Temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer and preparation method thereof

A technology of amphiphilic polymer and heavy oil viscosity reducer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large amount of heavy oil production and low viscosity reduction efficiency, so as to reduce the use concentration, Improve salt resistance performance, process cleaning and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

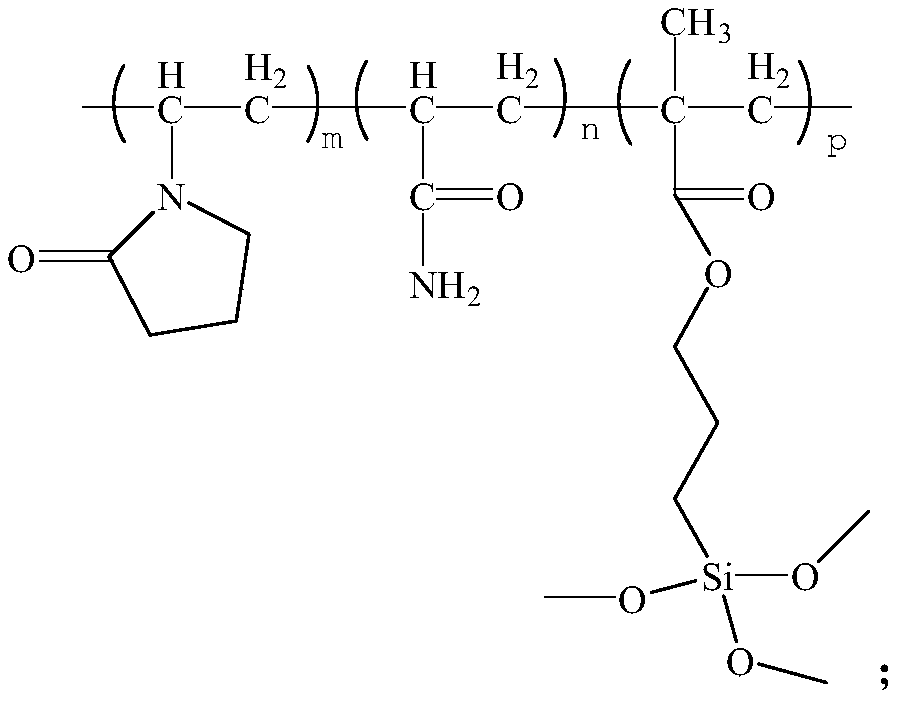

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Heat-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer G 1 preparation of

[0028] (1) First, add 1mol 1-vinyl-2-pyrrolidone, 0.5mol acrylamide and 0.05mol methacryloxypropyltrimethoxysilane into a four-necked flask, then add 777.98g dispersant ethyl acetate, Heating while stirring, the heating temperature is 50°C, and the stirring rate is 200rpm. After it is completely dissolved, add 0.5557g of initiator azobisisobutyronitrile, feed nitrogen for 3 minutes, turn off the nitrogen and adjust the heating temperature to 70°C, and adjust the stirring rate To 400rpm, react for 6h, after the reaction is completed, add 0.8892g polymerization inhibitor p-hydroxyanisole, after cooling, a light yellow mixed solution is obtained;

[0029] (2) Remove the dispersant ethyl acetate from the above-mentioned light yellow mixed solution with a rotary evaporator to obtain a yellow viscous liquid, which is then repeatedly washed 4 times with 222.28 g o...

Embodiment 2

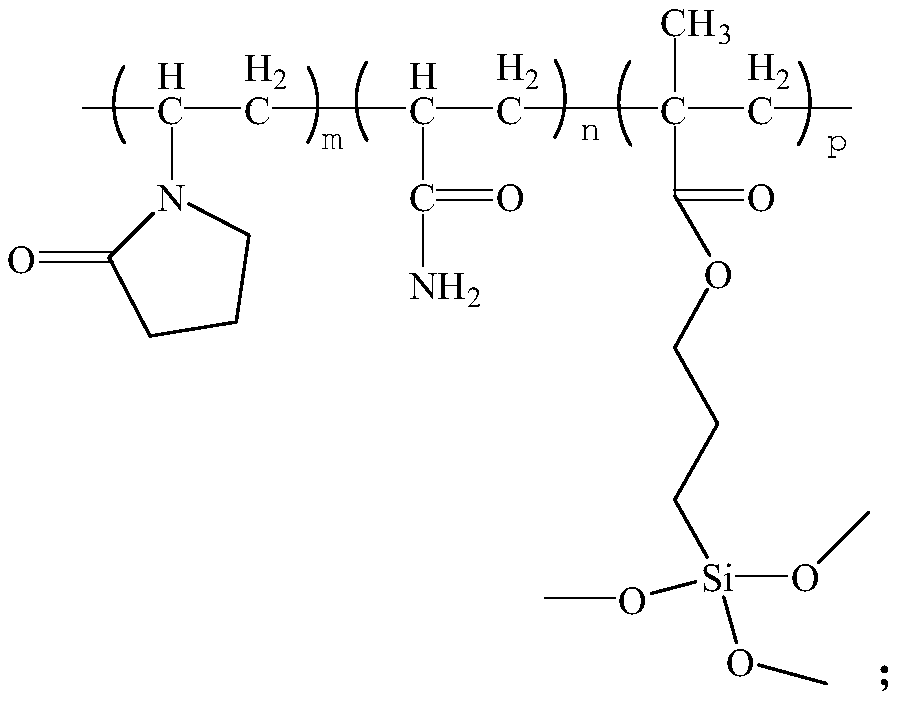

[0034] Example 2: Temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer G 2 preparation of

