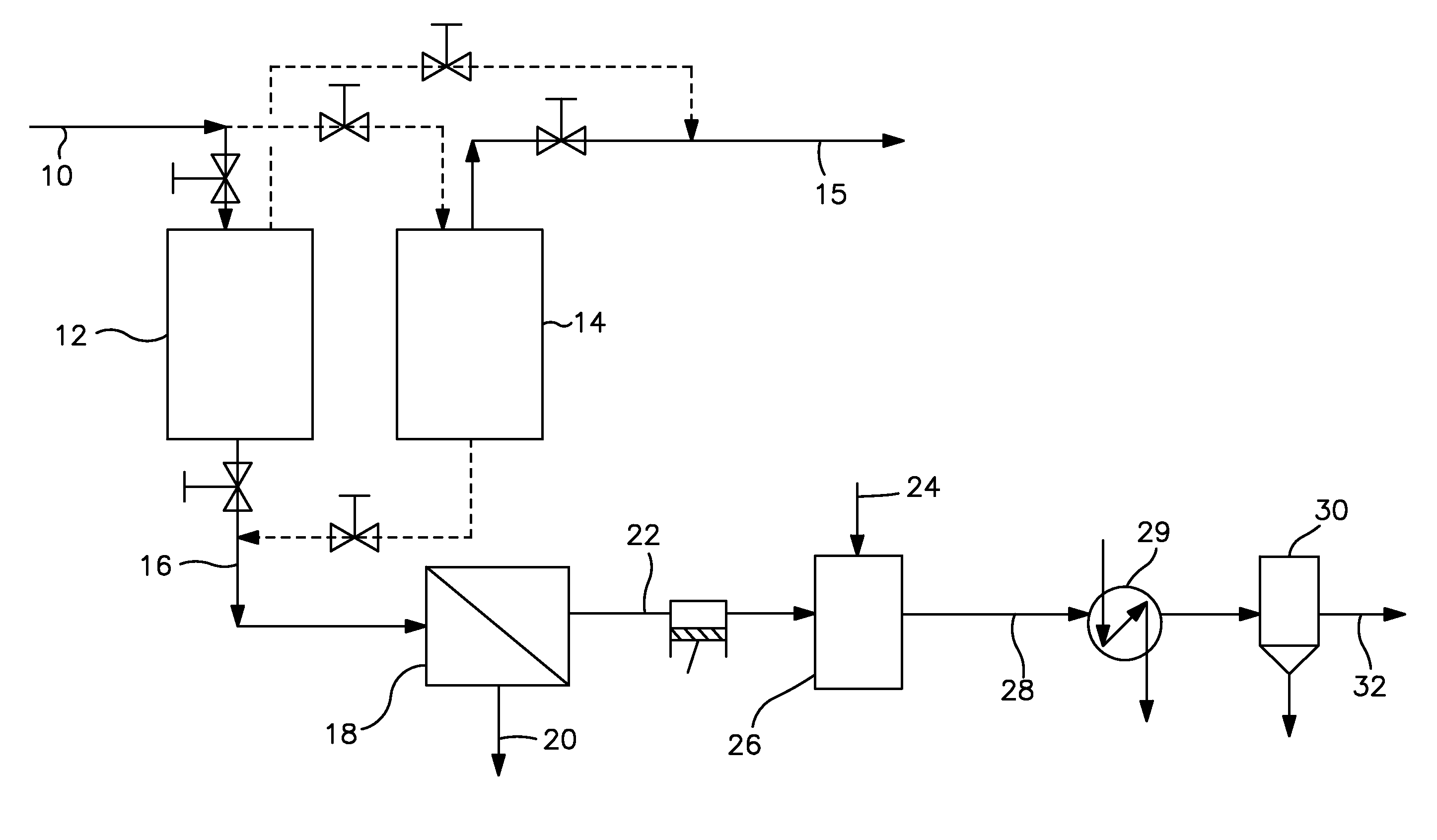

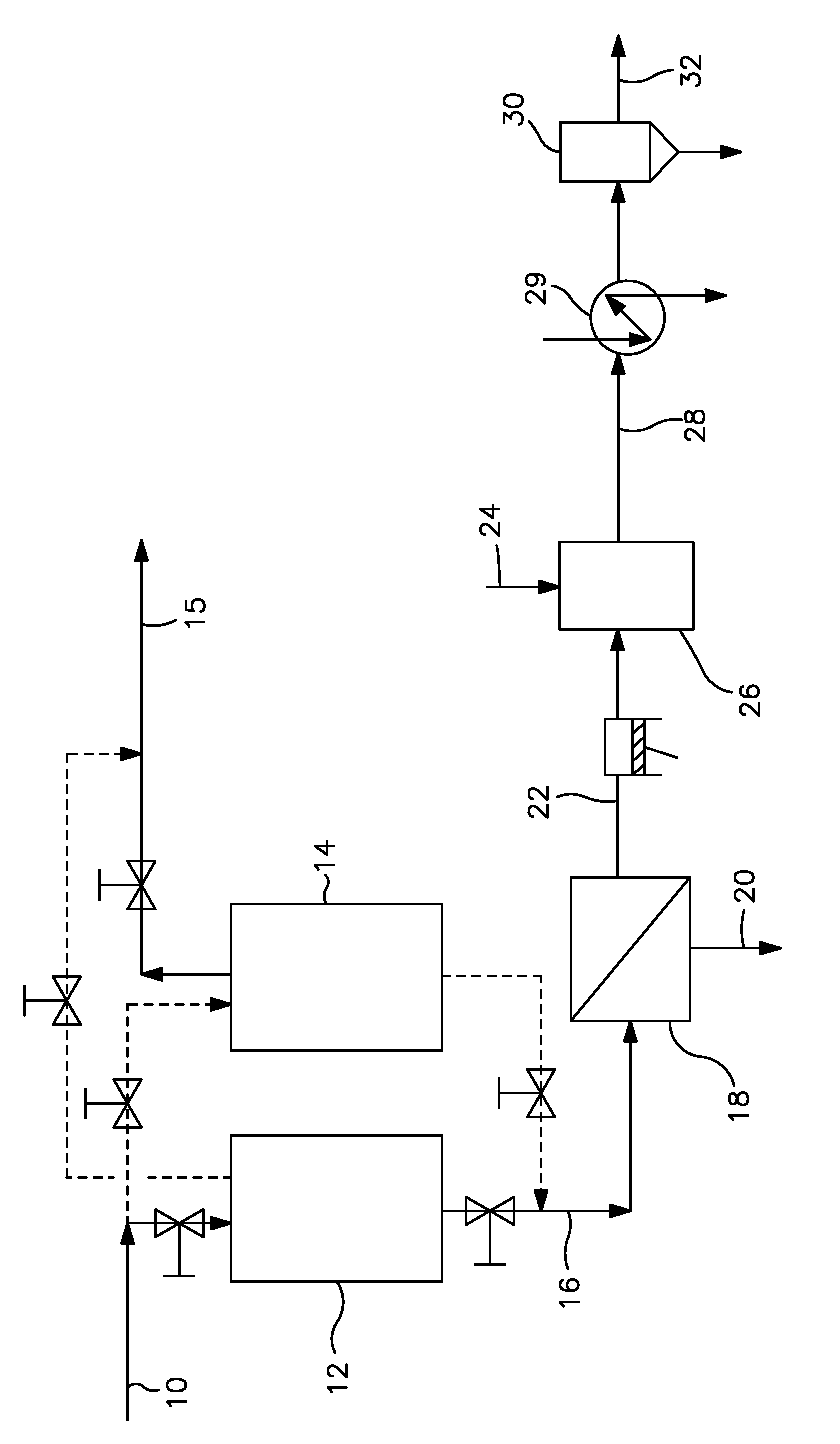

Helium recovery process

InactiveUS20100101410A1Helium concentration is increasedEnhances their economic viabilityHydrogen separation by selective and reversible uptakeIsotope separationHigh concentrationHydrogen

Helium is recovered from gas streams containing high concentrations of hydrogen gas and low concentrations of helium gas, such as from the recycle stream from the production of ammonia. The inventive process provides for an integrated process for the recovery of both an enriched helium gas stream product and a high purity hydrogen gas stream product.

Owner:PRAXAIR TECH INC

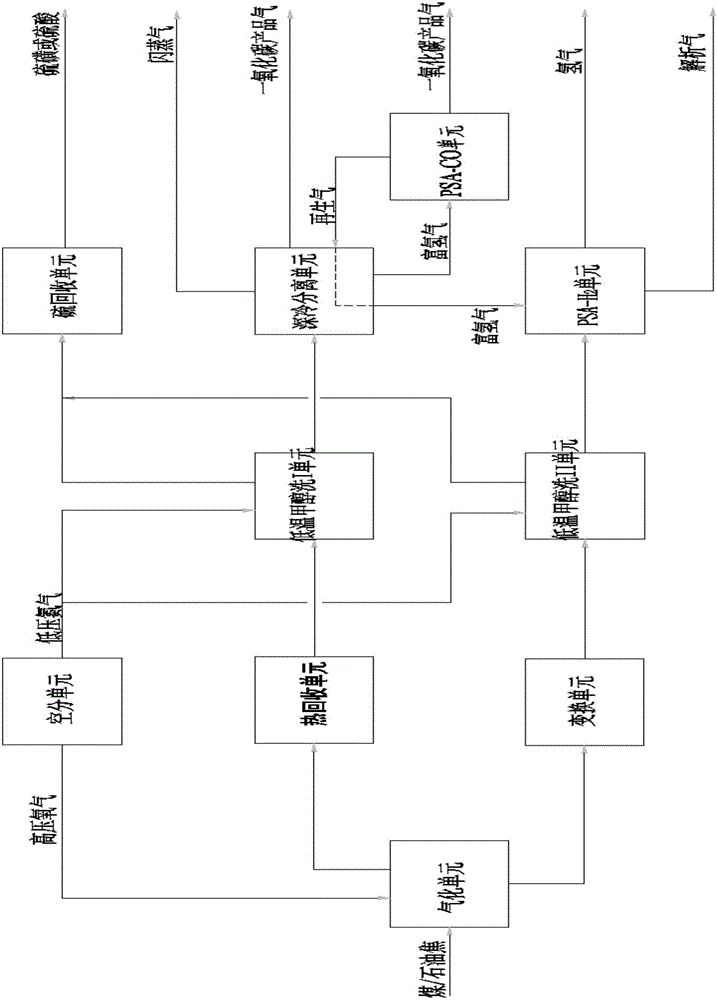

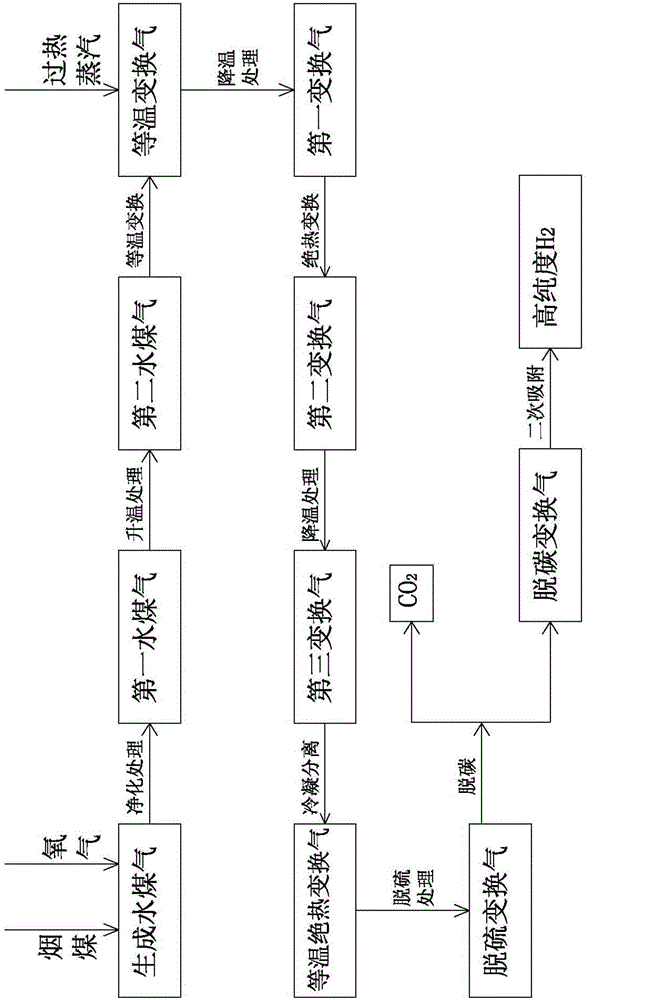

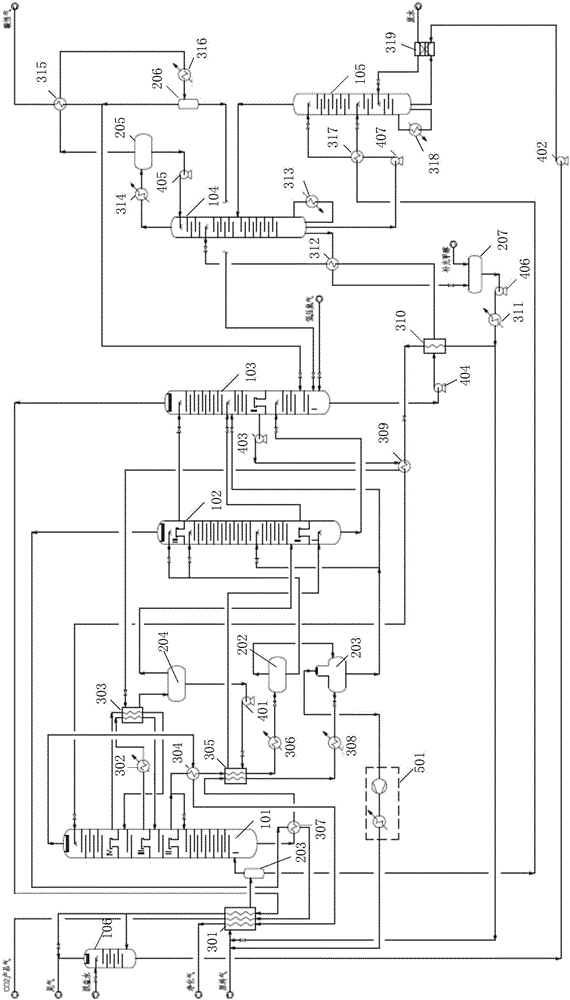

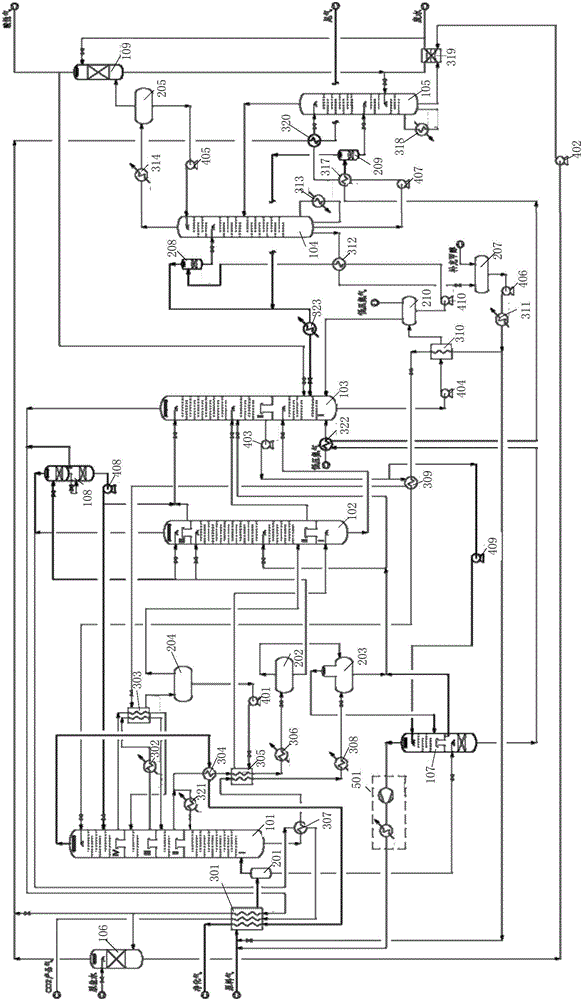

Method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation

ActiveCN105948046AFlexible scale adjustmentHigh recovery rateHydrogen separation by selective and reversible uptakeGas treatmentSyngasPhysical chemistry

The invention discloses a method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation. The crude synthetic gas prepared by the gasification unit is divided into two parts, one part is used for preparing pure carbon monoxide, and the other part is preparing pure hydrogen. The process of preparing pure carbon monoxide is divided into two parts: one part is used for preparing pure carbon monoxide with the crude synthetic gas prepared by gasification by a heat recovery unit, a low temperature methanol washing I unit, and a cryogenic separation unit; and the other part is used for preparing pure carbon monoxide by the hydrogen rich gas from the outlet of the cold box of the cryogenic separation unit sending into a PSA-CO unit. The feedstock of preparing hydrogen is divided into two parts: one part is the converted gas which is purified by a conversion unit and a low temperature methanol washing II unit with the crude synthetic gas prepared by gasification and contains carbon monoxide -1% (mol), and the other part is the hydrogen rich gas from a resurgent TSA device of the cryogenic separation unit, and the two parts of the gas are mixed and sent into the PSA-H2 unit to prepare pure hydrogen. The method has high recovery rates of carbon monoxide and hydrogen, has no desorbed gas circulation and no resurgent gas introduced by environment, has small investment and low energy consumption, and can adjust product gas scale of hydrogen and carbon monoxide flexibly.

