Patents

Literature

339results about How to "Process cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

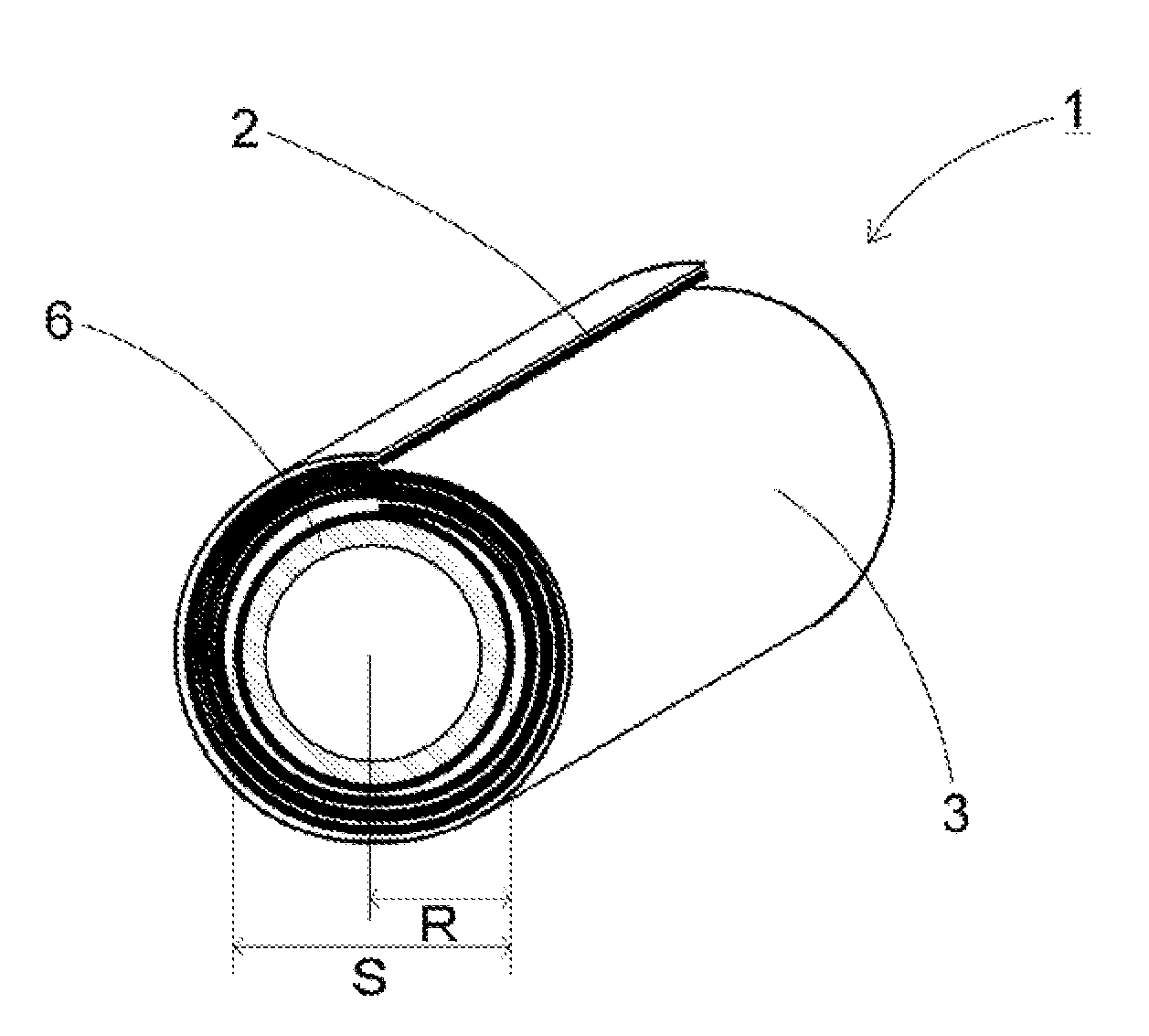

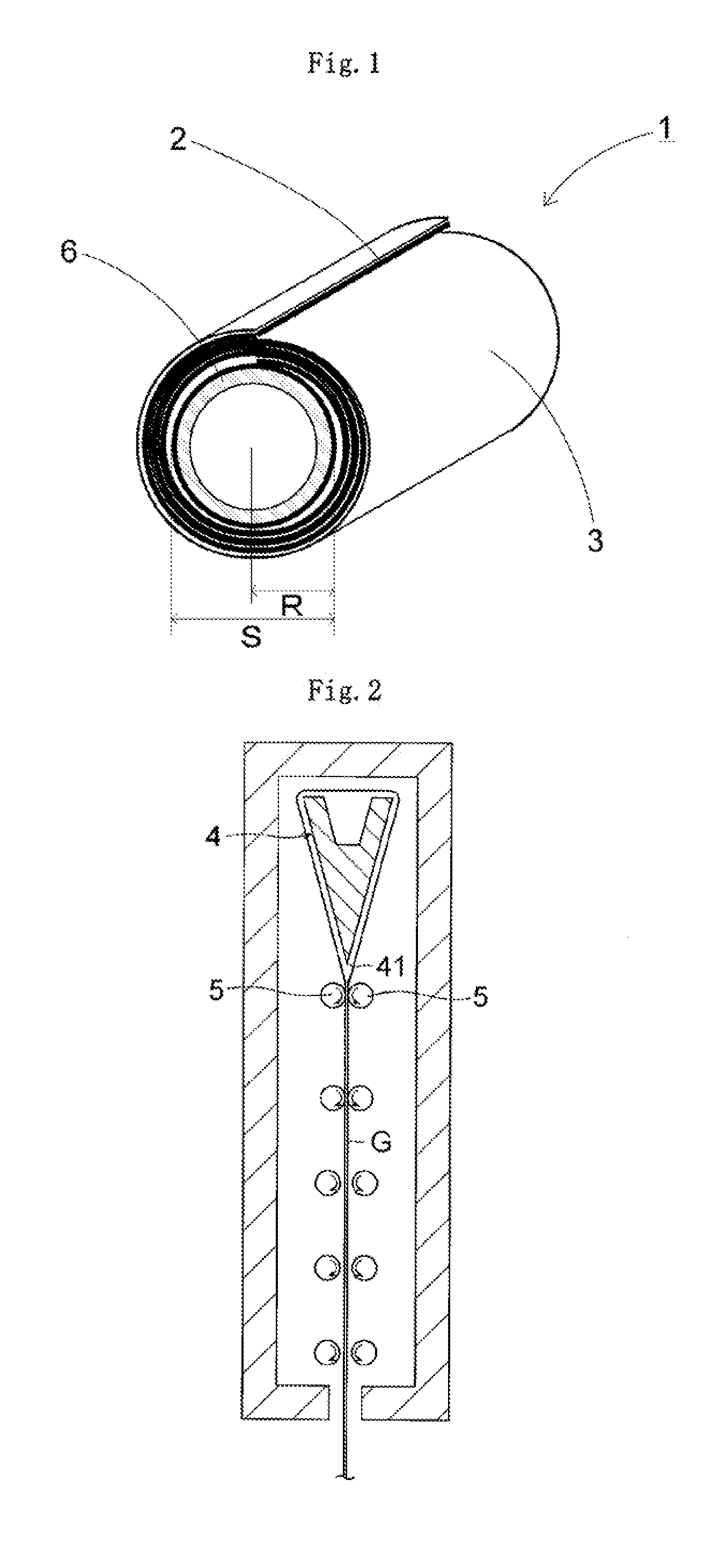

Glass roll, device for producing glass roll, and process for producing glass roll

ActiveUS20110177290A1Minimize numberPrevent be breakGlass drawing apparatusGlass forming apparatusGlass filmOverflow downdraw method

Provided is a package form, with which cleanness of a glass film is ensured and the glass film is prevented from breaking. The package form is effective in minimizing the number of glass film processing steps to be performed before packaging and after unpackaging. As the package form for a glass film, provided is a glass roll (1) formed by winding a glass film (2) into a roll while superposing the glass film (2) on a protective sheet (3), the glass film (2) being formed by an overflow downdraw method and having exposed front and back surfaces.

Owner:NIPPON ELECTRIC GLASS CO LTD

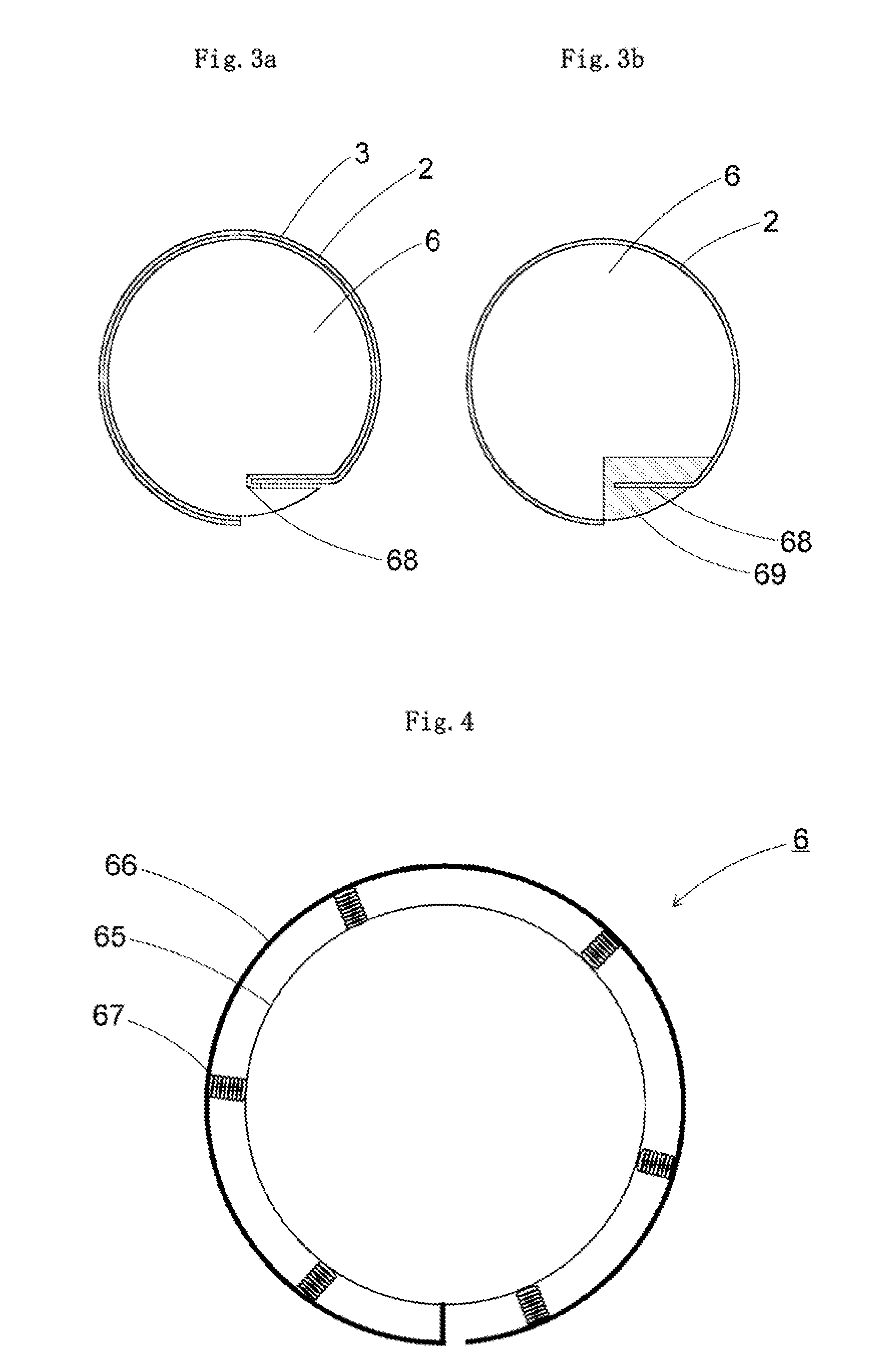

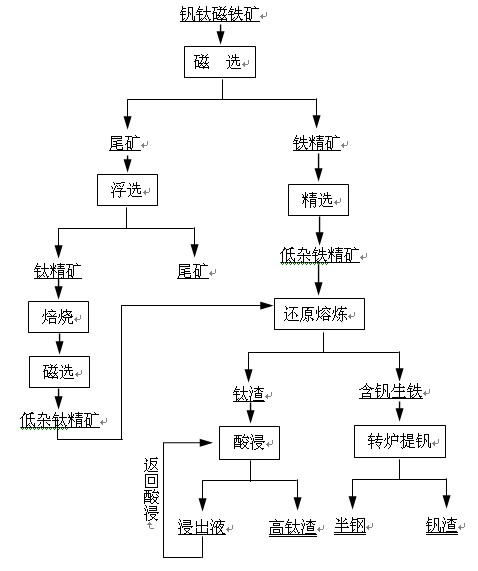

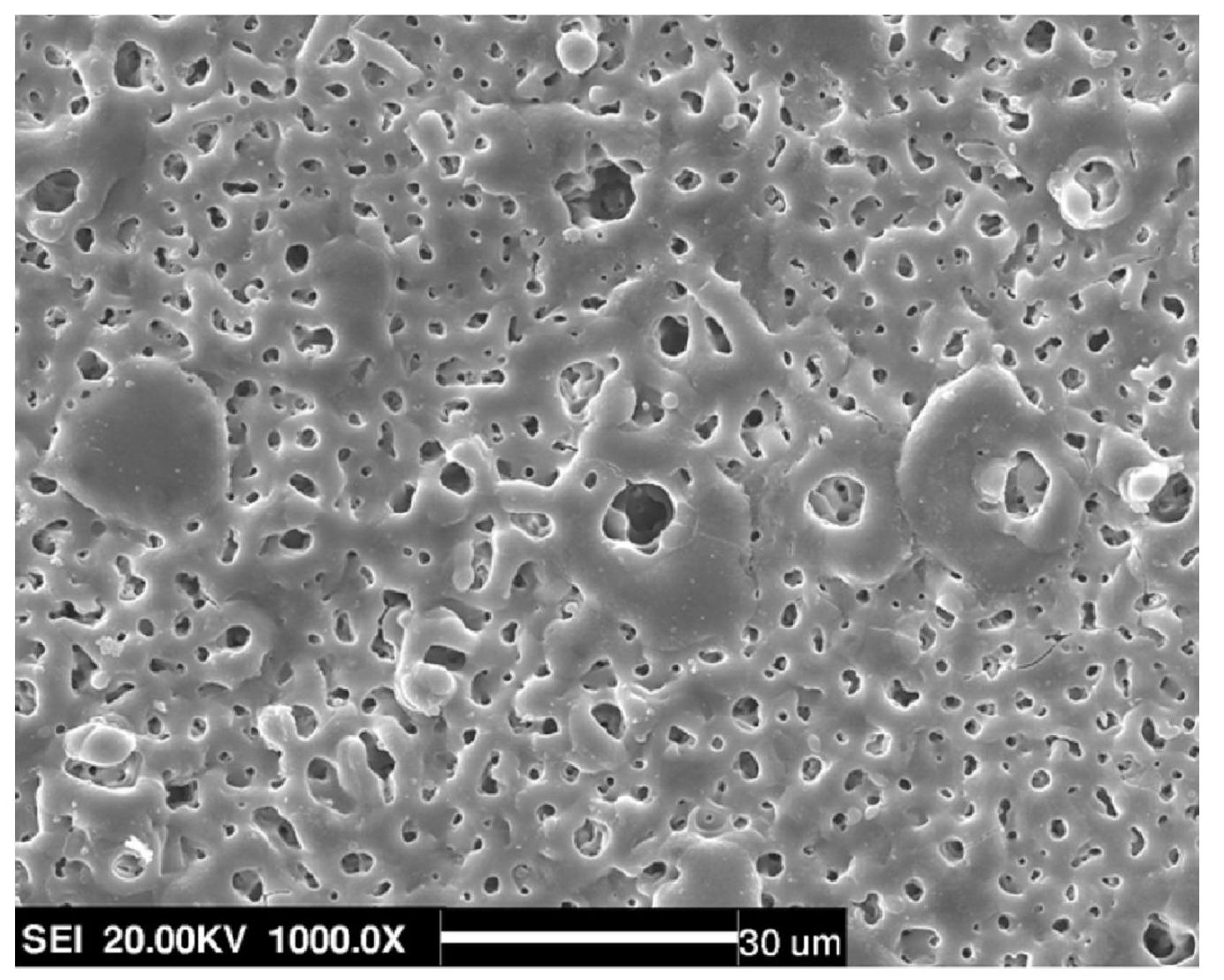

Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

InactiveCN102179292AHigh technical difficultyIncrease processing costWet separationSmelting processMagnetite

The invention discloses a method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium, comprising the following steps of: magnetically selecting raw magnetite, that is, acquiring iron-vanadium concentrate and tail magnetite after performing magnetic selection on the vanadium-titanium magnetite; sorting titanium concentrate from the tail magnetite, that is, acquiring the titanium concentrate after performing floating selection on the obtained tail magnetite; roasting and magnetically selecting the titanium concentrate, that is, performing enriched-titanium impurity-removing magnetic selection after roasting the titanium concentrate; finely selecting the iron-vanadium concentrate, that is, performing the magnetic selection and fine section again on the iron-vanadium concentrate obtained from magnetic selection; reducing and smelting, that is, mixing the titanium concentrate obtained from the impurity-removing process with the iron concentrate according to the beneficiation yield, adding in a reducer and soda ash to perform reduced iron and vanadium smelting process; purifying vanadium slag, that is, removing the impurity of the vanadium slag obtained by reducing and smelting by using the acidic dipping to obtain the high-quality titanium slag product with the content of TiO2 larger than 92%; and extracting vanadium from pig iron, that is, performing vanadium extraction by converter blowing on the vanadium-containing pig iron obtained by reducing and smelting to obtain the semi-steel and vanadium slag. The method not only improves the utilization ratio of titanium, iron and vanadium but also obtains the high-titanium slag product with the content of TiO2 larger than 92% so as to widen the application field of titanium.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

