Patents

Literature

41results about How to "Promote polycondensation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nano-silica rosin modified phenolic resin

ActiveCN104693679APromote polycondensation reactionIncrease stickinessHigh volume manufacturingHeat resistance

The invention belongs to the technical field of preparation of phenolic resin, and in particular relates to a preparation method of nano-silica rosin modified phenolic resin. The method is that xylenol, tert-butylphenol, dodecyl-phenol, hydrogenated bisphenol A and formaldehyde are used as the raw materials; the weak-base and weak-acid process is carried out to prepare phenolic resin; rosin and nano-silica are utilized for modifying, so as to prepare the nano-silica rosin modified phenolic resin. The preparation method is simple in process; the prepared phenolic resin is high in viscosity, high in softening point, small in free formaldehyde content, high in heat resistance and corrosion resistance, suitable for industrial mass production, and applicable to preparation of coating and ink, and can be also used as adhesive and rubber components.

Owner:桂林兴松林化有限责任公司

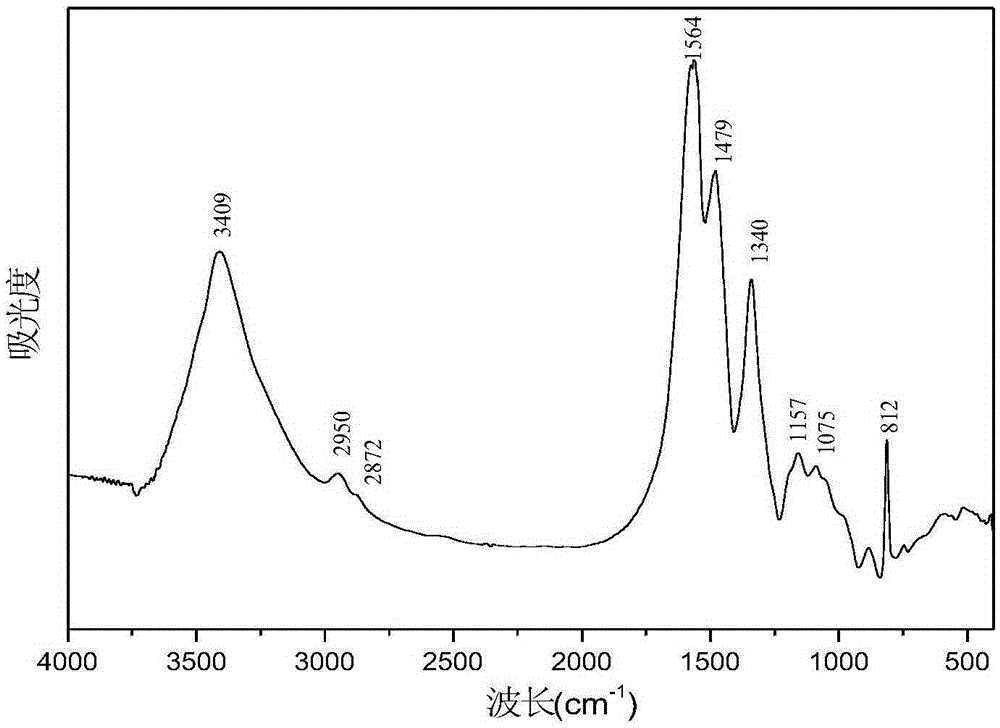

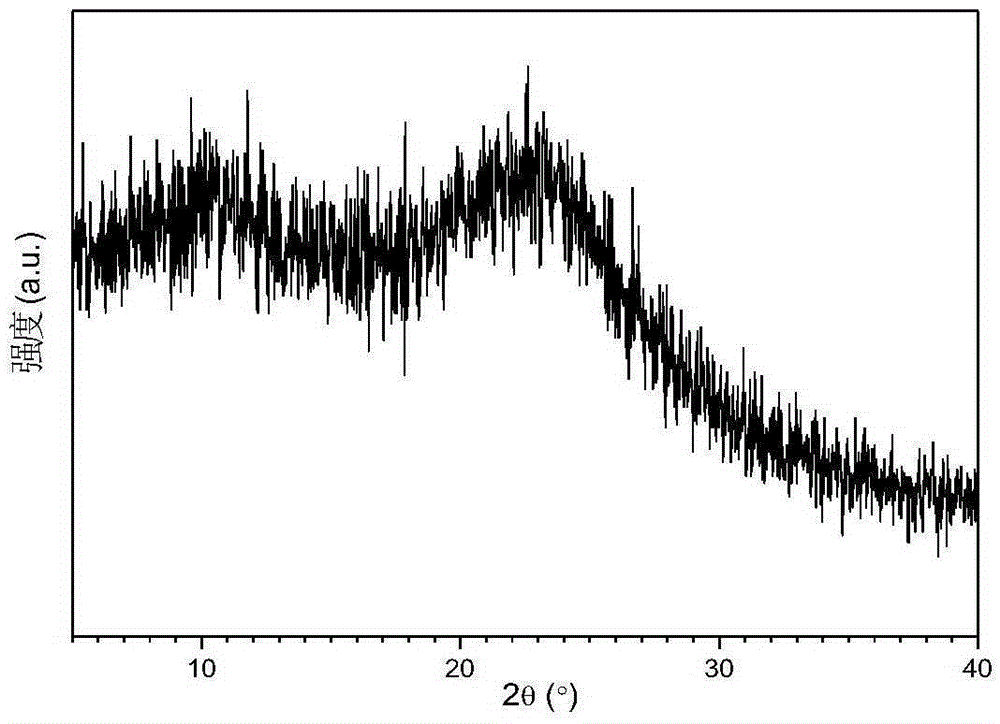

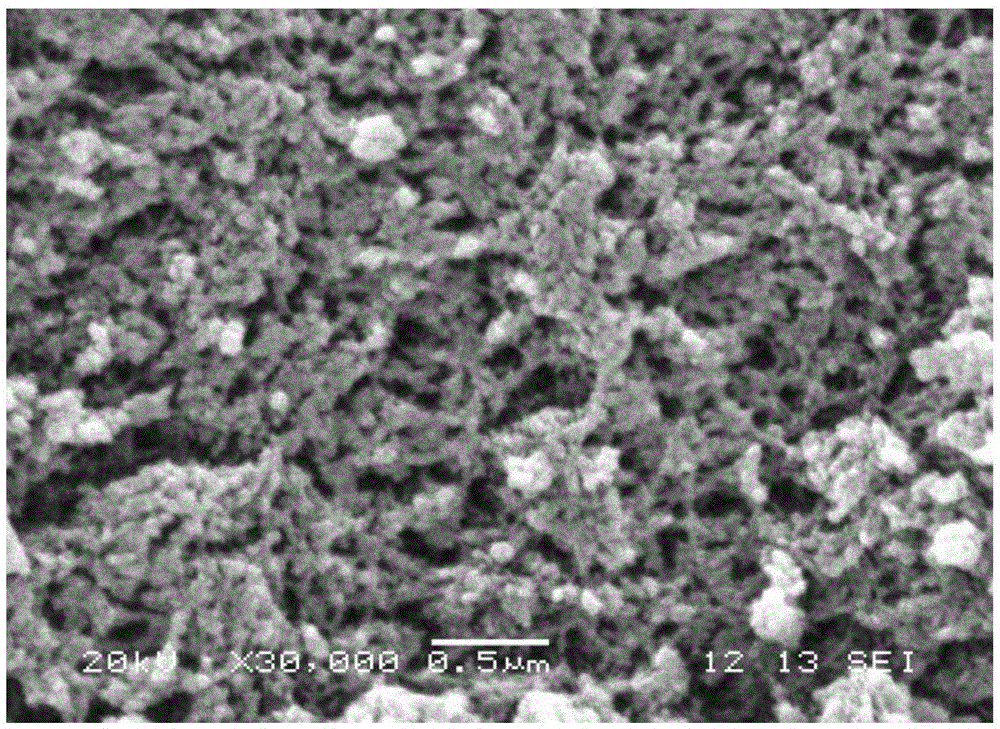

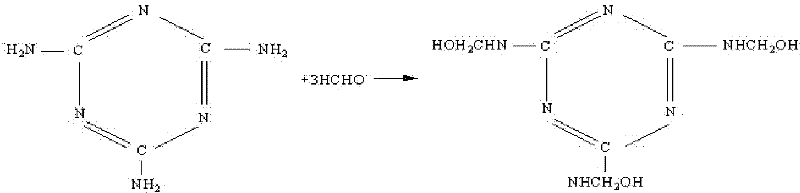

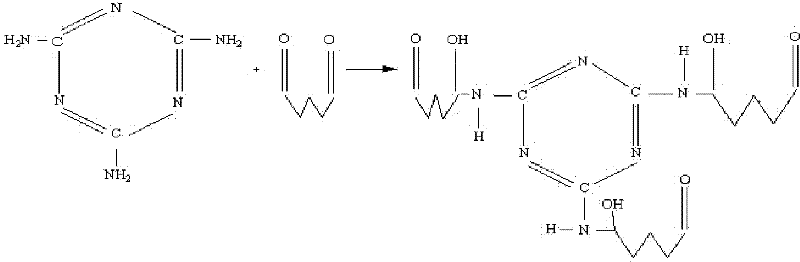

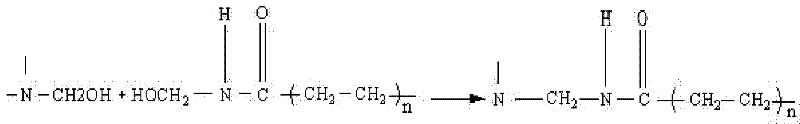

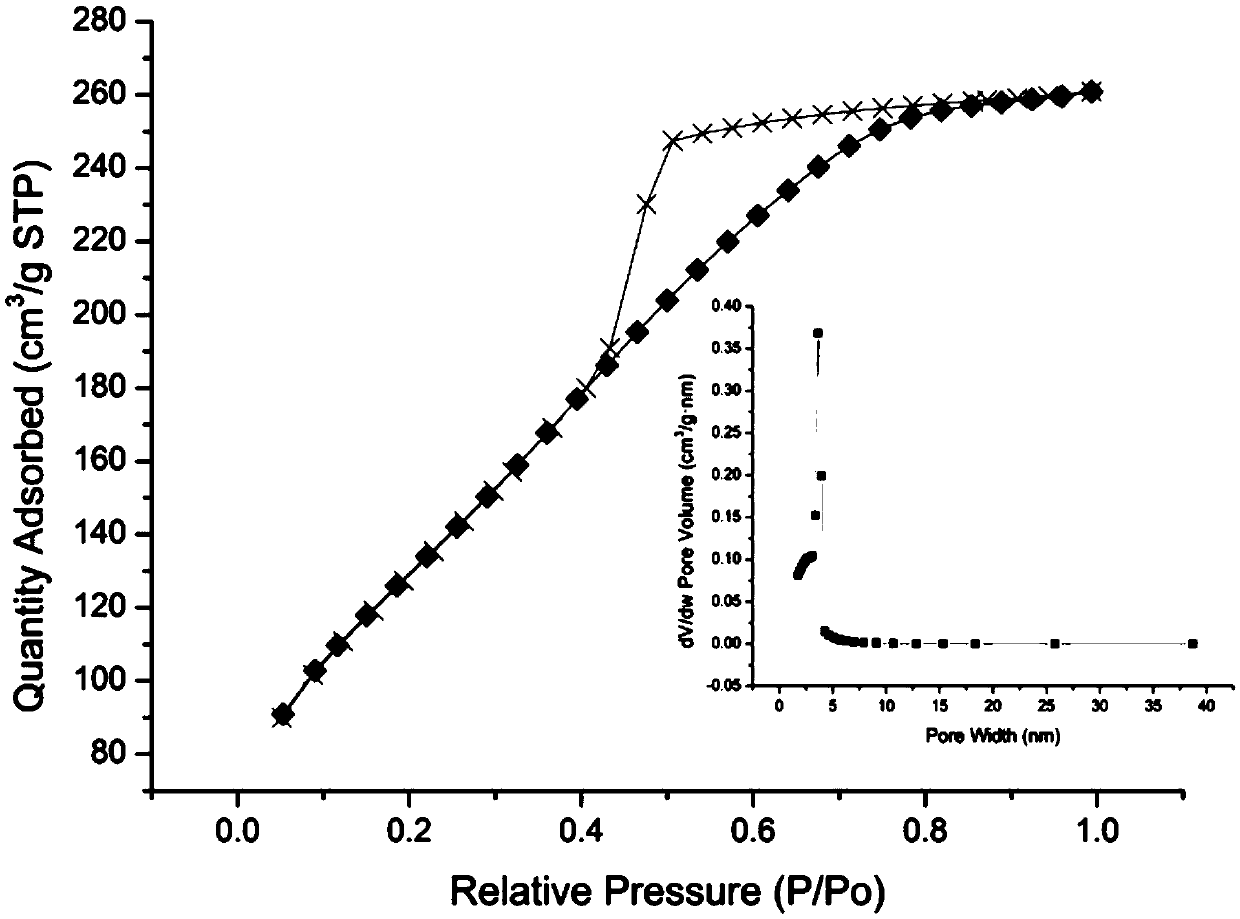

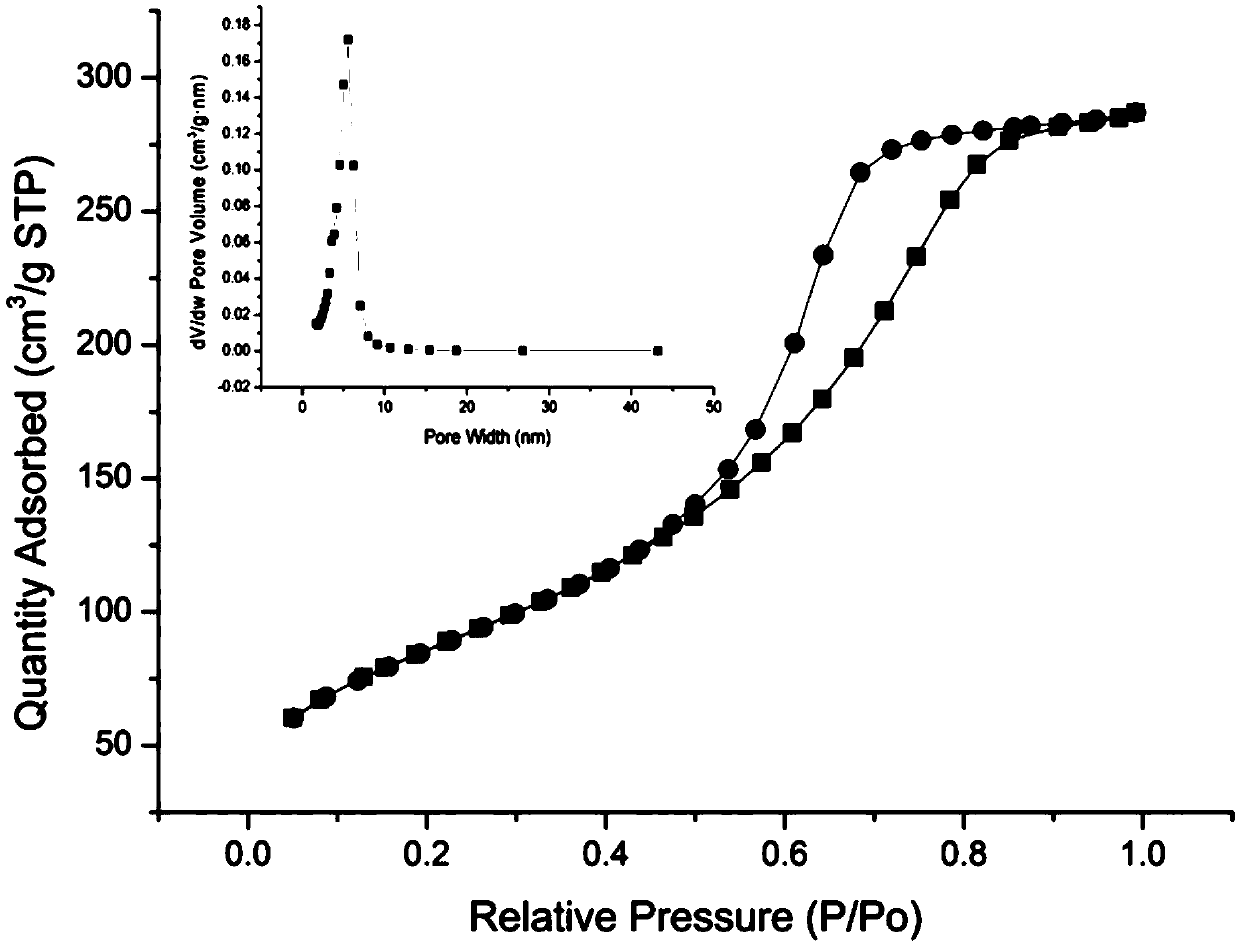

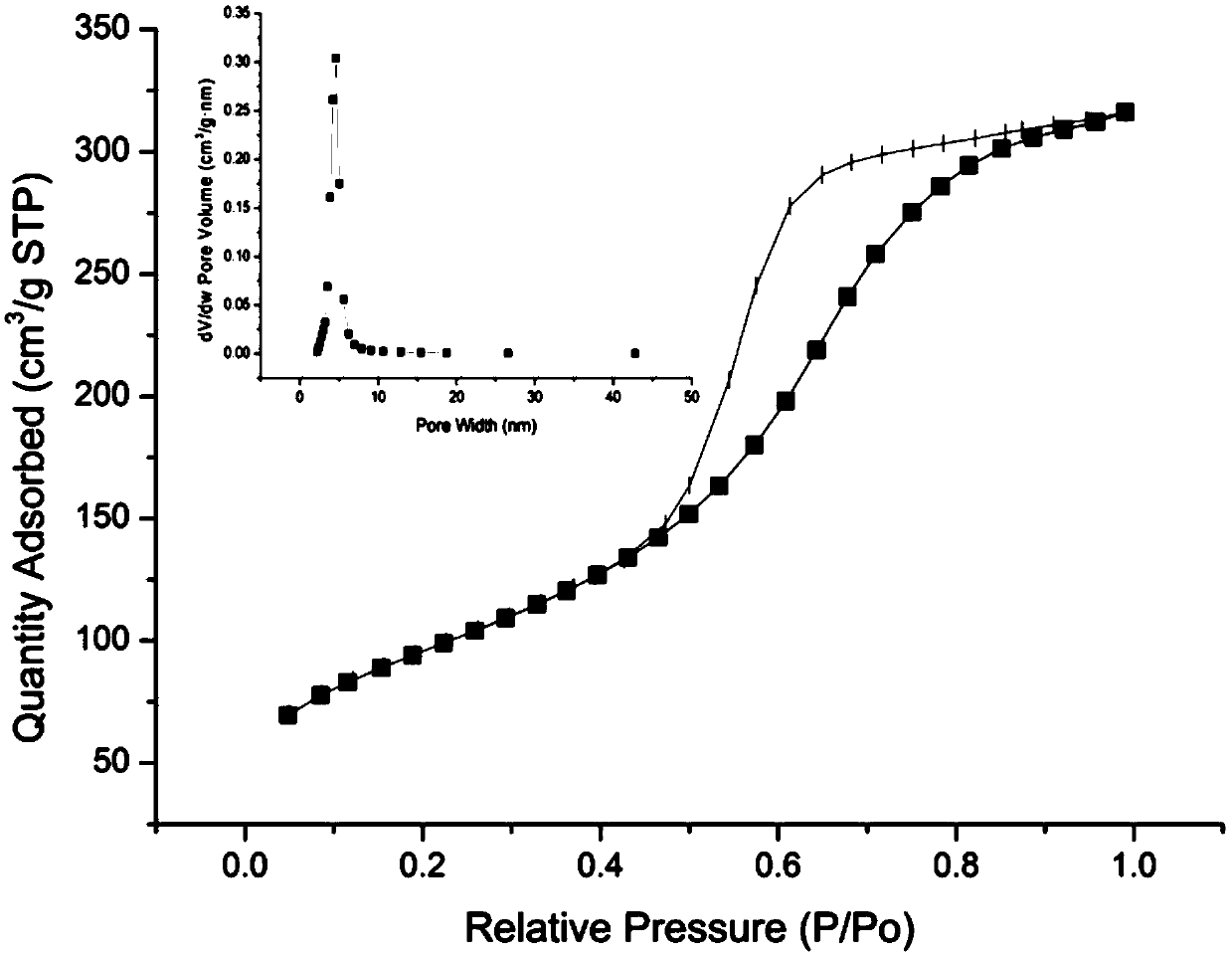

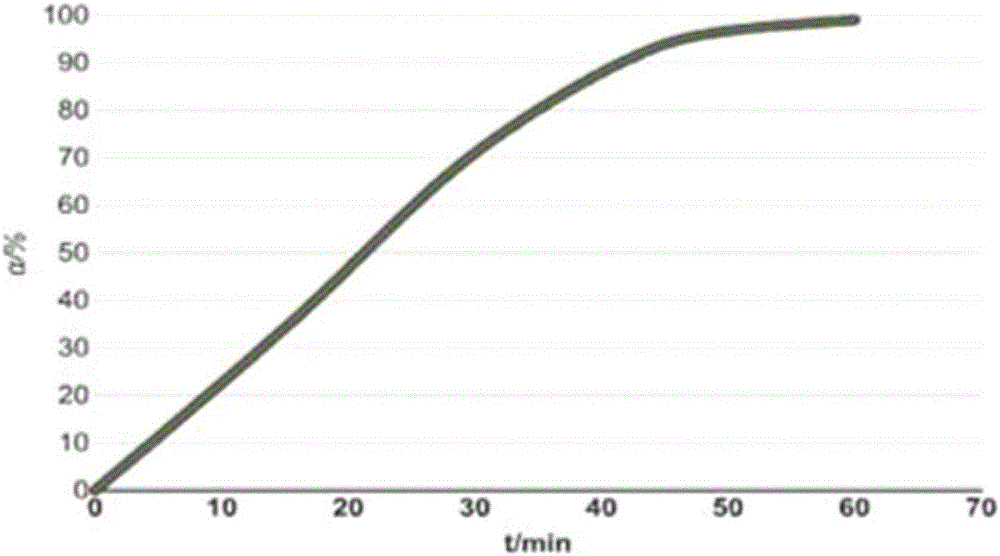

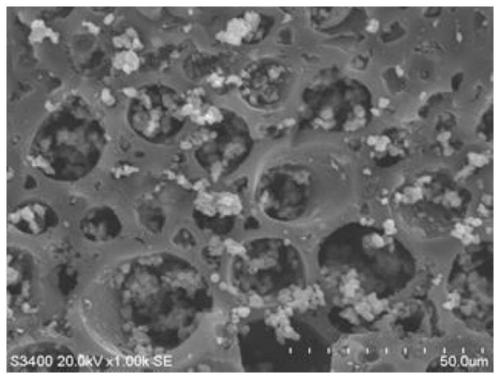

Triazinyl organic mesoporous polymer as well as preparation method and application thereof

ActiveCN105348462AHigh boiling pointHigh polarityOther chemical processesWater contaminantsFiberMulti pollutant

The invention discloses a triazinyl organic mesoporous polymer as well as a preparation method and application thereof, belonging to the field of synthesis and adsorption research of an organic porous material. According to the preparation method, a solvothermal method is adopted, ethylene glycol is taken as a reaction medium, tripolycyanamide and paraformaldehyde are taken as raw materials, and a reaction is