Owner:HUALU ENG & TECH

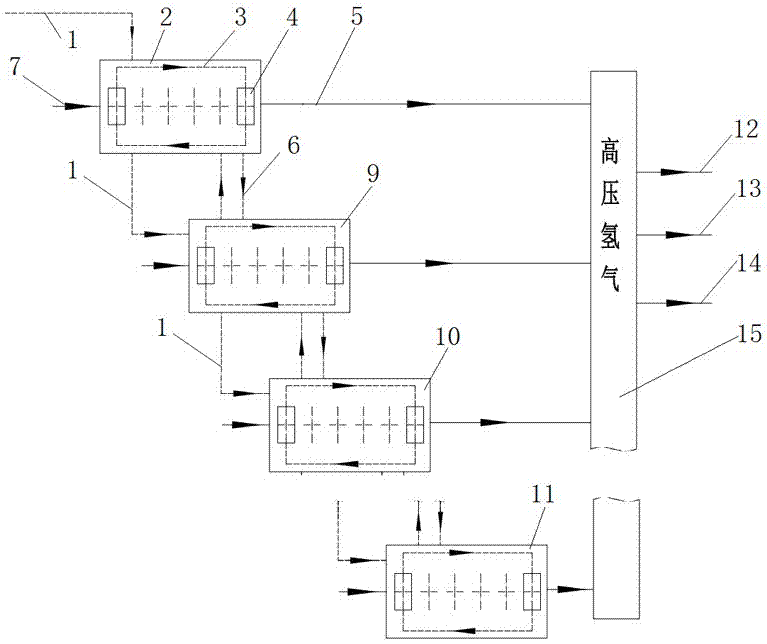

Energy gradient utilization type hydrogen thermal compression system

ActiveCN107285278AHigh thermal efficiencyExpand the scope ofHydrogen separation by selective and reversible uptakeEnergy inputEnergy gradientHigh pressure hydrogen

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

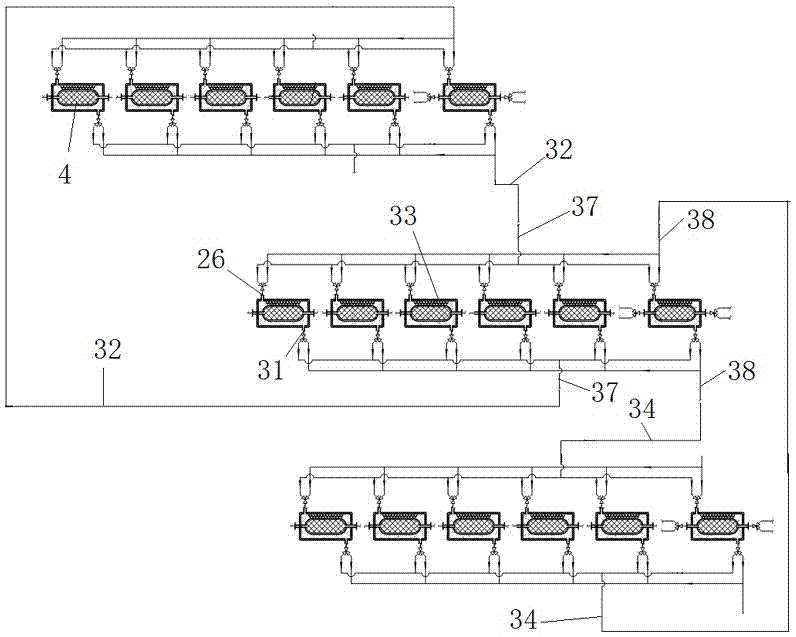

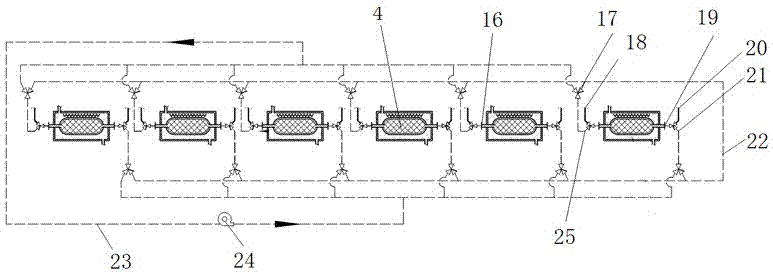

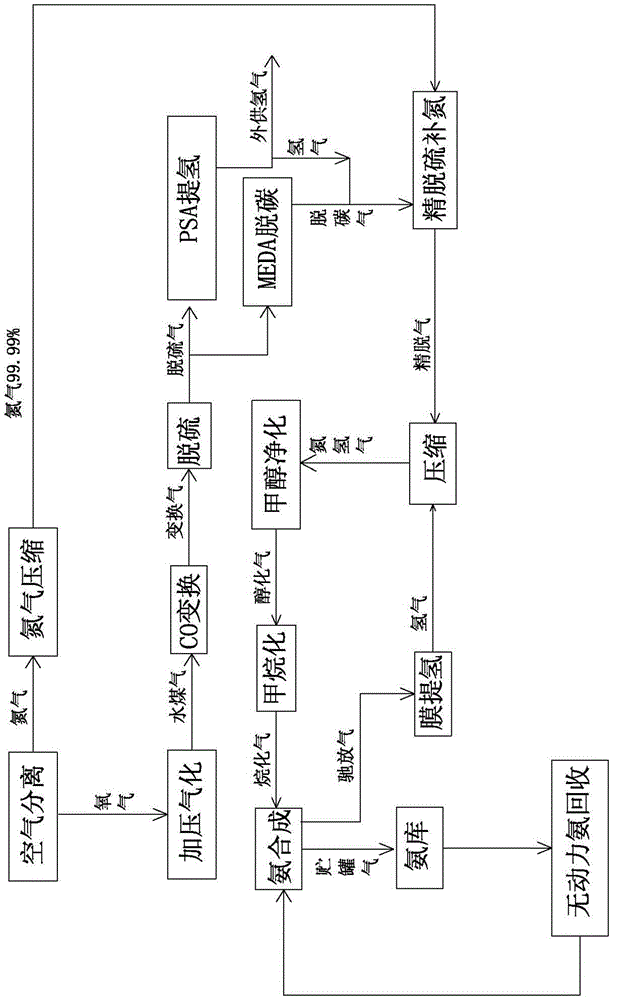

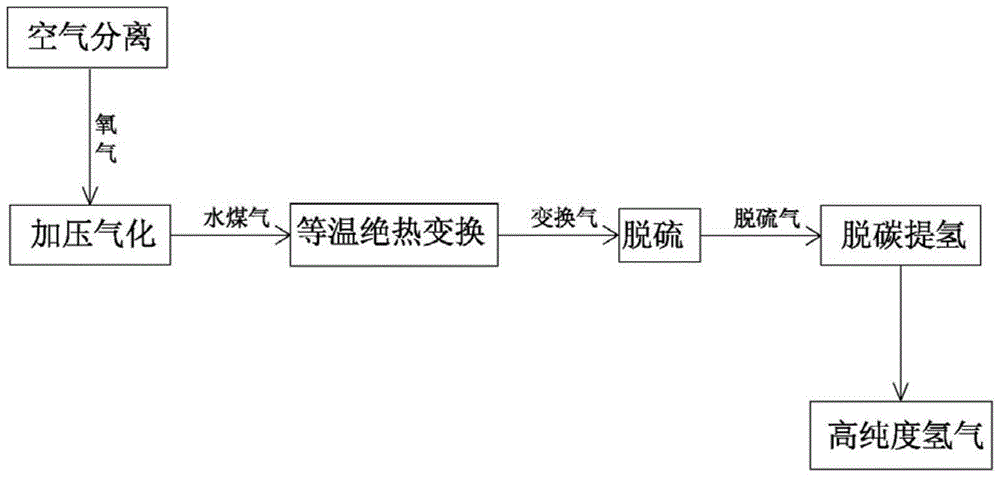

Production process and system of high-purity hydrogen and ammonia synthesis process and system

ActiveCN104560201AShort production processReduce resistanceHydrogen separation by selective and reversible uptakeHydrogen separation using solid contactOperating costOperating environment

The invention provides a production process and system of high-purity hydrogen and an ammonia synthesis process and system. The production process of high-purity hydrogen comprises the steps of generating water gas by using bituminous coal, generating shifted gas by using the water gas, desulfurizing the shifted gas, and carrying out decarbonization and hydrogen extraction on the shifted gas; the ammonia synthesis process comprises the steps of hydrogen nitrogen-feeding and deoxygenization, nitrogen-hydrogen compression and ammonia synthesis. The production system of high-purity hydrogen comprises a water gas generating part, a shifted gas generating part, a shifted gas desulfurizing part and a shifted gas decarbonization and hydrogen extraction part; and the ammonia synthesis system also comprises a hydrogen nitrogen-feeding and deoxygenization part, a nitrogen-hydrogen compression part and an ammonia synthesis part. The production process of high-purity hydrogen disclosed by the invention is short in flow, small in resistance, low in power consumption and low in operating cost; and the production system of high-purity hydrogen disclosed by the invention is high in degree of automation, less in catalyst consumption, less in species, less in operators, good in operating environment, low in operating cost and remarkable in energy saving and consumption reducing effect.

Owner:蓝星工程有限公司

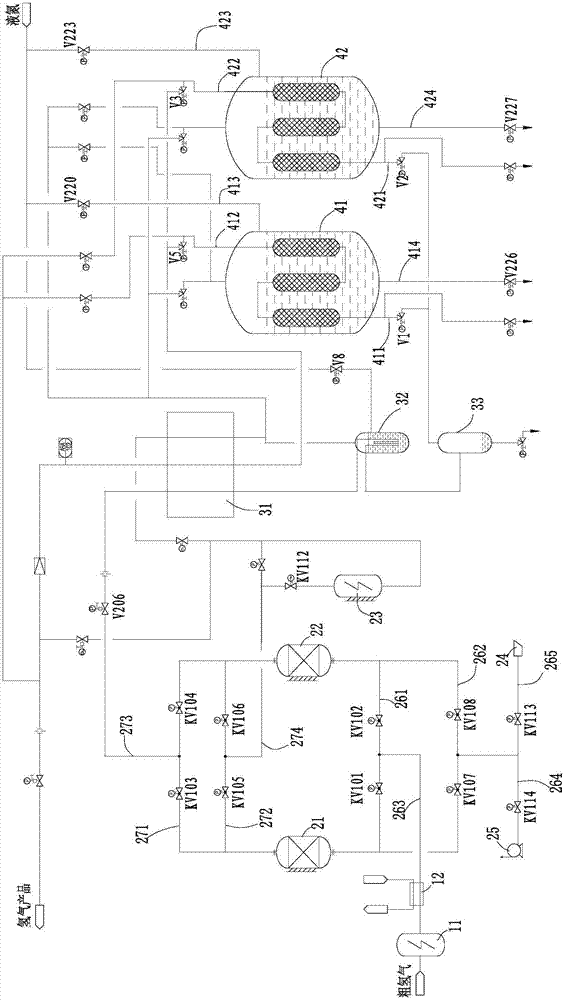

Low-temperature hydrogen purification device and control method

PendingCN107364832ALow oxygenReduce nitrogen contentHydrogen separation by selective and reversible uptakeHydrogen separation at low temperaturePhysical chemistryProcess engineering

The invention discloses a low-temperature hydrogen purification device which comprises a catalytic deoxidization device, a normal-temperature adsorption device, a low-temperature heat exchange device and a low-temperature adsorption device. Deoxidization is performed on crude hydrogen by the catalytic deoxidization device, the crude hydrogen is cooled to reach normal temperature by the catalytic deoxidization device, the normal-temperature adsorption device is used for adsorbing nitrogen in the crude hydrogen, the low-temperature heat exchange device is used for cooling the crude hydrogen, and the low-temperature adsorption device is used for adsorbing the nitrogen in the crude hydrogen. A gas inlet of the catalytic deoxidization device is connected with the crude hydrogen, a gas outlet of the catalytic deoxidization device is sequentially connected with the normal-temperature adsorption device, the low-temperature heat exchange device and the low-temperature adsorption device through pipelines, the normal-temperature adsorption device further can adsorb water and carbon dioxide in the crude hydrogen, and the low-temperature adsorption device further can adsorb micro-oxygen in the crude hydrogen. The invention further discloses a control method of the low-temperature hydrogen purification device. The low-temperature hydrogen purification device can obtain hydrogen with higher purity and better quality by the aid of tertiary purification technology, and the purification device further has the advantages of low operating cost, less equipment investment, convenience in operation, simplicity and convenience in maintenance and high reliability.