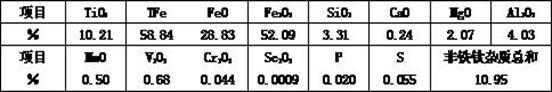

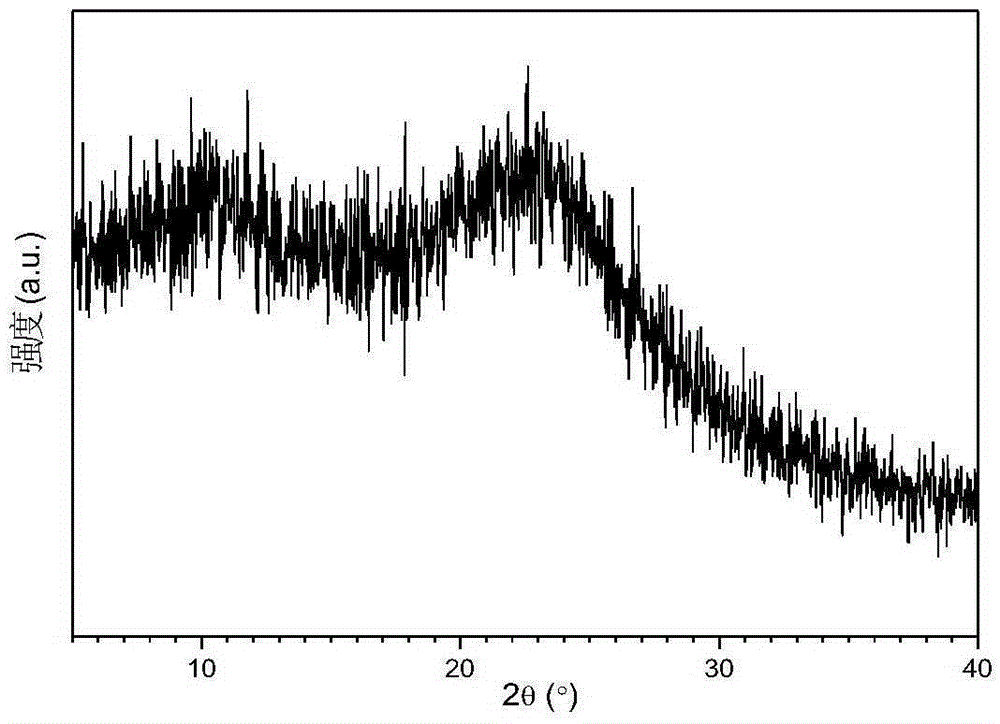

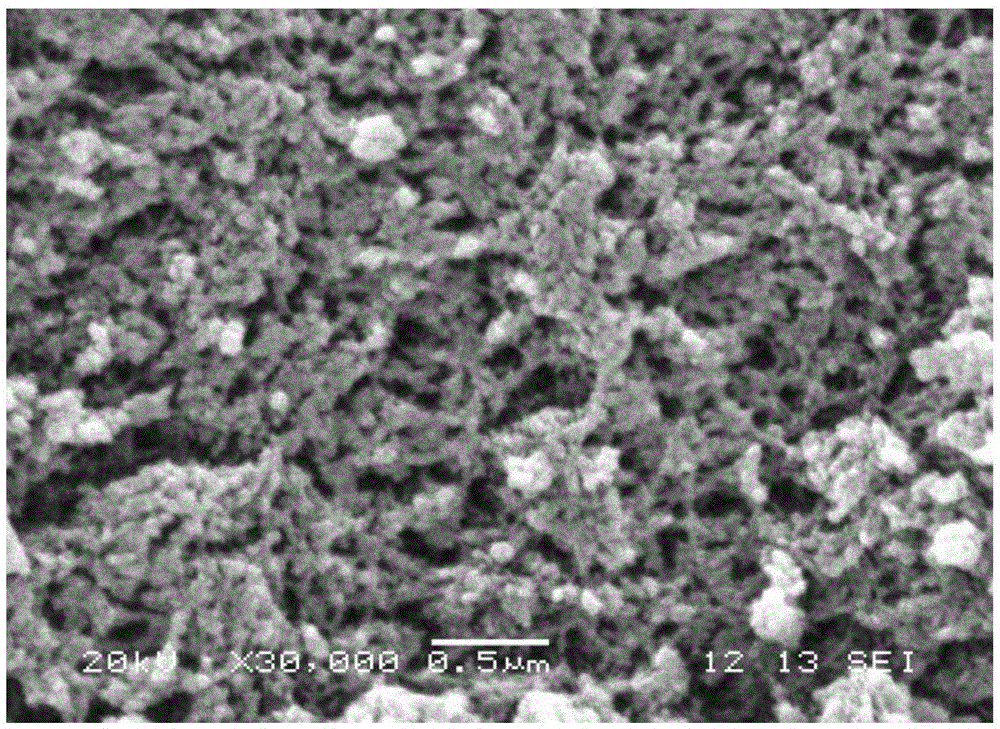

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

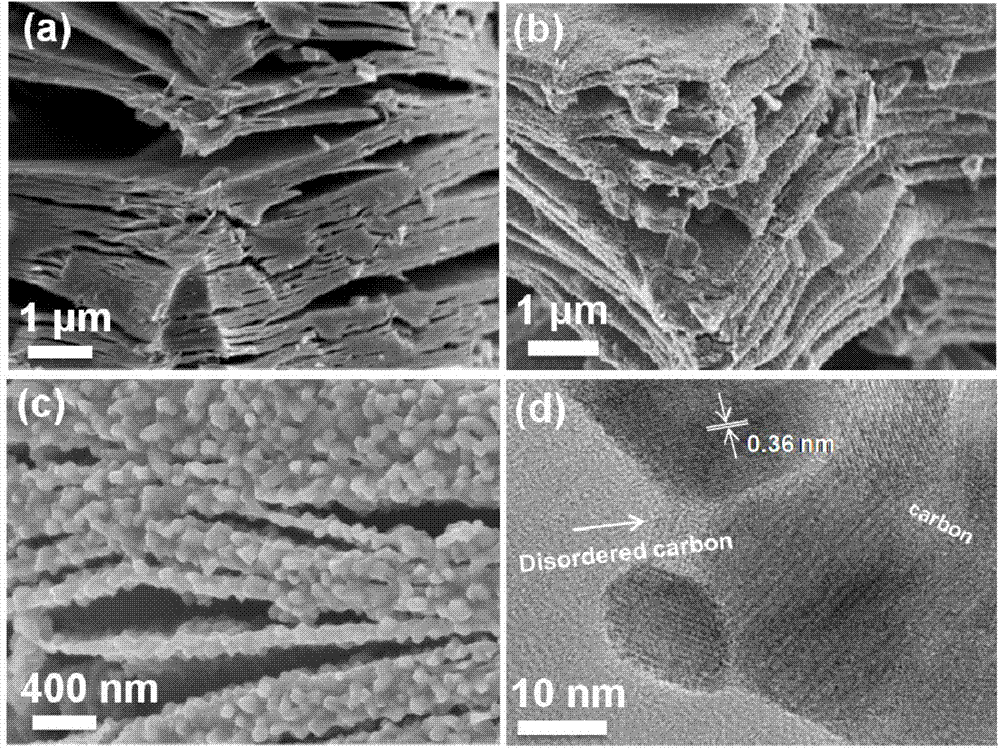

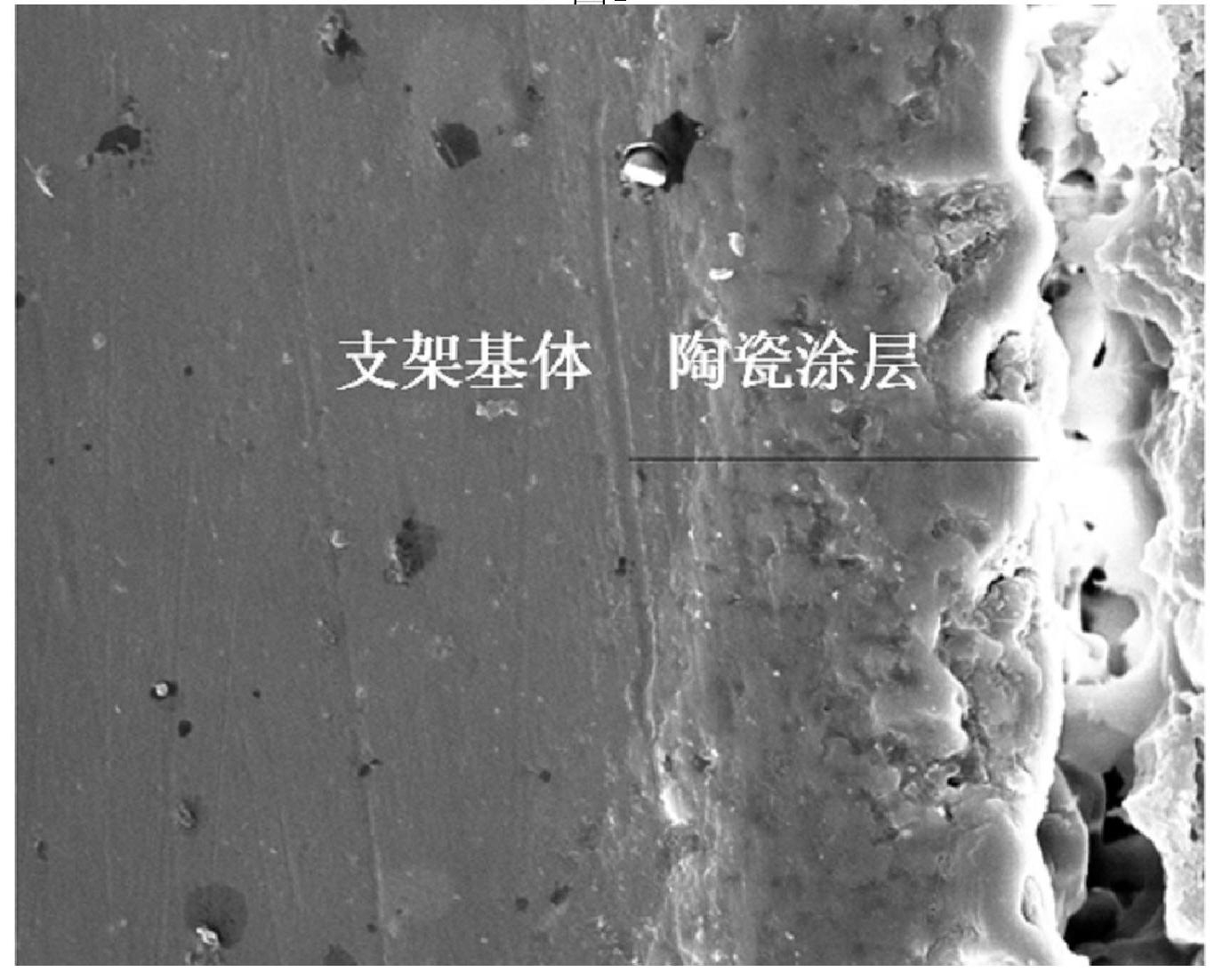

Corrosion-resistant magnesium alloy bracket and preparation method thereof

InactiveCN101797191AThe degradation rate can be adjustedUniform growthStentsAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a corrosion-resistant magnesium alloy bracket and a preparation method thereof, which relate to a magnesium alloy bracket with a corrosion-resistant coating and the preparation method thereof. The bracket and the method solve the problems of low bonding strength between the coating and a substrate, poor corrosion-resistant lasting stability, low mechanical bearing capacity and poor bracket coordination and deformation ability of the traditional magnesium alloy bracket. The corrosion-resistant magnesium alloy bracket is prepared by growing a ceramic coating in situ on the surface of the magnesium alloy by a micro-arc oxidation process. The method of the invention comprises the following steps: 1, processing the magnesium alloy to make a net-like bracket and removing oil to obtain the magnesium alloy bracket; 2, performing the micro-arc oxidation reaction; and 3, cleaning and drying the bracket to obtain the corrosion-resistant magnesium alloy bracket. The product of the invention is high in hardness and relatively high in tenacity and can coordinate with a substrate bracket to deform; and the ceramic coating is insusceptible to falling off and is high in body fluid corrosion resistance, so life cycle of the embedded bracket can be prolonged to a maximum extent. The method is simple and low in cost and can realize mass production. The product of the invention is suitable for implants with complex shapes, such as brackets, and is convenient to promote and use.

Owner:HARBIN INST OF TECH

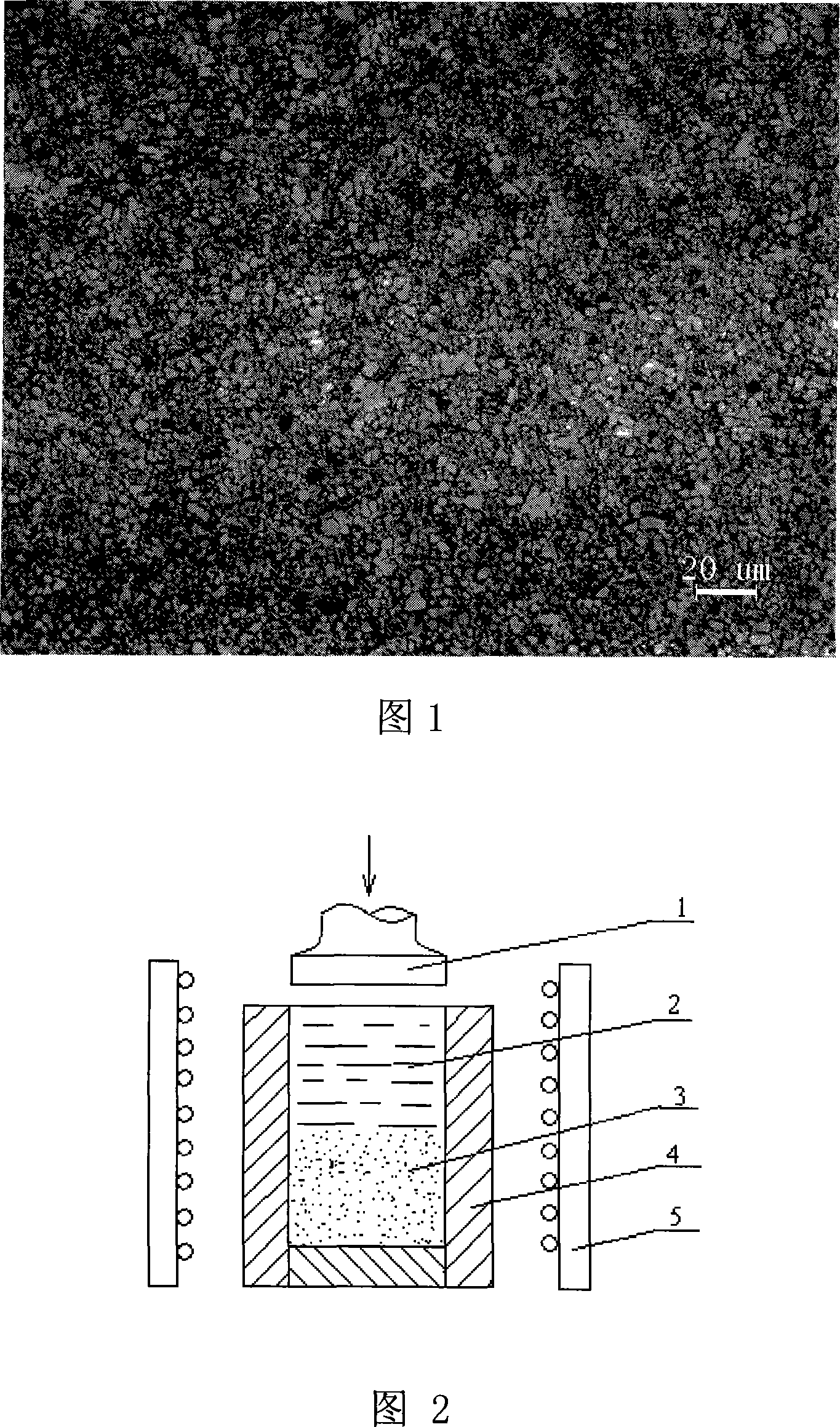

High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

The invention provides a high-plasticity aluminum-based composite material containing TiB2 particles and a preparation method thereof, and relates to an aluminum-based composite material and a preparation method thereof. The invention solves the problems of the prior art, such as poor plasticity and toughness and difficulty in secondary processing. The composite material contains (by volume) titanium diboride reinforcement particles 10-25 percent, aluminum particles 25-35 percent, and aluminum alloy matrix in balance. The preparation method comprises: (1) weighing titanium diboride reinforcement particles, aluminum particles and aluminum alloy matrix; (2) mixing by mechanical dry method to obtain a reinforcement powder; (3) placing the reinforcement powder in a die and compression-molding; (4) heating the die; (5) melting aluminum alloy and casting in the die; (6) applying a pressure on the die with molten aluminum and maintaining the pressure for a period of time and cooling; (7) demoulding and taking the cast ingot, that is reinforced aluminum-based composite material. The inventive aluminum-based composite material has high plasticity and good wear resistance and is adapted to secondary processing and machining.

Owner:HARBIN INST OF TECH

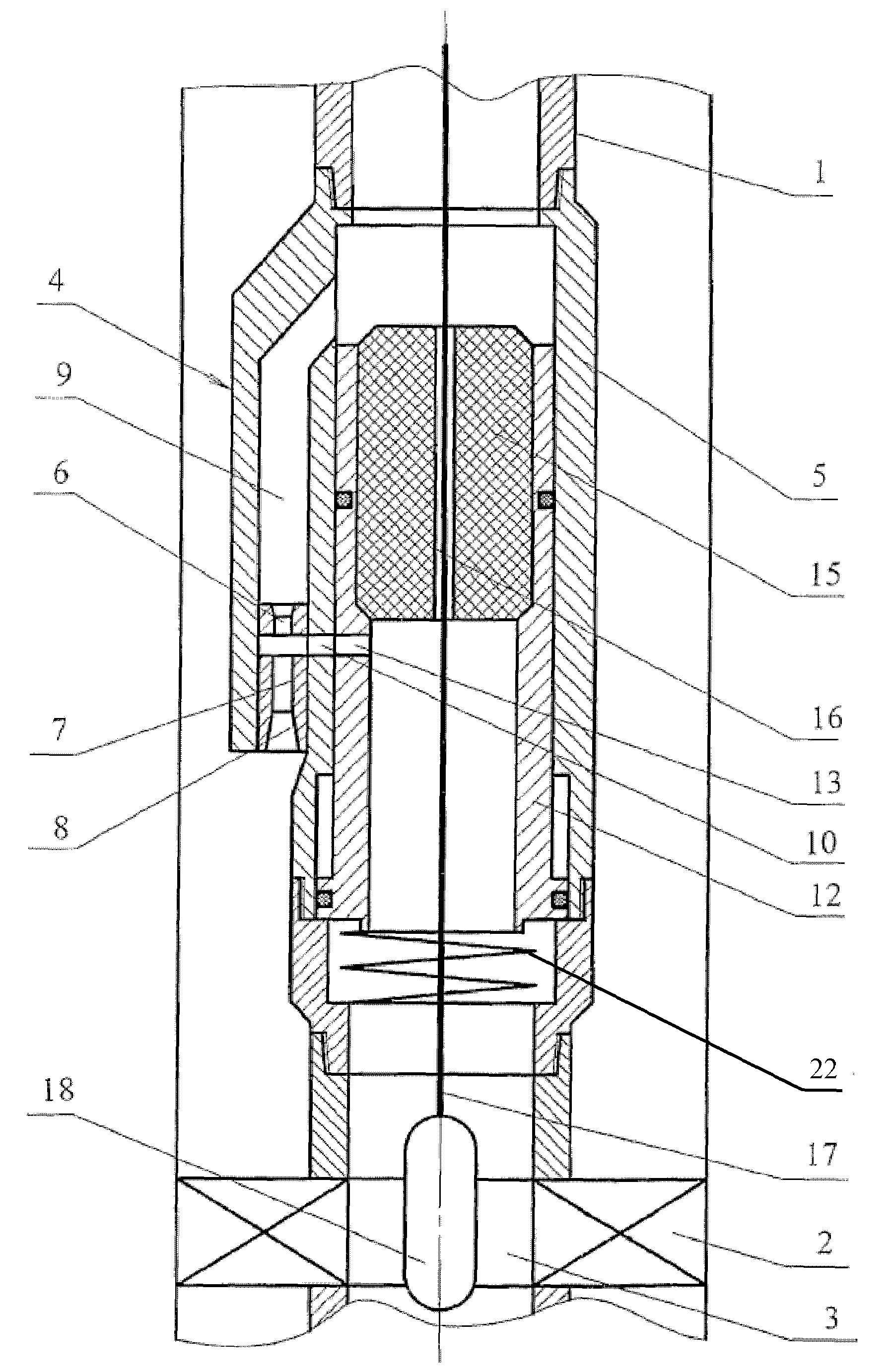

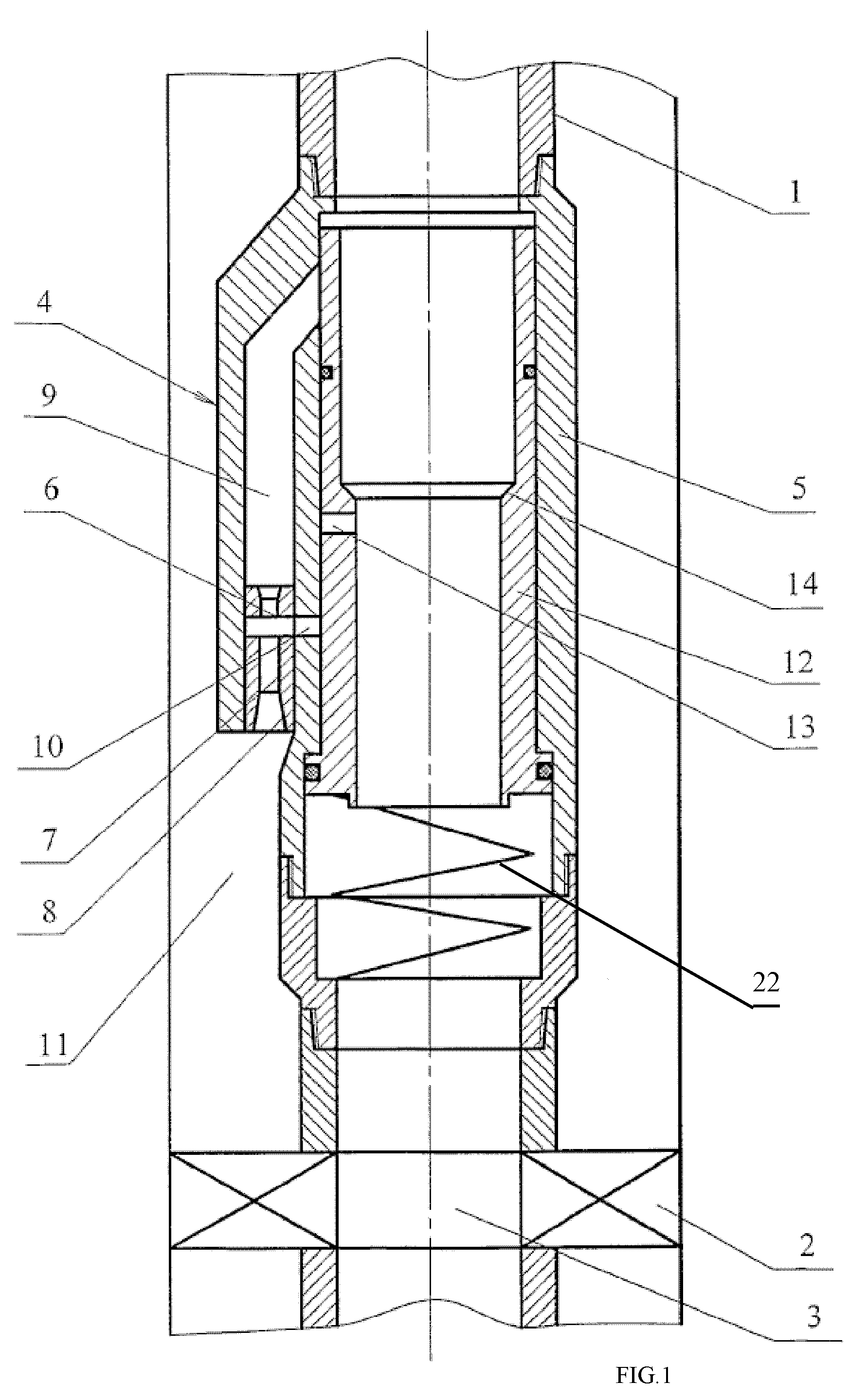

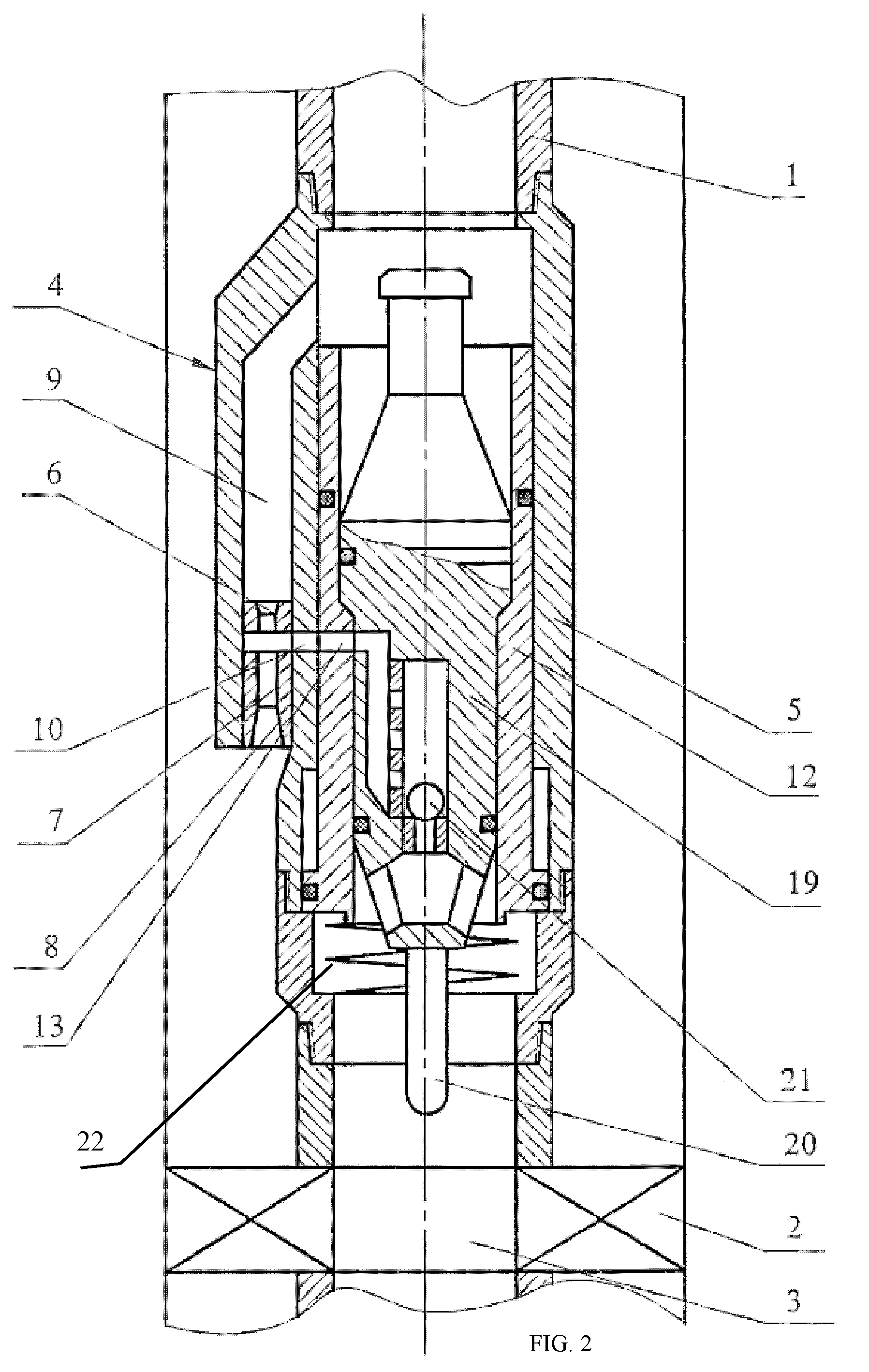

Well jet device and the operating method thereof

Owner:KHOMYNETS ZINOVIY DMITRIEVICH

Microbial oil extraction method

The invention discloses a microbial oil extraction method, and belongs to the field of bioengineering downstream technology. Oil-producing microorganism fermented liquor is used as a raw material, and is subjected to enzymolysis and extraction by organic solvent to obtain the microbial oil, wherein the extraction rate is up to 100% maximally. The microbial oil extraction method disclosed by the invention does not need concentration of the fermented liquor, recovery of strains, drying of the strains and other pretreatment operations, has mild enzymolysis conditions, short treatment time, low extraction temperature, high extraction rate, low requirements on equipment and low toxicity of the used organic solvent, greatly reduces the power and energy consumptions in the microbial oil extraction process, lowers the process cost and alleviates the environmental pollution and damage to human health. According to the method, a new way is provided for mass production and extraction of the microbial oil.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