[0035] (1) First add 1mol 1-vinyl-2-pyrrolidone, 1.2mol acrylamide and 2.3mol methacryloxypropyltrimethoxysilane into a four-necked flask, then add 1000.26g dispersant ethyl acetate, Heating while stirring, the heating temperature is 55°C, and the stirring rate is 320rpm. After it is completely dissolved, add 2..2228g of initiator azobisisobutyronitrile, feed nitrogen for 5 minutes, turn off the nitrogen and adjust the heating temperature to 76°C, and stir Adjust the speed to 420rpm and react for 10h. After the reaction is completed, add 1.3337g of polymerization inhibitor p-hydroxyanisole, and obtain a light yellow mixed solution after cooling;

[0036] (2) Remove the dispersant ethyl acetate from the above-mentioned light yellow mixed solution with a rotary evaporator to obtain a yellow viscous liquid, which is then repeatedly washed 6 times with 3...

Embodiment 3

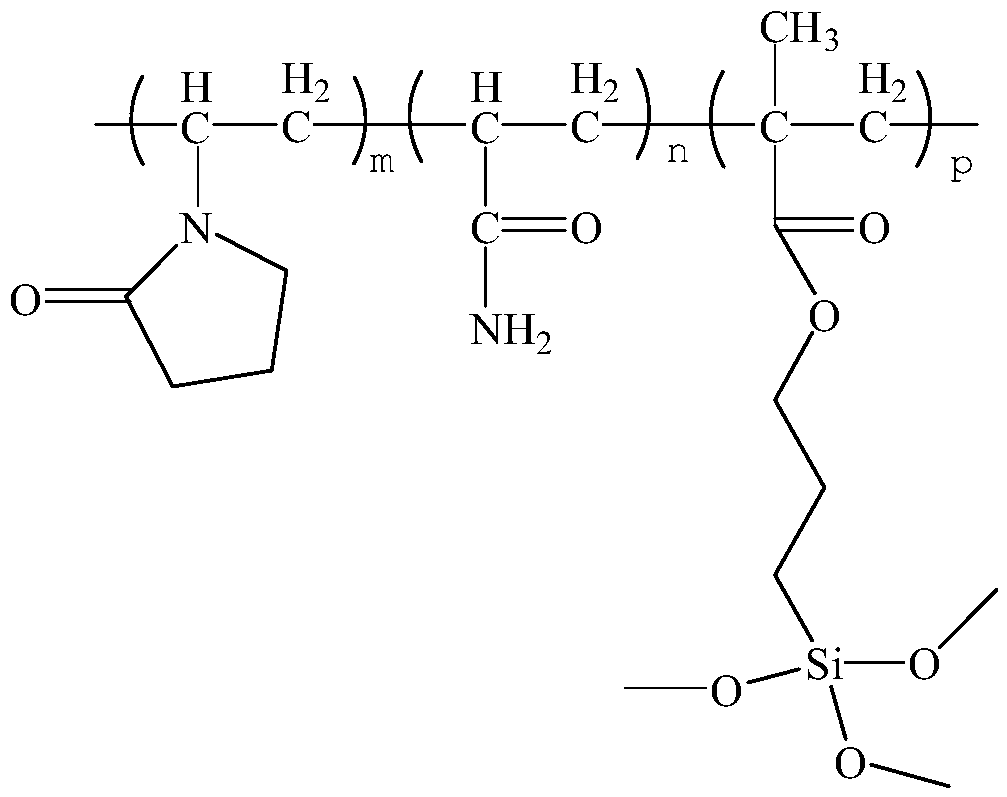

[0041] Example 3: Heat-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer G 3 preparation of

[0042] (1) First, 1mol 1-vinyl-2-pyrrolidone, 5.2mol acrylamide and 13.6mol methacryloxypropyltrimethoxysilane were added to a four-necked flask, and then 889.12g dispersant ethyl acetate was added, Heating while stirring, the heating temperature is 62°C, and the stirring rate is 450rpm. After it is completely dissolved, add 3.5565g of initiator azobisisobutyronitrile, feed nitrogen for 8 minutes, turn off the nitrogen and adjust the heating temperature to 83°C, and adjust the stirring rate To 550rpm, react for 8h, after the reaction is completed, add 2.7785g polymerization inhibitor p-hydroxyanisole, after cooling, a light yellow mixed solution is obtained;

[0043] (2) Remove the dispersant ethyl acetate from the above-mentioned light yellow mixed solution with a rotary evaporator to obtain a yellow viscous liquid, which is then repeatedly washed 7 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com