Owner:深圳市海格金谷工业科技有限公司

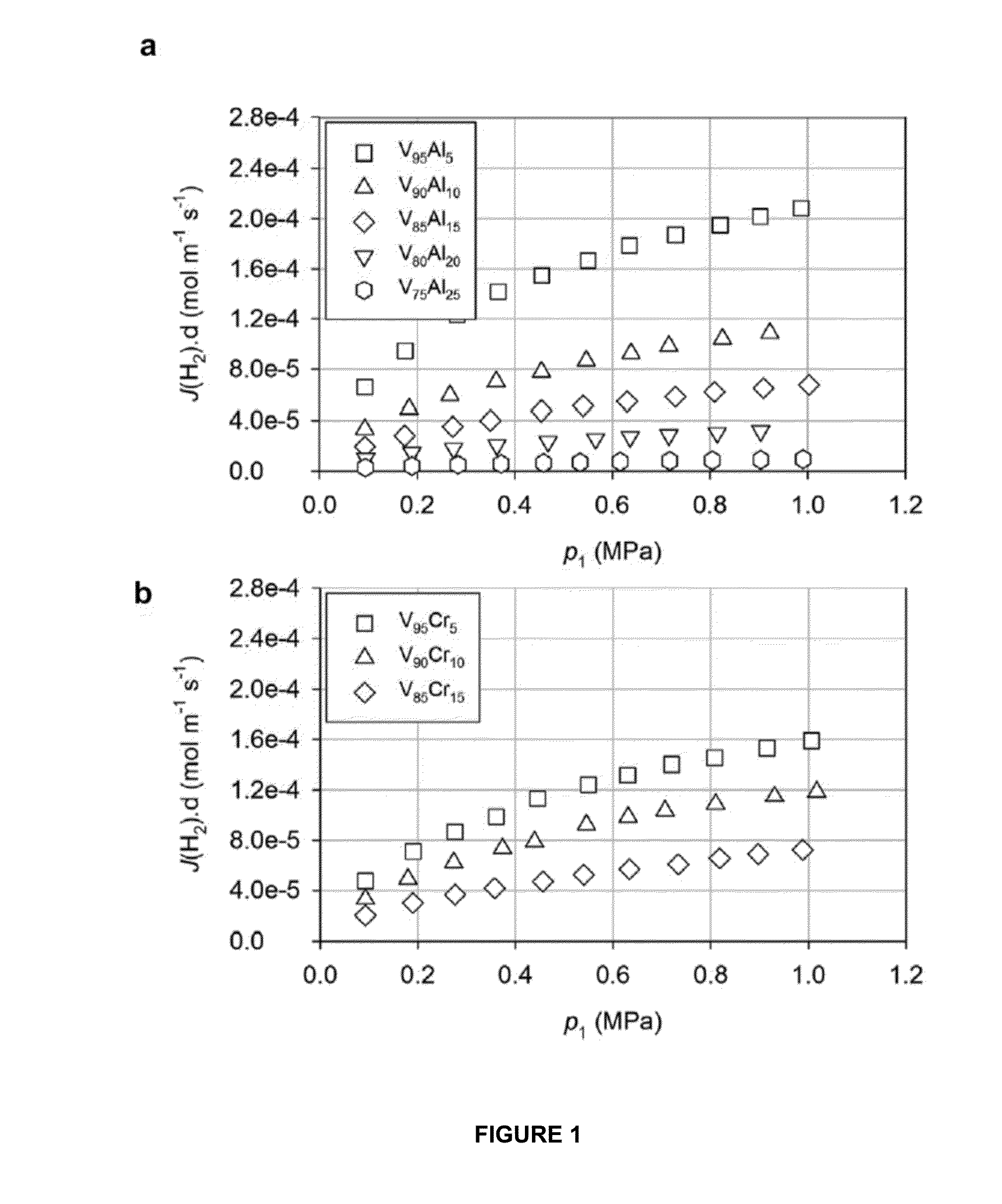

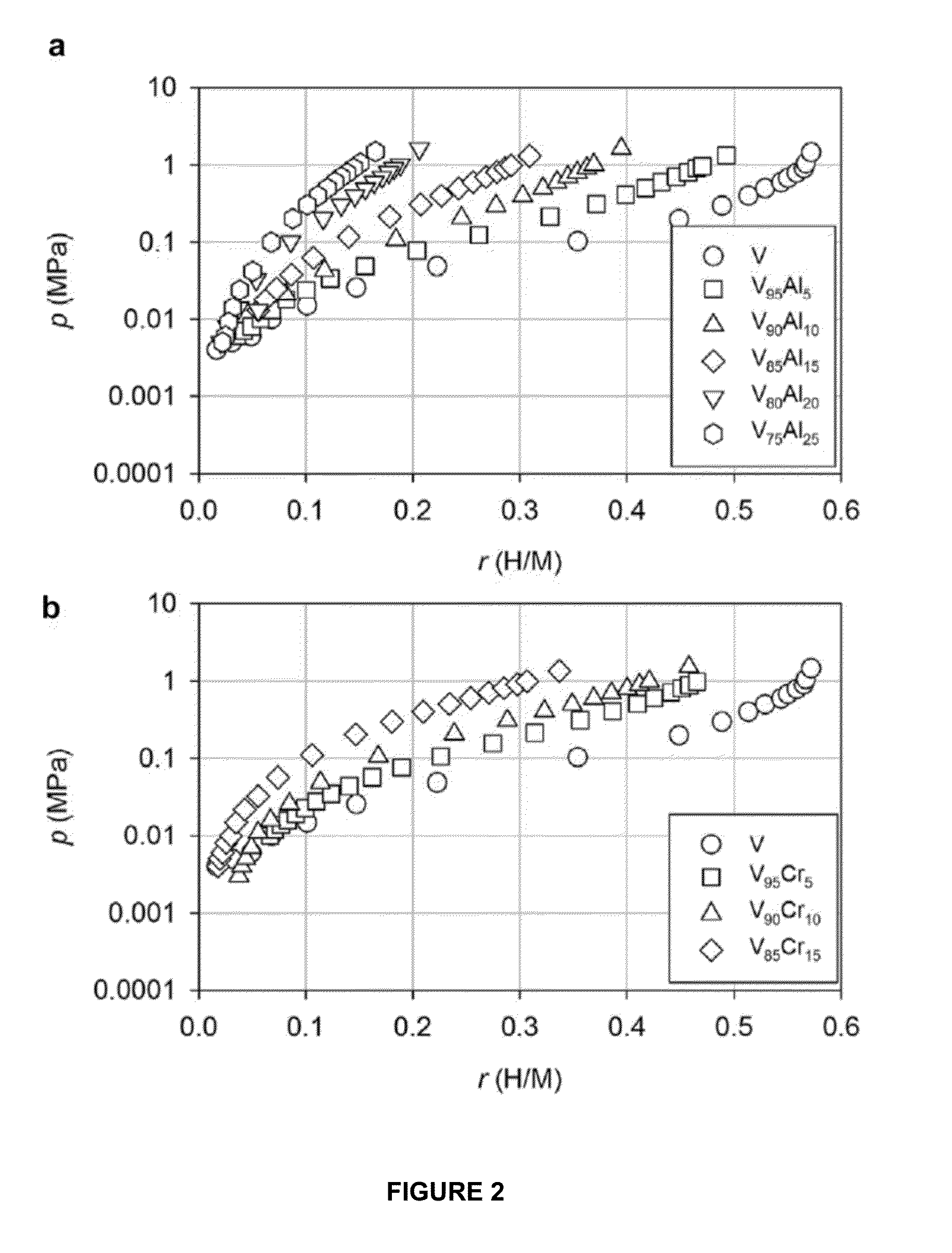

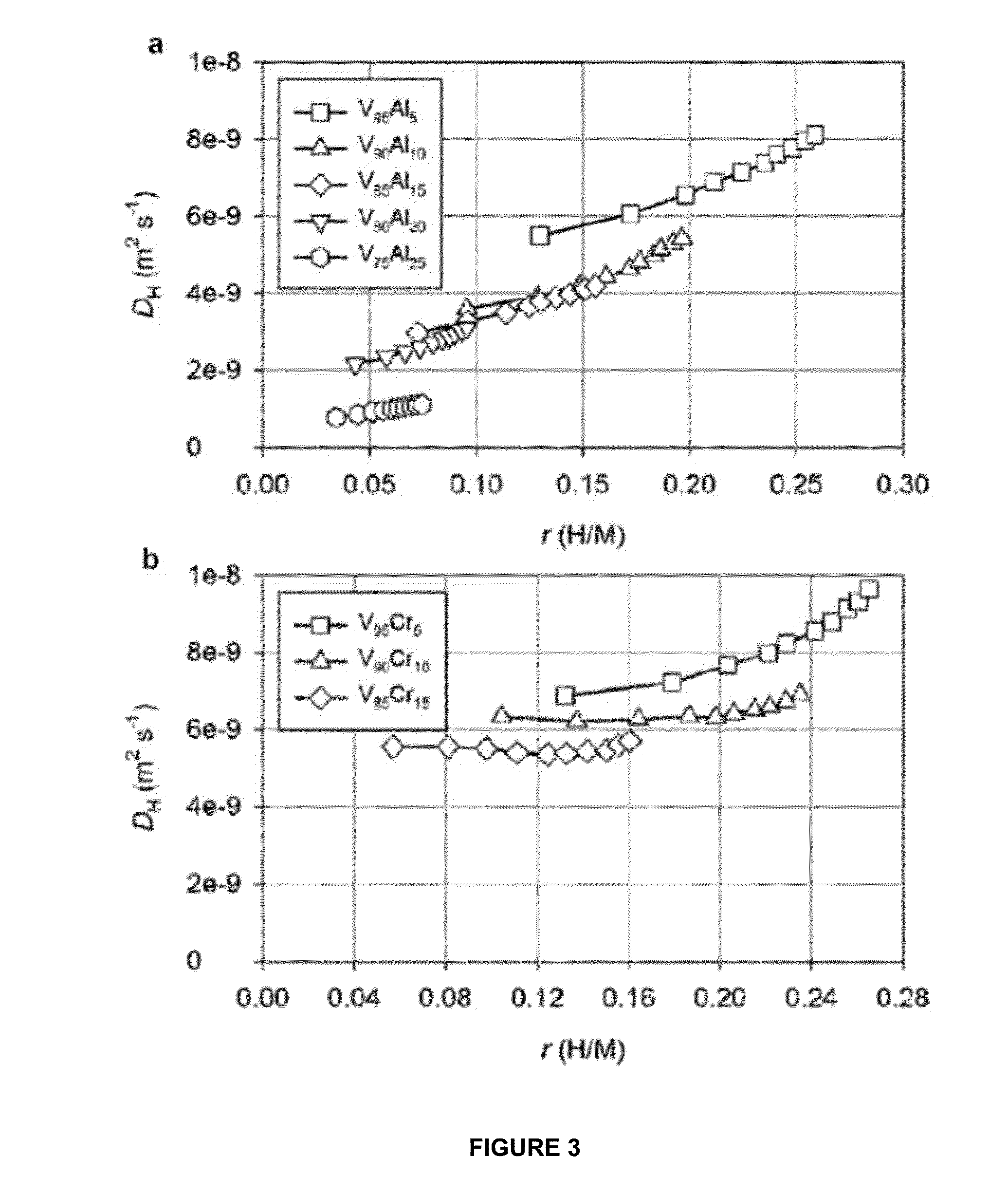

Alloy for catalytic membrane reactors

ActiveUS20150368762A1Reduce porosityImprove microstructureHydrogen separation by selective and reversible uptakeProductsAlloyCatalytic membrane

Owner:COMMONWEALTH SCI & IND RES ORG

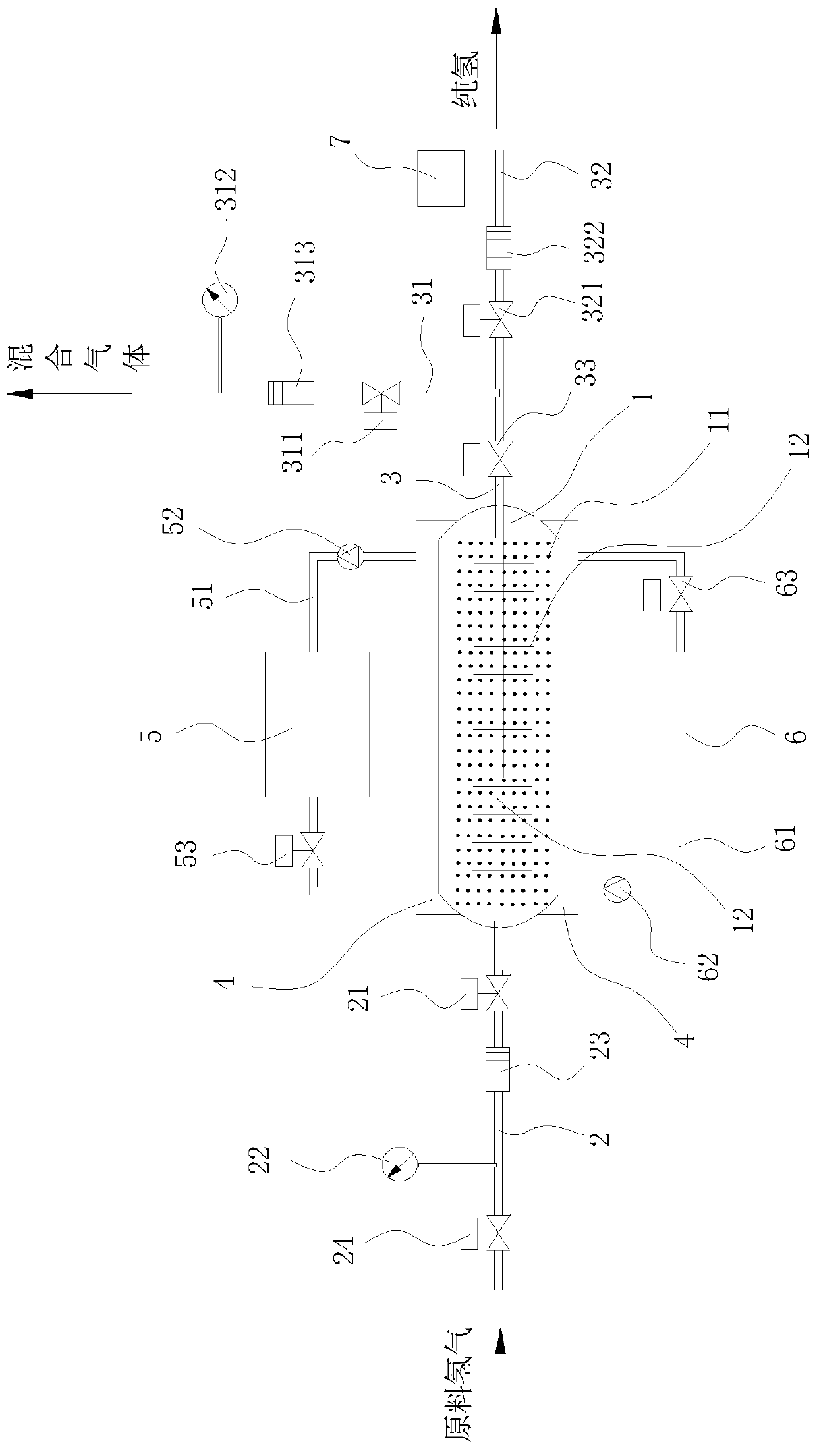

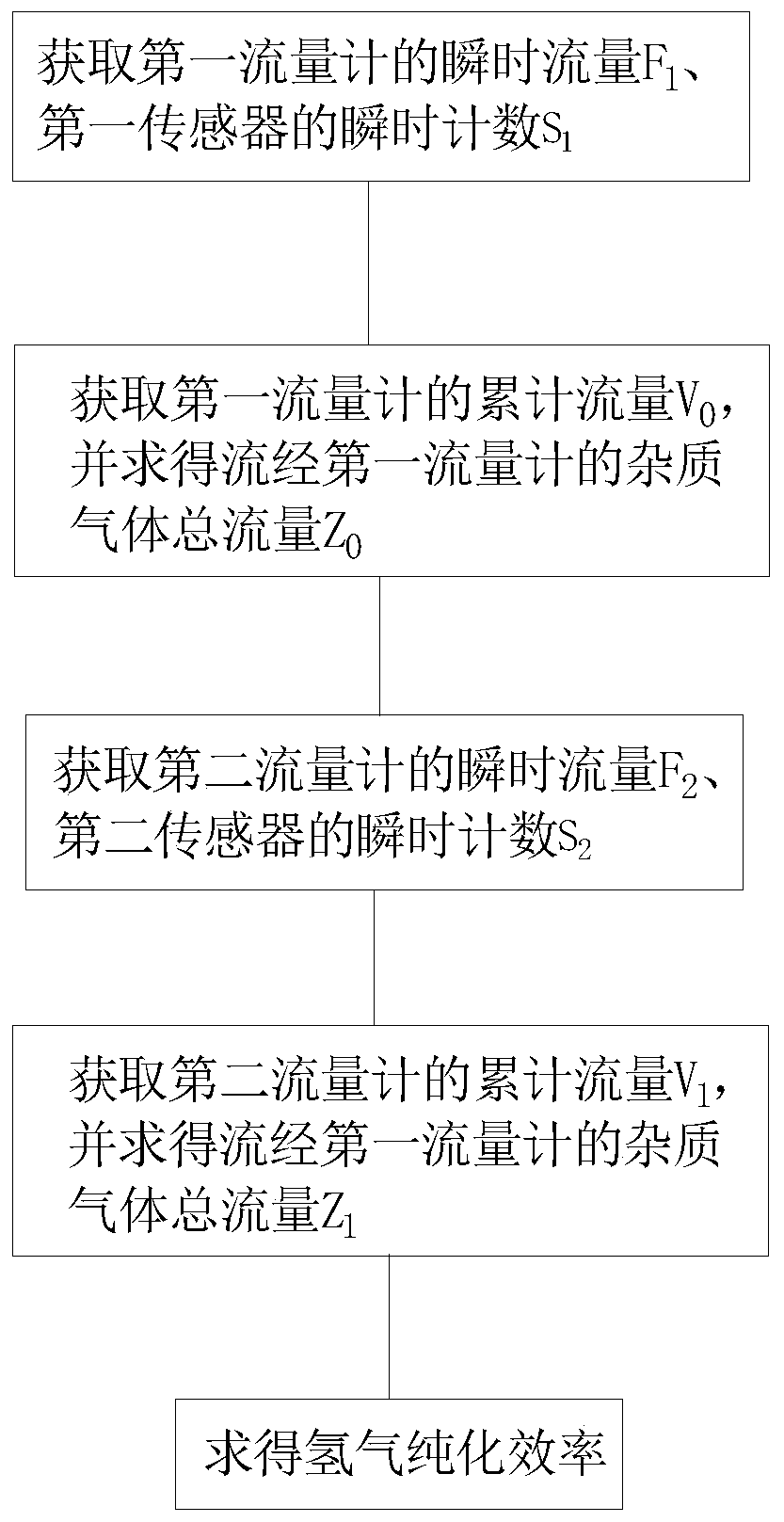

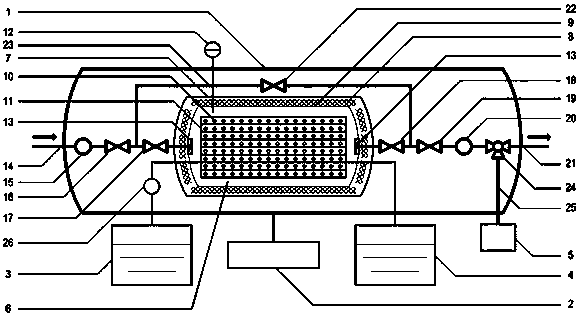

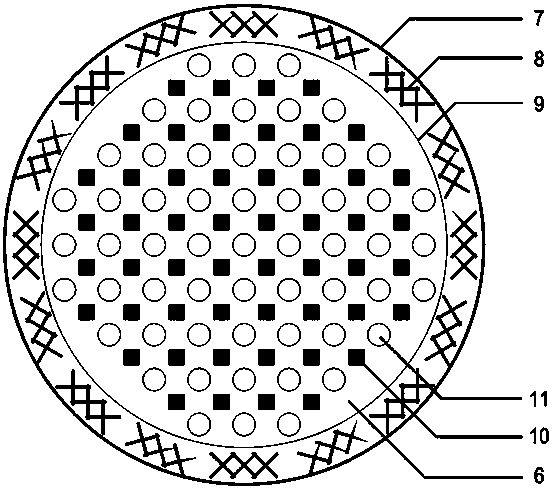

Hydrogen purification device and method for detecting hydrogen purification efficiency of hydrogen purification device

InactiveCN110171805AHigh hydrogen storage capacityOverall small sizeHydrogen separation by selective and reversible uptakeHydrogen separation using solid contactImpurityRaw material

The invention discloses a hydrogen purification device. The hydrogen purification device comprises a hydrogen storage device filled with hydrogen storage alloy powder, wherein one end of the hydrogenstorage device is connected with an inlet pipeline; the other end of the hydrogen storage device is connected with an outlet pipeline; and the hydrogen storage device is provided with a heat exchangedevice. When a hydrogen raw material mixed with impurity gas enters the hydrogen storage device through the inlet pipeline, hydrogen is absorbed by the hydrogen storage alloy powder in the hydrogen storage device; when the hydrogen raw material is stopped from entering the hydrogen storage device, gas in the hydrogen storage device is slowly discharged through the outlet pipeline, the content of impurity gas in the discharged gas is high, and then the hydrogen with gradually higher purity is slowly discharged. The complexity of the hydrogen purification device is simplified, the occupied spaceof the hydrogen purification device is reduced, the operation condition is mild, the safety is high, and the application range is wide. The invention also discloses a method for detecting hydrogen purification efficiency of the hydrogen purification device, the purification efficiency of pure hydrogen is obtained by calculating the content of impurities, and the detection precision of the hydrogen purification efficiency is improved.

Owner:CHINA JILIANG UNIV

Aluminum Metal Organic Framework Materials

ActiveUS20150152123A1High symmetryImprove solubilityCarbon compoundsNickel organic compoundsMetal-organic frameworkSingle crystal

The invention relates to monocrystalline single crystals of metal-organic framework materials comprising at least one aluminium metal ion, processes for preparing the same, methods for employing the same, and the use thereof. The invention also relates to monocrystalline aluminium metal-organic frameworks.

Owner:TEXAS A&M UNIVERSITY

Low-temperature methanol washing device and method for removing acid gas in synthesis gas

ActiveCN106281476AReduce lossesReduce dosageHydrogen separation by selective and reversible uptakeHydrogen separation at low temperatureCondensation processMethanol water

The invention discloses a low-temperature methanol washing device and a method for removing acid gas in synthesis gas. A main low-temperature methanol washing process is reconfigured, semi-lean solution methanol is additionally taken as main washing methanol on the basis of an original full-lean solution absorption process, and the dosage of lean solution methanol is decreased by 15%-30%, so that the dosages of thermal regeneration tower reboiler steam, thermal regeneration tower top condenser circulating water, lean methanol water cooler circulating water and H2S concentration tower gas stripping nitrogen are decreased by 15%-30% to achieve the energy saving and yield increasing targets; meanwhile, a traditional three-stage condensation process on a thermal regeneration tower top is canceled, therefore, methanol losses are reduced, and an ammonia crystallization phenomenon is avoided. Energy saving and yield increasing improvement on a traditional low-temperature methanol washing device is also suitable for the newly-built low-temperature methanol washing device.

Owner:SHANGHAI BEINENG CHEM TECH

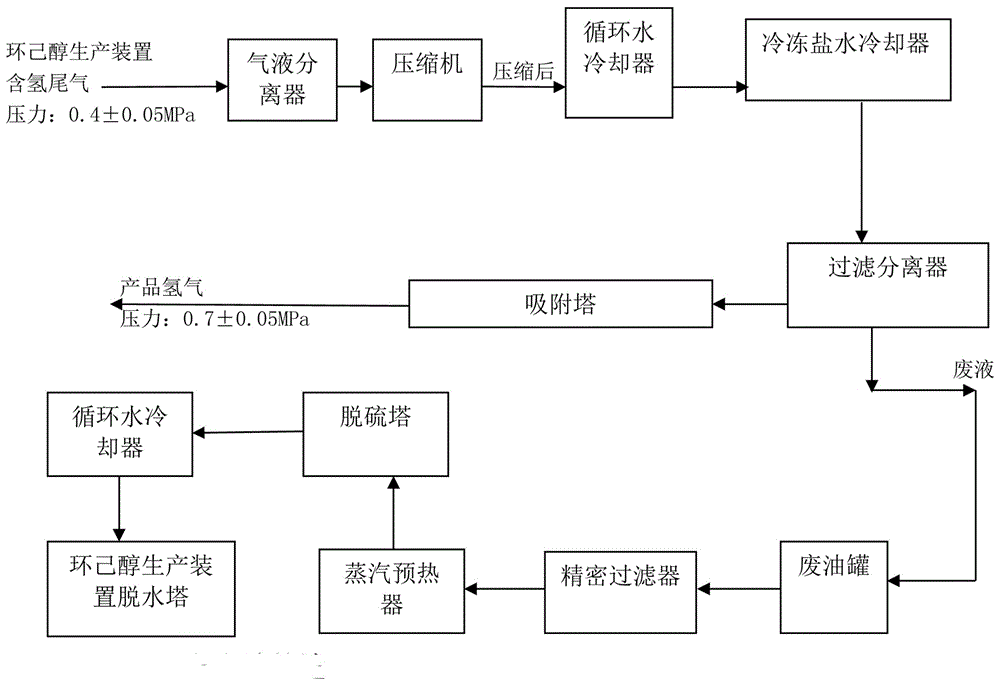

Hydrogen-containing tail gas recycling process of cyclohexanol production device

ActiveCN105688591AEfficient separationEasy to recycleHydrogen separation by selective and reversible uptakeHydrogen separation at low temperatureLiquid wasteCyclohexene

The invention belongs to a hydrogen-containing tail gas recycling process of a cyclohexanol production device. The hydrogen-containing tail gas recycling process comprises the following steps: conveying hydrogen-containing tail gas generated by the cyclohexanol production device into a gas-liquid separator, and compressing the gas separated from the gas-liquid separator to be 0.8MPa by a compressor; then cooling the gas to 8 DEG C to 12 DEG C; finally, enabling the gas to enter a filtering separator to obtain waste liquid and crude hydrogen gas, and adsorbing the crude hydrogen gas by an adsorption tower to obtain product hydrogen gas; collecting waste liquid obtained by the filtering separator to a waste oil tank, and standing and separating out water; filtering an organic phase with a fine filter, and heating to 120 DEG C to 140 DEG C; then conveying the organic phase into a desulfurizing tower, and then cooling and conveying the organic phase to the cyclohexanol production device to be used as the raw material. With the adoption of the hydrogen-containing tail gas recycling process of the cyclohexanol production device, moisture and impurities in the tail gas exhausted by a hydrogenation reaction system of the cyclohexanol production device can be effectively separated, and components including benzene, cyclohexene, cyclohexane and the like in the tail gas are recycled very well; with the adoption of the process, the tail gas can be returned back to a dehydration tower of the cyclohexanol production device to be recycled.