performed for certain time under a high-temperature and sealed condition to prepare the triazinyl organic mesoporous polymer. The preparation method provided by the invention is cheap in price, simple in process, clean, free of foreign smell, convenient to operate and is benefit for industrial production. The prepared triazinyl organic mesoporous polymer has an open fiber framework structure, is rich in nitrogenous functional groups, can absorb various pollutants in water, and has good application prospect in the aspects of adsorption separation, water body purification and the like.

Owner:罗开传

Novel environmental-friendly modified glue for impregnated paper and preparation method thereof

ActiveCN102304337AReduce usageReduce releaseNon-fibrous pulp additionNon-macromolecular adhesive additivesHardnessPerformance index

The invention relates to novel environmental-friendly modified glue for impregnated paper and a preparation method thereof. The modified glue comprises the following raw materials in parts by weight: 40-60 parts of water, 20-26 parts of tripolycyanamide, 5-25 parts of dialdehyde, 10-25 parts of monoaldehyde, 1-5 parts of crosslinking modifying agent, 1-5 parts of auxiliary synthetic agent and 1-2 parts of post eliminating agent. The invention also provides the preparation method of the modified glue; the invention solves the problem that the traditional glue for impregnated paper has stronger smell and high free formaldehyde, also ensures every performance index and increases the hardness and the chemical property resistance.

Owner:天津市盛世德新材料科技有限公司

A method for preparing aromatic polyamide fiber by adopting a micro-reactor

ActiveCN107200843AUniform responsePromote polycondensation reactionBulk chemical productionMonocomponent polyamides artificial filamentPolymer scienceLiquid carbon

The invention relates to a method for preparing aromatic polyamide fiber by adopting a micro-reactor. Liquid carbon dioxide and / or supercritical carbon dioxide are adopted as a solvent. The micro-reactor is adopted as a reactor in a pre-polymerization stage. The polymer intrinsic viscosity and the yield of the aromatic polyamide fiber prepared by the method are high. The solvent recovery rate is high.