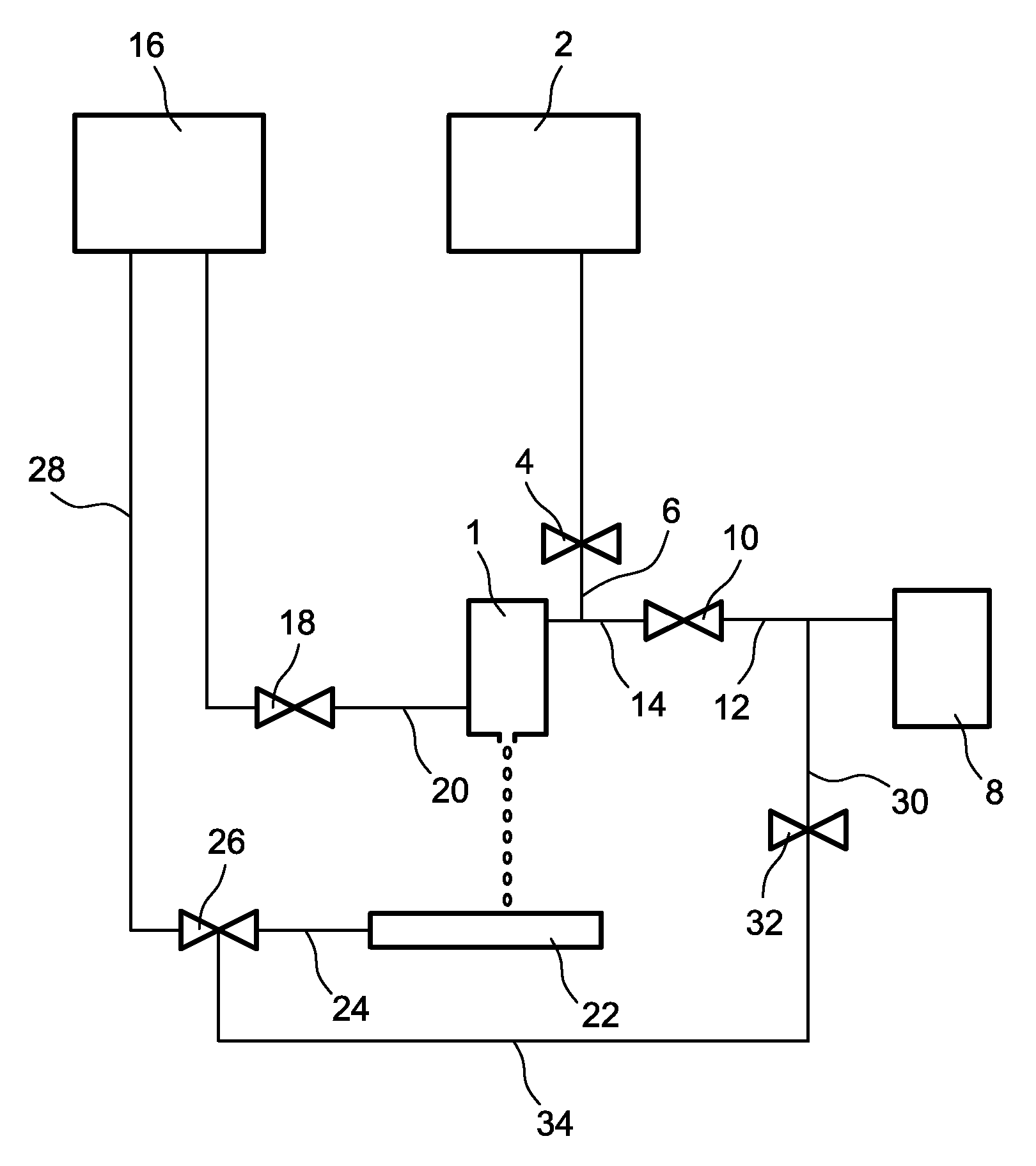

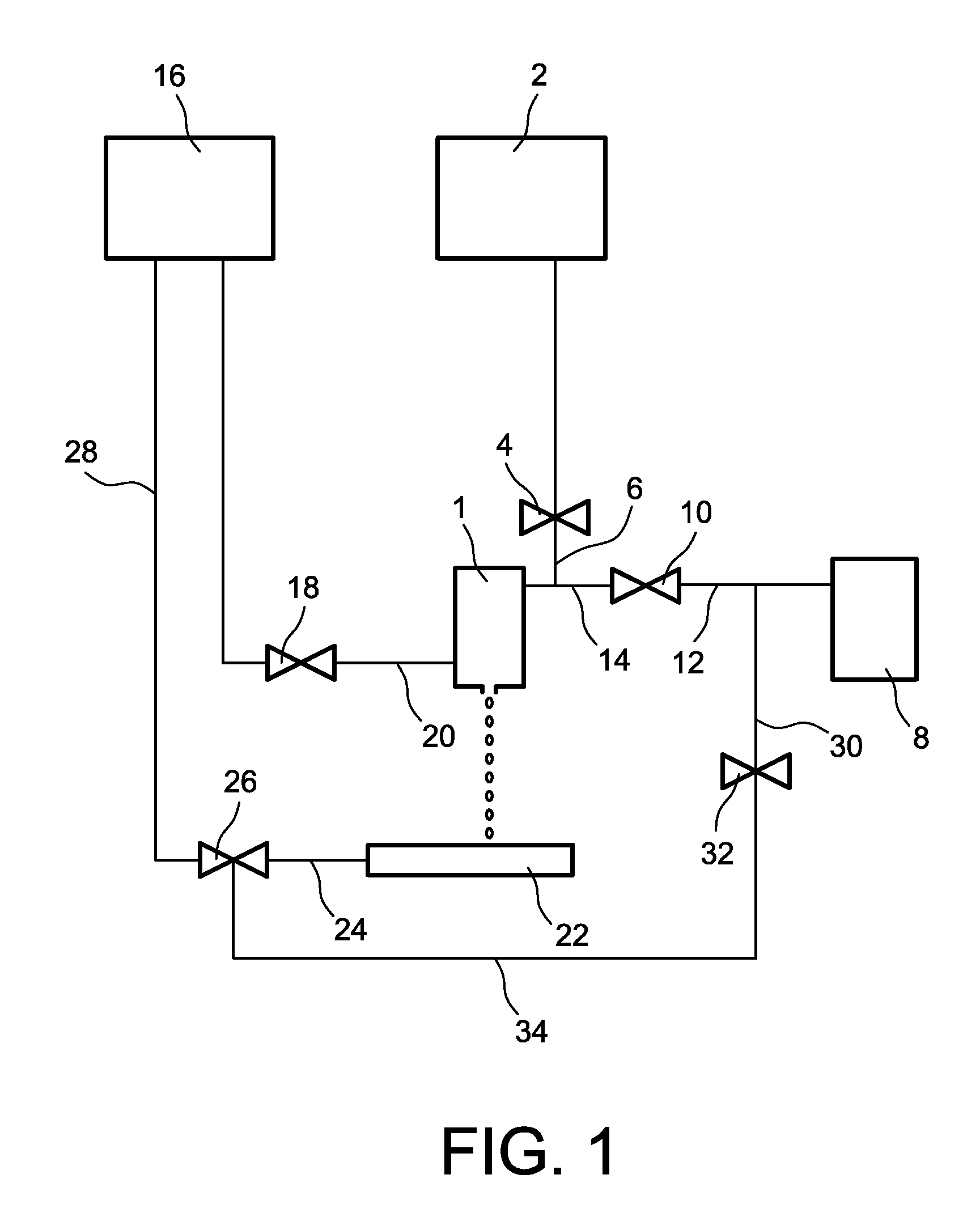

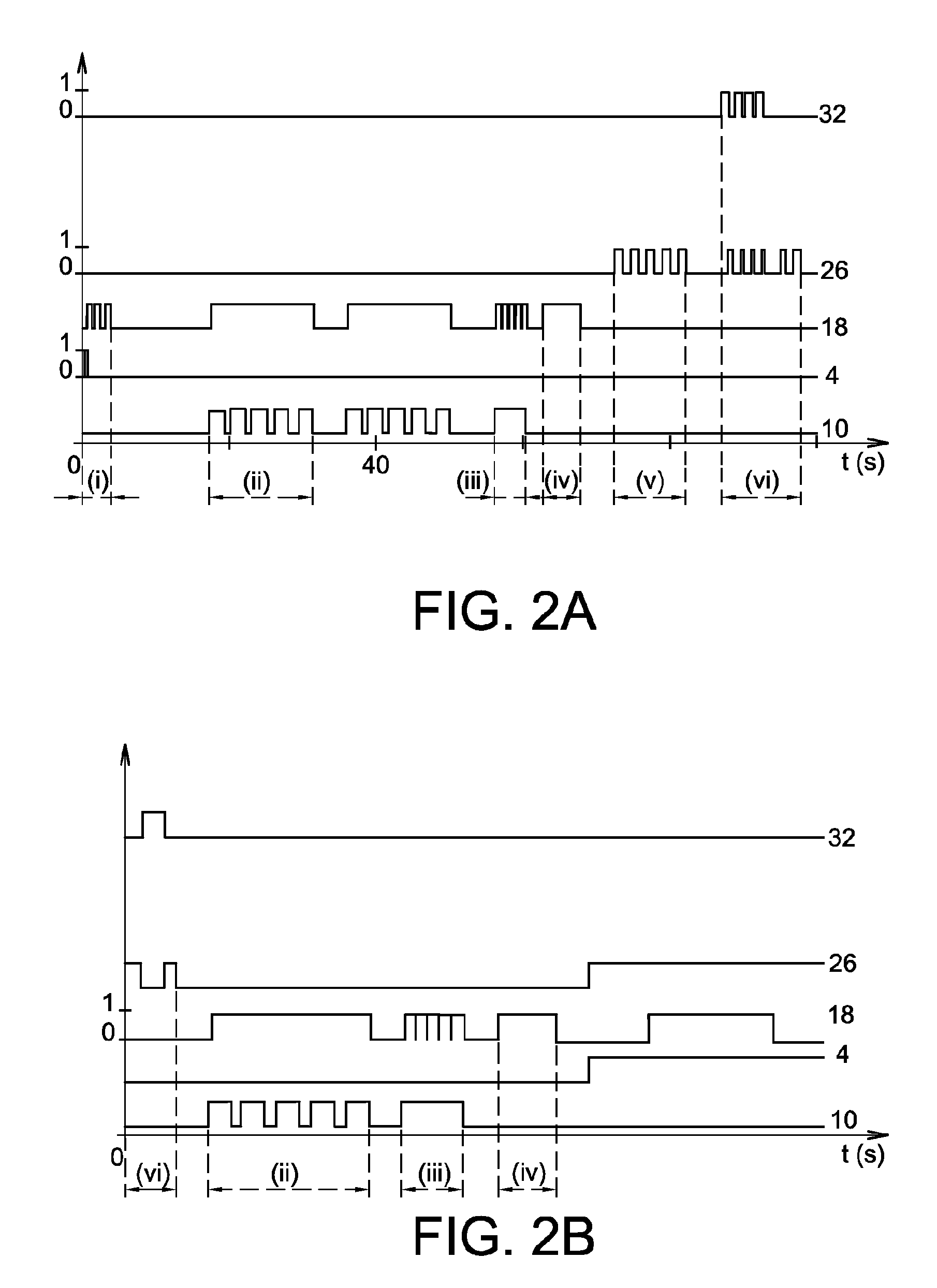

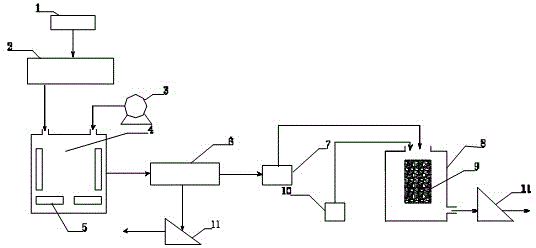

Print Head Cleaning

To clean a print head of an ink jet printer comprising an ink gun (1), connected, by means of devices capable of being controlled, to an ink chamber (2), a solvent chamber (8), a vacuum source (16), and an ink collection gutter (22) capable of being connected in a controlled manner to a vacuum source (16), the following steps are performed:(1) an interruption of a hydraulic connection between the gun (1) and the ink chamber (2) is ordered,(2) the gun (1) is connected to the vacuum source (16),(3) the solvent chamber (8) is hydraulically connected to the vacuum source (16) via a circuit (12, 14, 20) comprising the ink gun (1).

Owner:MARKEM IMAJE HLDG

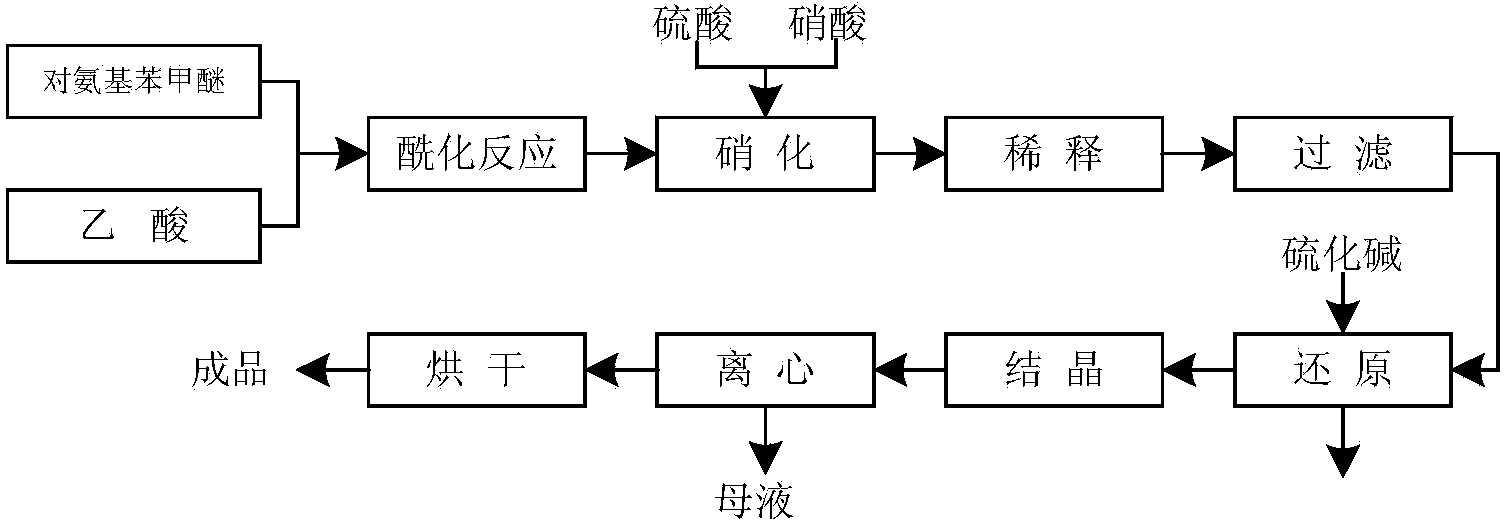

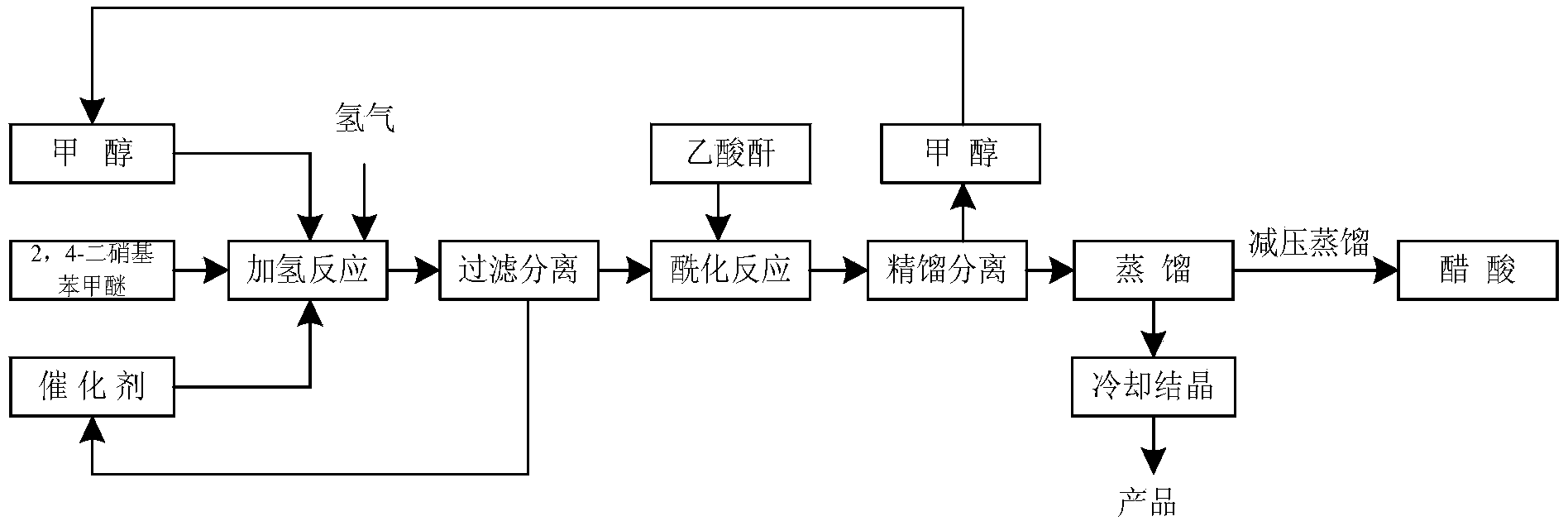

Preparation process of 2-amino-4-acetyl aminoanisole

ActiveCN103524371AHigh purityProcess safetyOrganic compound preparationCarboxylic acid amides preparationSolventAcetic anhydride

The invention discloses a preparation process of 2-amino-4-acetyl aminoanisole. The preparation process comprises the following steps of (1) taking methanol as a solvent and 2,4-dimitroanisole as a raw material, introducing hydrogen to perform catalytic hydrogenation reduction reaction in the presence of a catalyst; (2) performing solid-liquid separation, and recovering the catalyst; (3) adding acetic anhydride to perform acetylation reaction; (4) recovering methanol which is recycled as a solvent for follow-up hydrogenation reduction; (5) performing reduced pressure distillation to recover acetic acid; (6) performing cooling crystallization to obtain a 2-amino-4-acetyl aminoanisole product.