Owner:PINGDINGSHAN SHENMA WANLI CHEM

Hydrogen mitigation and energy generation with water-activated chemical heaters

InactiveUS20070272090A1Prevent release of hydrogenPreventing situationAluminium compoundsReversible hydrogen uptakeScavengerHydrogen

Less hazardous methods for generating energy for heating water, medical supplies or comestible products using improved flameless chemical heaters / flameless ration heaters by novel chemical or electrochemical means, each capable of suppressing the generation of hydrogen gas. Remote unit self heating meals may be heated by forming a reaction mixture comprising magnesium or a magnesium-containing alloy, a hydrogen scavenger and water, and reacting the reaction mixture to generate sufficient energy for heating the water, or other comestible product while simultaneously suppressing the generation of hydrogen. Alternatively, a battery may be employed using Mg and MnO2.

Owner:BOMMARAJU TILAK V

Application of porous structured organic films for gas storage

ActiveUS20130017141A1Hydrogen separation by selective and reversible uptakeGas treatmentOrganic filmInorganic chemistry

A porous structured organic film for storing gaseous a gaseous entity and method for storing gaseous entities in a porous structured organic film, the porous structured organic film including a plurality of segments and a plurality of linkers arranged as a covalent organic framework, wherein at a macroscopic level the covalent organic framework is a film and contains a plurality of sites accessible to one or more gaseous entity.

Owner:XEROX CORP

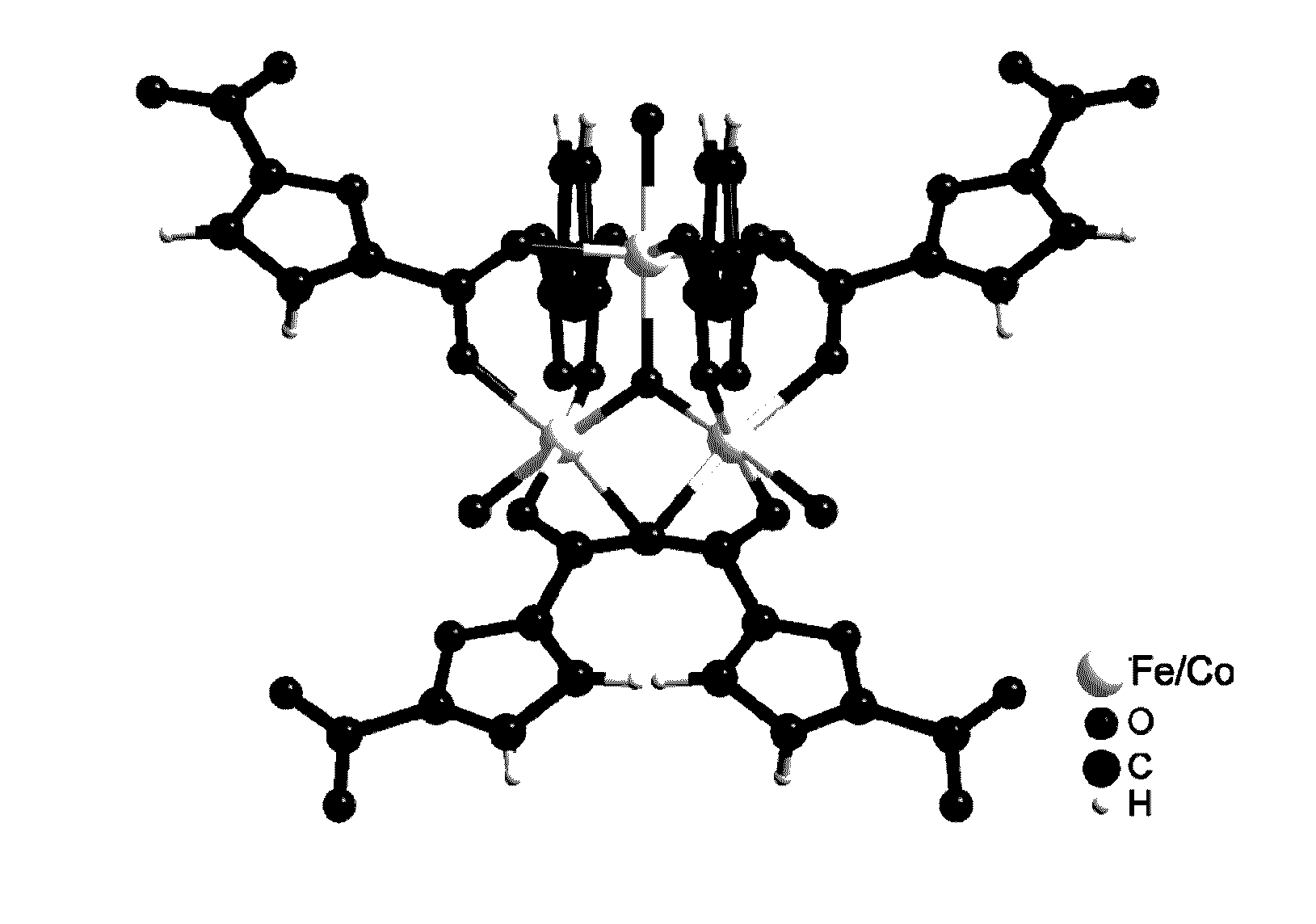

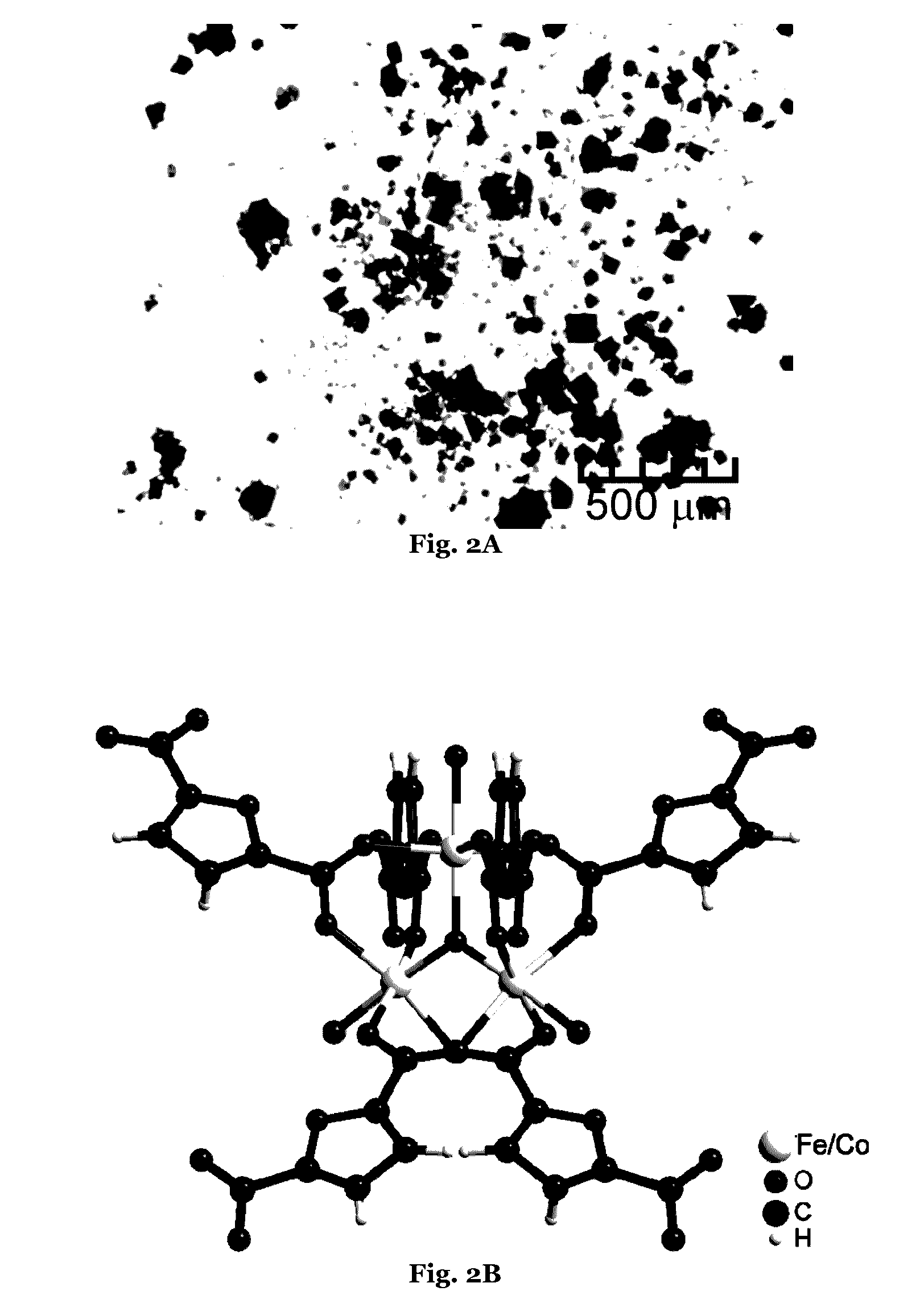

Iron Metal Organic Framework Materials

ActiveUS20160346759A1Design is limitedStructure moreNitrogen compoundsCarbon compoundsPhysical chemistryMetal-organic framework

The invention relates to an improved process for preparing metal-organic framework materials, metal-organic frameworks obtainable by such processes, methods using the same, and the use thereof. The process of the invention provides an improved process for preparing metal-organic frameworks in particular monocrystalline metal-organic frameworks having large crystal sizes. The invention also relates to metal organic frameworks comprising iron or titanium, and their uses.

Owner:TEXAS A&M UNIVERSITY

Helium recovery process

InactiveUS8152898B2Enhances their economic viabilityHydrogen separation by selective and reversible uptakeIsotope separationHigh concentrationHydrogen

Helium is recovered from gas streams containing high concentrations of hydrogen gas and low concentrations of helium gas, such as from the recycle stream from the production of ammonia. The inventive process provides for an integrated process for the recovery of both an enriched helium gas stream product and a high purity hydrogen gas stream product.

Owner:PRAXAIR TECH INC

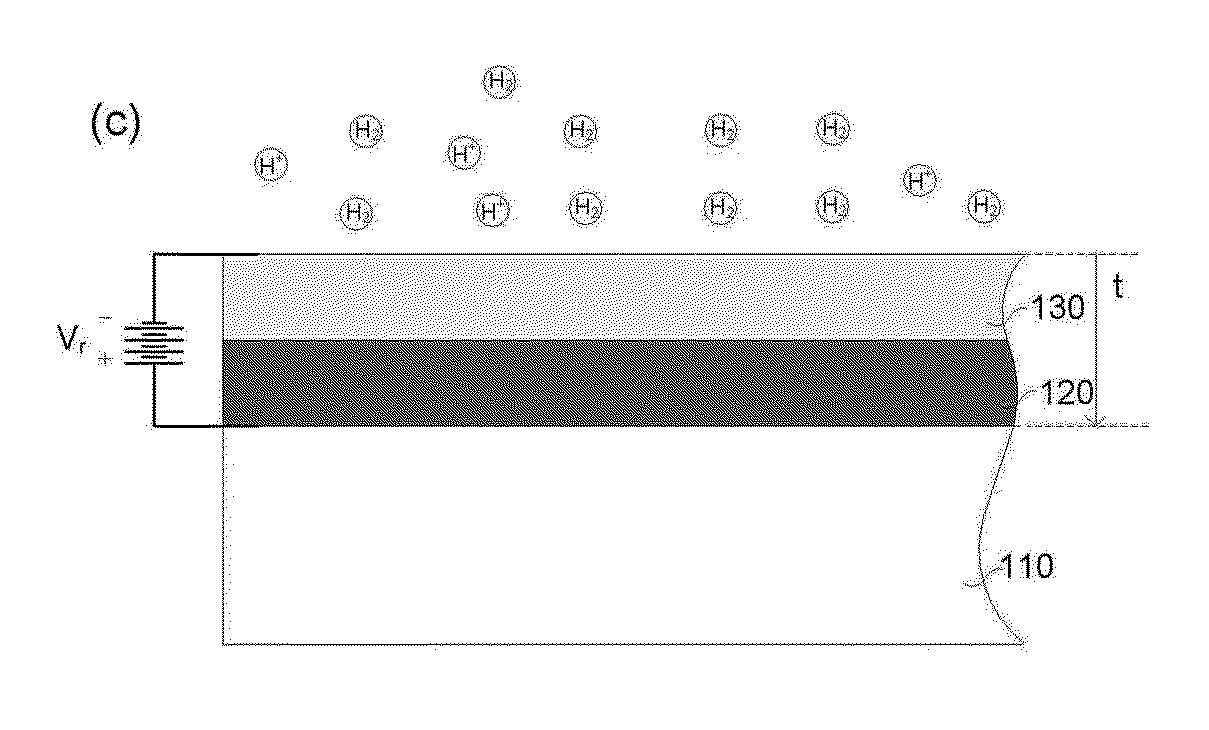

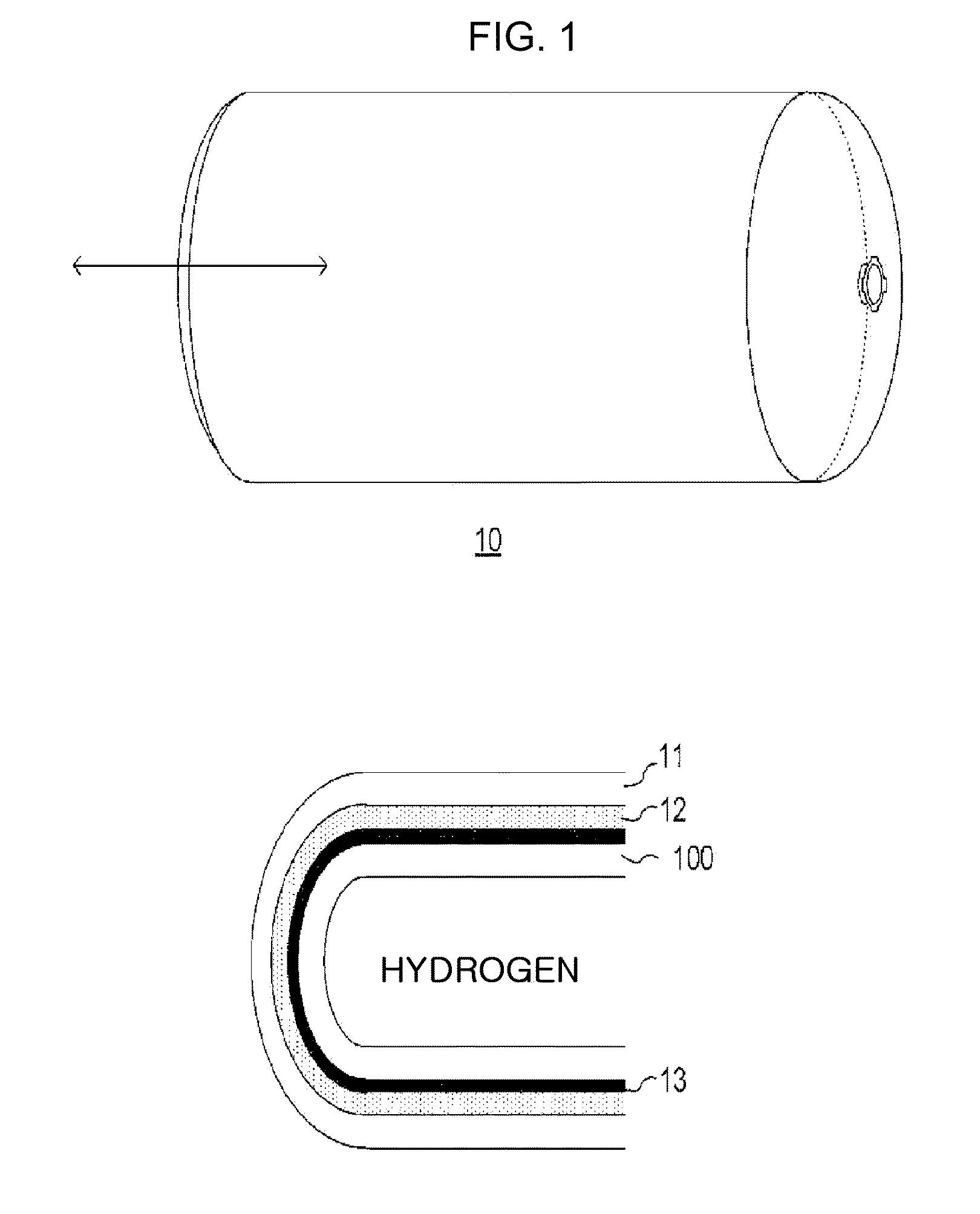

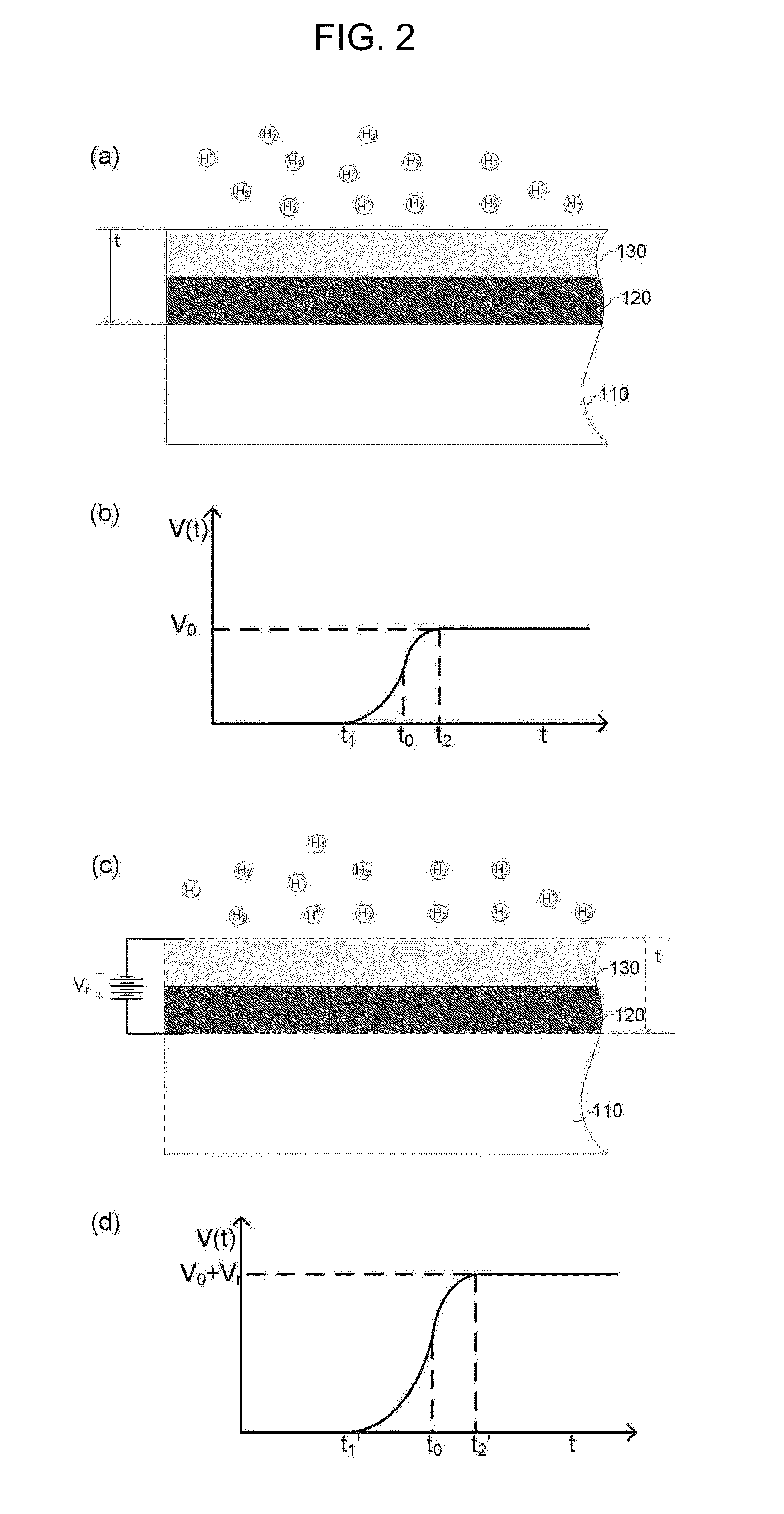

Hydrogen penetration barrier

ActiveUS20110175078A1Prevent penetrationPrevent materialHydrogen separation by selective and reversible uptakeSemi-permeable membranesHydrogen moleculeConductive materials

