Permeable protective agent for coating protection of oceanographic engineering concrete structure and preparation method

A technology of penetrating protective agent and concrete structure, which is applied in the field of penetrating protective agent and preparation for marine engineering concrete structure coating protection, which can solve the problem of water absorption reduction and the ability of chloride ion penetration is not clear, described in detail, not mentioned Penetration protectant durability and other issues to achieve the effect of enhancing resistance and ensuring permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

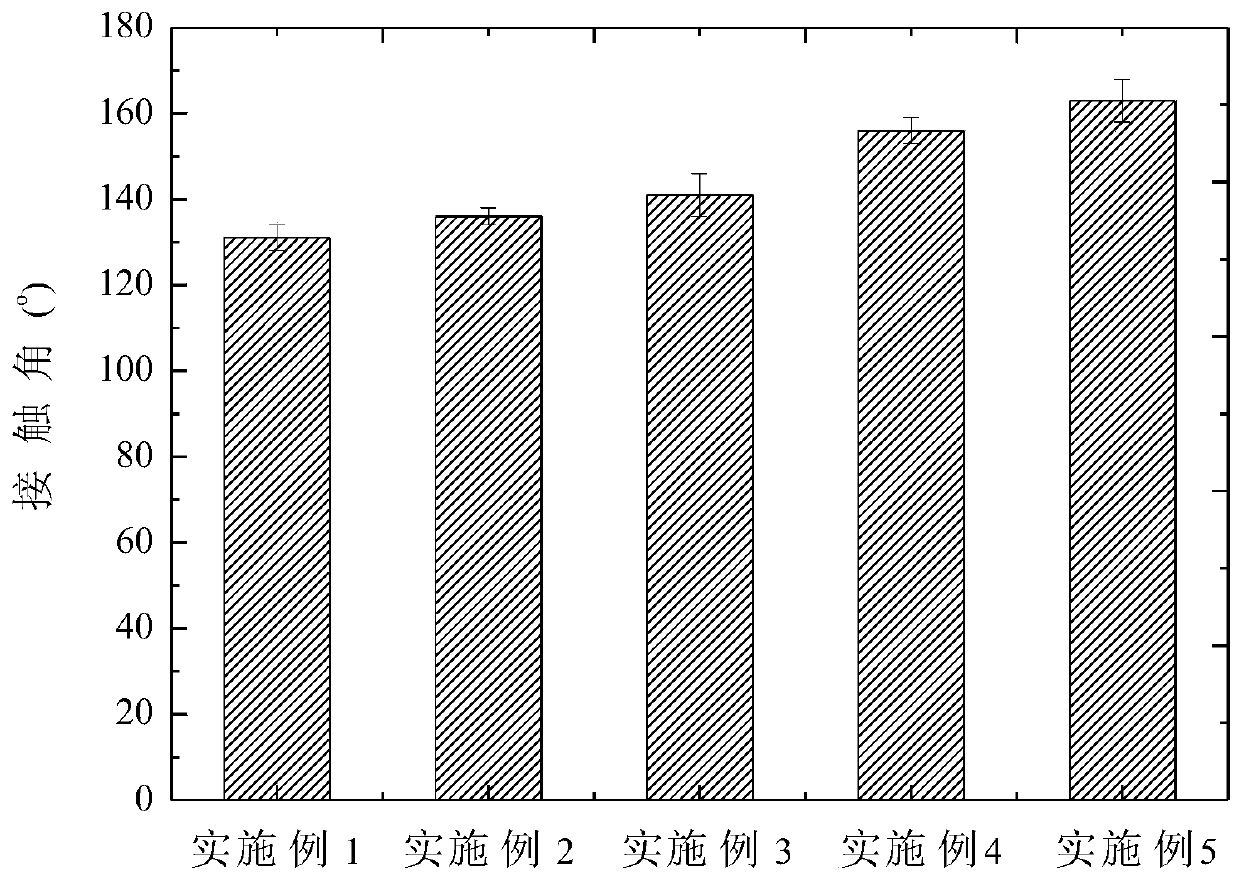

Examples

Embodiment 1

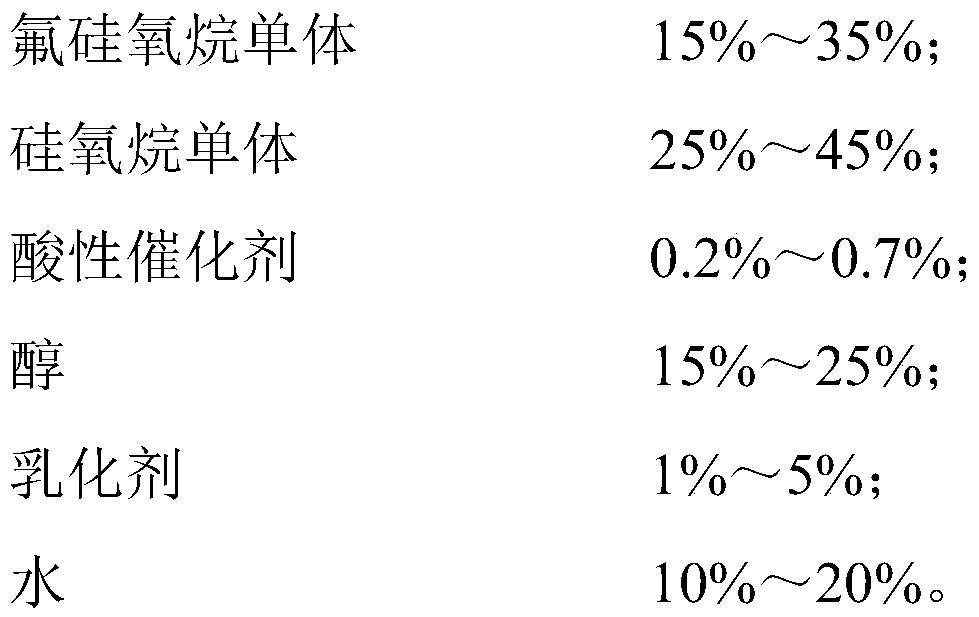

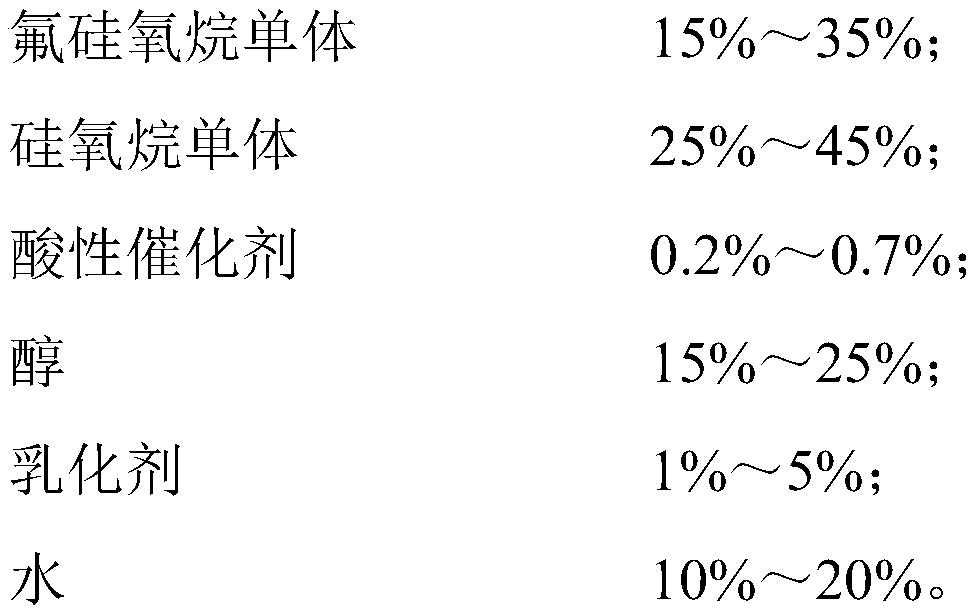

[0036] Take 15 parts of isopropanol and 19.8 parts of water and mix well;

[0037] Prepare 5 parts of mixed emulsifier according to the composition in the column of Example 1 of Table 2, and dissolve in the prepared alcoholic aqueous solution to obtain an emulsion;

[0038] Weigh 5 parts of (3,3,3-trifluoropropyl)methyldimethoxysilane, 5 parts of (3,3,3-trifluoropropyl)methyltrimethoxysilane, (3,3, 5 parts of 3-trifluoropropyl) methyltriethoxysilane, 15 parts in total,

[0039] 15 parts of methyl triethoxysilane, 15 parts of ethyl triethoxysilane, 15 parts of propyl triethoxysilane, 45 parts in total,

[0040] 0.2 parts of formic acid (concentration 0.01mol / L);

[0041] Slowly add the weighed fluorosiloxane monomer and siloxane monomer into the prepared emulsion at a speed of 15 drops / min, and at the same time stir and mix at a speed of 1000r / min. During the stirring process, drop Add formic acid, emulsify at 800r / min, 35°C, and react for 2 hours to obtain a uniform micro-n...

Embodiment 2

[0043] Take 17 parts of isopropanol and 18.7 parts of water and mix well;