Owner:SHANGHAI ZONGXING CHEM TECH CO LTD

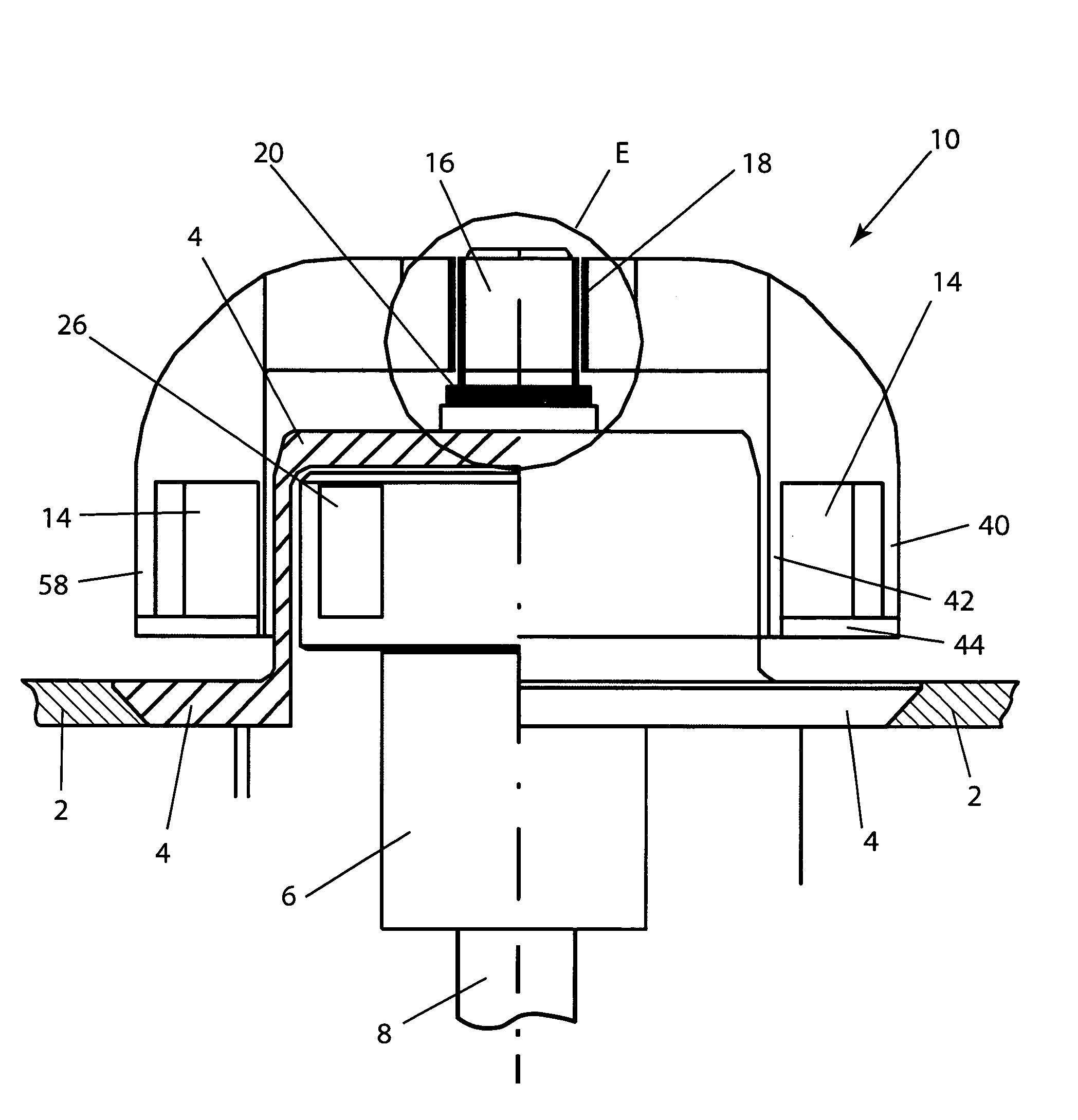

Ultraclean magnetic mixer

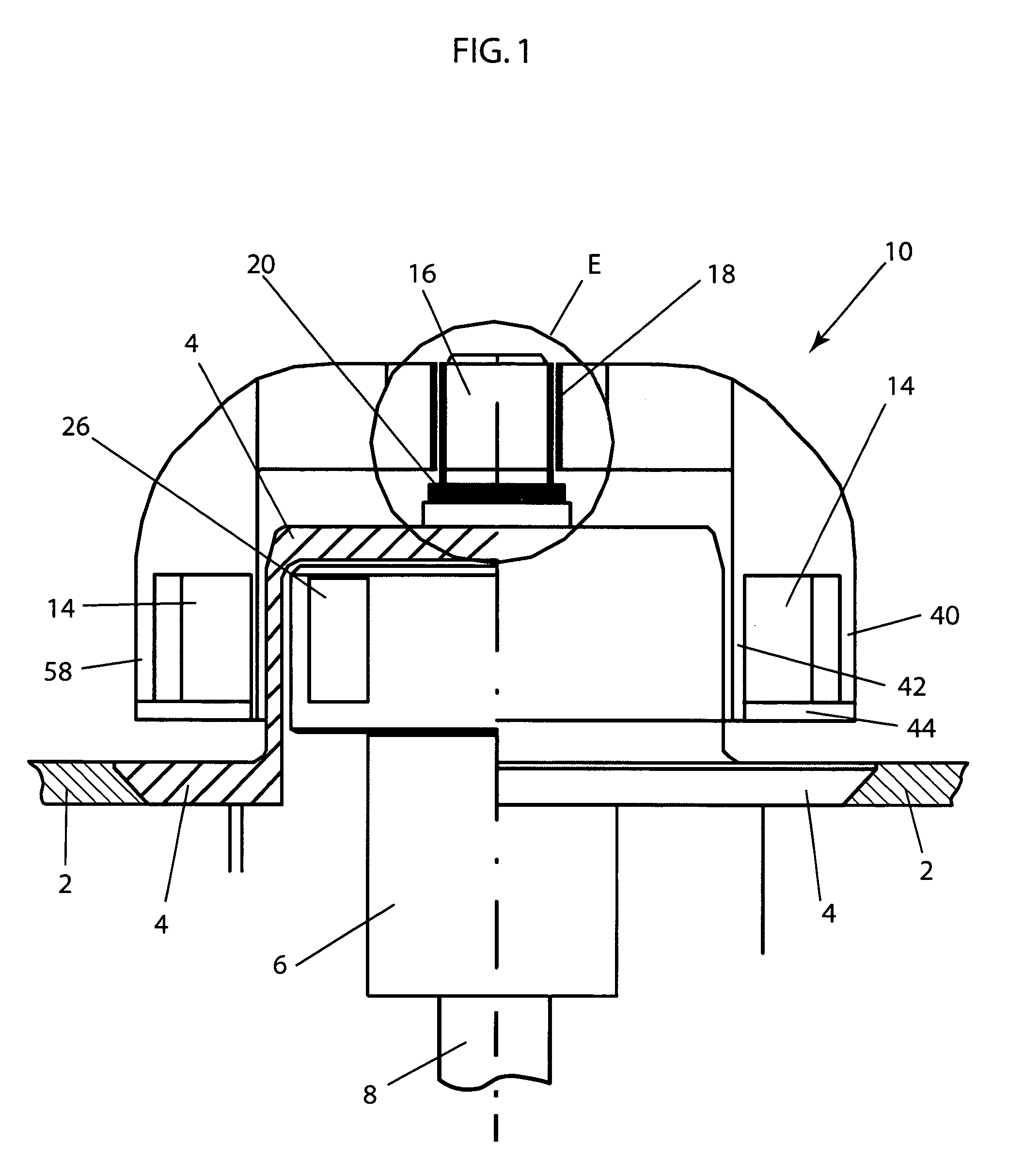

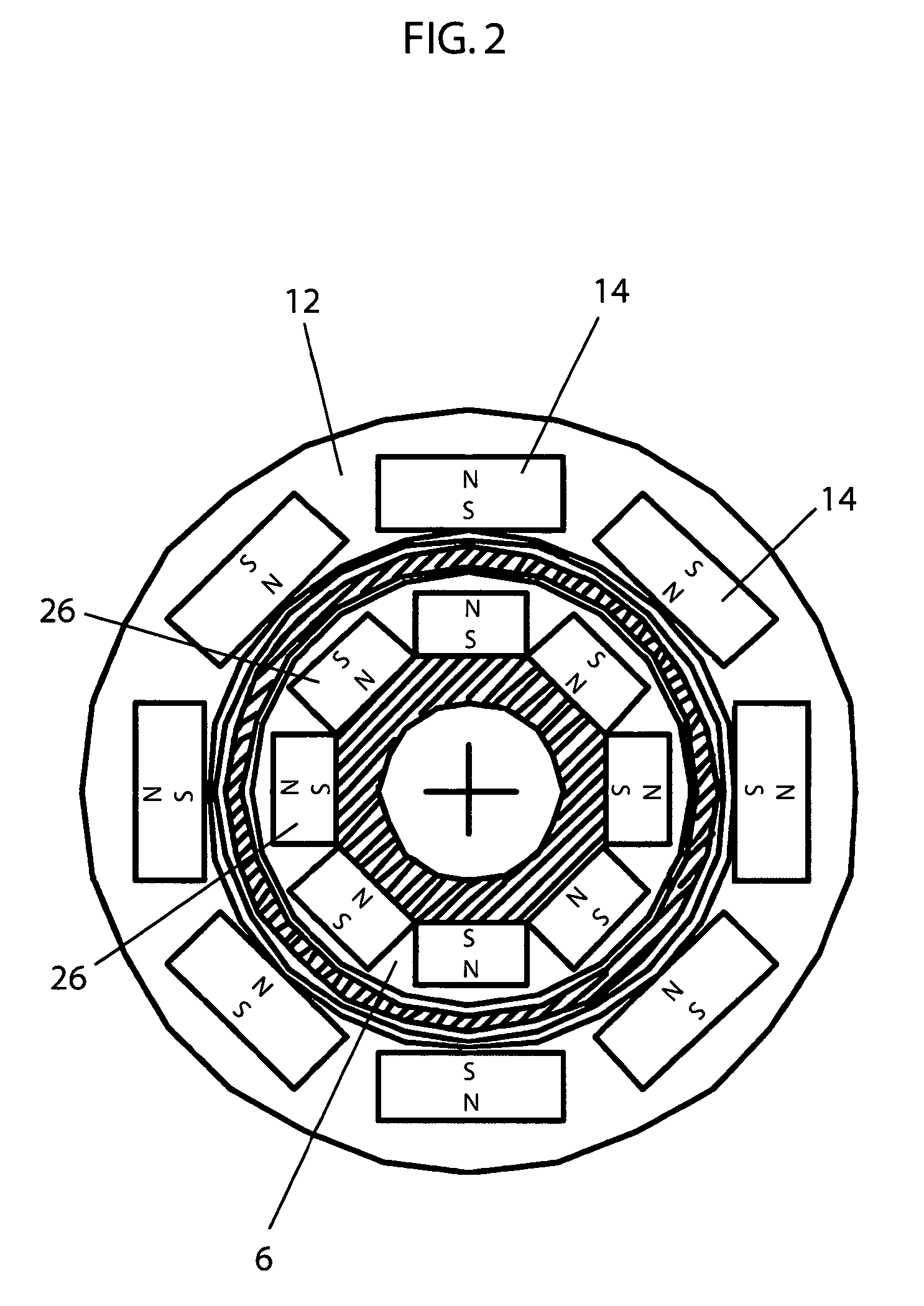

ActiveUS7396153B2Eliminate pollutionEliminate wear and tearTransportation and packagingMixer accessoriesThrust bearingMagnetic stirrer

In a magnetically-coupled liquid mixer of the type having a drive mount secured to and extending into a mixing vessel, an external first magnet array adjacent to the drive mount, a stub shaft extending from the drive mount into the vessel and having a first thrust bearing surface, and a driven portion rotatably-mounted on the stub shaft and having a second thrust bearing surface and a second magnet array, the improvement wherein the first and second arrays are positioned with respect to one another such that the first and second thrust bearing surfaces are spaced apart at least in the absence of above-threshold fluid dynamic thrust forces on the driven portion.

Owner:ALFA LAVAL CORP AB

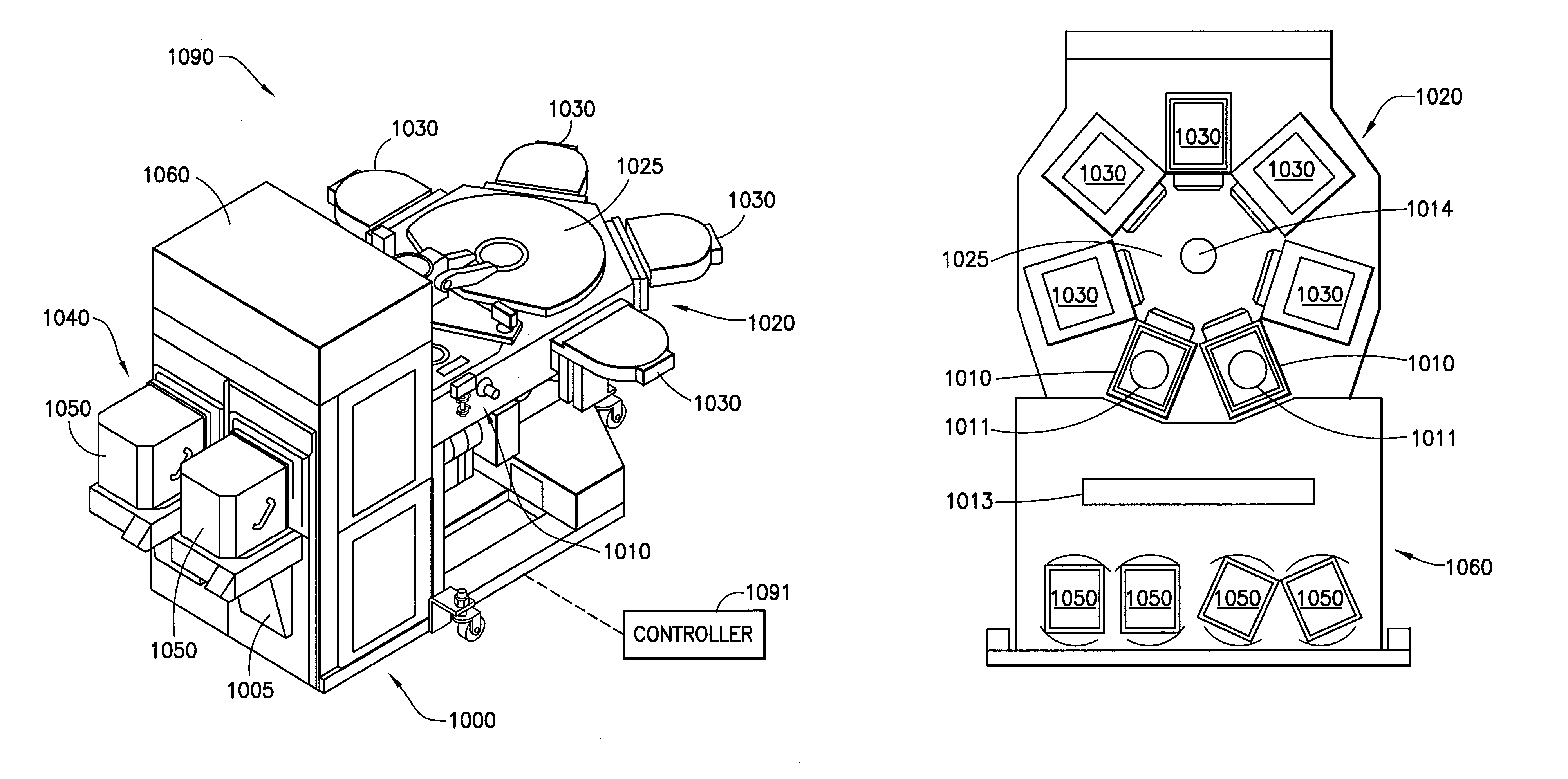

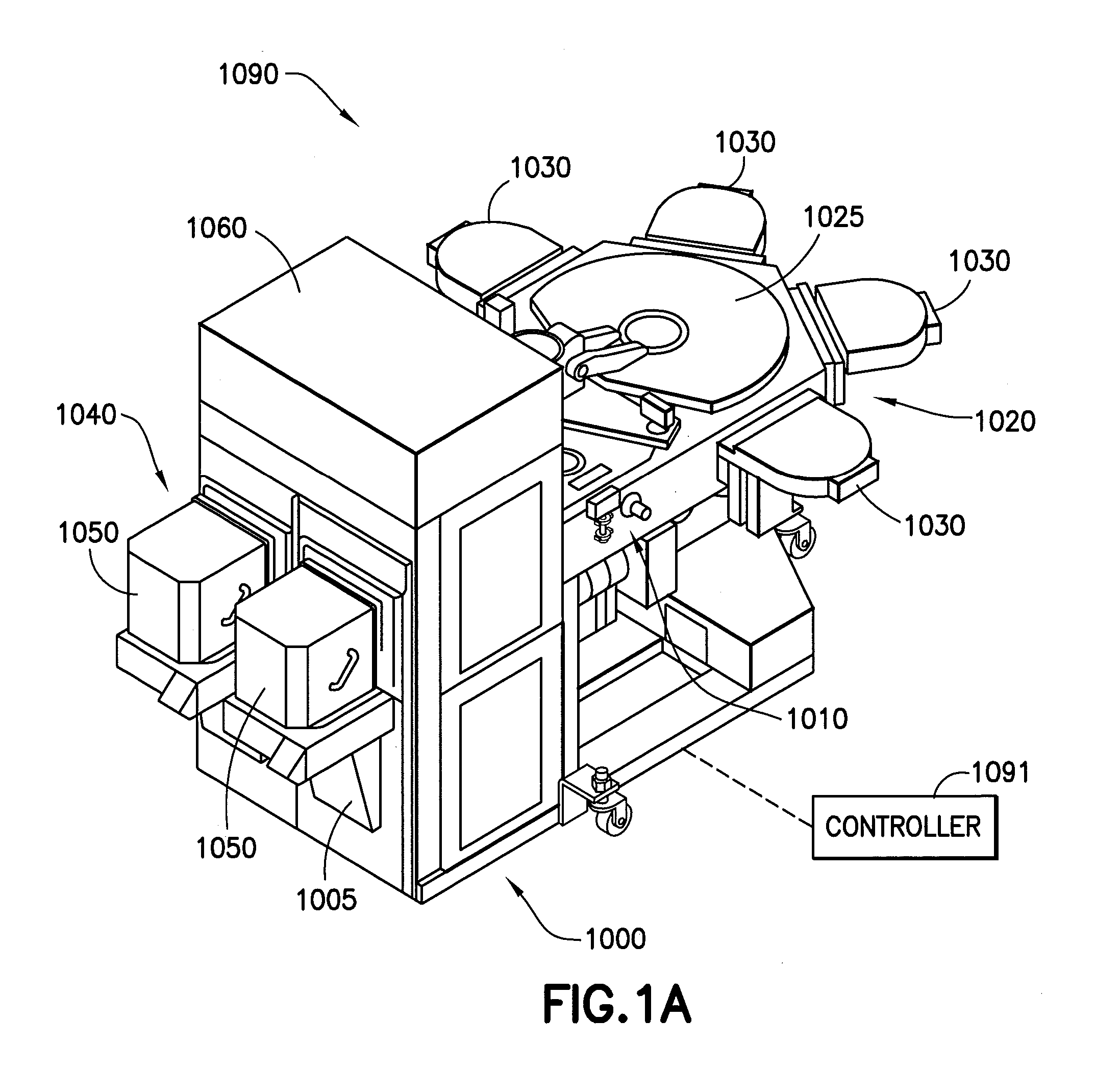

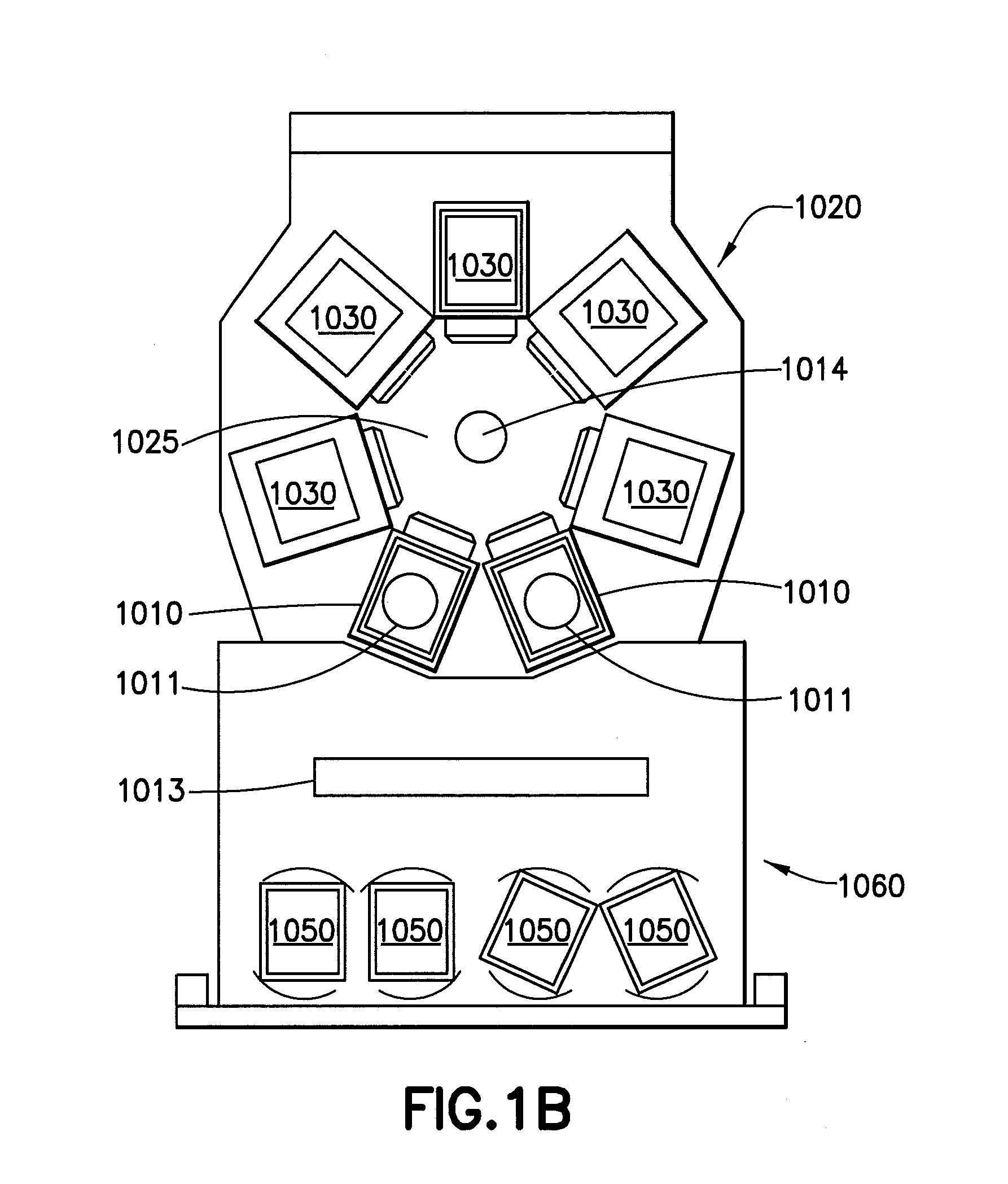

Transport apparatus

ActiveUS20140301818A1Improve adhesionReduce adhesionGripping headsSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transport apparatus for transporting substrates, the substrate transport apparatus including a frame, at least one transfer arm connected to the frame, at least one end effector mounted to the at least one transfer arm and at least one substrate support pad disposed on the at least one end effector, the at least one substrate support pad has a configuration that effects increased friction force, resulting from an increased friction coefficient, in at least one predetermined direction.

Owner:BOOKS AUTOMATION US LLC

Method for producing saponin and organic acid by using turmeric

InactiveCN101812499AFully clean productionHigh extraction rateUltrafiltrationSteroidsSlagBio engineering

The invention discloses a method for producing saponin and organic acid by using turmeric, which belongs to the field of biological engineering and solves the problem that the conventional method for extracting turmeric saponin by using a turmeric raw material has large discharge amounts of waste water and waste slag and cannot effectively use turmeric starch. The method comprises the steps of turmeric saponin release, turmeric starch saccharification, fermentation medium preparation, organic acid fermentation, saponin enrichment and saponin preparation. By pretreating the turmeric raw material by using fermentation and membrane separation coupling, the method has the advantages of pollution-free production of the saponin and the organic acid, high turmeric saponin extracting rate, full utilization of the turmeric starch, little waste water amount and little production during turmeric saponin production, pollution-free process and great industrial utilization value in the turmeric industry.

Owner:HUAZHONG UNIV OF SCI & TECH

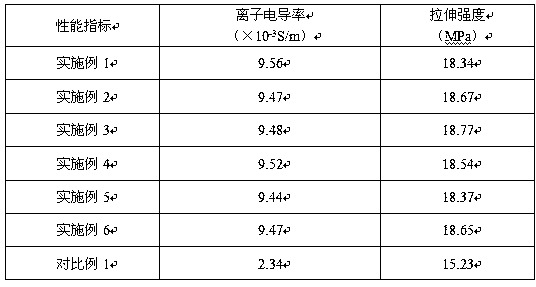

Method for cleaning type screw extrusion preparing of lithium battery polymer electrolyte membrane

The invention belongs to the technical field of lithium battery electrolyte membranes, and provides a method for cleaning type screw extrusion preparing of a lithium battery polymer electrolyte membrane. The method comprises the steps that after polyvinylidene fluoride, polyoxyethylene, lithium salt, a fast ion conductor, nano inorganic filler and plasticized plant fiber are mixed, strong airflowis used for impacts, a compound is prepared, and after the compound and elastomer are mixed, the mixture is conveyed into a double-screw extruder to be subjected to continuous shearing, mixing and scattering, die head sheet forming, roller calendering sheet forming, liquid nitrogen quenching and annealing treatment are continuously conducted, and the lithium battery composite polymer electrolyte membrane is prepared. Compared with a traditional method, the polymer composite electrolyte membrane prepared through the method has a large number of lithium ion transmission channels, conductivity isgood, meanwhile, good mechanical performance and heat resistance are achieved, meanwhile, the preparing process is clean and free of pollution, and cost is low.