Provided is a hydrogen penetration barrier for preventing hydrogen from being diffused and discharged through a barrier and preventing hydrogen embrittlement of a material due to diffusion of hydrogen ions into a material. In detail, the hydrogen penetration barrier prevents penetration of hydrogen ions by using a built-in potential of a semiconductor layer doped with a p-type impurity and a semiconductor layer doped with an n-type impurity and a potential applied by a reverse biased voltage and includes an absorption layer absorbing the hydrogen molecules to primarily prevent the penetration of the hydrogen molecules and uses the absorption layer made of the conductive material as an application electrode of the reverse biased voltage and ionizes the hydrogen absorbed to the absorption layer to secondarily prevent the penetration of the hydrogen molecules and prevent the hydrogen embrittlement.

Owner:KOREA RES INST OF STANDARDS & SCI

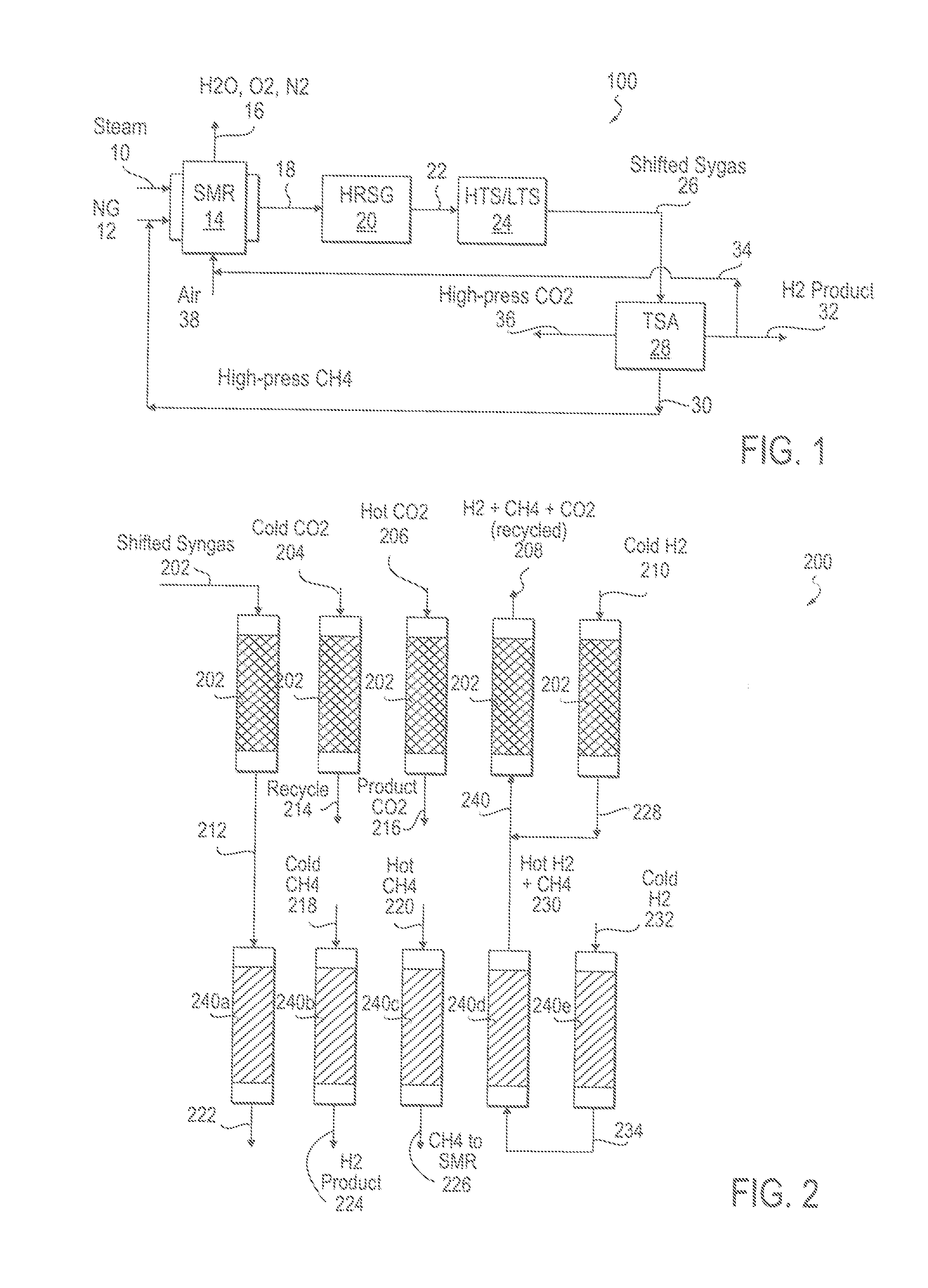

Capture of CO2 from Hydrogen Plants Using A Temperature Swing Adsorption Method

ActiveUS20140186255A1High purityHydrogen separation by selective and reversible uptakeProductsMethane reformerHydrogen

The invention involves the use of a temperature swing adsorption process in steam methane reforming or autothermal reforming H2-production processes to capture CO2 and produce nearly pure off gas streams of CO2 for sequestration or enhanced oil recovery (EOR). The hydrogen stream output is substantially pure and can be recycled as a fuel to the steam methane reformer furnace or used in other petroleum and petrochemical processes.

Owner:CHEVROU USA INC

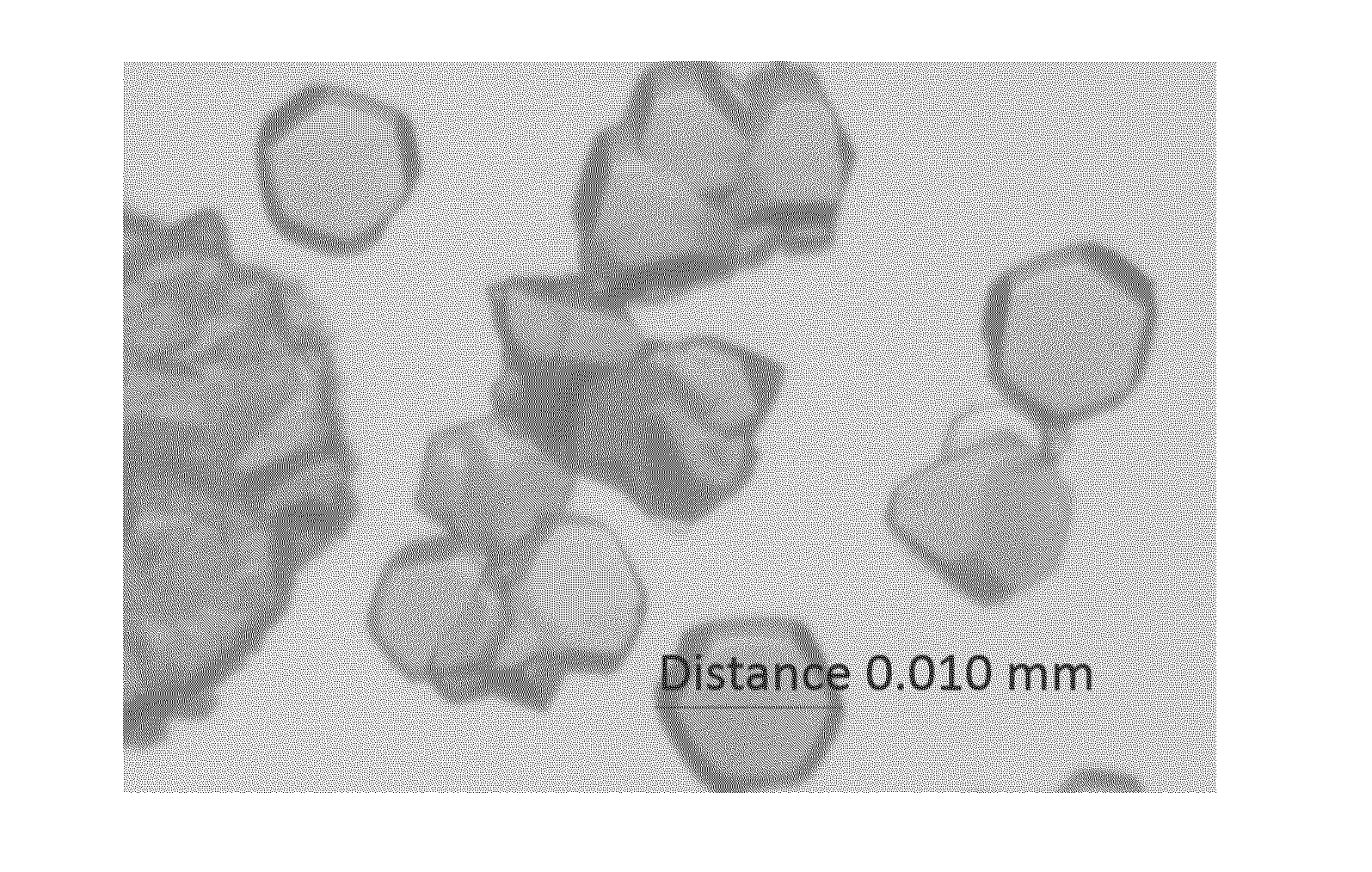

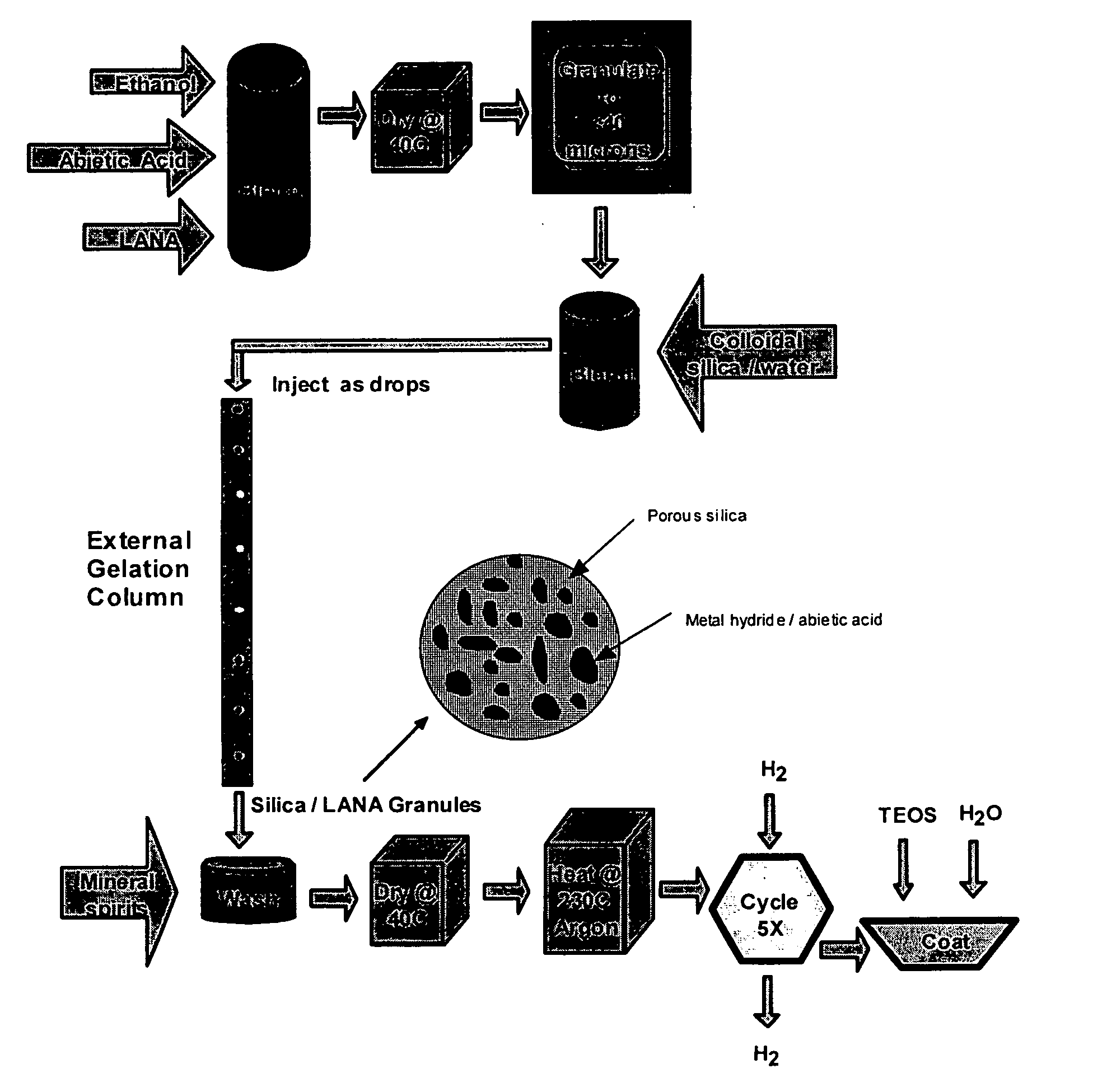

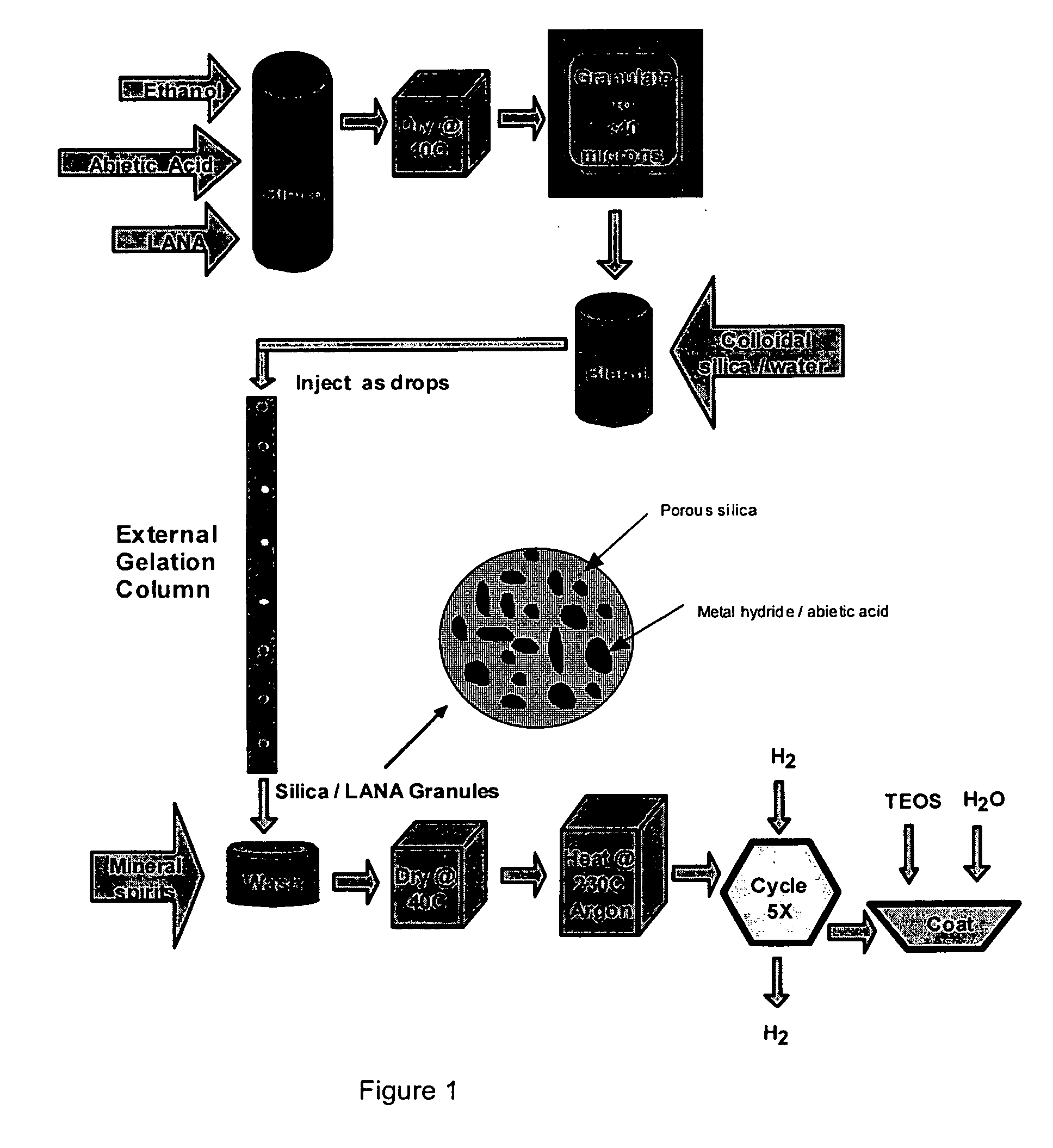

Sol-gel/metal hydride composite and process

InactiveUS20070172656A1High strengthReversible hydrogen uptakeCeramic layered productsSol gel matrixPhotochemistry