Owner:FININGS CO LTD

Method for preparing mesoporous silica material by hydroxyethyl cellulose serving as template

ActiveCN109574021APromote polycondensation reactionControl apertureSilicaBiocompatibility TestingMesoporous silica

The invention relates to a method for preparing a mesoporous silica material by hydroxyethyl cellulose serving as a template. The method particularly includes the steps: 1) adding hydroxyethyl cellulose into water, heating, stirring and dissolving to obtain hydroxyethyl cellulose water solution, slowly adding alkali metal silicate water solution into the hydroxyethyl cellulose water solution to uniformly mixing mixture, sufficiently stirring the mixture until clear and bright solution is acquired, adjusting a pH (potential of hydrogen) of a reaction system to reach 5-6 by acid solution, and standing for 1-24 hours to obtain reaction liquid; 2) centrifuging the reaction liquid, drying and collecting to obtain a solid matter, and calcining the solid matter to obtain the mesoporous silica material. According to the method, a non-ionic surface active agent serves as a hydroxyethyl cellulose template agent to assemble mesoporous silica, unformed mesoporous silica material is synthesized byan unconventional acid hydrolysis process, and the raw materials are rich, renewable and good in biocompatibility, and the method is simple in synthetic process, mild and controllable in preparation condition and simple, efficient and nontoxic in preparation process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Nano-composite coating material

InactiveCN110157329AOptimizing the curing processHigh hardnessCoatingsPolymethyl methacrylateAluminium isopropoxide

The invention discloses a nano-composite coating material. The nano-composite coating material is prepared by taking aluminium isopropoxide (AIP) and siloxane with relatively low price are used as main raw materials, and the composite coating is prepared with combination of a sol-gel method, wherein pencil hardness of the composite coating on polycarbonate (PC) and polymethyl methacrylate (PMMA) reaches 6H or above, and adhesive force reaches 2. According to the invention, firstly, a composite coating is modified by tetraethyl orthosilicate (TEOS), and the research shows that through additionof a tetraethyl orthosilicate hydrolysis product, a polycondensation reaction between AIP hydrolysis products and organosiloxane hydrolysis products is further promoted, so that curing process of thecomposite coating can be optimized, and hardness and adhesive force of the coating can be improved; and then, the composite coating is modified by an alcohol-water mixture of the graphene-like molybdenum disulfide, so that wear resistance of the coating can be improved, and gas-liquid barrier performance of the coating can be improved.

Owner:LANZHOU CITY UNIV

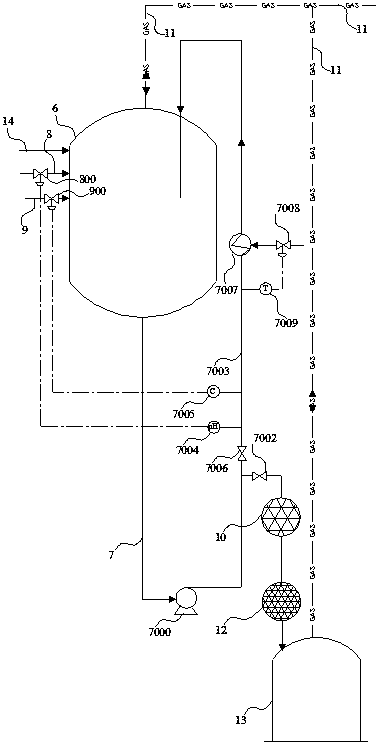

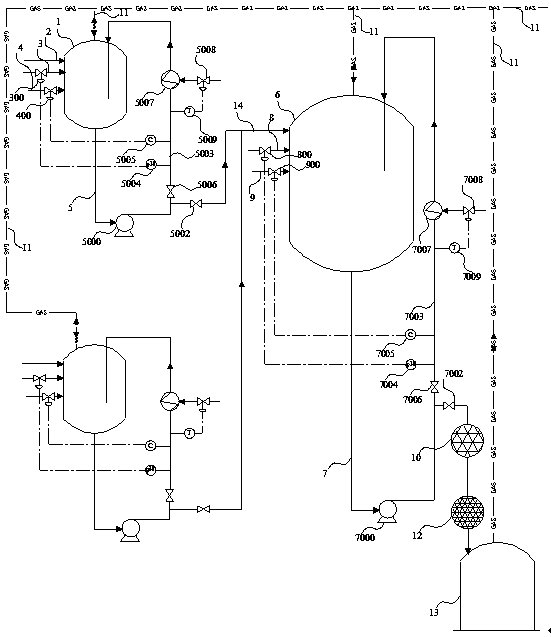

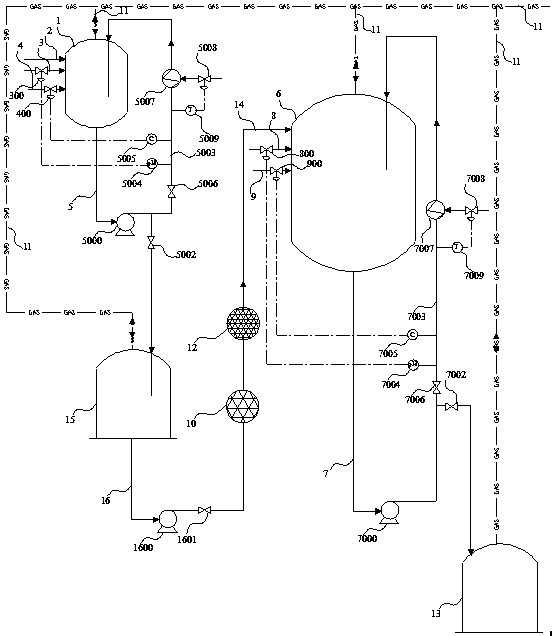

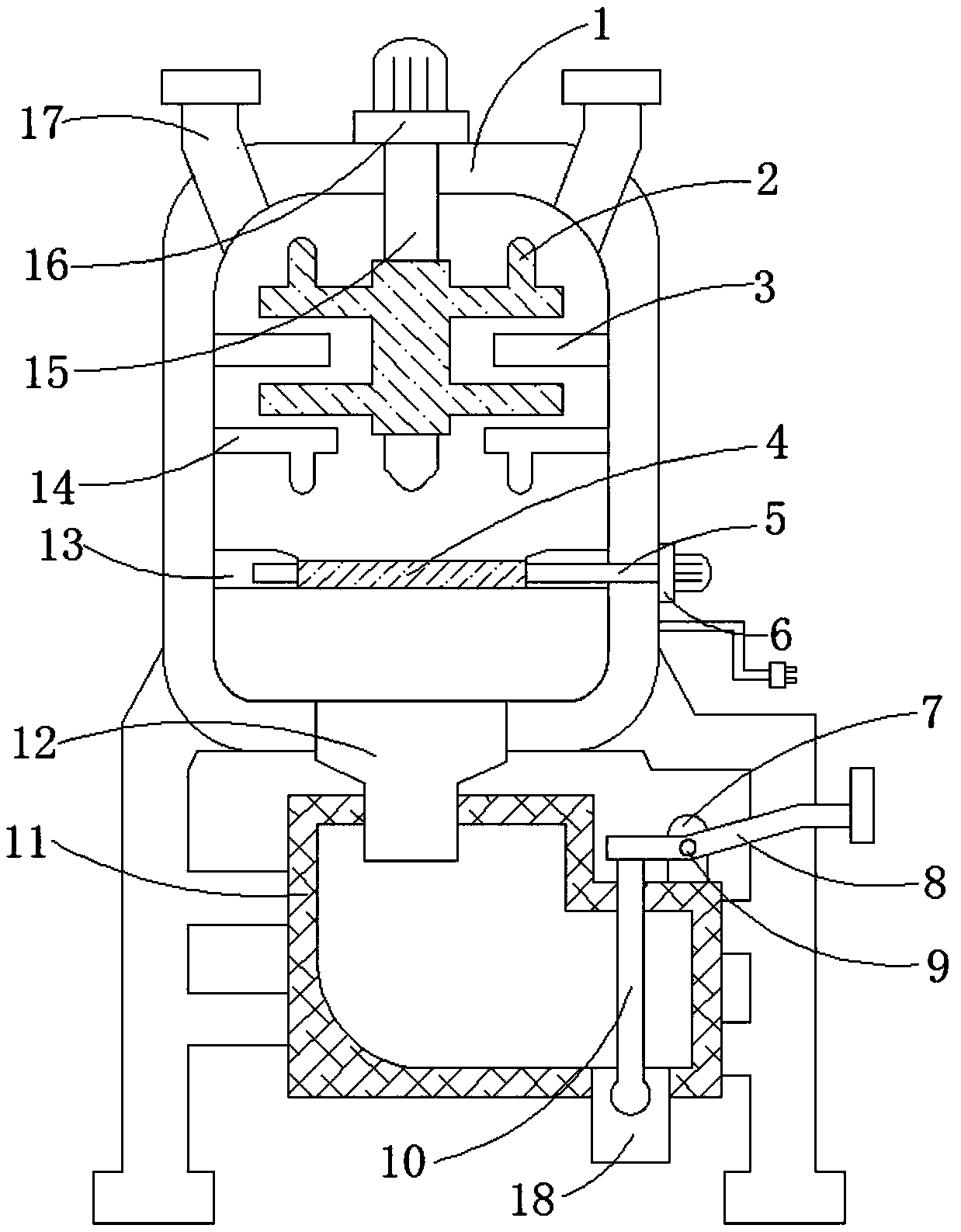

Polycarbonate synthesis process

A polycarbonate synthesis process comprises steps as follows: S1, a raw material mixing stage: melt isosorbide and dialkyl carbonate are stirred and uniformly mixed in a raw material mixing tank; S2, an ester exchange reaction stage: a tower reactor located behind the raw material mixing tank is taken as an ester exchange reactor, and released hydroxyl and aryl reaction products can be removed continuously; S3, a pre-polymerization reaction stage: a kettle pre-polycondensation reactor is arranged behind the ester exchange reactor, a pre-polymerization product is generated in the pre-polycondensation reactor, and meanwhile, released hydroxyl and aryl reaction products are removed continuously; S4: a polycondensation reaction stage: a hydraulic driven horizontal disk polycondensation reactor located behind the pre-polymerization reactor performs microwave processing on a pre-polycondensation product, and the pre-polycondensation product is subjected to polycondensation to form polycarbonate melts. The released hydroxyl and aryl reaction products are removed continuously, so that reaction balance is pushed in the positive direction, the pre-polycondensation product is heated through microwaves in the polycondensation stage, and the reaction rate can be effectively increased.

Owner:NINGBO ZHETIE DAPHOON CHEM

Preparation method of titanium dioxide modified polyamide fibers

InactiveCN107653507AGood dispersionImprove spinnabilityArtifical filament manufactureMonocomponent polyamides artificial filamentManufacturing technologyIn situ polymerization

The invention relates to the technical field of chemical fiber manufacturing, in particular to a method for preparing titanium dioxide-modified polyamide fibers. Caprolactam is used as a raw material, and a polyamide prepolymer is obtained after pressurized ring opening, and a certain amount of titanate is introduced into the system , continue the reaction under the condition of nitrogen protection, the water produced by the polycondensation reaction of the polyamide prepolymer reacts with the titanate, so that the titanate is slowly hydrolyzed to form titanium dioxide. Adopting the preparation method of titanium dioxide modified polyamide fiber provided by the present invention solves the problem that the current preparation method of titanium dioxide modified polyamide fiber cannot uniformly disperse titanium dioxide, and the method of adding a dispersant to in-situ polymerization has the problem that the dispersant is washed out during the extraction process At the same time, the dispersant has the problem of affecting the polymerization process of caprolactam.

Owner:HUIZHOU DHOMA IND CO LTD

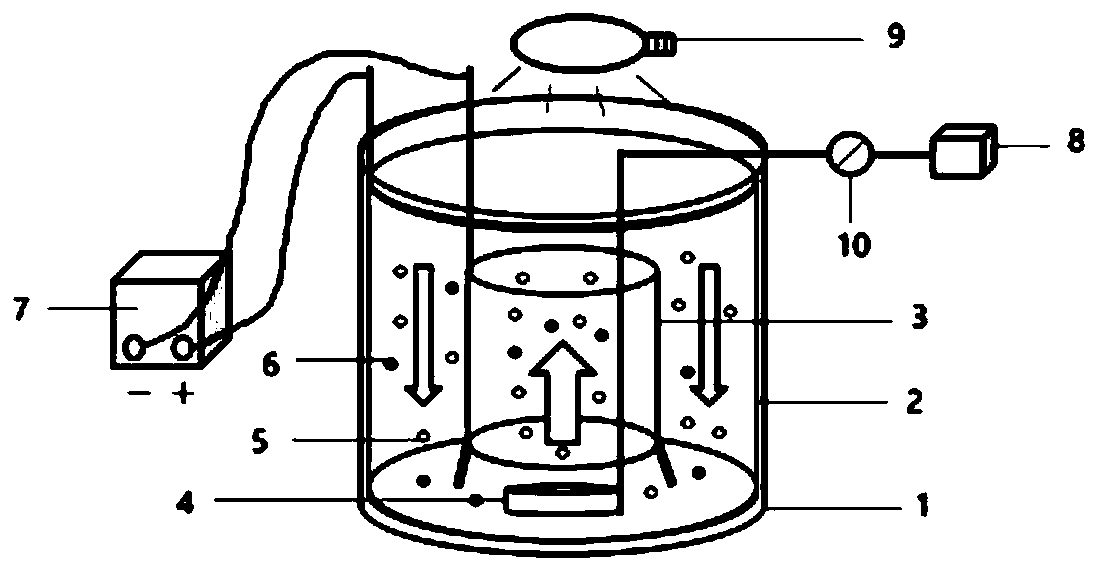

Particle electrode and preparation method thereof and three-dimensional electrolytic reactor and application of three-dimensional electrolytic reactor