Owner:湖北奇见新材料有限公司

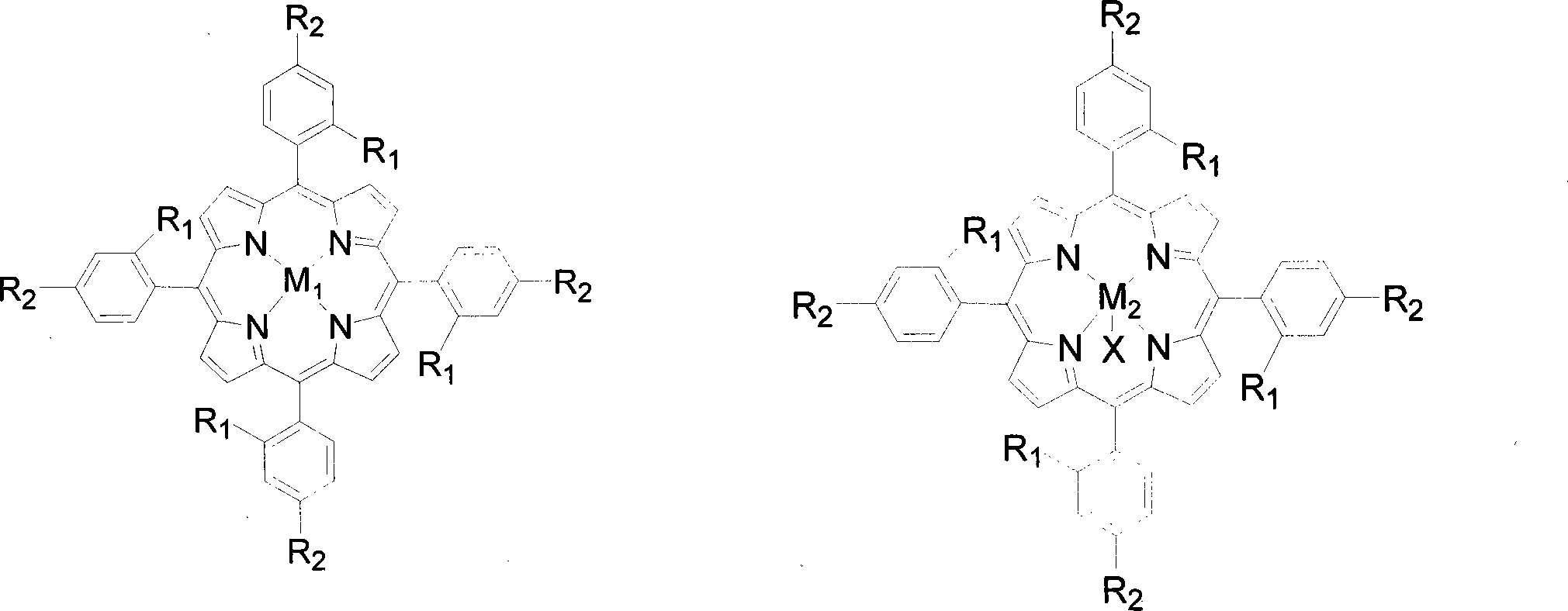

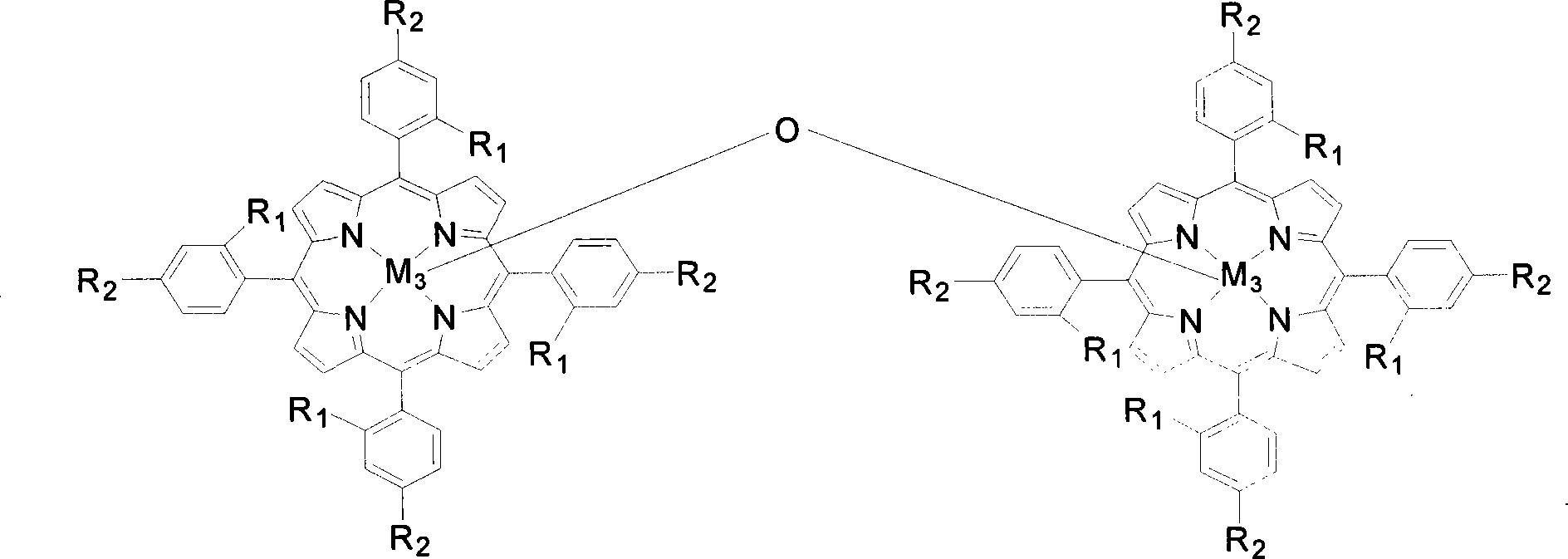

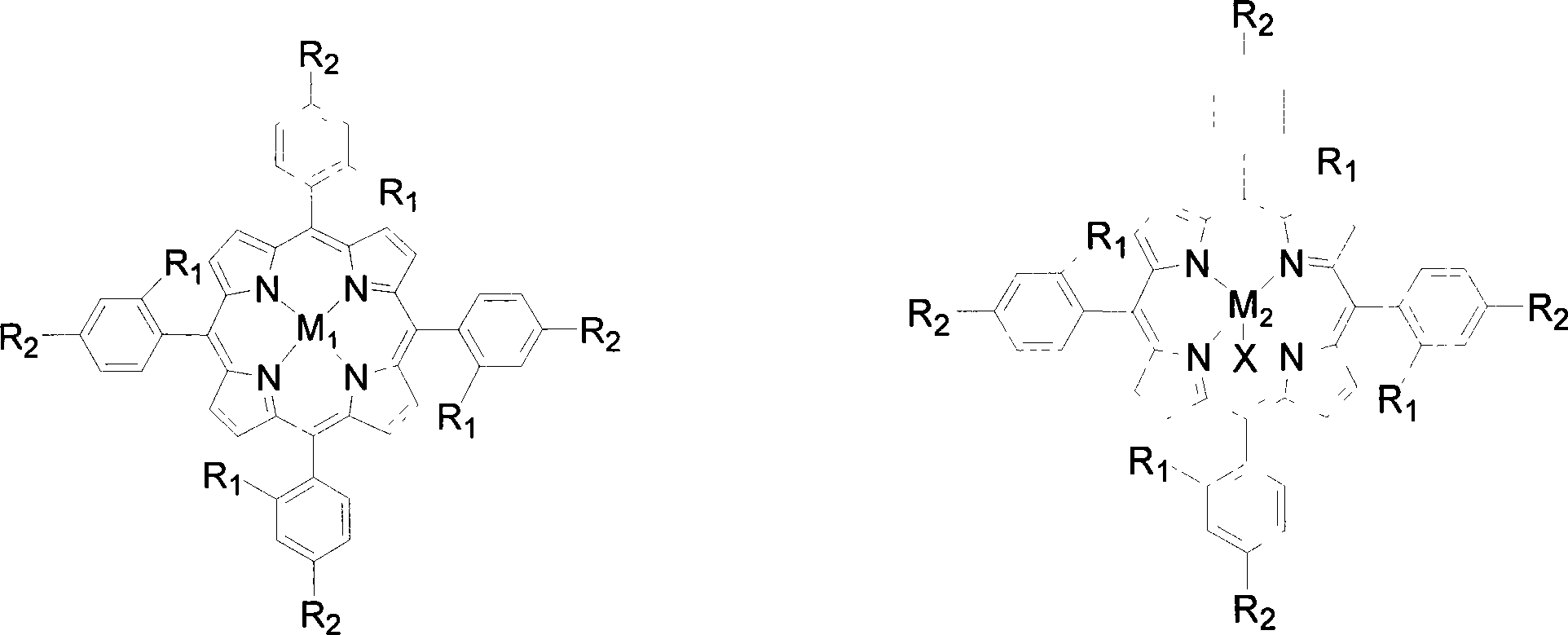

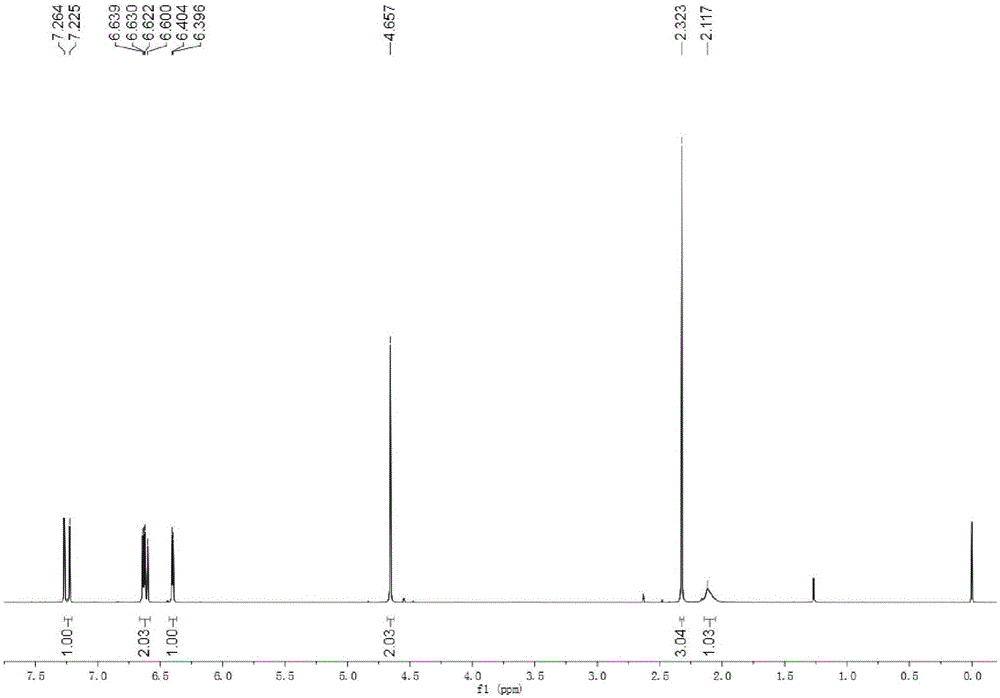

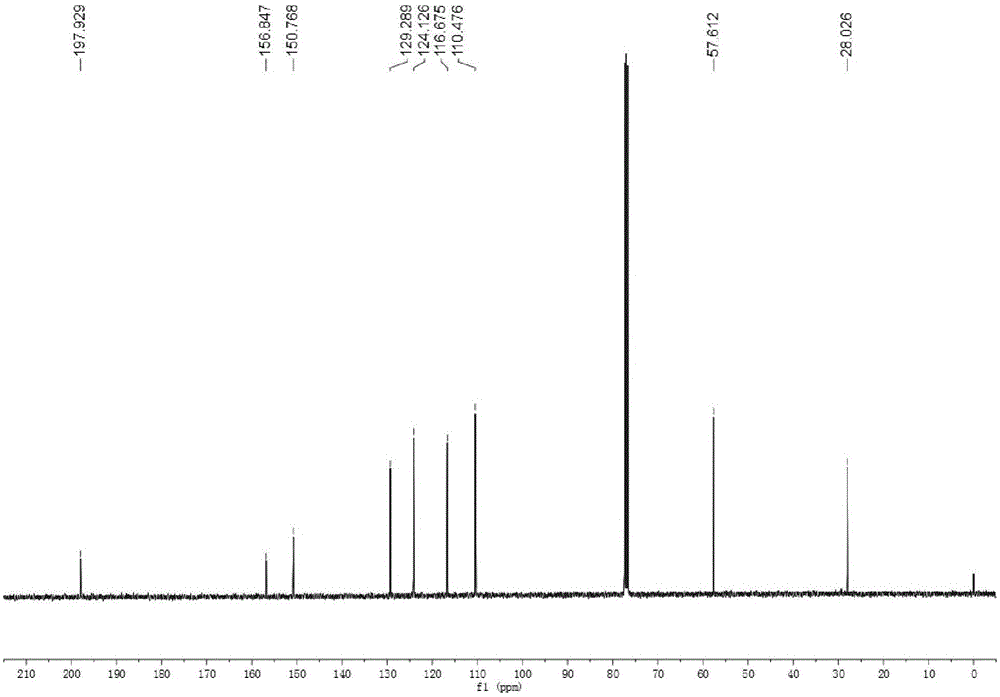

Method for preparing lactones by biomimetic catalytic oxidation of ketone compounds

InactiveCN101205225AMild reaction conditionsLow reaction temperatureOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsBenzaldehydeReaction temperature

The invention discloses a method for putting the oxydone compounds into the biomimetic catalysis to prepare the lactone. With the ketone compounds as the raw materials, the invention selects the mononuclear metalloporphyrins with structure in the general formulas (I) and (II) or Mu-oxygen-binuclear metalloporphyrins with structure in the general formula (III) as the catalysts; the concentration of the catalysts ranges from 2 multiplied by 10<-5>mol / L to 2 multiplied by 10<-2>mol / L and the concentration of the ketone compounds ranges from 0.02mol / L to 0.8mol / L; with the benzene, the toluene, the xylene, the benzotrifluoride or the cyclohexane as the solvents, the benzaldehyde, isobutyraldehyde or butyraldehyde with a molar ratio to the ketone compounds ranging from 0.5 to 1 to 20 to 1 is added in the mixtures; the oxygen with a pressure ranging from 0.1MPa to 1.6MPa is pumped in the mixtures; the reaction temperature is controlled to a range from 40 DEG C to 150 DEG C and the reaction time is controlled to a range from 1 to 10 hours. The invention has the advantages of gentile reaction conditions, a small dosage of catalysts, good catalytic effects, and high product selectivity, etc.

Owner:SOUTH CHINA UNIV OF TECH

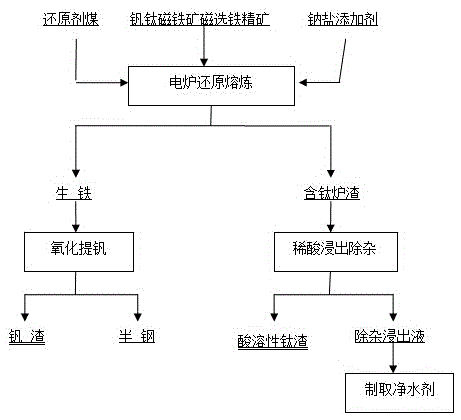

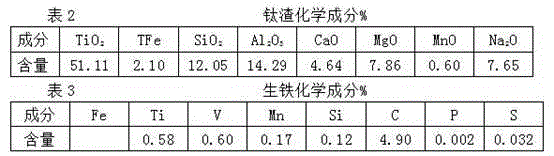

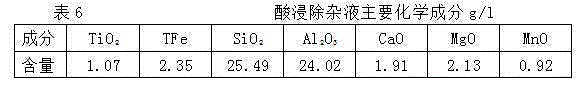

Method for extracting titanium from vanadium-titanium magnetite

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

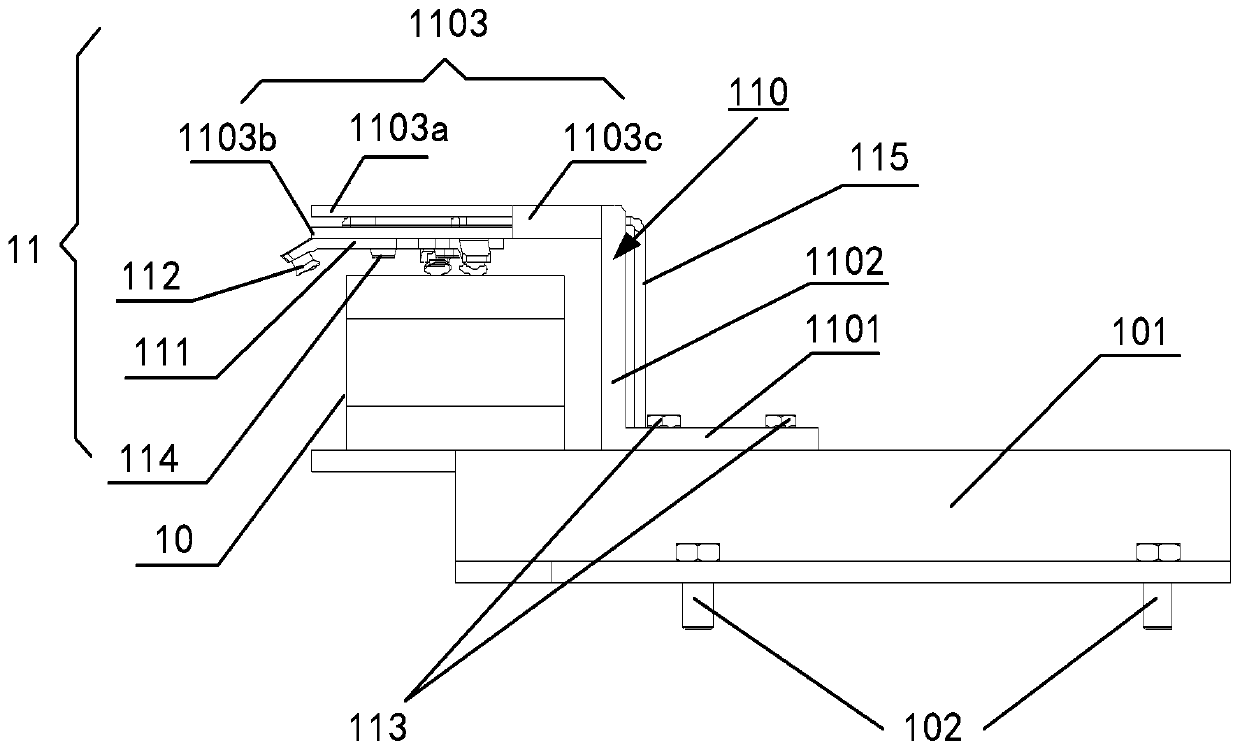

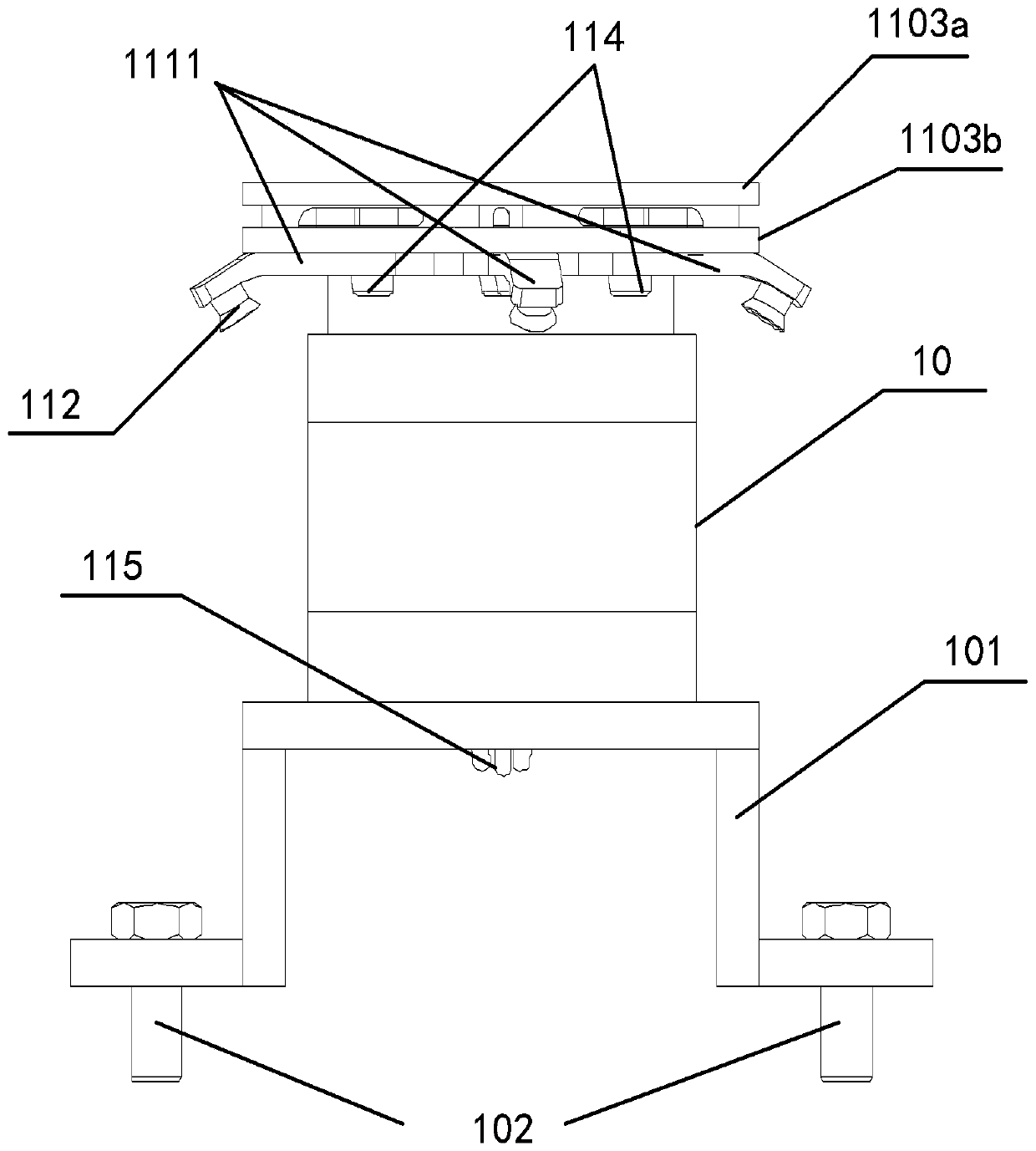

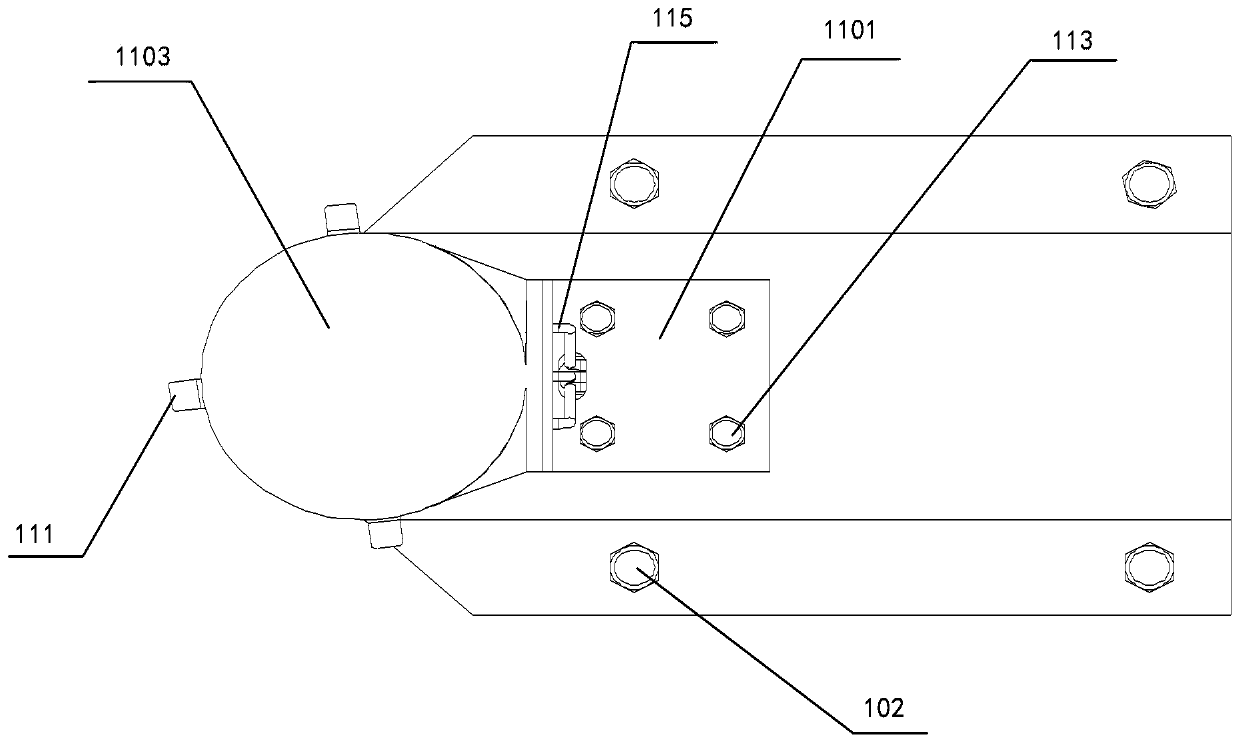

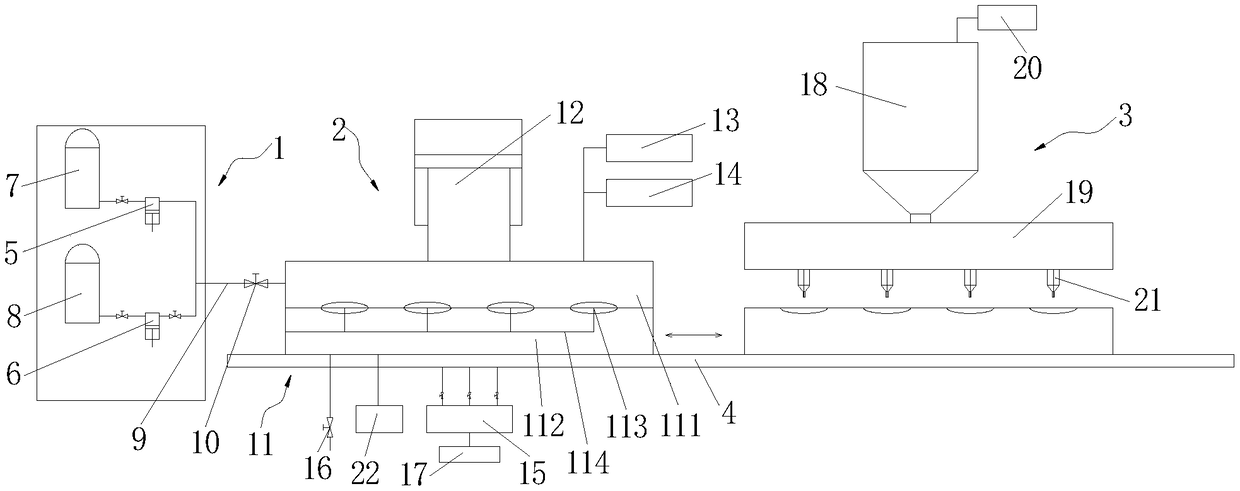

Cleaning and protection integrated device of laser radar, cleaning control method thereof and cleaning system

ActiveCN110586578AAvoid damageAchieve cleaningCleaning using gasesCleaning using liquidsRadarSpray nozzle

The invention discloses a cleaning and protection integrated device of a laser radar, a cleaning control method thereof and a cleaning system. The cleaning and protection integrated device comprises aprotection support, a spray nozzle support and a spray nozzle, wherein the protection support is arranged on a radar support bottom seat, and comprises a protection plate structure located above thelaser radar, the radar support bottom seat is used for supporting the laser radar 10, the spray nozzle support is fixed below the protection plate structure, and provided with a plurality of extensionarms, the extension arms are distributed above the top of the laser radar in an encircling mode, the spray nozzle is fixed on the end portions of the extension arms, an inlet of the spray nozzle is connected with a water-gas passing pipe, and an outlet of the spray nozzle faces the laser radar so as to spray out gas or a water-gas mixture. The cleaning and protection integrated device of the laser radar achieves integrated function of cleaning, protection and supporting, is simple in structure and strong in practicability, can simultaneously meet cleaning of various laser radars, such as a cylindrical type laser radar and a bevel type laser radar, widely used at present, and greatly improves applicability of the cleaning device.