An external gelation process is described which produces granules of metal hydride particles contained within a sol-gel matrix. The resulting granules are dimensionally stable and are useful for applications such as hydrogen separation and hydrogen purification. An additional coating technique for strengthening the granules is also provided.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

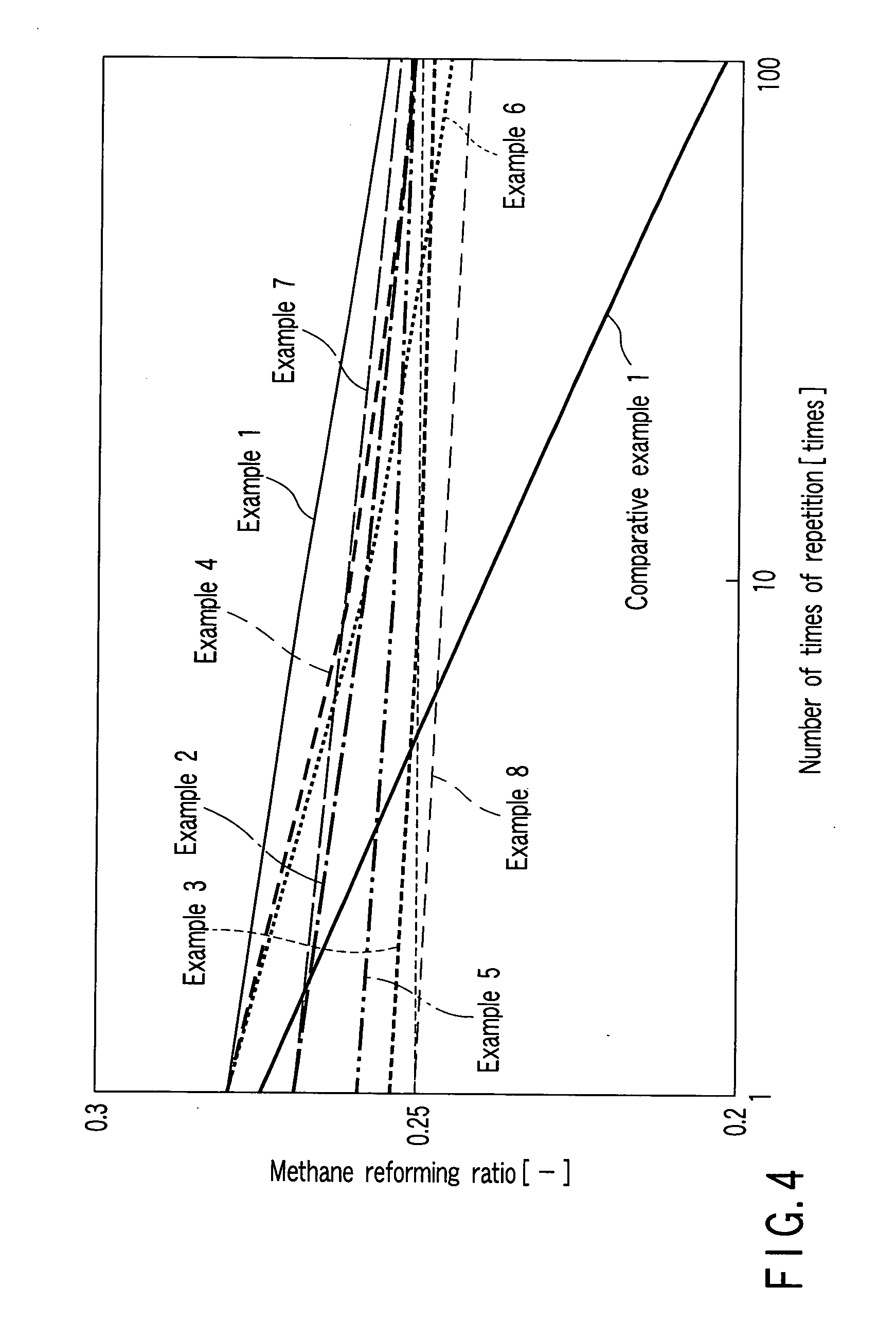

Catalyst-containing reaction accelerator and steam reforming method using hydrocarbon

InactiveUS20050214203A1Hydrogen separation by selective and reversible uptakeOther chemical processesSteam reformingLithium

A catalyst-containing reaction accelerator used in a steam reforming reaction of hydrocarbon comprises a solid catalyst to accelerate the steam reforming reaction, and a composite absorbent which is mixed with the solid catalyst. The composite absorbent has a main absorbent which contains a lithium-containing oxide for absorbing and desorbing carbon dioxide by-produced by the steam reforming reaction, and a molten carbonate holding material which does not react with the main absorbent at a temperature at which the main absorbent absorbs and desorbs carbon dioxide.

Owner:KK TOSHIBA

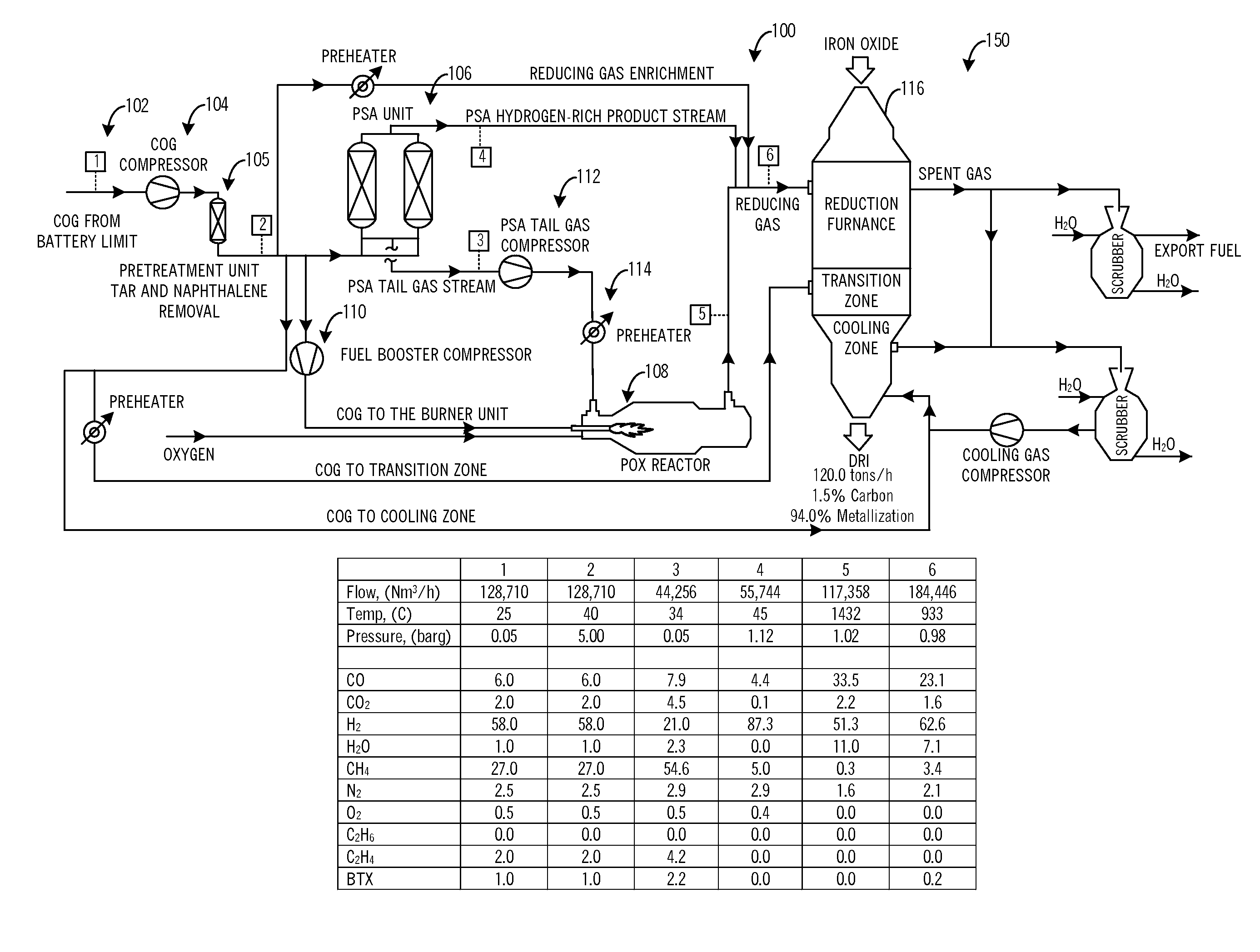

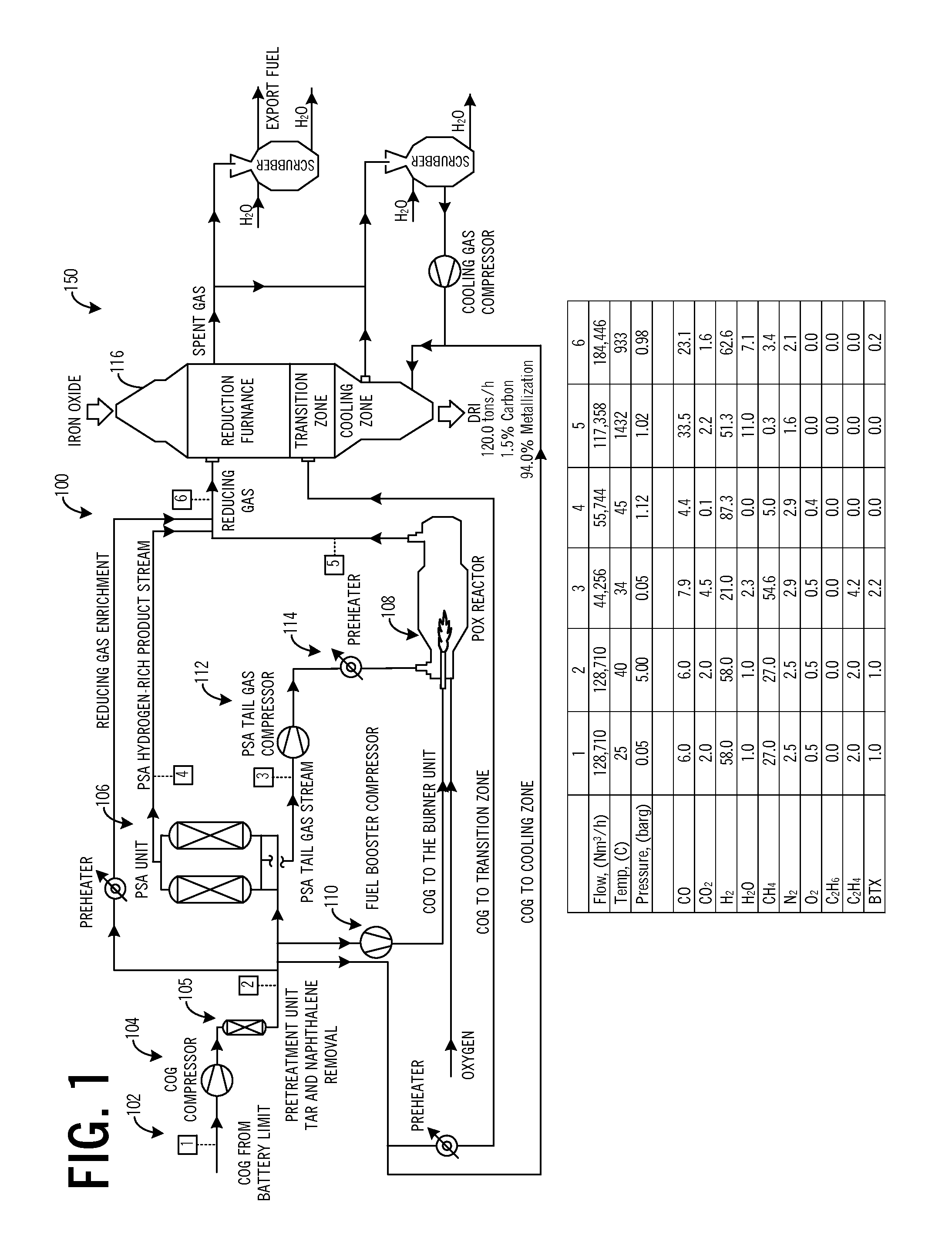

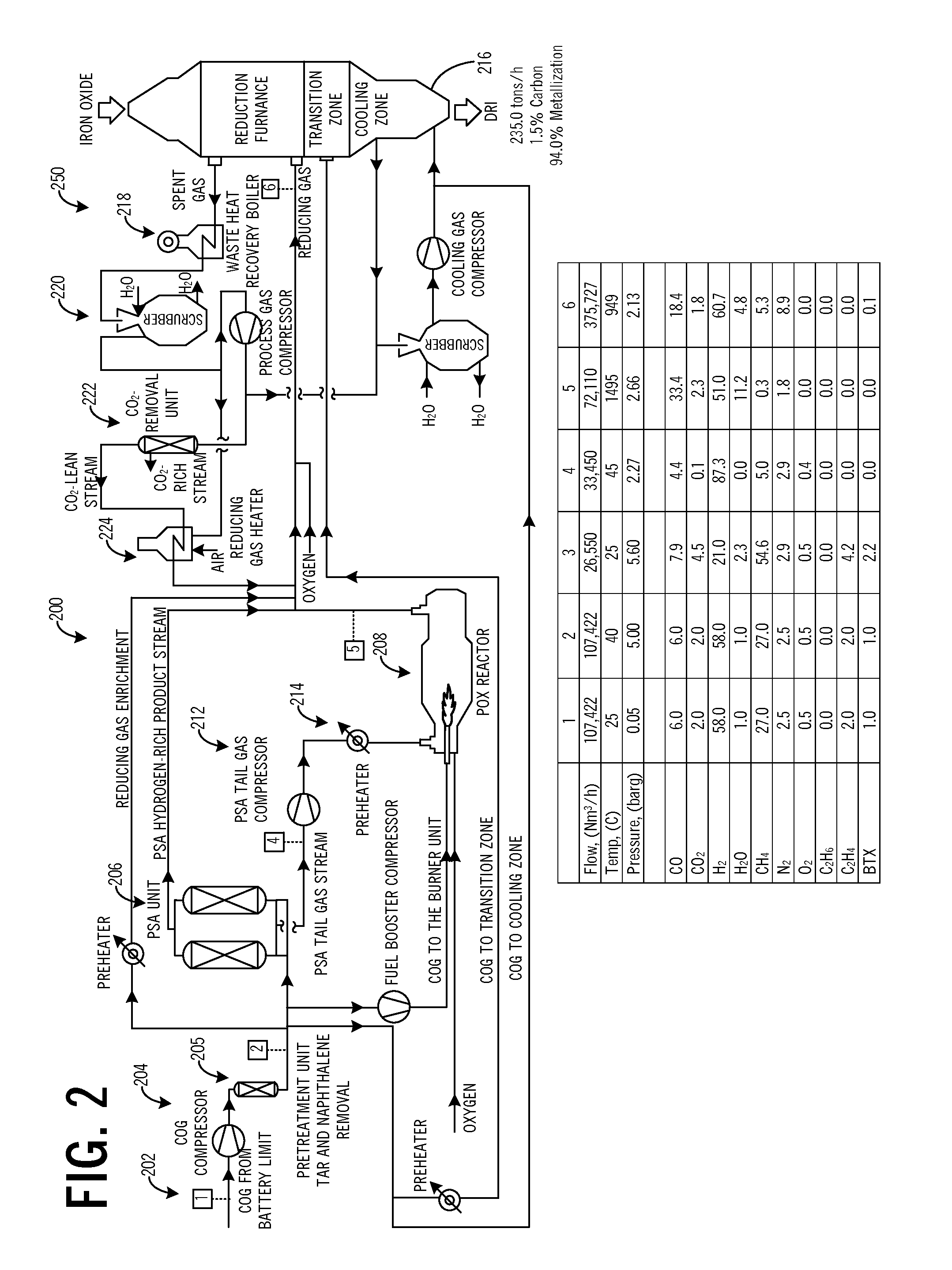

Method for reducing iron oxide to metallic iron using coke oven gas

ActiveUS20160083811A1High carbon contentHydrogen separation by selective and reversible uptakeEnergy inputHydrogenCoke oven

The present invention provides a method for reducing iron oxide to metallic iron using coke oven gas, including: dividing coke oven gas from a coke oven gas source into a plurality of coke oven gas streams; providing a first coke oven gas stream to a hydrogen enrichment unit to form a hydrogen-rich product stream that is delivered to a reduction shaft furnace as part of a reducing gas stream; and providing a tail gas stream from the hydrogen enrichment unit to a reforming reactor to form a reformed gas stream that is delivered to a reduction shaft furnace as part of the reducing gas stream. Optionally, a spent top gas stream from the reduction shaft furnace is cleansed of CO2 and recycled back to the reducing gas stream.