[0044] Prepare 4 parts of mixed emulsifiers according to the composition in Table 2, Example 2, and dissolve in the prepared alcoholic aqueous solution to obtain an emulsion;

[0045] Weigh 5 parts of (3,3,3-trifluoropropyl)methyldimethoxysilane, 5 parts of (3,3,3-trifluoropropyl)methyldiethoxysilane, (3,3 , 5 parts of 3-trifluoropropyl)methyltrimethoxysilane, 5 parts of (3,3,3-trifluoropropyl)methyltriethoxysilane, 20 parts in total,

[0046] 15 parts of ethyl triethoxysilane, 15 parts of propyl triethoxysilane, 10 parts of isobutyl ethyl triethoxysilane, 40 parts in total,

[0047] 0.3 parts of acetic acid (concentration 0.01mol / L);

[0048]Slowly add the weighed fluorosiloxane monomer and siloxane monomer into the prepared emulsion at a speed of 15 drops / min, and at the same time stir and mix at a speed of 1300r / min. During the stirring process, drop Add acetic acid, emulsify at 900r / min, 45°C, a...

Embodiment 3

[0050] Take 19 parts of ethanol and 17.6 parts of water and mix well;

[0051] Prepare 3 parts of mixed emulsifiers according to the composition in the column 3 of Example 3 of Table 2, and dissolve in the prepared alcoholic aqueous solution to obtain an emulsion;

[0052] Weigh 5 parts of (3,3,3-trifluoropropyl)methyldimethoxysilane, 5 parts of (3,3,3-trifluoropropyl)methyldiethoxysilane, (3,3 , 10 parts of 3-trifluoropropyl)methyltrimethoxysilane, 5 parts of (3,3,3-trifluoropropyl)methyltriethoxysilane, 25 parts in total,

[0053] 15 parts of methyl triethoxysilane, 15 parts of ethyl triethoxysilane, 5 parts of propyl triethoxysilane, 35 parts in total,

[0054] 0.4 parts of hydrochloric acid (concentration 0.01mol / L);

[0055] Slowly add the weighed fluorosiloxane monomer and siloxane monomer into the prepared emulsion at a speed of 15 drops / min, and at the same time stir and mix at a speed of 1200r / min. During the stirring process, drop Add hydrochloric acid, emulsify a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com