Owner:SHANGHAI YIAO TECH CO LTD

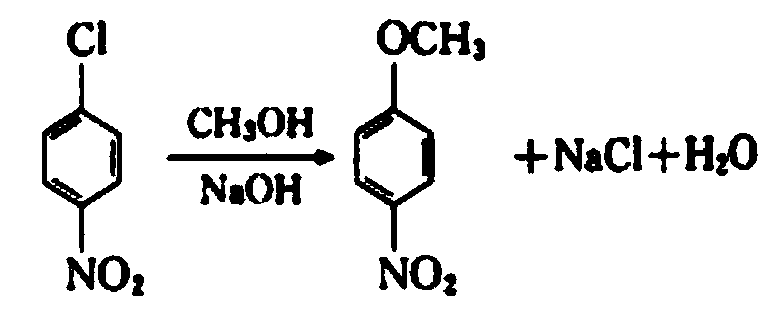

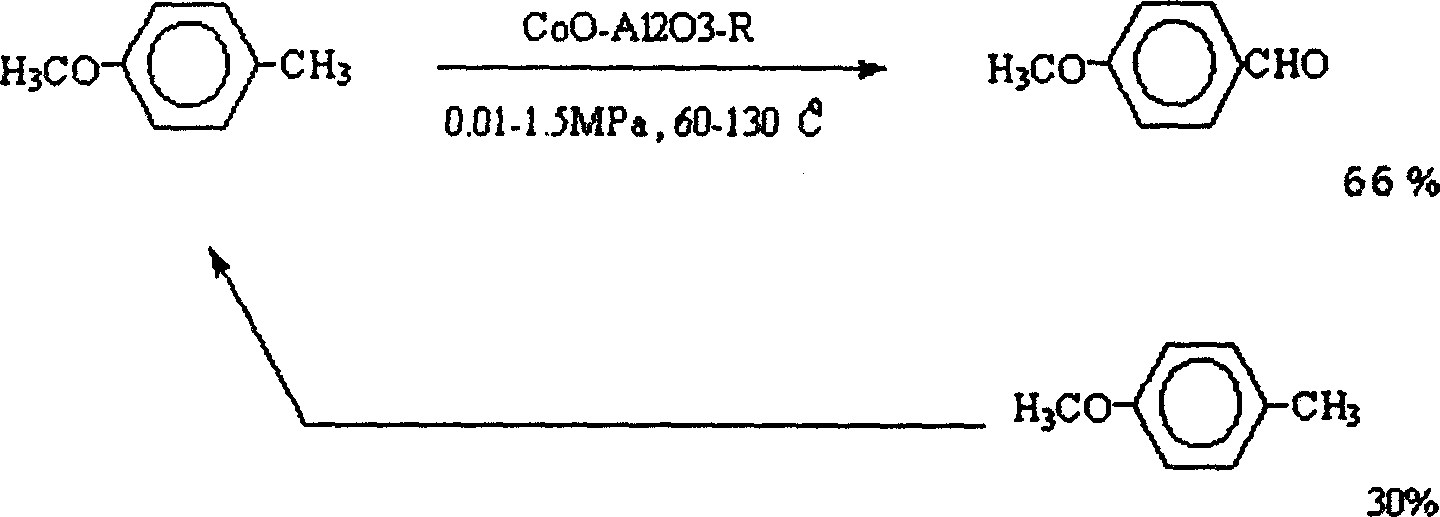

Synthetic process for p-methoxy benzaldehyde

InactiveCN1491930AEvenly dispersedEasy to separate and recycleCarbonyl compound preparation by oxidationBenzaldehydeCatalytic oxidation

The present invention relates to methoxy benzaldehyde compound, and is especially a catalytic oxidation process of synthesizing p-methoxy benzaldehyde. Methoxy methylbenzene material is oxidized with oxygen as oxygen source under the action of the catalyst CoO-Al2O3-R to synthesize p-methoxy benzaldehyde. In the catalytic oxidation process, nano level catalyst is dispersed in the reaction system homogeneously and may be recovered easily. The catalyst has p-methoxy benzaldehyde selectivity up to 92 %, and the catalytic oxidation process has single-path yield of 66 % and total yield up to 90 % and no environmental pollution, and is one clean and efficient technological process.

Owner:大化集团有限责任公司研究院 +1

Restoration method of soil polluted by radionuclide Cs-137

ActiveCN104690083AThe process is easy to implementEasy to implementContaminated soil reclamationFiltrationRestoration method

The invention discloses a restoration method of soil polluted by radionuclide Cs-137, and belongs to the field of environmental protection. The method comprises following steps: 1, soil extraction, crushing, and sieving; 2, physical leaching; 3, multi-stage separation and filtration; 4, chemical leaching; and 5, soil particle recovery, dehydration, pH adjustment and soil backfilling. A deionized water and ultrasonic wave combination technology is adopted in the physical leaching stage, so the decontamination percentage reaches 66%. The decontamination percentage of chemical leaching reaches 80%, and the total decontamination percentage reaches 93%, and is greatly higher than the decontamination efficiency of traditional methods. The method disclosed in the invention has the advantages of easy realization, clean process, simple device, good safety and low running cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing long-chain alkane from biomass derivativeS 5-HMF (hydroxymethyl furfural) or furaldehyde

InactiveCN105130731AHigh yieldReduce dosageHydrocarbon from oxygen organic compoundsAlkaneHydrogenation catalysis

The invention discloses a method for preparing long-chain alkane from biomass derivatives 5-HMF (hydroxymethyl furfural) or furaldehyde. According to the method, the biomass derivatives 5-HMF or furaldehyde are used as raw materials; a condensation product is formed after base catalysis and methyl ketone compound condensation; then, ketonic or alcoholic intermediates of tetrahydrofuran rings are obtained through hydrogenation catalysis; finally, the long-chain alkane is prepared through hydrogenation and ring opening dual catalysis preparation. The method has the advantages that the raw materials can be prepared from biological saccharides through hydrolysis and dehydration; the yield of the alkane is high; the consumption of catalysts is low; the reaction condition is mild; the process is clean and simple; in the reaction process of preparing the alkane from the condensation products, other operations and control are not needed except the program temperature rise; a new path for preparing the long-chain alkane from the biomass derivatives 5-HMF or furaldehyde by a one-pot method is opened up.

Owner:合肥利夫生物科技有限公司

Method for preparing biodiesel by utilizing high-acid value oil

InactiveCN103173293ALow acid valueNo post-processingFatty acid esterificationBiofuelsMonoglyceridePtru catalyst

The invention relates to a method for preparing biodiesel by utilizing high-acid value oil. The method comprises the following steps of: esterifying the raw materials of the high-acid value oil, enabling glycerol and the raw materials of the high-acid value oil to esterify with each other under the catalyzing action of an ionic liquid, and thus obtaining a mixture of a low-acid value esterification product-monoglyceride, diglyceride or triglyceride; then carrying out interesterification on the esterified oil, namely carrying out interesterification on the mixture of the low-acid value esterification product-monoglyceride, diglyceride or triglyceride and methanol under the action of a base catalyst, and thus generating crud low-acid value biodiesel fatty acid methyl ester; and vacuum distilling and refining the low-acid value biodiesel fatty acid methyl ester so as to obtain the high-purity low-acid value fatty acid methyl ester biodiesel. The details of the method are described in a specification. The method has the advantages that the method does not need post treatment and is shortened in reaction process, lowered in technological energy consumption and clean in process, equipment corrosion caused by conventional sulfuric acid catalyzing is eliminated, the equipment investment and production cost are lowered, and the yield of a target product-biodiesel (fatty acid methyl ester) is high.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

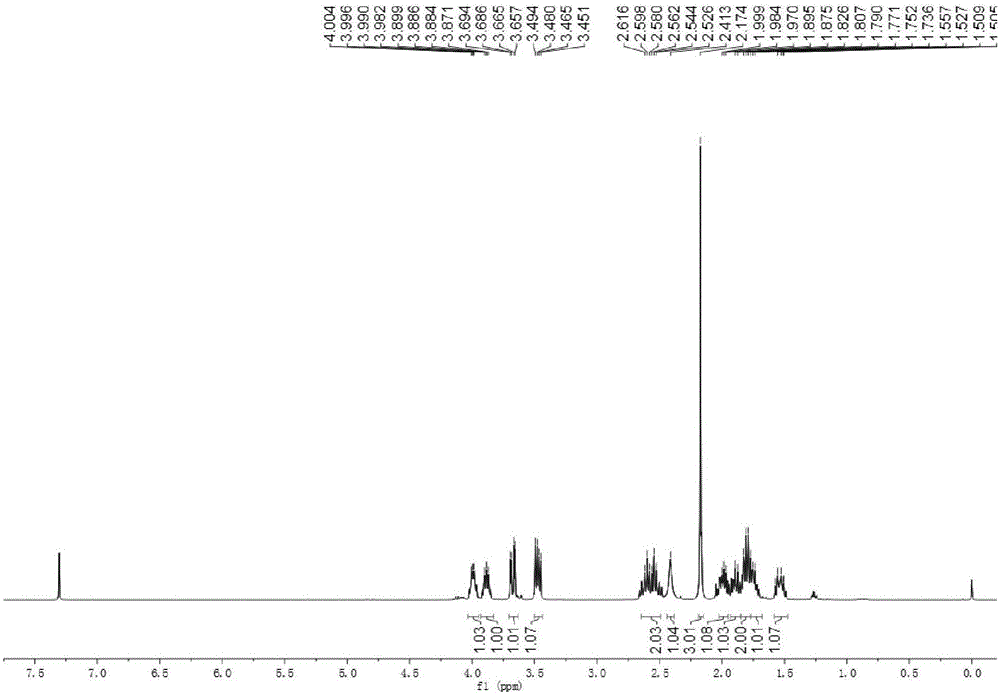

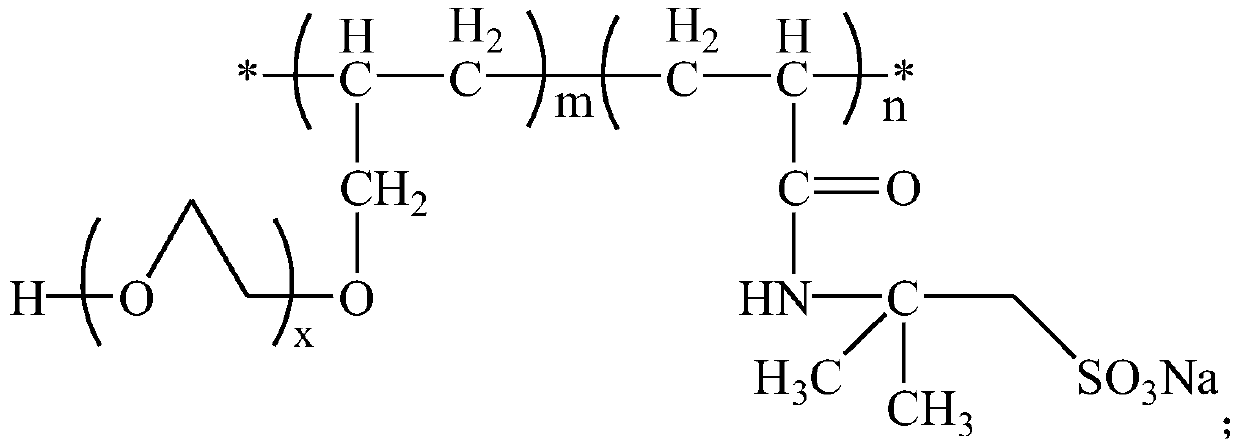

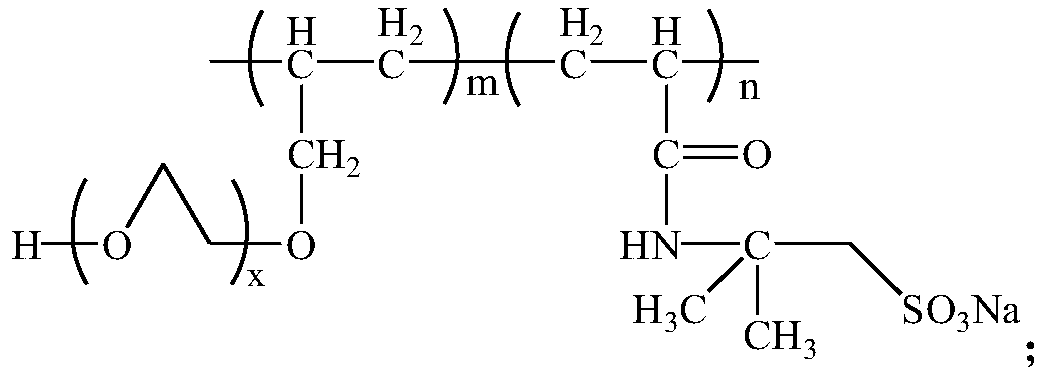

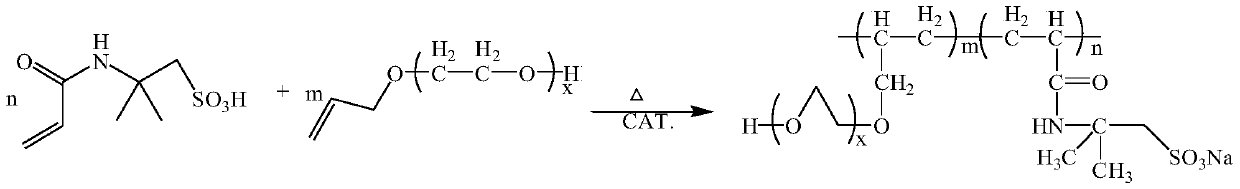

Permeable modified viscosity-reducing oil-displacing agent for water drive thickened oil as well as preparation method of oil-displacing agent

InactiveCN110699058AGood flexibilityExcellent change in wettabilityDrilling compositionChemistryPropanol

The invention relates to a chemical agent used in the exploitation process of thickened oil, in particular to a viscosity-reducing oil-displacing agent for water drive thickened oil and with effects of changing reservoir wettability and permeation depolymerization. The permeable modified viscosity-reducing oil-displacing agent is formed by performing free radical polymerization on 2-acrylic amide-2-methylpropanesulfonic acid and allyl alcohol polyoxyethylene ether in water, wherein the molar ratio of the 2-acrylic amide-2-methylpropanesulfonic acid to the allyl alcohol polyoxyethylene ether is1:(0.1-7), preferably 1:1.5. The molecular weight of the permeable modified viscosity-reducing oil-displacing agent is 8000 to 100000 g / mol. The viscosity reducer can resist mineralization degree of50000, can resist temperature of 150 DEG C, can adapt to a water drive thickened oil reservoir with the viscosity of 500 to 5000 mPa*s; and when the use concentration is 500 ppm, the viscosity of thethickened oil can be reduced to be less than 100 mPa*s. Therefore, the permeable modified viscosity-reducing oil-displacing agent can be widely applied to development of the water drive thickened oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

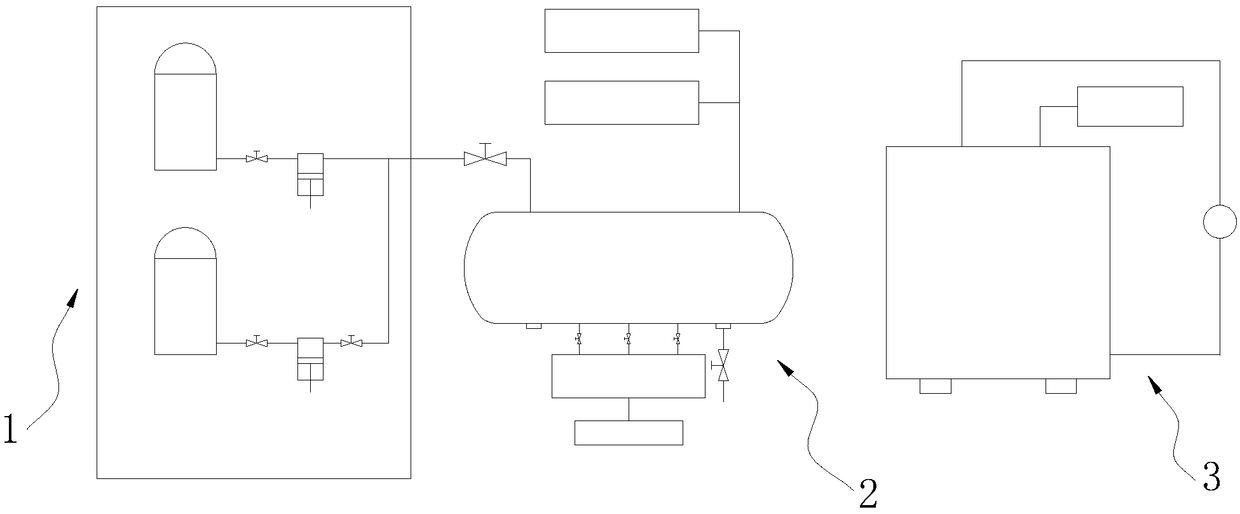

In-mold molded foaming forming device for thermoplastic polymer particles and forming method of forming device

PendingCN109016320AImprove heating efficiencyUniform temperatureBulk chemical productionPolymer scienceWater vapor

The invention discloses an in-mold molded foaming forming device for thermoplastic polymer particles and a forming method of the forming device. The forming device comprises a supercutical fluid conveying system, a mold pressing foaming system, a preheating quantitative feeding system and mobile guide rails, wherein the supercutical fluid conveying system is communicated with the mold pressing foaming system. The forming device is simple in structure, with the adoption of the one-step foaming forming method for the polymer particles, the polymer particles are not required to be pre-foamed andare directly added to a forming mold cavity, water and an anti-adhesion parting agent are not required, besides, a mold pressing weld forming process does not need high-pressure steam heating molding,the adhesion stress is large, the process is clean, and the process is suitable for polymer materials easy to hydrolyze; meanwhile, the heat demand in the processing procedure is less, heating efficiency of the polymer particles is high, temperature of the polymer particles is uniform, a polymer-particle microcellular-foaming mold pressing forming product with fine cells, accurate dimension and light weight is obtained, production efficiency is improved, automatic production is realized, and the device and the method are applicable to foaming mold pressing forming of most polymer particles.

Owner:GUANGDONG BENDI NEW MATERIAL TECH

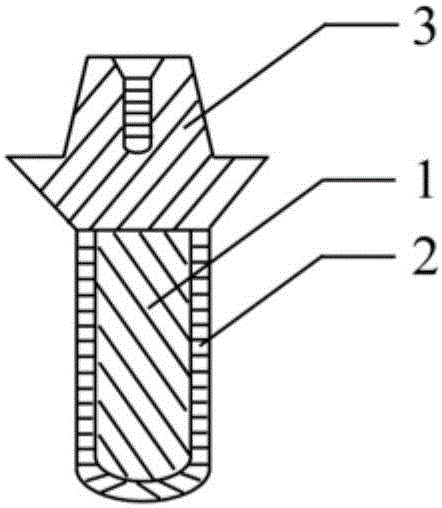

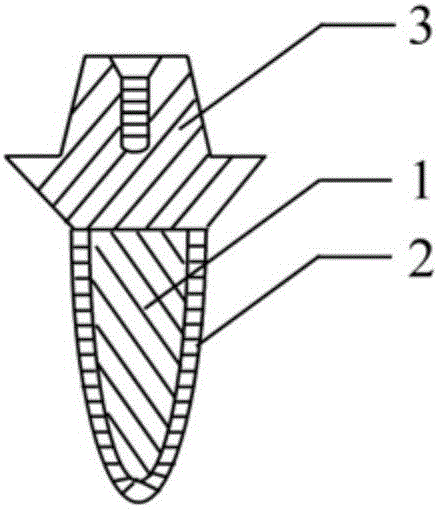

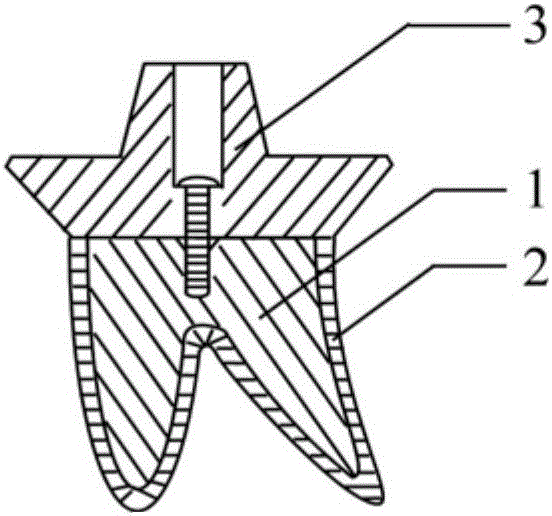

Individualized biomimetic dental implant and manufacture method thereof

InactiveCN106037965ALow elastic modulusImprove biomechanical compatibilityDental implants3d printCell adhesion

The invention relates to an individualized biomimetic dental implant and a manufacture method thereof. The invention is characterized in that the dental implant comprises an implant body for imitating the original tooth root tissue structure of a patient's missing tooth and also comprises a biomimetic artificial alveolar bone structure outer-layer for imitating a patient's alveolar bone tissue structure. The biomimetic artificial alveolar bone structure outer-layer and the external surface of the implant body are combined as a whole. The biomimetic tooth root implant body's outer layer is a 3D printed biomimetic artificial alveolar bone structure outer-layer which is combined with the implant body to form a whole structure, and is similar to the tissue structures of missing tooth's original tooth root and alveolar bone. Thus, the invention provides an ideal implementation scheme of a biomimetic artificial tooth root structure. What is the most important is that the invention provides a structure which is beneficial to bone marrow stem cell and osteogenesis-related cell adhesion, proliferation and mineralization and gives play to final osteogenic function and has good bioactivity. Therefore, a microenvironment for promoting osteogenesis is created, osteocyte generation is induced, and early rapid and firm synosteosis is realized.