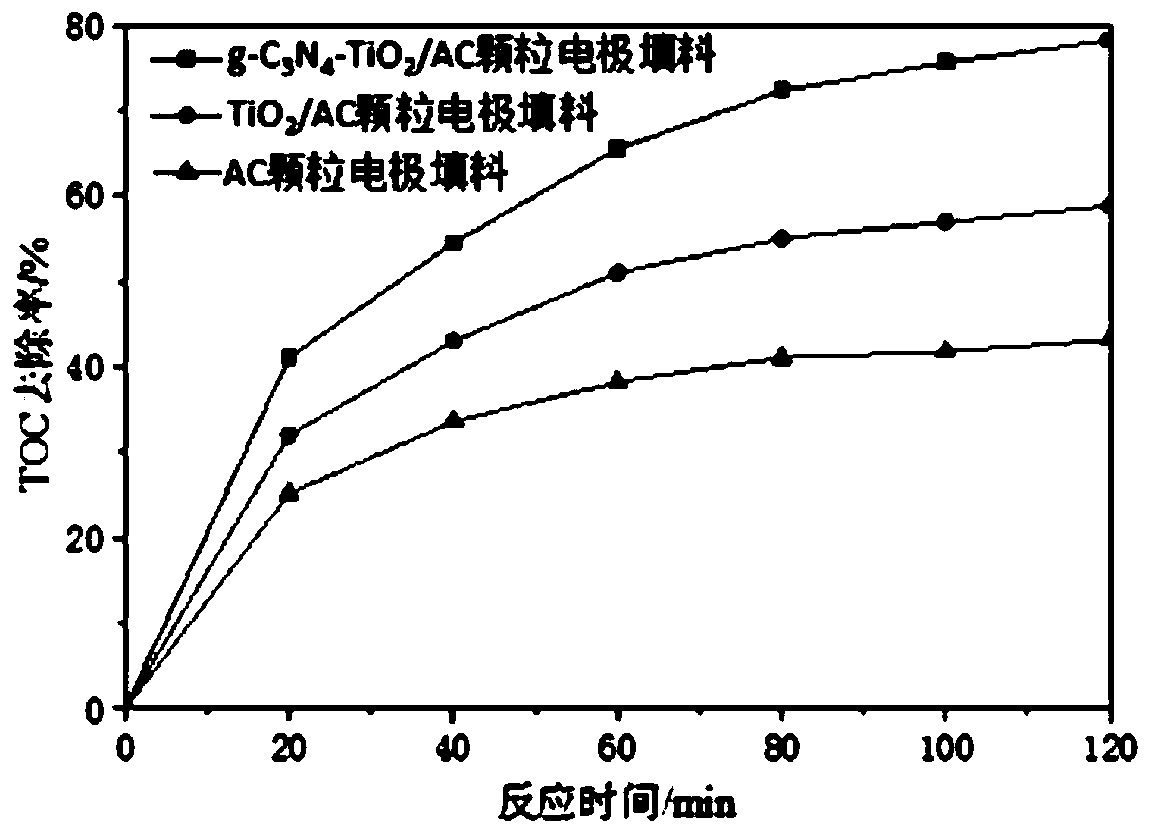

InactiveCN109809530AWide spectral response rangePromote absorptionWater/sewage treatment by irradiationWater contaminantsPhotocatalytic reactionElectrolysis

The invention belongs to the technical field of water treatment and water pollution prevention, and relates to a particle electrode and a preparation method thereof and a three-dimensional electrolytic reactor and application of the three-dimensional electrolytic reactor. The particle electrode is formed by loading g-C3N4 and TiO2 on activated carbon after g-C3N4 and TiO2 are compounded, wherein the mass of g-C3N4 accounts for 40%-50% of the total mass of a g-C3N4-TiO2 compound, and the particle electrode is a g-C3N4-TiO2 / AC particle with visible-light catalytic activity. The three-dimensionalelectrolytic reactor is filled with the g-C3N4-TiO2 / AC particle, the mass transfer effect of an upflow type fluidized bed is improved, the short circuit current is eliminated, and the current efficiency is improved; and under the conditions of the electric field and the illumination, the electrolysis reaction and the photocatalytic reaction generate synergistic effect on the g-C3N4-TiO2 / AC particle electrode, and the three-dimensional electrolytic reactor has a better treatment effect on nonbiodegradable matter.

Owner:JIANGSU UNIV OF TECH

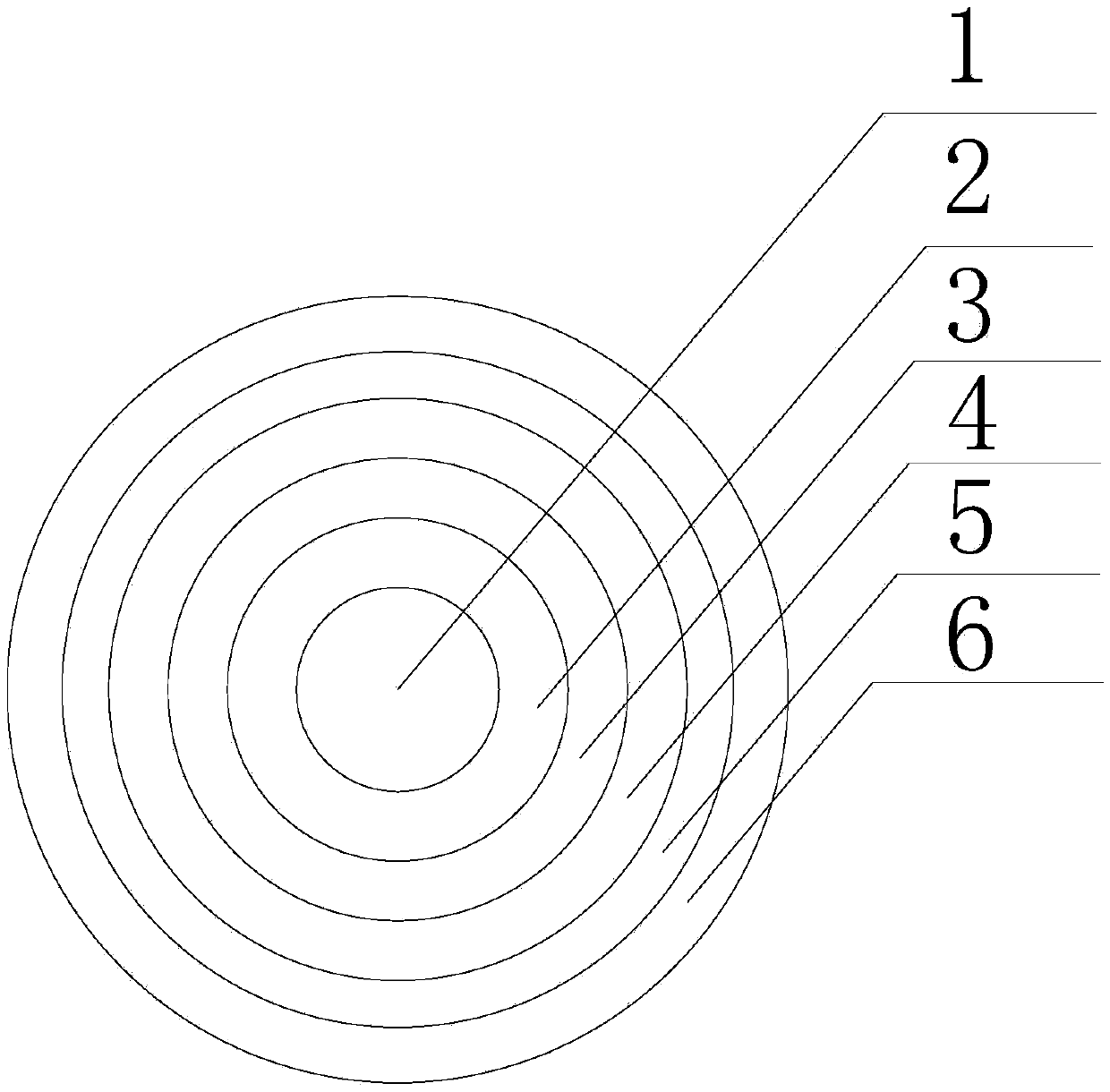

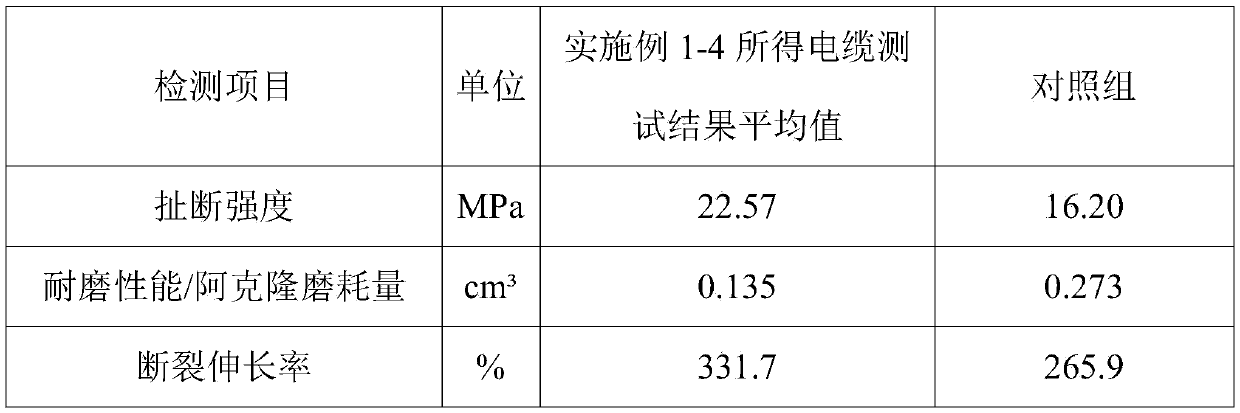

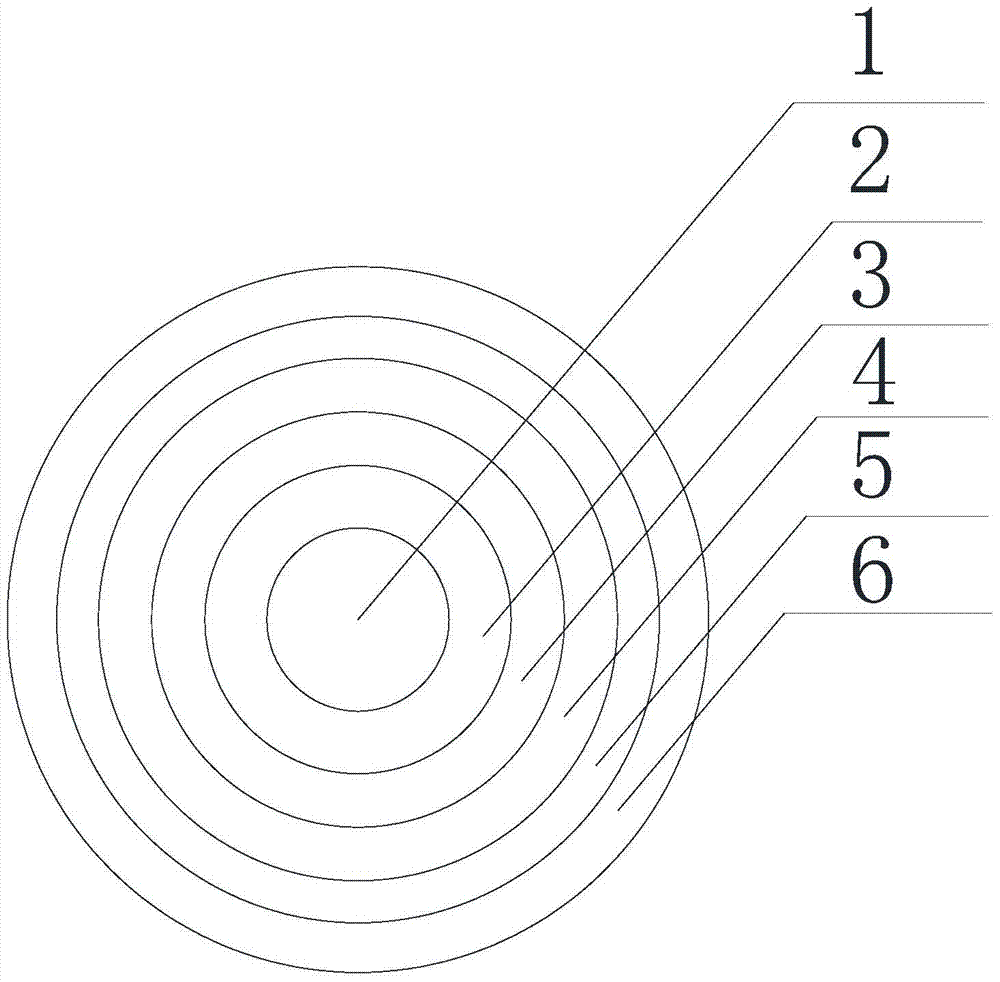

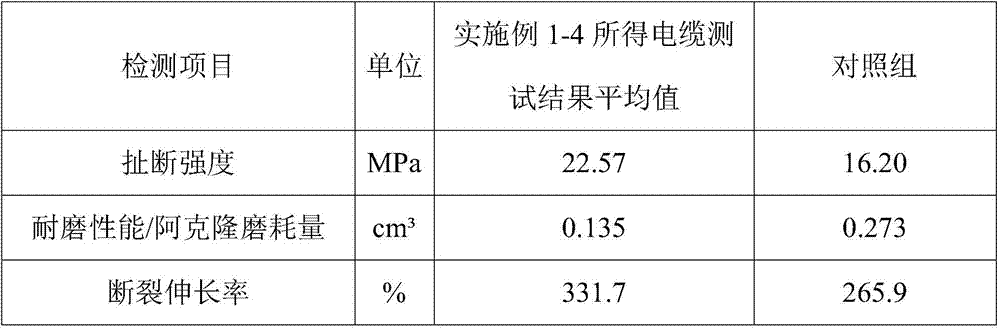

High-toughness abrasion-resistant damping cable used for ships

ActiveCN105374439APromote precipitationAvoid failureInsulated cablesInsulated conductorsWear resistantSulfur

