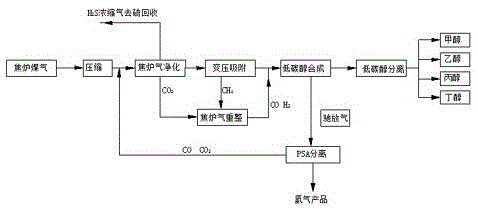

Technology for synthesizing low carbon alcohol and hydrogen as byproduct from coke oven gas

A technology of coke oven gas and low-carbon alcohol, which is applied in the field of synthesis of low-carbon alcohol, can solve problems such as environmental pollution and energy waste, achieve the effects of enriching composition, realizing comprehensive utilization, and promoting energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Coke oven gas (composed of H 2 : 51%, CO+CO 2 :18%, CH 4 : 24%, 5% N 2 and H 2 S: 1000ppm) enters the coke oven gas low-temperature methanol washing and purification system after being compressed, and desulfurizes and decarburizes at a temperature of -42°C and a pressure of 4.0MPa to obtain H 2 S2 2 S condensed gas desulfurization recovery, CO removal 2 De-coke oven gas reforming, the purified coke oven gas enters pressure swing adsorption, and the fine-pore silica gel is used as the adsorbent, the adsorption pressure is 4.0MPa, the desorption pressure is 0.3MPa, and the temperature is 8°C to remove CH 4 , the removed CH 4 with purified CO 2 Enter the coke oven gas reforming unit together, using a nickel-based catalyst, reforming at a reforming temperature of 560 ° C, and a pressure of 4.5 MPa. The reformed gas and coke oven gas after pressure swing adsorption are combined to form H 2 The low-carbon alcohol synthesis gas with a / CO molar ratio of 3.5 enters two l...

Embodiment 2

[0027] Coke oven gas (composed of H 2 : 55%, CO+CO 2 : 17%, CH 4 : 23%, 5%N 2 and H 2 S: 2000ppm) enters the coke oven gas NHD (polyethylene glycol dimethyl ether) purification system after being compressed, and desulfurizes and decarburizes at a temperature of 1°C and a pressure of 2.6MPa to obtain H 2 S2 2 S condensed gas desulfurization recovery, CO removal 2 De-coke oven gas reforming, the purified coke oven gas enters pressure swing adsorption, using fine-pore silica gel as the adsorbent, adsorption pressure 4.5MPa, desorption pressure 0.4MPa, and temperature 12°C to remove CH 4 , the removed CH 4 with purified CO 2 Enter the coke oven gas reforming unit together, using a cobalt-based catalyst, reforming at a reforming temperature of 600°C and a pressure of 4.0 MPa, and the reformed gas merges with the coke oven gas after pressure swing adsorption to form H 2 The low-carbon alcohol synthesis gas with a molar ratio of 4.0 / CO enters the low-carbon alcohol fixed-bed r...

Embodiment 3

[0029] Coke oven gas (composed of H 2 : 53%, CO+CO 2 :18%, CH 4 : 25%, 4%N 2 and H 2 S: 2500ppm) enters the coke oven gas low-temperature methanol washing and purification system after being compressed, and desulfurizes and decarburizes at a temperature of -45°C and a pressure of 5.0MPa to obtain H 2 S2 2 S condensed gas desulfurization recovery, CO removal 2 De-coking oven gas reforming, the purified coke oven gas enters pressure swing adsorption, using activated carbon as the adsorbent, adsorption pressure 4.8MPa, desorption pressure 0.2MPa, and temperature 15℃ to remove CH 4 , the removed CH 4 with purified CO 2 Enter the coke oven gas reforming unit together, using a cobalt-based catalyst, reforming at a reforming temperature of 620°C and a pressure of 5.0 MPa, and the reformed gas merges with the coke oven gas after pressure swing adsorption to form H 2 The low-carbon alcohol synthesis gas with a / CO molar ratio of 2.7 enters three low-carbon alcohol fixed-bed reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com