Inner-electric-arc plasma torch for gasifiers

A technology of arc plasma and gasifier, applied in the direction of plasma, electrical components, etc., which can solve the problems of low quality syngas, low gasification rate, and large consumption of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

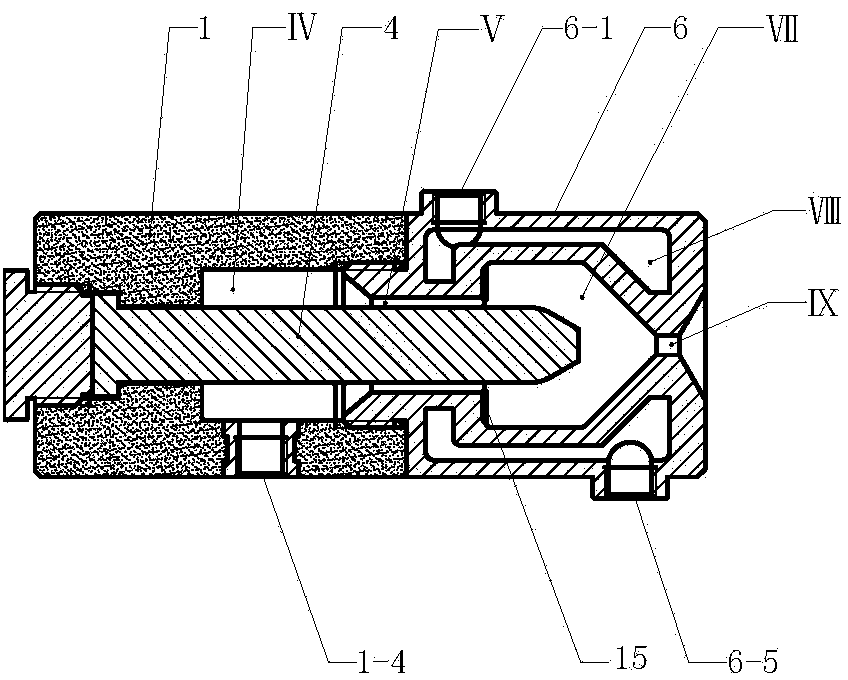

[0036] Example 1 figure 1 The embodiment shown is one of the inner arc plasma spray guns of the present invention, which is composed of the front gun body (6), the rear seat (1) and the first electrode (4), wherein: the structure of the front gun body (6) There are arc chamber (Ⅶ) and cooling water jacket (Ⅷ) inside, the space of arc chamber (Ⅶ) is cylindrical structure, the two ends of arc chamber (Ⅶ) have inlet (Ⅴ) and compression nozzle (Ⅸ) respectively, inlet ( Ⅴ) and the compression nozzle (Ⅸ) are circular through holes, the cooling water jacket (Ⅷ) is outside the arc cavity (Ⅶ), the front gun body (6) is installed on the rear seat (1), and the rear seat (1) The front end of the front gun body (6) is connected to the arc cavity entrance; the back seat (1) is made of bakelite material with insulating properties, the back seat (1) is a cylindrical structure, and the front part of the back seat (1) is There is an air chamber (Ⅳ), the air chamber (Ⅳ) is connected to the wo...