The invention discloses a high-toughness abrasion-resistant damping cable used for ships. The high-toughness wear-resistant damping cable comprises a conductor, an insulating layer, a filling layer, a shielding layer, an armored layer and an external sheath. The raw material of the external sheath includes the following parts by weight: 50-60 parts of polybutadiene rubber, 20-25 parts of EPDM rubber, 15-18 parts of chlorinated polyethylene 140B, 8-12 parts of high-toughness high-heat-insulation performance gel, 1-1.5 parts of sulfur powder, 1.4-1.7 parts of promoter DM, 2.1-2.4 parts of promoter TMTM, 5-7 parts of trioctyl trimellitate, 2-3.5 parts of tributyl citrate, 25-28 parts of barite powder, 17-20 parts of high-abrasion-resistant carbon black, 12-15 parts of nano calcium carbonate, 7-10 parts of ultrafine talcum powder, 6-9 parts of hard pottery clay, 5-8 parts of kaolin, 2-4 parts of red phosphorus, 0.3-0.6 part of NOBS, 0.5-1 part of antioxidant RD and 2.5-4 parts of antioxidant RD.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

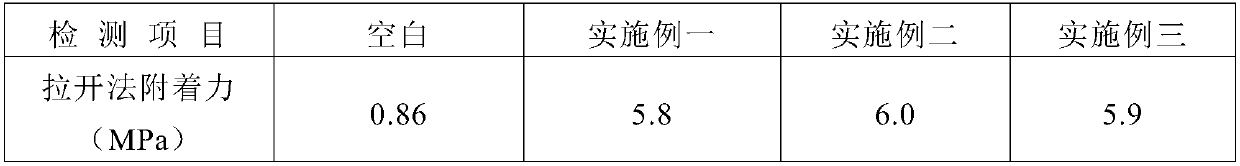

Titanium alloy surface adhesion promoter and preparation method thereof

The invention discloses a titanium alloy surface adhesion promoter and a preparation method thereof. The adhesion promoter comprises 25%-30% of silane coupling agents, 12%-15% of epoxy resin and 55%-60% of mixed solvents. Materials are prepared according to the formula, the epoxy resin and the mixed solvents are added into a reactor and uniformly stirred, temperature is increased to 55+ / -5 DEG C,the silane coupling agents are dropped into the reactor within 40-60 minutes under the condition of stirring, reaction temperature is controlled to be within the range of 70-80 DEG C after dropping, and heat reaction is performed for 4-5 hours to obtain the titanium alloy surface adhesion promoter. The adhesion promoter is an organic-inorganic self-curing resin functioning as a bridge between a titanium alloy surface and a coating, the resin facilitates formation of chemical valence bonds by the coating and a base material, surface energy of the titanium alloy base material can be improved, cohesive energy is high, and the adhesion of the coating on a titanium alloy is further improved.

Owner:中昊北方涂料工业研究设计院有限公司

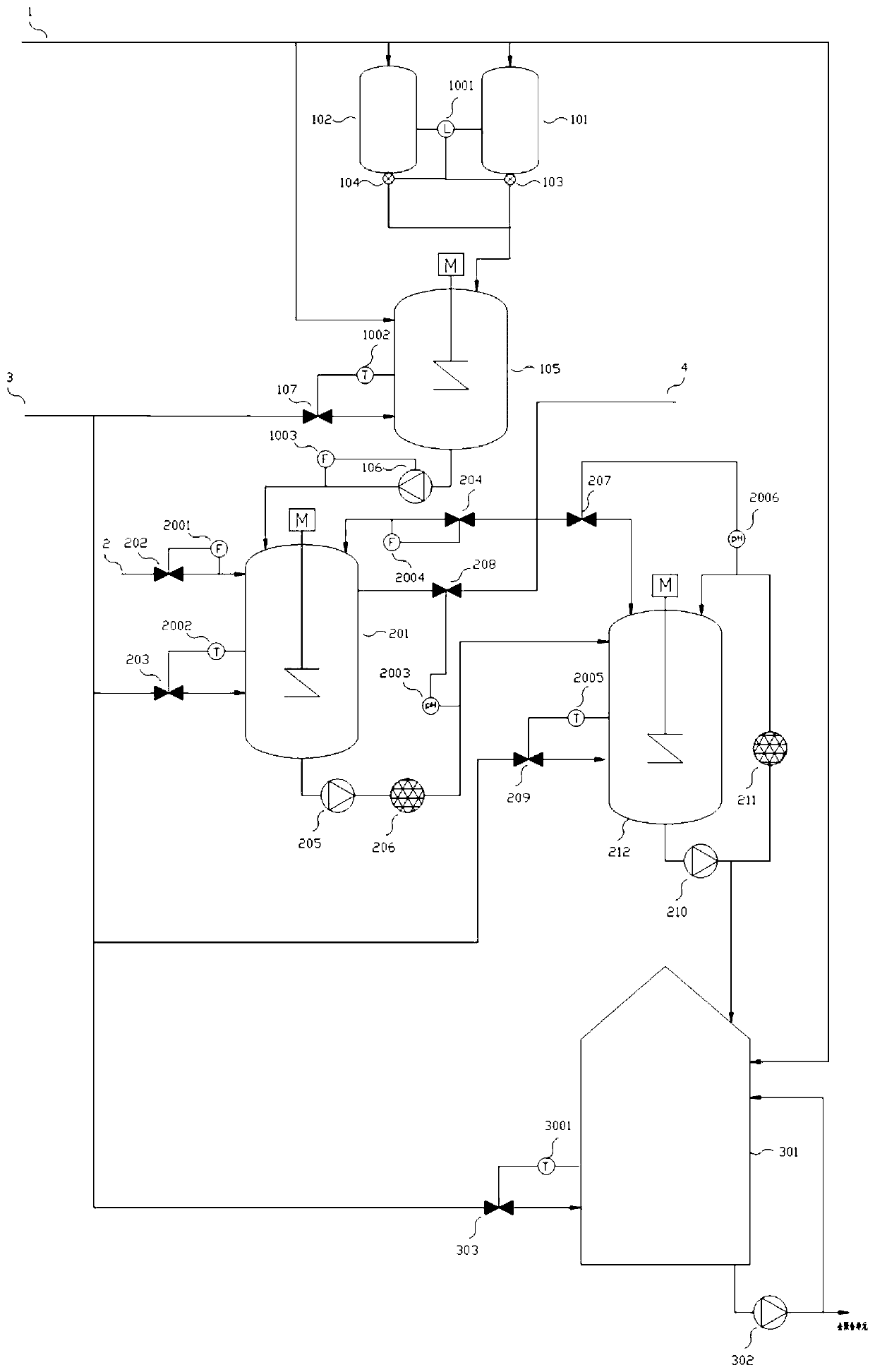

Method and device for continuously producing aqueous solution of long-carbon-chain nylon salt

PendingCN111039791AQuality assuranceReduce manufacturing costOrganic compound preparationCarboxylic acid salt preparationDiamineAqueous solution

The invention relates to a method and a device for continuously producing an aqueous solution of long-carbon-chain nylon salt, belonging to the field of preparation and production of nylon salts. Thepreparation method comprises the following steps: melting long-carbon-chain diacid, mixing the molten long-carbon-chain diacid with long-carbon-chain diamine and water, carrying out a secondary salifying reaction, and adjusting the pH value of the aqueous solution to obtain the aqueous nylon salt solution for a polycondensation reaction. The device comprises a continuous melting unit for the long-carbon-chain diacid and a corresponding control system thereof, a salifying reaction unit and a corresponding control system thereof, and a salt storage unit. According to the method, water is used asa solvent, organic solvents such as alcohol are avoided, production technological process is simplified, the quality of the produced long-carbon-chain nylon salt is guaranteed by flexibly controllingparameters such as temperature and pH in the production process, production cost is reduced, and large-scale production is facilitated.

Owner:WUXI YINDA NYLON

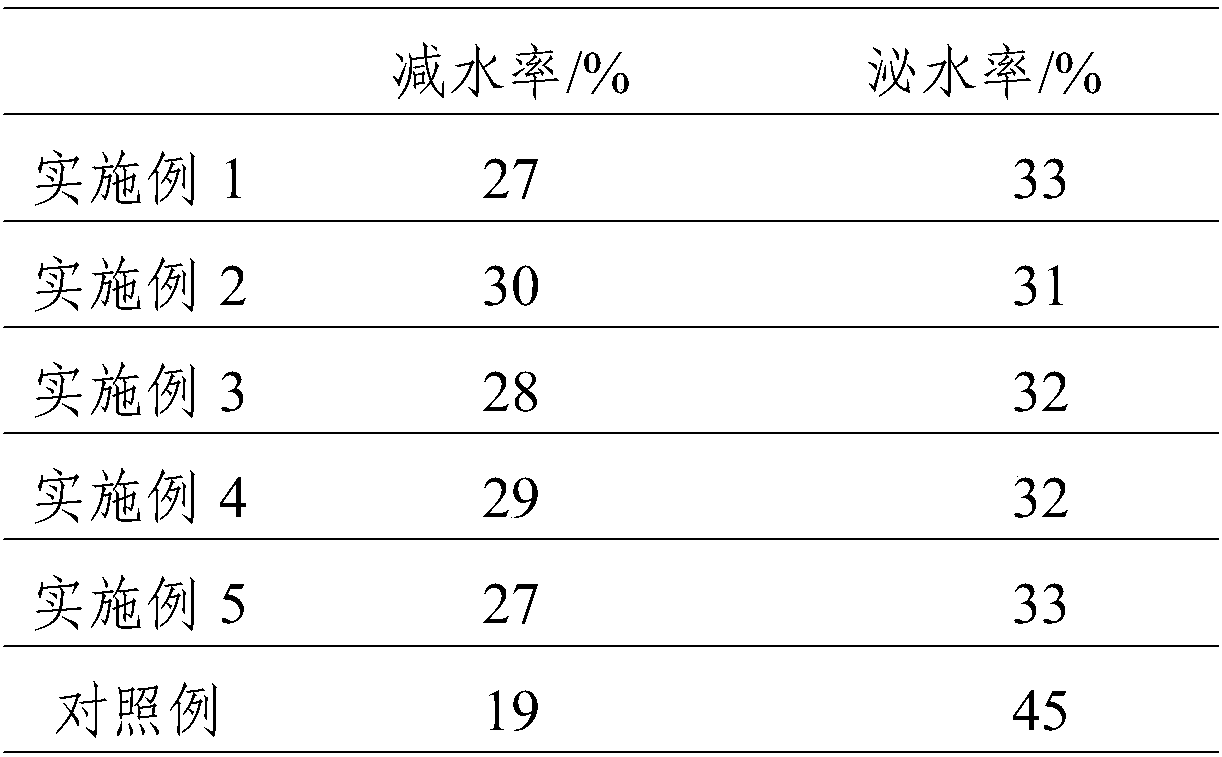

Hyperbranched cationic polymer emulsion, and application thereof in sludge dewatering

InactiveCN109897142ANot easy to tangleImprove dehydration effectSludge treatmentPolymer scienceChemical reaction

The invention provides a hyperbranched cationic polymer emulsion, and an application thereof in sludge dewatering. A first phase, a second phase and a third phase are prepared in advance, a key catalyst is introduced, an initiator, a chain transfer agent and a catalyst are added to the third phase, a lower temperature polymerization reaction is carried out, the second phase is slowly dropwise added in the polymerization to obtain a hyperbranched polymer system, the first phase is slowly dropwise added to the hyperbranched polymer system, and a high temperature polymerization reaction is carried out to obtain the hyperbranched cationic polymer emulsion. The emulsion is highly branched, forms a three-dimensional network structure, is not prone to entangle between molecules, contains a largenumber of terminal functional groups, and has the advantages of strong chemical reactivity, high molecular weight, high cationicity and good sludge dewatering effect.

Owner:湖北康创科技有限公司

Preparation method of coal mining closed filling material

InactiveCN107118560AIncrease the degree of hydrolysisPromote polycondensation reactionCarbon layerSpontaneous combustion

The invention discloses a preparation method of a coal mining closed filling material, and belongs to the technical field of sealing material preparation. The preparation method comprises the following steps: taking vinyl tri-methoxysilane as a raw material for reaction to obtain organic silicon resin; then after treating a coupling agent for carbon black, introducing sulfydryl and cobalt element, and catalyzing resin and carbon black for carbonization to form a carbon layer during burning so as to strengthen fire resistance; then ball-milling sodium silicate, metakaolin and the like; finally stirring and reacting with an accessory ingredient so as to obtain the coal mining closed filling material. The obtained filling material does not contain highly acidic toxic substances such as residual formaldehyde, cannot cause damage on constructors and underground environments, and simultaneously is good in material mechanics properties and excellent in material flame retardant property, so that the problems of smoking and spontaneous combustion caused by heat accumulation when a traditional filling material reacts are avoided, and the filling material has a wide application prospect.