Owner:STOMATOLOGICAL HOSPITAL TIANJIN MEDICAL UNIV

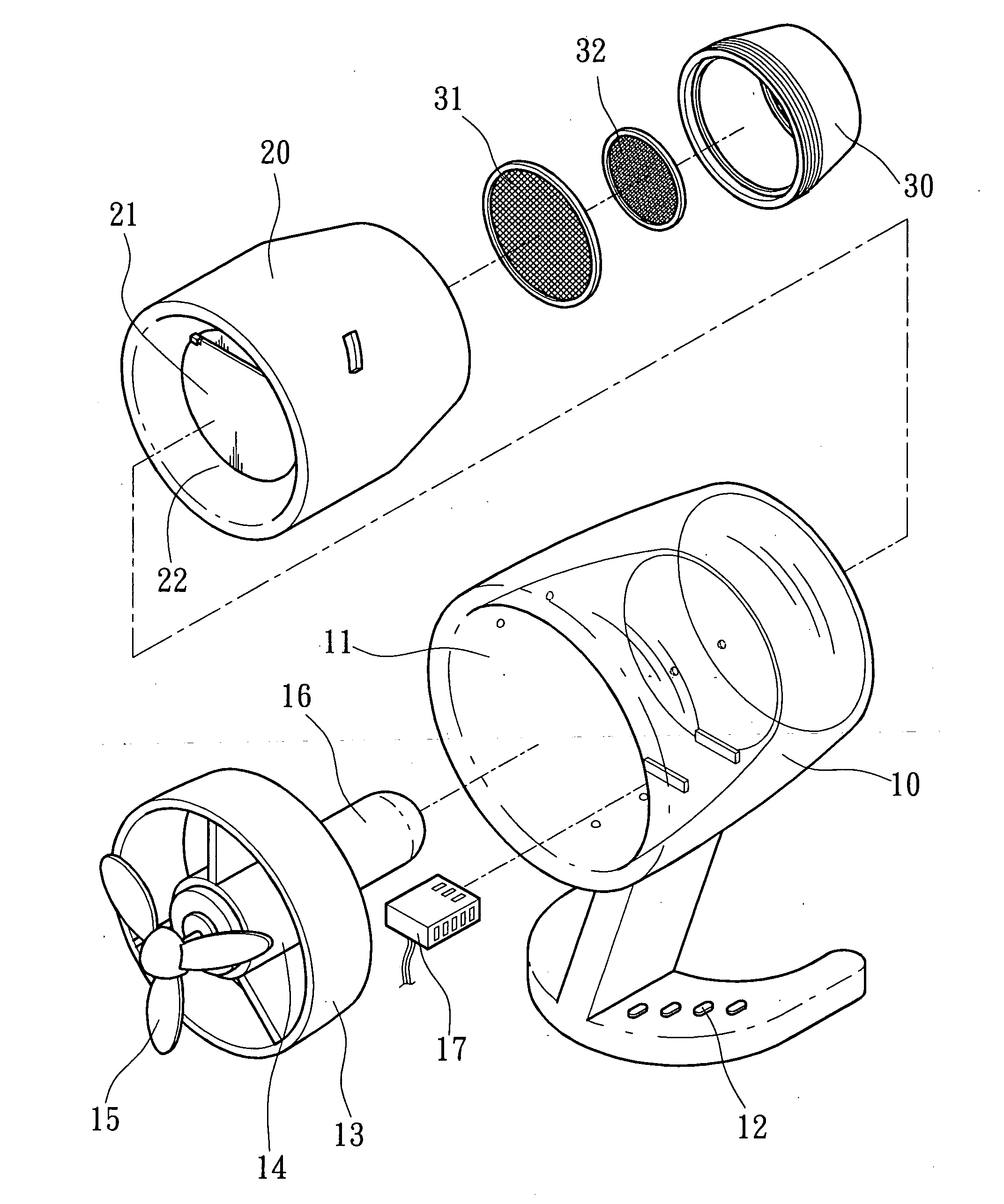

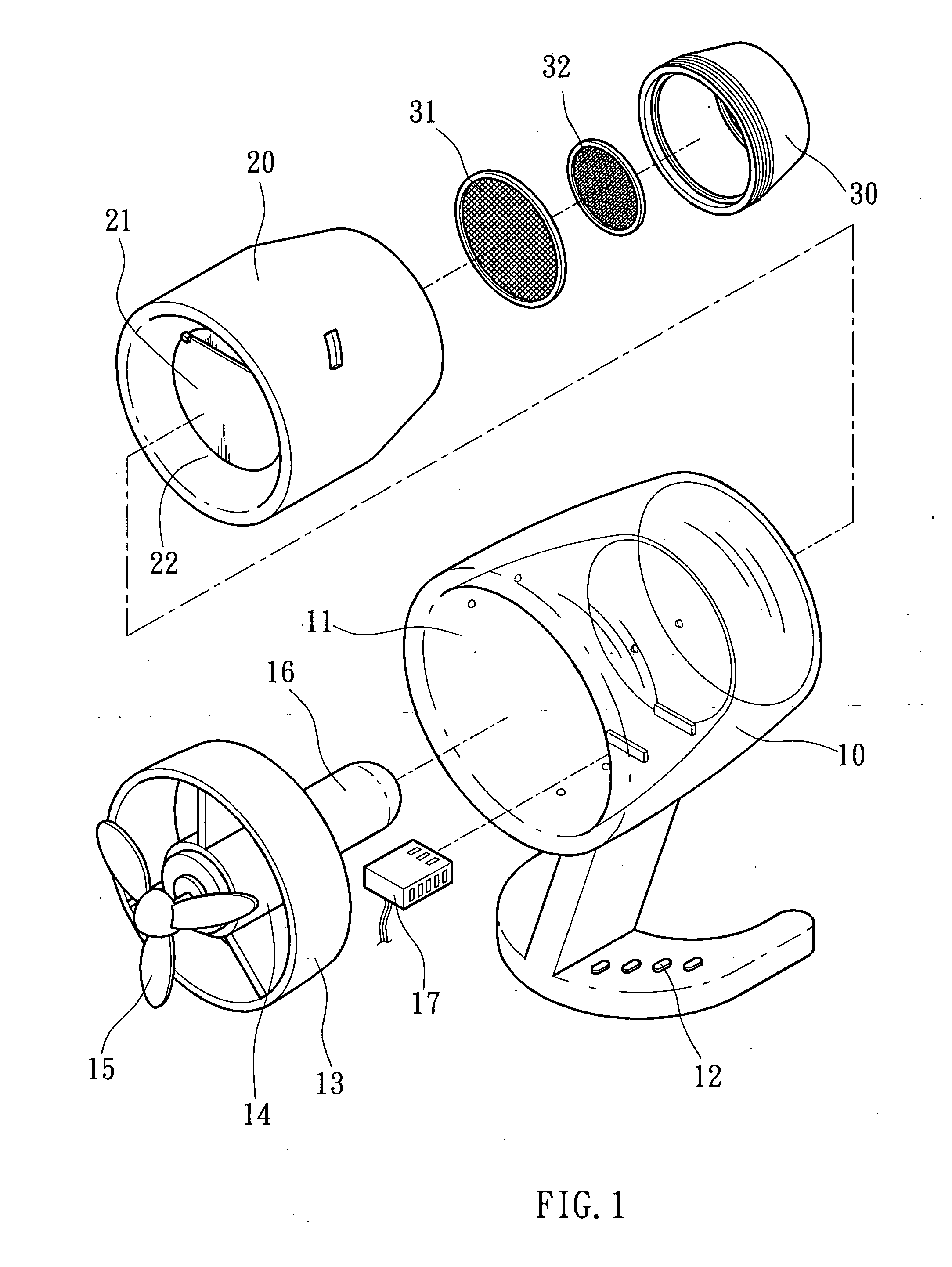

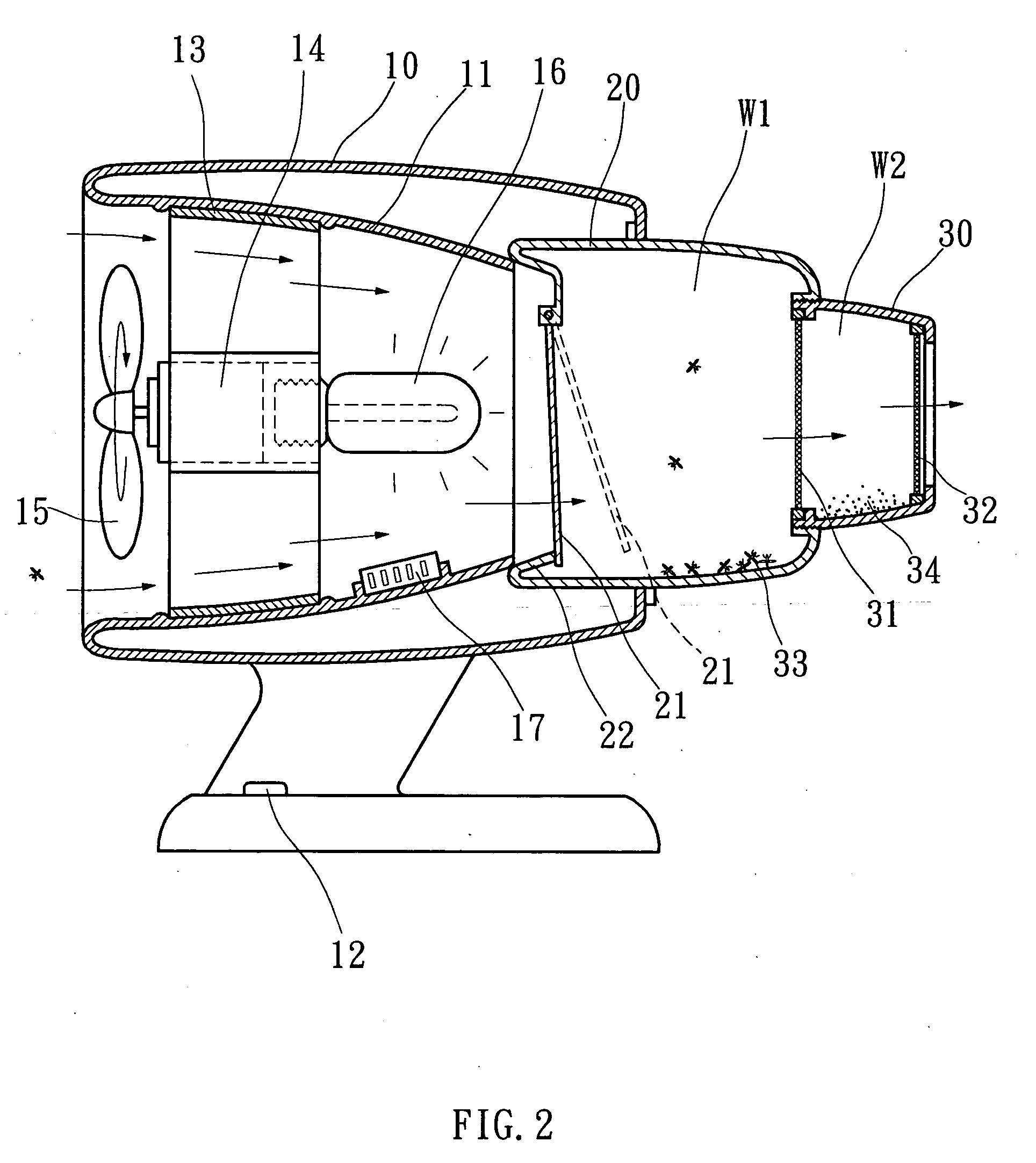

Multipurpose mosquito trap lamp

InactiveUS20060080887A1Process cleaningEfficient trappingInsect catchers and killersOzone generatorTrapping

A multipurpose mosquito trap lamp base includes a base that admits light, a holder frame mounted in the base and holds an induced-draft fan at the front side and an ultraviolet lamp at the rear side, a hollow shell coupled to the rear side of the base for trapping mosquitoes, a filter cap capped on the rear side of the hollow shell for removing dust from air passing through the hollow shell, and an ozone generator mounted inside the base for generating ozone to sterilize air passing through the base and the hollow shell and the filter cap.

Owner:CHEN CHANG HAO +1

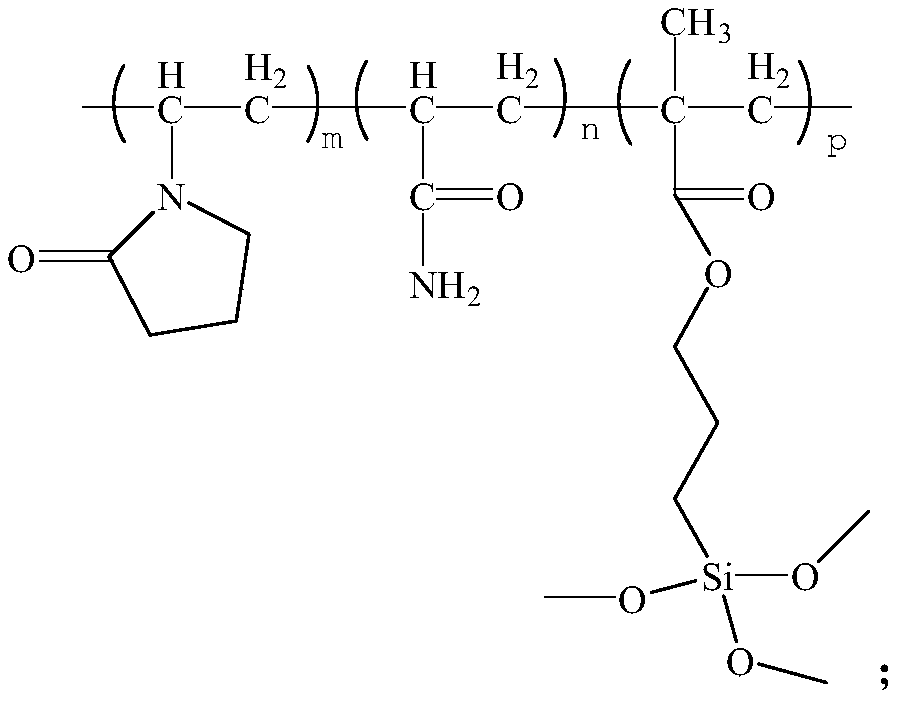

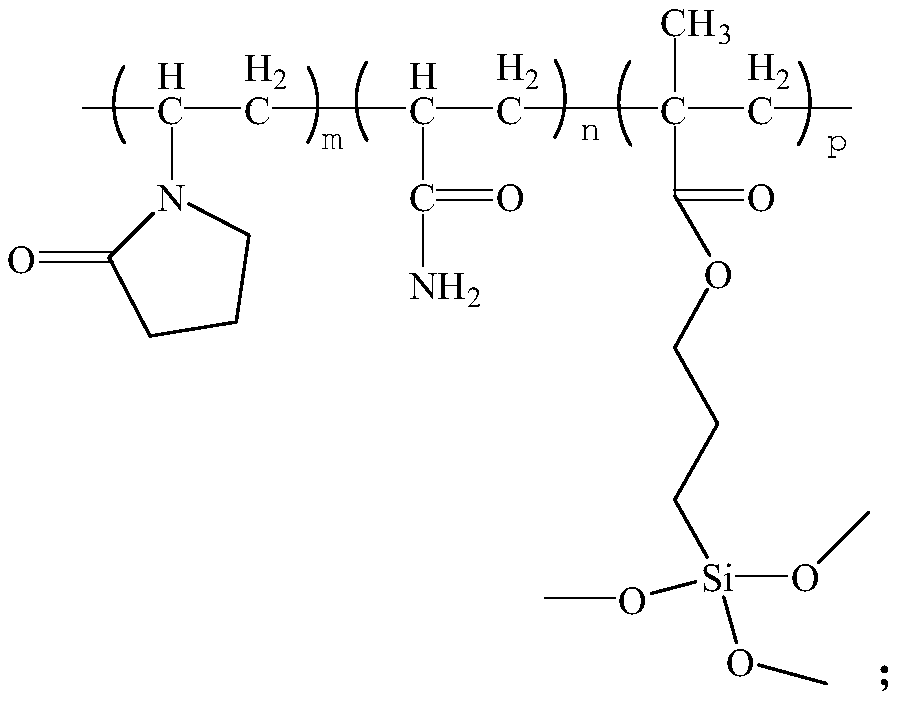

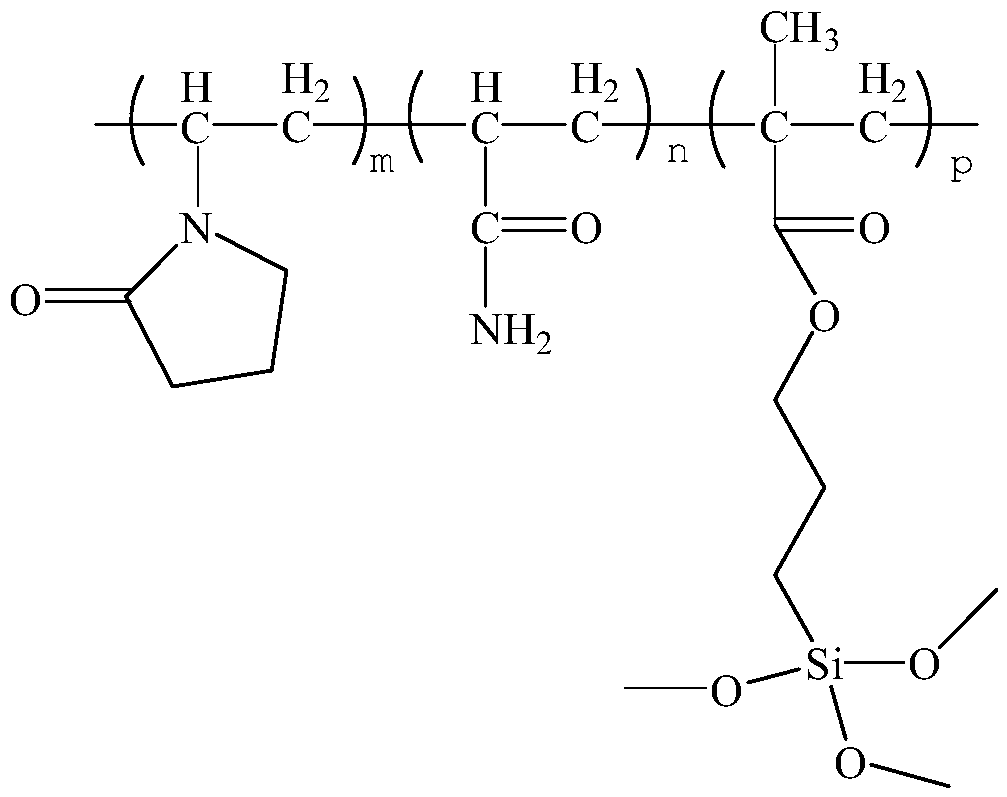

Temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer and preparation method thereof

ActiveCN110041462AImprove temperature resistanceImprove salt toleranceDrilling compositionTemperature resistanceChemistry

The invention relates to a polymer type viscosity reducer used in a heavy oil recovery process, concretely to a temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducerand a preparation method thereof. The viscosity reducer is generated by 1-vinyl-2-pyrrolidone, acrylamide and methacryloxypropyltrimethoxysilane under the action of an initiator. A mol ratio of the 1-vinyl-2-pyrrolidone, the acrylamide and the methacryloxypropyltrimethoxysilane is 1:0.05-10:0.05-20, preferably 1:1.2:2.3. The heavy oil viscosity reducer of the invention has good temperature resistance and salt resistance, the temperature resistance is above 220 DEG C, and the mineralization resistance is above 100000 mg / L. The heavy oil viscosity reducer of the invention has the characteristics of good universality, low use concentration and high viscosity reduction rate, and can reduce more than 98% of the viscosity of heavy oil within 1000-10000 mPa.s under the condition that the use concentration is 200 ppm. Therefore, the temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer and the preparation method thereof can be widely applied to heavy oil recovery.