Owner:MIDREX TECH INC

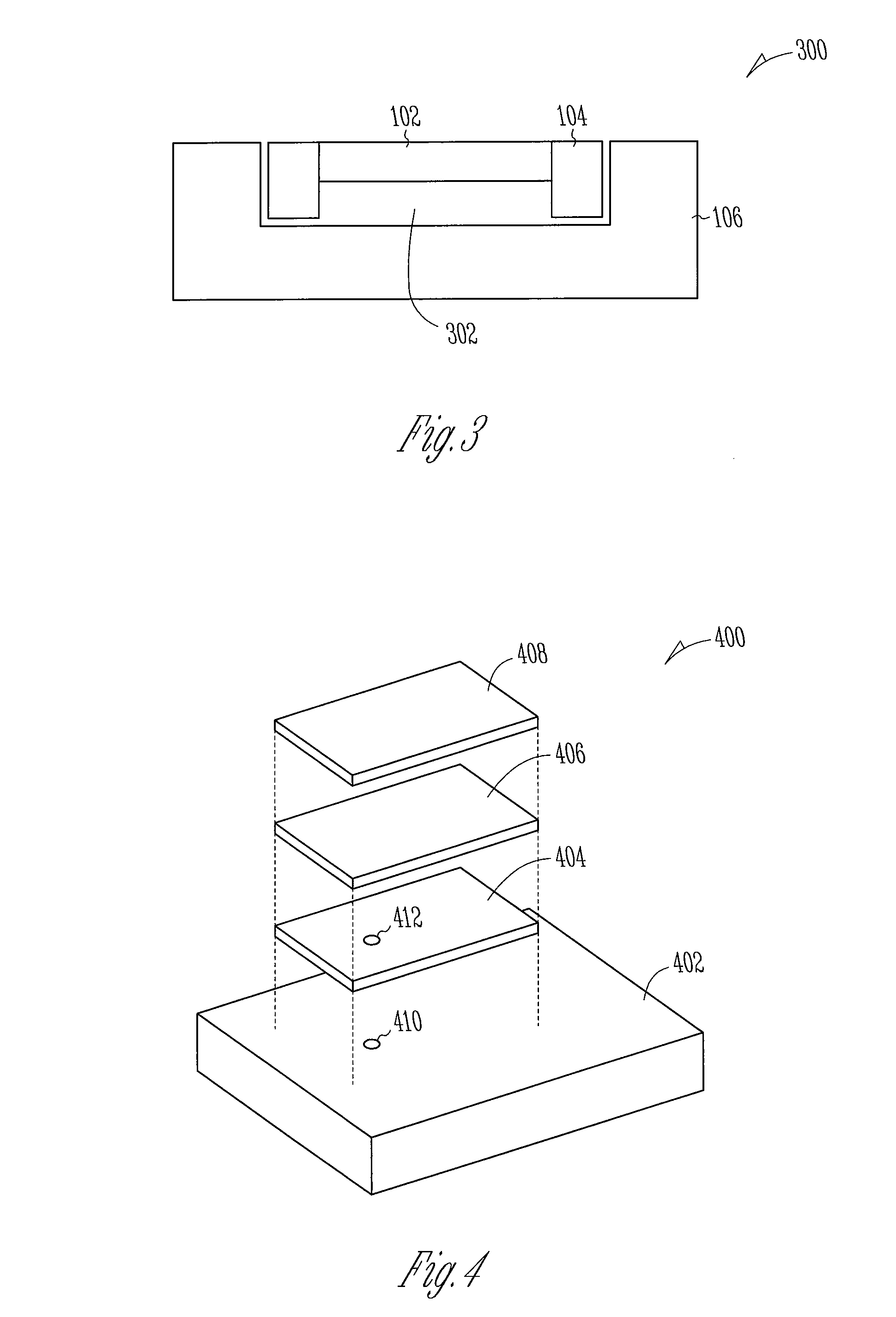

Separation, purification and recovery process of hydrogen in industrial waste gas

PendingCN109516438ADirect reuseSimple processHydrogen separation by selective and reversible uptakeHydrogen separation using solid contactInternal pressureExhaust valve

The invention discloses a separation, purification and recovery process of hydrogen in industrial waste gas. The process comprises the following steps that A, after being pressurized by a waste gas pressurizing device, hydrogen-containing industrial waste gas is led into a hydrogen storage alloy container; B, the hydrogen storage alloy container is heated by a hydrogen storage alloy container heating device to reach the temperature of 200-400 DEG C, the temperature is kept for two hours, and then the hydrogen storage alloy container heating device stops heating; C, after the hydrogen storage alloy container is cooled to 20-200 DEG C, an exhaust device is turned on, and the exhaust device is turned off when residual gas in the hydrogen storage alloy container is discharged until pressure inthe hydrogen storage alloy container is lowered to 0.001 Mpa; and D, the hydrogen storage alloy container is heated by the hydrogen storage alloy container heating device to reach the temperature of300-450 DEG C, an exhaust valve is opened, and hydrogen released by hydrogen storage alloy in the hydrogen storage alloy container is discharged into a recovery device. The purity of the recovered hydrogen is greater than 99.999%, recovery safety efficiency is high, and the recovered gas can be reutilized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

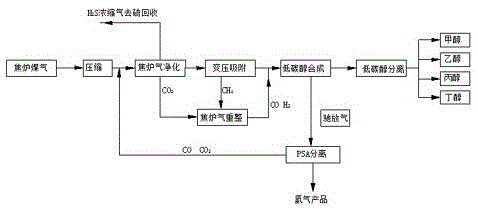

Technology for synthesizing low carbon alcohol and hydrogen as byproduct from coke oven gas

ActiveCN105061142AZero emissionAdjust the ratio of hydrogen to carbonHydrogen separation by selective and reversible uptakeOrganic compound preparationPropanolAlcohol

A technology for synthesizing low carbon alcohol and hydrogen as byproduct from coke oven gas comprises the following steps: compressing the coke oven gas, carrying out desulphurization and decarburization treatment to obtain purified coke oven gas with the H2S content being smaller than 1ppm, allowing the purified coke oven gas to enter a pressure swing adsorption unit in order to remove CH4, allowing removed CH4 and CO2 obtained after purification to enter a coke oven gas reforming unit, reforming, mixing the obtained reformed gas with the coke oven gas obtained after pressure swing adsorption to obtain synthetic gas meeting low carbon alcohol synthesis requirements, carrying out low carbon alcohol synthesis, allowing the obtained low carbon alcohol mixture to enter a low carbon alcohol separation unit, and separating to obtain methanol, ethanol, propanol and butanol products. The technology comprises the advantages of reasonable utilization of the coke oven gas, promotion of energy saving and emission reduction, energy structure adjustment, and obvious improvement of the economic and environmental benefits.

Owner:SEDIN ENG

Hydrogen purifier

PendingCN108328577AImprove securityImprove purification efficiencyHydrogen separation by selective and reversible uptakeGas-discharge lampPurification methods

The invention discloses a hydrogen purifier, which comprises a main body purifying device, an automatic controller, a heat exchange device and a waste gas treating device, wherein the main body purifying device comprises a gas inlet pipe, a gas inlet pump, a gas inlet valve, a gas inlet cut-off valve, a reaction tank, a gas discharge cut-off valve, a gas discharge valve, a gas discharge pump, a gas discharge pipe, a bypass valve, a reversing gas pipe, a gas discharge reversing valve and a waste gas discharge pipe, the reaction tank comprises a reaction tank outer wall, a reaction tank interlayer, a reaction tank inner wall, a hydrogen storage alloy reaction bed body, a pressure gauge and a filter, and the heat exchange device comprises a hot water box, a cold water box, a two-way water pump and a heat exchanger. According to the present invention, hydrogen purification is performed by using the characteristics of the hydrogen storage alloy; and the hydrogen purifier has characteristicsof small size, low cost, simple process and direct online / offline use, and has great advantages compared to other hydrogen purification methods.

Owner:BEIJING CHINA POWER UNITED TECH

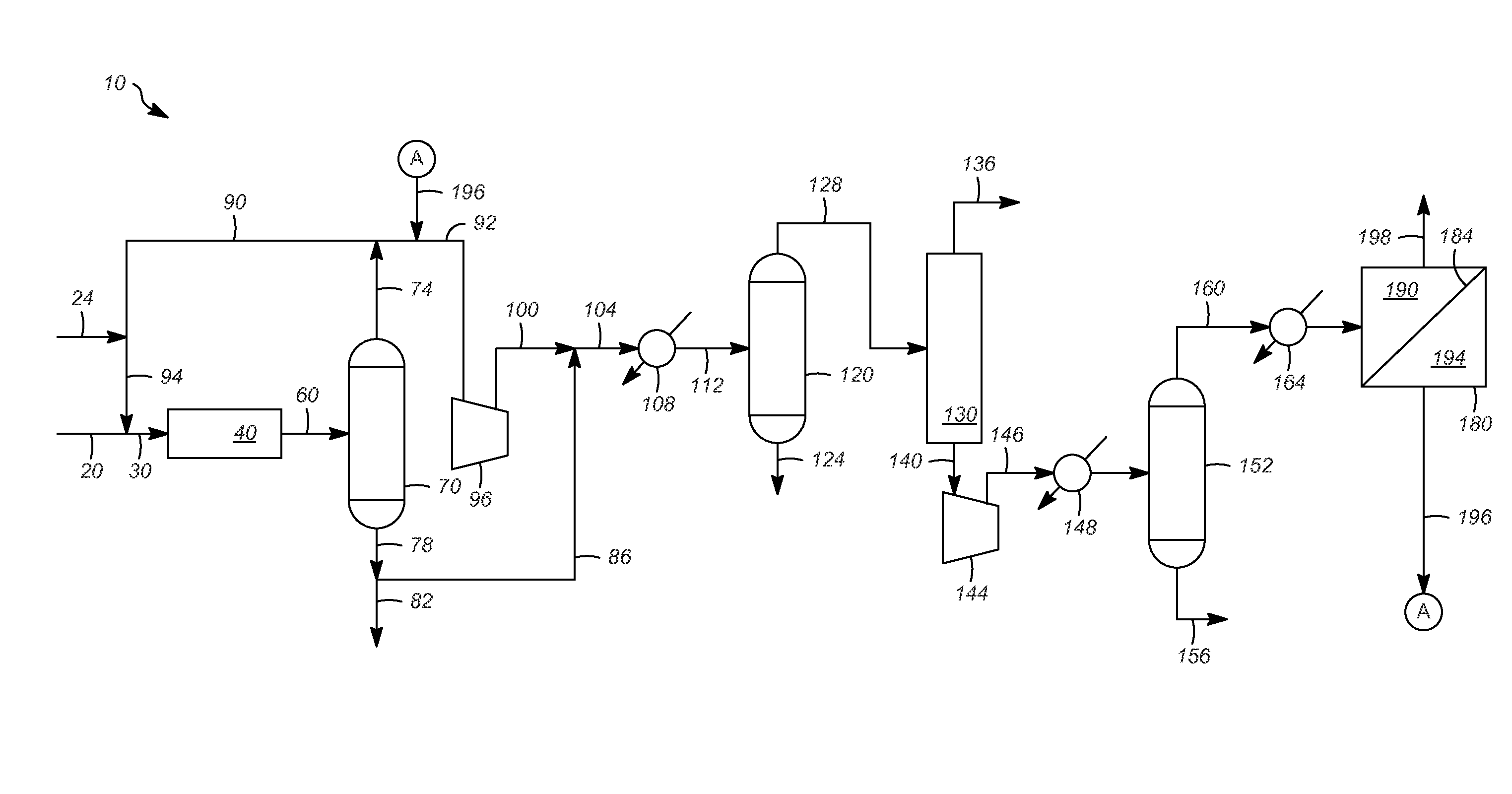

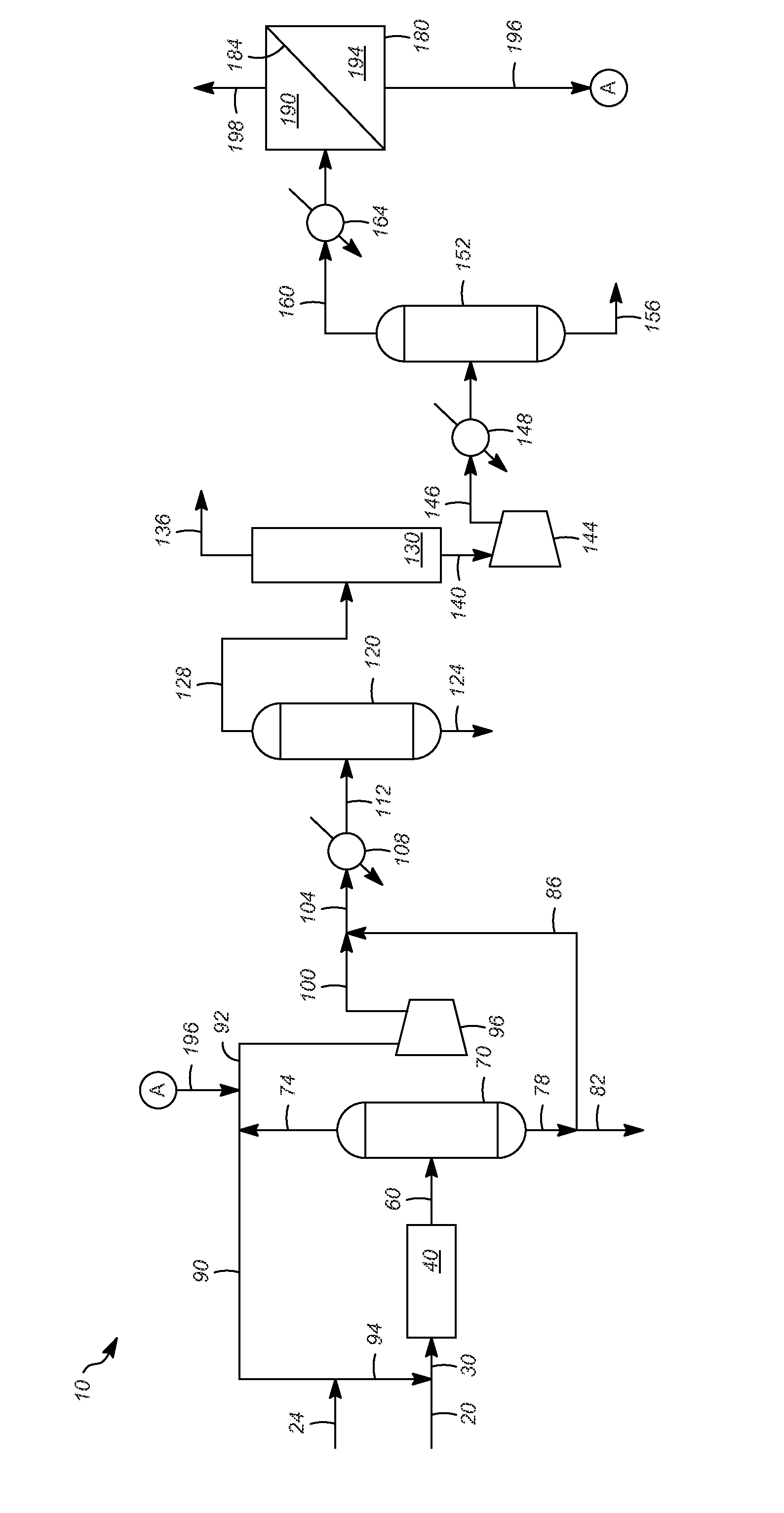

Process for catalytic reforming

ActiveUS20150086472A1Reduce compressor energy consumptionAvoid contaminationHydrogen separation by selective and reversible uptakeHydrogen/synthetic gas productionCatalytic reformingReaction zone