Owner:雷笑天

Method for preparing high-molecular-weight polylactic acid through direct condensation polymerization

The invention provides a method for preparing high-molecular-weight polylactic acid through direct condensation polymerization, which comprises the following steps of: stirring and heating dehydrated lactic acid to 90-120 DEG C; carrying out heat preservation for 10-30 minutes at a vacuum degree of 0.060-0.065MPa; dropwise adding the mixed solution of a tin catalyst, and carrying out heat preservation and reacting for 10-30 minutes; heating to 160-200 DEG C, and carrying out heat preservation and reacting for 4-9 hours at a vacuum degree of 0.065-0.095MPa to obtain a crude product; and purifying, filtering and drying the crude product to obtain high-molecular-weight polylactic acid. According to the invention, the tin catalyst is dispersed in an organic solvent and dropwise added into the reaction system, the inactivation of the tin catalyst can be effectively prevented, the condensation polymerization reaction of lactic acid can be uniformly accelerated, and the reaction time is shortened; and moreover, the reaction byproduct can be discharged out of the reaction system along with the organic solvent in the mixed solution of the tin catalyst at low vacuum degree so that the reaction goes rightward and the reaction speed is increased.

Owner:SHAANXI UNIV OF SCI & TECH

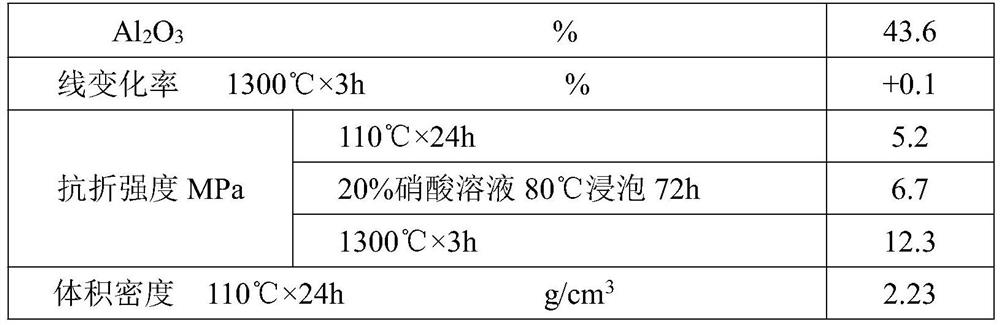

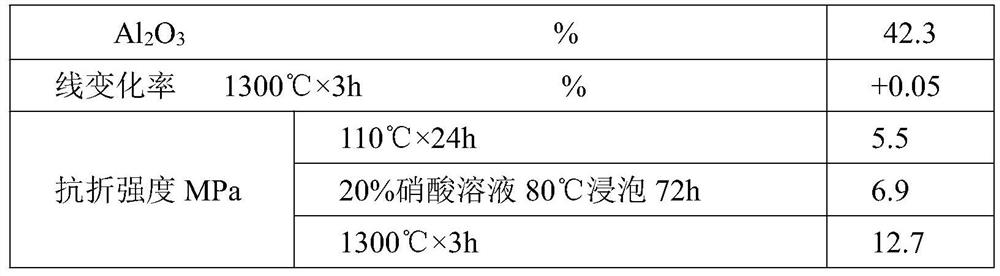

Acid-resistant spray coating suitable for globe roof of hot-blast stove

ActiveCN113354425AGuaranteed high temperature performancePromote polycondensation reactionSpray coatingFirming agent

The invention discloses an acid-resistant spray coating suitable for a globe roof of a hot blast stove. The acid-resistant spray coating comprises the following components in percentage by mass: 50 to 65 wt% of mullite aggregate, 16 to 25 wt% of 70 high aluminum powder, 3 to 6 wt% of alpha-Al2O3 micro powder, 2 to 6 wt% of quartz powder, 1 to 4 wt% of kyanite particles, 0.1 to 0.6 wt% of a tackifier, 0.5 to 2 wt% of a curing agent, 0.2 to 0.6 wt% of an accelerant and 10 to 13 wt% of modified quick-drying silica sol. According to the semi-dry spray coating with the silica sol as a binding agent, substances with low melting point are not brought in, and the high-temperature performance is ensured. The polycondensation reaction of silica sol siloxane bonds can be promoted in an acid environment, the strength is not reduced but also improved after acid erosion, the surface layer is intact, the sign of erosion does not occur, and the service life of the hot blast stove is prolonged.

Owner:中冶武汉冶金建筑研究院有限公司 +1

Method for preparing polyester containing isosorbide

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite material prepared from recycled material, forming method and application of composite material

The invention discloses a composite material prepared from a recycled material, a forming method and application of the composite material. The composite material is composed of a matrix and a functional bottom film, wherein the matrix is multi-polymer particles and is composed of multiple recycled material particles and a thermoplastic material, and the functional bottom film endows the compositematerial with multiple functional characteristics. The composite material is prepared by crushing leftover bits and pieces of a high polymer material generated in the industrial production process for preparing polymer particles from the crushed leftover bits and pieces and a thermoplastic material, and performing heating pressurization and applying a functional bottom film. The composite material can be directly used as a paving material; or can be used for a back bottom and a middle layer of a composite carpet; or can be used for foot pads, wheel covers, trunk left and right side coamings,spare tire bottom plates and cover plates for automobiles. Through the simple forming method, pollution in the production process is reduced, the source of raw materials is wide, and continuous production can be achieved. The composite material is high in strength and has elasticity after being formed; meanwhile, the purposes of reducing cost, achieving waste recycling and reducing environmental pollution are achieved, and very high economic benefits can be generated.

Owner:褚乃博

A kind of synthesis technique of polycarbonate

A polycarbonate synthesis process comprises steps as follows: S1, a raw material mixing stage: melt isosorbide and dialkyl carbonate are stirred and uniformly mixed in a raw material mixing tank; S2, an ester exchange reaction stage: a tower reactor located behind the raw material mixing tank is taken as an ester exchange reactor, and released hydroxyl and aryl reaction products can be removed continuously; S3, a pre-polymerization reaction stage: a kettle pre-polycondensation reactor is arranged behind the ester exchange reactor, a pre-polymerization product is generated in the pre-polycondensation reactor, and meanwhile, released hydroxyl and aryl reaction products are removed continuously; S4: a polycondensation reaction stage: a hydraulic driven horizontal disk polycondensation reactor located behind the pre-polymerization reactor performs microwave processing on a pre-polycondensation product, and the pre-polycondensation product is subjected to polycondensation to form polycarbonate melts. The released hydroxyl and aryl reaction products are removed continuously, so that reaction balance is pushed in the positive direction, the pre-polycondensation product is heated through microwaves in the polycondensation stage, and the reaction rate can be effectively increased.

Owner:NINGBO ZHETIE DAPHOON CHEM

Furan resin for casting and production method thereof

The invention relates to the technical field of sand casting, in particular to furan resin for casting and a production method thereof, which can improve the strength, can improve the adhesion property, and can reduce the influence on the sand casting. The furan resin for casting is prepared by performing addition reaction, condensation reaction and aldehyde reduction reaction on the following rawmaterials in parts by weight: 100 to 200 parts of water, 50 to 80 parts of furfuryl alcohol, 10 to 20 parts of formaldehyde, 5 to 10 parts of a catalyst, 1 to 2 parts of an aid, 20 to 30 parts of urea, 5 to 10 parts of an aldehyde reduction agent, and 2 to 5 parts of oxidized starch.

Owner:保定永强合成材料有限公司

Separation method of oily sludge and application of sludge impurities to preparation of active carbon

ActiveCN109761469AAggregation increasedHigh degree of separationWaste water treatment from quariesCarbon compoundsGas phaseSludge

The invention provides a separation method of oily sludge and application of sludge impurities to preparation of active carbon. The separation method comprises the following steps of (1) pretreating the oily sludge: putting the oily sludge under microwave conditions for microwave treatment; performing demulsification treatment and dewatering on the oily sludge subjected to microwave treatment to obtain pretreated oily sludge; (2) separating the oily sludge: in a nitrogen environment, putting the pretreated oily sludge under heating conditions; performing dry distillation; respectively collecting gas phase and impurities after dry distillation. The application concretely comprises the steps of under the existence condition of activating agents, under the inert gas protection conditions, putting the impurities after the dry distillation under the temperature condition of 280 to 350 DEG C; performing pre-activation for 20 to 30 min; then, performing activation for 1 to 2 h under the temperature condition of 700 to 850 DEG C to obtain the high specific area active carbon. The separation method achieves the effects that the separation effect is good; the separated impurities can be effectively utilized.

Owner:东营市康杰化工科技发展有限责任公司

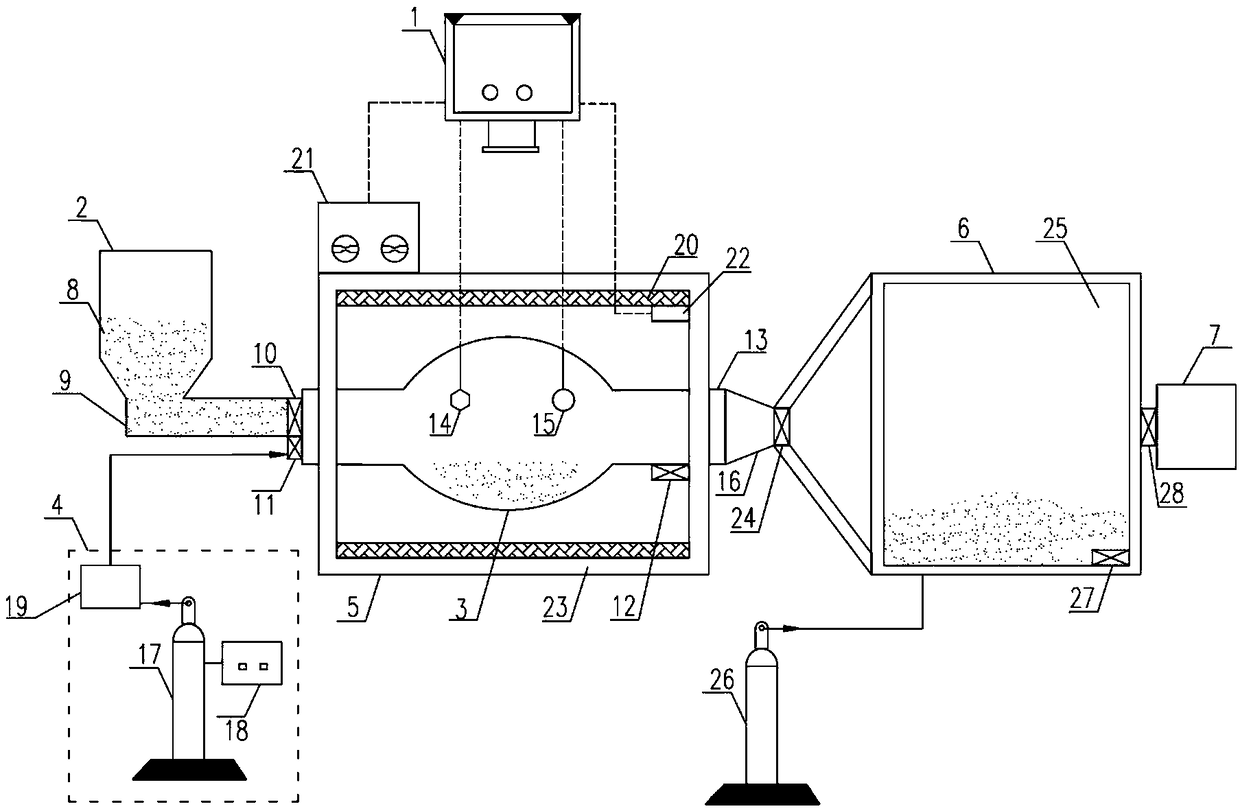

Device and method for rapidly preparing high-yield activated carbon by coupling of pressure pump with microwaves

The invention belongs to the technical field of carbon material preparation and provides a device and a method for rapidly preparing high-yield activated carbon by coupling of a pressure pump with microwaves. The device comprises a programmed controller, a feed unit, a reaction furnace, a pressure pump unit, a microwave heating unit, an explosive spraying and cooling unit and a pyrolysis gas treating unit. Friction and collision of raw material molecules are caused by the microwaves, reaction activation energy is reduced, and the process operation time is shortened greatly. Retention time of volatile matter is prolonged by pressing of the pressure pump, the volatile matter is promoted to be deposited on surface of semi-coke, and accordingly, yield of solid carbon is increased; condensationpolymerization of tar is also promoted by pressing, and production of the tar is reduced substantially or avoided. Besides, pyrolysis gas can be produced from inside of the raw materials by the aid of microwave heating, pyrolysis gas molecules retain in the raw material molecules under the pressing action to play a role of in-situ self-template and shuttle back and forth freely in the raw materials non-directionally to substantially promote pore development of the activated carbon, the instantaneous popcorn effect is beneficial to secondary pore forming of the pyrolysis gas, and the specificsurface area of a carbon material is increased.