Embodiment 2

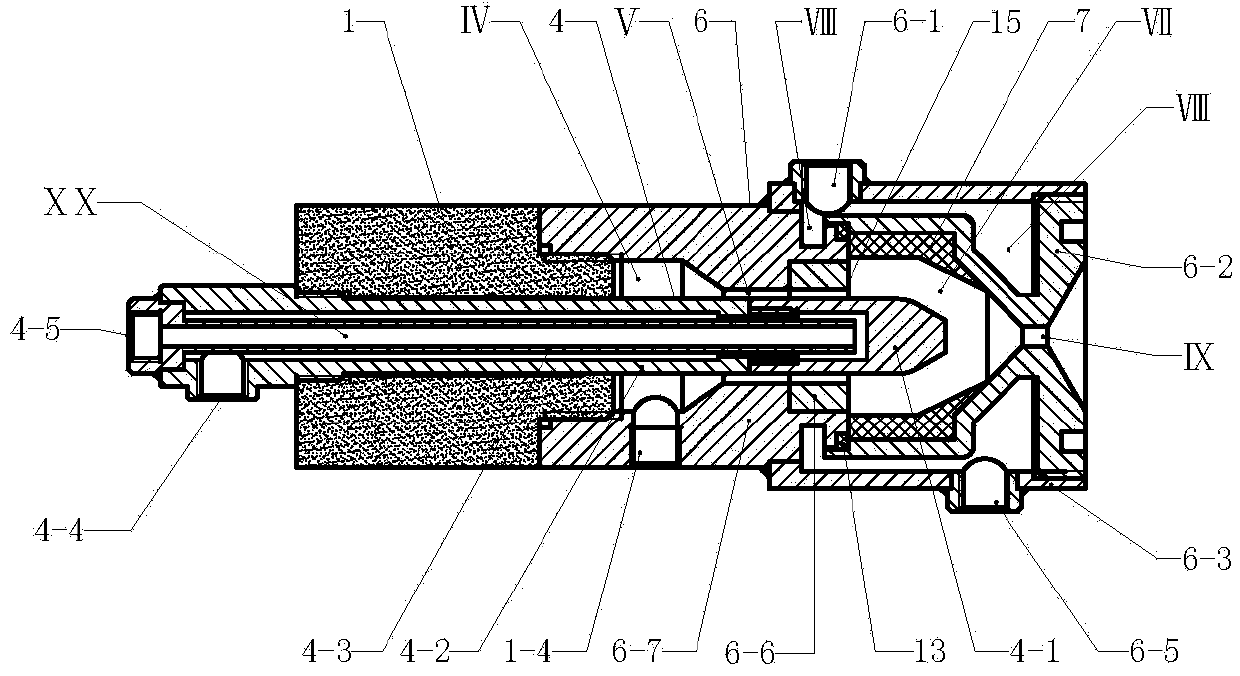

[0037] Example 2 figure 2 The embodiment shown is the second inner arc plasma spray gun of the present invention, which is based on the first embodiment, adding a thermal insulation lining (7) in the arc cavity (VII). In this embodiment, the front end of the rear seat (1) is connected to the entrance of the arc cavity of the front gun body (6); the rear seat (1) is a cylindrical structure, made of alumina material with insulating properties, and the rear seat ( 1) has a through hole in the center of the axis, the through hole is coaxial with the arc chamber entrance (Ⅴ), the first electrode (4) is connected to the axis center through hole of the rear seat (1); the rear part of the front gun body (6) There is an air chamber (Ⅳ) in the body, and the air chamber (Ⅳ) is connected to the working gas input interface (1-4). The front gun body (6) is decomposed into inner sleeve (6-2), outer casing (6-3), The second electrode (6-6) and the main part of the front gun body (6-7) are...

Embodiment 3

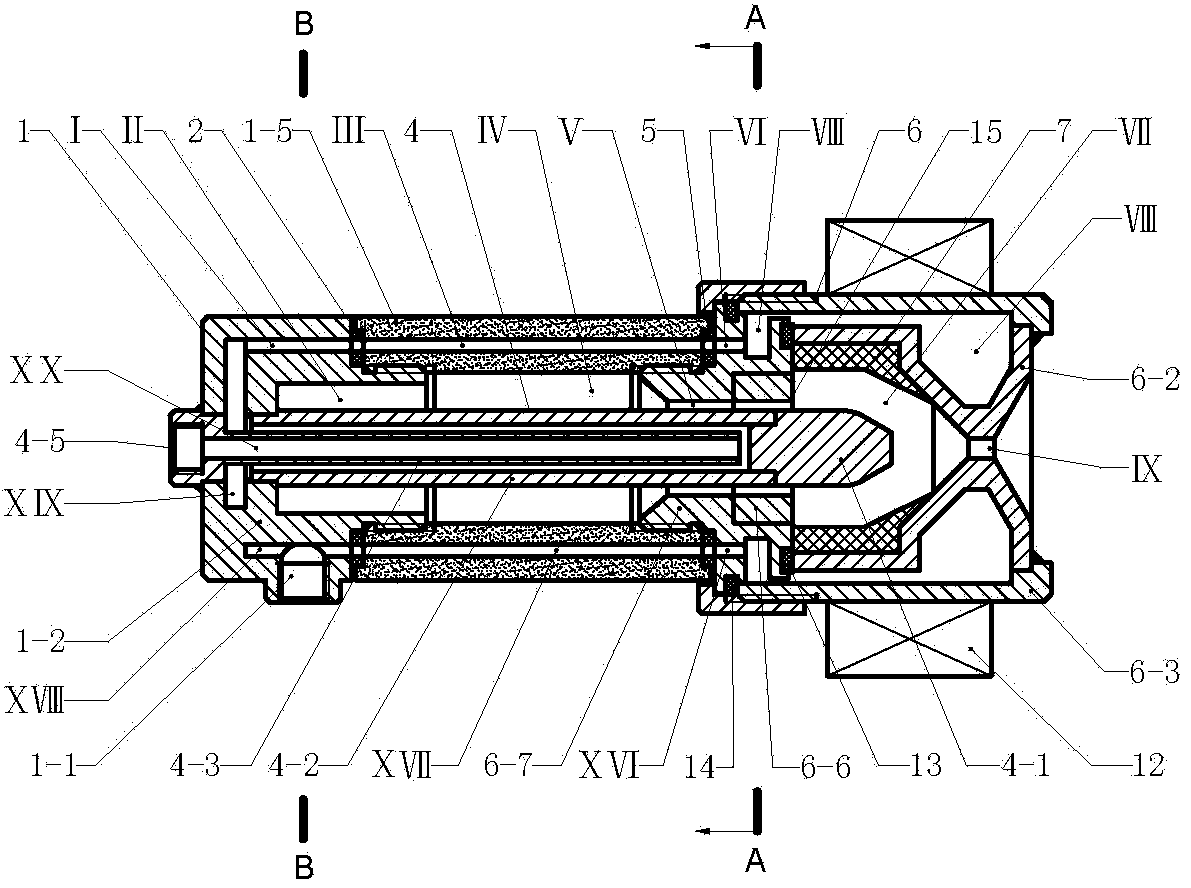

[0038] Example 3 image 3 The embodiment shown is the third inner arc plasma spray gun of the present invention. On the basis of the first embodiment, an insulating lining (7) is added in the arc cavity (VII), and the front gun body (6) Compression coils (12) are added on the outer wall. In this embodiment, the front end of the rear seat (1) is connected to the arc chamber entrance of the front gun body (6), the first electrode (4) is connected to the rear seat (1), and connected to the arc chamber entrance (Ⅴ) Coaxial; the rear seat (1) is a combined structure, the rear seat (1) is composed of the main part of the rear seat (1-2) and the insulating spacer (1-5), wherein the insulating spacer (1-5) is the rear The electrical isolation element between the seat main part (1-2) and the front gun body (6), the insulating spacer (1-5) is made of alumina ceramic material, and the insulating spacer (1-5) is a cylindrical structure, The inner space of the cylinder constitutes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com