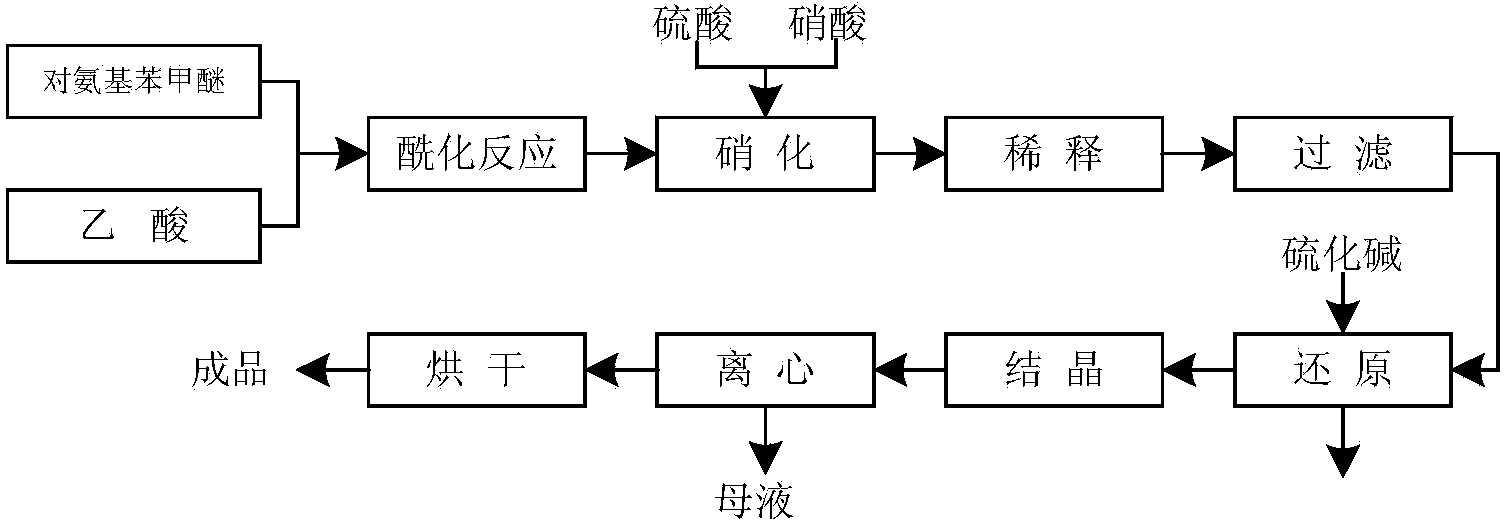

Preparation process of 2-amino-4-acetyl aminoanisole

A technology of acetamidoanisole and preparation process, which is applied in the field of preparation technology of 2-amino-4-acetamidoanisole, can solve the problems of complex process, many side reactions, and high product impurity content, and achieves process safety , the effect of no three waste discharge, short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

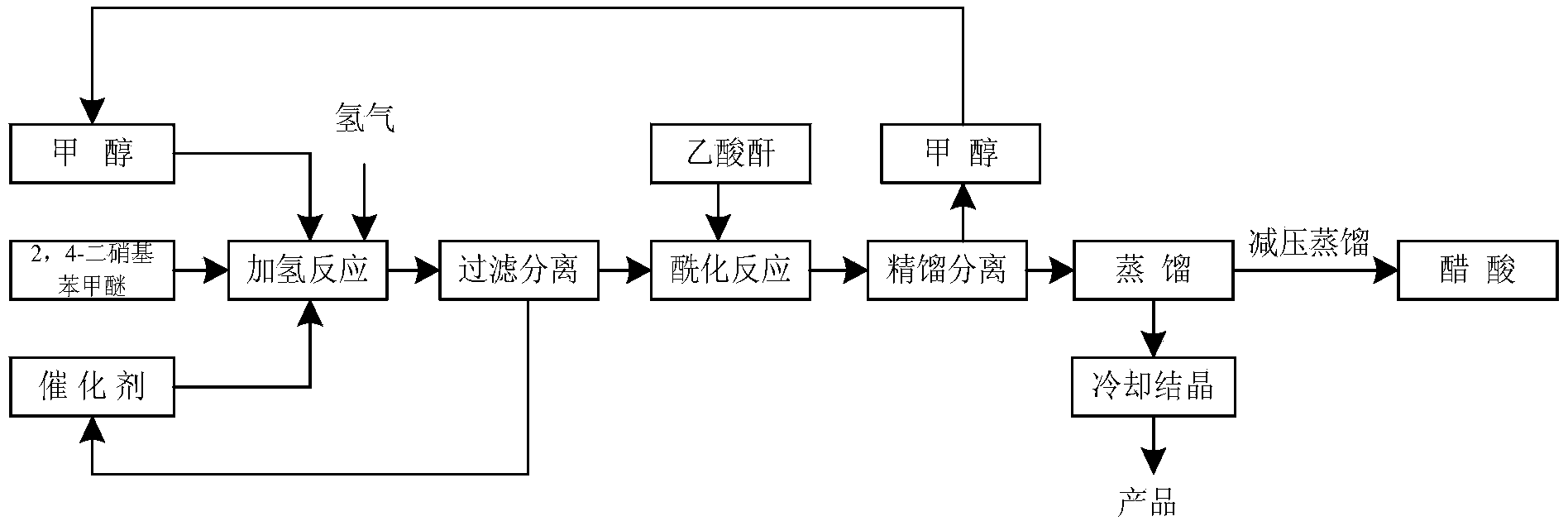

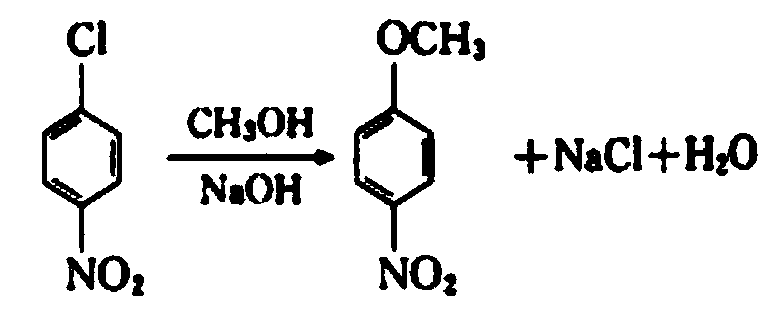

[0050] A kind of preparation technology of 2-amino-4-acetamidoanisole,

[0051] Add accurately measured methanol, 2,4-dinitroanisole, and catalyst into the hydrogenation tank, and carry out hydrogenation reaction after low-pressure nitrogen replacement. When the system no longer absorbs hydrogen, cool down, filter and recover the catalyst, and then acylate In the still, add acetic anhydride to carry out acylation reaction. The temperature is controlled at 5°C. After the acylation reaction is completed, methanol is recovered through a methanol rectification tower, and the material is sent to a vacuum distillation kettle to recover acetic acid. The material in the kettle is cooled and crystallized to obtain 2-amino-4-acetamidoanisole product.

[0052] The ratio of 2,4-dinitroanisole, acetic anhydride and catalyst is 1100:590:5. The catalyst referred to is Raney nickel.

[0053] The invention can provide an output of 6,000 tons per year. The total industrial output value of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com