Owner:DALIAN UNIV OF TECH

Method for preparing disposable and fully-degradable tableware from straw-based formaldehyde-free and plastic-free material

The invention discloses a method for preparing disposable and fully-degradable tableware from a straw-based formaldehyde-free and plastic-free material. A straw material composite modifying treatmentprocess comprises material rubbing and drying treatment, grinding for power preparation, grinding aiding and modifying as well as inoculation, fermentation and drying treatment, composite modified active straw powder obtained with the process is subjected to cold mixing and compounding with a forming and curing aid prepared with a forming and curing aid preparation process, and compression moldingis performed. The raw materials are wide and available, a polycondensation reaction, lignin dissolution and self polycondensation, crosslinking and gluing effects are produced in the preparation process, firm interface bonding is formed, and the product has the characteristics of being higher in mechanical strength, water repellence, oil repellence and high-temperature resistance, fully-degradable, non-toxic, high in weather resistance and recyclable after use; the preparation process of the product is simple, reasonable in design, convenient to operate and control, low in production cost, environmentally friendly, energy-saving and efficient, development of circular economy is improved, and economic and social benefits are remarkable.

Owner:辽源市汇鑫生物质能源开发有限公司

High-efficiency water reducing agent and preparation method thereof

InactiveCN108084383AThe sulfonation reaction went smoothlyProcess stabilitySuperplasticizerWater reducer

The invention relates to the field of water reducing agents, in particular to a high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared from, by weight, 10-15 parts of naphthalene oil, 4-9 parts of caustic soda liquid, 15-20 parts of acetone, 5-11 parts of formaldehyde, 7-12 parts of potassium permanganate, 4-9 parts of sodium nitrite, 13-21 parts of concentrated sulfuric acid and an appropriate amount of water; the water reducing agent effectively makes up for the defects to a certain degree that existing water reducing agents easily mildewand are low in production efficiency.

Owner:萧县沃德化工科技有限公司

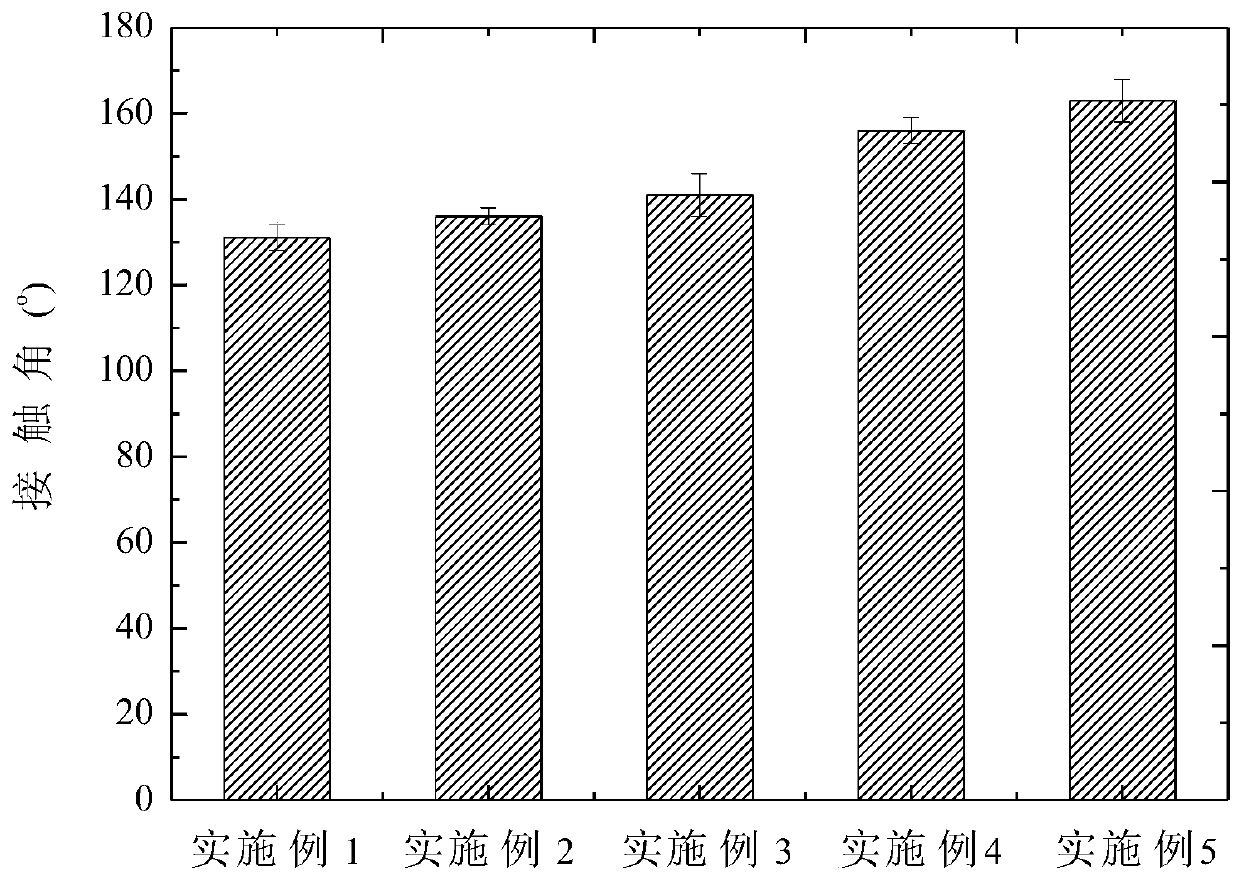

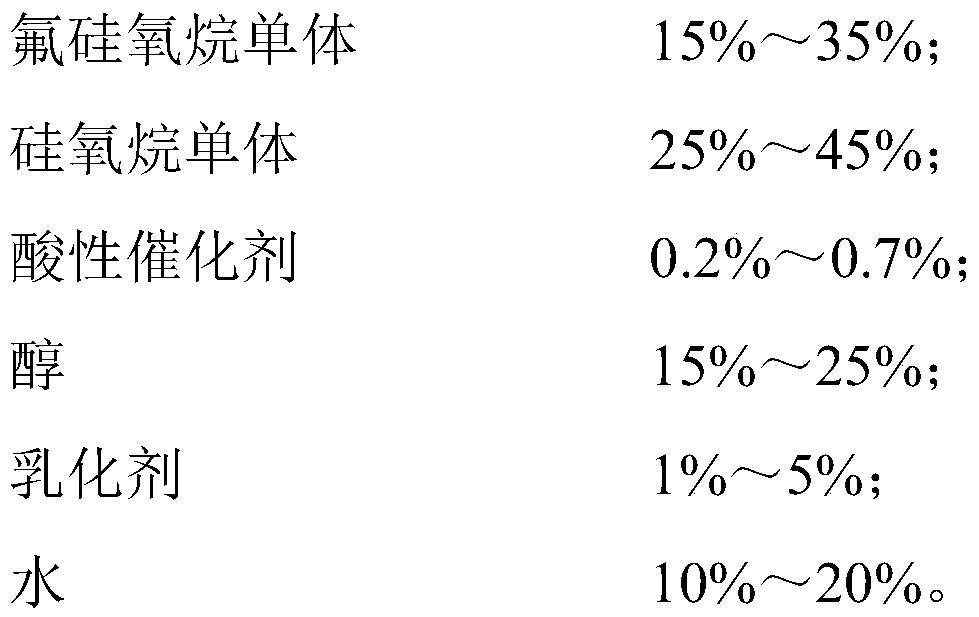

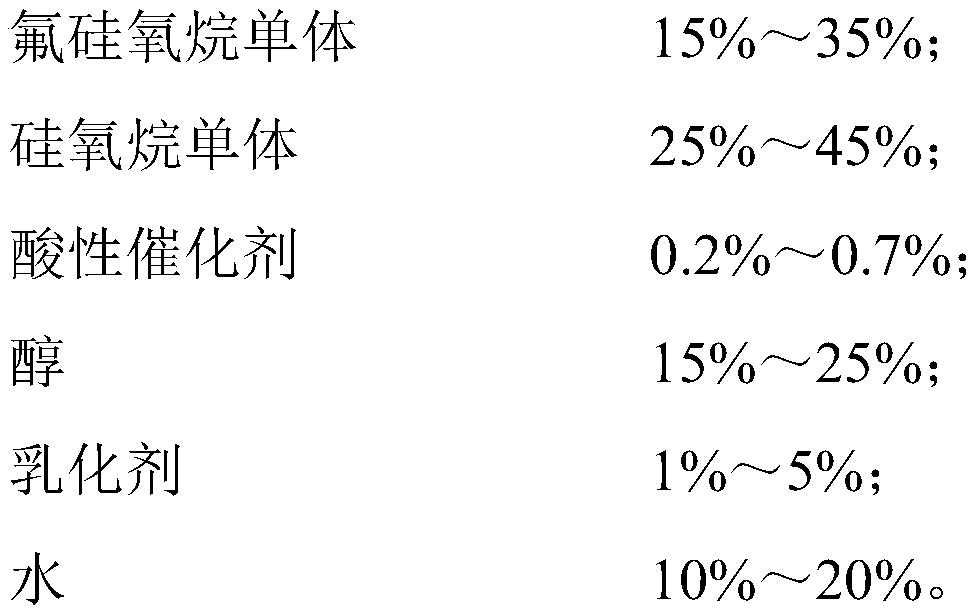

Permeable protective agent for coating protection of oceanographic engineering concrete structure and preparation method

ActiveCN109880102AImprove hydrophobicityEnhance resilienceAnti-corrosive paintsAlcoholStructure of the Earth

The invention discloses a permeable protective agent for coating protection of an ocean engineering concrete structure. The protective agent comprises the following components in percentage by weight:15-35% of fluorosiloxane monomer; 25%-45% of siloxane monomer; 0.2%-0.7% of acidic catalyst; 15%-25% of alcohol; 1%-5% of emulsifier; and 10%-20% of water. The permeable protective agent for coatingprotection of the oceanographic engineering concrete structure has excellent permeability and durability, can prolong the service life of the concrete structure, and is particularly suitable for coating protection of the oceanographic engineering concrete structure. The invention also discloses a preparation method of the permeable protective agent for coating protection of the ocean engineering concrete structure.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +3

A kind of preparation method of nano-silica rosin modified urea-formaldehyde resin

ActiveCN104725775BImprove performanceModerate heating temperatureNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesHigh volume manufacturingAging resistance

The invention belongs to the technical field of urea-formaldehyde resin preparation, and particularly relates to a preparation method of a nano silicon dioxide / rosin modified urea-formaldehyde resin. The method comprises the following steps: preparing a urea-formaldehyde resin from urea and formaldehyde by a weak alkali-weak acid-weak alkali technique, and modifying with nano silicon dioxide and rosin to obtain the nano silicon dioxide / rosin modified urea-formaldehyde resin. The method has the advantages of simple technique and accessible raw materials, and is suitable for industrialized mass production. The prepared urea-formaldehyde resin has the advantages of favorable viscosity, high softening point, low free formaldehyde content, environment friendliness, higher water resistance, favorable toughness and improved aging resistance, is suitable for artificial board production, and can be used as an adhesive in material binding, bamboo / wood processing, paper binding, steel paints, multicolor pattern paints and other industries.

Owner:桂林兴松林化有限责任公司

A kind of production method and device of nylon 66 saline solution

ActiveCN107141230BGood storage stabilityQuality assuranceOrganic compound preparationCarboxylic acid amide separation/purificationSalt waterNylon 66

The invention provides a production system for a nylon 66 salt water solution. The system comprises a plurality of reaction units, control systems corresponding to the reaction units and a maturation tank. The reaction units comprises reactors, each reactor is provided with a material discharging pipeline and a plurality of material feeding pipelines, the material discharging pipeline of the reactor of the headmost reaction unit is communicated with the maturation tank, a circulating pipeline is arranged outside each reactor and used for making the bottom and the top of the reactor communicated, and each circulating pipeline is sequentially provided with a heat exchanger and a pump from front to back. The production system is suitable for the production requirements of nylon 66 salt with water as a solvent, flexible control over temperature, pH, concentration and other industrial parameters in the production process can be achieved, meanwhile, no by-products are generated, the water also becomes one part of the nylon 66 salt product, the storage stability of the nylon 66 salt is improved, and convenience is brought to the subsequent polycondensation reaction.

