Triazinyl organic mesoporous polymer as well as preparation method and application thereof

A triazine-based, polymer-based technology, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the inconvenience of product cleaning, separation, and recovery, affect the working environment and health, and complicate the product washing process, etc. problems, to achieve the effect of clean and odor-free process, easy operation and large-scale production, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a triazine-based organic mesoporous polymer, comprising the following steps:

[0034] Add melamine (6mmol) and paraformaldehyde (10.8mmol) to 6.8mL of ethylene glycol, heat at 120°C for 1h and stir to obtain a white suspension; seal the obtained white suspension in an oven at 170°C for 48h at constant temperature , and then annealed and cooled, washed with water and ethanol respectively, centrifuged and dried to obtain the final product.

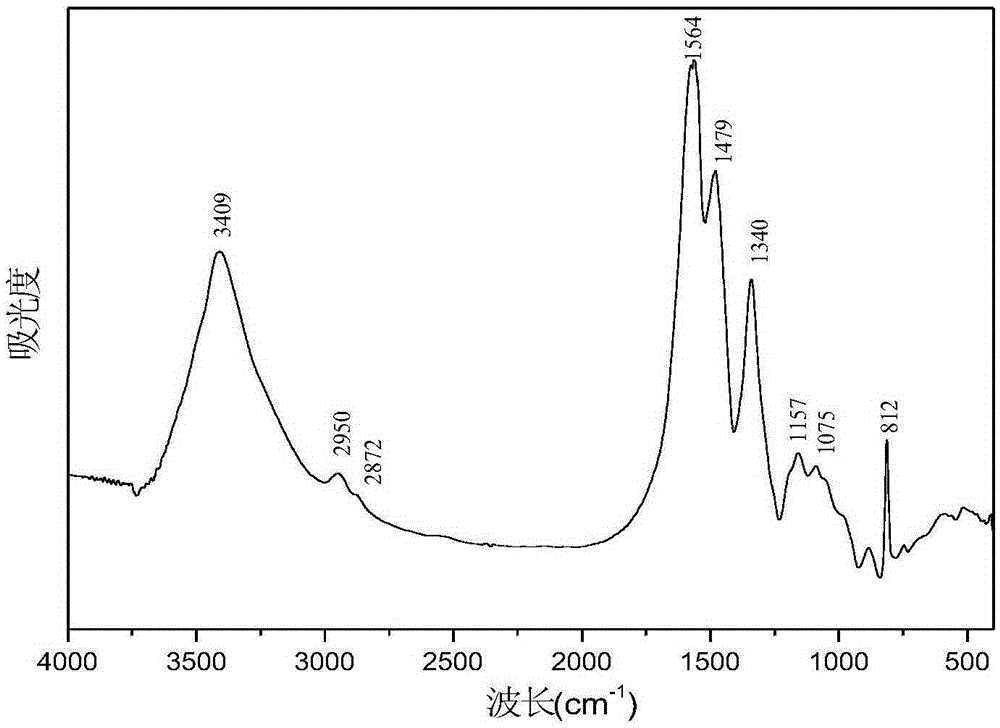

[0035] The infrared spectrogram of the product obtained in this embodiment is shown in figure 1 . 812cm in the picture -1 It is the external bending vibration absorption peak of the triazine ring, 1000-1564cm -1 The interval is the absorption band of asymmetric stretching vibration and NH bending vibration in the triazine torus, 3409cm -1 NH stretching vibration peak; 2950cm -1 and 2872cm -1 Respectively CH 2 The antisymmetric and symmetric stretching vibration peaks. The results show that the obtained ...

Embodiment 2

[0041] A preparation method of a triazine-based organic mesoporous polymer, comprising the following steps:

[0042] Add melamine (3mmol) and paraformaldehyde (9.0mmol) into 3.4mL ethylene glycol, heat at 120°C for 1 hour and stir to obtain a white suspension; seal the obtained white suspension in an oven at 170°C for 72 hours at constant temperature , annealed and cooled, washed with ethanol and water in sequence, centrifuged and dried to obtain the triazine-based organic mesoporous polymer.

Embodiment 3

[0044] A preparation method of a triazine-based organic mesoporous polymer, comprising the following steps:

[0045] Add melamine (3mmol) and paraformaldehyde (4.5mmol) into 3.4mL ethylene glycol, heat at 120°C for 1h and stir to obtain a white suspension; seal the obtained white suspension in an oven at 170°C for 6h at constant temperature , annealed and cooled, washed with ethanol and water in sequence, centrifuged and dried to obtain the triazine-based organic mesoporous polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com