Owner:UOP LLC

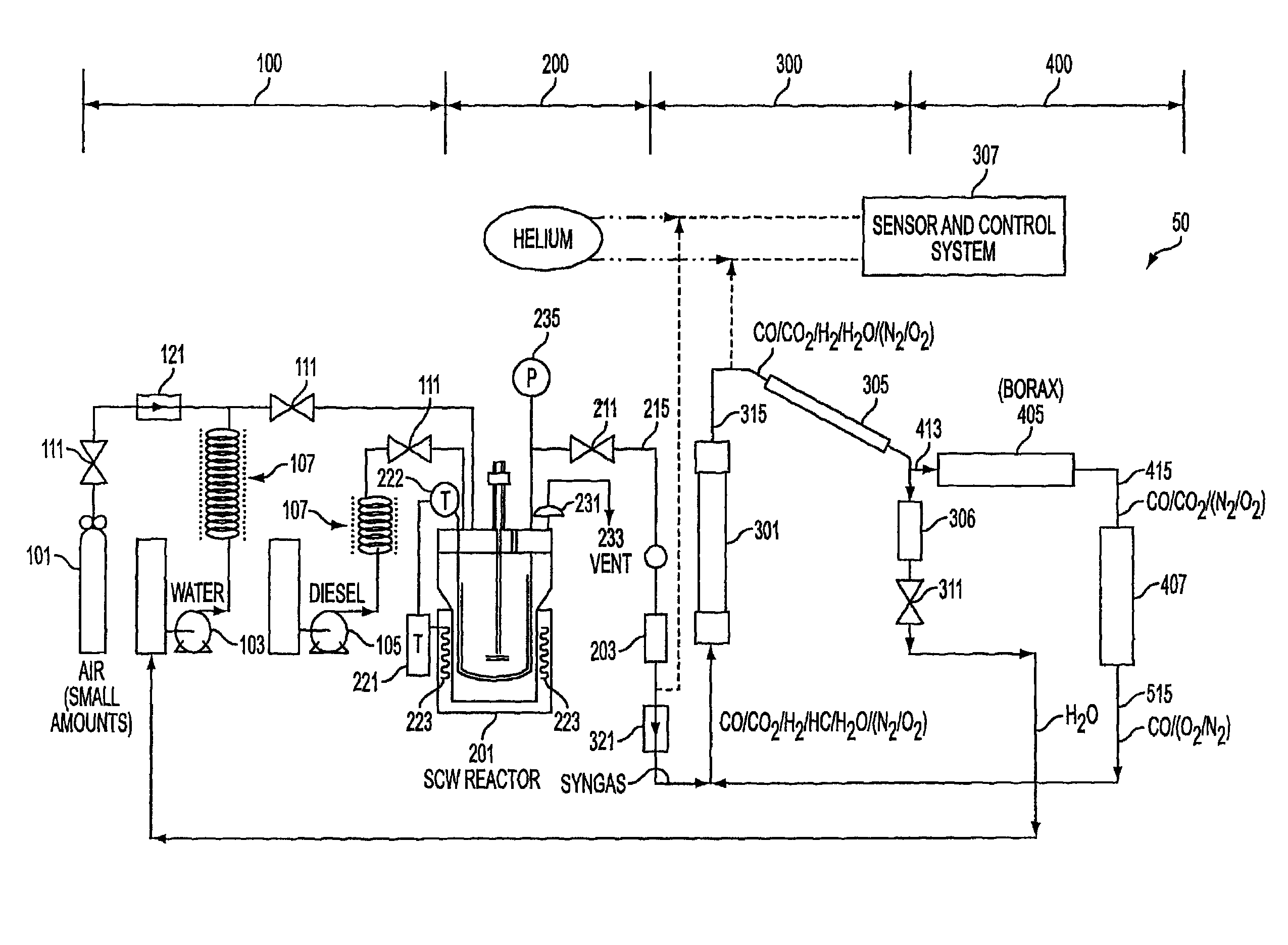

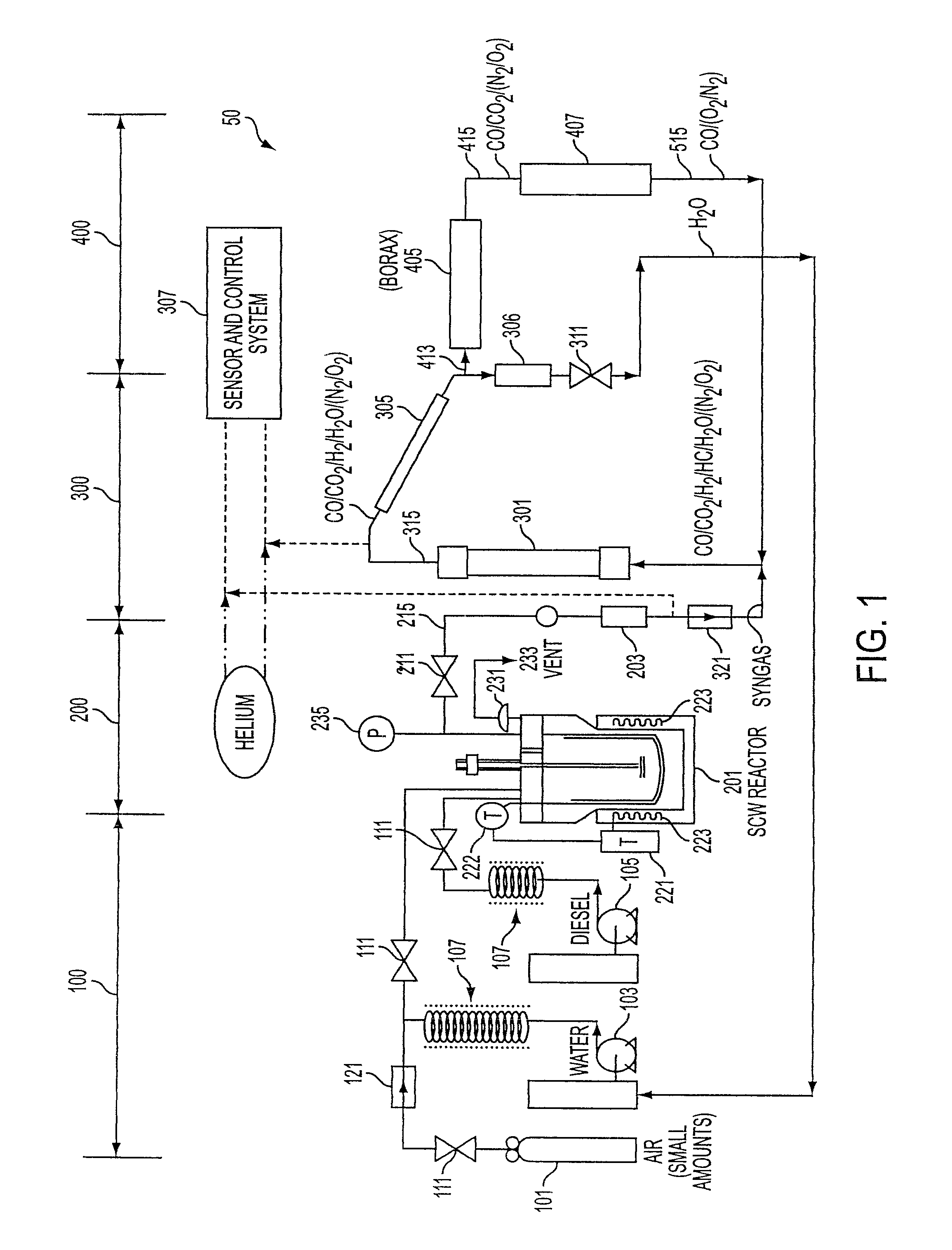

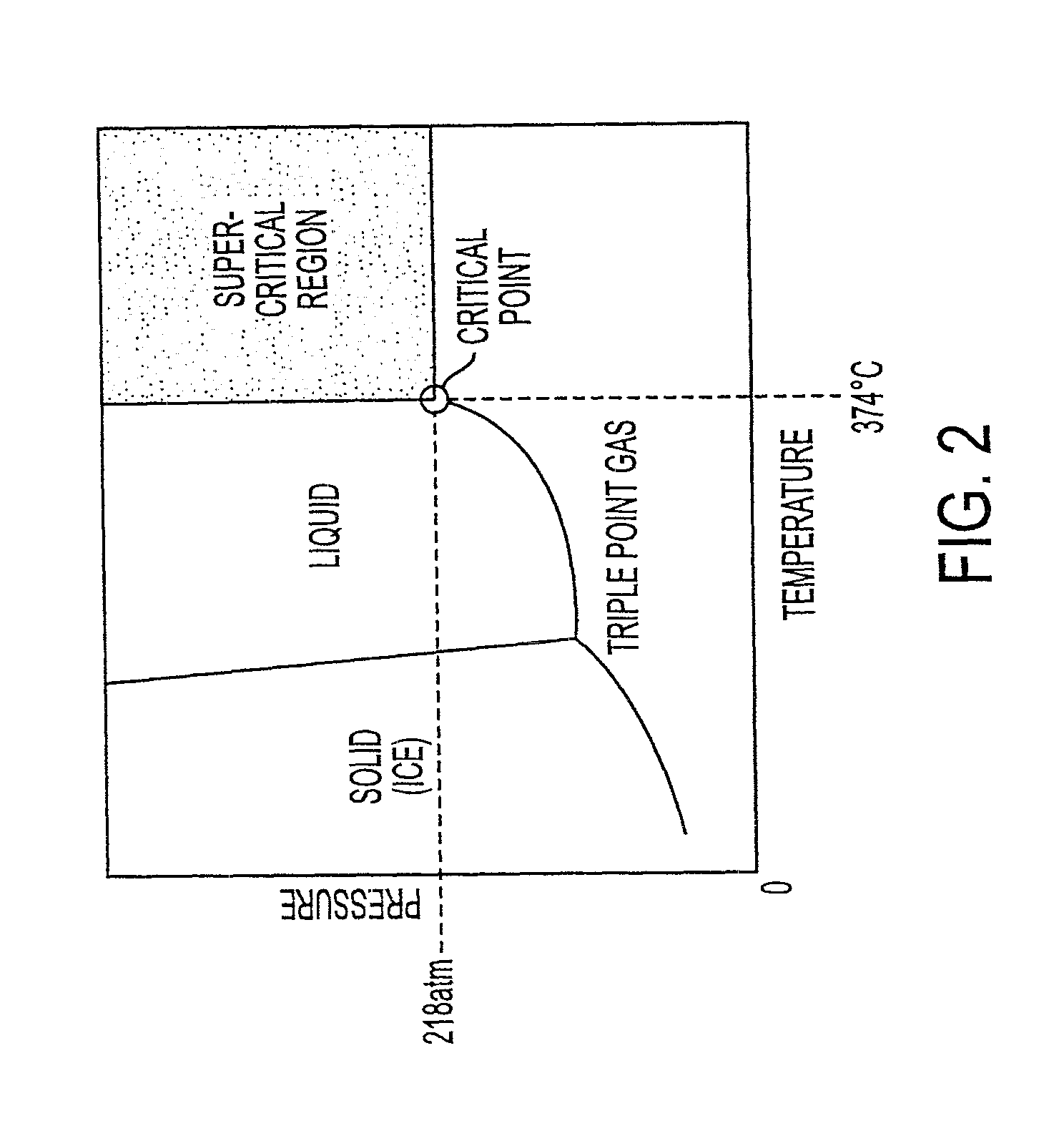

Methods for supercritical water reformation of fuels and generation of hydrogen using supercritical water

Methods for using supercritical water to convert hydrocarbons, particularly hydrocarbon fuels such as diesel fuel, jet fuel, or gasoline, into carbonaceous gases and hydrogen. The synthesis gas stream generated by the fuel reforming reaction can then be further refined to increase hydrogen content, and the resultant hydrogen can be utilized to power fuel cells.

Owner:DRS SUSTAINMENT SYST

Intermetallic articles of manufacture having high room temperature ductility

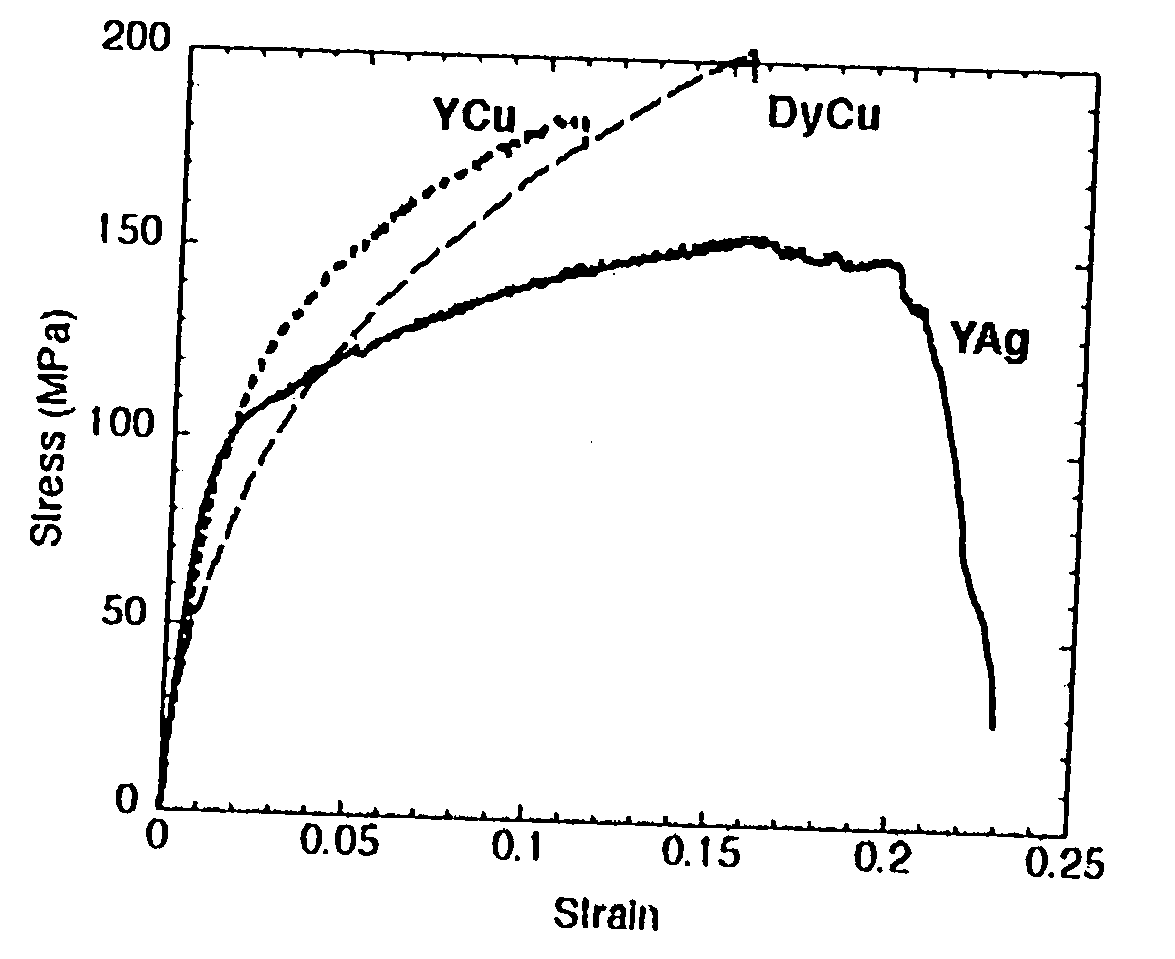

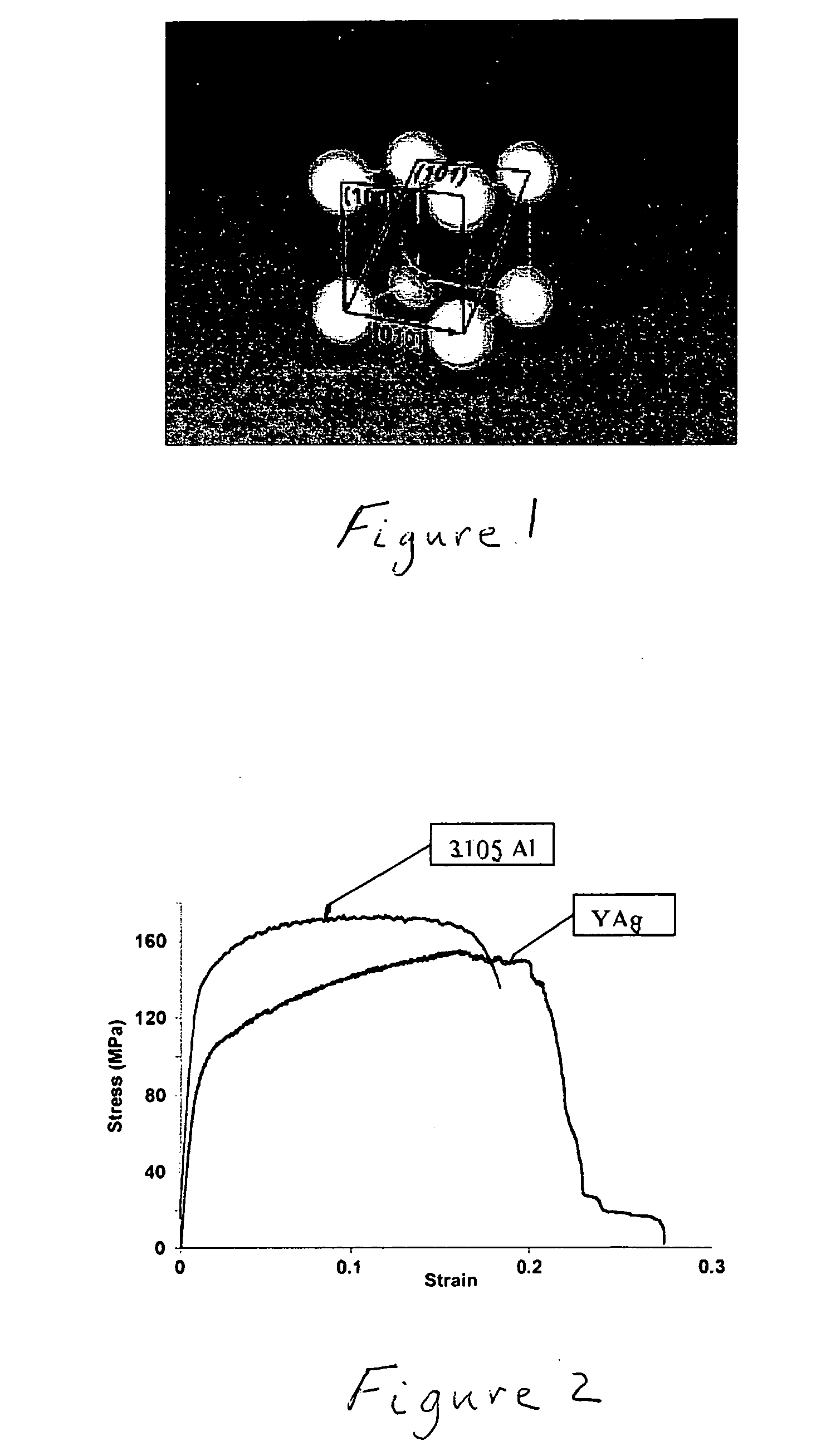

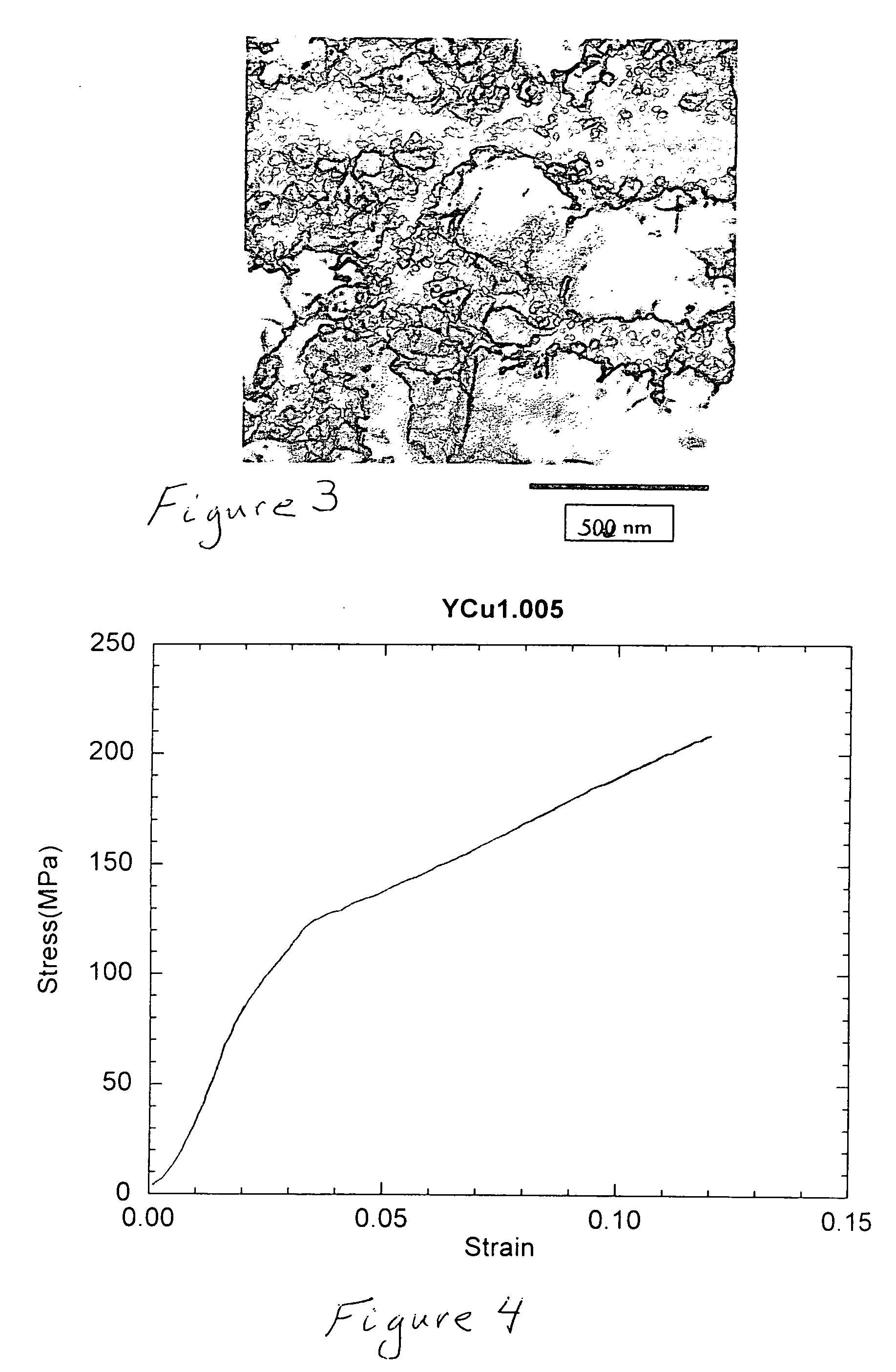

InactiveUS20050274439A1Improve ductilityHigh compressive ductilityHydrogen separation by selective and reversible uptakeReactant parameters controlRare-earth elementCrystal structure

Article of manufacture fabricated by plastic deformation of an intermetallic compound comprising R and M, such as an RM intermetallic compound and a higher order compound thereof, having a CsCl-type ordered crystal structure wherein R is one or more rare earth elements and M is one or more non-rare earth metals. The article of manufacture has a tensile elongation of at least about 5% prior to fracture when tensile tested at room temperature in ambient air. The article of manufacture also can be fabricated by plastic deformation of an intermetallic compound comprising a M′M compound and a higher order compound thereof having a CsCl-type ordered crystal structure wherein M′ and M are one or more different non-rare earth metals.

Owner:IOWA STATE UNIV RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com