Owner:HENAN SHENMA NYLON CHEM

A high toughness wear-resistant shock-absorbing cable for ships

ActiveCN105374439BPromote precipitationAvoid failureInsulated cablesInsulated conductorsWear resistantSulfur

The invention discloses a high-toughness wear-resistant shock-absorbing cable for ships, which comprises a conductor, an insulating layer, a filling layer, a shielding layer, an armor layer and an outer sheath; the raw materials of the outer sheath include: butadiene rubber 50 ‑60 parts, EPDM rubber 20‑25 parts, chlorinated polyethylene 140B 15‑18 parts, high toughness and high heat insulation gel 8‑12 parts, sulfur powder 1‑1.5 parts, accelerator DM 1.4‑1.7 2.1-2.4 parts of accelerator TMTM, 5-7 parts of trioctyl trimellitate, 2-3.5 parts of tributyl citrate, 25-28 parts of barite powder, 17-20 parts of high wear-resistant carbon black, 12-15 parts of nano calcium carbonate, 7-10 parts of superfine talc, 6-9 parts of hard clay, 5-8 parts of kaolin, 2-4 parts of red phosphorus, 0.3-0.6 parts of NOBS, 0.5-1 parts of anti-aging agent RD parts, antioxidant RD 2.5‑4 parts.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

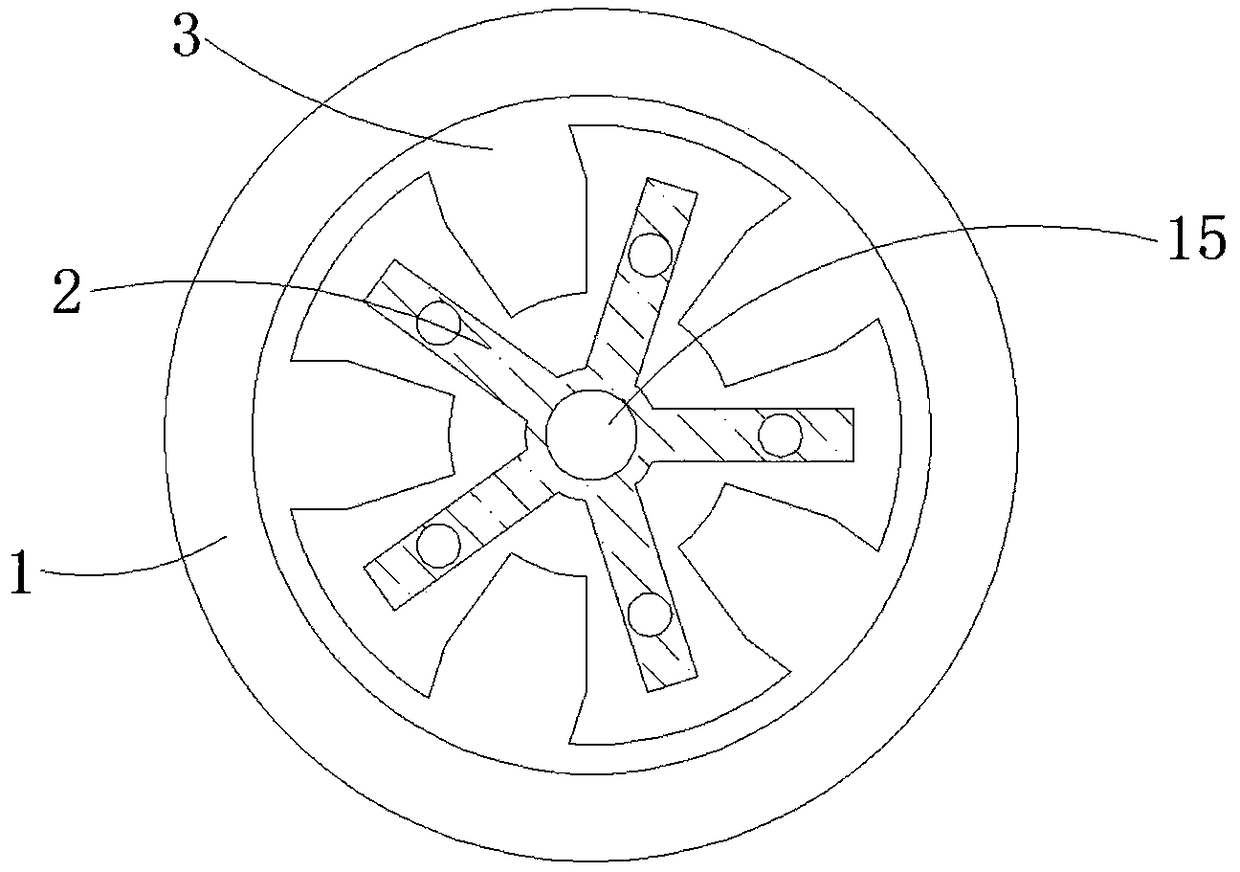

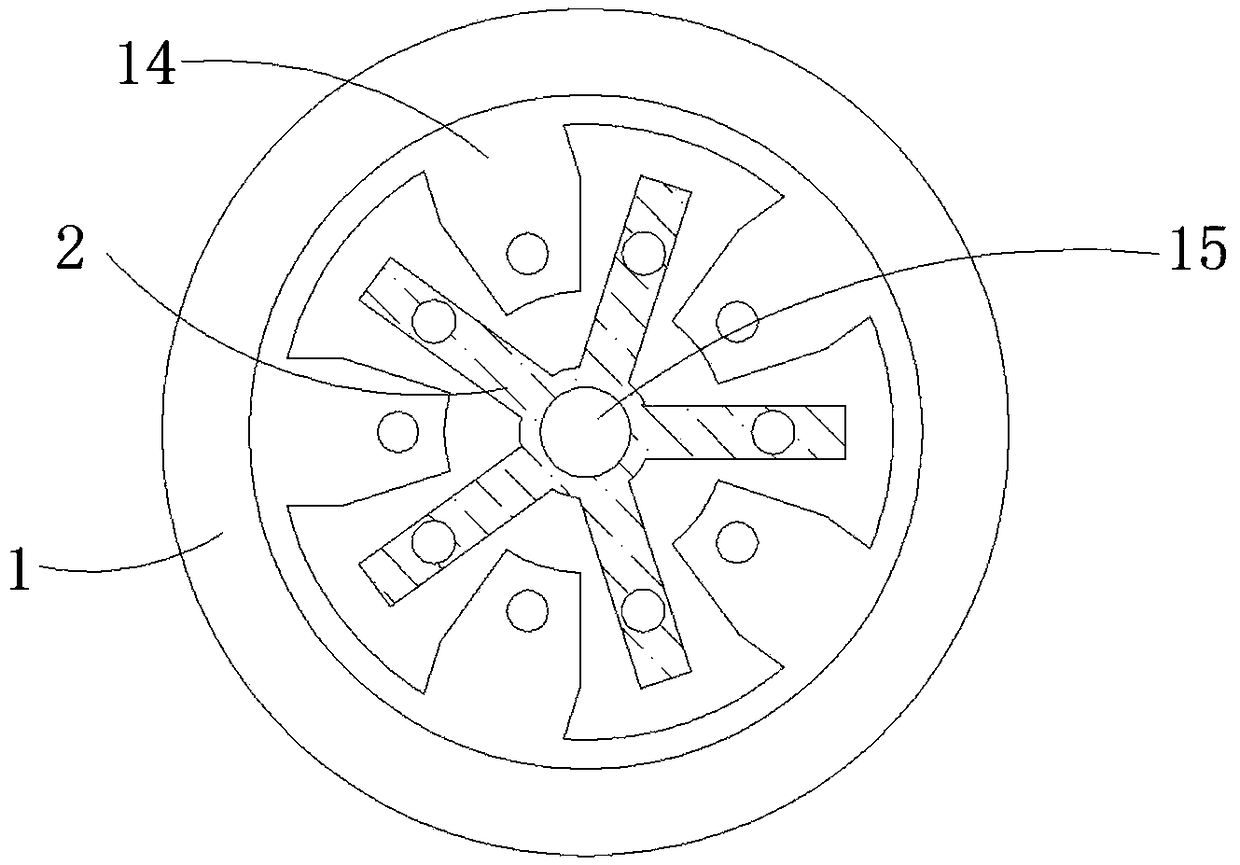

Polyester yarn production raw material conveying device

InactiveCN109317077AGuaranteed uniformityPromote polycondensation reactionChemical/physical/physico-chemical stationary reactorsFeed devicesTextile technologyYarn

The invention relates to the field of textile technology and particularly relates to a polyester yarn production raw material conveying device and solves the problems of the prior art that the conveying device does not have continuity and the structure is complicated, which have caused that the operation time in polyester yarn production is increased and the working efficiency is reduced. The polyester yarn production raw material conveying device comprises a reaction tank, a conveying channel, a conveying box and a discharge box, wherein a through hole is formed in the exterior of the reaction tank, and a feed pipe is arranged in the through hole; a second motor is arranged at the upper end, close to the feed pipe, of the reaction tank; an output end of the second motor is connected witha rotary rod; the rotary rod extends into the reaction tank; a stirring rod is arranged outside the rotary rod in a threaded manner. After flowing toward the lower side of the reaction tank through arotation plate, the raw material flows into the conveying box through the conveying channel, thus the conveying of the polyester yarn production raw material is continuous, the smoothness of the raw material conveying by the conveying device is guaranteed, and the working efficiency of the raw material conveying operation is improved.

Owner:浙江盛邦化纤有限公司

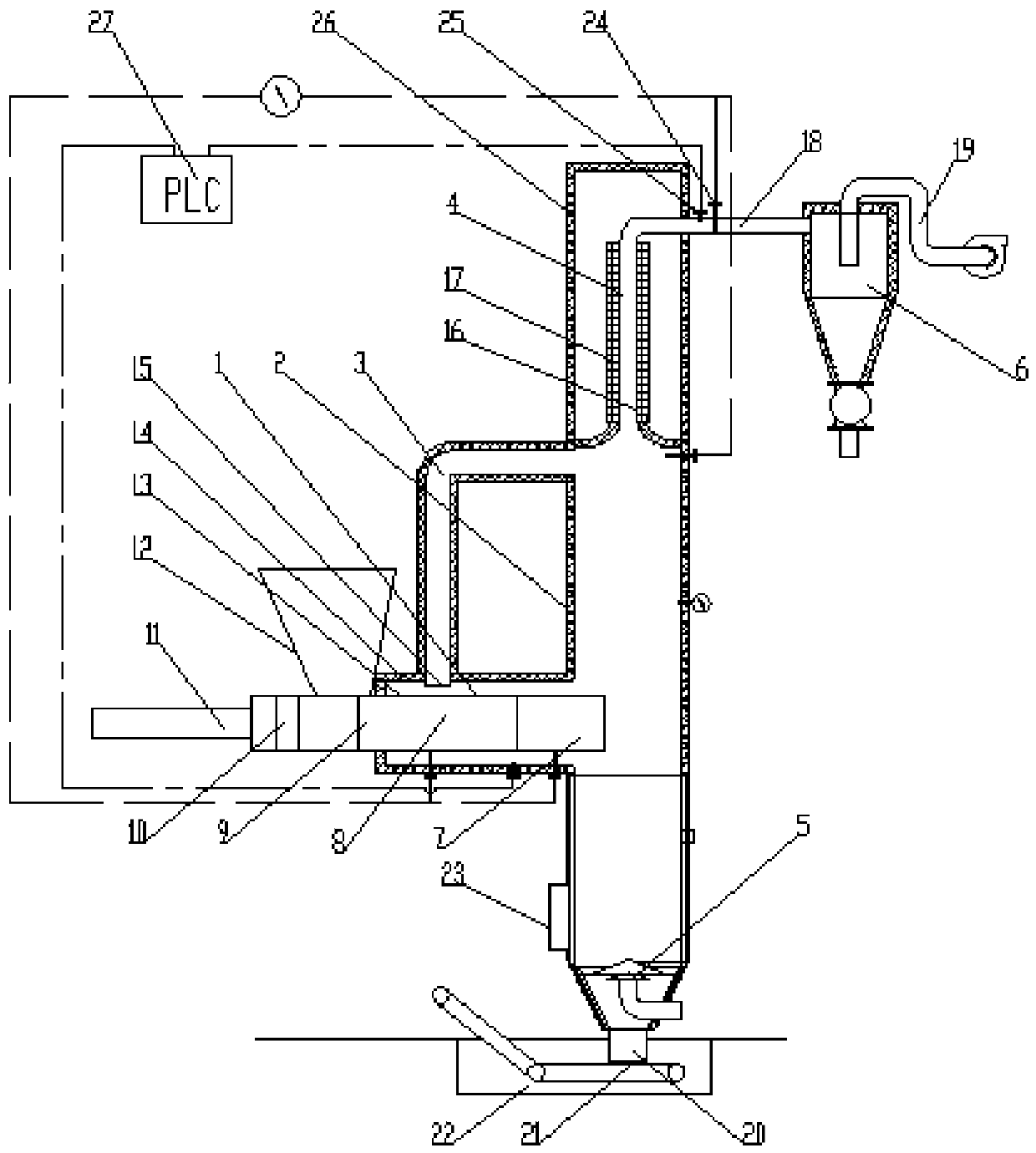

Combined pyrolysis gasifier

ActiveCN105505474BExtended stayProlong the time of pyrolysis and gasificationGasification processes detailsCombustible gas productionWater vaporCombustible gas

The invention discloses a combined type pyrolysis and gasification furnace. The whole device comprises a horizontal furnace body, a vertical furnace body, a vapor leading device, a tar thermal cracking catalysis device and a cyclone dust removal device. The horizontal furnace body is perpendicularly communicated with the middle-lower portion of the vertical furnace body, the middle of the horizontal furnace body is communicated with the vapor leading device, and the other end of the vapor leading device is communicated with the middle-upper portion of the vertical furnace body. The lower end of the vertical furnace body is provided with a deslagging device, the interior of the upper end of the vertical furnace body is provided with the tar thermal cracking catalysis device which is communicated with the cyclone dust removal device through a combustible gas discharge pipeline. The horizontal furnace body is divided into a feeding section, a drying section and a pyrolysis and gasification section, the feeding section, the drying section and the pyrolysis and gasification section are combined into an inner-layer furnace body, the drying section and the pyrolysis and gasification section are combined into an outer-layer furnace body, the inner-layer furnace body stretches into the vertical furnace body, the outer-layer furnace body is connected with the barrel wall of the vertical furnace body, and the inner-layer furnace body and the outer-layer furnace body form an annular cavity. The combined type pyrolysis and gasification furnace is simple in structure, reasonable in design, high in continuous working capacity and high in pyrolysis and gasification efficiency.

Owner:江苏交航环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com