Owner:北京安德兴石油技术有限公司

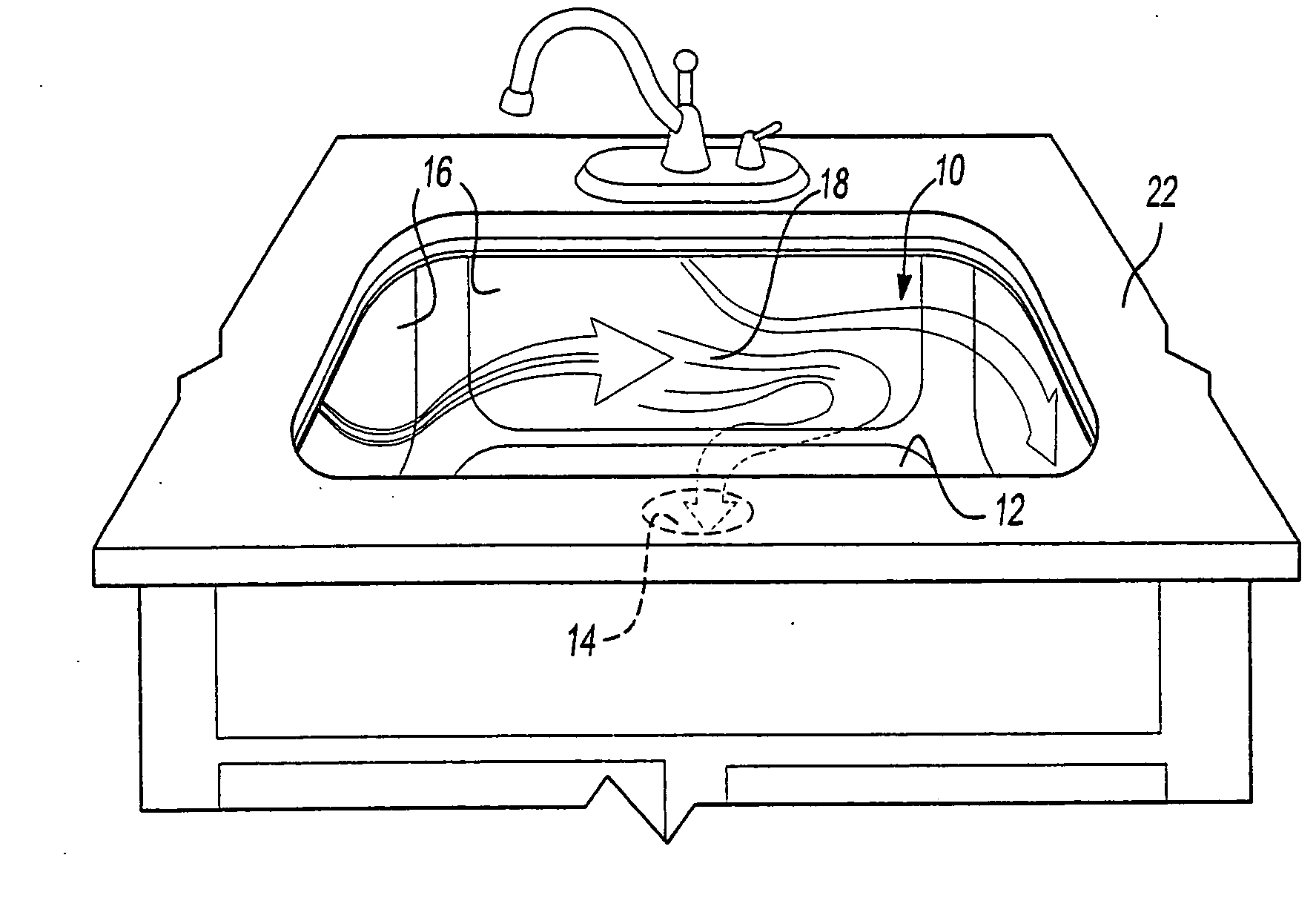

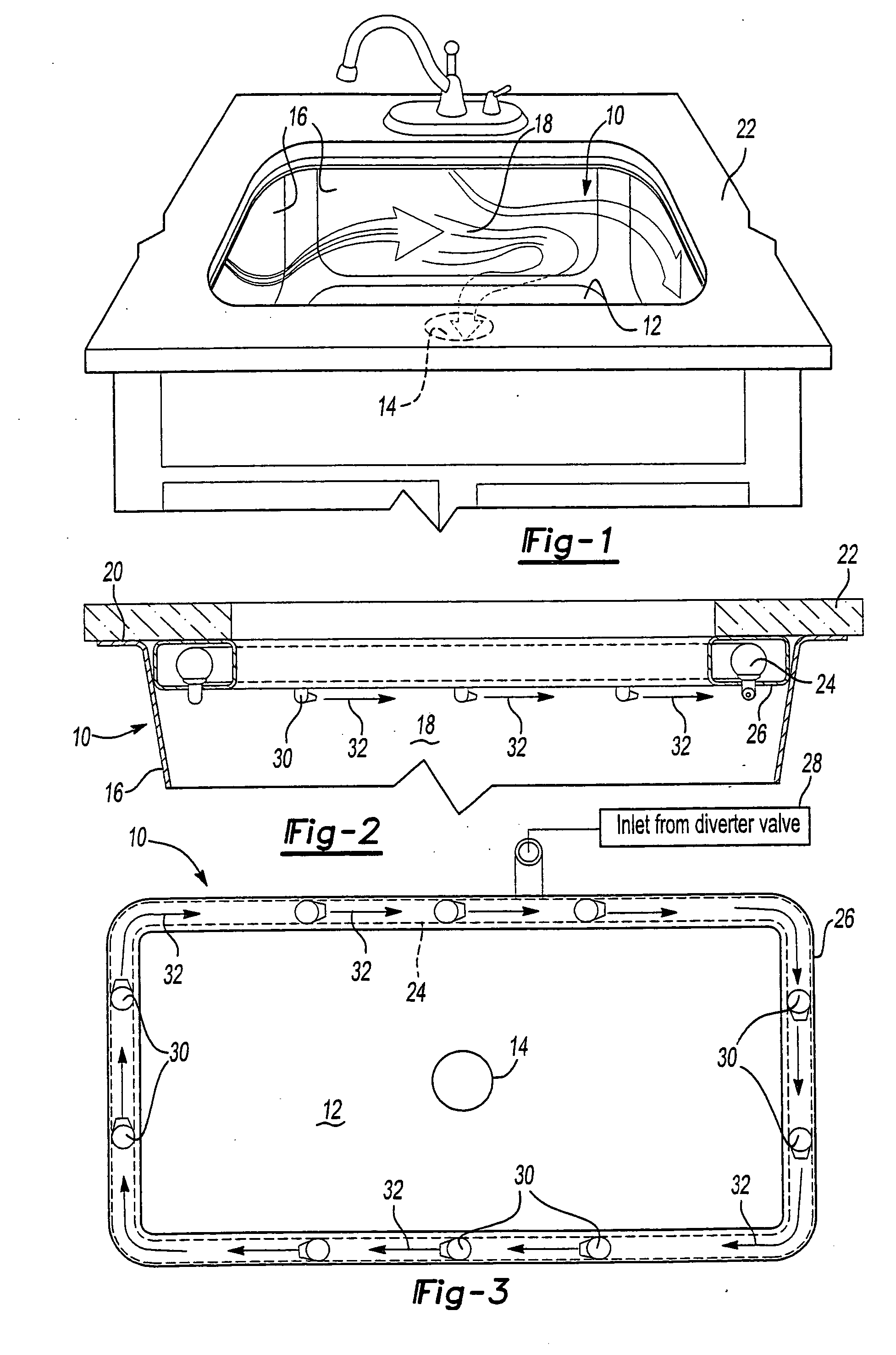

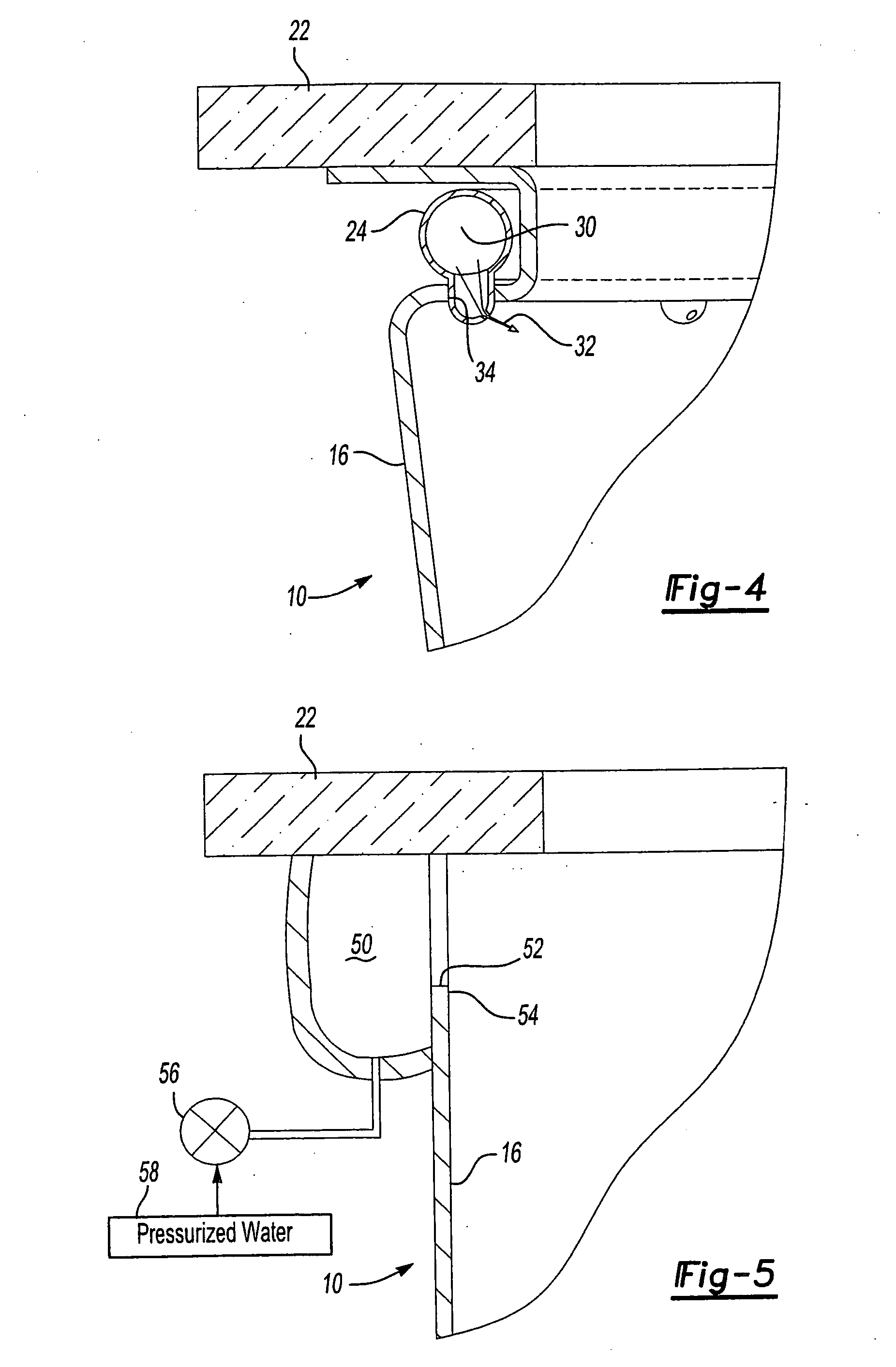

Sink construction

A sink having a base and at least one sidewall extending around and extending upwardly from the base. At least one fluid nozzle is attached to the sidewall adjacent its top so that, upon connection to a pressurized fluid source, the nozzle produces a fluid flow which is transverse to and intersects the sidewall adjacent its top. The nozzle thus produces a swirling action of the fluid around the sidewall of the sink thereby cleaning the sink.

Owner:MCKAY NICHOLAS D JR

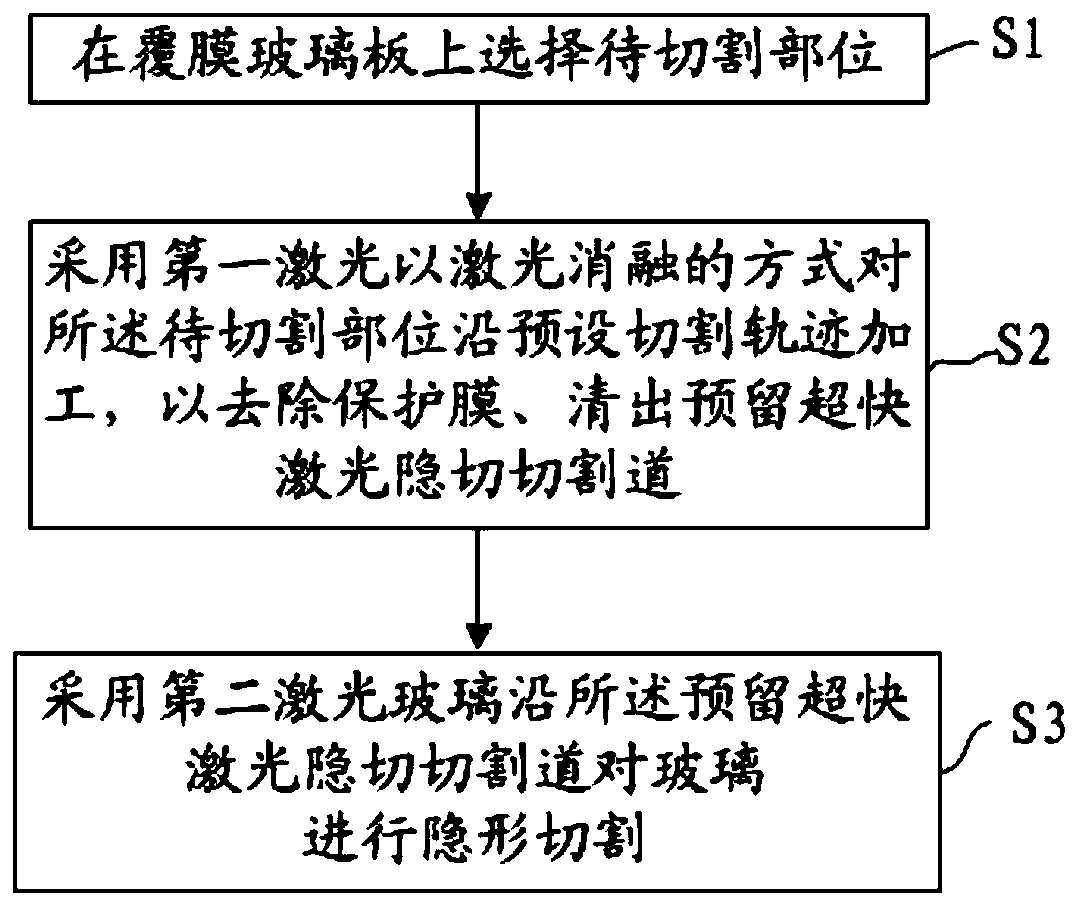

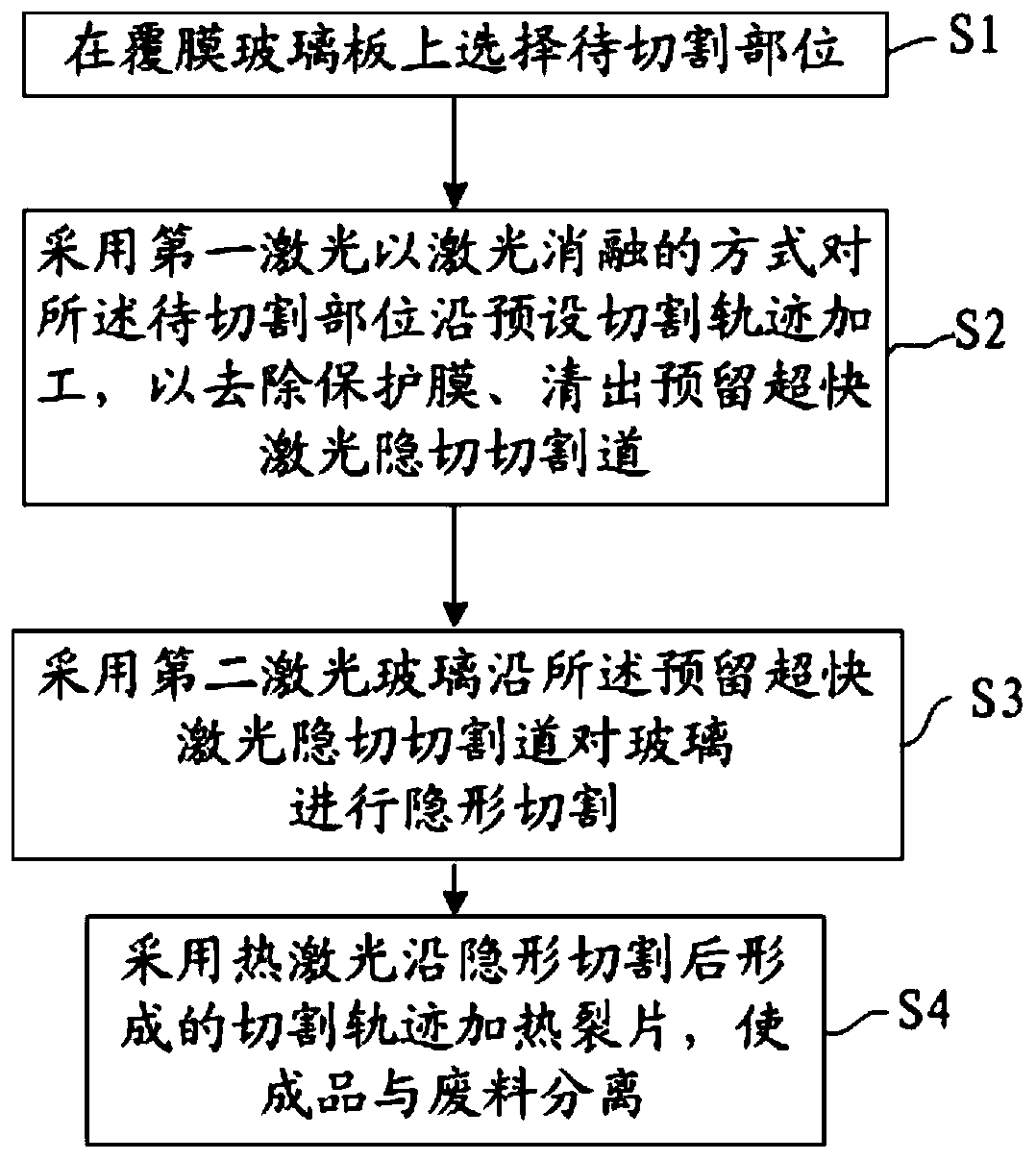

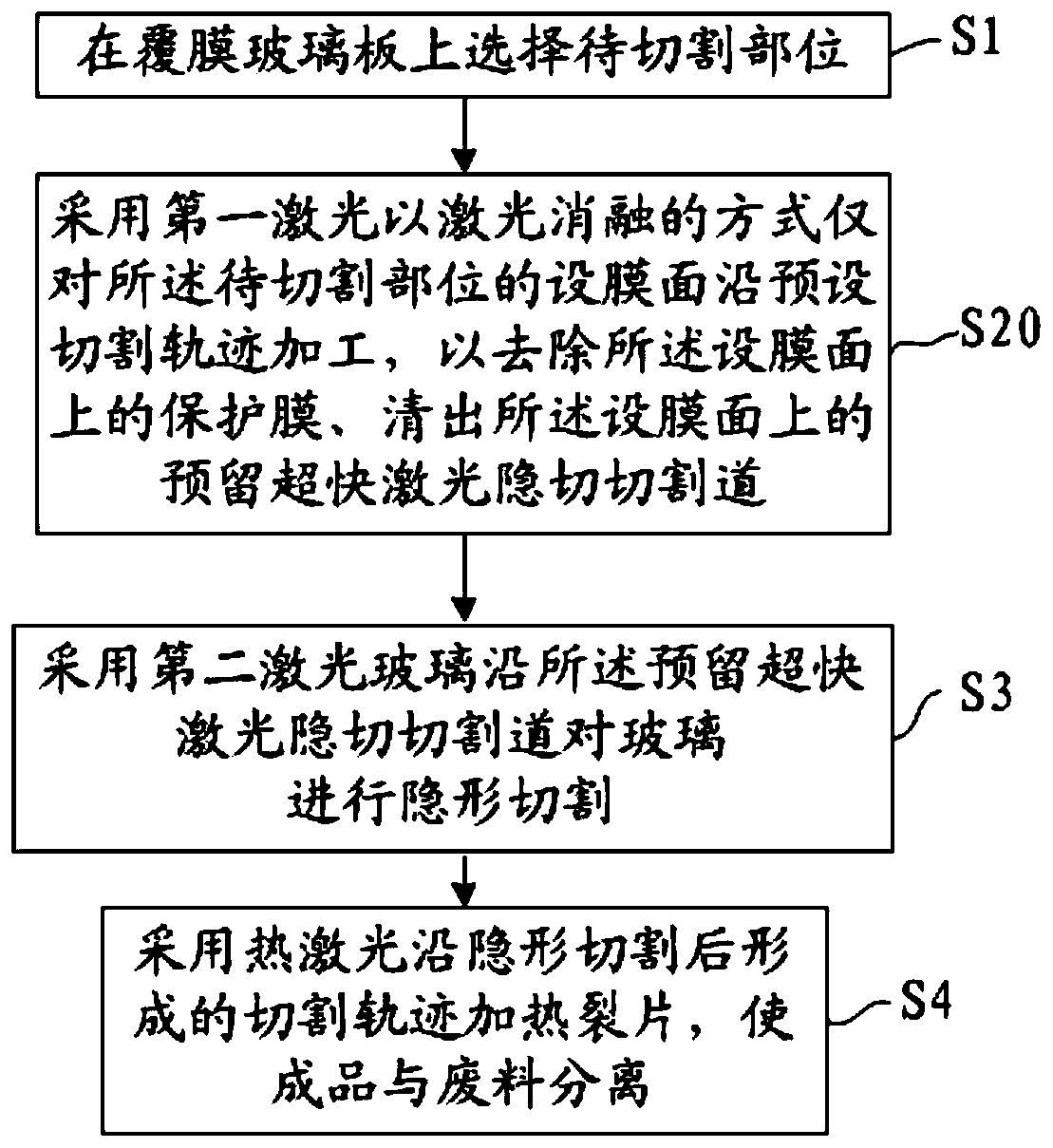

Method for laser-cutting glass covered with protective film

InactiveCN109702356AAvoid damageReduce the probability of scratchesLaser beam welding apparatusTectorial membraneCutting glass

The invention discloses a method for laser-cutting glass covered with a protective film. The method comprises the following steps of selecting a to-be-cut part on a coated glass plate; machining the to-be-cut part along a preset cutting trajectory in a laser ablation mode by a first laser so as to remove the protective film and reveal a reserved ultrafast laser invisible cutting channel; and adopting a second laser to perform invisible cutting on the glass along the reserved ultrafast laser invisible cutting channel. In the method, laser cutting is adopted to replace mechanical cutting in theprior art, the protective film is removed in the laser ablation mode by the first laser before the glass is cut, so that damage to the surface of the glass in the cutting process can be avoided, the scratch rate and the pollution rate of the glass surface can be reduced, and the production yield is improved; and when the glass is cut, the energy of the laser beam cuts the glass in a non-contact manner, so that debris, fragments and micro cracks can be prevented from being generated, the strength of cutting edges by the laser is higher than that of a traditional scribing and segmentation mode,and subsequent finish machining is not needed to be carried out.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

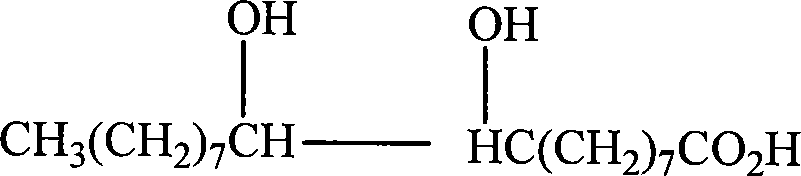

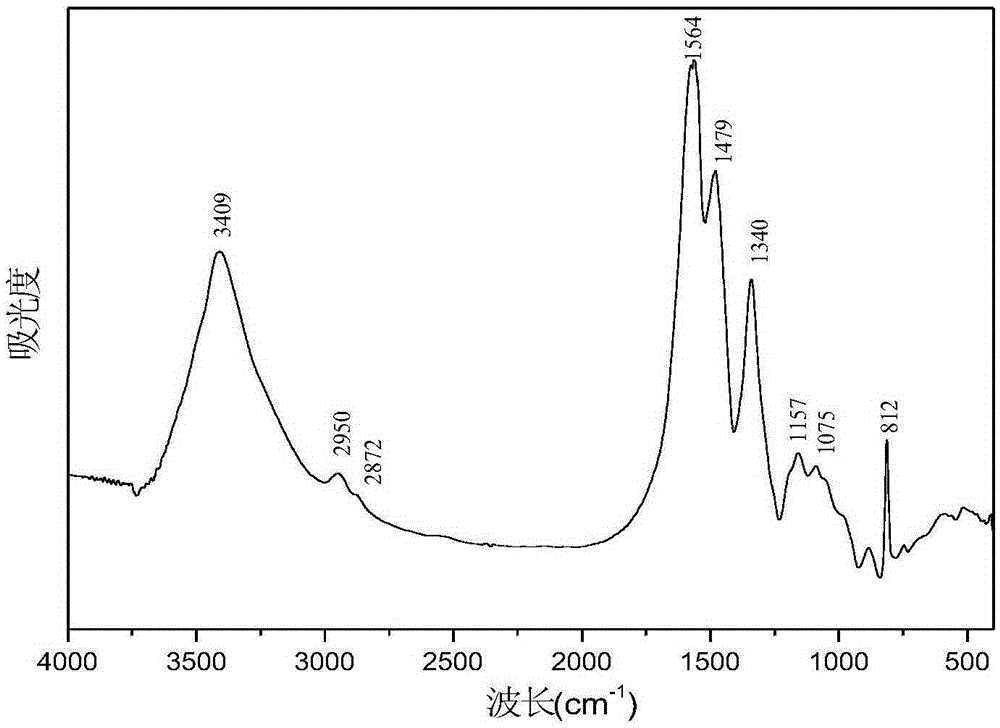

Method for preparing 9,10-dihydroxystearic acid and its methyl by hydrogen dioxide oxidation process

InactiveCN101177392AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationCalcium formate

The invention relates to a preparation method for 9, 10-dihydroxy stearic acid and methyl ester, which is characterized in that the oleic acid and the formic acid are mixed uniformly in room temperature; the mixture is added with hydrogen peroxide, and warmed up and separated from water phase; the solvent is recycled through decompression and distillation; the generative reaction admixture is recrystallized with organic solvent, so that the product 9, 10-dihydroxy stearic acid is prepared. The recovered formic acid solution can generate ice-cream calcium formate salt separation by adding calcium oxide and calcium carbonate; subsequently the methyl alcohol and oil of vitriol is arranged into the product 9, 10-dihydroxy stearic acid for a reflux reaction, and then is rotated and vaporized out the water phase and oil phase for being washed to be neutral, thereby the 9, 10-dihydroxy stearic acid methyl ester product is generated through dehydration. The invention has the advantages of clean process, safe implementation, easy operation, full utilization of the reactant, reduced waste emission, effective utilization of the low-concentration hydrogen peroxide, and favorableness to large-scale production.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Process for treating waste water of refined terephthalic acid

InactiveCN1927745AAchieve oxidative degradationEasy to handleMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIndustrial effluentTower

The process of treating waste water from refined terephthalic acid production belongs to the field of environment protecting engineering and industrial effluent treating technology. The process includes settling and filtering of the waste water, oxidizing degradation in an oxidizing tower with composite catalyst, blowing aeration treatment and the next biochemical treatment. The water solution of ClO2 as the main oxidant has concentration of 0.03 %-5 % and the thrown amount of 5 %-20 % of waste water COD concentration; and the auxiliary oxidant of O2, air and / or H2O2 has the volume ratio to the waste water of 100-110 to 1. The process of the present invention has the features of small covered area, low running cost, low chemical consumption, high treating efficiency, no waste water exhaust, closed water circulation, etc.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Triazinyl organic mesoporous polymer as well as preparation method and application thereof

ActiveCN105348462AHigh boiling pointHigh polarityOther chemical processesWater contaminantsFiberMulti pollutant

The invention discloses a triazinyl organic mesoporous polymer as well as a preparation method and application thereof, belonging to the field of synthesis and adsorption research of an organic porous material. According to the preparation method, a solvothermal method is adopted, ethylene glycol is taken as a reaction medium, tripolycyanamide and paraformaldehyde are taken as raw materials, and a reaction is performed for certain time under a high-temperature and sealed condition to prepare the triazinyl organic mesoporous polymer. The preparation method provided by the invention is cheap in price, simple in process, clean, free of foreign smell, convenient to operate and is benefit for industrial production. The prepared triazinyl organic mesoporous polymer has an open fiber framework structure, is rich in nitrogenous functional groups, can absorb various pollutants in water, and has good application prospect in the aspects of adsorption separation, water body purification and the like.

Owner:罗开传

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com